Hardness Enhancement in CoCrFeNi1−x(WC)x High-Entropy Alloy Thin Films Synthesised by Magnetron Co-Sputtering

Abstract

:1. Introduction

2. Materials and Methods

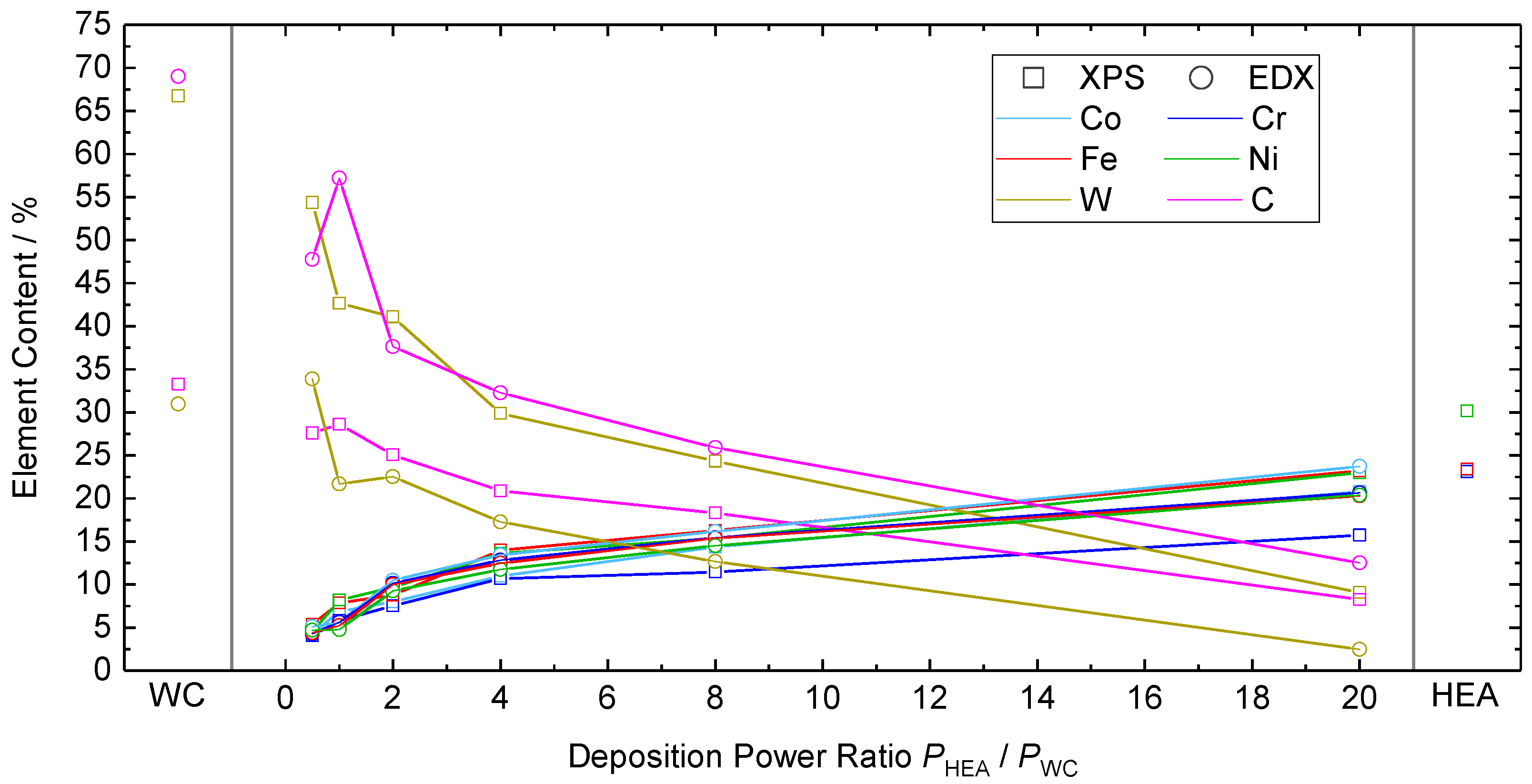

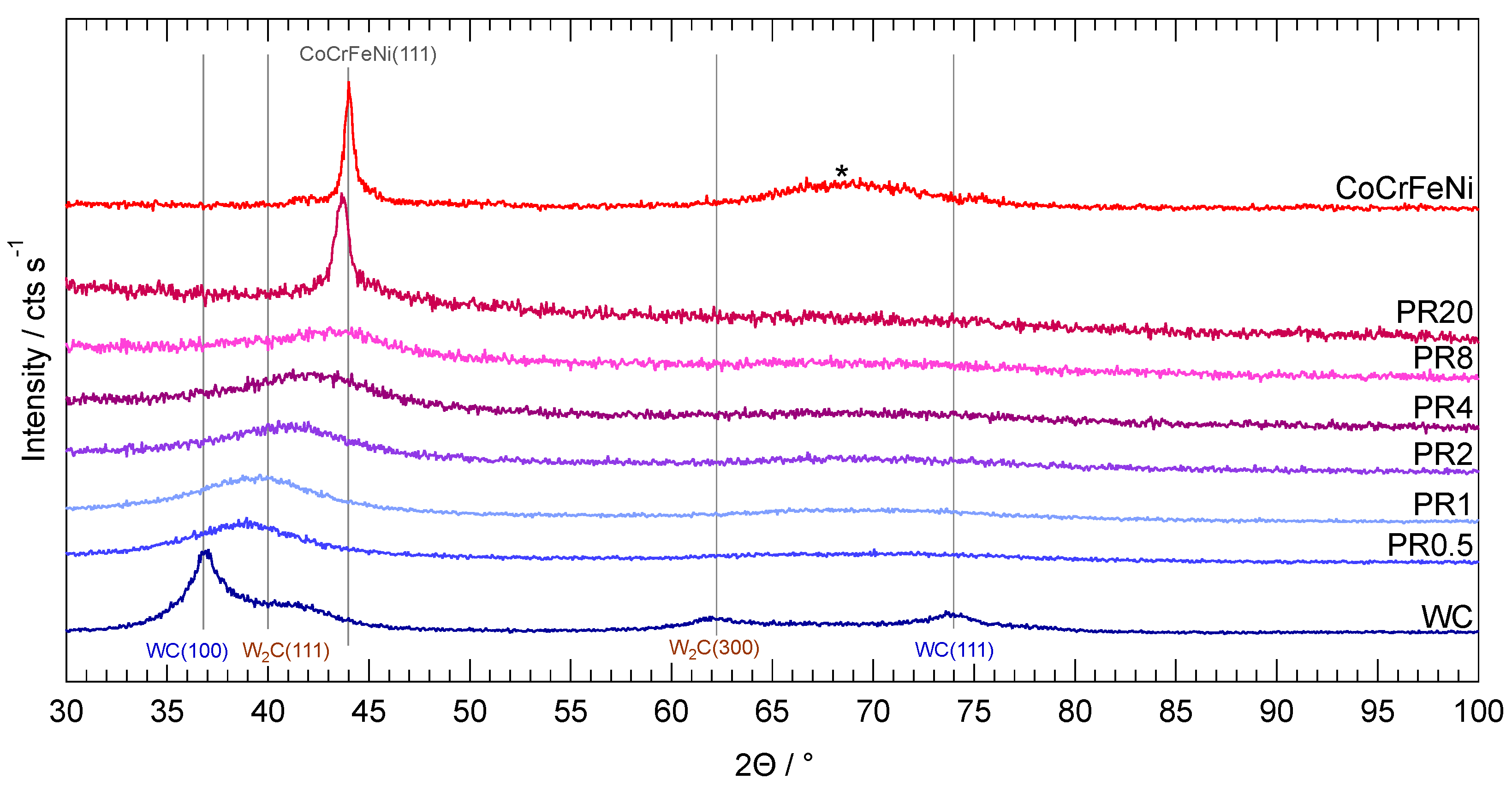

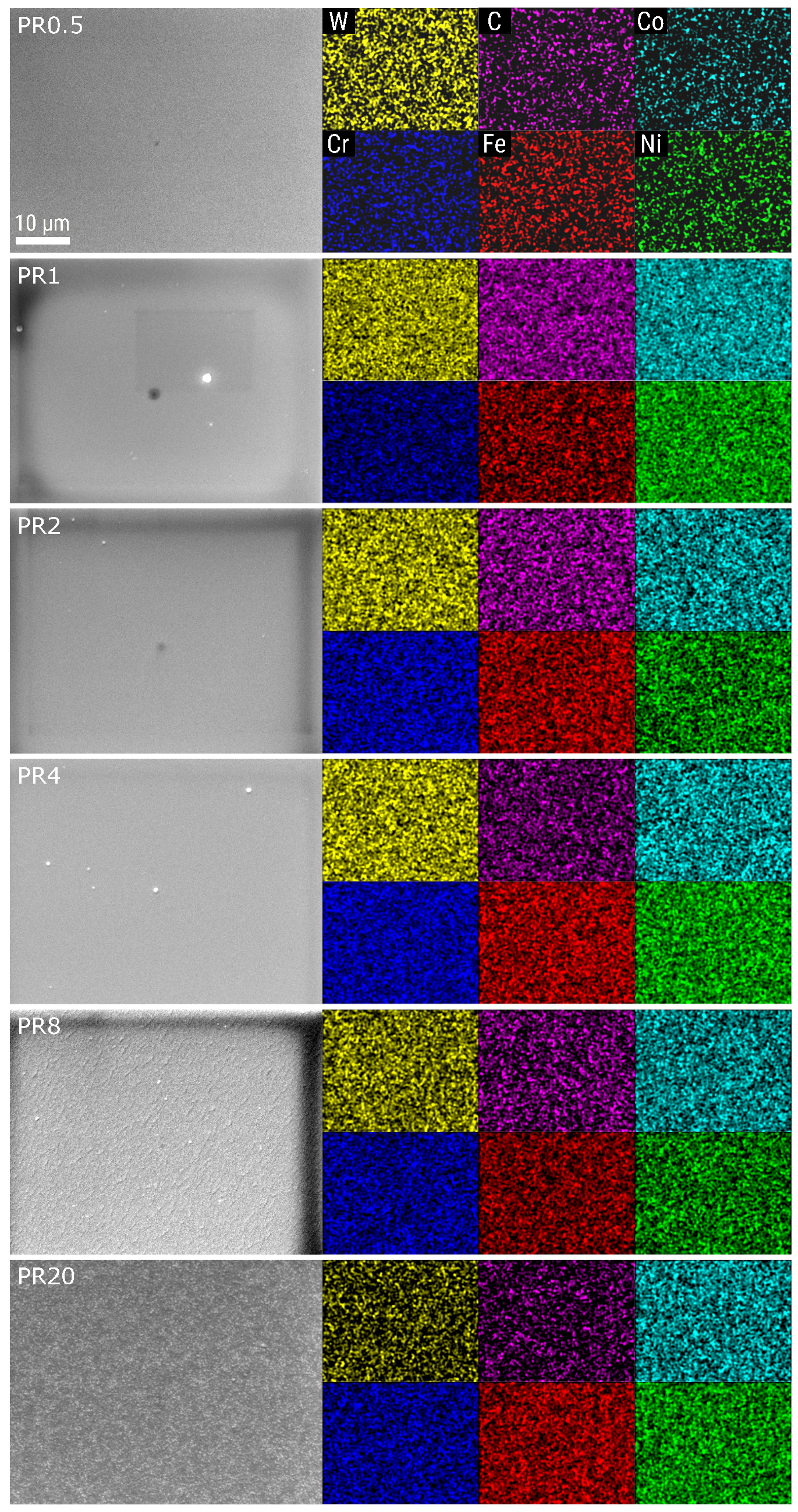

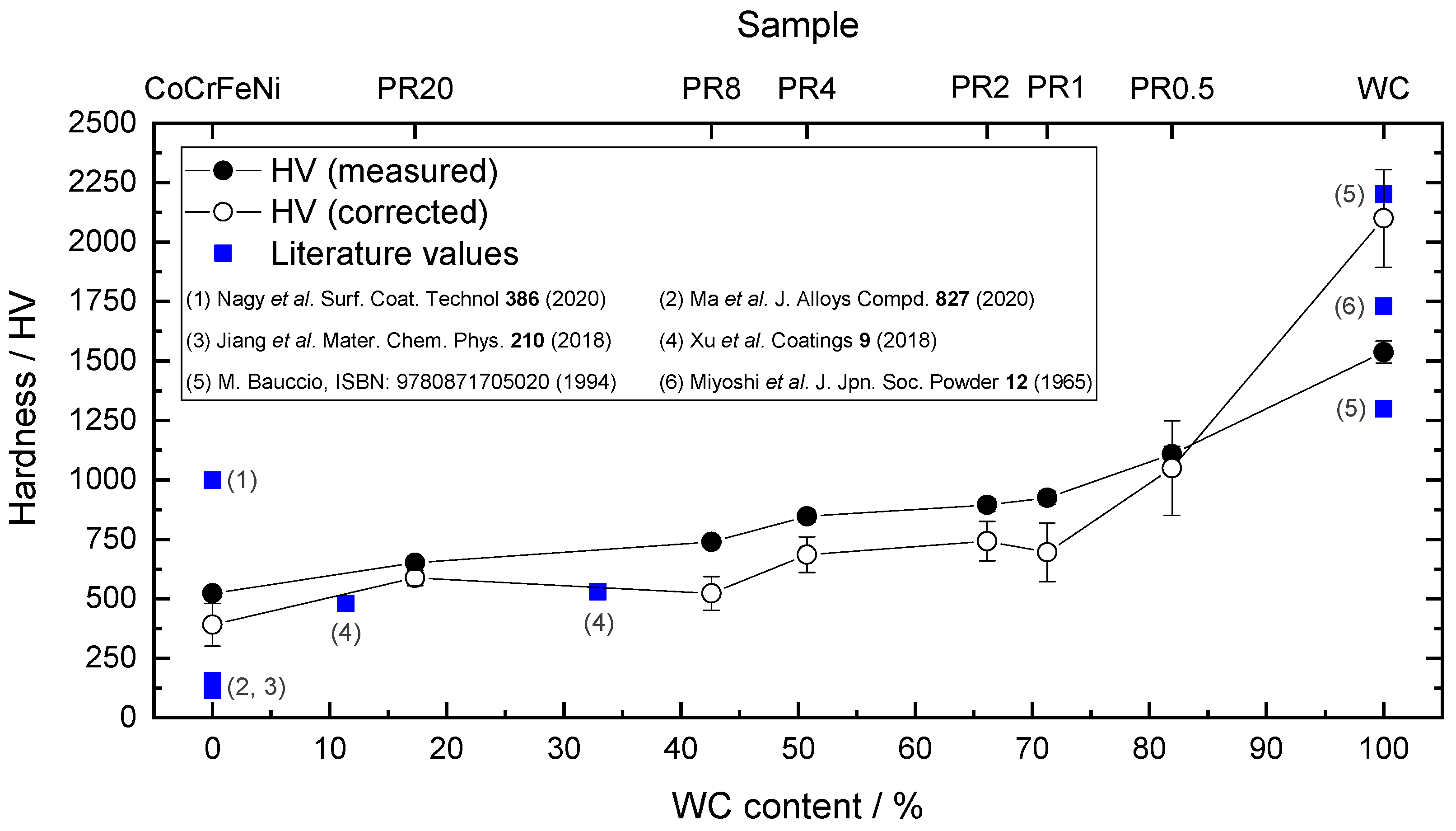

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.; Knight, P.; Vincent, A. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Miracle, D.; Senkov, O. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Li, J.; Zhao, M.; Jiang, Q. Effect of alloying elements on microstructure and properties of multiprincipal elements high-entropy alloys. J. Alloy. Compd. 2009, 475, 752–757. [Google Scholar] [CrossRef]

- Kao, Y.F.; Chen, T.J.; Chen, S.K.; Yeh, J.W. Microstructure and mechanical property of as-cast, -homogenized, and -deformed AlxCoCrFeNi (0 ≤ x ≤ 2) high-entropy alloys. J. Alloy. Compd. 2009, 488, 57–64. [Google Scholar] [CrossRef]

- Nagy, P.; Rohbeck, N.; Roussely, G.; Sortais, P.; Lábár, J.; Gubicza, J.; Michler, J.; Pethö, L. Processing and characterization of a multibeam sputtered nanocrystalline CoCrFeNi high-entropy alloy film. Surf. Coat. Technol. 2020, 386, 125465. [Google Scholar] [CrossRef]

- Shi, Y.; Yang, B.; Liaw, P. Corrosion-Resistant High-Entropy Alloys: A Review. Metals 2017, 7, 43. [Google Scholar] [CrossRef] [Green Version]

