Effect of Pre-Set Coating Thickness on the Quality of Electron Beam Cladding Forming of Aluminum Alloys

Abstract

:1. Introduction

2. Temperature Field Finite Element Simulation

2.1. Heat Transfer Equation System

2.2. Thermal and Physical Parameters of the Material

2.3. Establishment of Finite Element Model

2.4. Selection of Electron Beam Process Parameters

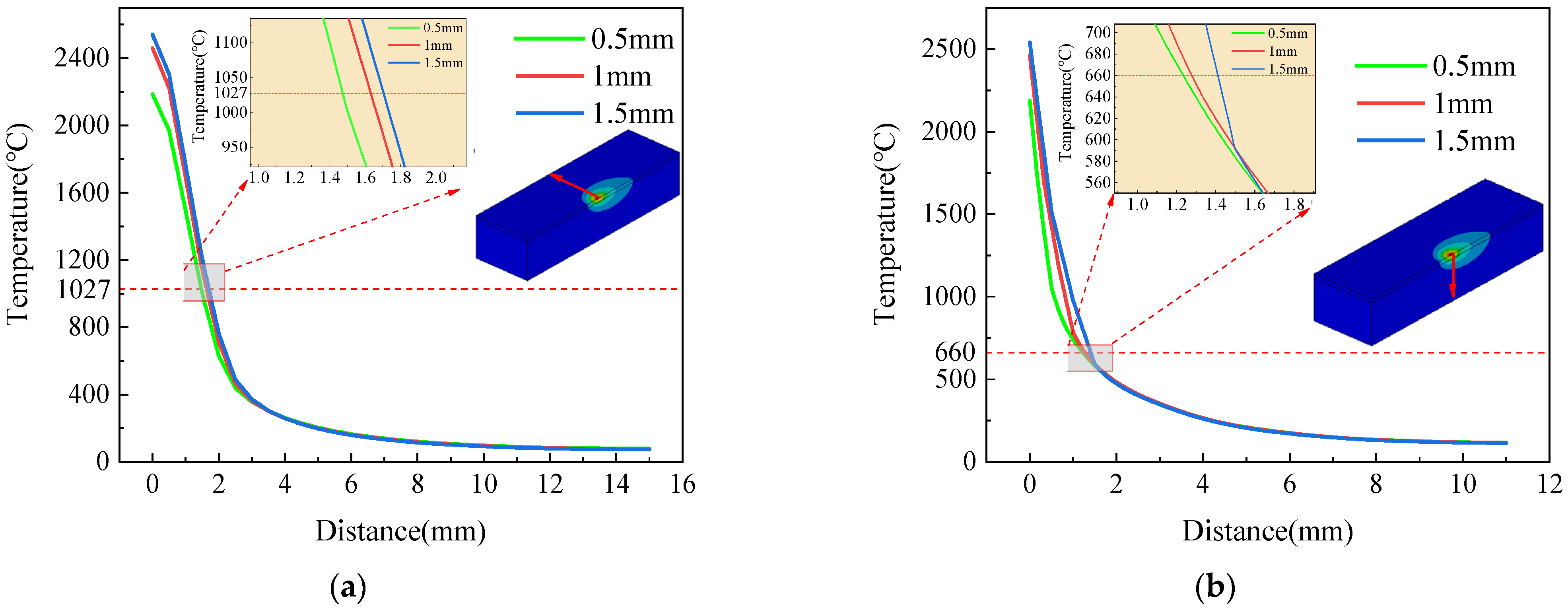

2.5. Simulation of Electron Beam Cladding Temperature Field and Analysis of Results

3. Numerical Simulation of Stress Field of Electron Beam Cladding

3.1. Model Building

3.2. Influence of Preset Coating Thickness on Residual Stress

4. Experimental Verification of Electron Beam Cladding

4.1. Macro Surface Morphology

4.2. Section Morphology and EDS Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chu, X.; Ren, X.; Hao, S.; Xu, Y. Progress State of Surface Modification Technology for Al Alloy. Hot Work. Technol. 2010, 39, 123–127. [Google Scholar]

- Yu, H.C.; Huang, X.Y.; Lei, F.H.; Tan, X.C.; Han, Y.Y. Preparation and electrochemical properties of Cr(III)–Ti-based coatings on 6063 Al alloy. Surf. Coat. Technol. 2013, 218, 137–141. [Google Scholar] [CrossRef]

