Numerical Simulation and Experimental Investigation of SiC/Ti-6Al-4V Metal Matrix Composites Produced by Laser Melt Injection

Abstract

:1. Introduction

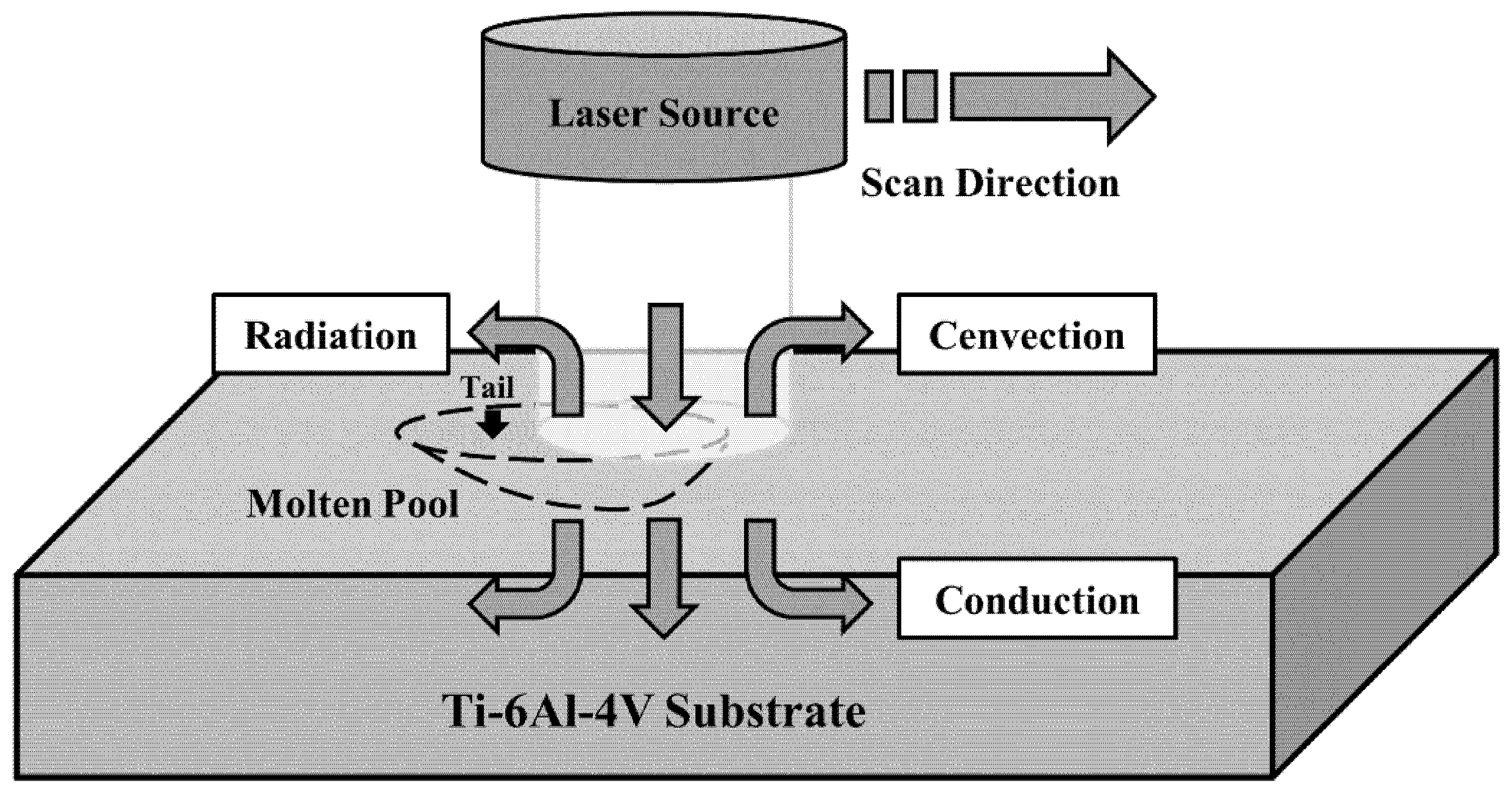

2. Finite Element Model

2.1. Governing Equation

2.2. Assumptions

- Material is isotropic, continuous, and uniform.

- The fluid flow of the molten pool is ignored.

- Vaporization of materials is ignored.

- The effect of adding particles to the molten pool is ignored.

- The thermal properties of the experimental platform do not vary with temperature.

