Crack-Free and Thickness-Controllable Deposition of TiO2–rGO Thin Films for Solar Harnessing Devices

Abstract

:1. Introduction

2. Materials and Methods

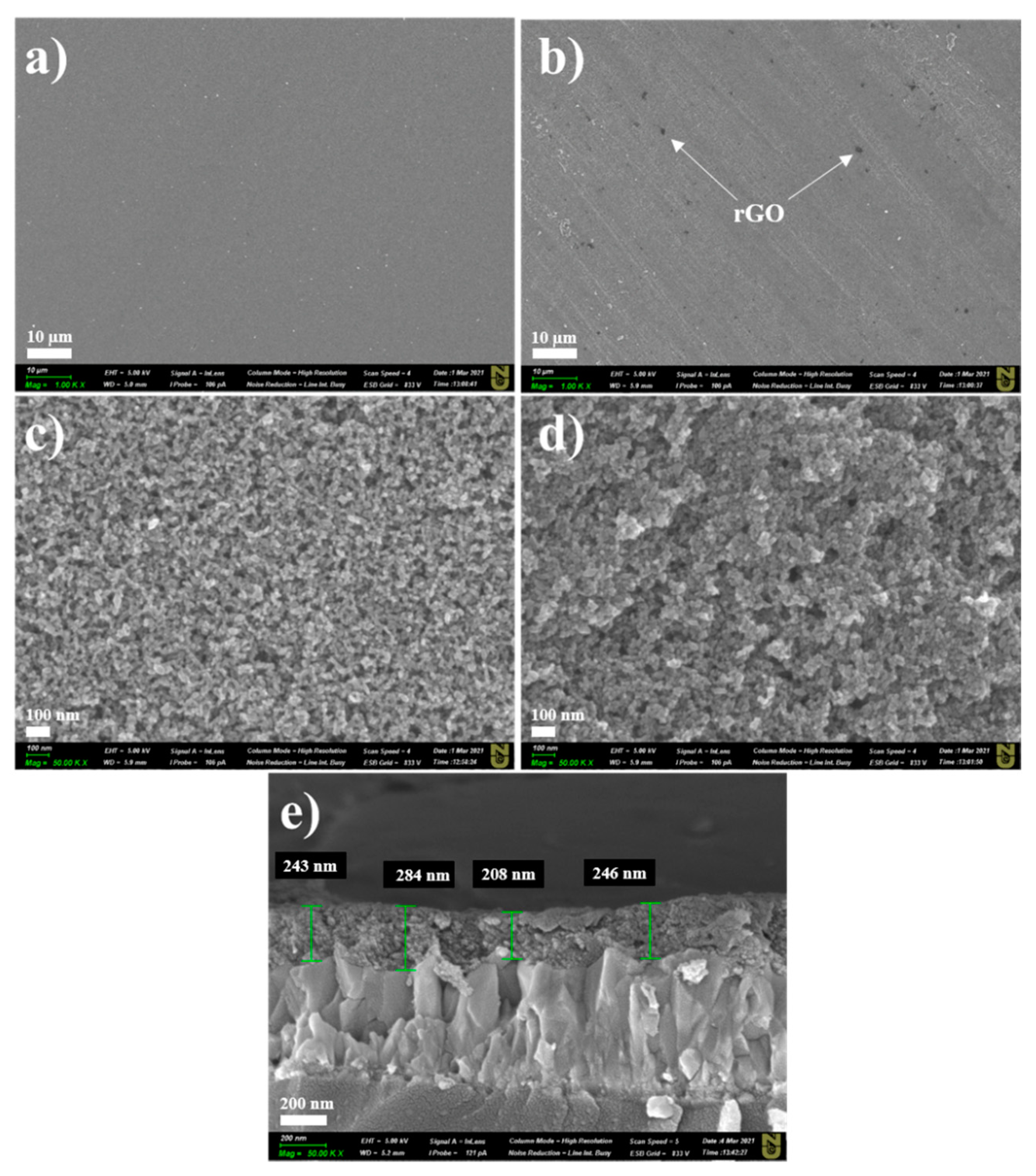

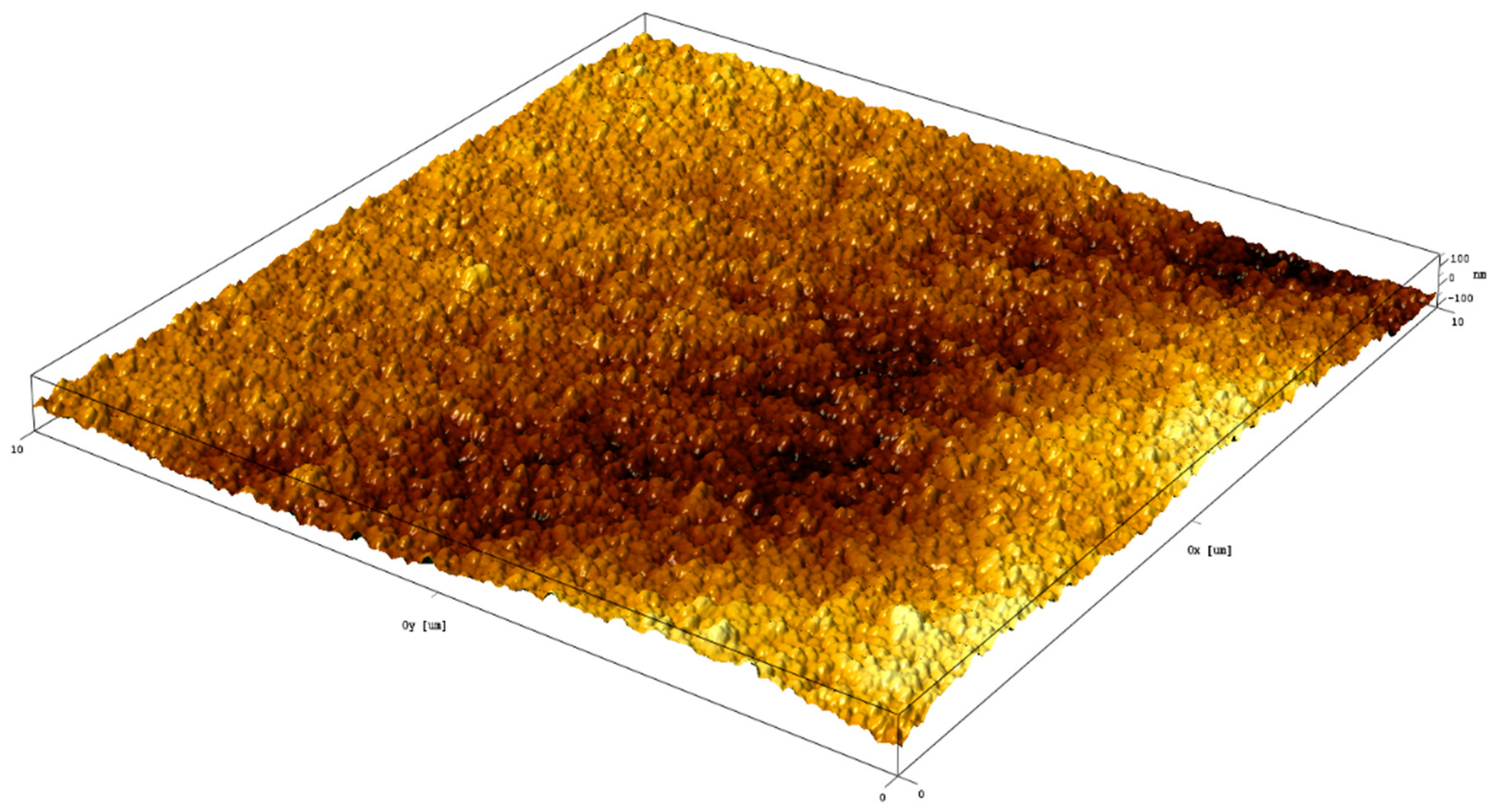

