Sliding Friction and Wear Properties of 40CrNiMo Steel after Laser Hardening against GCr15 Steel under Oil Lubrication

Abstract

:1. Introduction

2. Experimental Part

2.1. Specimen Preparation

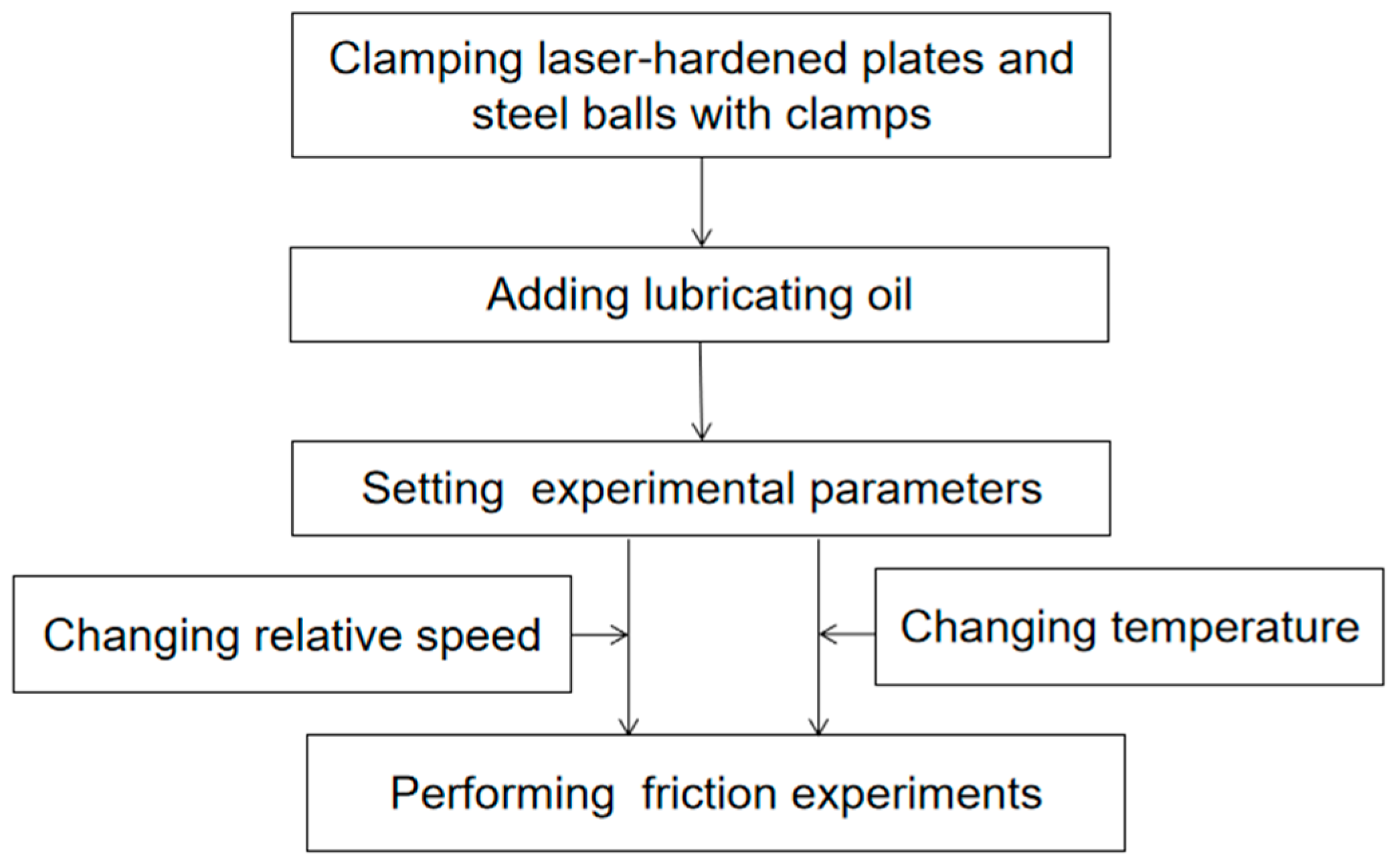

2.2. Experiment Method

3. Results and Discussion

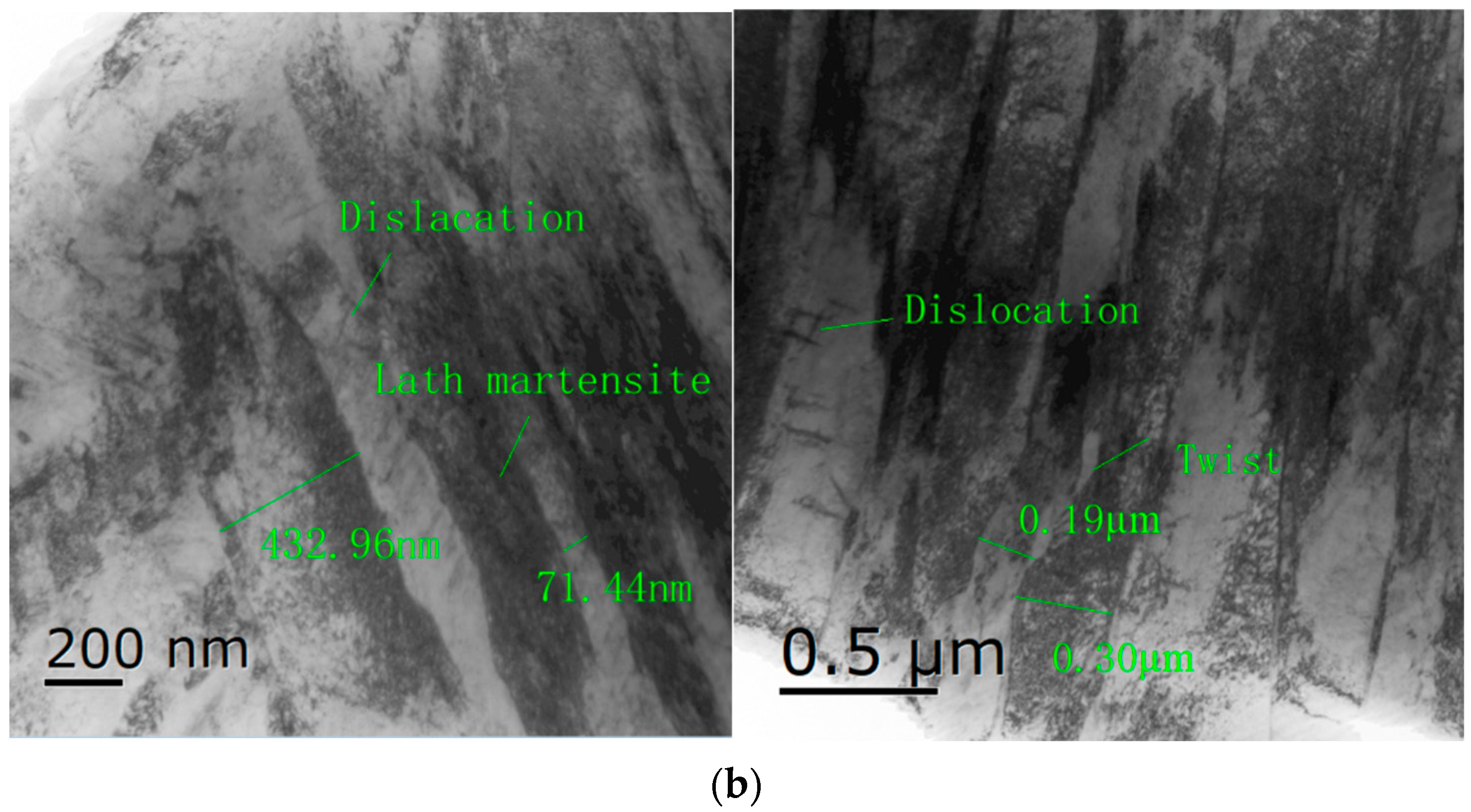

3.1. Organizational Observation

