Proposals of Frequency-Based and Direction Methods to Reduce the Influence of Surface Topography Measurement Errors

Abstract

1. Introduction

2. Materials and Methods

2.1. Studied Details

2.2. Measurement Process

2.3. Applied Methods and Procedures

2.3.1. Regular Methods and Procedures

2.3.2. Proposed Approaches for Surface Topography Characterisation

3. Results and Discussions

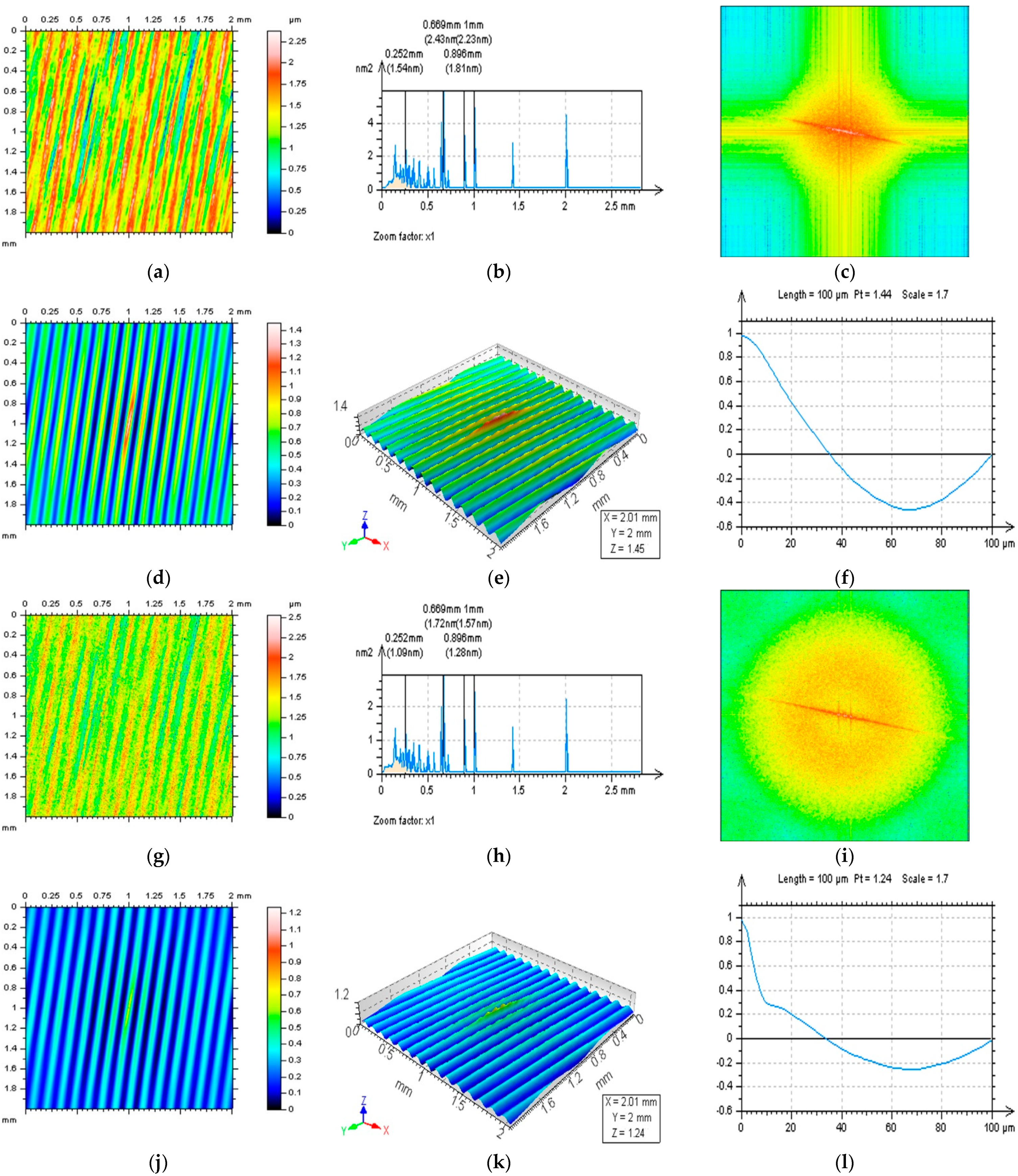

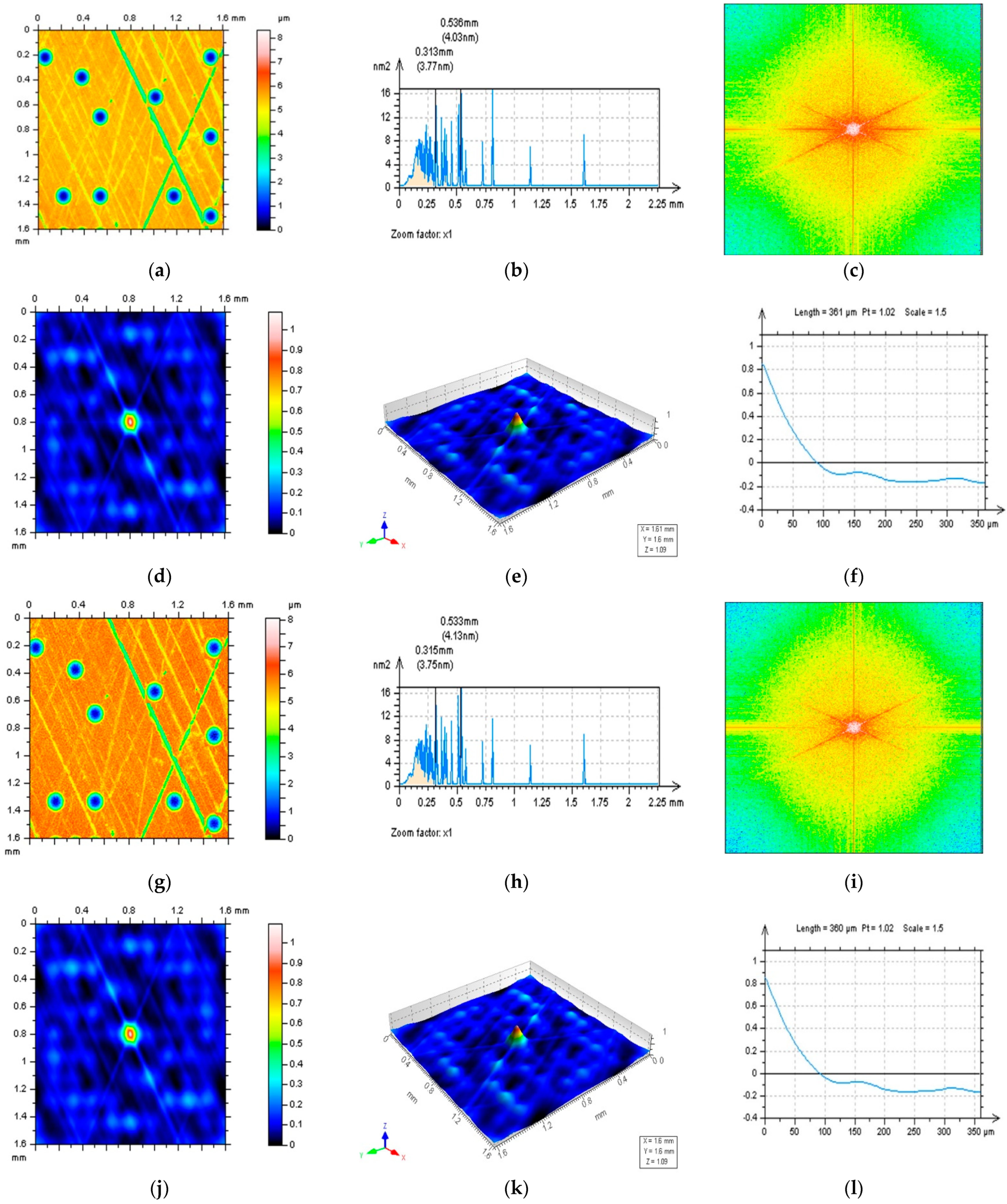

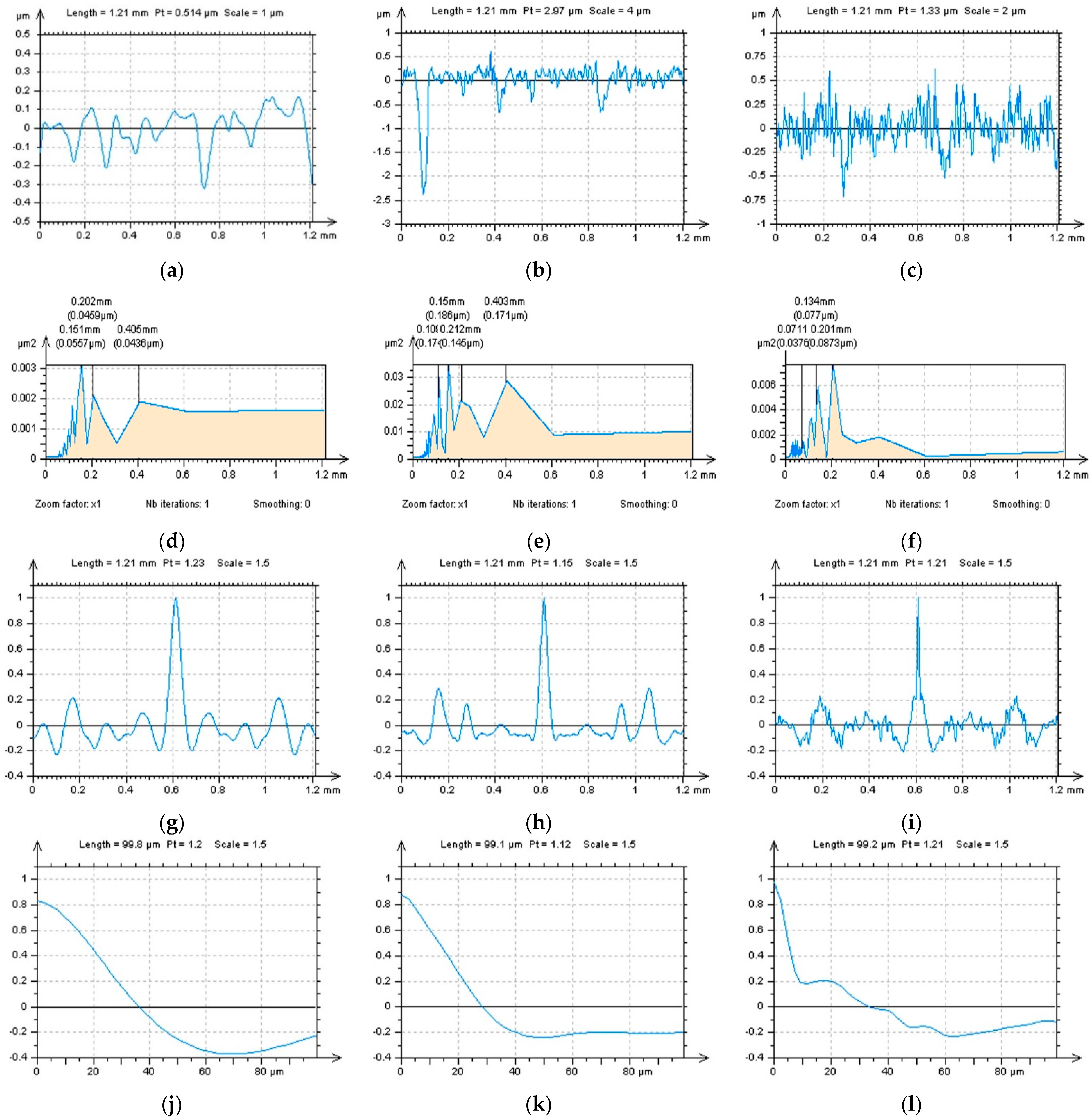