- Niu, Z.; Xu, J.; Wang, T.; Wang, N.; Han, Z.; Wang, Y. Microstructure, mechanical properties and corrosion resistance of CoCrFeNiW (x = 0, 0.2, 0.5) high entropy alloys. Intermetallics 2019, 112, 106550. [Google Scholar] [CrossRef]

- Fazakas, E.; Varga, B.; Geantă, V.; Berecz, T.; Jenei, P.; Voiculescu, I.; Coșniță, M.; Ștefănoiu, R. Microstructure, Thermal, and Corrosion Behavior of the AlAgCuNiSnTi Equiatomic Multicomponent Alloy. Materials 2019, 12, 926. [Google Scholar] [CrossRef] [Green Version]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.M.; Lin, S.J.; Yeh, J.W.; Chen, S.K.; Huang, Y.S.; Chen, H.C. Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear 2006, 261, 513–519. [Google Scholar] [CrossRef] [Green Version]

- Ma, H.; Shek, C.H. Effects of Hf on the microstructure and mechanical properties of CoCrFeNi high entropy alloy. J. Alloy. Compd. 2020, 827, 154159. [Google Scholar] [CrossRef]

- Jiang, H.; Han, K.; Qiao, D.; Lu, Y.; Cao, Z.; Li, T. Effects of Ta addition on the microstructures and mechanical properties of CoCrFeNi high entropy alloy. Mater. Chem. Phys. 2018, 210, 43–48. [Google Scholar] [CrossRef]

- Huang, T.; Jiang, L.; Zhang, C.; Jiang, H.; Lu, Y.; Li, T. Effect of carbon addition on the microstructure and mechanical properties of CoCrFeNi high entropy alloy. Sci. China Technol. Sci. 2017, 61, 117–123. [Google Scholar] [CrossRef]

- Zhou, R.; Chen, G.; Liu, B.; Wang, J.; Han, L.; Liu, Y. Microstructures and wear behaviour of (FeCoCrNi)1−x(WC)x high entropy alloy composites. Int. J. Refract. Met. Hard Mater. 2018, 75, 56–62. [Google Scholar] [CrossRef]

- Bauccio, M. ASM Engineering Materials Reference Book, 2nd ed.; Taylor & Francis: London, UK, 1994. [Google Scholar]

- Xu, J.; Wang, S.; Shang, C.; Huang, S.; Wang, Y. Microstructure and Properties of CoCrFeNi(WC) High-Entropy Alloy Coatings Prepared Using Mechanical Alloying and Hot Pressing Sintering. Coatings 2018, 9, 16. [Google Scholar] [CrossRef] [Green Version]

- Schwarz, H.; Uhlig, T.; Rösch, N.; Lindner, T.; Ganss, F.; Hellwig, O.; Lampke, T.; Wagner, G.; Seyller, T. CoCrFeNi High-Entropy Alloy Thin Films Synthesised by Magnetron Sputter Deposition from Spark Plasma Sintered Targets. Coatings 2021, 11, 468. [Google Scholar] [CrossRef]

- Luo, D.; Zhou, Q.; Ye, W.; Ren, Y.; Greiner, C.; He, Y.; Wang, H. Design and Characterization of Self-Lubricating Refractory High Entropy Alloy-Based Multilayered Films. ACS Appl. Mater. Interfaces 2021, 13, 55712–55725. [Google Scholar] [CrossRef]

- Jönsson, B.; Hogmark, S. Hardness measurements of thin films. Thin Solid Film. 1984, 114, 257–269. [Google Scholar] [CrossRef]

- Horcas, I.; Fernández, R.; Gómez-Rodríguez, J.M.; Colchero, J.; Gómez-Herrero, J.; Baro, A.M. WSXM: A software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instrum. 2007, 78, 013705. [Google Scholar] [CrossRef]

- Gražulis, S.; Chateigner, D.; Downs, R.T.; Yokochi, A.F.T.; Quirós, M.; Lutterotti, L.; Manakova, E.; Butkus, J.; Moeck, P.; Bail, A.L. Crystallography Open Database – an open-access collection of crystal structures. J. Appl. Crystallogr. 2009, 42, 726–729. [Google Scholar] [CrossRef] [PubMed]

- Matsunami, N.; Yamamura, Y.; Itikawa, Y.; Itoh, N.; Kazumata, Y.; Miyagawa, S.; Morita, K.; Shimizu, R.; Tawara, H. Energy dependence of the ion-induced sputtering yields of monatomic solids. At. Data Nucl. Data Tables 1984, 31, 1–80. [Google Scholar] [CrossRef]