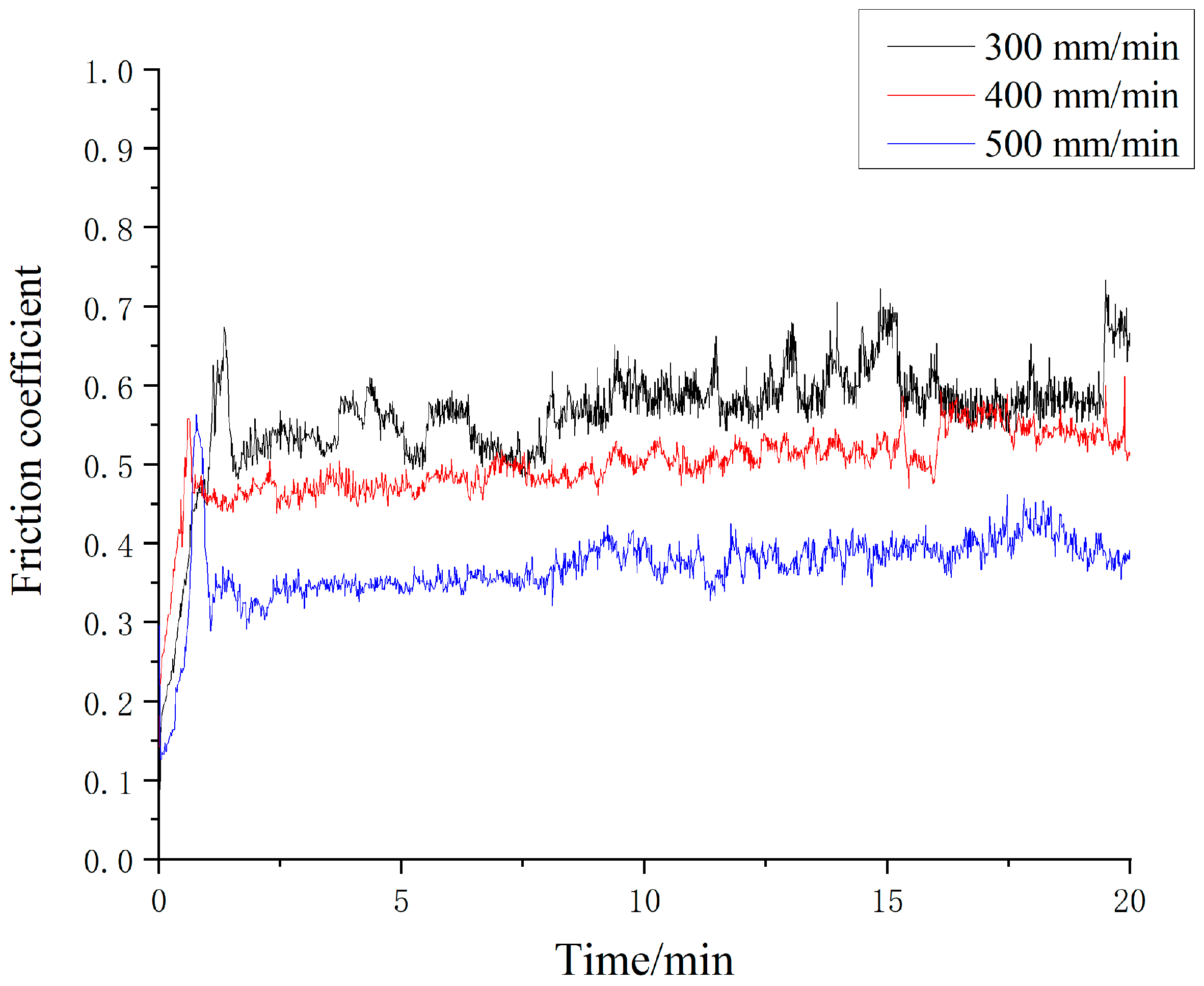

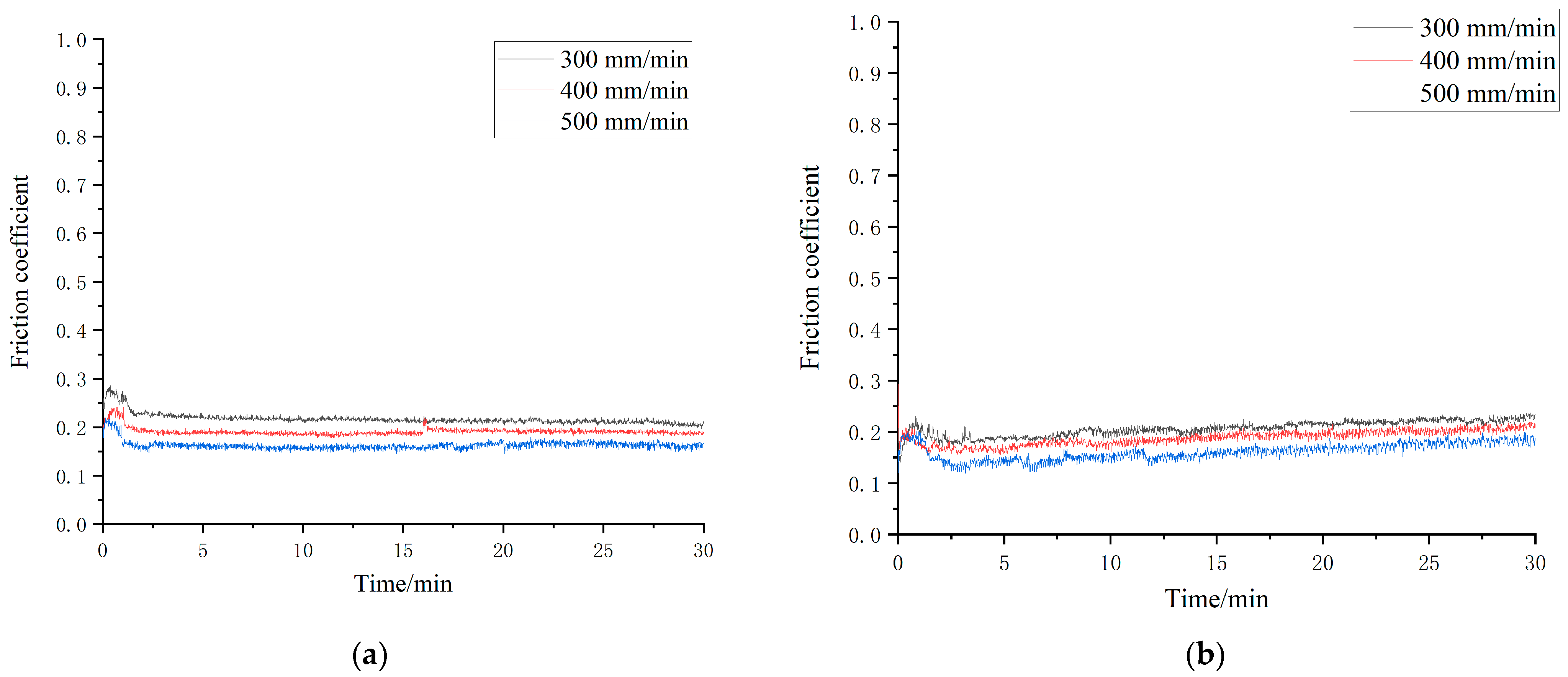

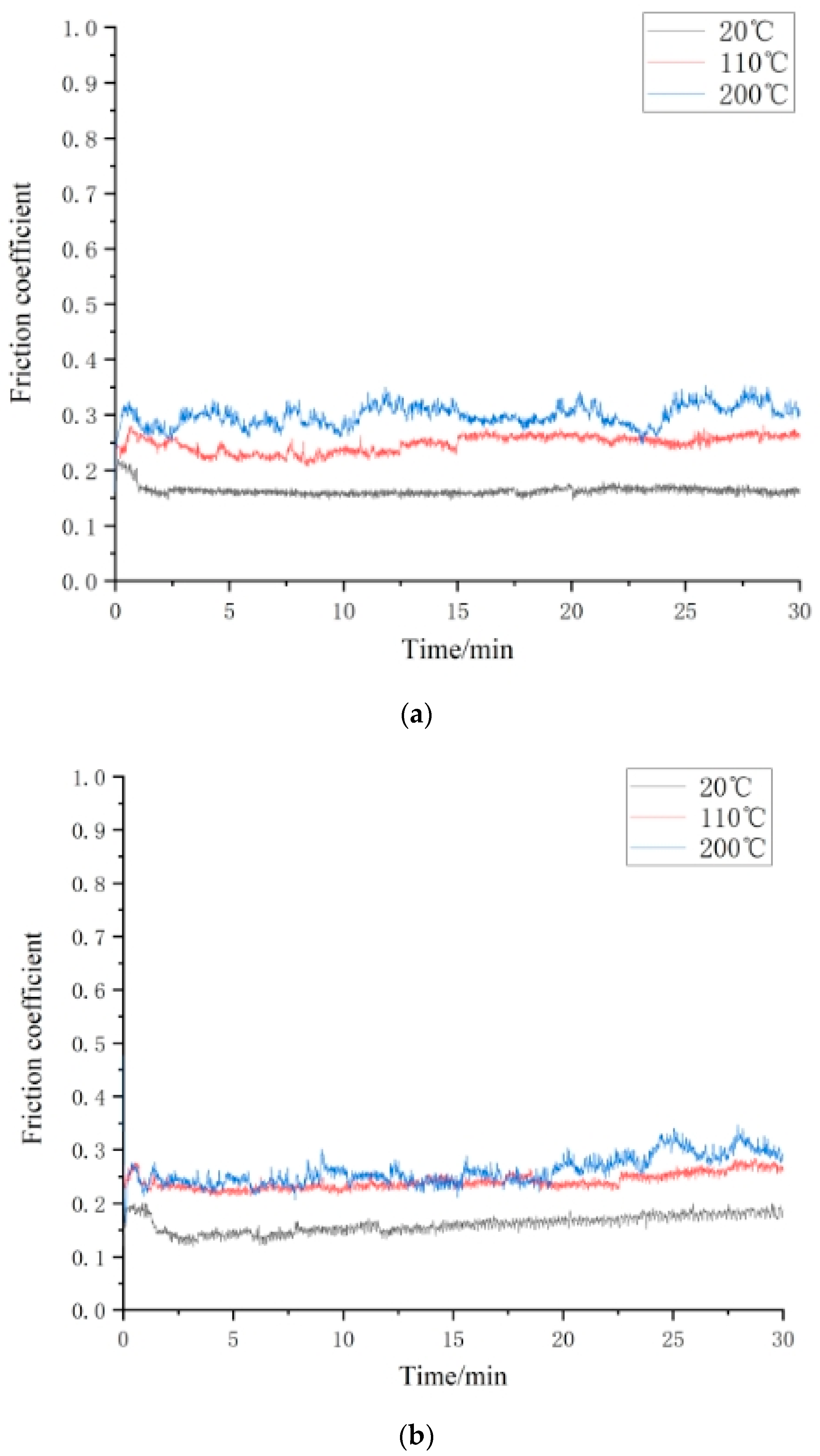

3.2. Friction Coefficient

- (1)

