Cold Spray Additive Manufacturing of Ti6Al4V: Special Nozzle Design Using Numerical Simulation and Experimental Validation

Abstract

:1. Introduction

2. Numerical Modeling and Experimental Methodology

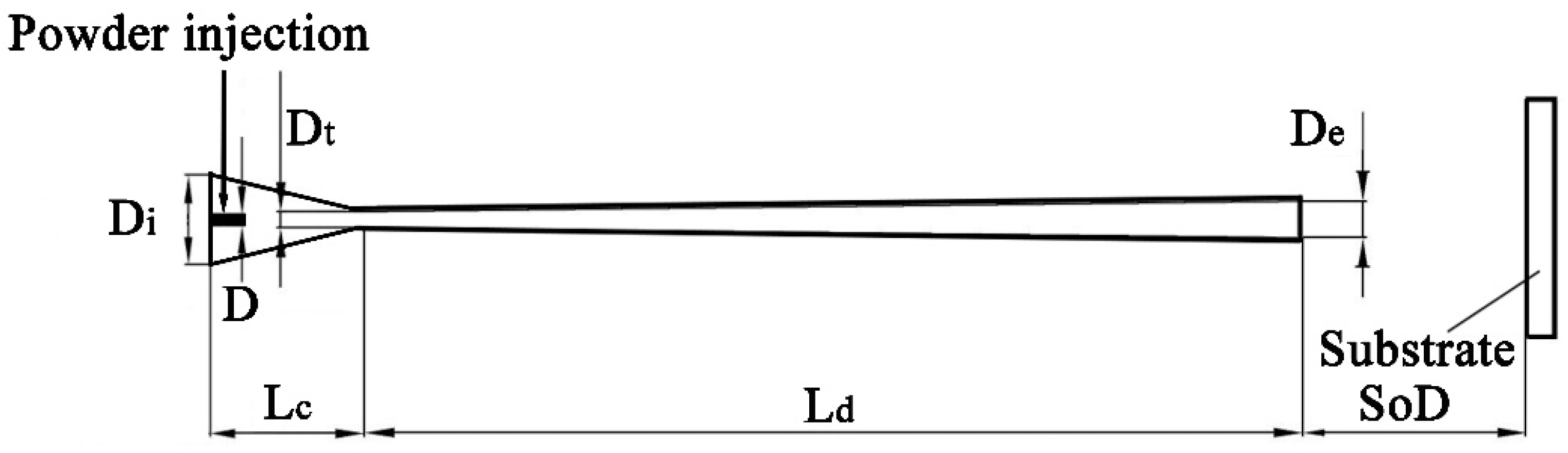

2.1. Numerical Model

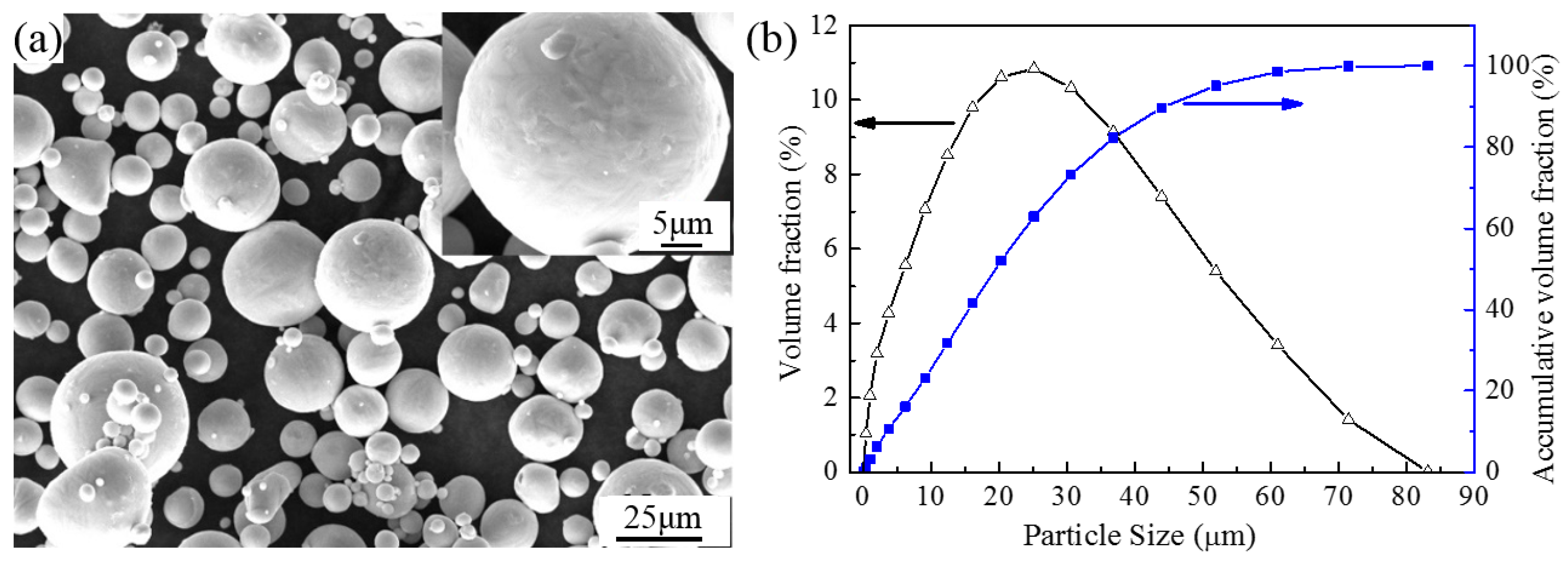

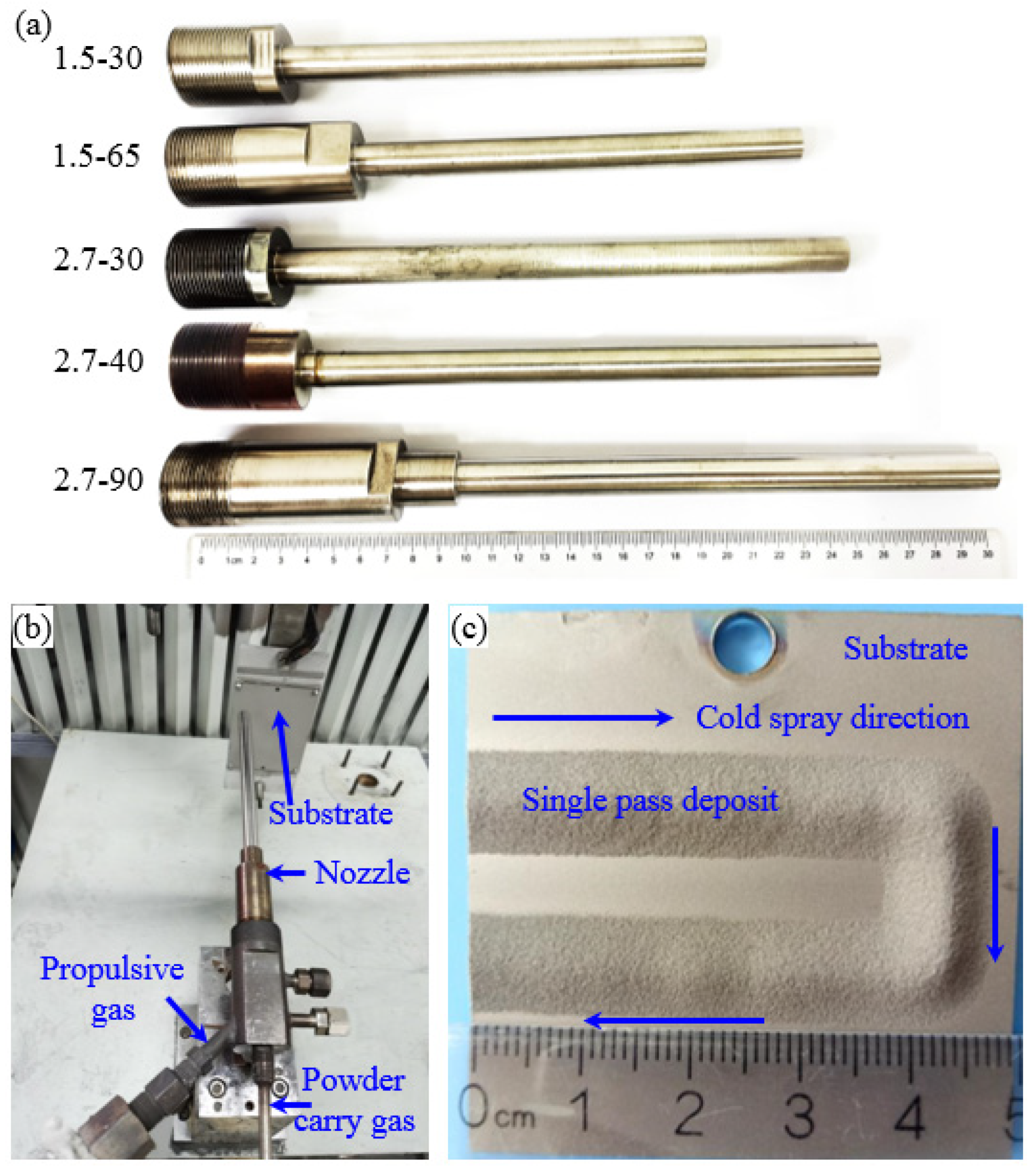

2.2. Experiment Materials and Method

3. Results and Discussion

