Robust Super-Amphiphobic Titanium Surface for Liquid/Liquid Mini Separations

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

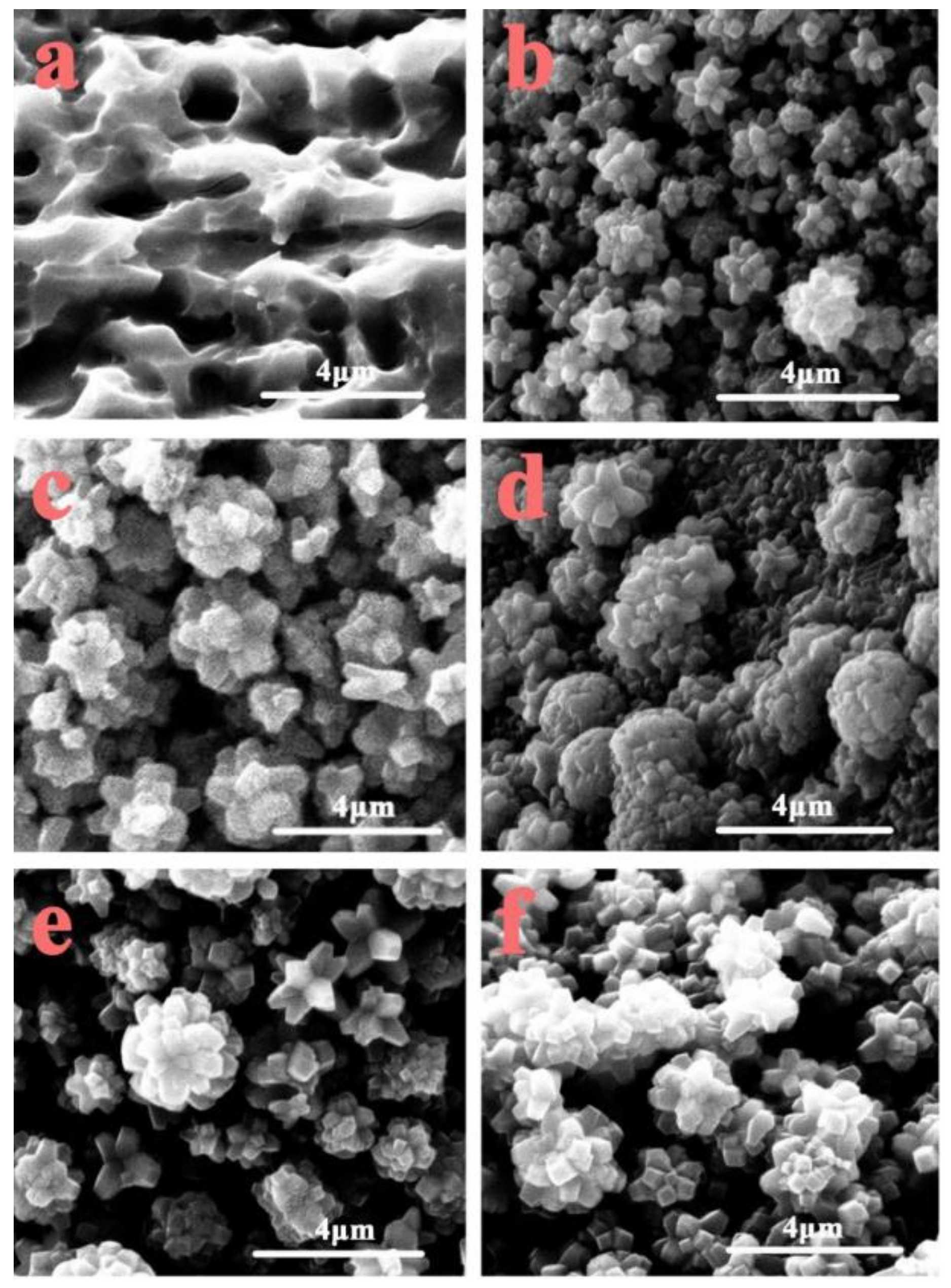

3.1. Characterization of Ti Mesh

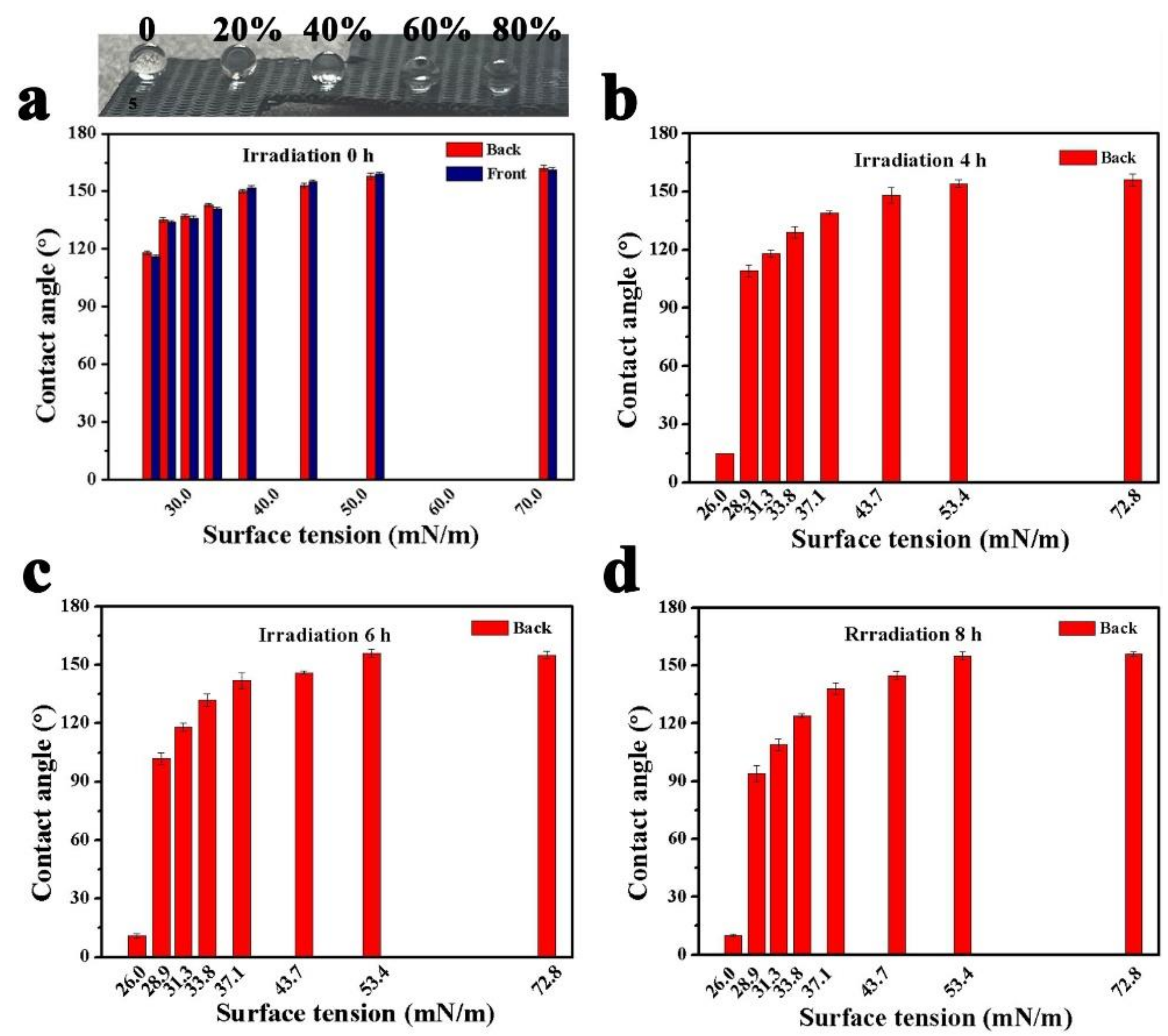