- Friction coefficient at different movement speeds

- (2)

- Friction coefficient at different temperatures

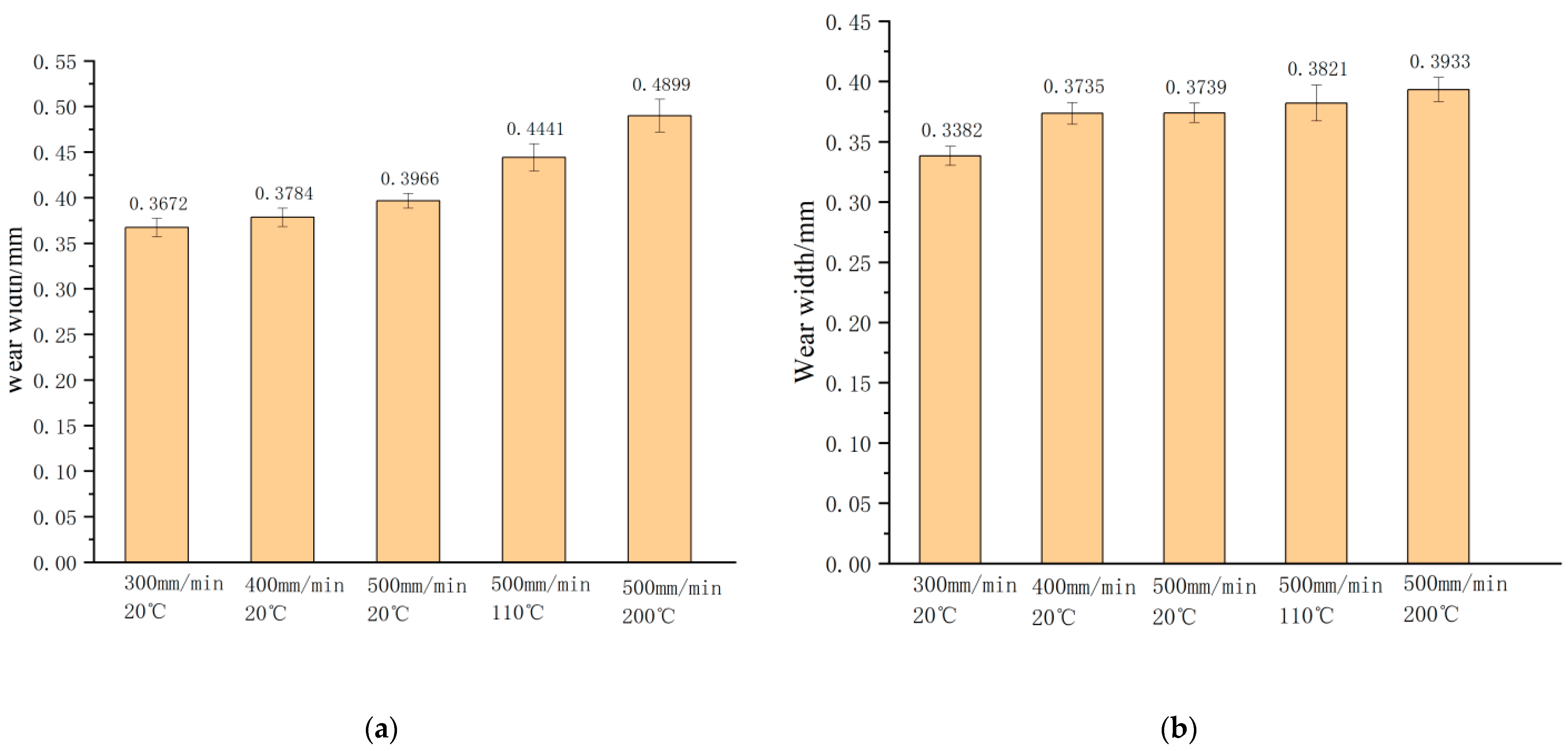

3.3. Wear Amount

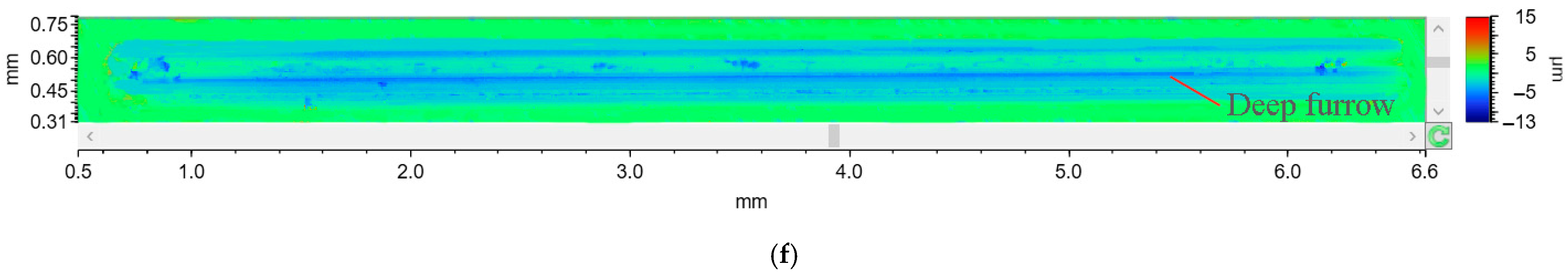

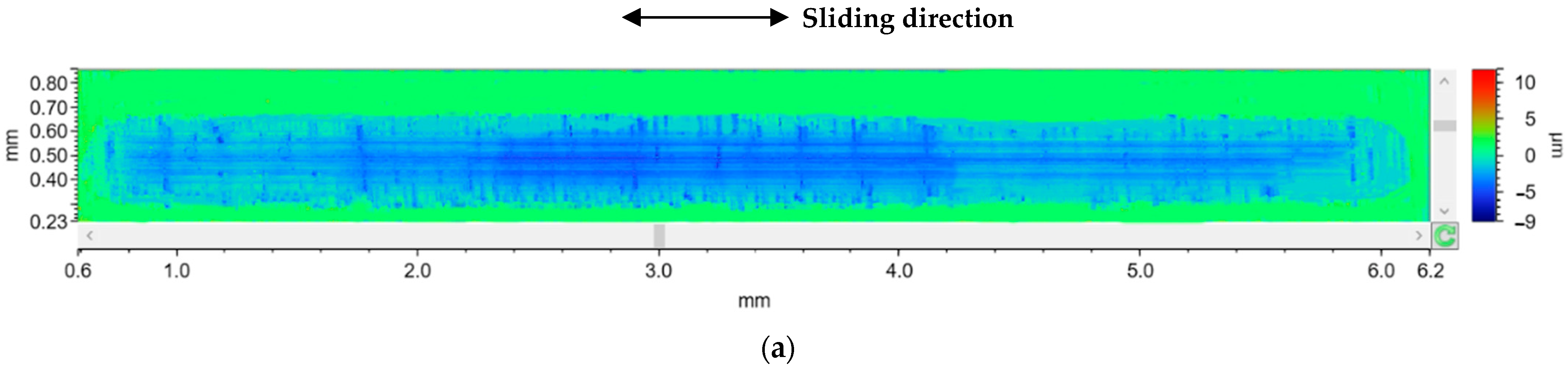