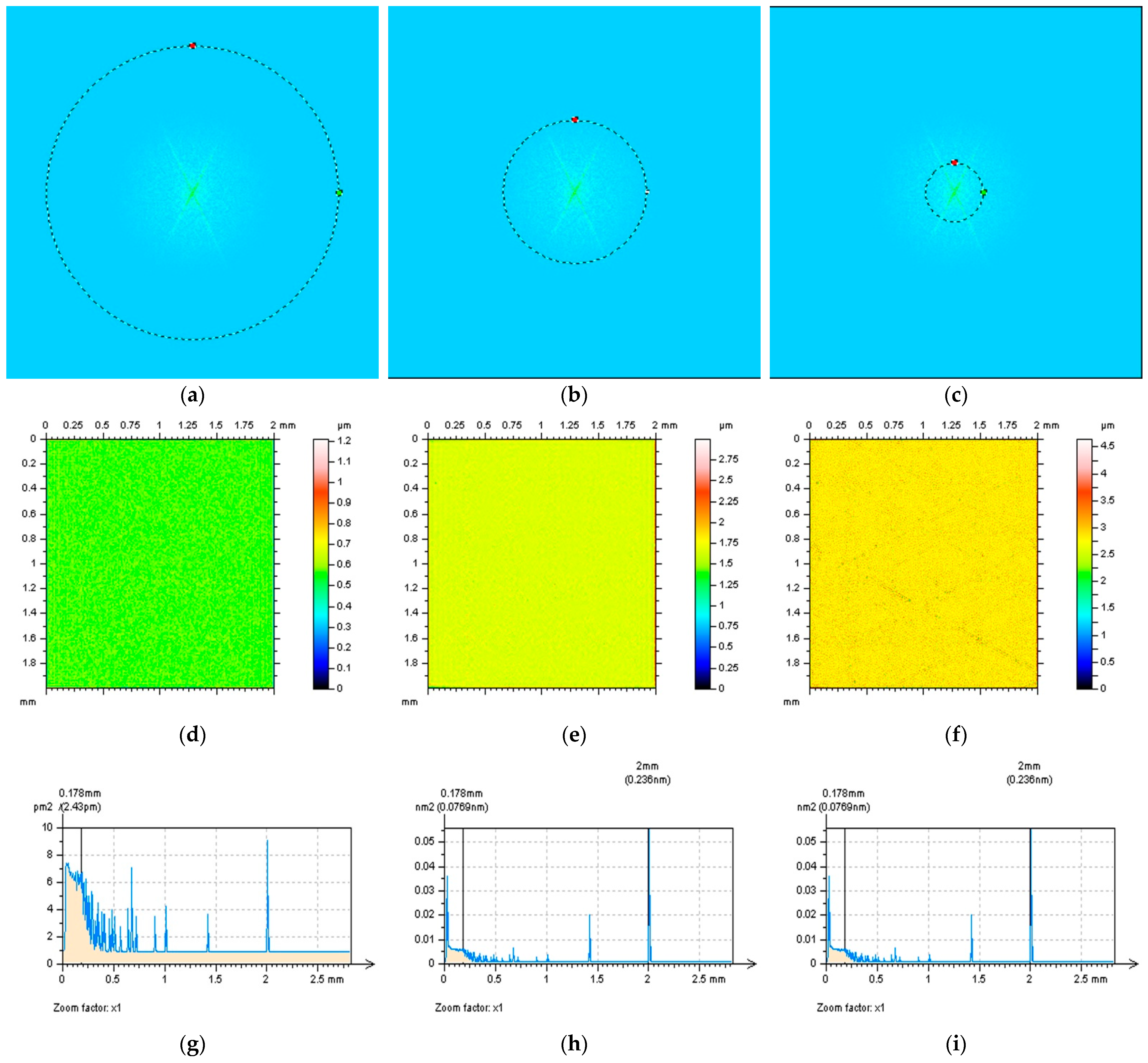

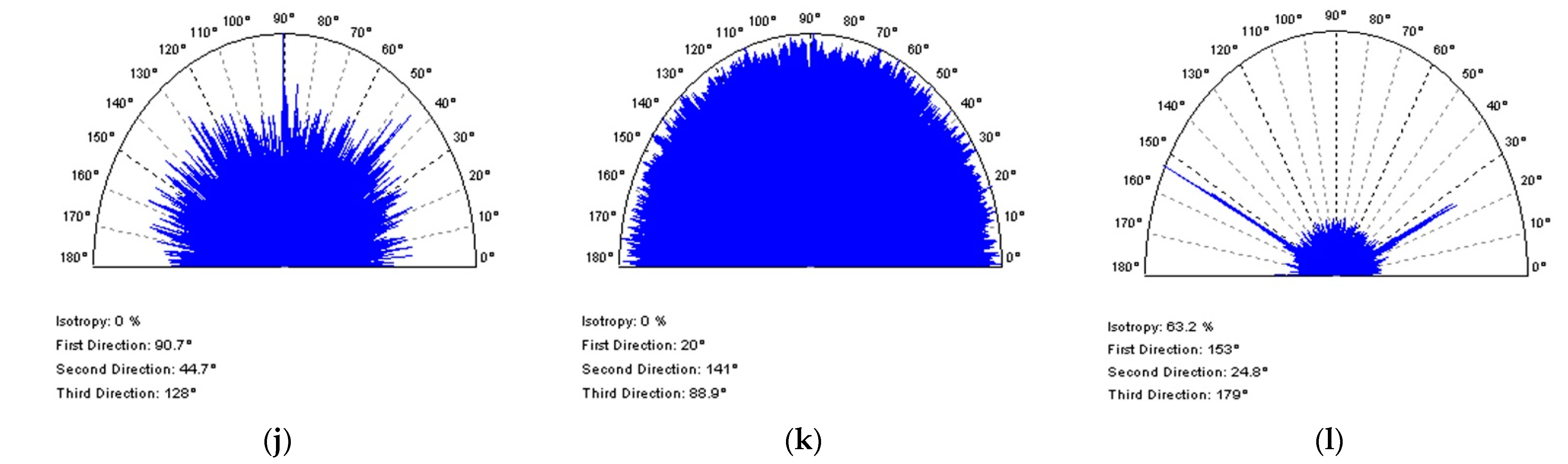

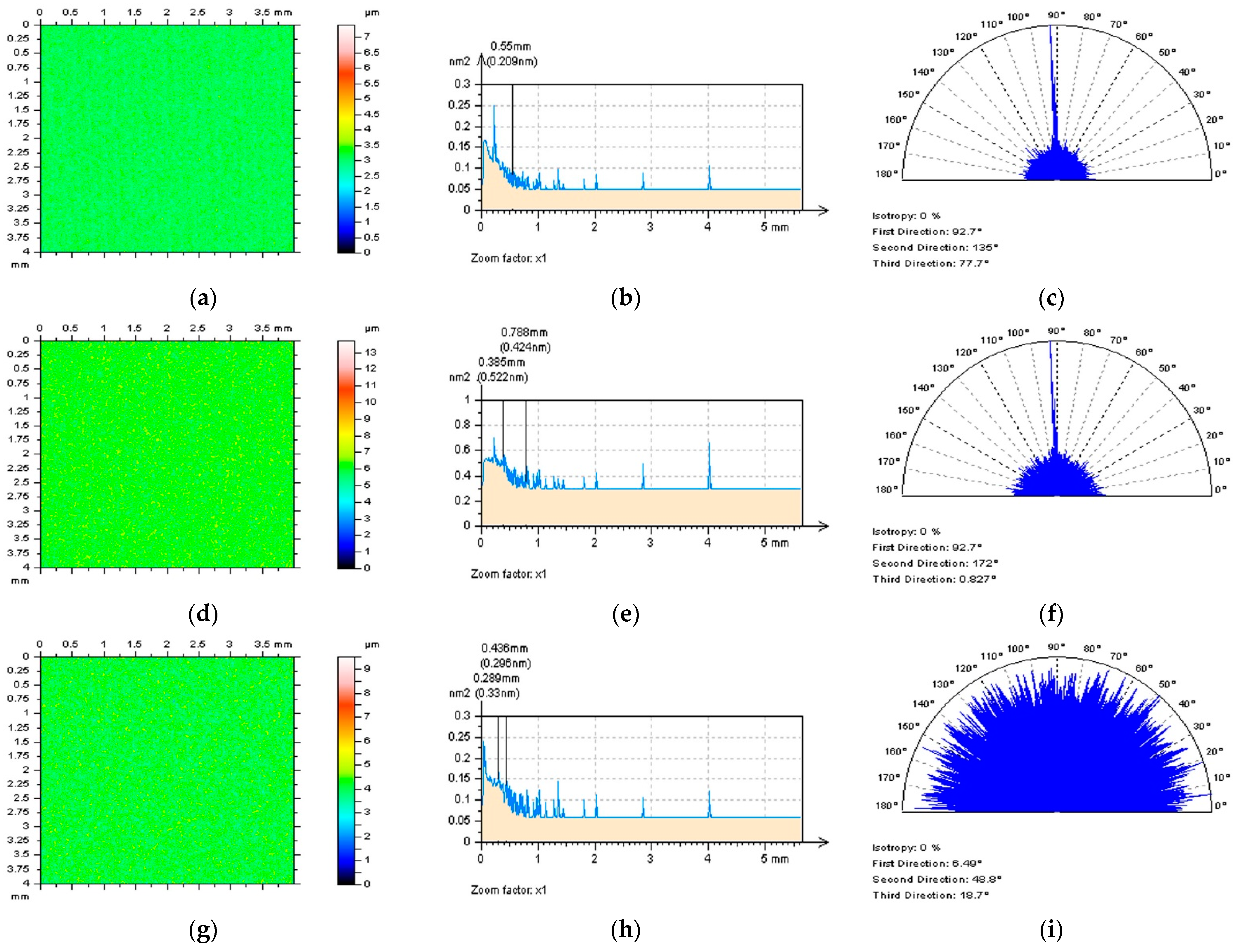

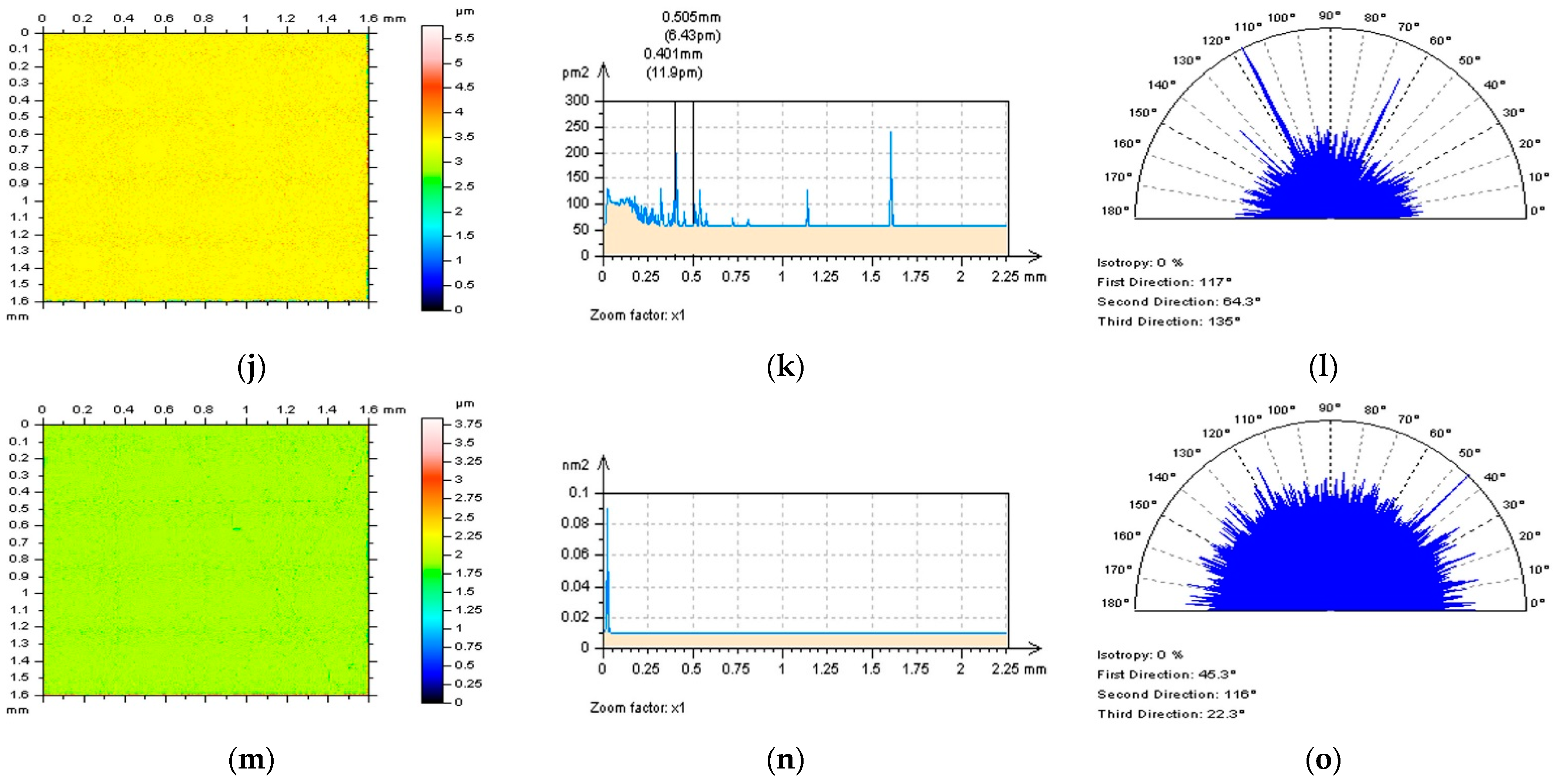

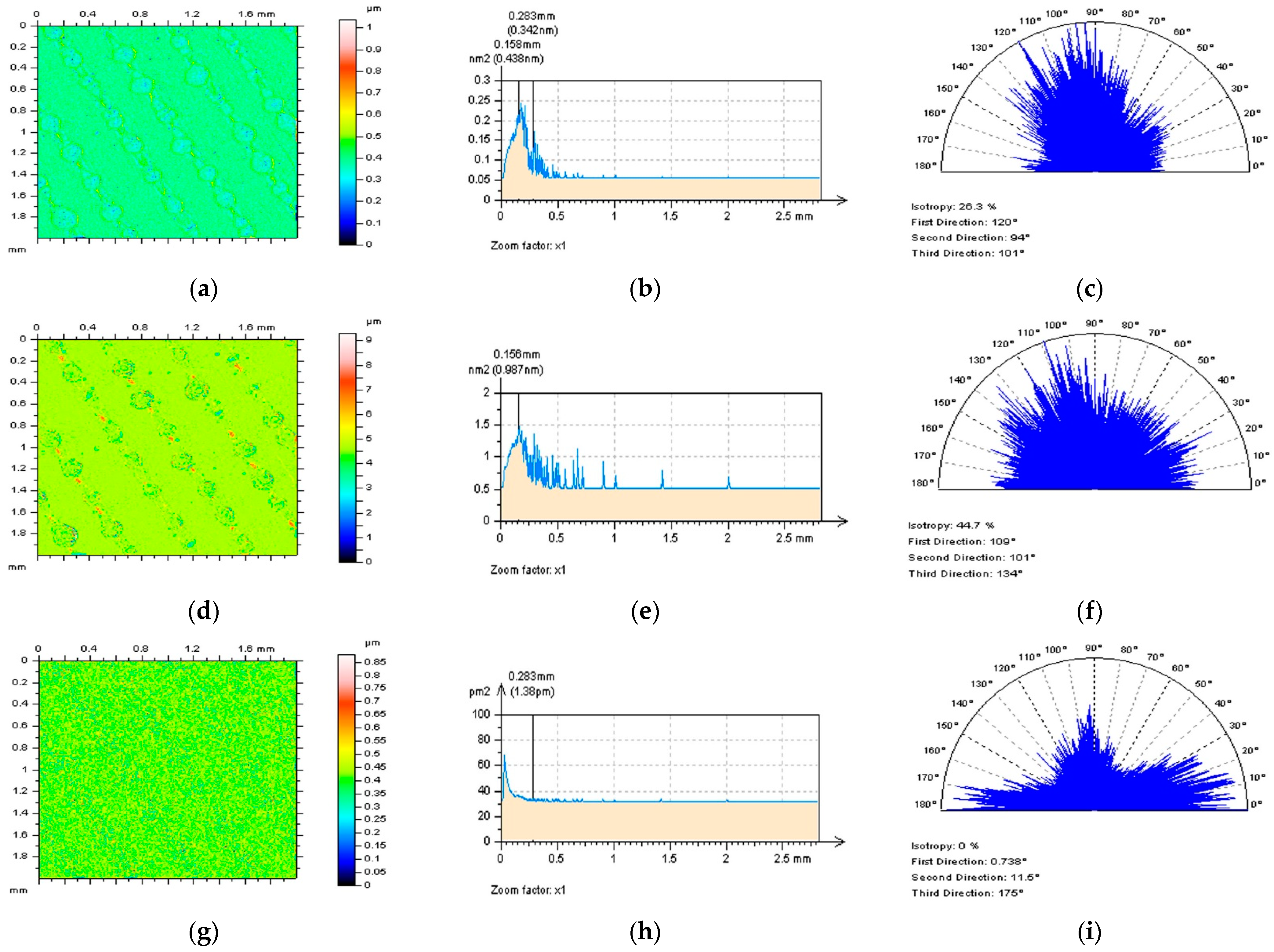