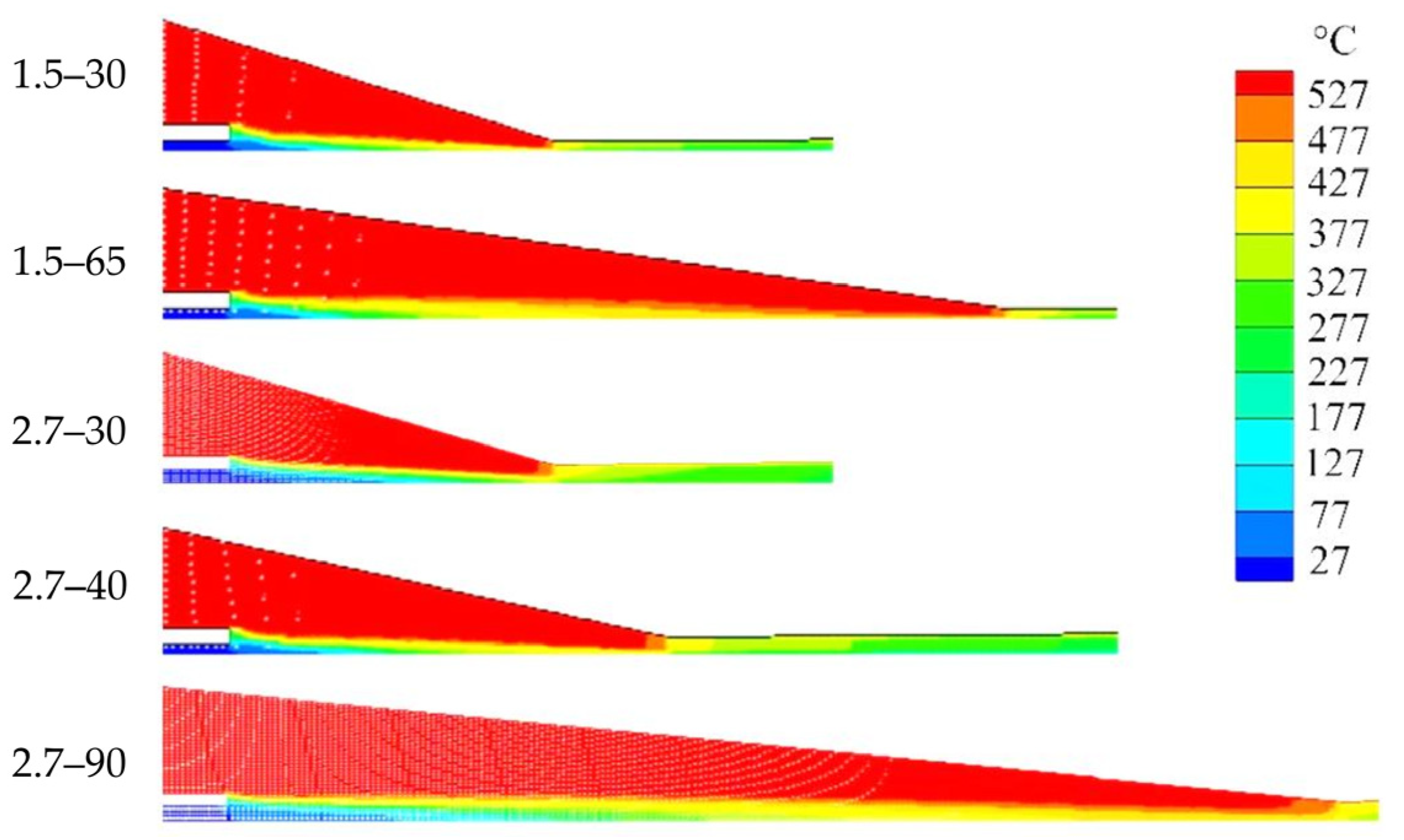

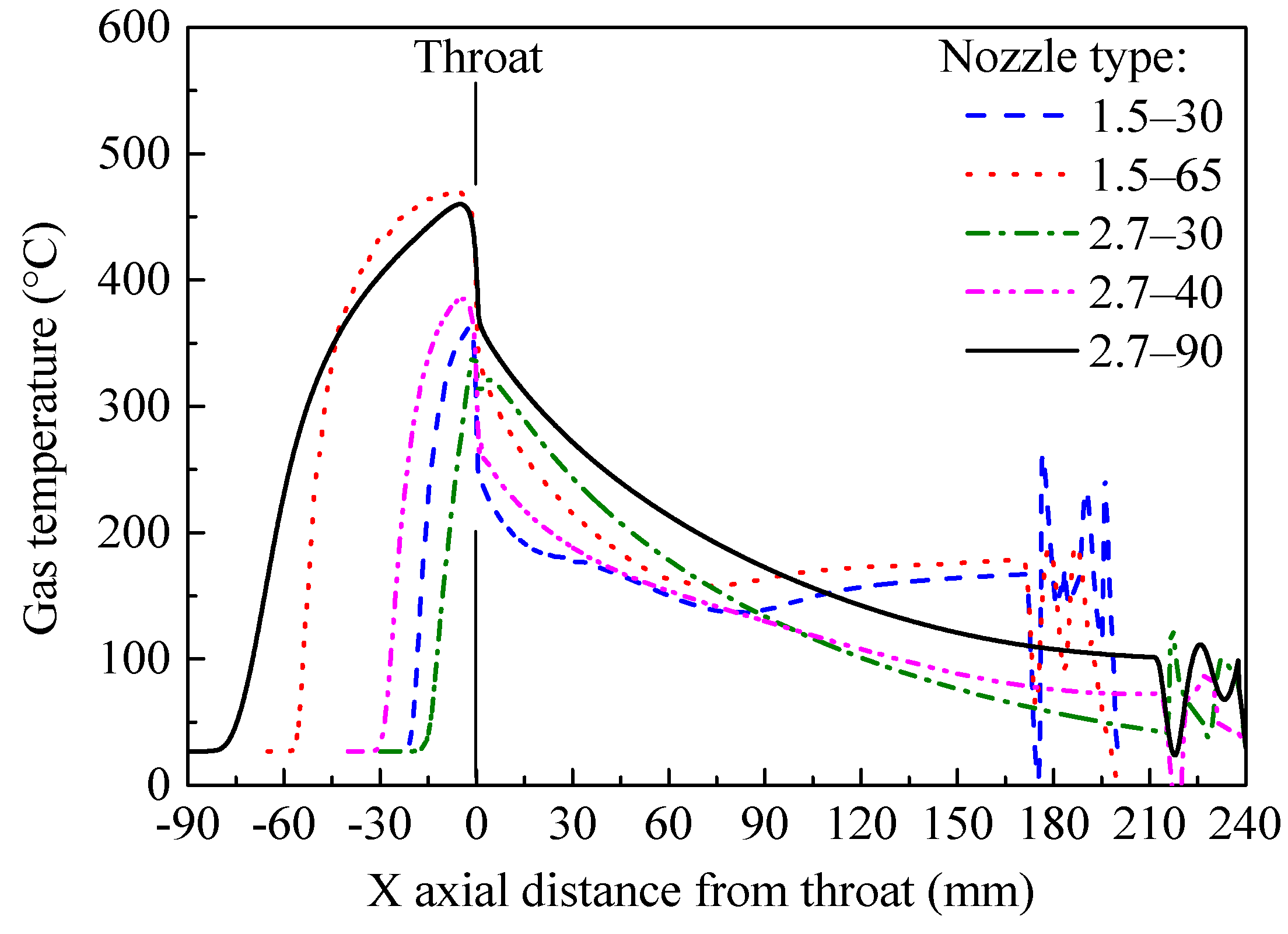

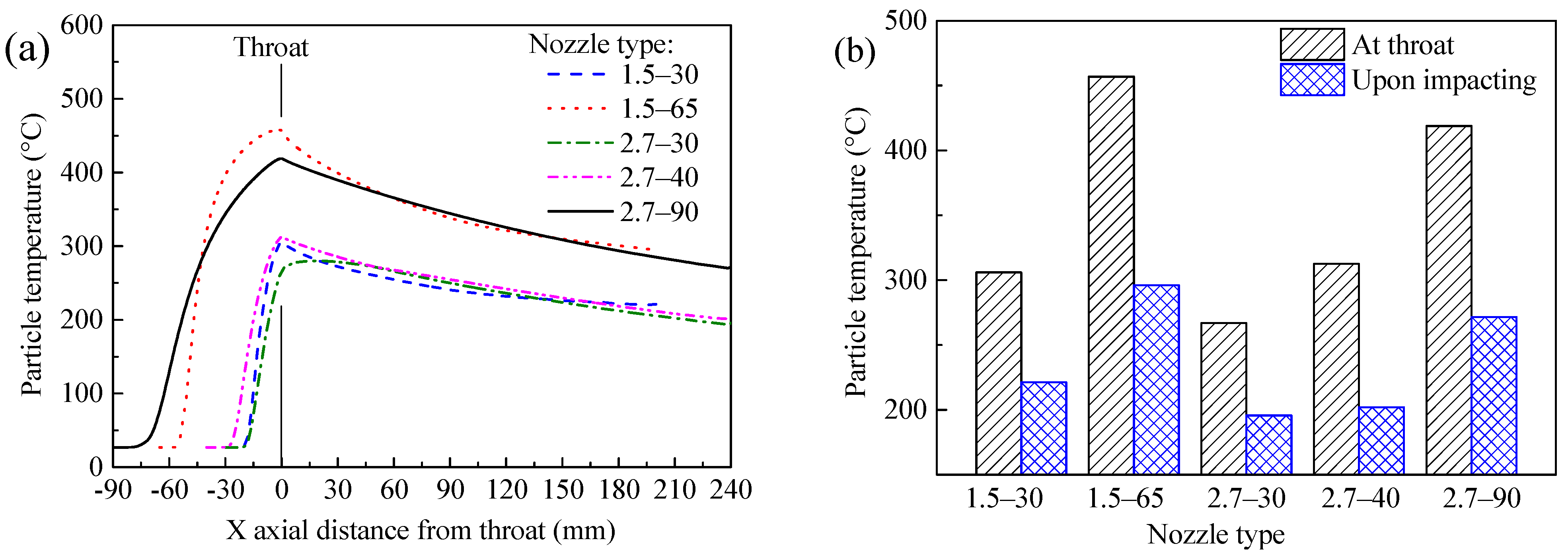

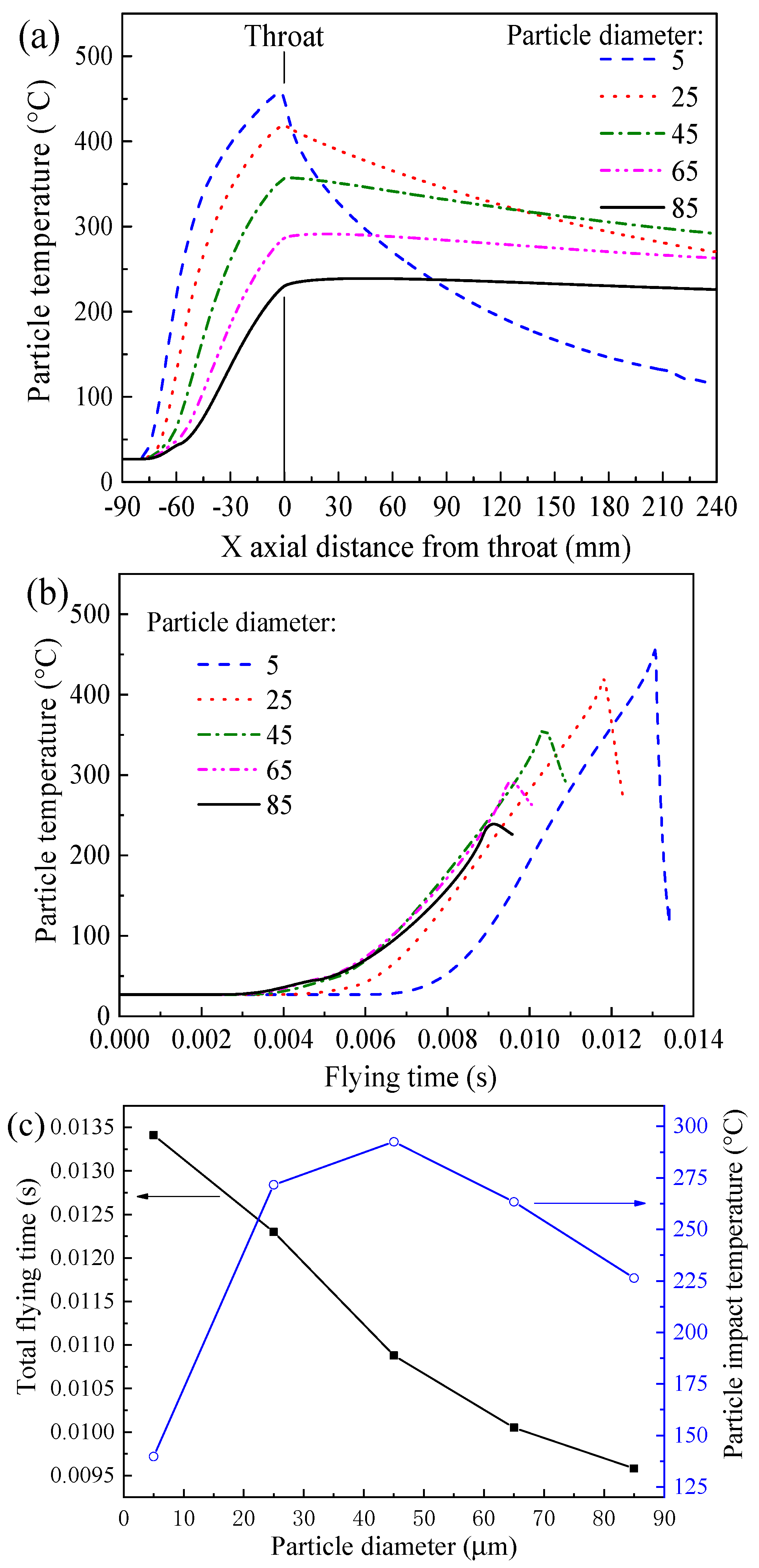

3.1. Gas Flow, Gas Temperature, and Particle Temperature

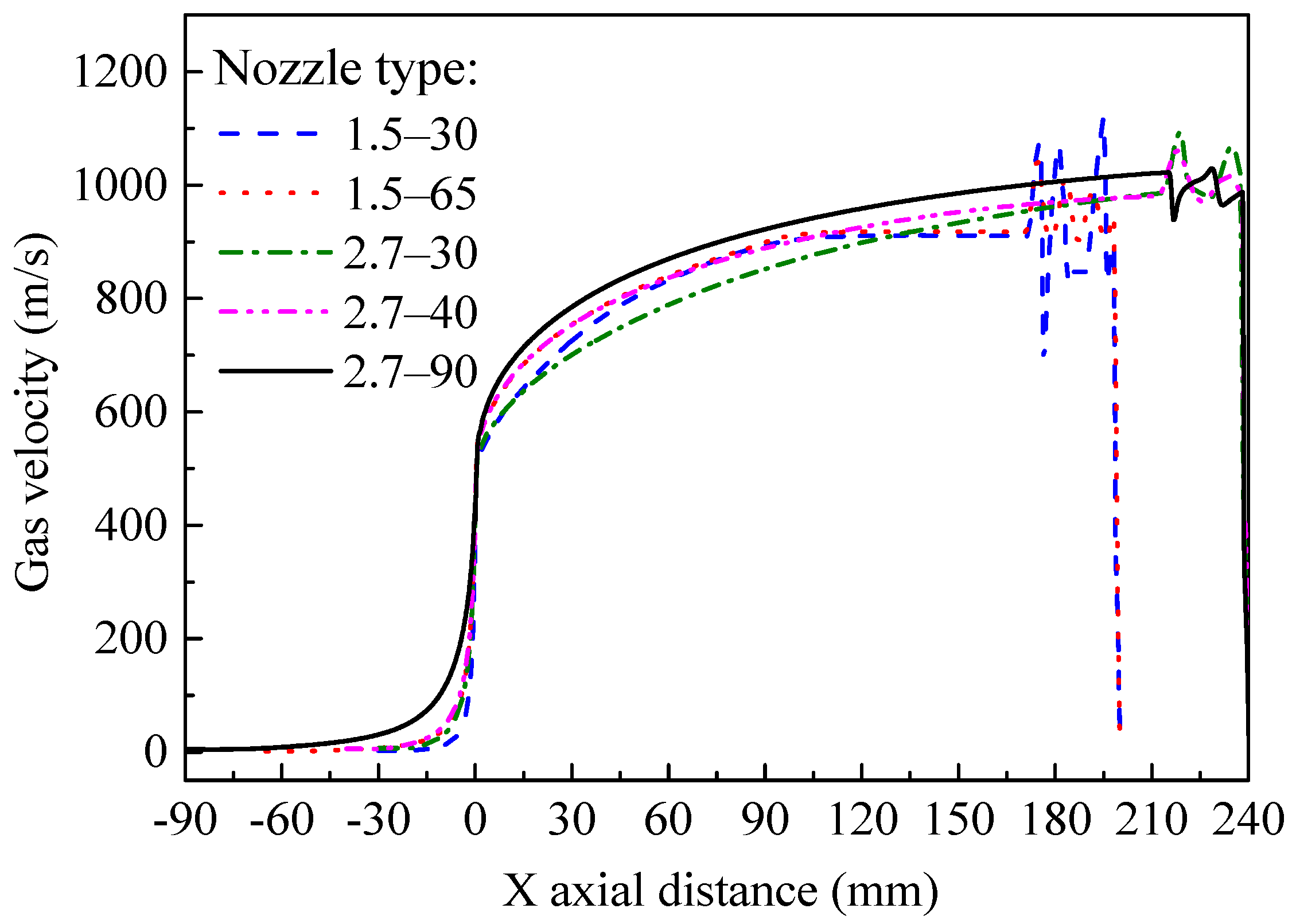

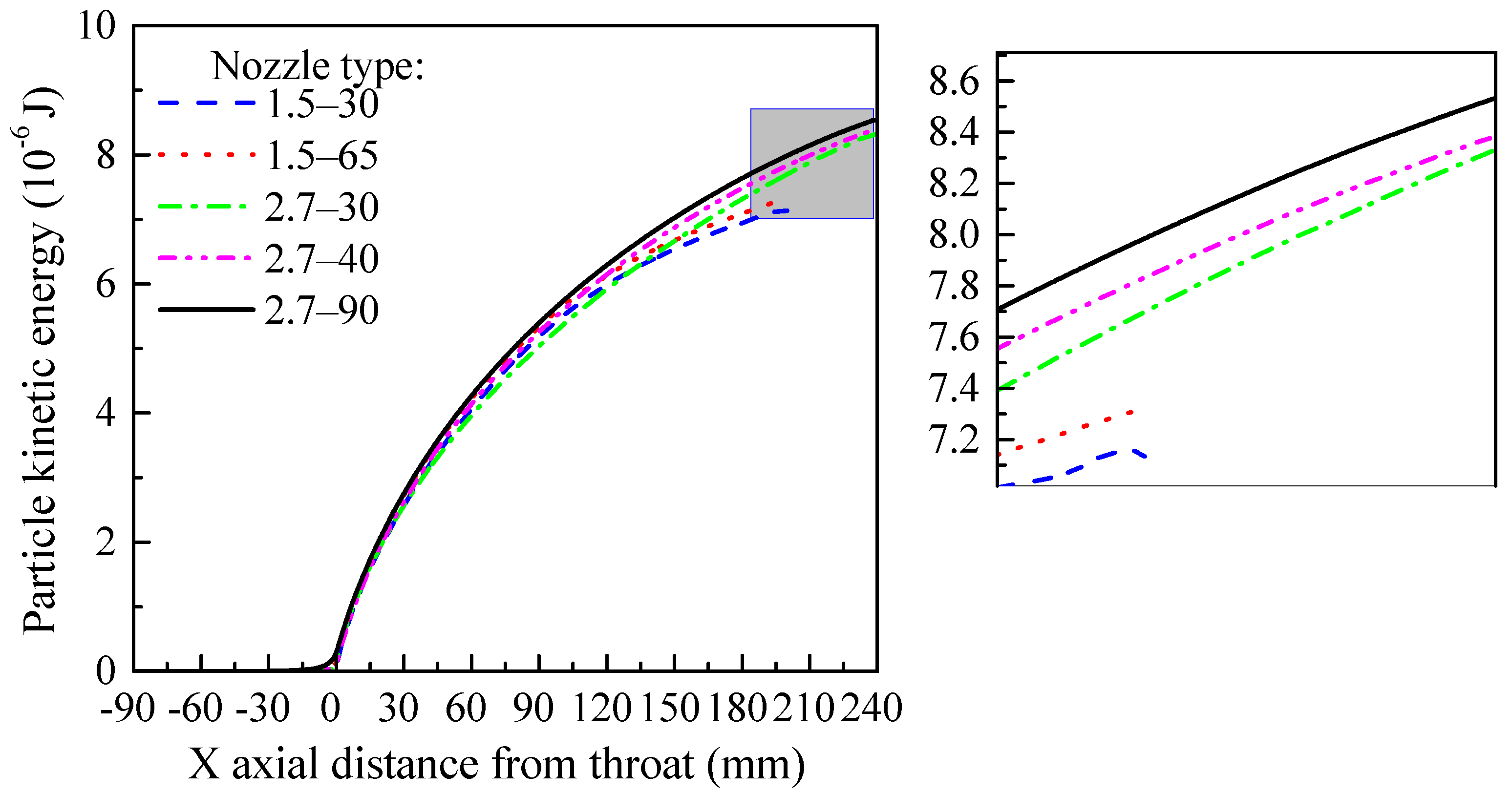

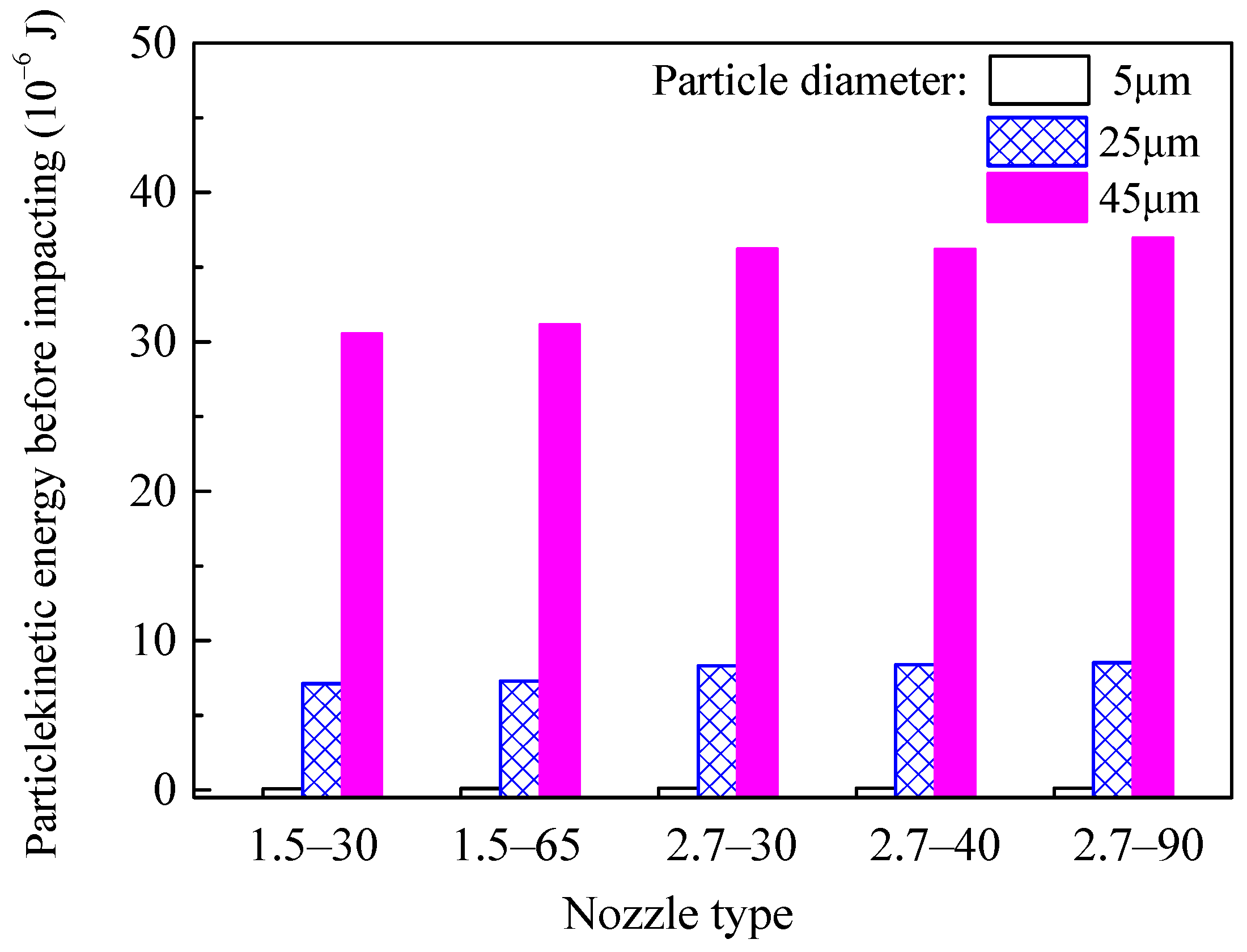

3.2. Gas Velocity and Particle Acceleration