3.4. Wear Morphology

- (1)

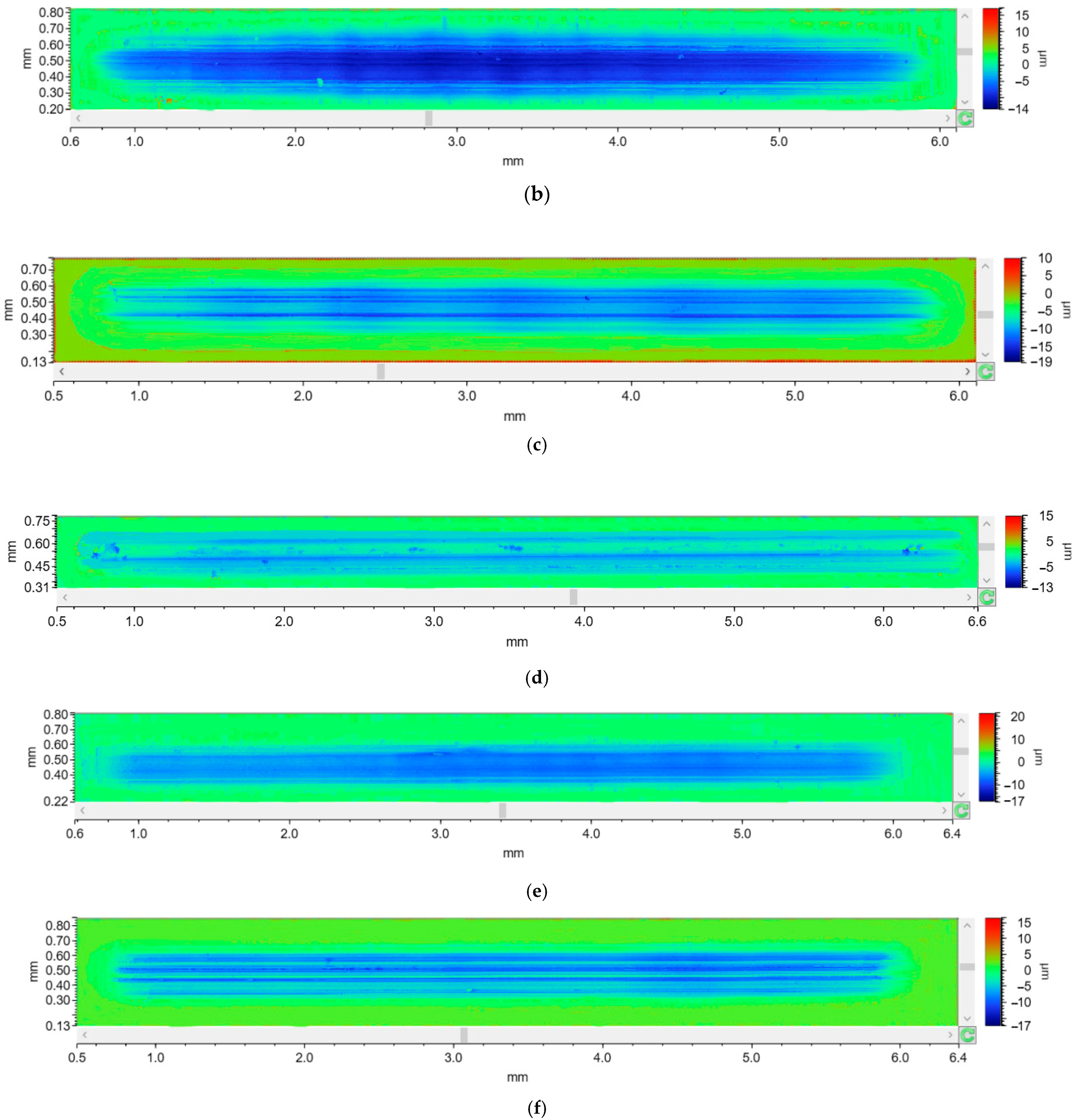

- 3D morphology analysis of friction at different speeds at room temperature

- (2)

- 3D morphology analysis of friction at different temperatures

- (3)