3.2. Preparation of Super-Amphiphobic Ti Mesh

3.3. Fabrication of Unidirectional Oil-Transport Ti Mesh

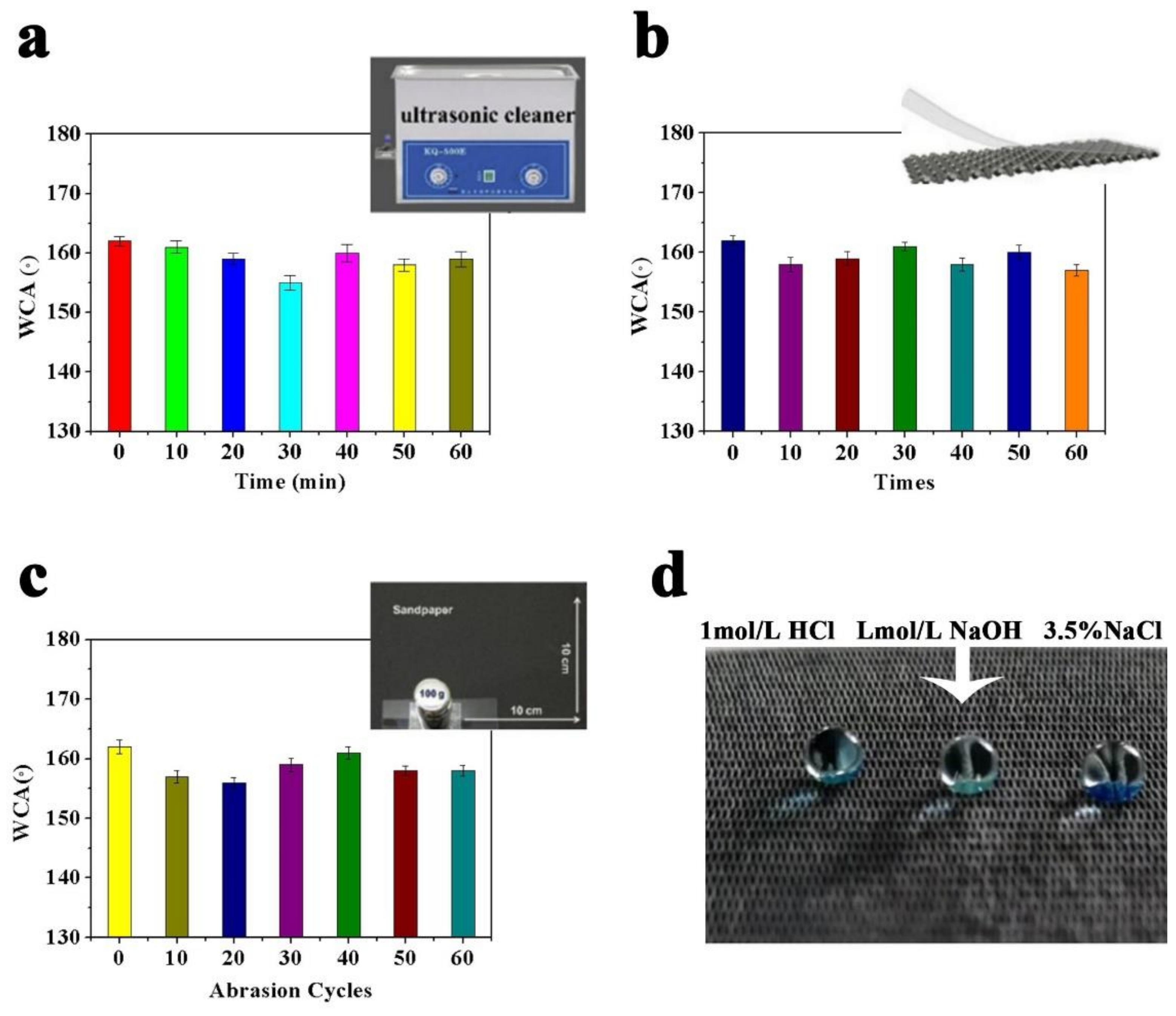

3.4. Self-Cleaning, Chemical, and Mechanical Stability of Super-Amphiphobic Ti Mesh

