The Synergistic Effect of the Laser Beam on the Thermionic Vacuum Arc Method for Titanium-Doped Chromium Thin Film Deposition

Abstract

1. Introduction

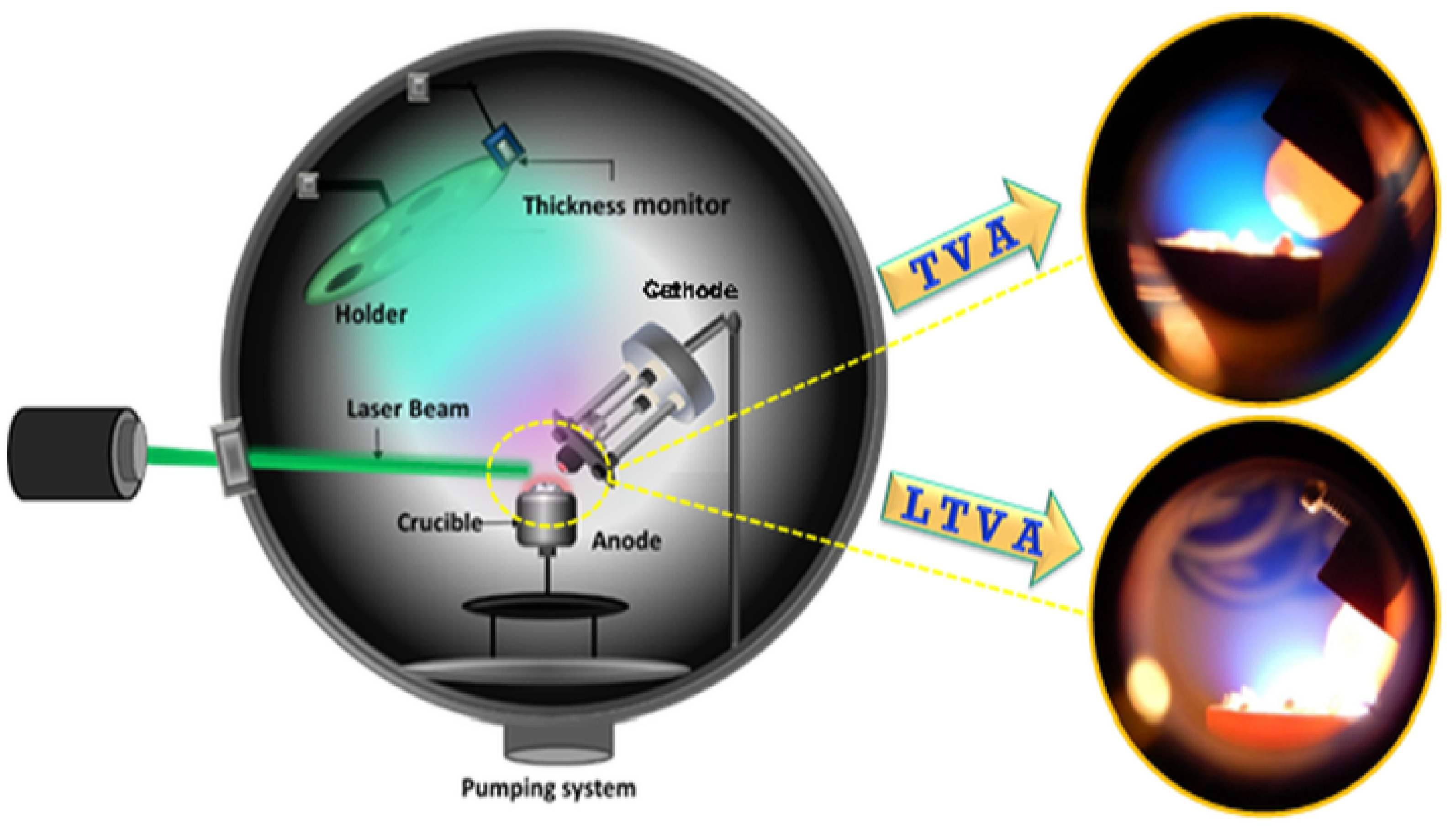

2. Materials and Methods

3. Results

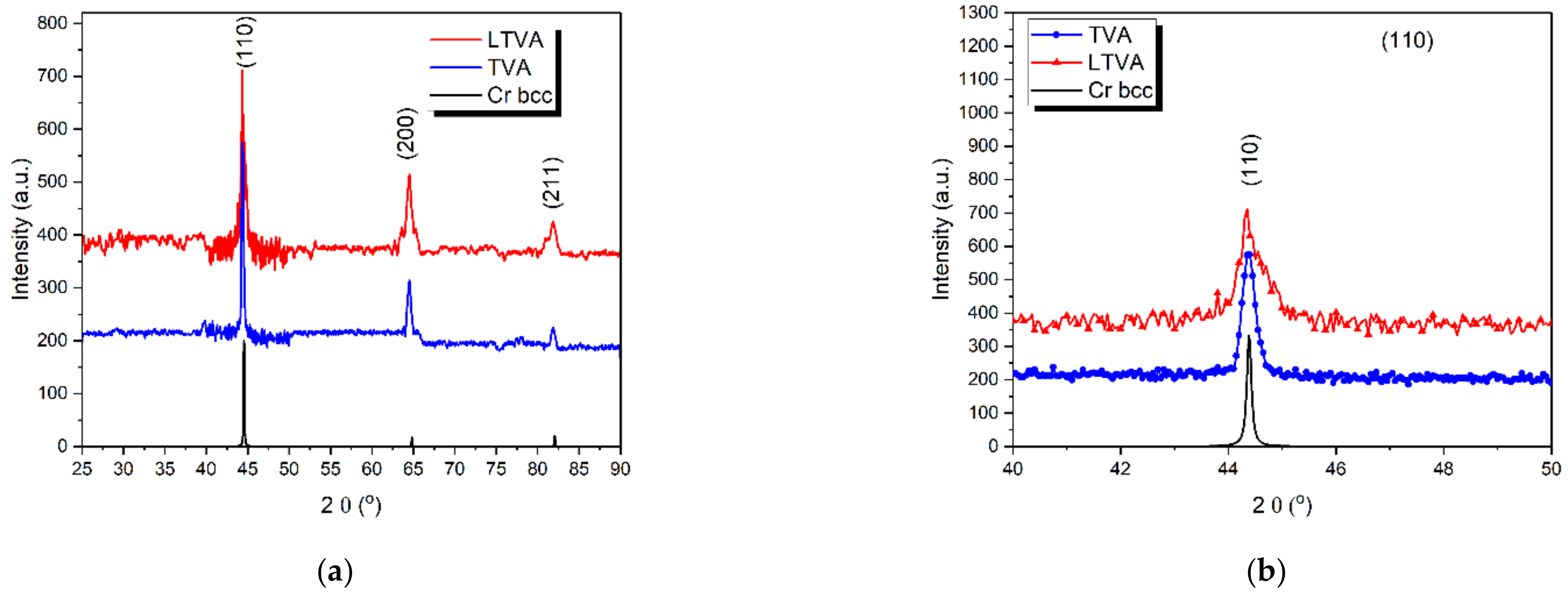

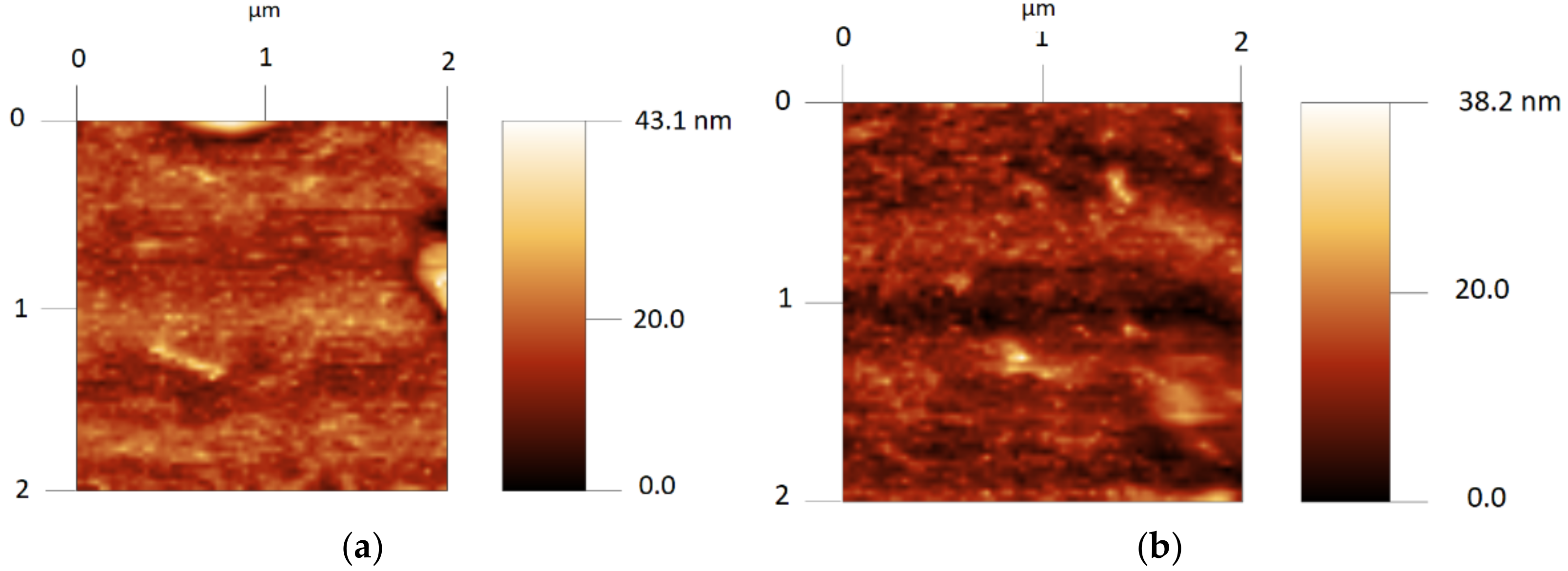