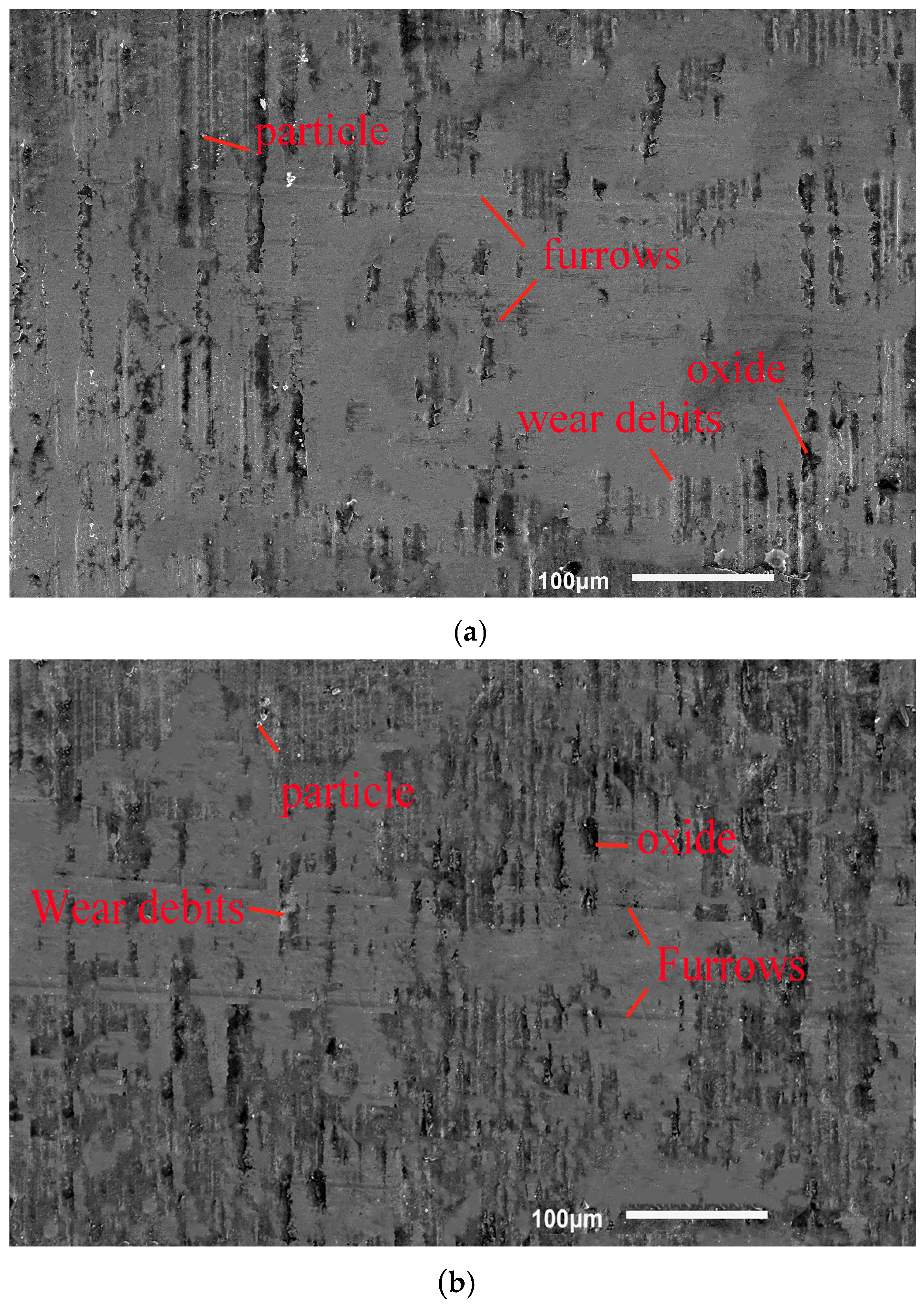

- SEM analysis of wear scars of the hardened layer with a scanning speed of 700 mm/min

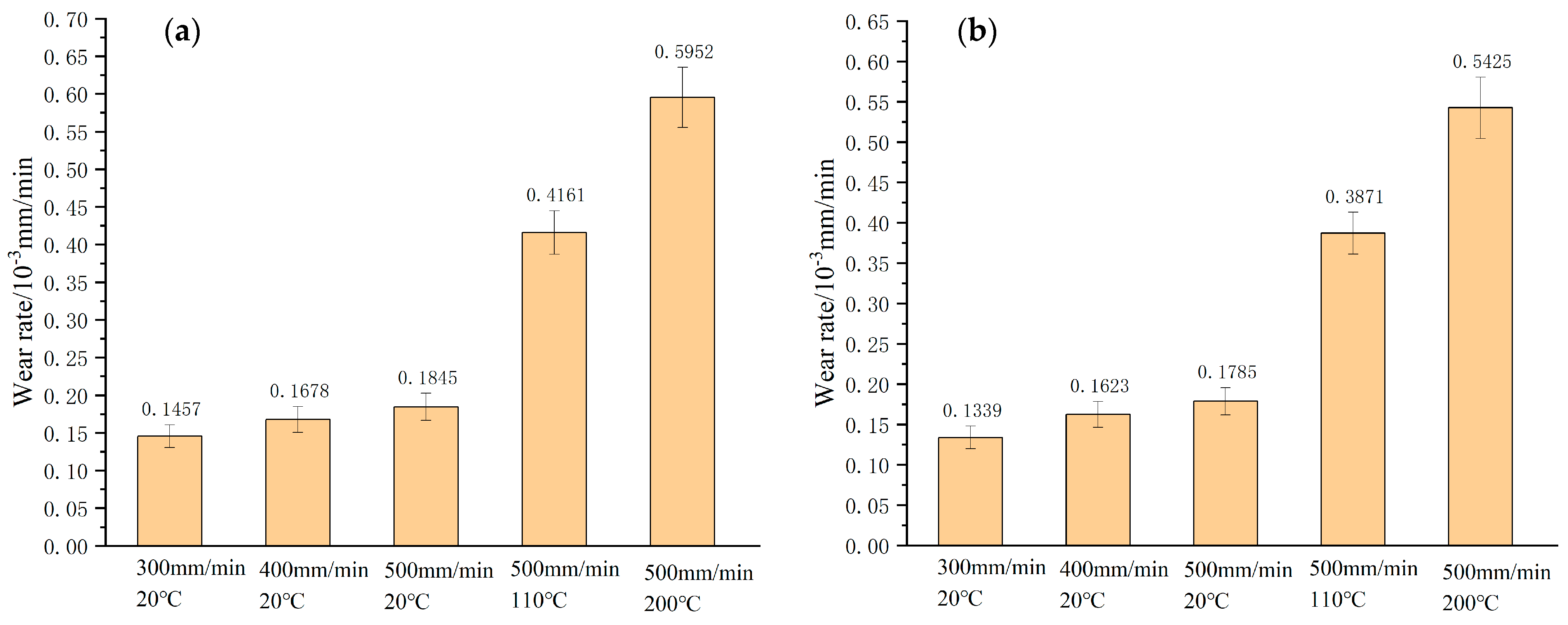

3.5. Wear Rate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kulkarni, A.; Mahale, R.; Kannan, C. Wear Based Lifetime Estimation of a Clutch Facing using Coupled Field Analysis. Int. J. Automot. Mech. Eng. 2021, 18, 9292. [Google Scholar] [CrossRef]

