Reflectance of Oil Paintings: Influence of Paint Layer Thickness and Binder Amount

Abstract

:1. Introduction

2. Materials and Methods

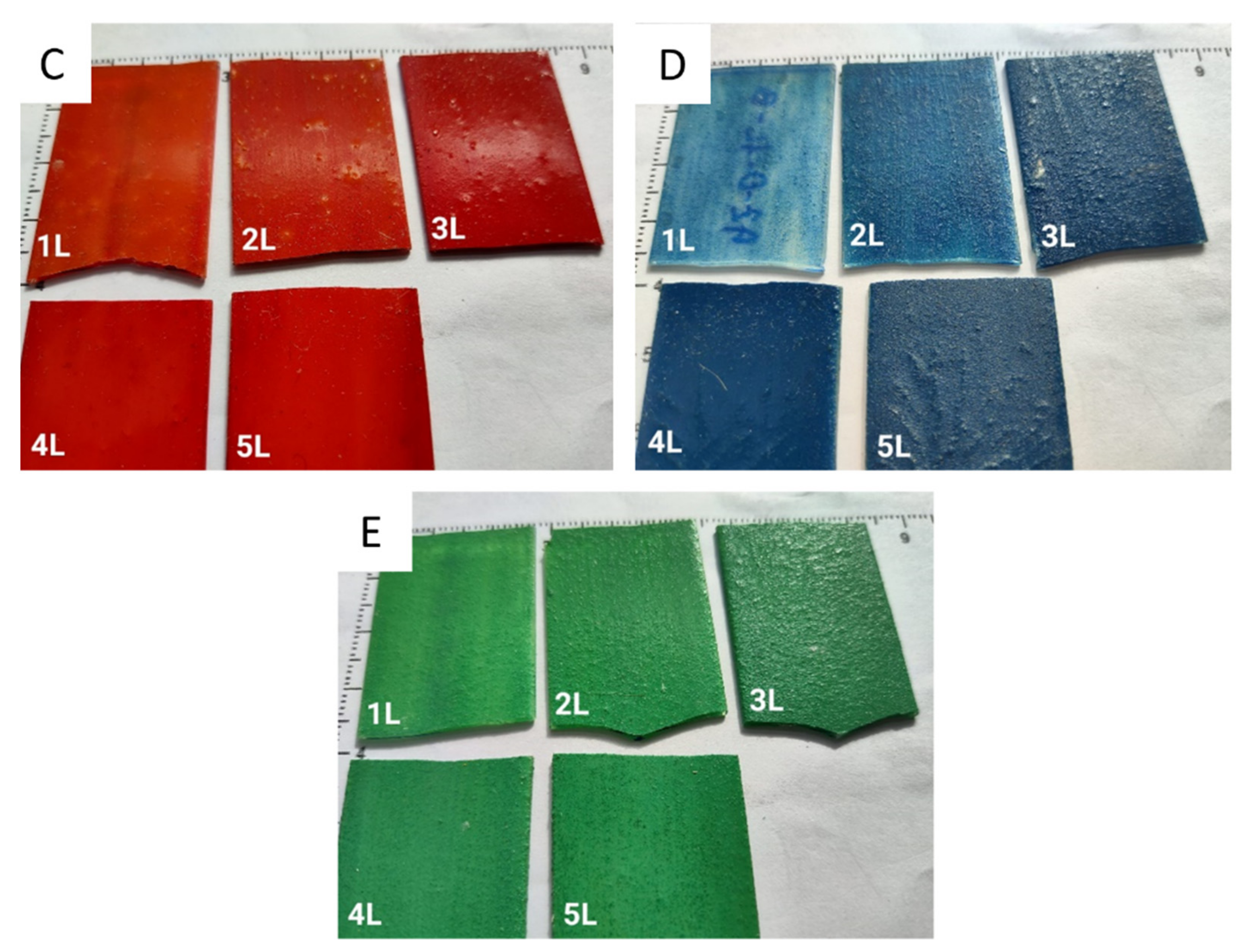

2.1. Paint Materials and Oil Painting Mock-Ups

2.2. Analytical Approach

- Prior to the pigments being mixed with the binder, the particle size was determined with a laser particle size analyzer (Mastersizer 2000LF, Malvern Instruments, Malvern, UK). Pigments were dispersed in alcohol by very gently mixing in order to prevent agglomeration. For each pigment, the volume distribution of the grain size was determined. Primary and secondary maximum particle sizes and the particle size range were determined following [14]. The presence of a secondary maximum particle size can significantly modify surface roughness and consequently alter surface physical properties such as reflectance [14].

- The pigment mineralogy was identified by X-ray diffraction (XRD) analysis (X’Pert PRO PANalytical B.V., Malvern, UK), with Cu-Kα radiation, Ni filter, 45 kV voltage, and 40 mA intensity. The exploration range was 3° to 60° 2θ, at a goniometer speed of 0.05° 2θ s1. Each mineral was identified and semi-quantified (±5%) using XPowder software (Granada, Spain) [18].