3.1. Structural Analysis

3.1.1. X-ray Diffraction

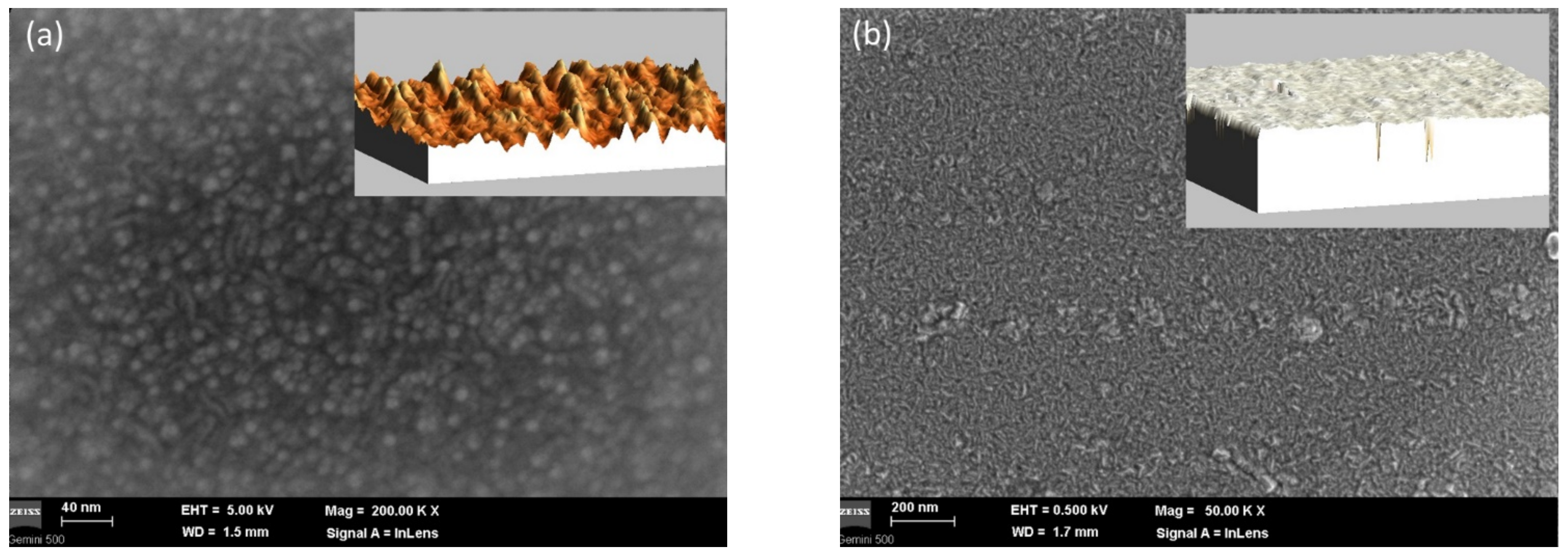

3.1.2. SEM and EDX Analysis

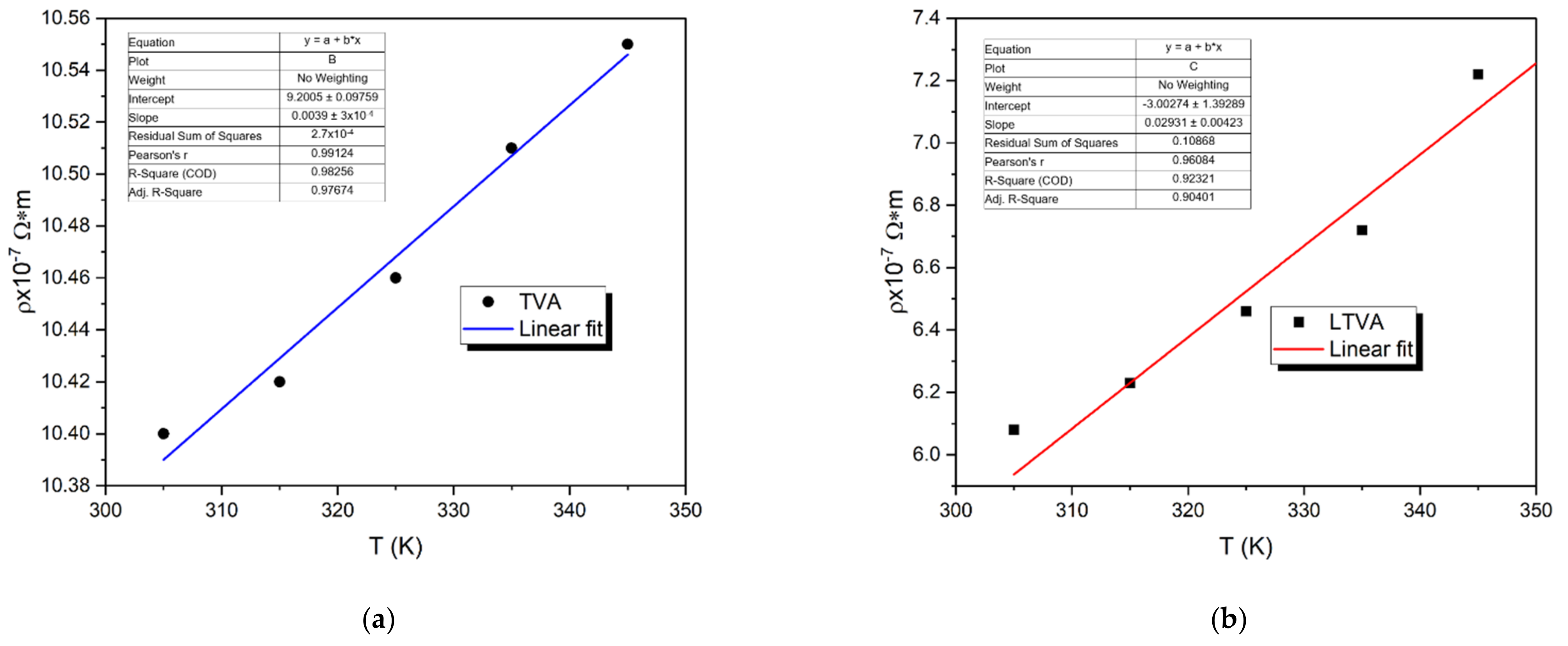

3.2. Electrical Measurements

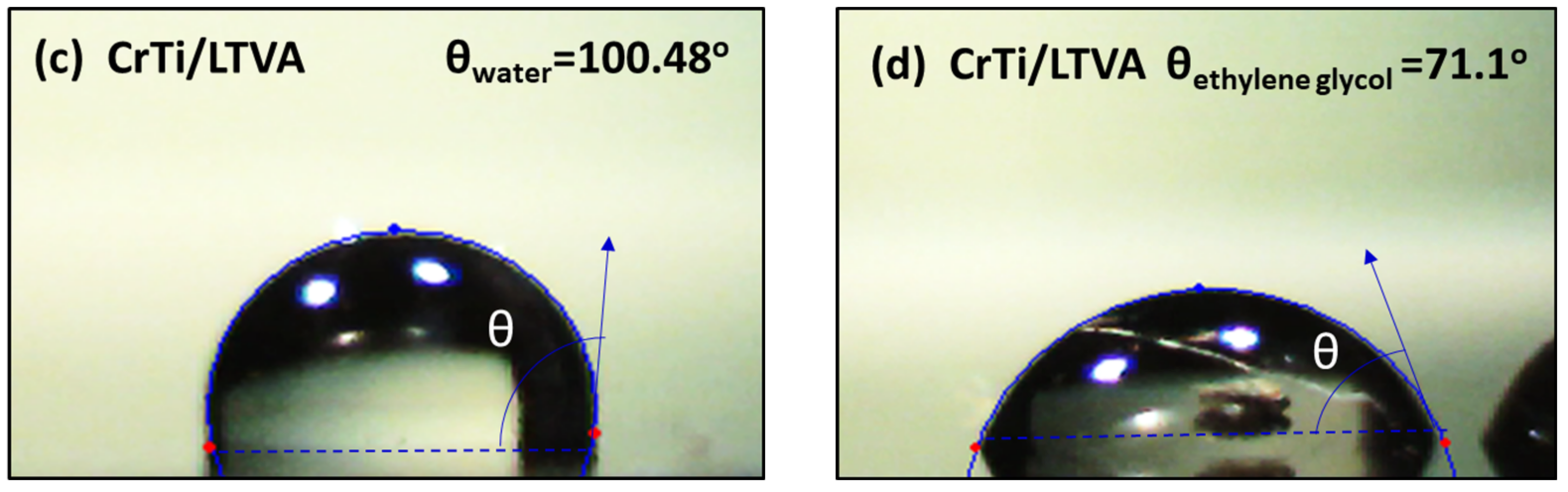

3.3. Wettability Measurements

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zarras, P.; Stenger-Smith, J.D. Smart