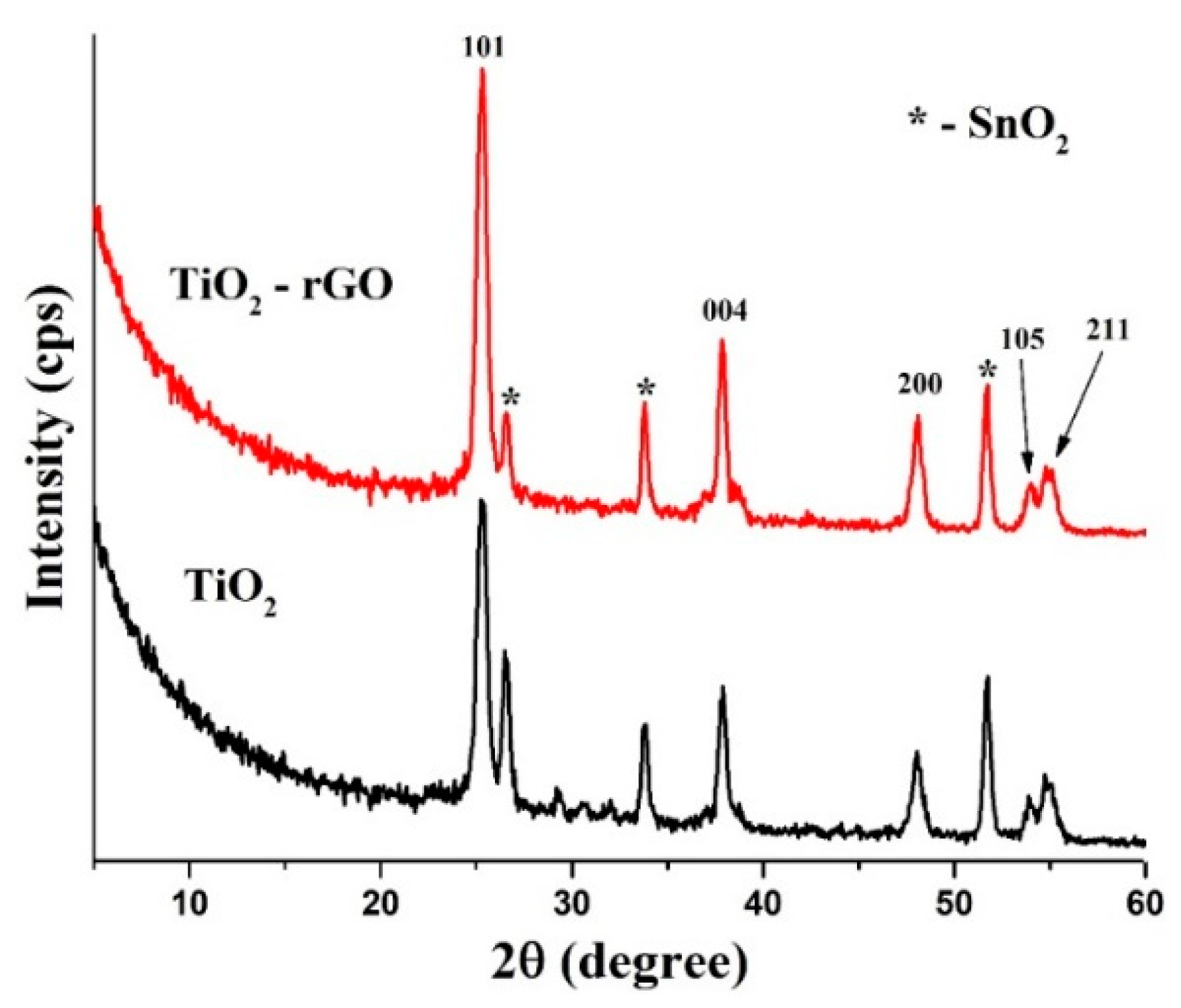

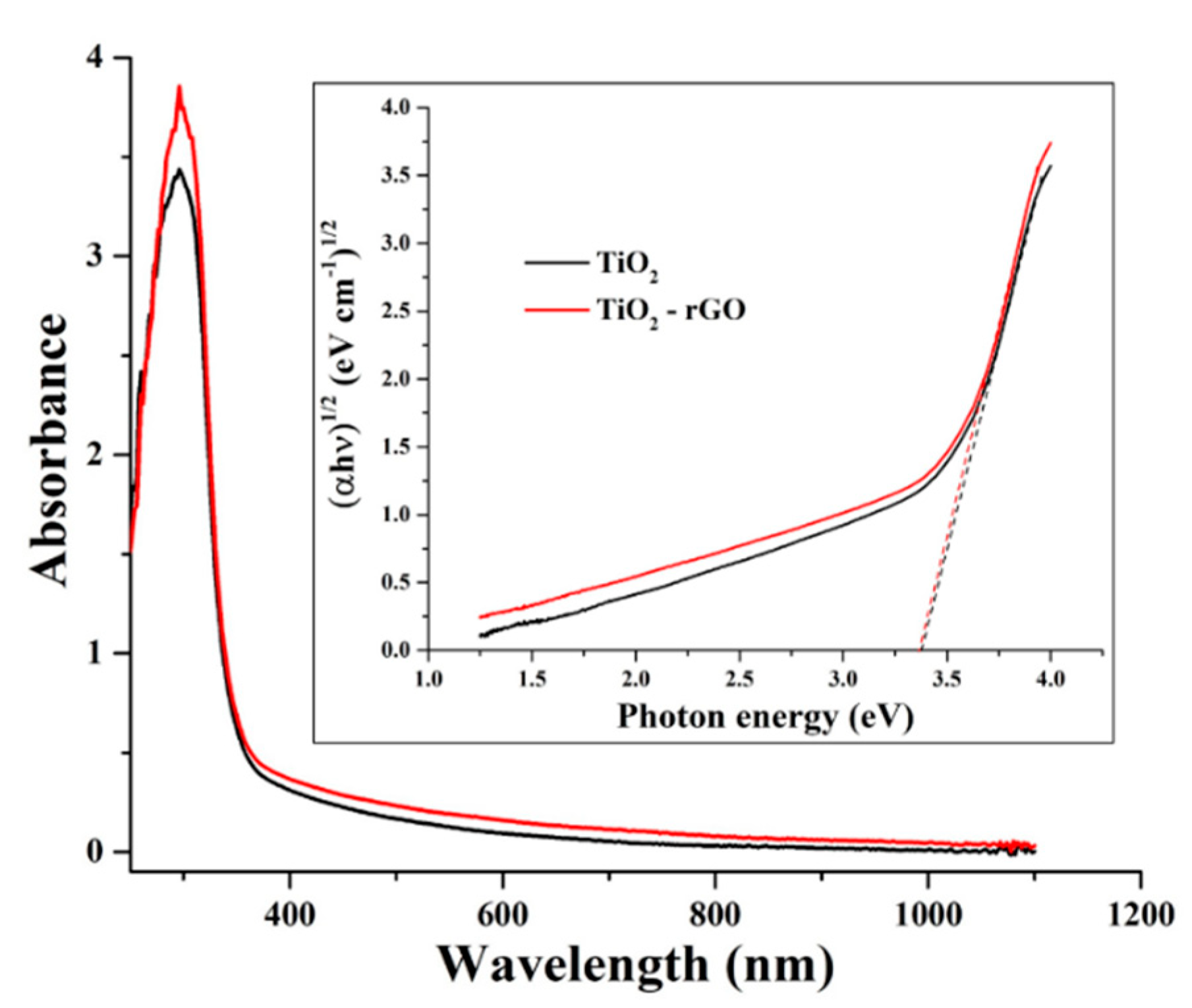

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Agrawal, A.; Siddiqui, S.A.; Soni, A.; Khandelwal, K.; Sharma, G.D. Performance analysis of TiO2 based dye sensitized solar cell prepared by screen printing and doctor blade deposition techniques. Sol. Energy 2021, 226, 9–19. [Google Scholar] [CrossRef]

- Vu, H.H.T.; Atabaev, T.S.; Ahn, J.Y.; Dinh, N.N.; Kim, H.-K.; Hwang, Y.-H. Dye-sensitized solar cells composed of photoactive composite photoelectrodes with enhanced solar energy conversion efficiency. J. Mater. Chem. A 2015, 3, 11130–11136. [Google Scholar] [CrossRef]