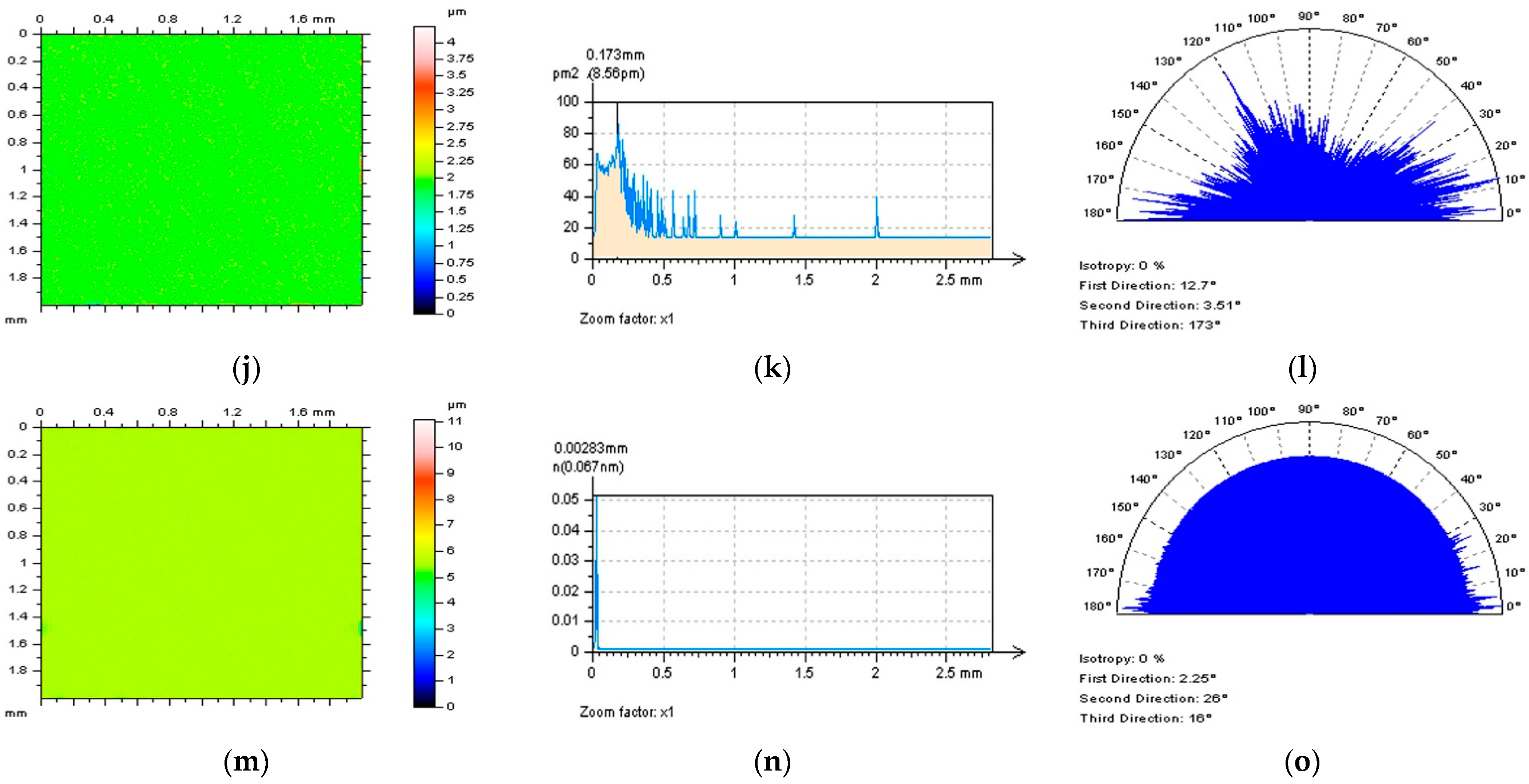

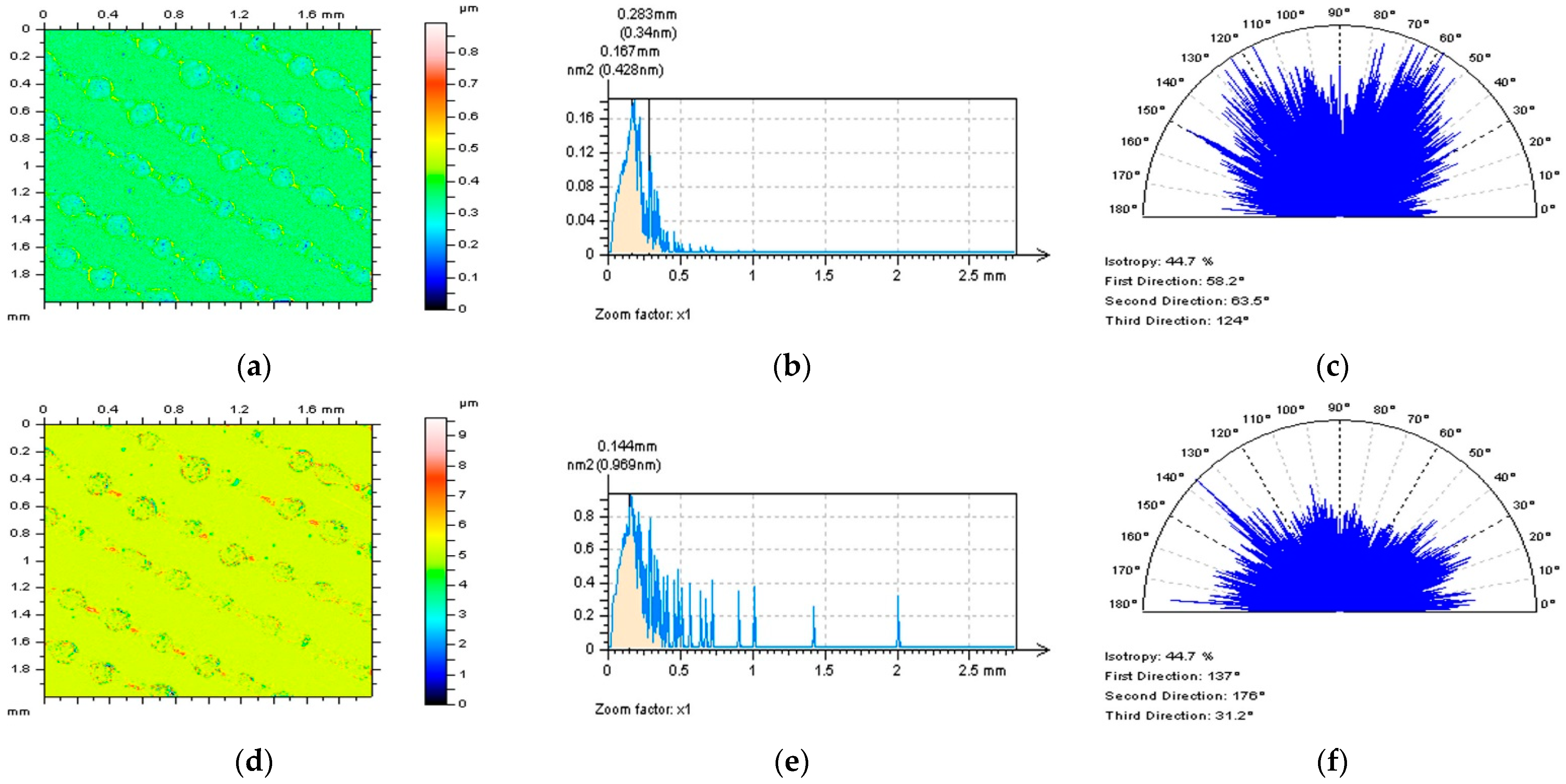

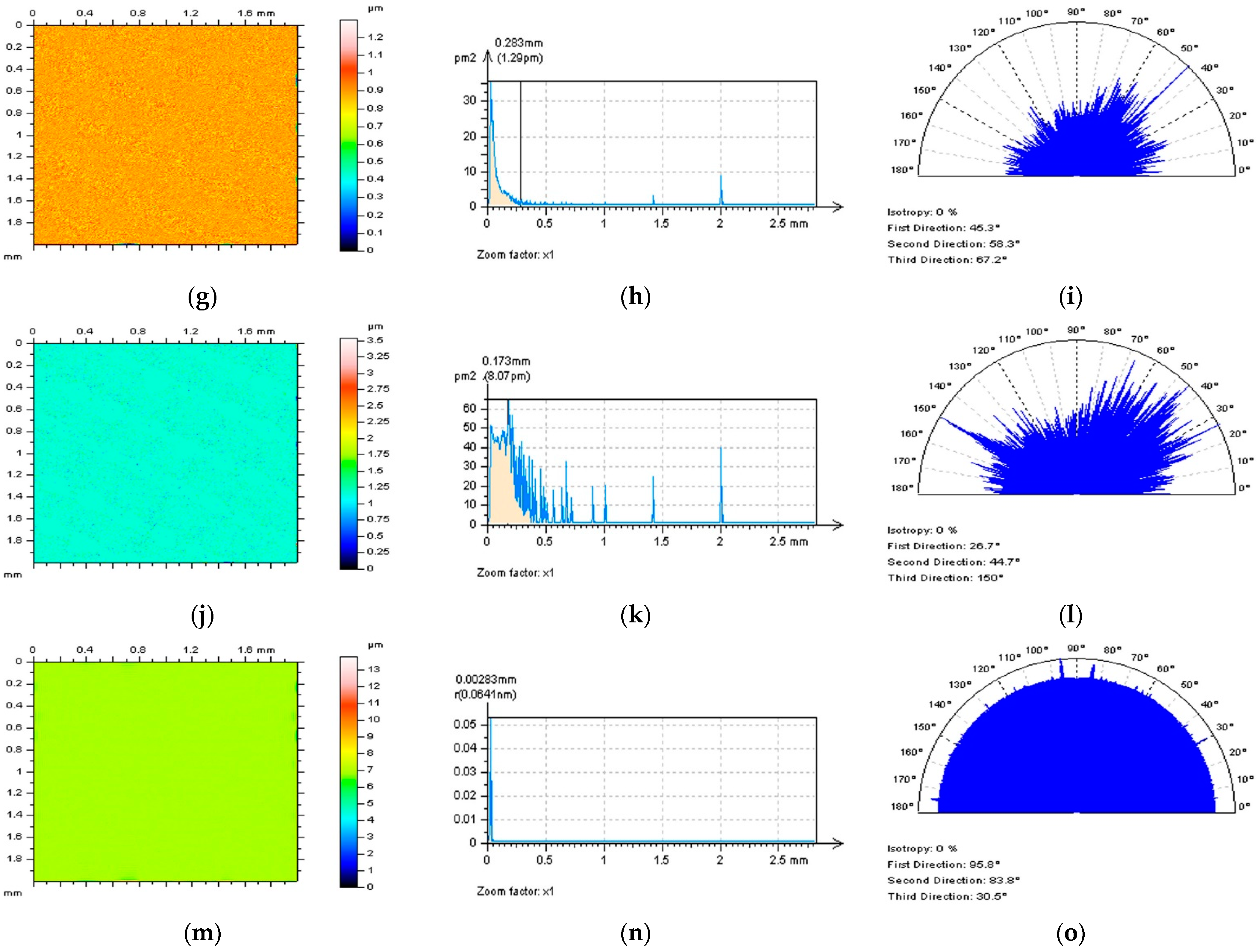

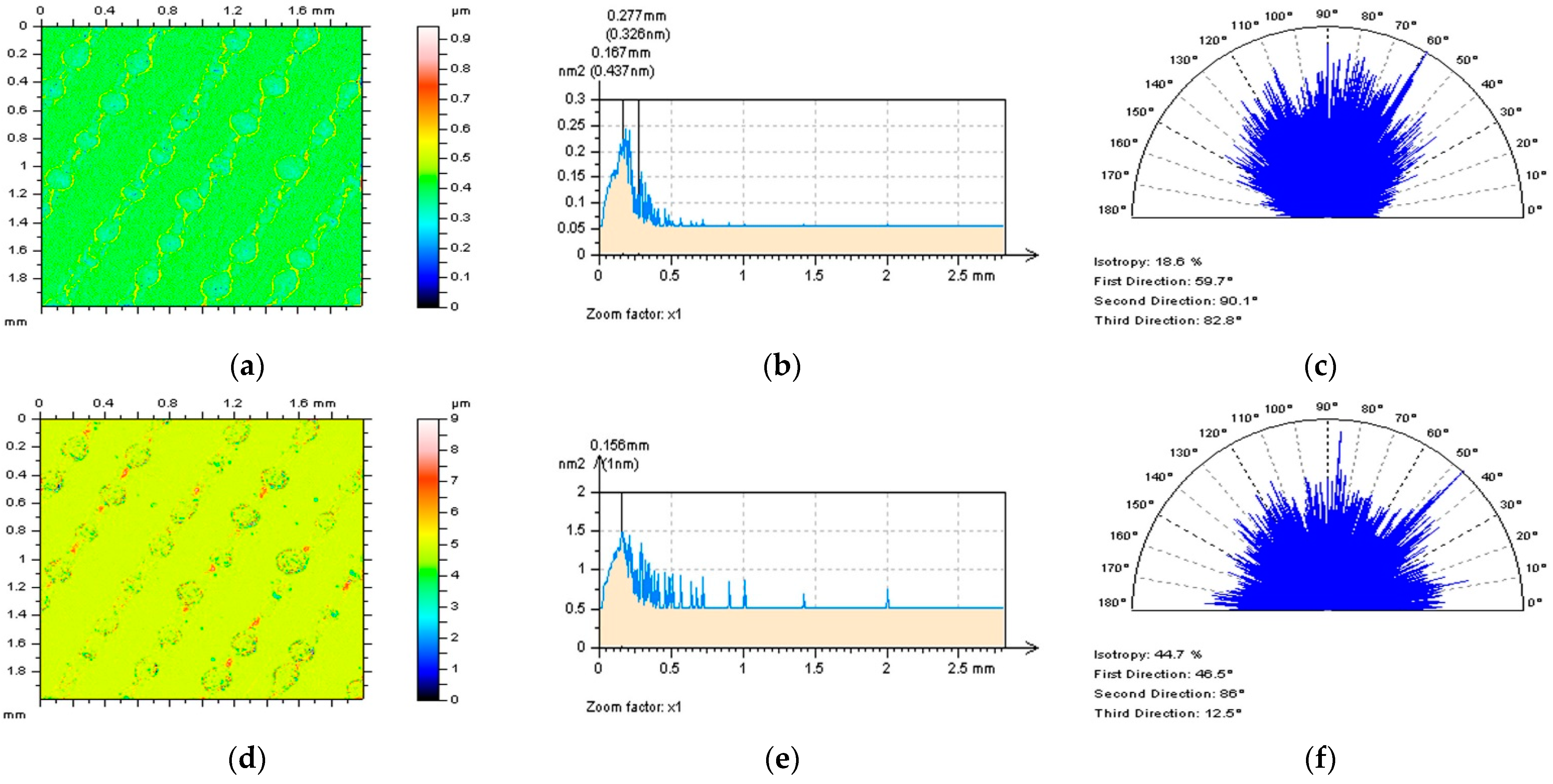

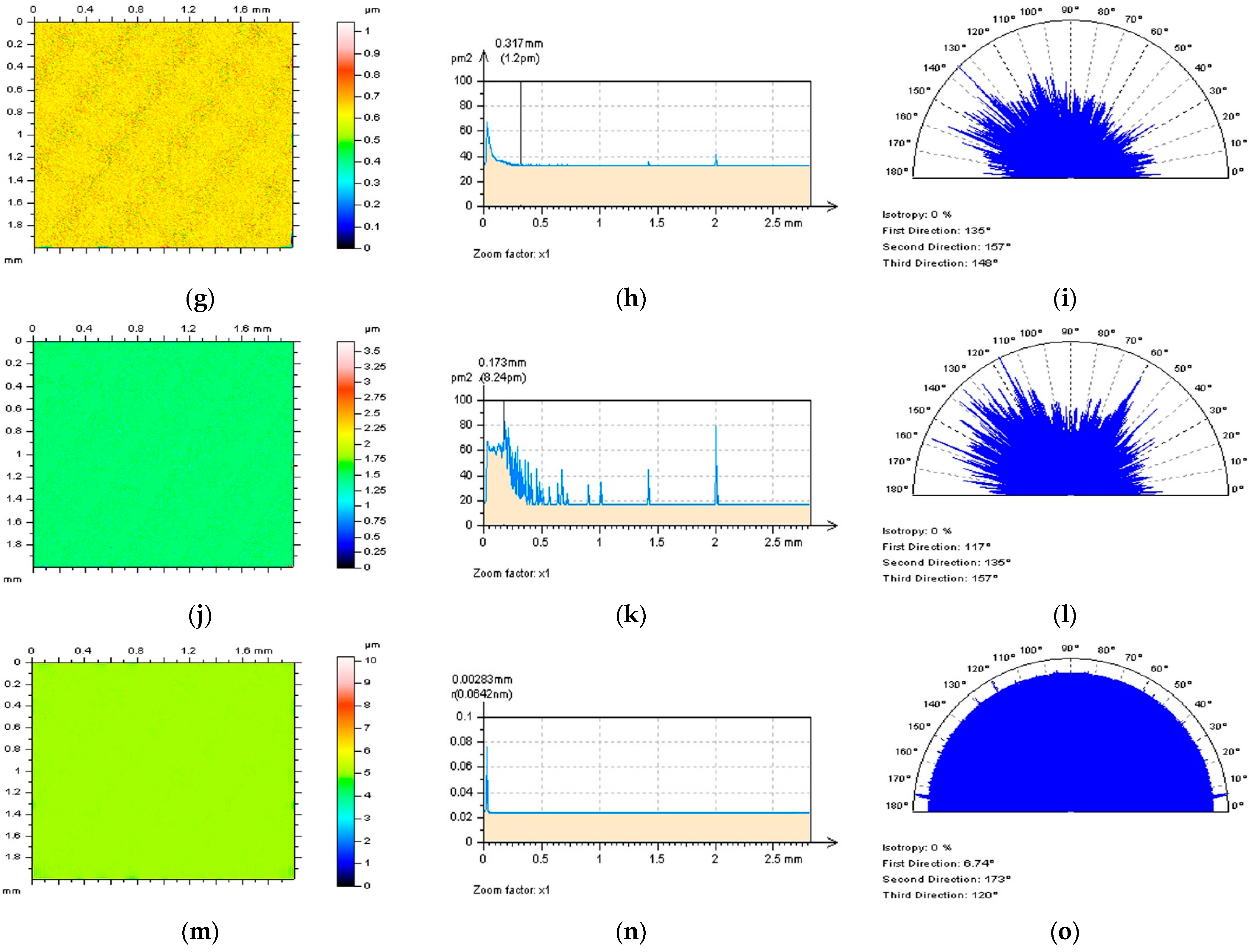

3.1. Analysis of Raw Measured Data with Proposed Directional Technique