- Grisharin, A.; Ablyaz, T.; Muratov, K.; Shlykov, E.; Morozov, E.; Shafranov, A.; Matigullina, E.; Sirotenko, L. Research of surface microstructure of the steel 40CrNiMo after EDM. IOP Conf. Ser. Mater. Sci. Eng. 2020, 754, 012007. [Google Scholar] [CrossRef]

- Li, K.; Wang, J.; Du, Z.; Wang, Q.; Liu, A. Hot Deformation Characteristics and Deformation Resistance Model of 40CrNiMo Steel. Materials for Mechanical Engineering. Mechanical Eng. Mater. 2018, 7, 57–66. (In Chinese) [Google Scholar] [CrossRef]

- Chen, H.; Feng, A.; Li, J.; Jia, T.; Liu, Y. Effects of Multiple Laser Peening impacts on Mechanical Properties and Microstructure Evolution of 40CrNiMo Steel. J. Mater. Eng. Perform. 2019, 28, 2522–2529. [Google Scholar] [CrossRef]

- Wang, W.; Ma, R.; Li, L.; Zhai, R.; Ma, S.; Yan, H.; Zhang, S.; Gong, S. Constitutive analysis and dynamic recrystallization behavior of as-cast 40CrNiMo alloy steel during iso-thermal compression. J. Mater. Res. Technol. 2020, 9, 1929–1940. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Z.; Zhang, J.; Yang, R.; Yu, C.; Qiao, J.; Han, L. Enhanced strength and toughness in 40CrNiMo steels by austempering below martensite start temperature. J. Iron Steel Res. Int. 2021, 9. [Google Scholar] [CrossRef]

- Li, J.; Feng, A.; Zhou, J.; Sun, Y.; Chen, H.; Huang, S.; Meng, X. High-temperature wear properties and microstructural characterization of 40CrNiMo structural steel treated by cryogenic laser peening. Vacuum 2018, 157, 320–323. [Google Scholar] [CrossRef]

- Ferreira, D.F.; Vieira, J.S.; Rodrigues, S.; Miranda, G.; Oliveira, F.J.; Oliveira, J.M. Dry sliding wear and mechanical behaviour of selective laser melting processed 18Ni300 and H13 steels for moulds. Wear 2021, 488–489, 204179. [Google Scholar] [CrossRef]

- Jovičević-Klug, P.; Sedlaček, M.; Jovičević-Klug, M.; Podgornik, B. Effect of Deep Cryogenic Treatment on Wear and Galling Properties of High-Speed Steels. Materials 2021, 14, 7561. [Google Scholar] [CrossRef]

- Jia, S.; Qu, S.; Hu, X.; Lai, F.; Duan, C.; Li, X. Effect of Shot Peening on Microstructures and High-Temperature Tribological Properties of 4Cr9Si2 Valve Steel. Steel Res. Int. 2021, 92, 2100250. [Google Scholar] [CrossRef]

- Liu, G.; Cao, Y.; Ji, S.; Yu, H.; Jiang, W.; Li, M.; Si, N. Effect of Laser Clad Ni60A Coating on High Temperature Dry Sliding Friction and Wear Characteristics of 20CrNiMo Steel. Rare Metal Mat. Eng. 2021, 50, 2281–2287. [Google Scholar]

- Pan, C.Y.; Chang, J.H.; Cao, G.Q. Influence of surface microstructure parameters on wear of steel ball unfolding wheel. Dig. J. Nanomater. Biostructures 2021, 16, 635–646. [Google Scholar]

- Meng, Y.; Deng, J.; Zhang, Y.; Wang, S.; Li, X.; Yue, H.; Ge, D. Tribological properties of textured surfaces fabricated on AISI 1045 steels by ultrasonic surface rolling under dry reciprocating sliding. Wear 2020, 107, 460–461. [Google Scholar] [CrossRef]

- Gao, Q.-Y.; Li, S.-X.; Su, Y.-S.; Cao, J.; Moliar, O. Grain coarsening of nano laminated structure in martensite steel under sliding wear. Tribol. Int. 2020, 151, 106381. [Google Scholar] [CrossRef]

- Klimpel, A.; Dobrzański, L.A.; Janicki, D. A study of worn wear plates of fan blades of steel mill fumes suction system. J. Mater. Process. Technol. 2005, 164, 1062–1067. [Google Scholar] [CrossRef]

- Jamari, J.; Ammarullah, M.I.; Saad, A.P.M.; Syahrom, A.; Uddin, M.; van der Heide, E.; Basri, H. The Effect of Bottom Profile Dimples on the Femoral Head on Wear in Metal-on-Metal Total Hip Arthro-plasty. J. Funct. Biomater. 2021, 12, 38. [Google Scholar] [CrossRef]

- Ammarullah, M.I.; Afif, I.Y.; Maula, M.I.; Winarni, T.I.; Tauviqirrahman, M.; Akbar, I.; Basri, H.; van der Heide, E.; Jamari, J. Tresca Stress Simulation of Metal-on-Metal Total Hip Arthroplasty during Normal Walking Activity. Materials 2020, 14, 7554. [Google Scholar] [CrossRef]

- Cheng, G.; Guo, F.; Ji, M.E.; Zhao, G.; Zhang, Z.; Jia, X. Influence of surface morphology parameters of steel on tribological properties between glass-fiber-reinforced polytetrafluoroethylene composites and steel under dry-friction and oil-lubrication conditions. Polym. Compos. 2021, 43, 1383–1394. [Google Scholar] [CrossRef]

- Lifan, S.; Dejun, K. Microstructure and Friction–Wear Performance of Laser Cladded Cu10Al–Ti–MoS2 Coatings Under Oil Lubrication Condition. Trans. Indian Inst. Met. 2021, 75, 57–67. [Google Scholar] [CrossRef]

- Hua, X.; Tian, Z.; Xie, X.; Zhang, P.; Xu, J.; Zhu, Y.; Du, H.; Yin, B. Tribological Behavior and Abrasion Resistance Mechanism of Laser Micro-Bulge Texturing Surface under Full Oil Lubrication. Tribol. Trans. 2020, 63, 726–735. [Google Scholar] [CrossRef]