- Karunakaran, M.; Vadivu, M.P. Magnetic and micro-mechanical behavior of Cu-Ni-P-W-TiO2 hybrid composite electroplating on Al alloy substrate—ScienceDirect. J. Magn. Magn. Mater. 2019, 475, 359–367. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhang, B.; Zhao, X.; Wang, B. Binary Additives Enhance Micro Arc Oxidation Coating on 6061Al Alloy with Improved Anti-Corrosion Property. Coatings 2020, 10, 128. [Google Scholar] [CrossRef] [Green Version]

- Man, H.C.; Zhang, S.; Yue, T.M.; Cheng, F.T. Laser surface alloying of NiCrSiB on Al6061 aluminium alloy. Surf. Coat. Technol. 2001, 148, 136–142. [Google Scholar] [CrossRef]

- Wang, R.; Li, M.S.; Wei, D.Q. Microstructure and Properties of 6061 Aluminum Alloy Superficially Modified by Electron Beam Alloying with 1Cr13 Stainless Steel. Appl. Mech. Mater. 2013, 470, 48–52. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, F.J.; Hao, J.J.; Ma, Y.J.; Ma, A.J.; Li, J.C. The application and development trend of surface modification technique induced by three beams. J. Agric. Univ. Hebei 2003, 26, 260–263+266. [Google Scholar]

- Durakov, V.; Gnyusov, S.; Schneider, A.; Popov, S.; Lavrinovich, V.; Batrakov, A.; Dampilon, B. Effect of substrate temperature on microstructure and properties of the CuCr25 alloys produced by electron beam cladding. In Proceedings of the International Symposium on Discharges and Electrical Insulation in Vacuum, ISDEIV, Mumbai, India, 28 September–3 October 2014; pp. 525–528. [Google Scholar]

- Liu, H.L.; Qi, Z.W.; Wang, B.; Zhang, G.; Wang, X.; Wang, D. Numerical simulation of temperature field during electron beam cladding for NbSi2 on the surface of Inconel617. Mater. Res. Express 2018, 5, 036528. [Google Scholar] [CrossRef]

- Wang, R.; Shen, G.B.; Wei, D.Q. Numerical simulation and experimental verification of temperature field for 6061 aluminum alloy surface modification by electron beam. Trans. Mater. Heat Treat. 2012, 33, 5. [Google Scholar]

- Jiang, Q.Y. The Temperature Field Simulation during Laser Cladding Process. Adv. Mater. Res. 2012, 450–451, 235–238. [Google Scholar] [CrossRef]

- Li, Y.M.; Yao, D.Z.; Fan, F.J. Numerical Simulation Study on Process Parameters Optimization of 718 Alloy induced by Laser Cladding. Appl. Laser 2018, 38, 7. [Google Scholar]

- Chen, B.; Pang, S.; Zhou, J.; Suo, H.; Chen, Z.; Gong, S. Numerical simulation of temperature field during scanning electron beam welding of TC4 titanium alloy. Trans. China Weld. Inst. 2013, 34, 33–37. [Google Scholar]

- Chen, H.; Wei, D.; Wang, R.; Shaoyuan, S. Numerical simulation of microstructure evolution on 45 steel surface during electron beam phase transformation hardening. Heat Treat. Met. 2014, 39, 130–135. [Google Scholar]

- Zhang, S.; Zhang, C.; Zhang, N.; Yu, L.; Liu, C.; Man, H.C. Simulation and experimental investigations of laser cladding temperature field on 6061 Al alloy. Trans. China Weld. Inst. 2007, 28, 1–4. [Google Scholar]

- Zheng, L.; Li, Y.; He, D.; Fu, X.; Fu, Y. Analysis on temperature field of multi-path laser claded and microstructure of coatings layer. Infrared Laser Eng. 2013, 35, 107–110. [Google Scholar]

- Wei, D.; Ren, X.; Wang, R. Microstructure and hardness of W alloy on 45 steel by electron beam scanning. Trans. China Weld. Inst. 2019, 40, 98–103. [Google Scholar]

- Cheng, J.; Sun, K.; Ma, L.F. Numerical simulation of temperature field and stress field of Fe-Al coating synthesized by laser remelting. J. Mater. Heat Treat. 2014, 35, 219–225. [Google Scholar]

- Huang, Y.; Wen, B.; Ming, H. Characteristics of the Temperature Field and Formation of the Microstructure for Laser Cladding Processing. Appl. Laser 2017, 37, 629–633. [Google Scholar]

