Investigation of Leakage and Heat Transfer Properties of the Labyrinth Seal on Various Rotation Speed and Geometric Parameters

Abstract

:1. Foreword

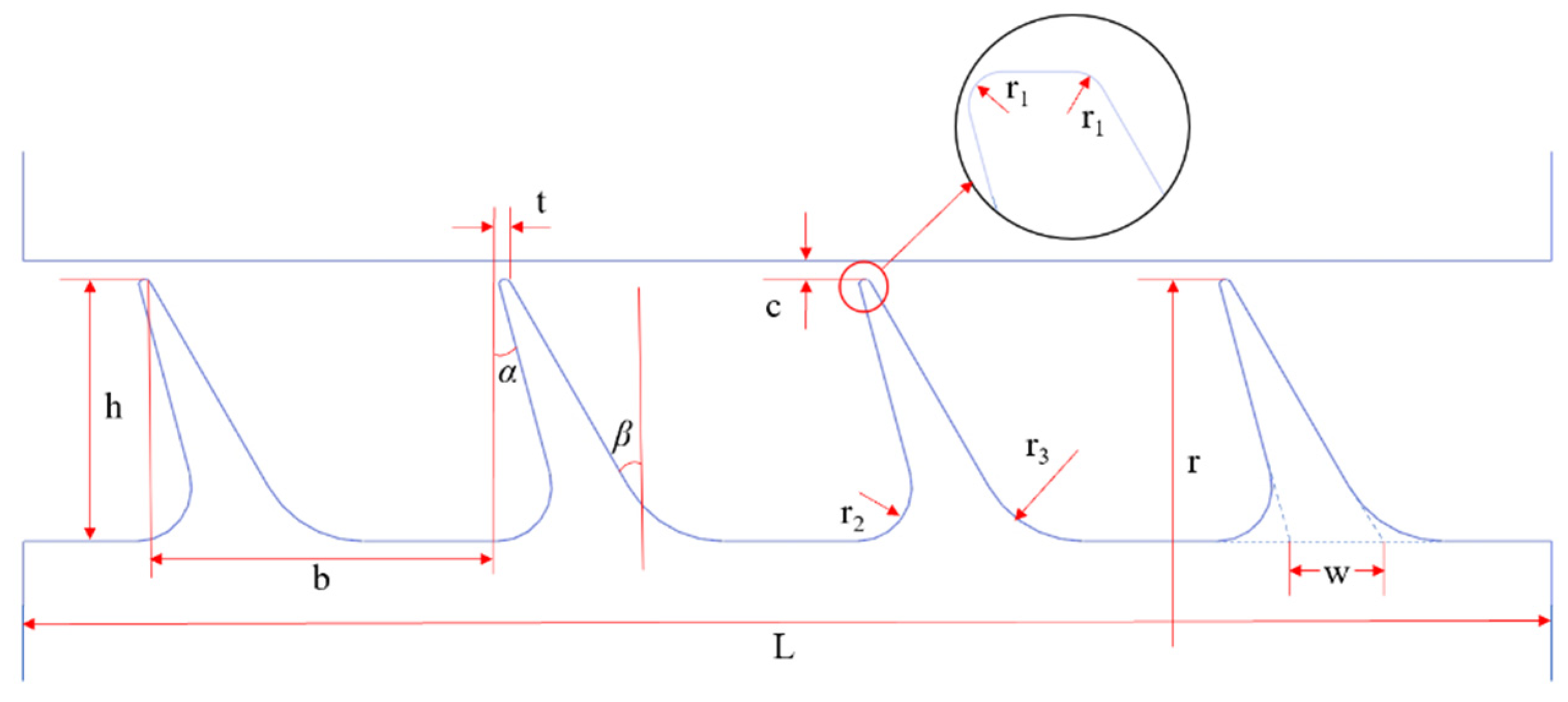

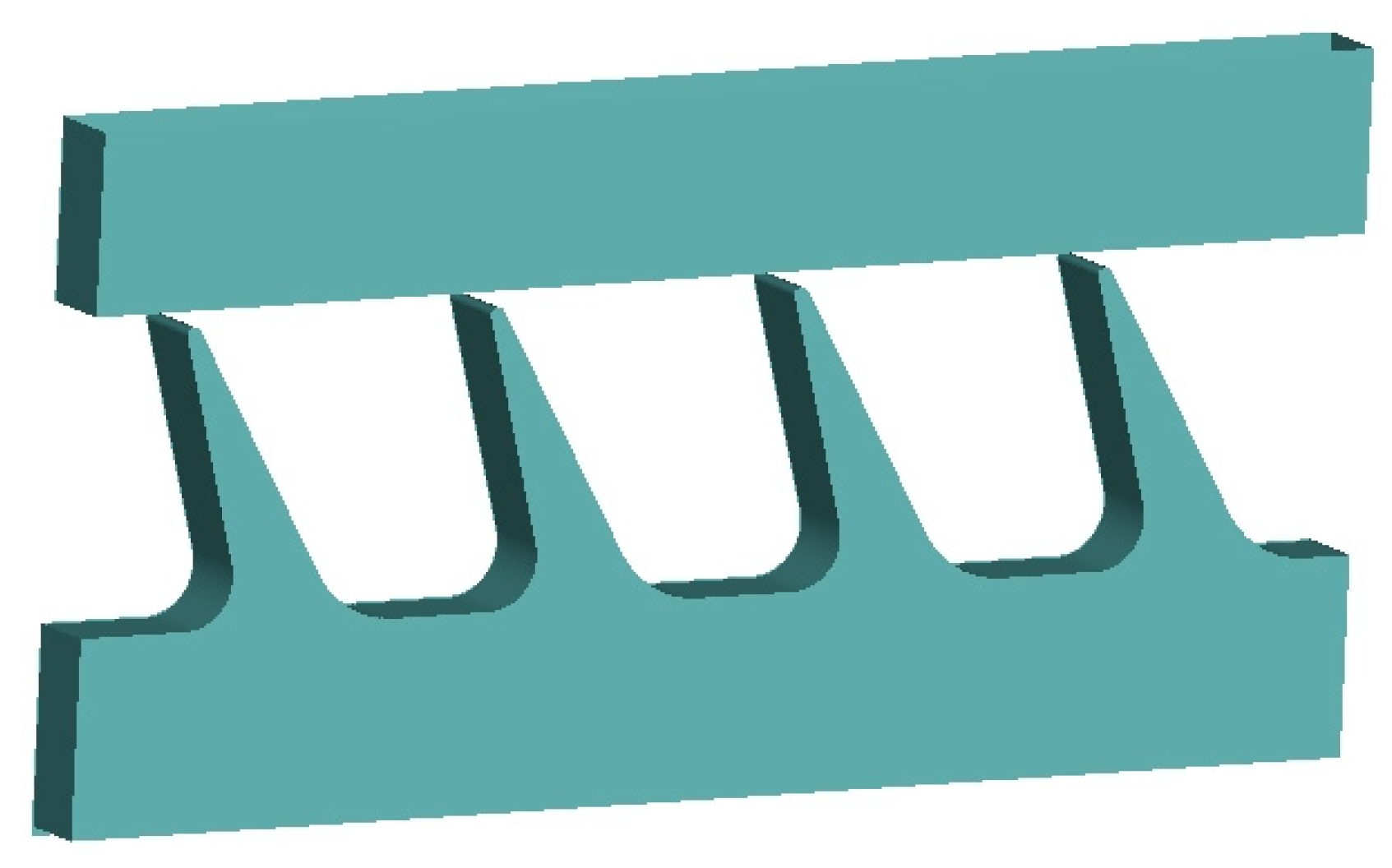

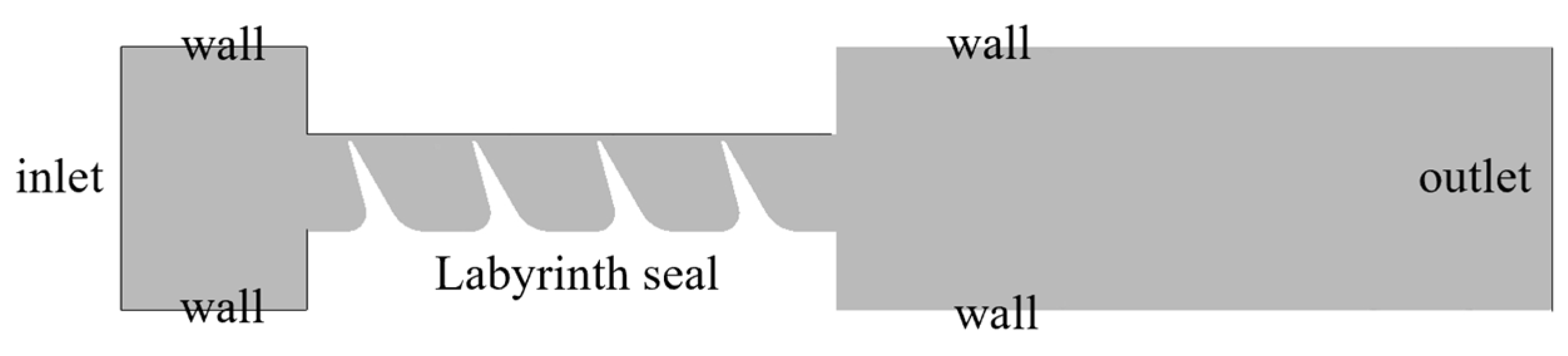

2. Computational Domain Model of Oblique Labyrinth Seal Structure

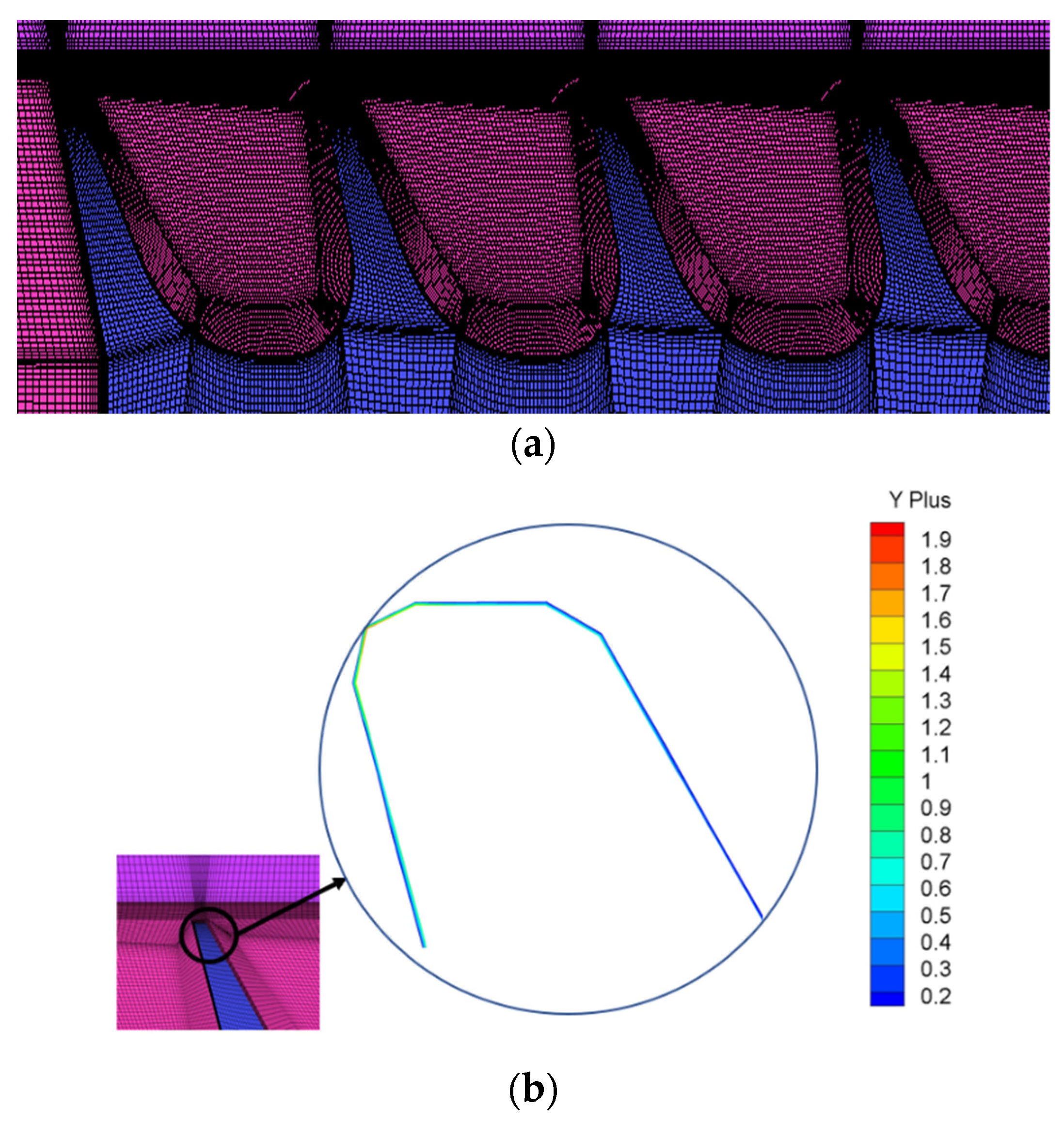

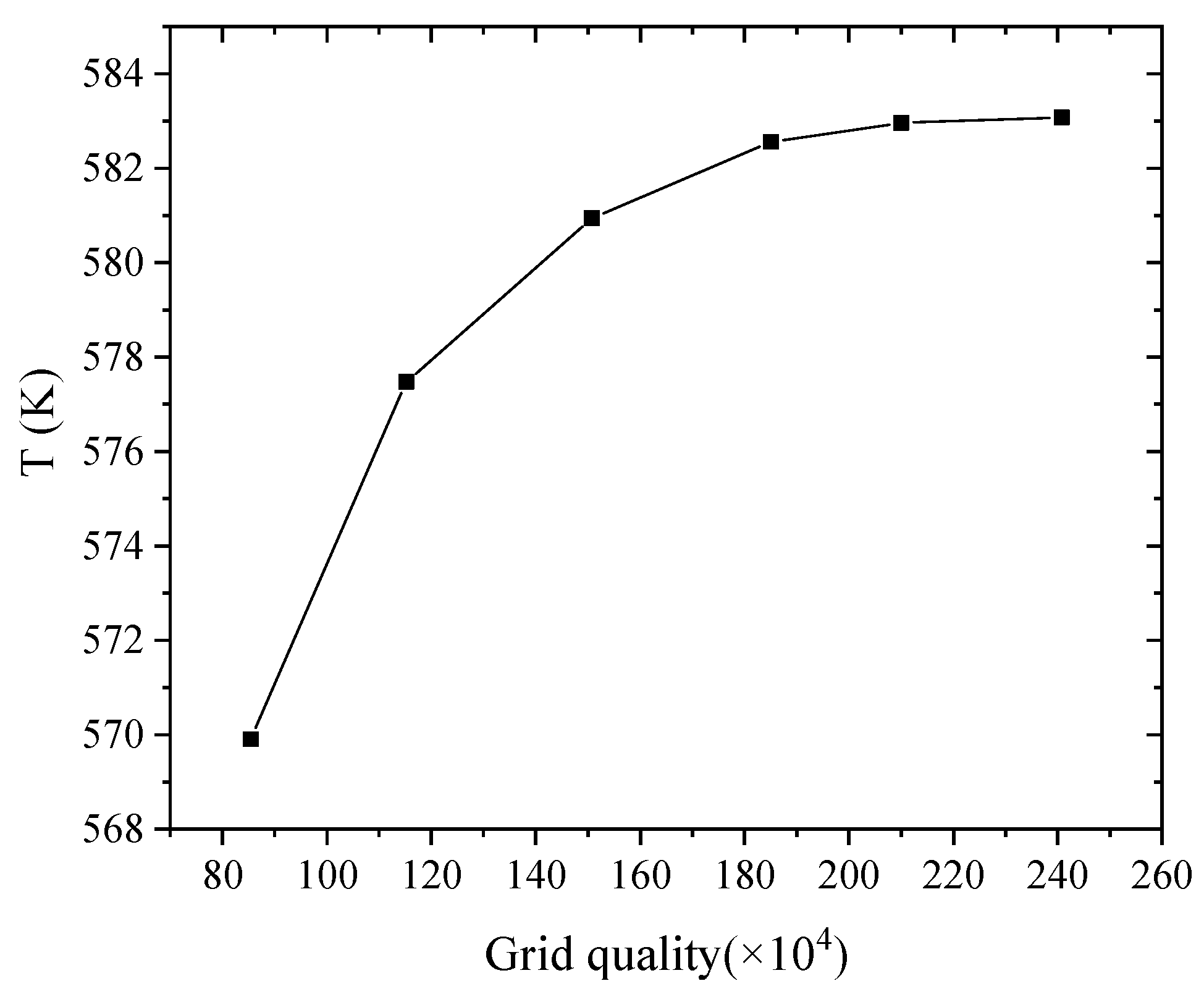

2.1. Model Structure and Meshing

2.2. Boundary Conditions and Parameter Definitions

3. Effect of Geometric Parameters of the Labyrinth Seal on Leakage Characteristics at Different Rotational Speeds

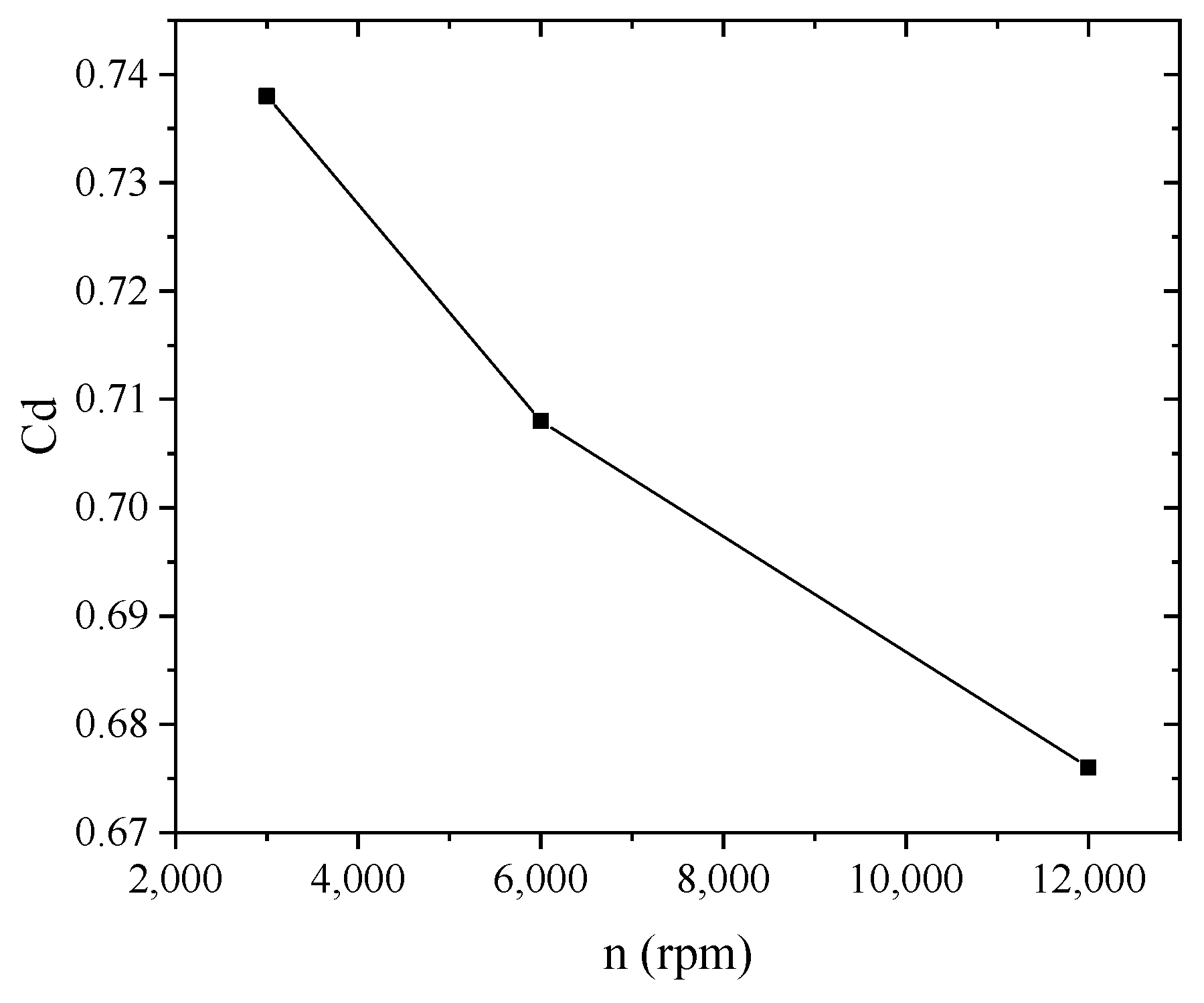

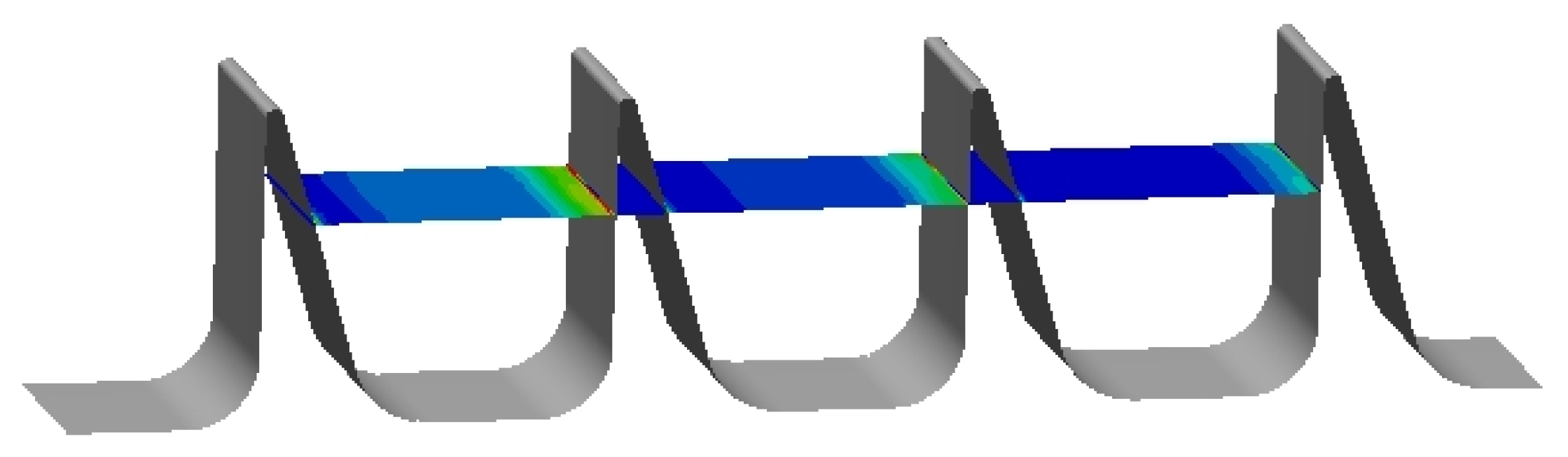

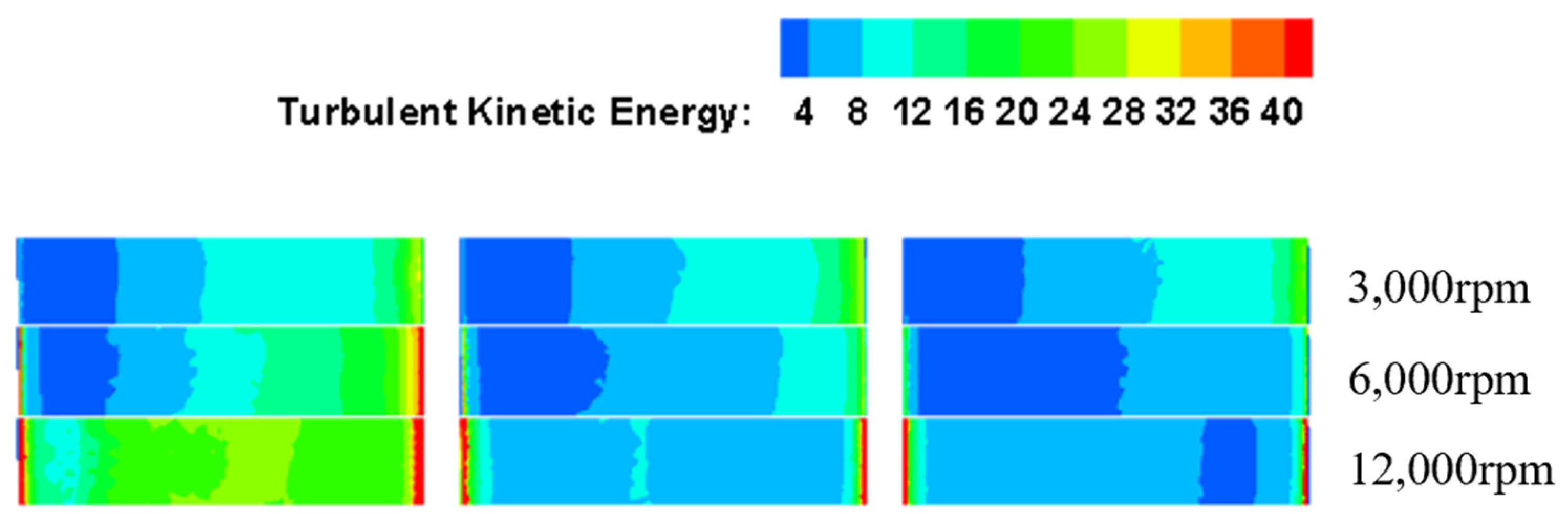

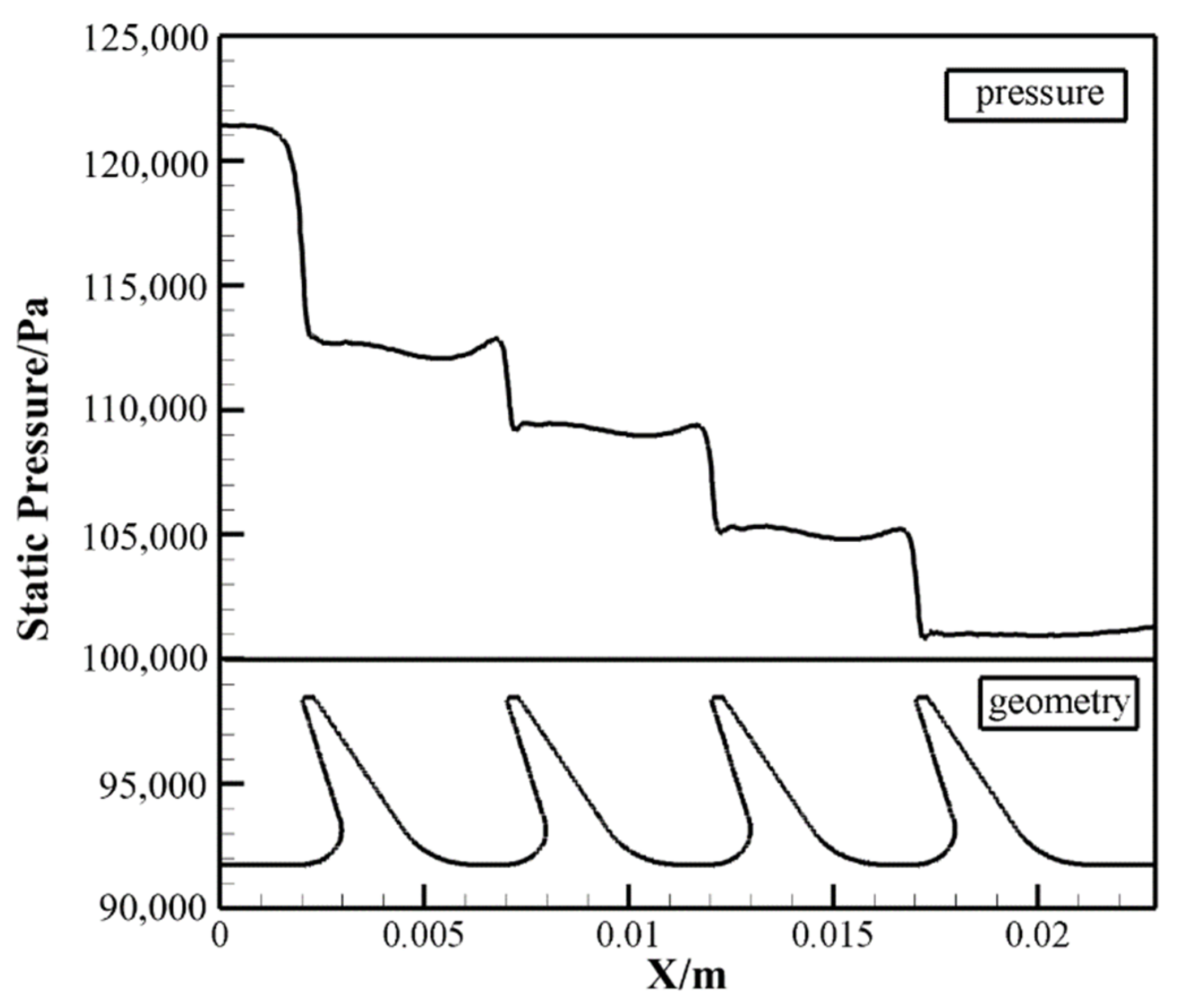

3.1. Effect of Rotational Speed on Labyrinth Seal Flow

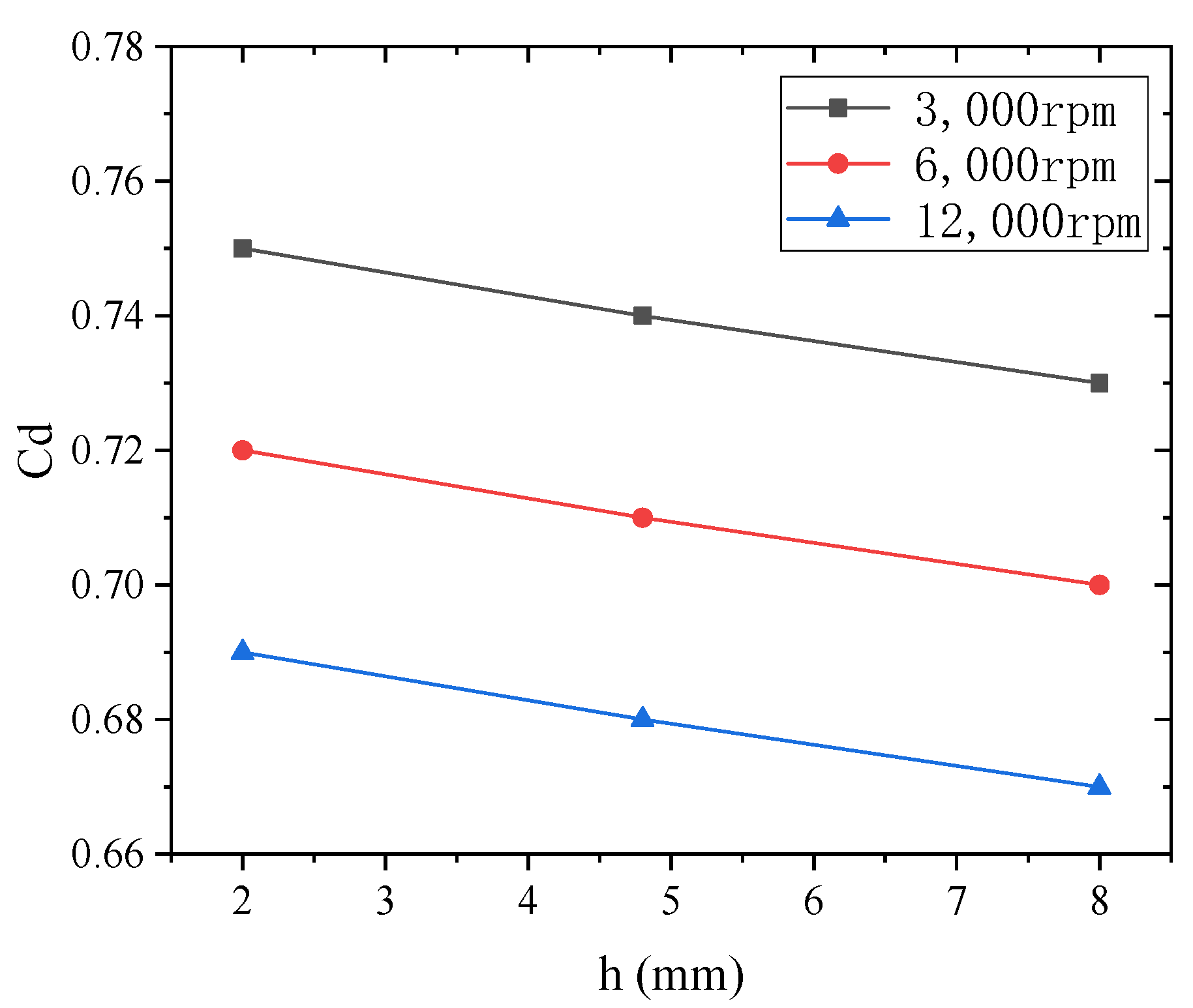