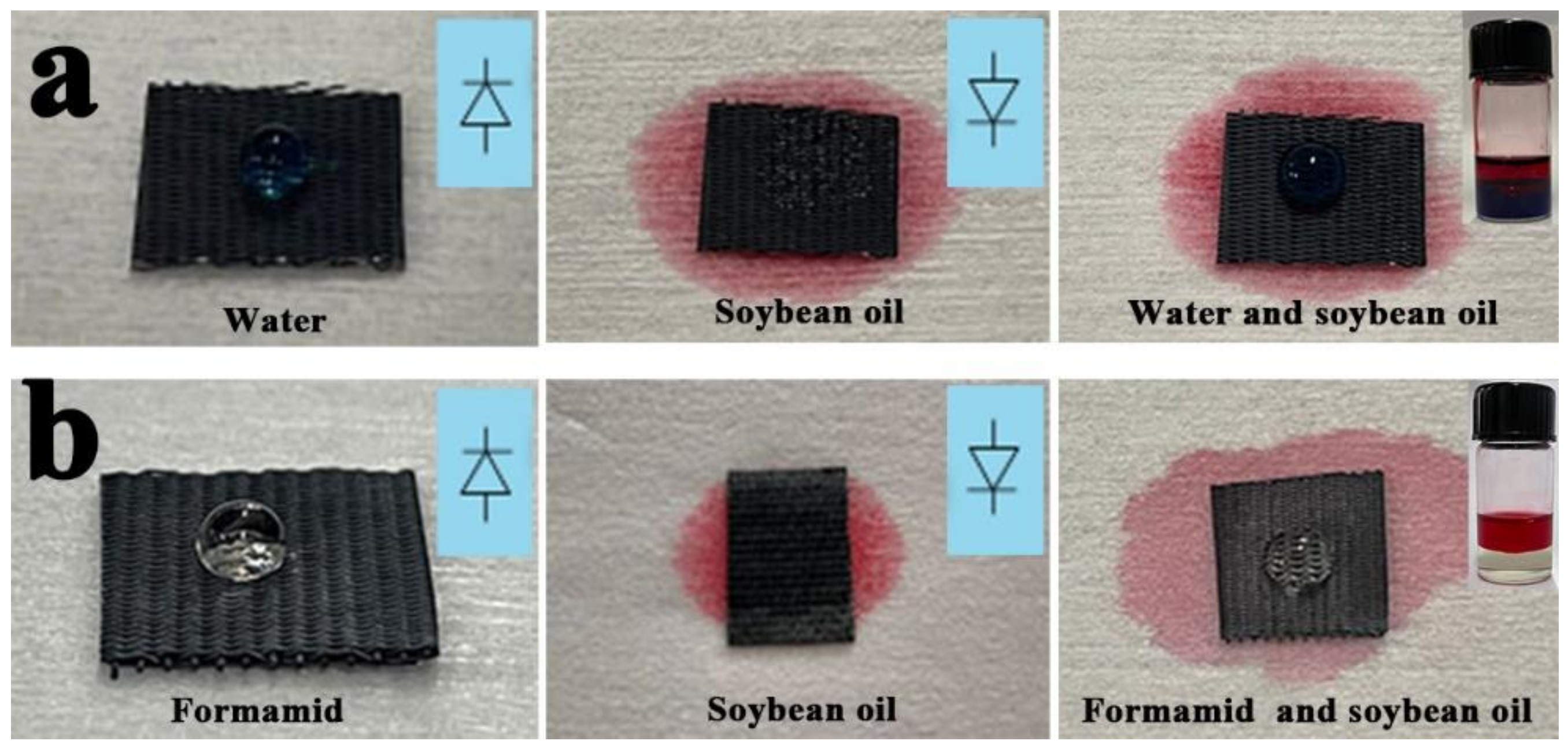

3.5. Liquid/Liquid Mini-Separations of Ti Mesh

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, S.T.; Liu, K.S.; Yao, X.; Lei, J. Bioinspired surfaces with superwettability: New insight on theory, design, and applications. Chem. Rev. 2015, 115, 8230–8293. [Google Scholar] [CrossRef] [PubMed]

- Miljkovic, N.; Preston, D.; Enright, R.; Wang, E.N. Electrostatic charging of jumping droplets. Nat. Commun. 2013, 4, 2517–2525. [Google Scholar] [CrossRef] [Green Version]