Inorganic and Organic Pretreatment Coatings for the Inhibition of Corrosion on Metals/Alloys. Intell. Coat. Corros. Control 2015, 11, 59–91. [Google Scholar] [CrossRef]

- Wang, S.F.; Lin, H.C.; Bor, H.Y.; Tsai, Y.L.; Wei, C.N. Characterization of chromium thin films by sputter deposition. J. Alloy. Comp. 2011, 509, 10110–10114. [Google Scholar] [CrossRef]

- Delmotte, F.; Ilse, J.M.; Salmassi, F.; Soufli, R.; Burcklen, C.; Rebellato, J.; Jerome, A.; Vickridge, I.; Briand, E.; Gullikson, E. Soft X-ray optical constants of sputtered chromium thin films with improved accuracy in the L and M absorption edge regions. J. Appl. Phys. 2018, 124, 035107. [Google Scholar] [CrossRef]

- Martinez-Galarce, D.S.; Soufli, R.; Windt, D.L.; Bruner, M.; Gullikson, E.; Khatri, S.; Spiller, E.; Robinson, J.C.; Baker, S.; Prast, E. Multisegmented, multilayer-coated mirrors for the Solar Ultraviolet Imager. Opt. Eng. 2013, 52, 095102. [Google Scholar] [CrossRef]