3.2. Effect of Varying Tooth Height on Labyrinth Seal Leakage Characteristics at Different Rotational Speeds

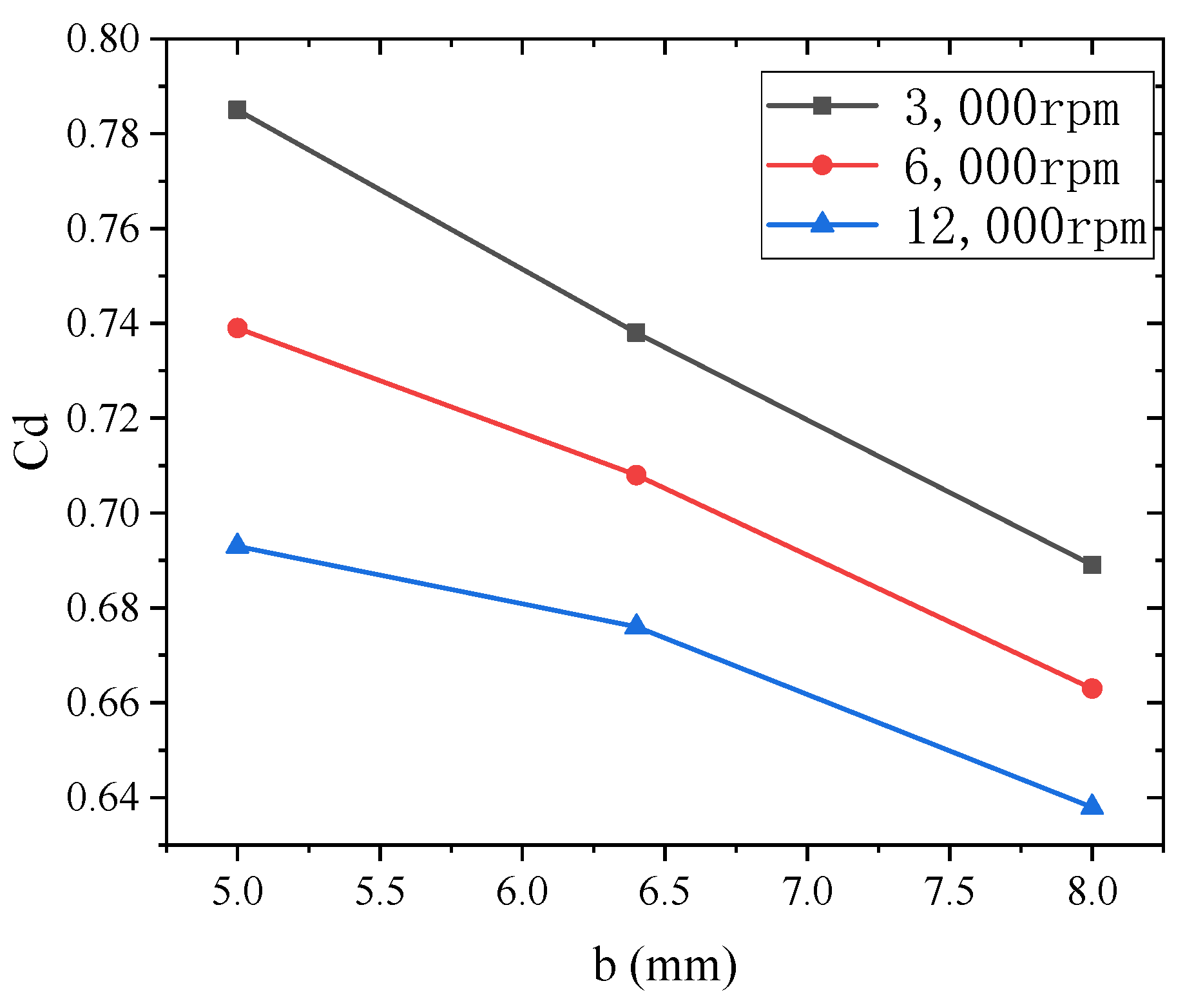

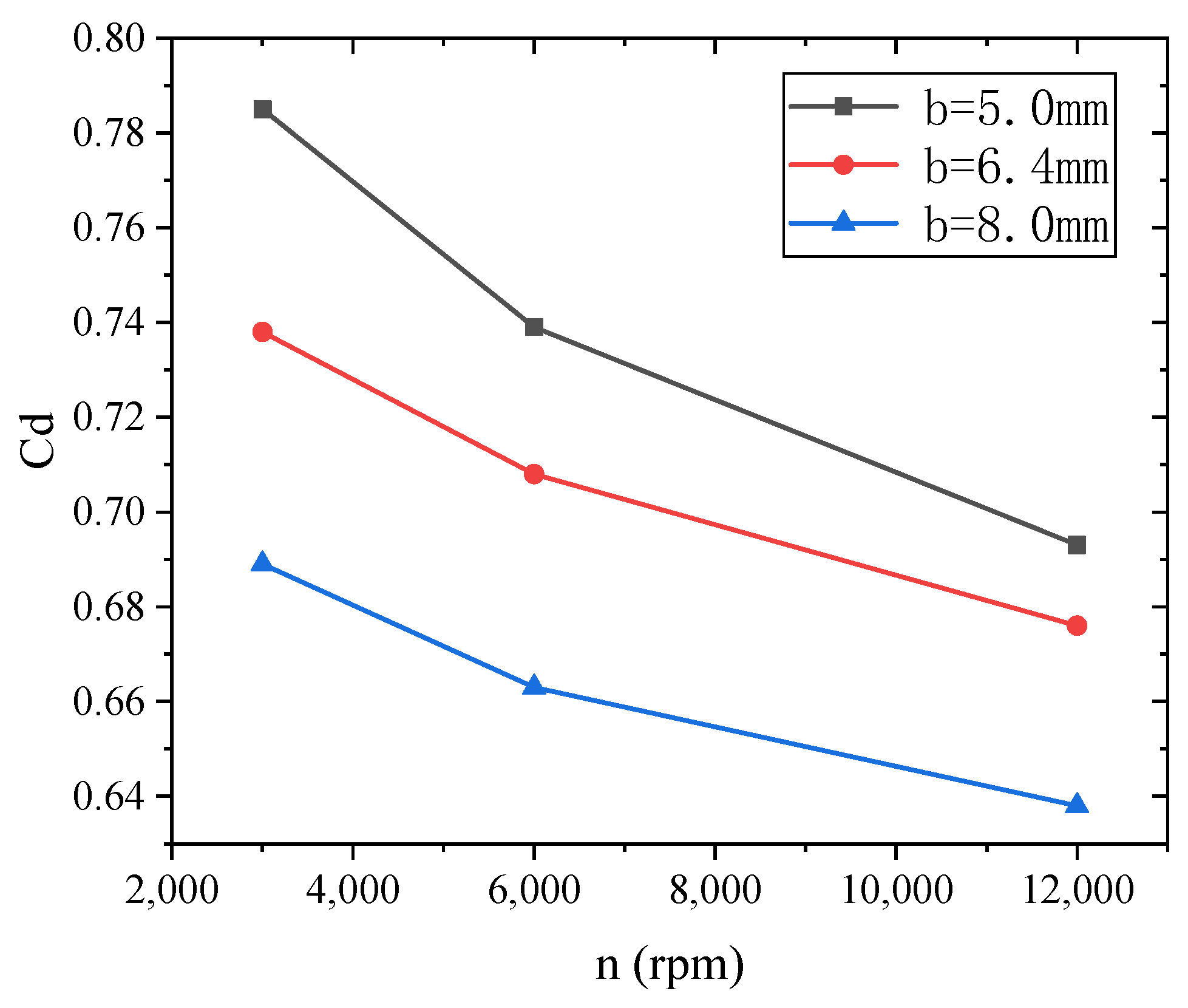

3.3. Effect of Pitch Variation on Labyrinth Seal Leakage Characteristics at Different Rotating Speeds

4. Thermodynamic Characteristics of Labyrinth Seal with Varying Tooth Pitch and Rotation Speeds

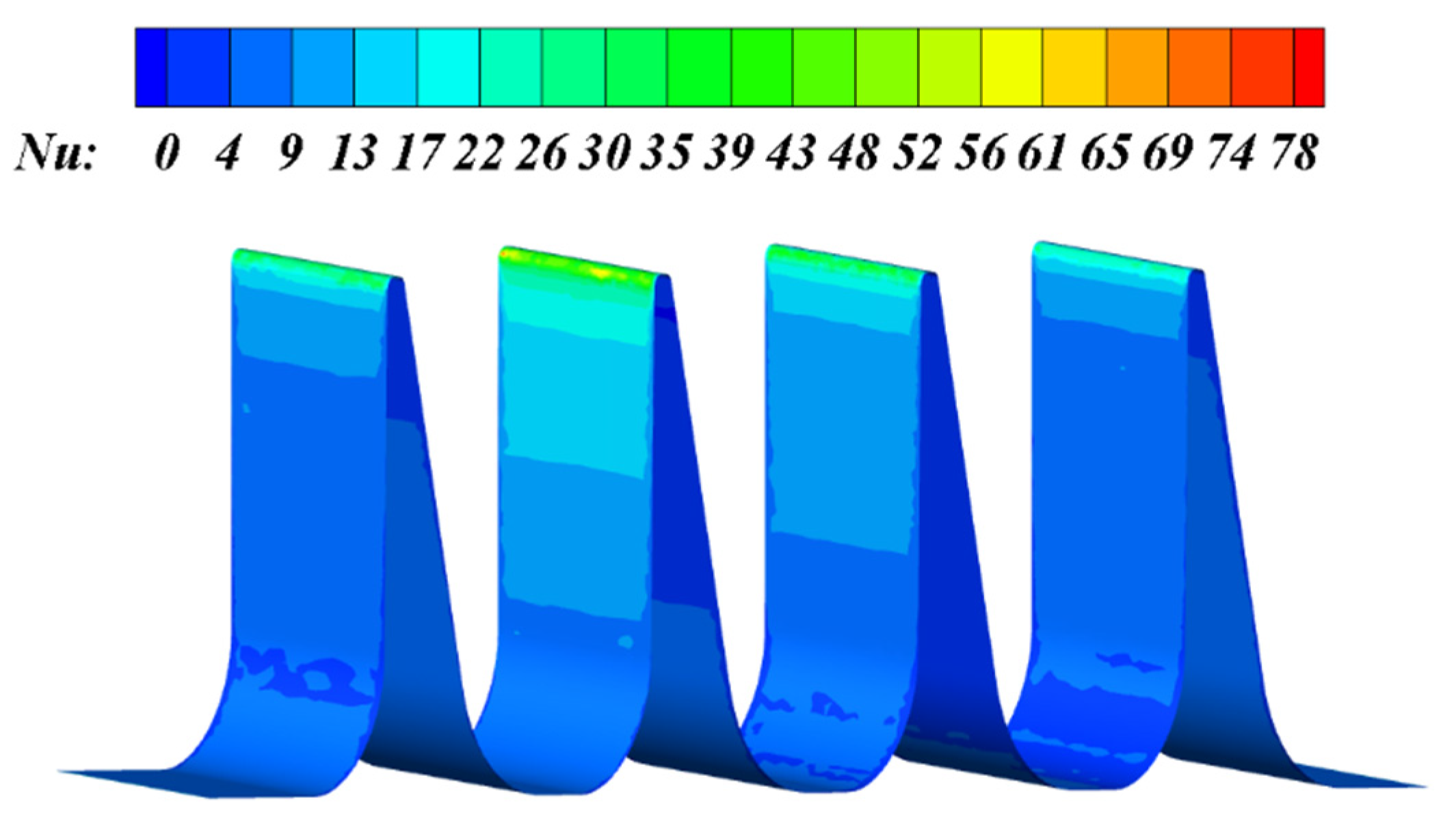

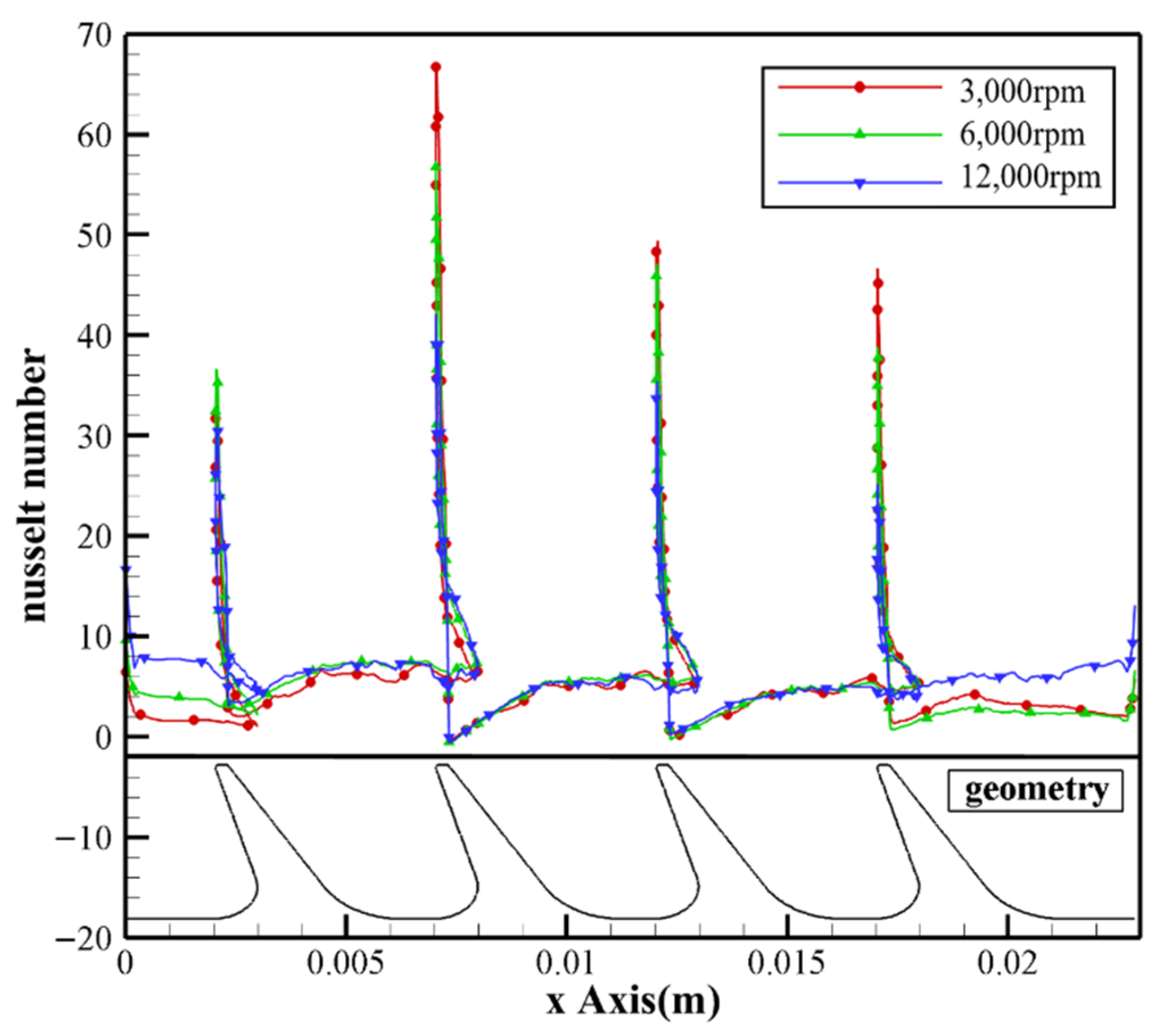

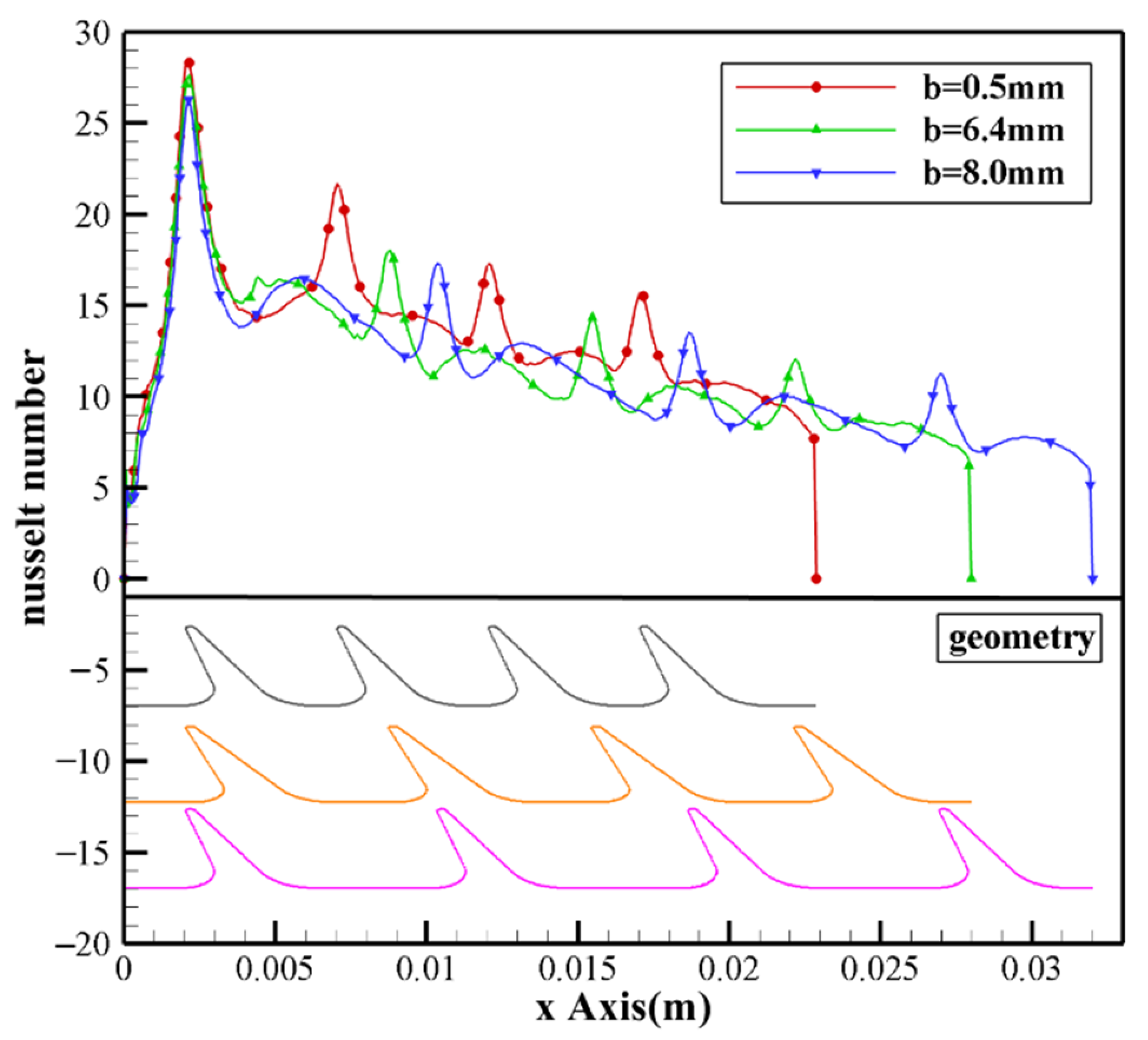

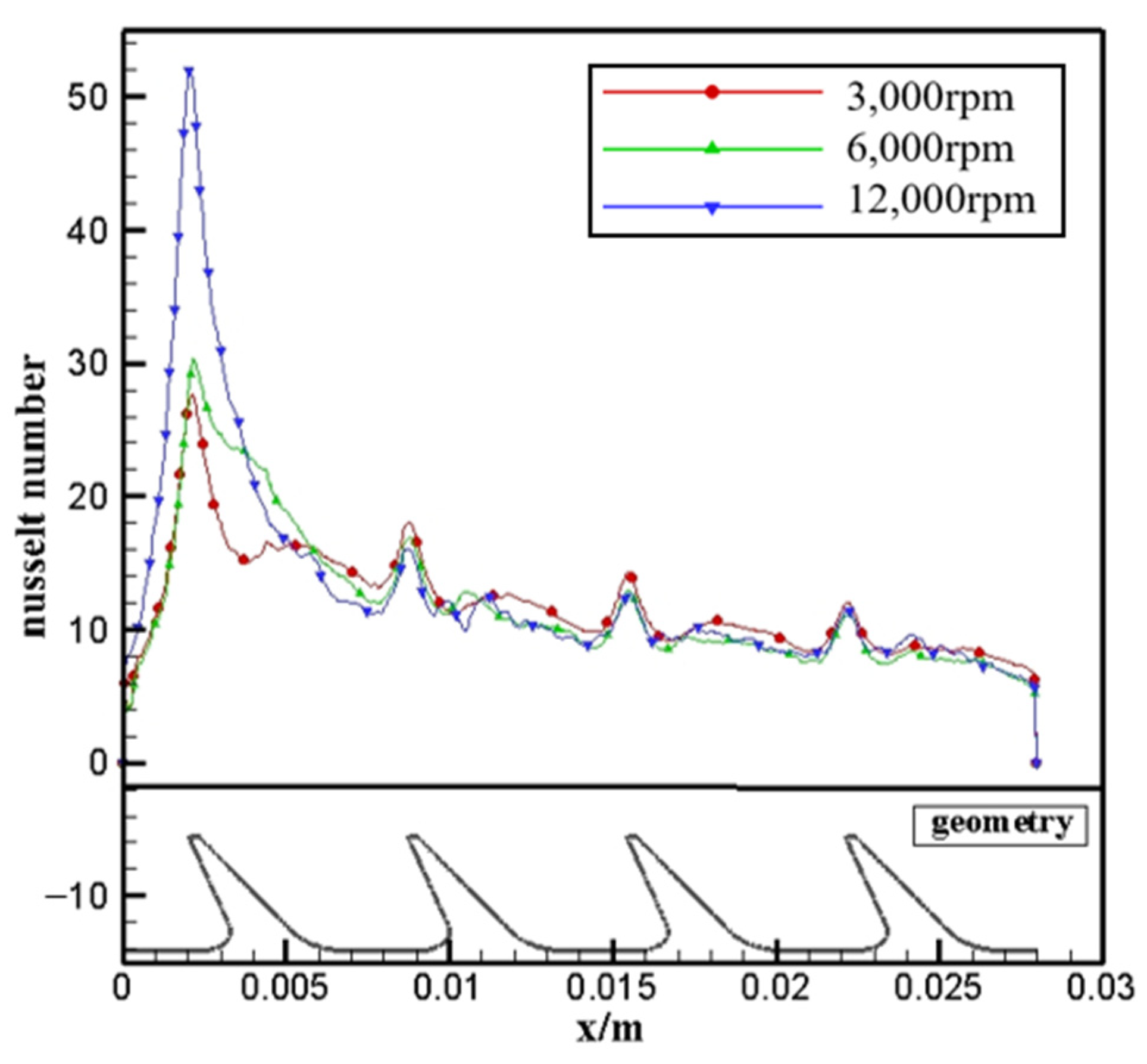

4.1. Analysis of Heat Transfer Characteristics of Rotor Surface

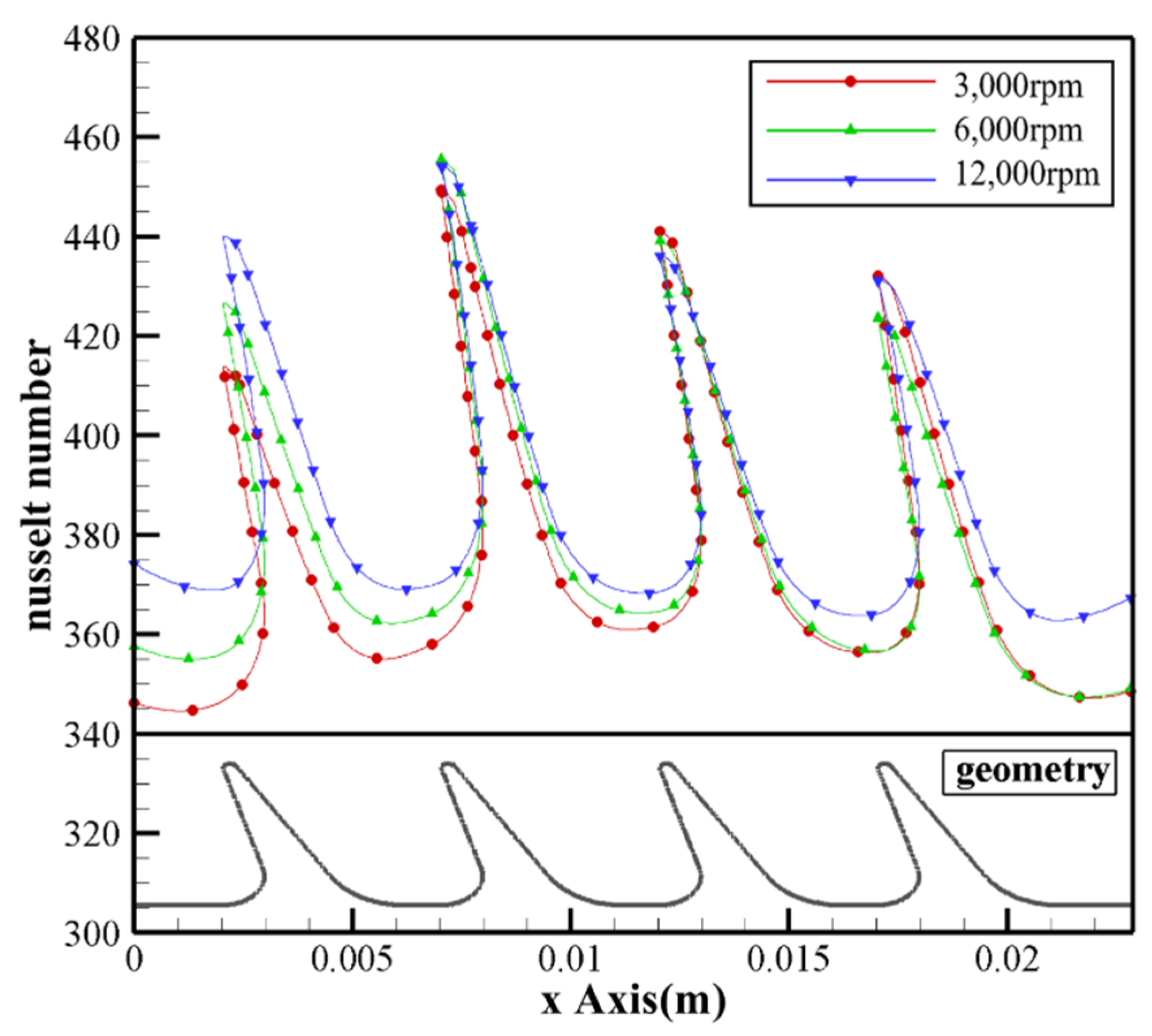

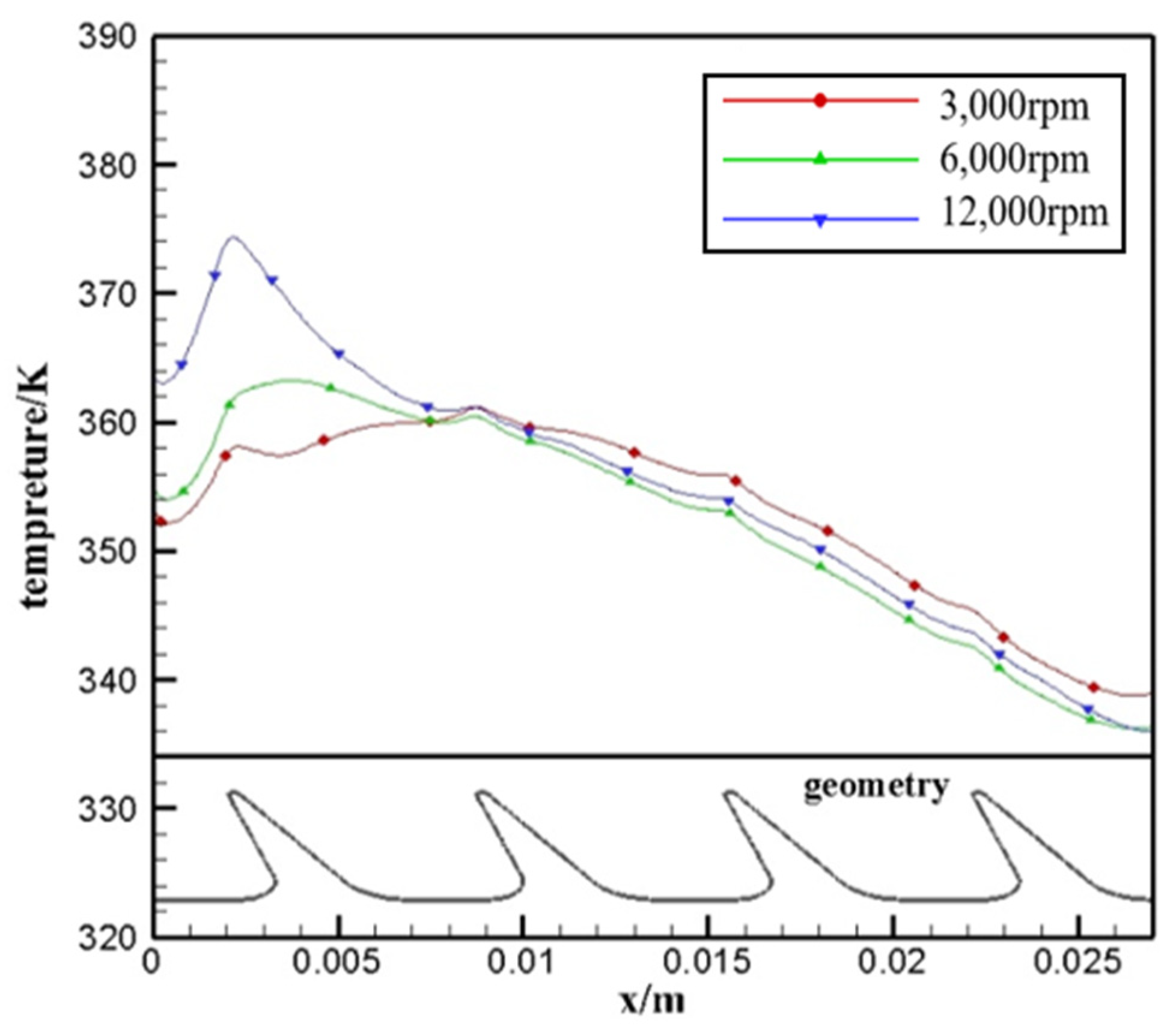

4.2. Analysis of Heat Transfer Characteristics of Stator Surface

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scherer, T.; Waschka, W.; Wittig, S. Numerical predictions of high-speed rotating labyrinth seal performance: Influence of rotation on power dissipation and temperature rise. Int. Symp. Heat Transf. 1992, 26, 1514–1522. [Google Scholar]