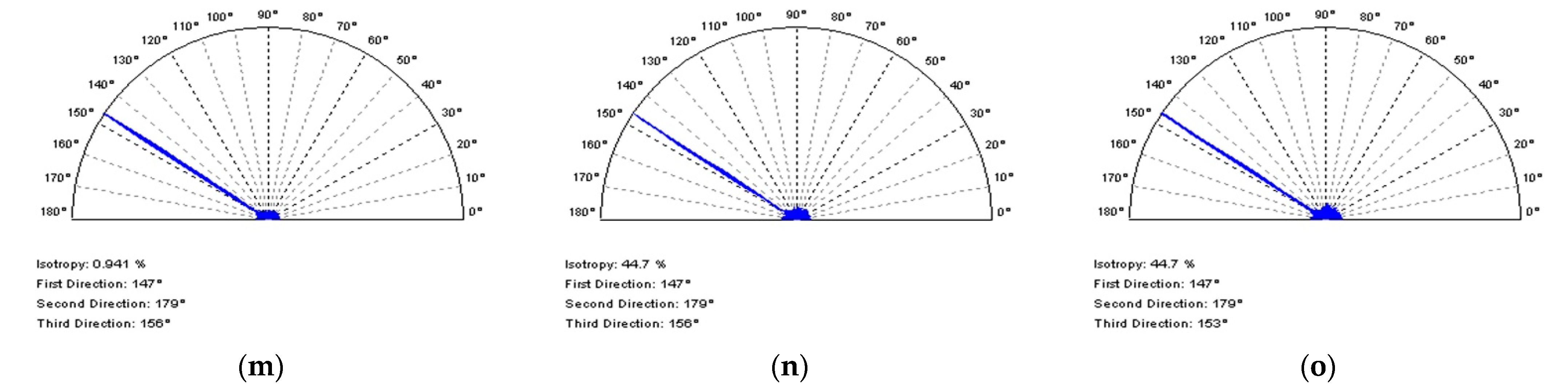

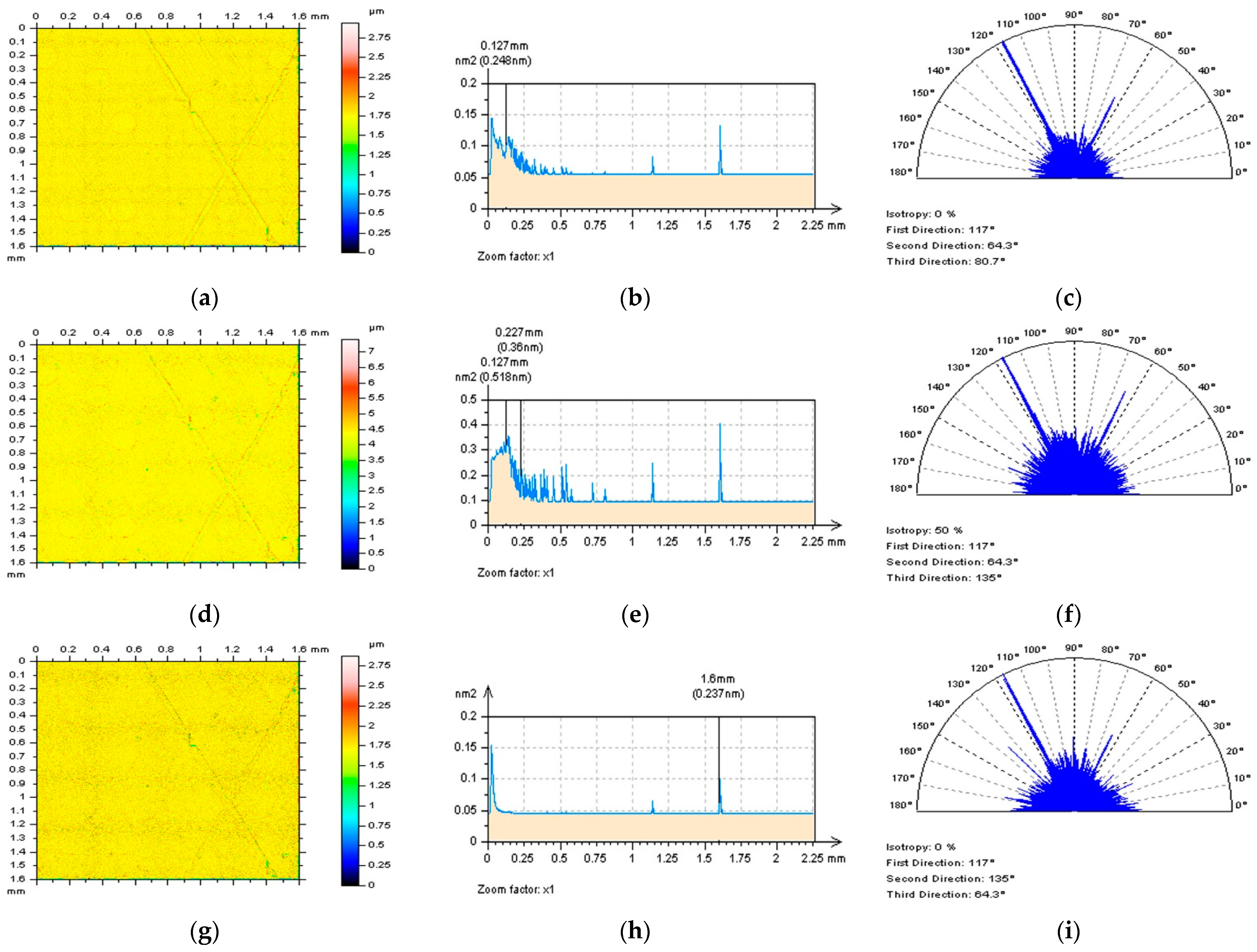

3.2. Validation of Proposed Method with a Data Rotation Process

4. The Outlook

- Studies of isotropic surface topography are still an encouraging issue when a high-frequency noise must be defined and reduced. There are no direction features that can be useful for defining the HFNS properties. From that point of view, other, non-feature-based methods must be proposed for this type of surface.