- -

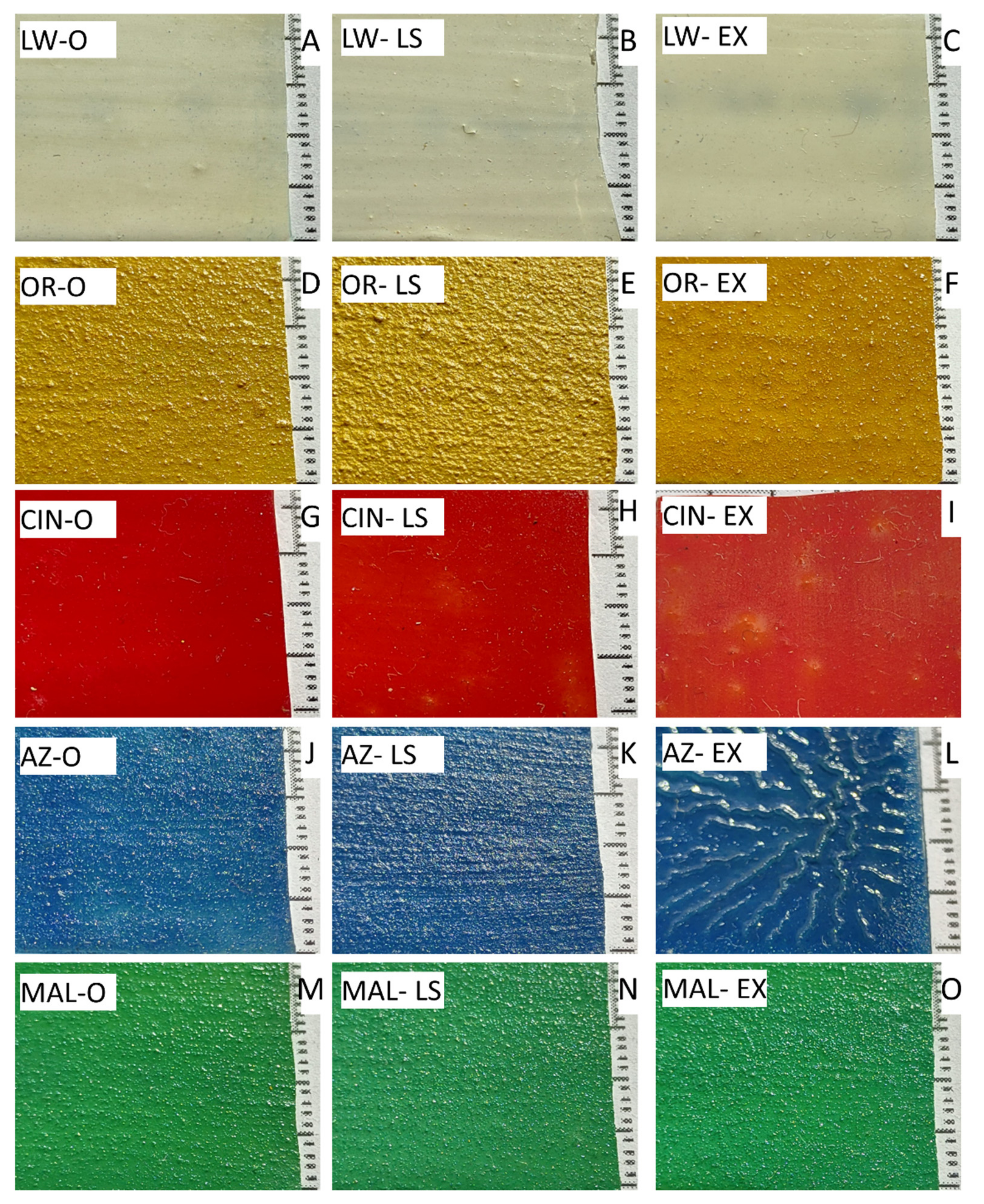

- Use of the stereomicroscope (SMZ 1000, Nikon, Istanbul, Turkey) allowed examination of the surface appearance of the painting mock-ups.