- Sun, Q.Q.; Wang, D.H.; Li, Y.N.; Zhang, J.H.; Ye, S.J.; Cui, J.X.; Chen, L.Q.; Wang, Z.K.; Hans-Jürgen, B.; Vollmer, D.; et al. Surface charge printing for programmed droplet transport. Nat. Mater. 2019, 18, 936–941. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, D.H.; Sun, Q.Q.; Hokkanen, M.; Zhang, C.L.; Lin, F.Y.; Liu, Q.; Zhu, S.P.; Zhou, T.F.; Chang, Q.; He, B.; et al. Design of robust superhydrophobic surfaces. Nature 2020, 582, 55–59. [Google Scholar] [CrossRef]

- Vahabi, H.; Wang, W.; Movafaghi, S.; Kota, A.K. Free-standing, flexible superomniphobic films. ACS Appl. Mater. 2016, 8, 21962–21967. [Google Scholar] [CrossRef] [PubMed]

- Huang, F.J.; Chen, Y.; Wang, Y.Q.; Xia, F. Tunable superamphiphobic surfaces: A platform for naked-eye ATP detection. Anal. Bioanal. Chem. 2019, 411, 4721–4727. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Luan, C.C.; Lu, Z.Y.; Chen, N.; Zhang, Y.J.; Cui, C.X. Brass wires with different surface wettability used for in-tube solid-phase microextraction. J. Chromatogra. A. 2022, 1670, 462948–462952. [Google Scholar] [CrossRef]

- Wen, Q.Y.; Guo, F.; Peng, Y.B.; Guo, Z.G. Simple fabrication of superamphiphobic copper surfaces with multilevel structures. Colloid Surf. A 2018, 539, 11–17. [Google Scholar] [CrossRef]

- Roldán-Carmona, C.; Malinkiewicz, O.; Soriano, A.; Espallargasa, G.M.; Garciac, A.; Reineckec, P.; Kroyerc, T.; Dare, M.I.; Nazeeruddine, M.K.; Bolinkaet, H.J. Flexible high efficiency perovskite solar cells. Energy Environ. Sci. 2014, 7, 994–997. [Google Scholar] [CrossRef]

- Liu, K.F.; Li, P.P.; Zhang, Y.P.; Liu, P.F.; Cui, C.X.; Wang, J.C.; Qu, L.B. Laboratory filter paper from superhydrophobic to quasi-superamphiphobicity: Facile fabrication, simplified patterning and smart application. Cellulose 2019, 26, 3859–3872. [Google Scholar] [CrossRef]

- Li, D.; Guo, Z. Versatile superamphiphobic cotton fabrics fabricated by coating with SiO2/FOTS. Appl. Surf. Sci. 2017, 426, 271–278. [Google Scholar] [CrossRef]

- Li, L.X.; Li, B.C.; Dong, J.; Zhang, J.P. Roles of silanes and silicones in forming superhydrophobic and superoleophobic materials. J. Mater. Chem. A 2016, 4, 13677–13725. [Google Scholar] [CrossRef]

- Lu, Y.; Sathasivam, S.; Song, J.L.; Crick, C.R.; Carmalt, C.J.; Parkin, I.P. Robust self-cleaning surfaces that function when exposed to either air or oil. Science 2015, 347, 1132–1135. [Google Scholar] [CrossRef] [PubMed]

- Movafaghi, S.; Wang, W.; Metzger, A.; Williams, D.D.; Williamsa, J.D.; Kota, A.K. Tunable superomniphobic surfaces for sorting droplets by surface tension. Lab Chip 2016, 16, 3204–3209. [Google Scholar] [CrossRef] [PubMed]

- Aria, A.I.; Gharib, M. Physicochemical characteristics and droplet impact dynamics of superhydrophobic carbon nanotube arrays. Langmuir 2014, 30, 6780–6790. [Google Scholar] [CrossRef] [Green Version]

- Wu, G.S.; Wang, J.P.; Thomas, D.F.; Chen, A.C. Synthesis of F-doped flower-like TiO2 nanostructures with high photoelectrochemical activity. Langmuir 2008, 24, 3503–3509. [Google Scholar] [CrossRef]

- Wu, Z.J.; Wu, Q.; Du, L.X.; Jiang, C.; Piao, L.Y. Progress in the synthesis and applications of hierarchical flower-like TiO2 nanostructures. Particuology 2014, 15, 61–70. [Google Scholar] [CrossRef]