- Cheng, J.; Gan, X.; Li, Z.; Lei, Q.; Zhou, K. Wear map for sliding wear behavior of Cu-15Ni-8Sn alloy against bearing steel under oil-lubricated condition. J. Cent. South Univ. 2020, 27, 311–324. [Google Scholar] [CrossRef]

- Wiśniowski, M.; Tanski, T.; Janicki, D. Laser heat treatment of titanium GRADE 1 with iron-nickel powder. Mater. Werkst. 2019, 50, 509–518. [Google Scholar] [CrossRef]

- Obergfell, K.; Schulze, V.; Löhe, D.; Vöhringer, O. Application of X-Ray Diffraction Analysis on Microstructural Investigations of Laser-Hardened Steel Surfaces. Int. J. Mater. Res. 2022, 92, 265–269. [Google Scholar]

- Yang, Z.; Fan, X.; Qiu, Z.; Li, Y.; Liu, N. Effects of laser power on the surface quenched microstructure and friction and wear properties of 40CrNiMoA steel. Met. Heat Treat. 2020, 45, 128–133. (In Chinese) [Google Scholar]

- Zhao, D.; Su, T.; Rodríguez-Padrón, D.; Lü, H.; Len, C.; Luque, R.; Yang, Z. Efficient transfer hydrogenation of alkyl levulinates to γ-valerolactone catalyzed by simple Zr–TiO2 metal oxide systems. Mater. Today Chem. 2022, 24, 100745. [Google Scholar] [CrossRef]

- Karamimoghadam, M.; Moradi, M.; Azami, M. A comparative investigation of different overlaps of the diode laser hardening in low-carbon steel and stainless steel. Optik 2021, 251, 168093. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Ni | Mo | Fe | |

|---|---|---|---|---|---|---|---|

| 40CrNiMo | 0.39 | 0.23 | 0.68 | 0.77 | 1.33 | 0.18 | Balance |

| GCr15 | 0.97 | 0.25 | 0.4 | 1.46 | 0.07 | 0.01 | Balance |

| Project (mm/s2) | Temperature (°C) | Value |

|---|---|---|

| Kinematic viscosity | 200 | 1.5 |

| 110 | 4.11 | |

| 20 | 18.24 |

| Load (N) | Laser Scanning Speed (mm/min) | Sliding Speed (mm/min) | Time (min) | Temperature (°C) |

|---|---|---|---|---|

| 20 | 700 | 300 | 30 | 20 ± 1 |

| 400 | ||||

| 500 | ||||

| 800 | 300 | |||

| 400 | ||||

| 500 |

| Load (N) | Laser Scanning Speed (mm/min) | Sliding Speed (mm/min) | Time (min) | Temperature (°C) |

|---|---|---|---|---|

| 20 | 700 | 500 | 30 | 20 ± 1 |

| 100 ± 2 | ||||

| 200 ± 2 | ||||

| 800 | 20 ± 1 | |||

| 100 ± 2 | ||||

| 200 ± 2 |

| Specimen Code | Sliding Speed (mm/min) | Laser Scan Speed (mm/min) | Friction Coefficient |

|---|---|---|---|

| 1 | 300 | 700 | 0.215 ± 0.014 |

| 2 | 400 | 700 | 0.189 ± 0.012 |

| 3 | 500 | 700 | 0.161 ± 0.009 |

| 4 | 300 | 800 | 0.207 ± 0.013 |

| 5 | 400 | 800 | 0.189 ± 0.010 |

| 6 | 500 | 800 | 0.160 ± 0.008 |

| Specimen Code | Temperature (°C) | Sliding Speed (mm/min) | Laser Scan Speed (mm/min) | Friction Coefficient |

|---|---|---|---|---|

| 1 | 20 | 500 | 800 | 0.160 ± 0.008 |

| 2 | 110 | 500 | 800 | 0.241 ± 0.015 |

| 3 | 200 | 500 | 800 | 0.261 ± 0.019 |

| 4 | 20 | 500 | 700 | 0.161 ± 0.009 |

| 5 | 110 | 500 | 700 | 0.248 ± 0.016 |

| 6 | 200 | 500 | 700 | 0.299 ± 0.020 |

| Specimen Code | Temperature (°C) | Sliding Speed (mm/min) | Laser Scan Speed (mm/min) | Wear Rate (10−3 mm/min) |

|---|---|---|---|---|

| 1 | 20 | 300 | 700 | 0.1457 ± 0.015 |

| 2 | 20 | 400 | 700 | 0.1678 ± 0.017 |

| 3 | 20 | 500 | 700 | 0.1845 ± 0.018 |

| 4 | 110 | 500 | 700 | 0.4161 ± 0.029 |

| 5 | 200 | 500 | 700 | 0.5952 ± 0.04 |

| 6 | 20 | 300 | 800 | 0.1339 ± 0.014 |

| 7 | 20 | 400 | 800 | 0.1623 ± 0.016 |

| 8 | 20 | 500 | 800 | 0.1785 ± 0.017 |

| 9 | 110 | 500 | 800 | 0.3871 ± 0.026 |

| 10 | 200 | 500 | 800 | 0.5425 ± 0.038 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Yan, H.; Li, S.; Zhang, Y.; Wu, S. Sliding Friction and Wear Properties of 40CrNiMo Steel after Laser Hardening against GCr15 Steel under Oil Lubrication. Coatings 2022, 12, 604. https://doi.org/10.3390/coatings12050604

Li J, Yan H, Li S, Zhang Y, Wu S. Sliding Friction and Wear Properties of 40CrNiMo Steel after Laser Hardening against GCr15 Steel under Oil Lubrication. Coatings. 2022; 12(5):604. https://doi.org/10.3390/coatings12050604

Chicago/Turabian StyleLi, Jia, Hongzhi Yan, Songbai Li, Yin Zhang, and Shunxing Wu. 2022. "Sliding Friction and Wear Properties of 40CrNiMo Steel after Laser Hardening against GCr15 Steel under Oil Lubrication" Coatings 12, no. 5: 604. https://doi.org/10.3390/coatings12050604

APA StyleLi, J., Yan, H., Li, S., Zhang, Y., & Wu, S. (2022). Sliding Friction and Wear Properties of 40CrNiMo Steel after Laser Hardening against GCr15 Steel under Oil Lubrication. Coatings, 12(5), 604. https://doi.org/10.3390/coatings12050604