- -

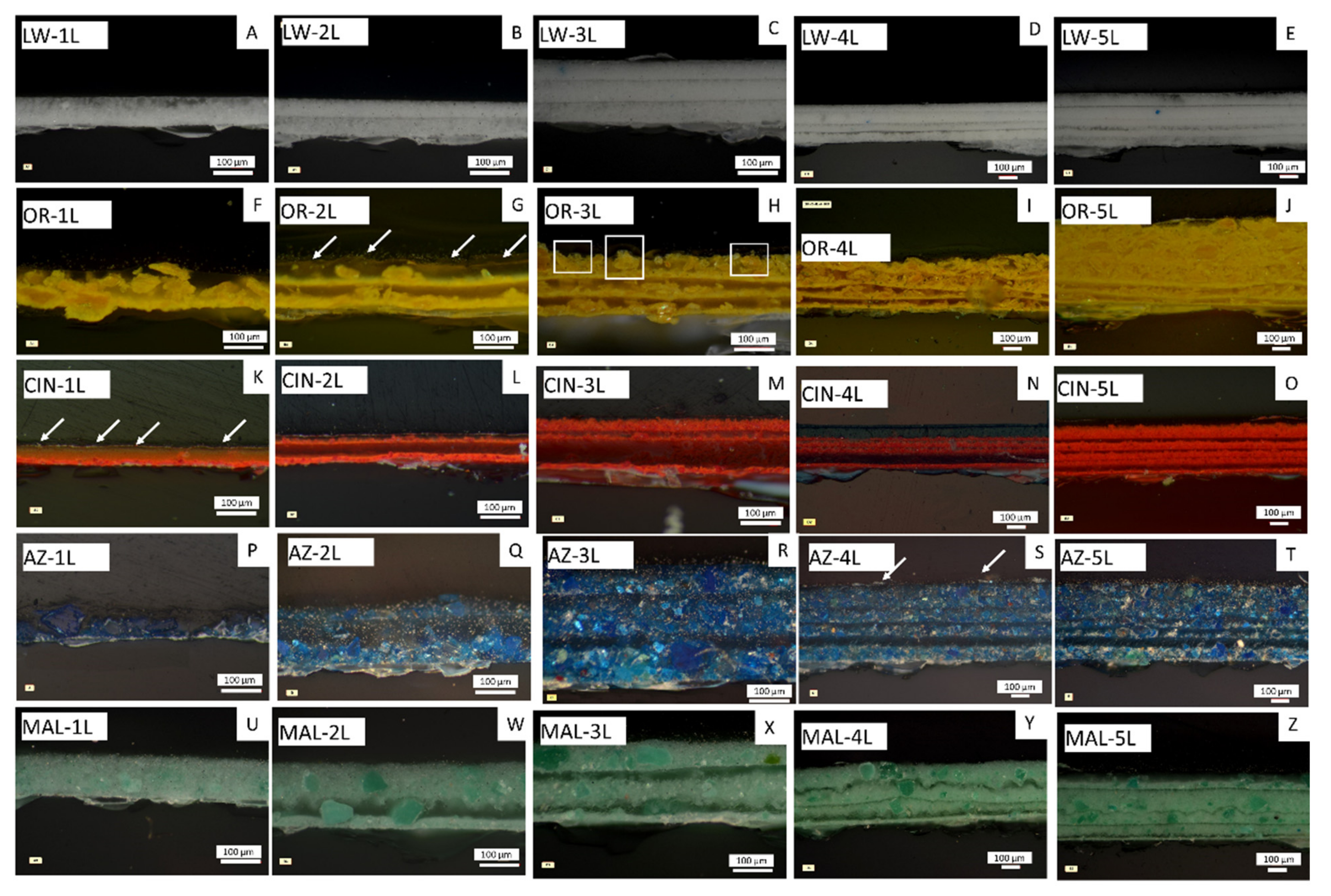

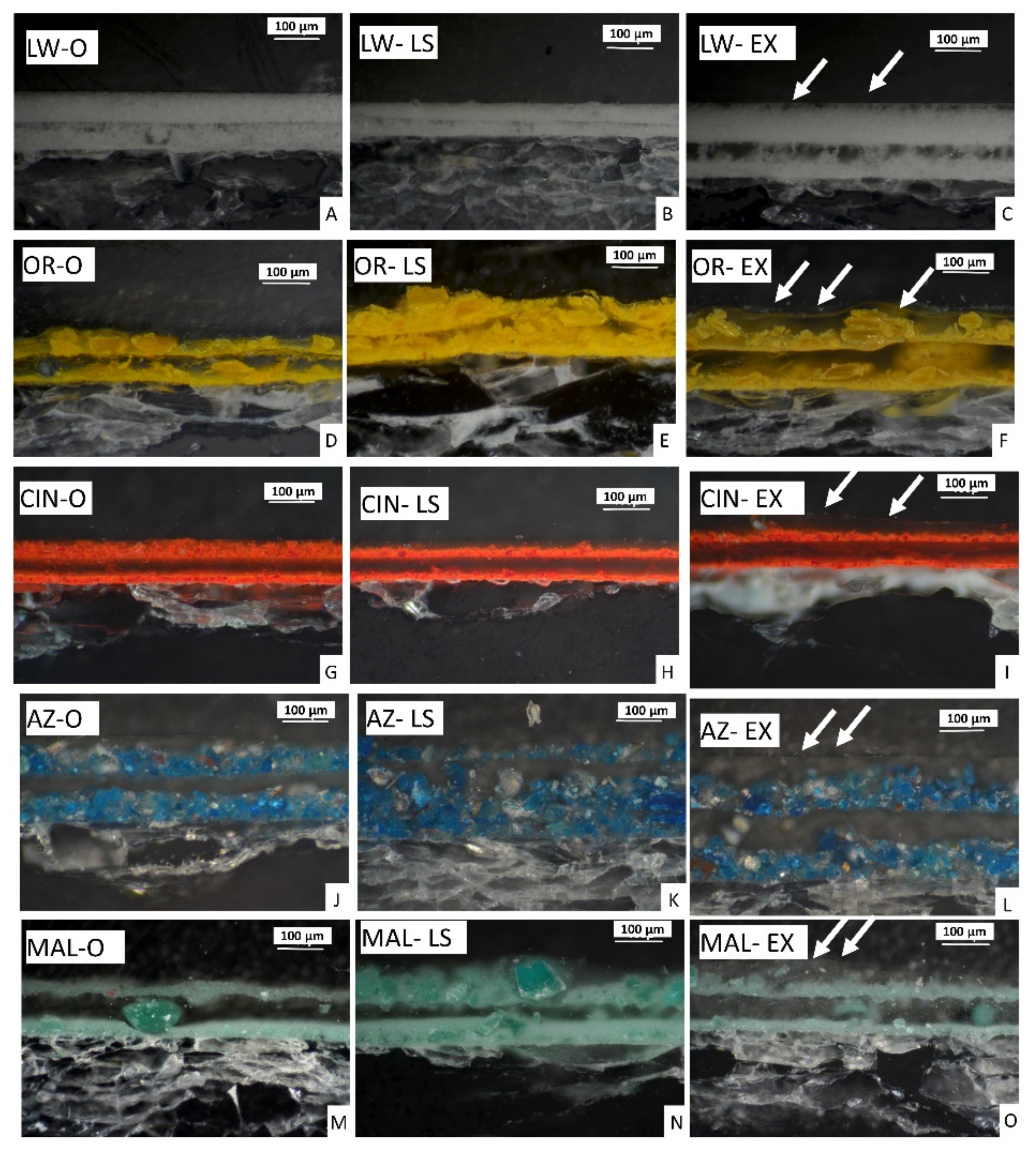

- Each mock-up was cut into two parts of different sizes with a diamond-tipped pen. The smallest part (25 mm × 25 mm × 1 mm) was embedded in resin (GTS Pro Soloplast) and cross-sectioned for transverse analysis of the paint layers. The thickness of the paint was measured in an Axioscope 5 (Zeiss, Jena, Germany) polarized light microscope.