- Soufli, R.; Robinson, J.C.; Fernandez-Perea, M.; Spiller, E.; Brejnholt, N.F.; Descalle, M.A.; Pivovaroff, M.J.; Gullikson, E.M. Recent advances in reflective optics for EUV/x-ray laser sources. X-ray Lasers 2014, 169, 331. [Google Scholar] [CrossRef]

- Graessle, D.E.; Soufli, R.; Nelson, A.J.; Evans, C.L.; Aquila, A.L.; Gullikson, E.M.; Blake, R.L.; Burek, A.J. Iridium optical constants from synchrotron reflectance measurements over 0.05 to 12 keV X-ray energies. Proc. SPIE 2004, 5538, 72–83. [Google Scholar]

- Shrivastava, R.; Upreti, R.K.; Seth, P.K.; Chaturvedi, U.C. Effects of chromium on the immune system. FEMS Immunol. Med. Microbiol. 2002, 34, 112. [Google Scholar] [CrossRef]

- Wang, G.; Long, X.; Zhang, L.; Wang, G.; Polosan, S.; Tsuboi, T. Spectroscopic characteristic and energy levels of Cr3+ in Cr3+:KAl(MoO4)2 crystal”. J. Lum. 2008, 128, 1556. [Google Scholar] [CrossRef]

- Marcinkowski, M.J.; Lipsitt, H.A. Electrical Resistivity of Chromium in the Vicinity of the Néel Temperature. J. Appl. Phys. 1961, 32, 1238. [Google Scholar] [CrossRef]

- Ferreira, A.A.; Silva, F.J.G.; Pinto, A.G.; Sousa, V.F.C. Characterization of Thin Chromium Coatings Produced by PVD Sputtering for Optical Applications. Coatings 2021, 11, 215. [Google Scholar] [CrossRef]

- Davis, J.R. Corrosion: Understanding the Basics; Davis, J.R., Ed.; ASM International: Materials Park, OH, USA, 2000; pp. 331–358. [Google Scholar]

- Korinek, K.A. Chromate conversion coatings. In ASM Handbook; Korb, L.J., Olson, D.L., Eds.; ASTM International: West Conshohocken, PA, USA, 1998; Volume 13, pp. 389–395. [Google Scholar]

- Angadi, M.A.; Udachan, L.A. The effect of substrate temperature on the electrical properties of thin chromium films. J. Mater. Sci. 1981, 16, 1412–1415. [Google Scholar] [CrossRef]

- Angadi, M.A.; Udachan, L.A. Influence of DC electric field on sheet resistance of thin tin and chromium films. J. Phys. D Appl. Phys. 1981, 14, L81. [Google Scholar] [CrossRef]

- Lozanova, V.; Lalova, A.; Soserov, L.; Todorov, R. Optical and electrical properties of very thin chromium films for optoelectronic devices. J. Phys. Conf. Ser. 2014, 514, 012003. [Google Scholar] [CrossRef]

- Angadi, M.A.; Udachan, L.A. The effect of the deposition rate on the electrical resistivity of thin tin films. Thin Solid Film 1981, 78, 299–302. [Google Scholar] [CrossRef]

- Musa, G.; Mustata, I.; Blideran, M.; Ciupina, V.; Vlădoiu, R.; Prodan, G.; Vasile, E.; Ehrich, H. Thermionic Vacuum Arc (TVA) new technique for high purity carbon thin film deposition. Acta Phys. Slovaka. 2005, 55, 417–421. [Google Scholar]

- Vladoiu, R.; Tichý, M.; Mandes, A.; Dinca-Balan, V.; Kudrna, P. Thermionic Vacuum Arc-A versatile technology for thin film deposition and its applications. Coatings 2020, 10, 211. [Google Scholar] [CrossRef]

- Vladoiu, R.; Ciupina, V.; Lungu, C.P.; Bursikova, V.; Musa, G. Thermionic vacuum arc (TVA) deposited tungsten thin film characterization. J. Optoel. Adv. Mater. 2006, 8, 71–73. [Google Scholar]