- Wang, D.J.; Su, Y.L.; Luo, X. Experimental investigation on leakage flow characteristics in rotating labyrinth seals. Gas Turbine Exp. Res. 2007, 2, 41–44. [Google Scholar]

- Wang, P.F.; Liu, Y.F.; Guo, W.; Li, J.; Liu, B. Influence of high rotational speeds on the labyrinth sealing characteristics. Gas Turbine Exp. Res. 2007, 2, 45–48. [Google Scholar]

- Kong, X.Z.; Liu, G.W.; Lei, Z.; Chang, R.; Liu, Y. Experiment on influence of rotational speeds on labyrinth seal in compressor stator well. J. Aerosp. Power 2016, 31, 1575–1582. [Google Scholar]

- Denecke, J.; Dullenkopf, K.; Wittig, S.; Bauer, H.-J. Experimental investigation of the total temperature increase and swirl development in rotating labyrinth seals. In Proceedings of the ASME Turbo Expo 2005: Power for Land, Sea, and Air, Reno, NV, USA, 6–9 June 2005. [Google Scholar]

- Kong, X.; Liu, G.; Liu, Y.; Zheng, L. Experimental testing for the influences of rotation and tip clearance on the labyrinth seal in a compressor stator well. Aerosp. Sci. Technol. 2017, 71, 556–567. [Google Scholar] [CrossRef]

- Fang, J.; Liu, C.L.; Simos, T.E.; Famelis, I.T. Neural network solution of single-delay differential equations. Mediterr. J. Math. 2020, 17, 30. [Google Scholar] [CrossRef]

- Li, T.; Yang, W. Solution to chance constrained programming problem in swap trailer transport organisation based on improved simulated annealing algorithm. Appl. Math. Nonlinear Sci. 2020, 5, 47–53. [Google Scholar] [CrossRef]

- Waschka, W.; Wittig, S.; Kim, S. Influence of high rotational speeds on the heat transfer and discharge coefficients in labyrinth seals. J. Turbomach. 1992, 114, 462–468. [Google Scholar] [CrossRef]

- Micio, M.; Facchini, B.; Innocenti, L.; Simonetti, F. Experiment investigation on leakage loss and heat transfer in a straight through labyrinth seal. In Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011. [Google Scholar]