3. Results and Discussion

3.1. Characterization of Powdered Pigments

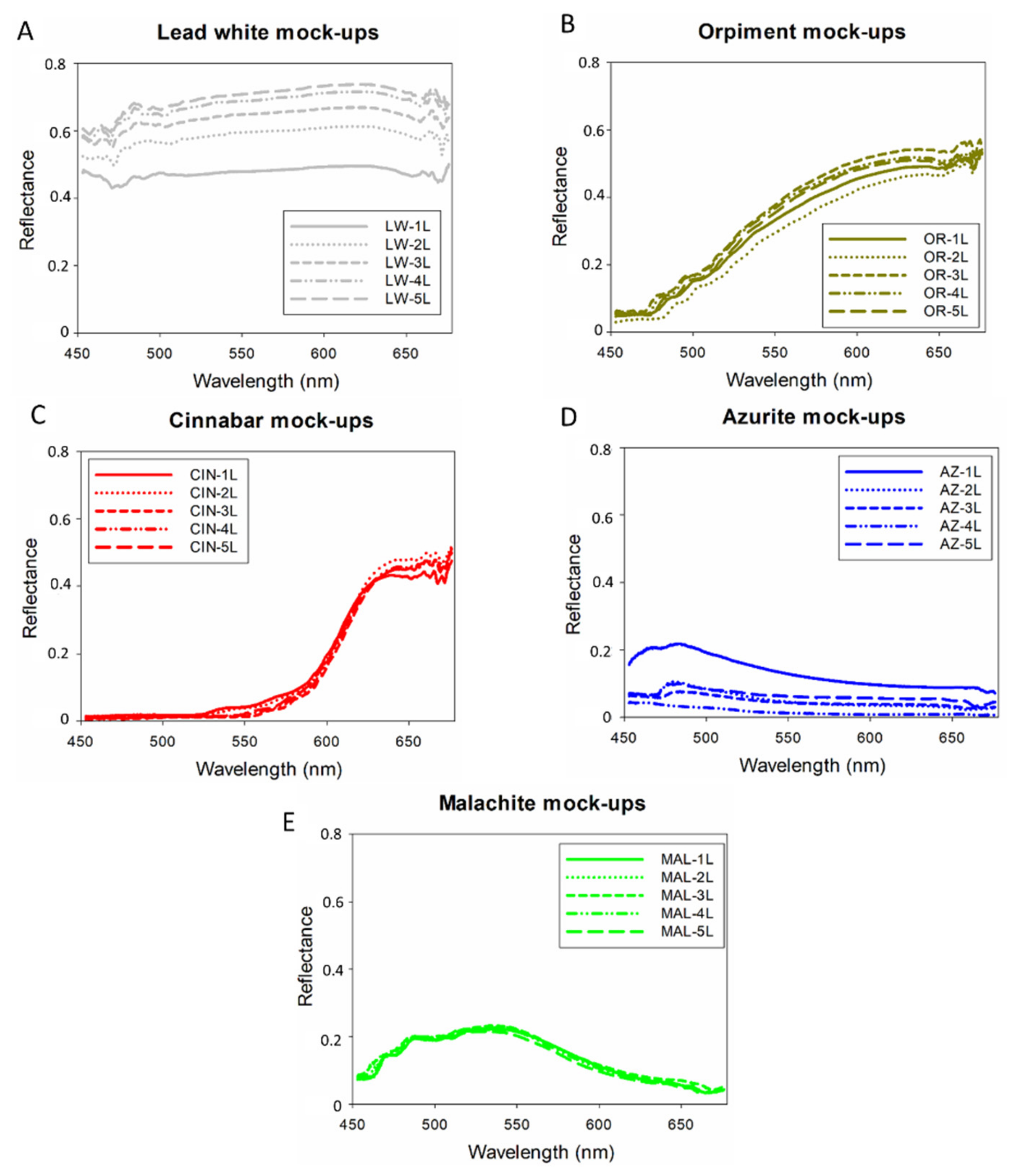

3.2. Influence of the Thickness of the Paint Layer on the Reflectance

- 1.

- 2.

- For the other mock-ups (Figure 2B–E), no relationship was observed between the thickness of the coating and the reflectance value. Thus, for OR-based paint, the reflectance value was lowest for the mock-up with two layers (157 ± 4.5 µm thick) and highest for the mock-up with three layers (188 ± 6.2 µm thick) (Figure 2B). For the CIN-based paint, the reflectance value was lowest for the mock-up with 1 layer (59 ± 0.9 µm thick) and highest for the mock-up with two layers (78 ± 1.9 µm thick) (Figure 2C). For the AZ-based paint, the highest reflectance value (by far) corresponded to the mock-up with one layer (81 ± 5.5 µm thick) due to the low hiding power as was explained before, and the lowest value corresponded to the mock-up with four layers (441 ± 4.6 µm thick) (Figure 2D). For the MAL-based paint, although the differences in reflectance values were very small, the highest reflectance value corresponded to the mock-up with three layers (219 ± 5.1 µm thick) and the lowest value corresponded to the mock-up with five layers (347 ± 2.9 µm thick) (Figure 2E).