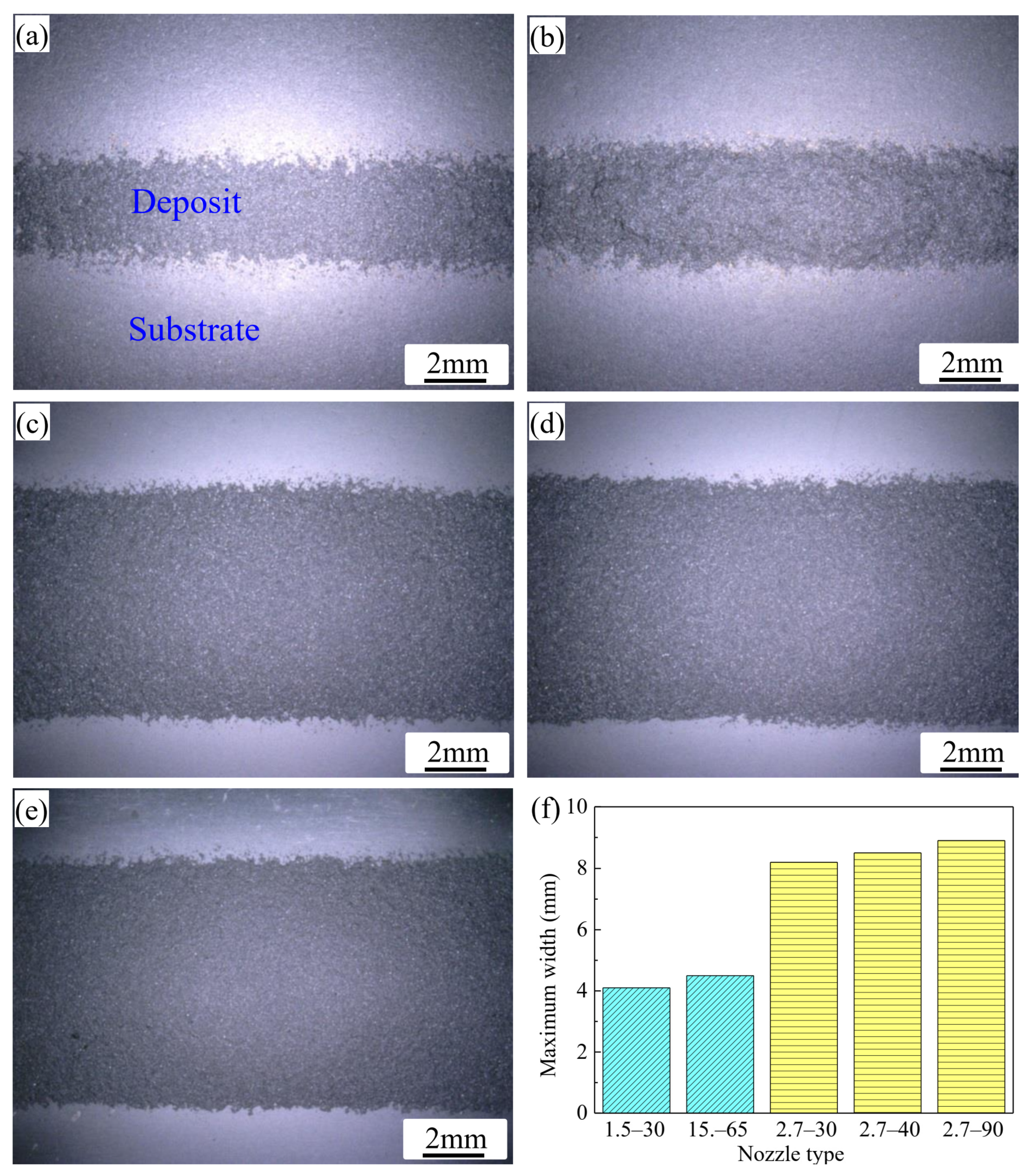

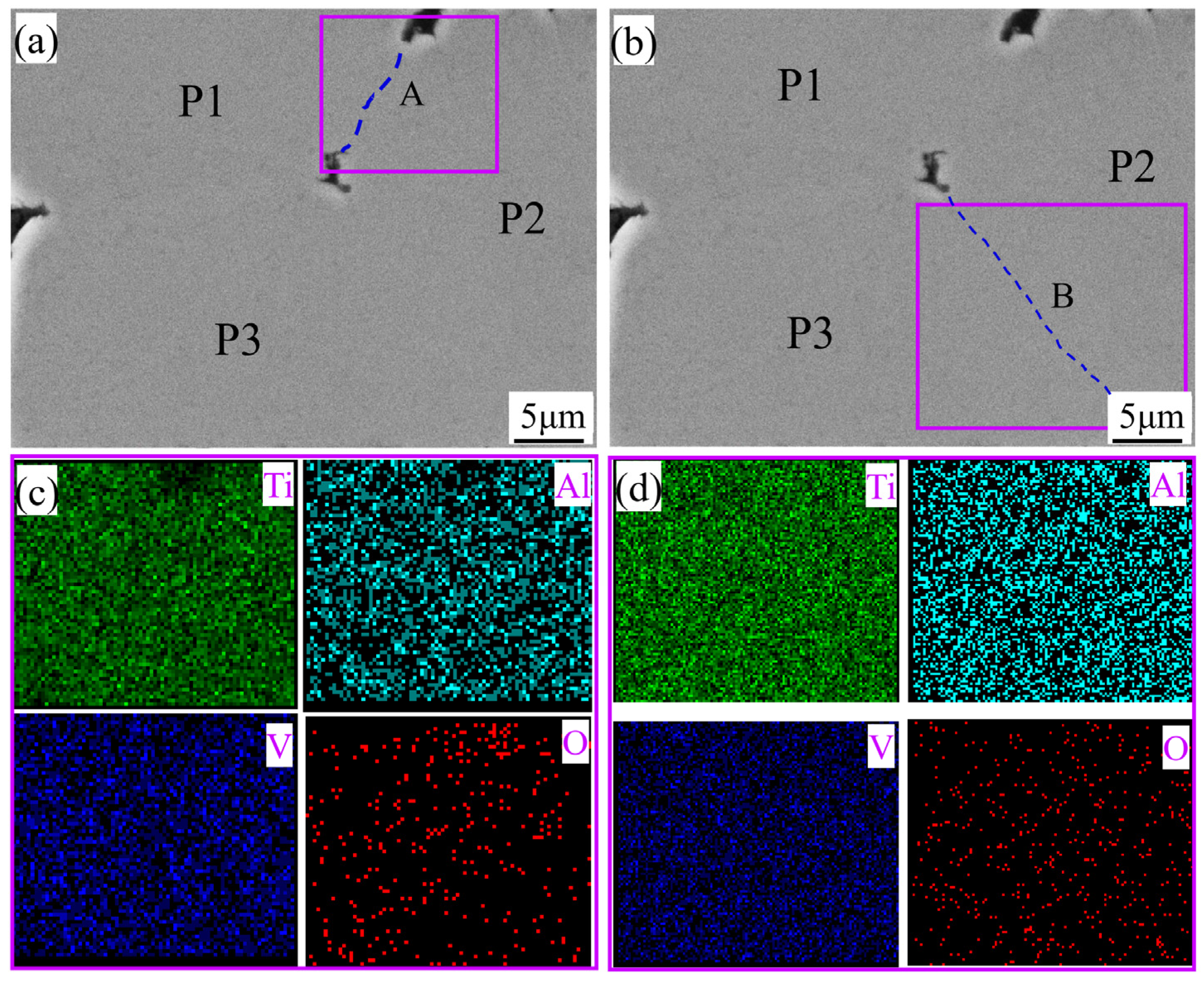

3.3. Microstructure of Single-Pass CSAMed Ti6Al4V Deposit

4. Conclusions

- The temperature of gas and particles increases with increasing length of the nozzle convergent section, while the particle temperatures at the nozzle throat and upon impact on the substrate both rise, which is of benefit for the softening of particles, as well