- Xin, Z.K.; Zhao, X.D.; Jia, H.M.; Ma, T.Y.; Li, H.; Zhong, S.H. Amorphous carbon-linked TiO2/carbon nanotube film composite with enhanced photocatalytic performance: The effect of interface contact and hydrophilicity. Chin. Chem. Lett. 2021, 7, 2151–2154. [Google Scholar] [CrossRef]

- Wang, X.R.; Li, Y.; Tang, L.P.; Gan, W.; Zhou, W.; Zhao, Y.F.; Bai, D.S. Fabrication of Zn-Ti layered double hydroxide by varying cationic ratio of Ti4+ and its application as UV absorbent. Chin. Chem. Lett. 2017, 2, 394–399. [Google Scholar] [CrossRef]

- Zhu, X.T.; Zhang, Z.Z.; Ren, G.N.; Men, X.H.; Ge, B.; Zhou, X.Y. Designing transparent superamphiphobic coatings directed by carbon nanotubes. J. Colloid Interface Sci. 2014, 421, 141–145. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, M.Y.; Guo, Z.G. Multifunctional superamphiphobic SiO2 coating for crude oil transportation. Chem. Eng. J. 2018, 334, 1584–1593. [Google Scholar] [CrossRef]

- Liu, M.L.; Zhang, Y.P.; Cui, C.X.; Liu, P.F.; Li, R.L.; Qu, L.B. Integrated Janus membrane for smart “dual fuid diode” with multifunctional applications. J. Mater. Res. 2021, 36, 1948–1959. [Google Scholar] [CrossRef]

- Zhou, H.; Guo, Z. Superwetting Janus membranes: Focusing on unidirectional transport behaviors and multiple applications. J. Mater. Chem. A 2019, 7, 12921–12950. [Google Scholar] [CrossRef]

- Zhang, S.M.; Zhang, Y.P.; Liu, M.L.; Wang, B.X.; Liu, P.F.; Bai, X.Z.; Cui, C.X.; Qu, L.B. Smart Janus titanium mesh used as a diode for both liquid droplet and air bubble transport. New J. Chem. 2021, 45, 17862–17870. [Google Scholar] [CrossRef]

- Hou, L.L.; Wang, N.; Man, X.K.; Cui, Z.M.; Wu, J.; Liu, J.C.; Li, S.; Gao, Y.; Li, D.M.; Jiang, L.; et al. Interpenetrating Janus Membrane for High Rectification Ratio Liquid Unidirectional Penetration. ACS Nano 2019, 13, 4124–4132. [Google Scholar] [CrossRef]

- Chen, L.; Jing, H.Y.; Xu, L.Y.; Lu, G.Q. Study on Non-Cyanide Silver Electroplating with Copper Substrate. Adv. Mater. Res. 2012, 24, 2936–2939. [Google Scholar] [CrossRef]

- Liu, Y.N.; Qu, R.X.; Zhang, W.F.; Li, X.Y.; Wei, Y.; Feng, L. A Lotus- and Mussel-inspired PDA-PET/PTFE Janus membrane: Towards integrated separation of light oil and heavy oil from water. ACS Appl. Mater. Interfaces 2019, 11, 20545–20556. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wang, N.; Cui, C.; Chen, J.; Chen, N.; Zhang, Y. Robust Super-Amphiphobic Titanium Surface for Liquid/Liquid Mini Separations. Coatings 2022, 12, 805. https://doi.org/10.3390/coatings12060805

Zhang Y, Wang N, Cui C, Chen J, Chen N, Zhang Y. Robust Super-Amphiphobic Titanium Surface for Liquid/Liquid Mini Separations. Coatings. 2022; 12(6):805. https://doi.org/10.3390/coatings12060805

Chicago/Turabian StyleZhang, Yuping, Ning Wang, Chengxing Cui, Jun Chen, Na Chen, and Yijun Zhang. 2022. "Robust Super-Amphiphobic Titanium Surface for Liquid/Liquid Mini Separations" Coatings 12, no. 6: 805. https://doi.org/10.3390/coatings12060805

APA StyleZhang, Y., Wang, N., Cui, C., Chen, J., Chen, N., & Zhang, Y. (2022). Robust Super-Amphiphobic Titanium Surface for Liquid/Liquid Mini Separations. Coatings, 12(6), 805. https://doi.org/10.3390/coatings12060805