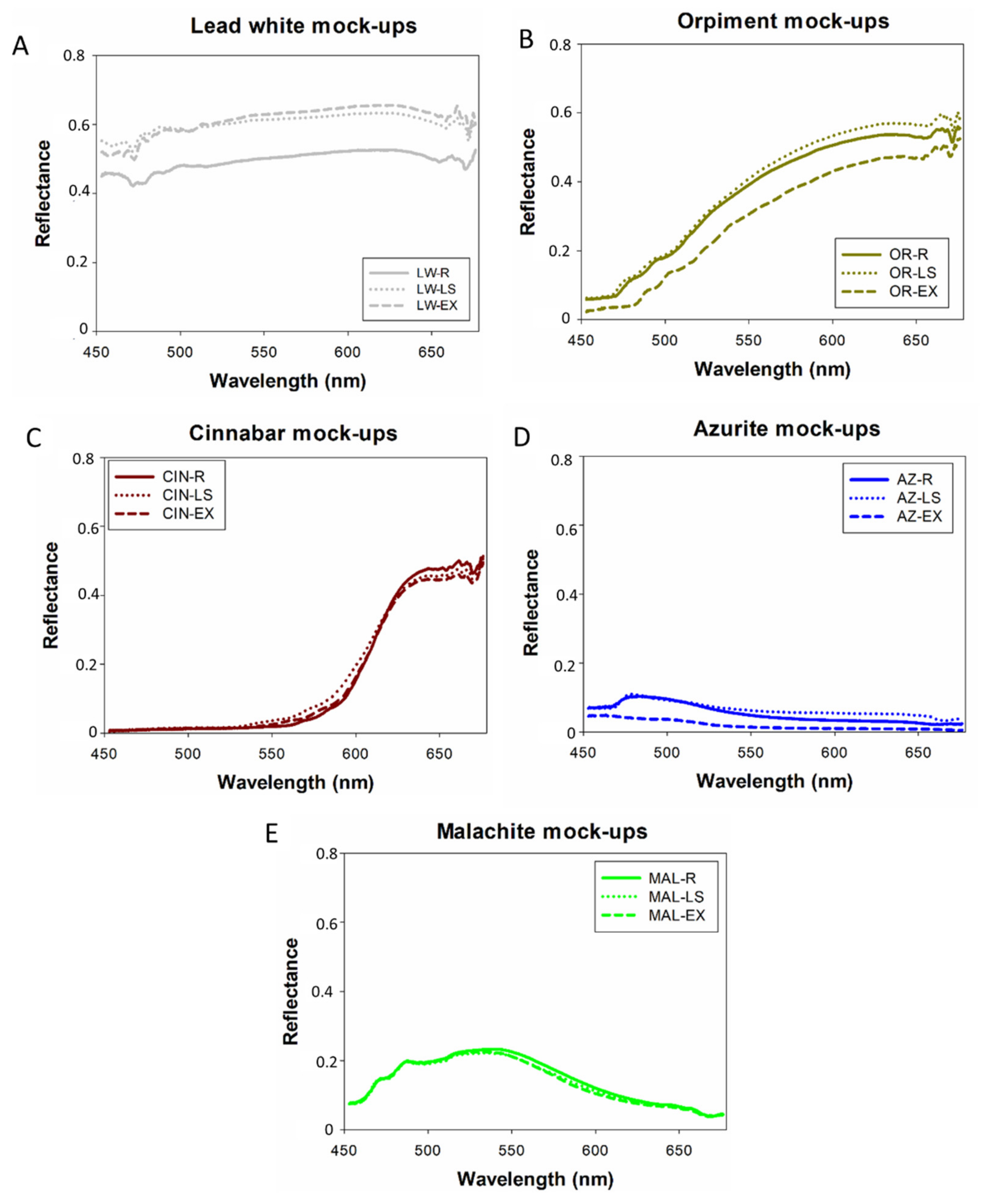

3.3. Influence of the Oil Quantity on the Reflectance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pacheco, F. El Arte de la Pintura; Cátedra: Madrid, Spain, 1990; p. 782. [Google Scholar]

- Casini, A.; Bacci, M.; Cucci, C.; Lotti, F.; Porcinai, S.; Picollo, M.; Radicati, B.; Poggesi, M.; Stefani, L. Fiber optic reflectance spectroscopy and hyper-spectral image spectroscopy: Two integrated techniques for the study of the Madonna dei Fusi. In Optical Methods for Arts and Archaeology; International Society for Optics and Photonics: Bellingham, WA, USA, 2005. [Google Scholar] [CrossRef]

- Cotte, P.; Dupraz, D. Spectral imaging of Leonardo Da Vinci’s Mona Lisa: A true color smile without the influence of aged varnish. In Proceedings of the 3rd European Conference on Color in Graphics, Imaging and Vision (IS&T), Amsterdam, The Netherlands, 19–22 June 2006; pp. 311–317. [Google Scholar]

- Zhao, Y.; Berns, R.S.; Taplin, L.A.; Coddington, J. An investigation of multispectral imaging for the mapping of pigments in paintings. In Computer Image Analysis in the Study of Art; SPIE: Bellingham, WA, USA, 2008; pp. 68100–681007. [Google Scholar]

- Kirchner, E.; van der Lans, E.; Ligterink, F.; Hendriks, E.; Delaney, J. Digitally reconstructing Van Gogh’s Field with Irises near Arles part 1: Varnish. Color Res. Appl. 2018, 43, 150–157. [Google Scholar] [CrossRef] [Green Version]

- Kirchner, E.; van der Lans, E.; Ligterink, F.; Geldof, M.; Ness Proaño Gaibor, A.; Hendriks, E.; Janssens, K.; Delaney, J. Digitally reconstructing Van Gogh’s Field with Irises near Arles part 2: Pigment concentration maps. Color Res. Appl. 2018, 43, 158–176. [Google Scholar] [CrossRef]

- Fazlali, F.; Gorji Kandi, S. Identification of pigments in artworks by inverse tangent derivative of spectrum and a new filtering method. Herit. Sci. 2020, 8, 93. [Google Scholar] [CrossRef]

- Saunders, D.; Cupitt, J. Image Processing at the National Gallery: The VASARI Project. Natl. Gallery Tech. Bull. 1993, 14, 72–85. [Google Scholar]

- Liang, H.; Saunders, D.; Cupitt, J.A. A new multispectral imaging system for examining paintings. J. Imaging Sci. Technol. 2005, 49, 551–562. [Google Scholar]