2.3. Material Properties

2.4. The Meshing of 3D Finite Element Model

2.5. Initial and Boundary Conditions

3. Experiment Condition

4. Numerical Simulation Results and Discussion

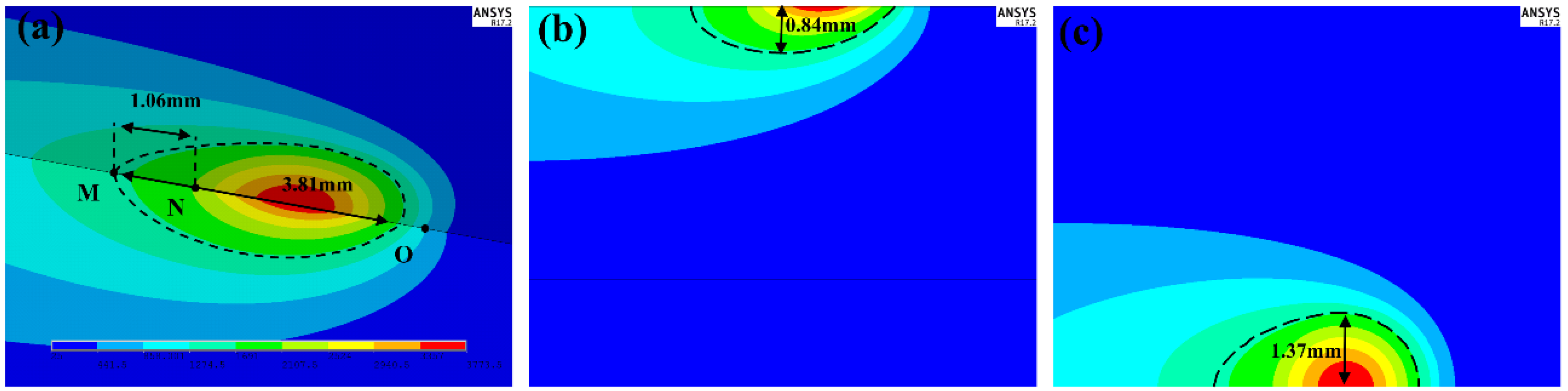

4.1. Effect of Laser Power on Molten Pool

4.2. Effect of Scanning Velocity on Molten Pool

5. Simulation Validation

6. Conclusions

- (1)

- The laser power significantly affects the size of the tail length; tail length increases with laser power. The scanning velocity has a considerable impact on the lifetime of the tail area; the lifetime of the tail decreases with increasing scanning velocity.

- (2)

- The length of the tail is adjusted by laser power, and the temperature of the tail area is changed by scanning velocity. Considering the tail’s length, temperature, and lifetime, the process parameters are determined as a laser power of 2.5 kW and a scanning velocity of 60 mm/s.

- (3)

- Metal matrix composites coatings with a thickness of about 250 μm were prepared. The microstructure and the hardness of the coating vary in gradients along the depth direction. the maximum hardness can reach 1729.5 HV, much higher than the Ti-6Al-4V substrate (310.3 HV).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Farotade, G.A.; Adesina, O.S.; Popoola, A.; Pityana, S.L. Laser Cladding and Characterization of Ni-SiC-ZrB2 Cermet Coatings on TC4 for High-Temperature Applications. Metallogr. Microstruct. Anal. 2019, 23, 53–63. [Google Scholar]

- Sun, Y.; Luo, G.; Zhang, J.; Chen, J.; Wang, G.; Shen, Q.; Zhang, L. Microstructure, Mechanical Properties and Reinforcement Mechanism of Dual-scale TC4 titanium Alloy prepared by Cryomilling and Plasma Activated Sintering. Mater. Sci. Eng. A 2018, 736, 120–129. [Google Scholar] [CrossRef]

- Li, N.; Xiong, Y.; Xiong, H.; Shi, G.; Blackburn, J.; Liu, W.; Qin, R. Microstructure, formation mechanism and property characterization of Ti + SiC laser cladded coatings on Ti6Al4V alloy. Mater. Charact. 2019, 148, 43–51. [Google Scholar] [CrossRef]

- Ganesh, B.K.C.; Sha, W.; Ramanaiah, N.; Krishnaiah, A. Effect of shot peening on sliding wear and tensile behavior of titanium implant alloys. Mater. Des. 2014, 56, 480–486. [Google Scholar]

- Lei, J.; Shi, C.; Zhou, S.; Gu, Z.; Zhang, L.C. Enhanced corrosion and wear resistance properties of carbon fiber reinforced Ni-based composite coating by laser cladding. Surf. Coat. Technol. 2018, 334, 274–285. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Li, J.; Wang, T.; Chai, L.; Deng, C.; Wang, Y.; Huang, Y. Microstructure and properties of pure titanium coating on TC4 alloy by laser cladding. Surf. Coat. Technol. 2021, 416, 127137. [Google Scholar] [CrossRef]