- Musa, G.; Vladoiu, R.; Ciupina, V.; Lungu, C.P.; Mustata, I.; Pat, S.; Akan, T.; Ekem, N. Characteristics of boron thin films obtained by TVA technology. J. Optoel. Adv. Mater. 2006, 8, 617–620. [Google Scholar]

- Vladoiu, R.; Mandes, A.; Dinca-Balan, V.; Prodan, G.; Kudrna, P.; Tichý, M. Magnesium plasma diagnostics by heated probe and characterization of the Mg thin films deposited by thermionic vacuum arc technology. Plasma Sources Sci. Technol. 2015, 24, 035008. [Google Scholar] [CrossRef]

- Ekem, N.; Musa, G.; Pat, S.; Balbag, Z.; Cenik, I.; Vladoiu, R. Carbon thin film deposition by Thermionic Vacuum Arc (TVA). J. Optoel. Adv. Mater. 2008, 10, 672–674. [Google Scholar]

- Tamer, A.; Ekem, N.; Pat, S.; Issever, U.G.; Balbag, M.Z.; Cenik, M.I.; Vladoiu, R.; Musa, G. Boron thin film deposition by using Thermionic Vacuum Arc (TVA) technology. Mater. Lett. 2007, 61, 23. [Google Scholar] [CrossRef]

- Vladoiu, R.; Mandes, A.; Dinca, V.; Kudrna, P.; Tichý, M.; Polosan, S. Magnesium-silver cathodes for efficient charge-injection into Organic Light Emitting Diodes deposited by LTVA method. J. Alloy. Comp. 2021, 869, 159364. [Google Scholar] [CrossRef]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; López de Lacalle, L.N.; Polvorosa, L. Enhanced Performance of Nanostructured Coatings for Drilling by Droplet Elimination. Mater. Manuf. Processes 2014, 11, 3582. [Google Scholar] [CrossRef]

- Fernández-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N.; Martínez-Pellitero, S. Behavior of austenitic stainless steels at high speed turning using specific force coefficients. Int. J. Adv. Manuf. Technol. 2012, 62, 505. [Google Scholar] [CrossRef]

- Rachinger, W.A. A Correction for the α1 α2 Doublet in the Measurement of Widths of X-ray Diffraction Lines. J. Sci. Instrum. 1948, 25, 254–255. [Google Scholar] [CrossRef]

- Vladoiu, R.; Dinca, V.; Musa, G. Surface energy evaluation of unhydrogenated DLC thin film deposited by thermionic vacuum arc (TVA) method. Eur. Phys. J. D 2009, 54, 433–437. [Google Scholar] [CrossRef]

- Kasap, S.; Koughia, C.; Ruda, H.E. Electrical Conduction in Metals and Semiconductors. In Springer Handbook of Electronic and Photonic Materials; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Rauf, A.; Ahmed, K.; Nasim, F.; Khan, A.N.; Gul, A. Optical and structural properties of Cr and Ag thin films deposited on glass substrate. IOP Conf. Ser. Mater. Sci. Eng. 2016, 146, 012013. [Google Scholar] [CrossRef]

- Rudawska, A. Surface treatment methods. Surf. Treat. Bond. Technol. 2019, 11, 47–62. [Google Scholar] [CrossRef]

- Yuan, Y.; Lee, T.R. Contact Angle and Wetting Properties. In Surface Science Techniques; Bracco, G., Holst, B., Eds.; Springer Series in Surface Sciences; Springer: Berlin/Heidelberg, Germany, 2013; Volume 51, pp. 3–34. [Google Scholar] [CrossRef]

- Wyckoff, R.W.G. Crystal Structures, 2nd ed.; Interscience Publishers: New York, NY, USA, 1963; pp. 7–83. [Google Scholar]

- Gasgnier, M.; Nevot, L. Analysis and crystallographic structures of chromium thin films. Phys. Stat. Sol. 1981, 66, 525–540. [Google Scholar] [CrossRef]