- Liang, H. Advances in multispectral and hyperspectral imaging for archaeology and art conservation. Appl. Phys. Mater. Sci. Processing 2012, 106, 309–323. [Google Scholar] [CrossRef] [Green Version]

- Fischer, C.; Kakoulli, I. Multispectral and hyperspectral imaging technologies in conservation: Current research and potential applications. Stud. Conserv. 2006, 51 (Suppl. 1), 3–16. [Google Scholar] [CrossRef]

- Cosentino, A. Identification of pigments by multispectral imaging; a flowchart method. Herit. Sci. 2014, 2, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Cosentino, A. Effects of different binders on technical photography and infrared reflectography of 54 historical pigments. Int. J. Conserv. Sci. 2015, 6, 287–298. [Google Scholar]

- Pozo-Antonio, J.S.; Barral, D.; Herrera, A.; Elert, K.; Rivas, T.; Cardell, C. Effect of tempera paint composition on their superficial physical properties—Application of interferometric profilometry and hyperspectral imaging techniques. Prog. Org. Coat. 2018, 117, 56–68. [Google Scholar] [CrossRef]

- Dupuis, G.; Menu, M. Quantitative characterization of pigment mixtures used in art by fiber-optics diffuse-reflectance spectroscopy. Appl. Phys. 2006, 83, 469–474. [Google Scholar] [CrossRef]

- Gueli, A.M.; Bonfiglio, G.; Pasqueale, S.; Troja, S.O. Effect of Particle Size on Pigments Colour. Color Res. Appl. 2016, 42, 236–243. [Google Scholar] [CrossRef] [Green Version]

- González-Cabrera, M.; Domínguez-Vidal, A.; Ayora-Cañada, M.J. Monitoring UV-accelerated alteration processes of paintings by means of hyperspectral micro-FTIR imaging and chemometrics. Spectrochim. Acta Mol. Biomol. Spectrosc. 2021, 253, 119568. [Google Scholar] [CrossRef] [PubMed]

- Martín-Ramos, J.D. Using X-Powder: A Software Package for Powder X-ray Diffraction Analysis; Universidad de Granada: Granada, Spain, 2004; ISBN 8460914976. [Google Scholar]

- Ramil, A.; Vázquez-Nion, D.; Pozo-Antonio, J.S.; Sanmartín, P.; Prieto, B. Using hyperspectral imaging to quantify phototrophic biofilms on granite. J. Environ. Inform. 2020, 35, 1. [Google Scholar] [CrossRef]

- Pérez, M.; Castro, K.; Rodríguez, M.D.; Olazabal, M.A.; Madariaga, J.M. A critical analysis of commercial pigments. In Proceedings of the ART 2002, 7th International Conference on Non-destructive Testing and Microanalysis for the Diagnostics and Conservation of the Cultural and Environmental Heritage, University of Antwerp, Antwerp, Belgium, 2–6 June 2002; pp. 173–182. [Google Scholar]

- O’Hanlon, G. Why Some Paints Are Transparent and Others Opaque. Natural Pigments Inc. 6 December 2013. Available online: www.naturalpigments.com/artist-materials/transparent-opaque-paints (accessed on 4 April 2021).

- Cotte, M.; Checroun, E.; Susini, J.; Dumas, P.; Tchoreloff, T.; Besnard, M.; Walter, P. Kinetics of oil saponification by lead salts in ancient preparations of pharmaceutical lead plasters and painting lead mediums. Atlanta 2006, 70, 1136–1142. [Google Scholar] [CrossRef] [PubMed]

- Plater, M.J.; De Silva, B.; Gelbrich, T.; Hursthouse, M.B.; Higgitt, C.L.; Saunders, D.R. The characterization of lead fatty acid soaps in ‘protrusions’ in aged traditional oil paint. Polyhedron 2003, 22, 3171–3179. [Google Scholar] [CrossRef]

- Noble, P.; van Loon, A.; Boon, J.J. Chemical changes in Old Master paintings II: Darkening due to increased transparency as a result of metal soap formation. In ICOM-CC 14th Triennial Preprints; Verger, I., Ed.; James and James: London, UK, 2005; pp. 496–503. [Google Scholar]

- Noble, P.; van Loon, A.; Boon, J.J. Selective darkening of ground and paint layers associated with the wood structure in seventeenth-century panel paintings. In Preparation for Painting: The Artist’s Choice and Its Consequences, Proceedings of the Paintings Group Interim Meeting ICOM Committee for Conservation, London, UK, 31 May–1 June 2007; Townsend, J.H., Ed.; Archetype Publications Ltd.: London, UK, 2008; pp. 68–78. [Google Scholar]

- Shimadzu, Y.; van den Berg, K.J. On metal soap related colour and transparency changes in a 19th century painting by Millais. Report. Highlights Mayerne Programme 2006, 2006, 43–52. [Google Scholar]