- The high-frequency measurement errors can be difficult to detect as suggested in paper methods when the amplitude of the noise is relatively small. Some improvement of the proposed method must be included with modifications of the noise amplitude.

- Furthermore, the effect of the high-frequency measurement noise amplitude on the results of applied techniques was not considered. The influence of the amplitude of noise on the results of filter application and, correspondingly, on the surface topography parameters (from ISO 25178 standard) must be also considered to provide more surface functional advantages.

5. Conclusions

- General functions, available in the commercial software, like Power Spectral Density, Autocorrelation Function, Frequency Spectrum or Texture Direction, are very useful in the processes of definition and then reduction of the high-frequency measurement errors. The most important criteria for the selection of relevant procedures is to remove (reduce) the high-frequency noise without any modification of the other feature of the characterized surface data.

- For a high-frequency measurement noise characterisation, both profile (2D) and an areal (3D) analysis can offer other benefits. The 3D analysis can be valuable only when Frequency Spectrum or eye-view studies are performed, nonetheless, this technique may require experienced users. The Power Spectral Densities, Autocorrelation Function and Frequency Spectrum methods did not always give clear results, e.g., for plateau-honed surface topography, an areal analysis was useless instead of a profile. Therefore, for some cases, the profile (2D) analysis is proposed contrary to an areal (3D).

- The technique based on the analysis of the Frequency Spectrum is suggested to select the most appropriate cut-off value when a digital filter is used for a high-frequency measurement noise reduction. The Frequency Spectrum-based technique proposes to select the bandwidth of the filter with the filter selector range. When the range is too big and exceeds the Fast Fourier Transform graph features with a known direction, the filter can not separate the entire noise data and, respectively, on the other hand, when a range is too small other features can be also removed from the raw measured data. From that matter, it is difficult to propose one cut-off value for each type of surface that should be dependent on the density and direction of the surface topography features. The main purpose is to increase the value of the cut-off until the non-noise data is detected on the high-frequency noise surface.

- Considering the studies of Texture Direction graphs, it was found that the rotation (direction) has a significant influence on the isotropy of the high-frequency noise surface when Gaussian filters were applied. When the angle of the surface features (e.g., those after honing process) was changed, the isotropy could be defined more than in the rest of the feature directions so, respectively, for these types of filtering methods, the Texture Direction and Frequency Spectrum Based Technique, must be improved with analysis of the isometric view and Power Spectral Density of the high-frequency noise surface.

- Generally, the usage of 3D Power Spectral Density characterisation improved that the rotation process has no significant influence on the validation of the process of high-frequency noise detection. For analysed types of directional surfaces, differences were not found or, respectively, they were negligible. Usually, analysis of the Power Spectral Density graph can give some encouraging response to the high-frequency noise occurrence.

- The most encouraging results were received when a Fast Fourier Transform Filter method was applied. All of the high-frequency noise surface requirements, containing analysis of the isometric view, their Power Spectral Density, Autocorrelation Function, Frequency Spectrum and Texture Direction, gave an appropriate response to the occurrence of the high-frequency measurement errors. Considering all of the analysed, commonly used or, in the other words, available in commercial software, filters, the Fast Fourier Transform Filter method can be the most suitable for definition (detection and removal) of the high-frequency measurement errors from the results of surface topography measurement of plateau-honed, turned, ground, milled or laser-textures surfaces.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| ACF | autocorrelation function |

| AFM | atomic force microscopy |

| F-surface | form surface |

| FFTF | Fast Fourier Transform Filter |

| FS | Frequency spectrum characterisation |

| FSBT | Frequency Spectrum-Based Technique |

| GF | Gaussian filter |

| HFNS | high-frequency noise surface |

| L-surface | long-wavelength surface |

| MDF | median denoising filter |

| MQCL | Minimum Quantity Cooling Lubrication |

| PSD | power spectral density |

| RGF | robust Gaussian filter |

| S-F surface | is a surface after S- and F- filtering |

| S-surface | short-wavelength noise surface |

| SF | spline filter |

| TD | texture direction graph |

References

- Trzepieciński, T.; Fejkiel, R. On the influence of deformation of deep drawing quality steel sheet on surface topography and friction. Tribol. Int. 2017, 115, 78–88. [Google Scholar] [CrossRef]

- Shao, Y.; Yin, Y.; Du, S.; Xia, T.; Xi, L. Leakage Monitoring in Static Sealing Interface Based on Three Dimensional Surface Topography Indicator. ASME J. Manuf. Sci. Eng. 2018, 140, 101003. [Google Scholar] [CrossRef]

- Morehead, J.; Zou, M. Superhydrophilic surface on Cu substrate to enhance lubricant retention. J. Adhes. Sci. Technol. 2014, 28, 833–842. [Google Scholar] [CrossRef]

- Zheng, M.; Wang, B.; Zhang, W.; Cui, Y.; Zhang, L.; Zhao, S. Analysis and prediction of surface wear resistance of ball-end milling topography. Surf. Topogr. Metrol. Prop. 2020, 8, 025032. [Google Scholar] [CrossRef]

- Dzierwa, A.; Galda, L.; Tupaj, M.; Dudek, K. Investigation of wear resistance of selected materials after slide burnishing process. Eksploat. Niezawodn. 2020, 22, 432–439. [Google Scholar] [CrossRef]

- Szala, M.; Świetlicki, A.; Sofińska-Chmiel, W. Cavitation erosion of electrostatic spray polyester coatings with different surface finish. Bull. Pol. Acad. Sci. Tech. Sci. 2021, 69, e137519. [Google Scholar] [CrossRef]

- Macek, W. Correlation between Fractal Dimension and Areal Surface Parameters for Fracture Analysis after Bending-Torsion Fatigue. Metals 2021, 11, 1790. [Google Scholar] [CrossRef]

- Liewald, M.; Wagner, S.; Becker, D. Influence of Surface Topography on the Tribological Behaviour of Aluminium Alloy 5182 with EDT Surface. Tribol. Lett. 2010, 39, 135–142. [Google Scholar] [CrossRef]

- Leach, R.K.; Evans, C.; He, L.; Davies, A.; Duparré, A.; Henning, A.; Jones, C.W.; O’Connor, D. Open questions in surface topography measurement: A roadmap. Surf. Topogr. Metrol. Prop. 2015, 3, 013001. [Google Scholar] [CrossRef]

- Podulka, P. Selection of Methods of Surface Texture Characterisation for Reduction of the Frequency-Based Errors in the Measurement and Data Analysis Processes. Sensors 2022, 22, 791. [Google Scholar] [CrossRef]

- Pawlus, P.; Wieczorowski, M.; Mathia, T. The Errors of Stylus Methods in Surface Topography Measurements; Zapol: Szczecin, Poland, 2014. [Google Scholar]

- Pawlus, P. Digitisation of surface topography measurement results. Measurement 2007, 40, 672–686. [Google Scholar] [CrossRef]

- Podulka, P. Bisquare robust polynomial fitting method for dimple distortion minimisation in surface quality analysis. Surf. Interface Anal. 2020, 52, 875–881. [Google Scholar] [CrossRef]

- Podulka, P. The effect of valley depth on areal form removal in surface topography measurements. Bull. Pol. Acad. Sci. Tech. Sci. 2019, 67, 391–400. [Google Scholar] [CrossRef]

- Magdziak, M. Selection of the Best Model of Distribution of Measurement Points in Contact Coordinate Measurements of Free-Form Surfaces of Products. Sensors 2019, 19, 5346. [Google Scholar] [CrossRef]

- Podulka, P.; Pawlus, P.; Dobrzanski, P.; Lenart, A. Spikes removal in surface measurement. J. Phys. Conf. Ser. 2014, 483, 012025. [Google Scholar] [CrossRef]

- De Groot, P.; DiSciacca, J. Definition and evaluation of topography measurement noise in optical instruments. Opt. Eng. 2020, 59, 064110. [Google Scholar] [CrossRef]

- Servin, M.; Estrada, J.C.; Quiroga, J.A.; Mosiño, J.F.; Cywiak, M. Noise in phase shifting interferometry. Opt. Express 2009, 17, 8789–8794. [Google Scholar] [CrossRef]

- Šarbort, M.; Holá, M.; Pavelka, J.; Schovánek, P.; Rerucha, Š.; Oulehla, J.; Fo, T.; Lazar, J. Comparison of three focus sensors for optical topography measurement of rough surfaces. Opt. Express 2019, 27, 33459. [Google Scholar] [CrossRef]

- Podulka, P. Comparisons of envelope morphological filtering methods and various regular algorithms for surface texture analysis. Metrol. Meas. Syst. 2020, 27, 243–263. [Google Scholar] [CrossRef]

- Podulka, P. Suppression of the High-Frequency Errors in Surface Topography Measurements Based on Comparison of Various Spline Filtering Methods. Materials 2021, 14, 5096. [Google Scholar] [CrossRef]

- ISO 2016 25178-600; Geometrical Product Specification (GPS)—Surface Texture: Areal Part 600: Metrological Characteristics for Areal-Topography Measuring Methods. International Organization for Standardization: Geneva, Switzerland, 2016.