as their subsequent plastic deformation. The relationship between the particle impact temperature and particle diameter first increases, and then decreases.

- Particles traveling inside longer convergent sections have higher velocities at the throat, and are then subsequently accelerated by the expanding gas in the divergent section. Hence, they reach higher kinetic energy at impact, which results in more intense plastic deformation during CSAM. Particle impact kinetic energy is positively related to particle size.

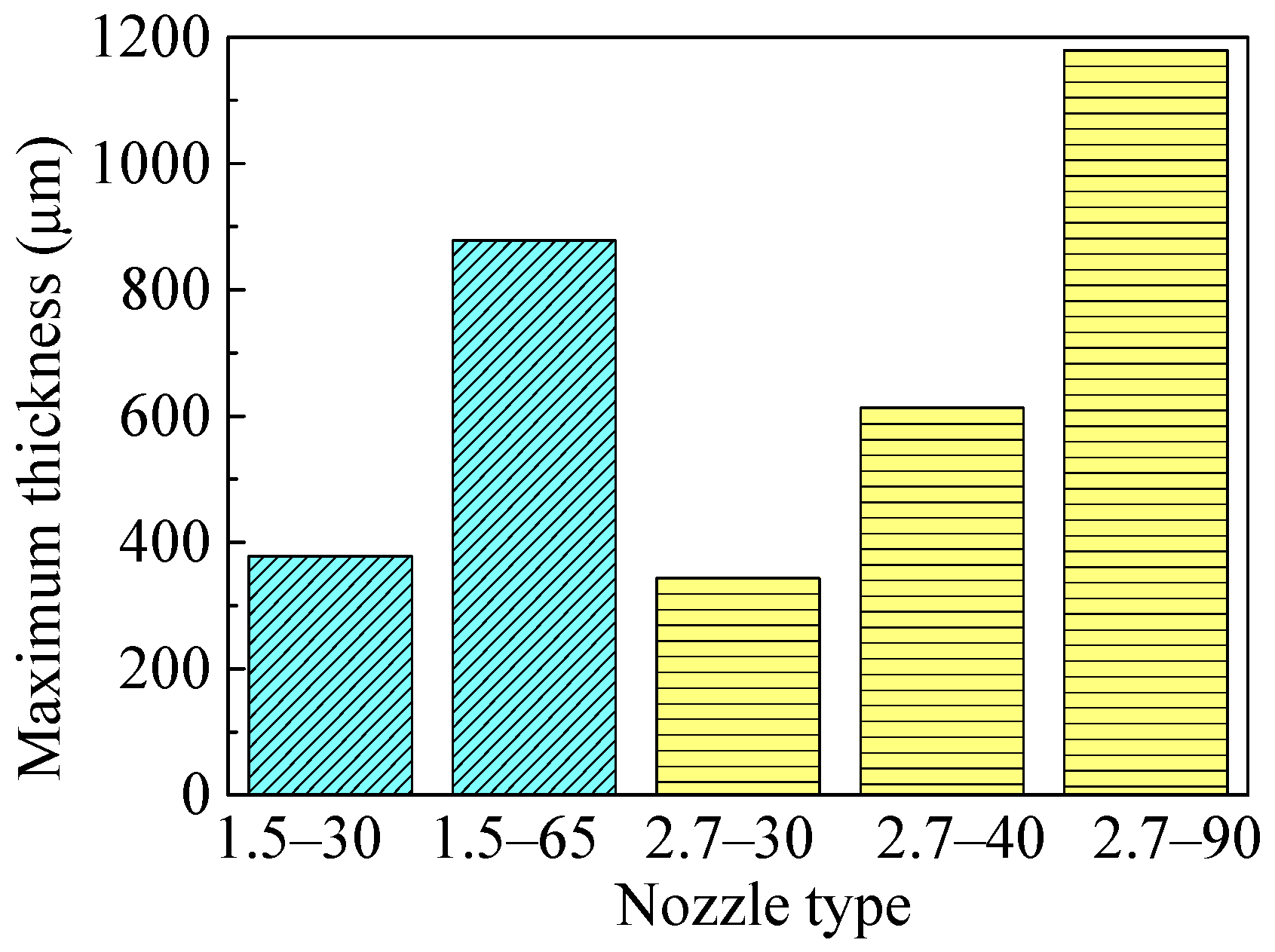

- With a longer convergent section of the nozzle, the edges of the single-pass deposits change from rough to smooth, and deposit width increases. In addition, the deposit microstructure changes from porous to dense, and the particles in the 2.7–90 deposit are tightly bonded. The increase in the maximum thickness and microhardness of the deposit indicate the improved deposition efficiency and mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raoelison, R.N.; Verdy, C.; Liao, H. Cold gas dynamic spray additive manufacturing today: Deposit possibilities, technological solutions and viable applications. Mater. Des. 2017, 133, 266–287. [Google Scholar] [CrossRef]