- Cotte, M.; Checroun, E.; De Nolf, W.; Taniguchi, Y.; De Viguerie, L.; Burghammer, M.; Walter, P.; Rivard, C.; Salomé, M.; Janssens, K.; et al. Lead soaps in paintings: Friends or foes? Stud. Conserv. 2017, 62, 2–23. [Google Scholar] [CrossRef] [Green Version]

- Laurie, A.P. On the Change of Refractive Index of Linseed Oil in the Process of Drying and its Effect on the Deterioration of Oil Paintings. Proc. R. Soc. Lond. 1926, 112, 176–181. [Google Scholar] [CrossRef]

- Townsend, J.H. The refractive index of 19th-century paint Media: A preliminary study. In Proceedings of the ICOM Committee for Conservation 10th Triennial Meeting, Washington, DC, USA, 22–27 August 1993; pp. 586–592. [Google Scholar]

| Supplier Pigment Code | Abbreviated Pigment Name | Pigment Particle Size (µm), According to Supplier | Pigment Composition, According to Supplier | Pigment Particle Size (µm) * Determined in This Study | Pigment Composition β (wt.%) Determined in This Study | |

|---|---|---|---|---|---|---|

| Lead White 46000 | LW | <45 | Hydrocerussite (PbCO3·Pb(OH)2) | 3 | Hydrocerussite (PbCO3·Pb(OH)2) | 50 |

| 0.1–10 | Cerussite (PbCO3) | 50 | ||||

| Genuine orpiment K10700 | OR | <175 | Orpiment (As2S3) | 84 | Orpiment (As2S3) | 100 |

| 1–270 | ||||||

| Cinnabar, very fine 10624 | CIN | <20 | Cinnabar (HgS) | 12 | Cinnabar (HgS) | 100 |

| 0.4–40 | ||||||

| Azurite standard 10200.Deep greenish blue | AZ | <120 | Azurite (Cu3(CO3)2(OH)2) | 22 0.2–55 | Azurite (Cu3(CO3)2(OH)2) | 90 |

| Quartz (SiO2) | <5 | |||||

| Malachite (Cu2(CO3)(OH)2) | <5 | |||||

| Malachite K10300 | MAL | <120 | Malachite (Cu2(CO3)(OH)2) | 3 (70) | Malachite (Cu2(CO3)(OH)2) | 95 |

| 0.2–200 | Pseudomalachite (Cu5(PO4)2(OH)4) | <5 | ||||

| ID | Thickness (µm) |

|---|---|

| LW-1L | 85 ± 1 |

| LW-2L | 110 ± 1 |

| LW-3L | 172 ± 2 |

| LW-4L | 214 ± 1 |

| LW-5L | 303 ± 1 |

| OR-1L | 125 ± 1 |

| OR-2L | 157 ± 4 |

| OR-3L | 188 ± 6 |

| OR-4L | 315 ± 9 |

| OR-5L | 504 ± 2 |

| CIN-1L | 59 ± 1 |

| CIN-2L | 78 ± 2 |

| CIN-3L | 163 ± 3 |

| CIN-4L | 238 ± 3 |

| CIN-5L | 315 ± 5 |

| AZ-1L | 81 ± 5 |

| AZ-2L | 172 ± 7 |

| AZ-3L | 347 ± 9 |

| AZ-4L | 441 ± 5 |

| AZ-5L | 441 ± 8 |

| MAL-1L | 116 ± 4 |

| MAL-2L | 188 ± 5 |

| MAL-3L | 219 ± 5 |

| MAL-4L | 315 ± 3 |

| MAL-5L | 347 ± 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pozo-Antonio, J.S.; Cardell, C.; Sánchez, S.; Montes Rueda, J. Reflectance of Oil Paintings: Influence of Paint Layer Thickness and Binder Amount. Coatings 2022, 12, 601. https://doi.org/10.3390/coatings12050601

Pozo-Antonio JS, Cardell C, Sánchez S, Montes Rueda J. Reflectance of Oil Paintings: Influence of Paint Layer Thickness and Binder Amount. Coatings. 2022; 12(5):601. https://doi.org/10.3390/coatings12050601

Chicago/Turabian StylePozo-Antonio, José Santiago, Carolina Cardell, Sonia Sánchez, and Jesús Montes Rueda. 2022. "Reflectance of Oil Paintings: Influence of Paint Layer Thickness and Binder Amount" Coatings 12, no. 5: 601. https://doi.org/10.3390/coatings12050601

APA StylePozo-Antonio, J. S., Cardell, C., Sánchez, S., & Montes Rueda, J. (2022). Reflectance of Oil Paintings: Influence of Paint Layer Thickness and Binder Amount. Coatings, 12(5), 601. https://doi.org/10.3390/coatings12050601