- Kulkarni, A.K.; Chang, L.C. Electrical and structural characteristics of chromium thin films deposited on glass and alumina substrates. Thin Solid Film. 1997, 301, 17–22. [Google Scholar] [CrossRef]

- Fuchs, K. Electrical resistance in thin metal films. Math. Proc. Cambr. Philo. Soc. 1938, 34, 100–193. [Google Scholar] [CrossRef]

- Mayadas, A.F.; Shatzkes, M. Electrical-resistivity model for polycrystalline films: The case of arbitrary reflection at external surfaces. Phys. Rev. B 1970, 1, 1382–1389. [Google Scholar] [CrossRef]

- Suezaki, Y.; Mori, H. Dynamic Critical Phenomena in Magnetic Systems: Electrical Resistivity near the Néel Point. Prog. Theor. Phys. 1969, 41, 1177–1189. [Google Scholar] [CrossRef]

| Parameters | TVA | LTVA |

|---|---|---|

| Energy/pulse of laser E (mJ) | 0 | 102 |

| Irradiance of laser IL (GW/cm2) | 0 | 20 |

| Base pressure pB (Pa) | 4.1 × 10−5 | |

| Working pressure pw (Pa) | 1.5 × 10−4 | |

| Distance dA-C (m) | 5 × 10−3 | |

| Distance dA-S (m) | 6 × 10−2 | |

| Intensity current on the filament IF (A) | 57 | |

| Input arc power P (W) | 460 | |

| Film thickness t (nm) | 100 | |

| Time of deposition Tdep (s) | 210 | |

| Sample | Peak (°) | hkl | Peak Width | d-Spacing | D (nm) |

|---|---|---|---|---|---|

| TVA | 44.3793 | (110) | 0.3420 | 2.0395 | 25 |

| LTVA | 44.4243 | (110) | 0.7759 | 2.0376 | 11 |

| Sample | Element | Series | Atomic Number | Atomic Conc. % | Errors % |

|---|---|---|---|---|---|

| TVA | Si | K-series | 14 | 92.34 | 3.2 |

| Ti | K-series | 22 | 0.19 | 0.0 | |

| Cr | K-series | 24 | 7.47 | 0.4 | |

| LTVA | Si | K-series | 14 | 93.15 | 3.3 |

| Ti | K-series | 22 | 0.19 | 0.0 | |

| Cr | K-series | 24 | 6.66 | 0.3 |

| Sample Ti:Cr/Si | Contact Angle θ (°) | Owens–Wendt (mJ/m2) | |

|---|---|---|---|

| Water | Ethylene Glycol | ||

| TVA | 92.67 | 63.40 | 29.01 |

| LTVA | 100.48 | 71.23 | 21.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vladoiu, R.; Mandes, A.; Dinca, V.; Ciupina, V.; Matei, E.; Polosan, S. The Synergistic Effect of the Laser Beam on the Thermionic Vacuum Arc Method for Titanium-Doped Chromium Thin Film Deposition. Coatings 2022, 12, 470. https://doi.org/10.3390/coatings12040470

Vladoiu R, Mandes A, Dinca V, Ciupina V, Matei E, Polosan S. The Synergistic Effect of the Laser Beam on the Thermionic Vacuum Arc Method for Titanium-Doped Chromium Thin Film Deposition. Coatings. 2022; 12(4):470. https://doi.org/10.3390/coatings12040470

Chicago/Turabian StyleVladoiu, Rodica, Aurelia Mandes, Virginia Dinca, Victor Ciupina, Elena Matei, and Silviu Polosan. 2022. "The Synergistic Effect of the Laser Beam on the Thermionic Vacuum Arc Method for Titanium-Doped Chromium Thin Film Deposition" Coatings 12, no. 4: 470. https://doi.org/10.3390/coatings12040470

APA StyleVladoiu, R., Mandes, A., Dinca, V., Ciupina, V., Matei, E., & Polosan, S. (2022). The Synergistic Effect of the Laser Beam on the Thermionic Vacuum Arc Method for Titanium-Doped Chromium Thin Film Deposition. Coatings, 12(4), 470. https://doi.org/10.3390/coatings12040470