- Yin, S.; Cavaliere, P.; Aldwell, B.; Jenkins, R.; Liao, H.; Li, W.Y.; Lupoi, R. Cold spray additive manufacturing and repair: Fundamentals and applications. Addit. Manuf. 2018, 21, 628–650. [Google Scholar] [CrossRef]

- Yin, S.; Cizek, J.; Cupera, J.; Hassani, M.; Luo, X.T.; Jenkins, R.; Xie, Y.C.; Li, W.Y.; Lupoi, R. Formation conditions of vortex-like intermixing interfaces in cold spray. Mater. Des. 2021, 200, 109444. [Google Scholar] [CrossRef]

- Xie, X.; Ma, Y.; Chen, C.; Ji, G.; Verdy, C.; Wu, H.; Chen, Z.; Yuan, S.; Normand, B.; Yin, S.; et al. Cold spray additive manufacturing of metal matrix composites (MMCs) using a novel nano-TiB2-reinforced 7075Al powder. J. Alloys Compd. 2020, 819, 152962. [Google Scholar] [CrossRef]

- Li, W.Y.; Assadi, H.; Gaertner, F.; Yin, S. A Review of advanced composite and nanostructured coatings by solid-state cold spraying process. Crit. Rev. Solid State Mater. Sci. 2018, 44, 109–156. [Google Scholar] [CrossRef] [Green Version]

- Li, W.Y.; Cao, C.C.; Yin, S. Solid-state cold spraying of Ti and its alloys: A literature review. Prog. Mater. Sci. 2019, 110, 100633. [Google Scholar] [CrossRef]

- Bagherifard, S.; Monti, S.; Zuccoli, M.V.; Riccio, M.; Kondás, J.; Guagliano, M. Cold spray deposition for additive manufacturing of freeform structural components compared to selective laser melting. Mater. Sci. Eng. A. 2018, 721, 339–350. [Google Scholar] [CrossRef]

- Feng, Y.; Li, W.Y.; Guo, C.; Gong, M.; Yang, K. Mechanical property improvement induced by nanoscaled deformation twins in cold-sprayed Cu coatings. Mater. Sci. Eng. A. 2018, 727, 119–122. [Google Scholar] [CrossRef]

- Li, W.Y.; Wu, D.; Hu, K.W.; Xu, Y.X.; Yang, X.W.; Zhang, Y. A comparative study on the employment of heat treatment, electric pulse processing and friction stir processing to enhance mechanical properties of cold-spray-additive-manufactured copper. Surf. Coat. Technol. 2021, 409, 126887. [Google Scholar] [CrossRef]

- Huang, C.; Li, W.Y.; Feng, Y.; Xie, Y.; Planche, M.-P.; Liao, H.; Montavon, G. Microstructural evolution and mechanical properties enhancement of a cold-sprayed Cu Zn alloy coating with friction stir processing. Mater. Charact. 2017, 125, 76–82. [Google Scholar] [CrossRef]

- Liu, T.; Leazer, J.D.; Menon, S.K.; Brewer, L.N. Microstructural analysis of gas atomized Al-Cu alloy feedstock powders for cold spray deposition. Surf. Coat. Technol. 2018, 350, 621–632. [Google Scholar] [CrossRef]

- Zhao, H.; Tan, C.; Yu, X.; Ning, X.; Nie, Z.; Cai, H.; Wang, F.; Cui, Y. Enhan-ced reactivity of Ni-Al reactive material formed by cold spraying combined with cold-pack rolling. J. Alloys Compd. 2018, 741, 883–894. [Google Scholar] [CrossRef]

- Liu, T.; Leazer, J.D.; Brewer, L.N. Particle deformation and microstructure evolution during cold spray of individual Al-Cu alloy powder particles. Acta Mater. 2019, 168, 13–23. [Google Scholar] [CrossRef]

- Zeng, G.; Zahiri, S.H.; Gulizia, S.; Chen, Y.; Xu, C.; Chen, X.-B.; Cole, I. A comparative study of cell growth on a cold sprayed Ti-Ta composite. J. Alloys Compd. 2020, 826, 154014. [Google Scholar] [CrossRef]

- Li, W.Y.; Guo, X.P.; Verdy, C.; Dembinski, L.; Liao, H.L.; Coddet, C. Improvement of microstructure and property of cold-sprayed Cu-4 at.%Cr-2 at.%Nb alloy by heat treatment. Scripta Mater. 2006, 55, 327–330. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, L.; Liu, C.; Mai, Y.; Zhang, Y.; Jie, X. Deposition of Zn-G/Al composite coating with excellent cathodic protection on low-carbon steel by l-ow-pressure cold spraying. J. Alloys Compd. 2020, 821, 153483. [Google Scholar] [CrossRef]

- Yang, K.; Li, W.Y.; Niu, P.; Yang, X.; Xu, Y. Cold sprayed AA2024/Al2O3 metal matrix composites improved by friction stir processing: Microstructure characterization, mechanical performance and strengthening mechanisms. J. Alloys Compd. 2018, 736, 115–123. [Google Scholar] [CrossRef]

- Huang, C.J.; Li, W.Y.; Zhang, Z.; Fu, M.; Planche, M.-P.; Liao, H.; Montavon, G. Modification of a cold sprayed SiCp/Al5056 composite coating by friction stir processing. Surf. Coat. Technol. 2016, 296, 69–75. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Zhou, X.; Wu, W.; Jie, X. Corrosion behavior of Al2O3-reinforced graphene encapsulated Al composite coating fabricated by low pressure cold spraying. Surf. Coat. Technol. 2020, 386, 125486. [Google Scholar] [CrossRef]

- Yang, K.; Li, W.Y.; Xu, Y.X.; Yang, X.W. Using friction stir processing to augment corrosion resistance of cold sprayed AA2024/Al2O3 composite coatings. J. Alloys Compd. 2019, 774, 1223–1232. [Google Scholar] [CrossRef]

- Ma, W.; Xie, Y.; Chen, C.; Fukanuma, H.; Wang, J.; Ren, Z.; Huang, R. Microstructural and mechanical properties of high-performance Inconel 718 alloy by cold spraying. J. Alloys Compd. 2019, 792, 456–467. [Google Scholar] [CrossRef]

- Luo, X.T.; Yao, M.L.; Ma, N.; Takahashi, M.; Li, C.J. Deposition behavior, microstructure and mechanical properties of an in-situ micro-forging assisted cold spray enabled additively manufactured Inconel 718 alloy. Mater. Design. 2018, 155, 384–395. [Google Scholar] [CrossRef]

- Sun, W.; Bhowmik, A.; Tan, A.W.Y.; Li, R.; Xue, F.; Marinescu, I.; Liu, E. Improving microstructural and mechanical characteristics of cold-sprayed Inconel 718 deposits via local induction heat treatment. J. Alloys Compd. 2019, 797, 1268–1279. [Google Scholar] [CrossRef]

- Aydin, H.; Alomair, M.; Wong, W.; Vo, P.; Yue, S. Cold spray ability of mixed commercial purity Ti plus Ti6Al4V metal powders. J. Therm. Spray Technol. 2017, 26, 360–370. [Google Scholar] [CrossRef] [Green Version]

- Tan, A.W.Y.; Sun, W.; Phang, Y.P.; Dai, M.; Marinescu, I.; Dong, Z.; Liu, E. Effects of traverse scanning speed of spray nozzle on the microstructure and mechanical properties of cold-sprayed Ti6Al4V coatings. J. Therm. Spray Technol. 2017, 26, 1484–1497. [Google Scholar] [CrossRef]