- De Groot, P.J. The Meaning and Measure of Vertical Resolution in Optical Surface Topography Measurement. Appl. Sci. 2017, 7, 54. [Google Scholar] [CrossRef]

- Podulka, P. Reduction of Influence of the High-Frequency Noise on the Results of Surface Topography Measurements. Materials 2021, 14, 333. [Google Scholar] [CrossRef] [PubMed]

- Pawlus, P. An analysis of slope of surface topography. Metrol. Meas. Syst. 2005, 12, 295–313. [Google Scholar]

- Santoso, T.; Syam, W.P.; Darukumalli, S.; Leach, R. Development of a compact focus variation microscopy sensor for on-machine surface topography measurement. Measurement 2022, 187, 110311. [Google Scholar] [CrossRef]

- Syam, W.P.; Jianwei, W.; Zhao, B.; Maskery, I.; Elmadih, W.; Leach, R. Design and analysis of strut-based lattice structures for vibration isolation. Precis. Eng. 2018, 52, 494–506. [Google Scholar] [CrossRef]

- Muhamedsalih, H.; Jiang, X.; Gao, F. Vibration compensation of wavelength scanning interferometer for in-process surface inspection. In Proceedings of the 10th Proceedings of Computing and Engineering Annual Researchers’ Conference 2010; University of Huddersfield: Huddersfield, UK, 2010; pp. 148–153. [Google Scholar]

- Syam, W.P. In-process surface topography measurements. In Advances in Optical Surface Texture Metrology; Leach, R.K., Ed.; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Zhang, Z.; Zhang, Y.; Zhu, Y. A new approach to analysis of surface topography. Precis. Eng. 2010, 34, 807–810. [Google Scholar] [CrossRef]

- Alcock, S.G.; Ludbrook, G.D.; Owen, T.; Dockree, R. Using the power spectral density method to characterise the surface topography of optical surfaces. Proc. SPIE 2010, 7801, 780108. [Google Scholar] [CrossRef]

- Elson, J.; Bennett, J. Calculation of the power spectral density from surface profile data. Appl. Opt. 1995, 34, 201–208. [Google Scholar] [CrossRef]

- Podulka, P. Fast Fourier Transform detection and reduction of high-frequency errors from the results of surface topography profile measurements of honed textures. Eksploat. Niezawodn. 2021, 23, 84–89. [Google Scholar] [CrossRef]

- Románszki, L.; Klébert, S.; Héberger, K. Estimating Nanoscale Surface Roughness of Polyethylene Terephthalate Fibers. ACS Omega 2020, 5, 3670–3677. [Google Scholar] [CrossRef]

- Tian, H.; Ribeill, G.; Xu, C.; Reece, C.E.; Kelley, M.J. A novel approach to characterizing the surface topography of niobium superconducting radio frequency (SRF) accelerator cavities. Appl. Surf. Sci. 2011, 257, 4781–4786. [Google Scholar] [CrossRef]

- Jacobs, T.D.B.; Junge, T.; Pastewka, L. Quantitative characterisation of surface topography using spectral analysis. Surf. Topogr. Metrol. Prop. 2017, 5, 013001. [Google Scholar] [CrossRef]

- Duparré, A.; Ferre-Borrull, J.; Gliech, S.; Notni, G.; Steinert, J.; Bennett, J. Surface characterization techniques for determining the root-mean-square roughness and power spectral densities of optical components. Appl. Opt. 2002, 41, 154–171. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Wang, S.; Qin, H.; Li, B.; Li, Q. Similarity quantification of 3D surface topography measurements. Measurement 2021, 186, 110207. [Google Scholar] [CrossRef]

- Walsh, C.; Leistner, A.; Oreb, B. Power spectral density analysis of optical substrates for gravitational-wave interferometry. Appl. Opt. 1999, 38, 4790–4801. [Google Scholar] [CrossRef]

- Jiang, Z.; Wang, H.; Fei, B. Research into the application of fractal geometry in characterising machined surfaces. Int. J Mach. Tool Manu. 2001, 41, 2179–2185. [Google Scholar] [CrossRef]

- Czifra, Á.; Goda, T.; Garbayo, E. Surface characterisation by parameter-based technique, slicing method and PSD analysis. Measurement 2011, 44, 906–916. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Nieslony, P.; Wieczorowski, M. Surface morphology analysis of Duplex Stainless Steel (DSS) in Clean Production using the Power Spectral Density. Measurement 2016, 94, 464–470. [Google Scholar] [CrossRef]

- Raoufi, D. Fractal analyses of ITO thin films: A study based on power spectral density. Phys. B Condens. Matter 2010, 405, 451–455. [Google Scholar] [CrossRef]

- Xu, C.; Tian, H.; Reece, C.E.; Kelley, M.J. Enhanced characterization of niobium surface topography. Phys. Rev. Accel. Beams 2011, 14, 123501. [Google Scholar] [CrossRef]

- Sun, J.; Song, Z.; Heb, G.; Sang, Y. An improved signal determination method on machined surface topography. Precis. Eng. 2018, 51, 338–347. [Google Scholar] [CrossRef]

- Zuo, X.; Peng, M.; Zhou, Y. Influence of noise on the fractal dimension of measured surface topography. Measurement 2020, 152, 107311. [Google Scholar] [CrossRef]

- Lin, T.Y.; Blunt, L.; Stout, K.J. Determination of proper frequency bandwidth for 3D topography measurement using spectral analysis. Part I: Isotropic surfaces. Wear 1993, 166, 221–232. [Google Scholar] [CrossRef]

- Podulka, P. Proposal of frequency-based decomposition approach for minimization of errors in surface texture parameter calculation. Surf. Interface Anal. 2020, 52, 882–889. [Google Scholar] [CrossRef]

- Baofeng, H.; Haibo, Z.; Siyuan, D.; Ruizhao, Y.; Zhaoyao, S. A review of digital filtering in evaluation of surface roughness. Metrol. Meas. Syst. 2021, 28, 217–253. [Google Scholar] [CrossRef]

- Podulka, P. Selection of reference plane by the least squares fitting methods. Adv. Sci. Technol. Res. J. 2016, 10, 164–175. [Google Scholar] [CrossRef][Green Version]

- Podulka, P. The Effect of Surface Topography Feature Size Density and Distribution on the Results of a Data Processing and Parameters Calculation with a Comparison of Regular Methods. Materials 2021, 14, 4077. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Problem on non-measured points in surface texture measurements. Metrol. Meas. Syst. 2017, 24, 525–536. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Functional Importance of Surface Texture Parameters. Materials 2021, 14, 5326. [Google Scholar] [CrossRef]

- ISO 25178-3:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 3: Specification Operators. International Organization for Standardization: Geneva, Switzerland, 2012.

- Podulka, P. Edge-area form removal of two-process surfaces with valley excluding method approach. Matec. Web. Conf. 2019, 252, 05020. [Google Scholar] [CrossRef][Green Version]

- Podulka, P. Improved Procedures for Feature-Based Suppression of Surface Texture High-Frequency Measurement Errors in the Wear Analysis of Cylinder Liner Topographies. Metals 2021, 11, 143. [Google Scholar] [CrossRef]

- ISO 16610-21:2011; Geometrical Product Specifications (GPS)—Filtration—Part 21: Linear Profile Filters: Gaussian Filters. International Organization for Standardization: Geneva, Switzerland, 2011.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Podulka, P. Proposals of Frequency-Based and Direction Methods to Reduce the Influence of Surface Topography Measurement Errors. Coatings 2022, 12, 726. https://doi.org/10.3390/coatings12060726

Podulka P. Proposals of Frequency-Based and Direction Methods to Reduce the Influence of Surface Topography Measurement Errors. Coatings. 2022; 12(6):726. https://doi.org/10.3390/coatings12060726

Chicago/Turabian StylePodulka, Przemysław. 2022. "Proposals of Frequency-Based and Direction Methods to Reduce the Influence of Surface Topography Measurement Errors" Coatings 12, no. 6: 726. https://doi.org/10.3390/coatings12060726

APA StylePodulka, P. (2022). Proposals of Frequency-Based and Direction Methods to Reduce the Influence of Surface Topography Measurement Errors. Coatings, 12(6), 726. https://doi.org/10.3390/coatings12060726