- Willenborg, K.; Kim, S.; Wittig, S. Effects of reynolds number and pressure ratio on leakage loss and heat transfer in a stepped labyrinth seal. J. Turbomach. 2001, 123, 815–822. [Google Scholar] [CrossRef]

- Liu, G.W.; Chen, K.; Gang, T.; Zheng, H.L. Influences of pressure ratio and Reynolds number on flow characteristics of labyrinth seal in compressor stator well. J. Aerosp. Power 2015, 30, 1554–1560. [Google Scholar]

- Alizadeh, M.; Nikkhahi, B.; Farahani, A.S.; Fathi, A. Numerical study on the effect of geometrical parameters on the labyrinth-honeycomb seal performance. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2018, 232, 362–373. [Google Scholar] [CrossRef]

- Simos, T.E.; Tsitouras, C. Explicit, ninth order, two step methods for solving inhomogeneous linear problems x″(T) = Lambda X(T) Plus F(T). Appl. Numer. Math. 2020, 153, 334–351. [Google Scholar] [CrossRef]

- Abozaid, A.A.; Selim, H.H.; Gadallah, K.A.; Hassan, I.A.; Abouelmagd, E.I. Periodic orbit in the frame work of restricted three bodies under the asteroids belt effect. Appl. Math. Nonlinear Sci. 2020, 5, 157–176. [Google Scholar] [CrossRef]

- Du, X.; Tian, W.; Pan, J.; Hui, B.; Sun, J.; Zhang, K.; Xia, Y. Piezo-phototronic effect promoted carrier separation in coaxial p-n junctions for self-powered photodetector. Nano Energy 2022, 92, 106694. [Google Scholar] [CrossRef]

- Zhang, B.; Dou, Y.; Hong, Q.; Ji, H. Experimental investigation of effect of tooth geometrical parameters to flow characteristics in slant labyrinth seals. Concurr. Comput. Pract. Exp. 2018, 30, e4951. [Google Scholar] [CrossRef]

- Liu, G.; Jiang, Z.; Wu, W.; Xia, Q.Z. Investigation on effects of rectangular groove on leakage of straight-trough labyrinth seal based on numerical simulation. J. Propuls. Technol. 2013, 34, 181–186. [Google Scholar]