- Fuchs, K.; Rödhammer, P.; Bertel, E.; Netzer, F.; Gornik, E. Reactive and non-reactive high rate sputter deposition of Tungsten carbide. Thin Solid Film. 1987, 151, 383–395. [Google Scholar] [CrossRef]

- Clementi, E.; Raimondi, D.L.; Reinhardt, W.P. Atomic Screening Constants from SCF Functions. II. Atoms with 37 to 86 Electrons. J. Chem. Phys. 1967, 47, 1300–1307. [Google Scholar] [CrossRef]

- Shi, Y.; Yang, B.; Rack, P.D.; Guo, S.; Liaw, P.K.; Zhao, Y. High-throughput synthesis and corrosion behavior of sputter-deposited nanocrystalline Al (CoCrFeNi)100- combinatorial high-entropy alloys. Mater. Des. 2020, 195, 109018. [Google Scholar] [CrossRef]

- Miyoshi, A.; Hara, A. High Temperature Hardness of WC, TiC, TaC, NbC and Their Mixed Carbides. J. Jpn. Soc. Powder Powder Metall. 1965, 12, 78–84. [Google Scholar] [CrossRef]

- Beegan, D.; Chowdhury, S.; Laugier, M. The nanoindentation behaviour of hard and soft films on silicon substrates. Thin Solid Film. 2004, 466, 167–174. [Google Scholar] [CrossRef]

- Walls, M.G.; Chaudhri, M.M.; Tang, T.B. STM profilometry of low-load Vickers indentations in a silicon crystal. J. Phys. Appl. Phys. 1992, 25, 500–507. [Google Scholar] [CrossRef]

| Sample | CoCrFeNi Target Power (W) | WC Target Power (W) | Time (min) | Film Thickness (nm) |

|---|---|---|---|---|

| CoCrFeNi | 200 | - | 15 | 201 |

| PR0.5 | 100 | 200 | 15 | 197 |

| PR1 | 200 | 200 | 15 | 305 |

| PR2 | 400 | 200 | 15 | 411 |

| PR4 | 800 | 200 | 15 | 443 |

| PR8 | 800 | 100 | 15 | 481 |

| PR20 | 1000 | 50 | 15 | 820 |

| WC | - | 200 | 15 | 209 |

| Sample | (HV) | (HV) | Indentation Depth D (nm) | Thickness t (nm) |

|---|---|---|---|---|

| WC | 209 | |||

| PR0.5 | 197 | |||

| PR1 | 305 | |||

| PR2 | 411 | |||

| PR4 | 443 | |||

| PR8 | 481 | |||

| PR20 | 820 | |||

| CoCrFeNi | 201 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schwarz, H.; Uhlig, T.; Lindner, T.; Lampke, T.; Wagner, G.; Seyller, T. Hardness Enhancement in CoCrFeNi1−x(WC)x High-Entropy Alloy Thin Films Synthesised by Magnetron Co-Sputtering. Coatings 2022, 12, 269. https://doi.org/10.3390/coatings12020269

Schwarz H, Uhlig T, Lindner T, Lampke T, Wagner G, Seyller T. Hardness Enhancement in CoCrFeNi1−x(WC)x High-Entropy Alloy Thin Films Synthesised by Magnetron Co-Sputtering. Coatings. 2022; 12(2):269. https://doi.org/10.3390/coatings12020269

Chicago/Turabian StyleSchwarz, Holger, Thomas Uhlig, Thomas Lindner, Thomas Lampke, Guntram Wagner, and Thomas Seyller. 2022. "Hardness Enhancement in CoCrFeNi1−x(WC)x High-Entropy Alloy Thin Films Synthesised by Magnetron Co-Sputtering" Coatings 12, no. 2: 269. https://doi.org/10.3390/coatings12020269

APA StyleSchwarz, H., Uhlig, T., Lindner, T., Lampke, T., Wagner, G., & Seyller, T. (2022). Hardness Enhancement in CoCrFeNi1−x(WC)x High-Entropy Alloy Thin Films Synthesised by Magnetron Co-Sputtering. Coatings, 12(2), 269. https://doi.org/10.3390/coatings12020269