- Ayers, J.D.; Schaefer, R.J. A Laser Processing Technique for Improving the Wear Resistance of Metals. JOM 1981, 33, 19–23. [Google Scholar] [CrossRef]

- Gilev, V.G.; Evgenii, M. Laser Melt Injection of Austenitic Cast Iron Ch16D7GKh with Titanium. Russ. J. Non-Ferr. Met. 2016, 57, 625–632. [Google Scholar]

- Xu, B.N.; Ping, J.; Geng, S.N.; Wang, Y.L.; Zhao, J.T.; Mi, G.Y. In-Situ Reactions and Mechanical Properties of 6061 Aluminum Alloy Weld Joint with Sicp by Laser Melting Injection. Mater. Des. 2021, 203, 109538. [Google Scholar] [CrossRef]

- Li, L.; Wang, D.; Song, W.; Gong, J.; Hu, Q.; Zeng, X. Microstructures and mechanical properties of WCP/TC4 composite coatings by laser melt injection and laser-induction hybrid melt injection. Surf. Coat. Technol. 2020, 205, 4366–4373. [Google Scholar]

- Li, L.; Liu, D.; Chen, Y. Electron microscopy study of reaction layers between single-crystal W.C. particle and TC4 after laser melt injection. Acta Mater. 2009, 57, 3606–3614. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, D.; Li, F.; Li, L. WCp/Ti-6Al-4V graded metal matrix composites layer produced by laser melt injection. Surf. Coat. Technol. 2008, 202, 4780–4787. [Google Scholar] [CrossRef]

- Kloosterman, A.B.; Kooi, B.J.; Hosson, J.T. Electron microscopy of reaction layers between SiC and Ti–6Al–4V after laser embedding. Acta Mater. 1998, 46, 6205–6217. [Google Scholar] [CrossRef] [Green Version]

- Pei, Y.T.; Ocelik, V.; Hosson, J.T. SiCp/TC4 Functionally Graded Materials Produced by Laser Melt Injection. Acta Mater. 2002, 50, 2035–2051. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.; Yu, H. Research status of laser cladding on titanium and its alloys: A review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Liang, W.; Yao, J.H.; Hu, Y.; Zhang, Q.L.; Sun, Z.; Liu, R. Influence of Electric-Magnetic Compound Field on the Wc Particles Distribution in Laser Melt Injection. Surf. Coat. Technol. 2017, 315, 32–43. [Google Scholar]

- Xu, B.A.; Jiang, P.; Wang, Y.L.; Zhao, J.T.; Geng, S.N. Multi-Physics Simulation of Wobbling Laser Melting Injection of Aluminum Alloy with Sic Particles: Sic Particles Gradient Distribution in Fusion Zone. Int. J. Heat Mass Transf. 2022, 182, 121960. [Google Scholar] [CrossRef]

- Liu, H.; Li, M.; Qin, X.; Huang, S.; Hong, F. Numerical Simulation and experimental analysis of wide-beam laser cladding. Int. J. Adv. Manuf. Technol. 2019, 100, 237–249. [Google Scholar] [CrossRef]

- Sun, S.; Fu, H.; Chen, S.; Ping, X.; Wang, K.; Guo, X.; Lin, J.; Lei, Y. A numerical-experimental investigation of heat distribution, stress field and crack susceptibility in Ni60A coatings. Opt. Laser Technol. 2019, 117, 175–185. [Google Scholar] [CrossRef]

- Akbari, M.; Saedodin, S.; Toghraie, D.; Shoja-Razavi, R.; Kowsari, F. Experimental and numerical investigation of temperature distribution and melt pool geometry during pulsed laser welding of Ti6Al4V alloy. Opt. Laser Technol. 2014, 59, 52–59. [Google Scholar] [CrossRef]

- Gao, J.; Wu, C.; Hao, Y.; Xu, X.; Guo, L. Numerical Simulation and experimental investigation on three-dimensional modelling of single-track geometry and temperature evollution by laser cladding. Opt. Laser Technol. 2020, 129, 106287. [Google Scholar] [CrossRef]

- Gan, Y.; Wang, W.; Cui, Z.; Yan, X.; Guan, Z.; Xu, B. Numerical and experimental study of the temperature fifield evolution of Mg alloy during high power diode laser surface melting. Optik 2015, 126, 739–743. [Google Scholar] [CrossRef]

- Mills, K.C. Recommended Values of Thermophysical Properties for Selected Commercial Alloys; Antony Rowe Ltd.: Chippenham, UK, 2002. [Google Scholar]

- Du, Y.; You, X.; Qiao, F.; Guo, L.; Liu, Z. A model for predicting the temperature field during selective laser melting. Results Phys. 2019, 12, 52–60. [Google Scholar] [CrossRef]