- Hernández-Granados, A.; Corpus-Mendoza, A.N.; Moreno-Romero, P.M.; Rodríguez-Castañeda, C.A.; Pascoe-Sussoni, J.E.; Castelo-González, O.A.; Menchaca-Campos, C.; Escorcia-García, J.; Hu, H. Optically uniform thin films of mesoporous TiO2 for perovskite solar cell applications. Opt. Mater. 2019, 88, 695–703. [Google Scholar] [CrossRef]

- Slawek, A.; Starowicz, Z.; Lipinski, M. The influence of the thickness of compact TiO2 electron transport layer on the performance of planar CH3NH3PbI3 perovskite solar cells. Materials 2021, 14, 3295. [Google Scholar] [CrossRef] [PubMed]

- Atabaev, T.S.; Lee, D.H.; Hong, N.H. Fabrication of TiO2/CuO photoelectrode with enhanced solar water splitting activity. Funct. Mater. Lett. 2017, 10, 1750084. [Google Scholar] [CrossRef]

- Gillespie, P.N.O.; Martsinovich, N. Origin of charge trapping in TiO2/reduced graphene oxide photocatalytic composites: Insights from theory. ACS Appl. Mater. Interfaces 2019, 11, 31909–31922. [Google Scholar] [CrossRef] [Green Version]

- Bell, N.J.; Ng, Y.H.; Du, A.; Coster, H.; Smith, S.; Amal, R. Understanding the enhancement in photoelectrochemical properties of photocatalytically prepared TiO2-reduced graphene oxide composite. J. Phys. Chem. C 2011, 115, 6004–6009. [Google Scholar] [CrossRef]

- Tayebi, M.; Kolaei, M.; Tayebi, A.; Masoumi, Z.; Belbasi, Z.; Lee, B.-K. Reduced graphene oxide (RGO) on TiO2 for an improved photoelectrochemical (PEC) and photocatalytic activity. Sol. Energy 2019, 190, 185–194. [Google Scholar] [CrossRef]

- Lee, E.; Lee, D.; Yoon, J.; Yin, Y.; Na Lee, Y.; Uprety, S.; Yoon, Y.S.; Kim, D.-J. Enhanced gas-sensing performance of GO/TiO2 composite by photocatalysis. Sensors 2018, 18, 3334. [Google Scholar] [CrossRef] [Green Version]

- Raja, R.; Govindaraj, M.; Antony, M.D.; Krishnan, K.; Velusamy, E.; Sambandam, A.; Subbaiha, M.; Williams Rayar, V. Effect of TiO2/reduced graphene oxide composite thin film as a blocking layer on the efficiency of dye-sensitized solar cells. J. Solid State Electrochem. 2017, 21, 891–903. [Google Scholar] [CrossRef]

- Han, G.S.; Song, Y.H.; Jin, Y.U.; Lee, J.-W.; Park, N.-G.; Kang, B.K.; Lee, J.-K.; Cho, I.S.; Yoon, D.H.; Jung, H.S. Reduced graphene oxide/mesoporous TiO2 nanocomposite based perovskite solar cells. ACS Appl. Mater. Interfaces 2015, 7, 23521–23526. [Google Scholar] [CrossRef] [PubMed]

- Cho, K.T.; Grancini, G.; Lee, Y.; Konios, D.; Paek, S.; Kymakis, E.; Nazeeruddin, M.K. Beneficial role of reduced graphene oxide for electron extraction in highly efficient perovskite solar cells. ChemSusChem 2016, 9, 3040–3044. [Google Scholar] [CrossRef]

- Jumeri, F.A.; Lim, H.N.; Zainal, Z.; Huang, N.M.; Pandikumar, A. Titanium dioxide-reduced graphene oxide thin film for photoelectrochemical water splitting. Ceram. Int. 2014, 40, 15159–15165. [Google Scholar] [CrossRef]

- Agrawal, Y.; Kedawat, G.; Kumar, P.; Dwivedi, J.; Singh, V.N.; Gupta, R.K.; Gupta, B.K. High-performance stable field emission with ultralow turn on voltage from rGO conformal coated TiO2 nanotubes 3D arrays. Sci. Rep. 2015, 5, 11612. [Google Scholar] [CrossRef] [PubMed]