- Zhang, B.; Li, J.; Li, W.; Ji, H. Influence of geometric Tooth Shape parameters of labyrinth seals on the Flow Law and the Algorithm. Russ. Phys. J. 2021, 64, 1122–1129. [Google Scholar] [CrossRef]

- Du, F.Q.; Ji, H.H.; Shuai, H.S.; Zhang, B.; Wang, D.; Lu, H.Y.; Deng, M.C. Orthogonal experiment of effect of fin geometrical parameters on leakage of straight-through labyrinth seals. J. Aerosp. Power 2013, 28, 825–831. [Google Scholar]

- Adam, B. Sutherland formula for a square-well fluid. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2006, 73, 011203. [Google Scholar]

| Model | Depth h/mm | Pitch b/mm |

|---|---|---|

| M1 | 4.8 | 6.4 |

| M2 | 4.8 | 5 |

| M3 | 4.8 | 8 |

| M4 | 3 | 6.4 |

| M5 | 6 | 6.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Zhang, B.; Chen, Y.; Yang, S.; Liu, H.; Ji, H. Investigation of Leakage and Heat Transfer Properties of the Labyrinth Seal on Various Rotation Speed and Geometric Parameters. Coatings 2022, 12, 586. https://doi.org/10.3390/coatings12050586

Wang Z, Zhang B, Chen Y, Yang S, Liu H, Ji H. Investigation of Leakage and Heat Transfer Properties of the Labyrinth Seal on Various Rotation Speed and Geometric Parameters. Coatings. 2022; 12(5):586. https://doi.org/10.3390/coatings12050586

Chicago/Turabian StyleWang, Zhiguo, Bo Zhang, Yuanxiang Chen, Sheng Yang, Hongmei Liu, and Honghu Ji. 2022. "Investigation of Leakage and Heat Transfer Properties of the Labyrinth Seal on Various Rotation Speed and Geometric Parameters" Coatings 12, no. 5: 586. https://doi.org/10.3390/coatings12050586

APA StyleWang, Z., Zhang, B., Chen, Y., Yang, S., Liu, H., & Ji, H. (2022). Investigation of Leakage and Heat Transfer Properties of the Labyrinth Seal on Various Rotation Speed and Geometric Parameters. Coatings, 12(5), 586. https://doi.org/10.3390/coatings12050586