- Li, M.; Han, B.; Cai, C.; Wang, Y.; Song, L. Numerical simulation on temperature and stress fields of laser cladded Ni-based coating. Trans. China Weld. Inst. 2015, 36, 25–28. [Google Scholar]

| Temperature/°C | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 |

|---|---|---|---|---|---|---|---|---|---|

| λ/(J/kg·°C) | 113 | 160 | 162.8 | 162.4 | 168.3 | 169.5 | 172.5 | 177.4 | 179.2 |

| c/(W/m·°C) | 931 | 962 | 1006 | 1052 | 1091 | 1129 | 8894 | 8894 | 1152 |

| Temperature/°C | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 |

|---|---|---|---|---|---|---|---|---|---|

| λ/(J/kg·°C) | 12.7 | 12.9 | 13.1 | 13.4 | 13.7 | 14.1 | 14.5 | 15.2 | 16.0 |

| c/(W/m·°C) | 410 | 425 | 440 | 460 | 470 | 488 | 508 | 532 | 558 |

| Acceleration Voltage U/KV | Electron Beam Flow | Scanning Speed mm/s | Scanning Frequency f/Hz | Focused Current | Bunch Spot Diameter D/mm |

|---|---|---|---|---|---|

| 60 | 20~30 | 6~15 | 600 | 400~750 | 4~8 |

| Temperature/°C | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

|---|---|---|---|---|---|---|---|---|

| /MPa | 80 | 80 | 60 | 48 | 40 | 30 | 20 | 3 |

| E/GPa | 70 | 65.4 | 59.8 | 49.4 | 38.9 | 28.5 | 18.2 | 3.8 |

| G/GPa | 27 | 26.2 | 25.1 | 22.9 | 20.7 | 18.5 | 7 | 2 |

| α/10−6/°C | 22.2 | 23.8 | 24.9 | 25.8 | 26.7 | 27.6 | 28.5 | 29.4 |

| Temperature/°C | 20 | 100 | 200 | 300 | 400 | 600 | 1000 | 1200 | 1800 |

|---|---|---|---|---|---|---|---|---|---|

| /MPa | 400 | 410 | 390 | 380 | 350 | 310 | 250 | 160 | 90 |

| E/GPa | 221 | 217 | 212 | 206 | 194 | 184 | 113 | 56 | 25 |

| G/GPa | 355 | 318 | 305 | 302 | 300 | 299 | 268 | 245 | 234 |

| α/10−6/°C | 11.5 | 11.6 | 11.8 | 12.2 | 12.6 | 12.9 | 13.2 | 14.0 | 15.5 |

| Element | Mg | Si | Fe | Cu | Mn | Zn | Cr | Ti | Zr | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| Wt/% | 0.8~1.2 | 0.4~0.8 | 0.7 | 0.2~0.4 | 0.15 | 0.25 | 0.04~0.4 | 0.15 | 0.15 | marginal |

| Element | C | Si | Fe | B | Cr | Ni |

|---|---|---|---|---|---|---|

| Wt/% | 0.8 | 4.0 | 12 | 3.5 | 15 | 64.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Z.; Liu, H.; Tang, J.; Peng, Z.; Gong, Y. Effect of Pre-Set Coating Thickness on the Quality of Electron Beam Cladding Forming of Aluminum Alloys. Coatings 2022, 12, 350. https://doi.org/10.3390/coatings12030350

Zeng Z, Liu H, Tang J, Peng Z, Gong Y. Effect of Pre-Set Coating Thickness on the Quality of Electron Beam Cladding Forming of Aluminum Alloys. Coatings. 2022; 12(3):350. https://doi.org/10.3390/coatings12030350

Chicago/Turabian StyleZeng, Zhuangji, Hailang Liu, Jie Tang, Zhiguo Peng, and Yubing Gong. 2022. "Effect of Pre-Set Coating Thickness on the Quality of Electron Beam Cladding Forming of Aluminum Alloys" Coatings 12, no. 3: 350. https://doi.org/10.3390/coatings12030350

APA StyleZeng, Z., Liu, H., Tang, J., Peng, Z., & Gong, Y. (2022). Effect of Pre-Set Coating Thickness on the Quality of Electron Beam Cladding Forming of Aluminum Alloys. Coatings, 12(3), 350. https://doi.org/10.3390/coatings12030350