- AlShammari, A.S.; Halim, M.M.; Yam, F.K.; Kaus, N.H.M. Synthesis of titanium dioxide (TiO2)/reduced graphene oxide (rGO) thin-film composite by spray pyrolysis technique and its physical properties. Mater. Sci. Semicond. Process. 2020, 116, 105140. [Google Scholar] [CrossRef]

- Ito, S.; Chen, P.; Comte, P.; Nazeeruddin, M.K.; Liska, P.; Péchy, P.; Grätzel, M. Fabrication of screen-printing pastes from TiO2 powders for dye-sensitised solar cells. Prog. Photovolt Res. Appl. 2007, 15, 603–612. [Google Scholar] [CrossRef]

- Nan, H.Y.; Ni, Z.H.; Wang, J.; Zafar, Z.; Shi, Z.X.; Wang, Y.Y. The thermal stability of graphene in air investigated by Raman spectroscopy. J. Raman Spectrosc. 2013, 44, 1018–1021. [Google Scholar] [CrossRef]

- Liu, F.; Wang, M.; Chen, Y.; Gao, J. Thermal stability of graphene in inert atmosphere at high temperature. J. Solid. State Chem. 2019, 276, 100–103. [Google Scholar] [CrossRef]

- Al-Sherbini, A.-S.; Bakr, M.; Ghoneim, I.; Saad, M. Exfoliation of graphene sheets via high energy wet milling of graphite in 2-ethylhexanol and kerosene. J. Adv. Res. 2017, 8, 209–215. [Google Scholar] [CrossRef]

- Makuła, P.; Pacia, M.; Macyk, W. How to correctly determine the band gap energy of modified semiconductor photocatalysts based on UV–Vis spectra. J. Phys. Chem. Lett. 2018, 9, 6814–6817. [Google Scholar] [CrossRef] [Green Version]

- Bo, Z.; Shuai, X.; Mao, S.; Yang, H.; Qian, J.; Chen, J.; Yan, J.; Cen, K. Green preparation of reduced graphene oxide for sensing and energy storage applications. Sci. Rep. 2014, 4, 4684. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Anitha, V.S.; Lekshmy, S.S.; Joy, K. Effect of annealing on the structural, optical, electrical, and photocatalytic activity of ZrO2-TiO2 nanocomposite thin films prepared by sol-gel dip coating technique. J. Mater. Sci. Mater. Electron. 2017, 28, 10541–10554. [Google Scholar] [CrossRef]

- Mohan, R.; Drbohlavova, J.; Hubalek, J. Water-dispersible TiO2 nanoparticles via a biphasic solvothermal reaction method. Nanoscale Res. Lett. 2013, 8, 503. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khamkhash, L.; Em, S.; Molkenova, A.; Hwang, Y.-H.; Atabaev, T.S. Crack-Free and Thickness-Controllable Deposition of TiO2–rGO Thin Films for Solar Harnessing Devices. Coatings 2022, 12, 218. https://doi.org/10.3390/coatings12020218

Khamkhash L, Em S, Molkenova A, Hwang Y-H, Atabaev TS. Crack-Free and Thickness-Controllable Deposition of TiO2–rGO Thin Films for Solar Harnessing Devices. Coatings. 2022; 12(2):218. https://doi.org/10.3390/coatings12020218

Chicago/Turabian StyleKhamkhash, Laura, Svetlana Em, Anara Molkenova, Yoon-Hwae Hwang, and Timur Sh. Atabaev. 2022. "Crack-Free and Thickness-Controllable Deposition of TiO2–rGO Thin Films for Solar Harnessing Devices" Coatings 12, no. 2: 218. https://doi.org/10.3390/coatings12020218

APA StyleKhamkhash, L., Em, S., Molkenova, A., Hwang, Y.-H., & Atabaev, T. S. (2022). Crack-Free and Thickness-Controllable Deposition of TiO2–rGO Thin Films for Solar Harnessing Devices. Coatings, 12(2), 218. https://doi.org/10.3390/coatings12020218