- Kumara, C.; Dasa, M.; Paulb, C.P.; Singh, B. Experimental investigation and metallographic characterization of fiber laser beam welding of Ti-6Al-4V alloy using response surface method. Opt. Laser Eng. 2017, 95, 52–68. [Google Scholar] [CrossRef]

- Yang, L.X.; Peng, X.F.; Wang, B.X. Numerical modeling and experimental investigation on the characteristics of molten pool during laser processing. Int. J. Heat Mass Transf. 2001, 44, 4465–4473. [Google Scholar] [CrossRef]

- Yin, J.; Zhu, H.; Ke, L.; Lei, W.; Dai, C.; Zuo, D. Simulation of temperature distribution in single metallic powder layer for laser micro-sintering. Comp. Mater. Sci. 2012, 53, 333–339. [Google Scholar] [CrossRef]

- Hao, M.; Sun, Y. A FEM model for simulating temperature field in coaxial laser cladding of TI6AL4V alloy using an inverse modeling approach. Int. J. Heat Mass Transf. 2013, 64, 352–360. [Google Scholar] [CrossRef]

- Freisse, H.; Annika, B.; Thomas, S. Determination of the particle contentin laser melt injected tracks. J. Mater. Process. Technol. 2019, 267, 167–185. [Google Scholar] [CrossRef]

- Yang, J.H.; Sun, S.J.; Brandt, M.; Yan, W.Y. Experimental investigation and 3D finite element prediction of the heat affected zone during laser assisted machining of Ti6Al4V alloy. J. Mater. Process. Technol. 2010, 210, 2215–2222. [Google Scholar] [CrossRef]

| T/℃ | 100 | 400 | 800 | 995 a | 995 b | 1300 | 1650 a | 1650 b | 1800 | 1900 |

|---|---|---|---|---|---|---|---|---|---|---|

| ρ/Kg1m−3 | 4420 | 4366 | 4309 | 4282 | 4282 | 4240 | 4189 | 3920 | 3818 | 3750 |

| C/JK−1g- | 0.562 | 0.629 | 0.714 | 0.753 | 0.641 | 0.696 | 0.759 | 0.831 | 0.831 | 0.831 |

| λ/Wm−1K−1 | 7.45 | 11.35 | 17.8 | 22.7 | 19.3 | 23.7 | 28.4 | 33.4 | - | - |

| Parameters | Values |

|---|---|

| Laser power | 2.5 kW |

| Scanning velocity | 60 mm/s |

| Spot diameter | 3 mm |

| Powder feeding rate | 10.8 g/min |

| Carrier gas | 2 L/min |

| Shielding gas | 5 L/min |

| Position | Ti | Al | C | Si | V |

|---|---|---|---|---|---|

| A | 30.29 | 2.56 | 55.91 | 11.24 | - |

| B | 35.83 | 2.69 | 57.32 | 3.70 | 0.46 |

| C | 45.12 | 3.18 | 46.45 | 3.33 | 1.92 |

| D | 43.14 | 5.58 | 39.96 | 9.40 | 1.91 |

| E | 30.63 | 1.76 | 66.11 | 1.50 | - |

| F | 71.62 | 11.33 | 10.07 | 3.93 | 3.05 |

| G | 34.54 | 2.34 | 60.94 | 1.33 | 0.85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, Z.; Zhang, J.; He, P.; Luo, G.; Shen, Q. Numerical Simulation and Experimental Investigation of SiC/Ti-6Al-4V Metal Matrix Composites Produced by Laser Melt Injection. Coatings 2022, 12, 808. https://doi.org/10.3390/coatings12060808

Zhai Z, Zhang J, He P, Luo G, Shen Q. Numerical Simulation and Experimental Investigation of SiC/Ti-6Al-4V Metal Matrix Composites Produced by Laser Melt Injection. Coatings. 2022; 12(6):808. https://doi.org/10.3390/coatings12060808

Chicago/Turabian StyleZhai, Zijia, Jian Zhang, Peng He, Guoqiang Luo, and Qiang Shen. 2022. "Numerical Simulation and Experimental Investigation of SiC/Ti-6Al-4V Metal Matrix Composites Produced by Laser Melt Injection" Coatings 12, no. 6: 808. https://doi.org/10.3390/coatings12060808

APA StyleZhai, Z., Zhang, J., He, P., Luo, G., & Shen, Q. (2022). Numerical Simulation and Experimental Investigation of SiC/Ti-6Al-4V Metal Matrix Composites Produced by Laser Melt Injection. Coatings, 12(6), 808. https://doi.org/10.3390/coatings12060808