- Sun, W.; Tan, A.W.Y.; Marinescu, I.; Toh, W.Q.; Liu, E. Adhesion, tribological and corrosion properties of cold-sprayed CoCrMo and Ti6Al4V coatings on 6061-T651 Al alloy. Surf. Coat. Technol. 2017, 326, 291–298. [Google Scholar] [CrossRef]

- Munagala, V.N.V.; Imbriglio, S.I.; Chromik, R.R. The influence of powder properties on the adhesion strength and microstructural evolution of cold sprayed Ti6Al4V single splats. Mater. Lett. 2019, 244, 58–61. [Google Scholar] [CrossRef]

- Li, W.Y.; Yang, K.; Yin, S.; Yang, X.W.; Xu, Y.X.; Lupoi, R. Solid-state additive manufacturing and repairing by cold spraying: A review. J. Mater. Sci. Technol. 2018, 34, 440–457. [Google Scholar] [CrossRef]

- Li, W.Y.; Cao, C.C.; Wang, G.Q.; Wang, F.F.; Xu, Y.X.; Yang, X.W. ‘Cold spray +’ as a new hybrid additive manufacturing technology: A literature review. Sci. Technol. Weld. Join. 2019, 24, 420–445. [Google Scholar] [CrossRef]

- Luo, X.T.; Wei, Y.K.; Wang, Y.; Li, C.J. Microstructure and mechanical property of Ti and Ti6Al4V prepared by an in-situ shot peening assisted cold spraying. Mater. Des. 2015, 85, 527–533. [Google Scholar] [CrossRef]

- Zhou, H.X.; Li, C.J.; Yang, H.; Luo, X.T.; Yang, G.; Li, W.Y.; Hussain, T.; Li, C.J. Pores structure change induced by heat treatment in cold-sprayed Ti6Al4V coating. J. Therm. Spray Technol. 2019, 28, 1199–1211. [Google Scholar] [CrossRef]

- Chen, C.; Xie, Y.; Yan, X.; Yin, S.; Fukanuma, H.; Huang, R.; Zhao, R.; Wang, J.; Ren, Z.; Liu, M.; et al. Effect of hot isostatic pressing (HIP) on microstructure and mechanical properties of Ti6Al4V alloy fabricated by cold spray additive manufacturing. Addit. Manuf. 2019, 27, 595–605. [Google Scholar] [CrossRef]

- Yin, S.; Meyer, M.; Li, W.Y.; Liao, H.; Lupoi, R. Gas flow, particle acceleration, and heat transfer in cold spray: A review. J. Therm. Spray Technol. 2016, 25, 874–896. [Google Scholar] [CrossRef]

- Yin, S.; Zhang, M.; Guo, Z.; Liao, H.; Wang, X. Numerical investigations on the effect of total pressure and nozzle divergent length on the flow character and particle impact velocity in cold spraying. Surf. Coat. Technol. 2013, 232, 290–297. [Google Scholar] [CrossRef]

- Li, W.Y.; Li, C.J. Optimal design of a novel cold spray gun nozzle at a limited space. J. Therm. Spray Technol. 2005, 14, 391–396. [Google Scholar] [CrossRef]

- Li, W.Y.; Liao, H.; Douchy, G.; Coddet, C. Optimal design of a cold spray nozzle by numerical analysis of particle velocity and experimental validation with 316L stainless steel powder. Mater. Des. 2007, 28, 2129–2137. [Google Scholar] [CrossRef]

- Alhulaifi, A.S.; Buck, G.A.; Arbegast, W.J. Numerical and experimental investigation of cold spray gas dynamic effects for polymer coating. J. Therm. Spray Technol. 2012, 21, 852–862. [Google Scholar] [CrossRef]

- Belbaki, A.; Mebdoua-Lahmar, Y. Influence of diverging section length on the supersonic jet delivered from micro-nozzle: Application to cold spray coating process. In Applied Mechanics, Behavior of Materials, and Engineering Systems; Boukharouba, T., Pluvinage, G., Azouaoui, K., Eds.; Springer: New York, NY, USA, 2017; pp. 465–473. [Google Scholar]

- Jung, H.B.; Park, J.I.; Park, S.H.; Kim, H.J.; Lee, C.H.; Han, J.W. Effect of the expansion ratio and length ratio on a gas-particle flow in a converging-dive-rging cold spray nozzle. Met. Mater. Int. 2009, 15, 967–970. [Google Scholar] [CrossRef]

- Sova, A.; Okunkova, A.; Grigoriev, S.; Smurov, I. Velocity of the particles accelerated by a cold spray micronozzle: Experimental measurements and numerical simulation. J. Therm. Spray Technol. 2012, 22, 75–80. [Google Scholar] [CrossRef]

- Sova, A.; Smurov, I.; Doubenskaia, M.; Petrovskiy, P. Deposition of aluminum powder by cold spray micronozzle. Int. J. Adv. Manuf. Technol. 2017, 95, 3745–3752. [Google Scholar] [CrossRef]

- Buhl, S.; Breuninger, P.; Antonyuk, S. Optimization of a Laval nozzle for energy-efficient cold spraying of microparticles. Mater. Manuf. Processes. 2017, 33, 115–122. [Google Scholar] [CrossRef]

- Faizan-Ur-Rab, M.; Zahiri, S.H.; King, P.C.; Busch, C.; Masood, S.H.; Jahedi, M.; Nagarajah, R.; Gulizia, S. Utilization of titanium particle impact location to validate a 3D multicomponent model for cold spray additive manufacturing. J. Therm. Spray Technol. 2017, 26, 1874–1887. [Google Scholar] [CrossRef]

- Lupoi, R. Current design and performance of cold spray nozzles: Experimental and numerical observations on deposition efficiency and particle velocity. Surf. Eng. 2013, 30, 316–322. [Google Scholar] [CrossRef] [Green Version]

- Daroonparvar, M.; Kasar, A.-K.; Khan, M.-U.-F.; Menezes, P.-L.; Kay, C.-M.; Misra, M.; Gupta, R.-K. Improvement of wear, pitting corrosion resistance and repassivation ability of mg-based alloys using high pressure cold sprayed (HPCS) commercially pure-titanium coatings. Coatings 2021, 11, 57. [Google Scholar] [CrossRef]

- Zórawski, W.; Molak, R.; Madry, J.; Sienicki, J.; Góral, A.; Makrenek, M.; Scendo, M.; Dobosz, R. Experimental and numerical investigations of titanium deposition for cold spray additive manufacturing as a function of standoff distance. Materials 2021, 14, 5492. [Google Scholar] [CrossRef]

- Schmidt, T.; Gärtner, F.; Assadi, H.; Kreye, H. Development of a generalized parameter window for cold spray deposition. Acta Mater. 2006, 54, 729–742. [Google Scholar] [CrossRef]

- Li, W.Y.; Zhang, C.; Guo, X.; Li, C.J.; Liao, H.; Coddet, C. Study on impact fusion at particle interfaces and its effect on coating microstructure in cold spraying. Appl. Surf. Sci. 2007, 254, 517–526. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Gartner, F.; Klassen, T. Cold spraying-A materials perspective. Acta Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef] [Green Version]

- Cao, C.C.; Han, T.P.; Xu, Y.X.; Li, W.Y.; Yang, X.W.; Hu, K.W. The associated effect of powder carrier gas and powder characteristics on the optimal design of the cold spray nozzle. Surf. Eng. 2020, 36, 1081–1089. [Google Scholar] [CrossRef]

- Li, C.J.; Li, W.Y. Deposition characteristics of titanium coating in cold spraying. Surf. Coat. Technol. 2003, 167, 278–283. [Google Scholar] [CrossRef]

| Material | Inlet Diameter (mm) | Convergent Length (mm) | Throat Diameter (mm) | Divergent Length (mm) | Exit Diameter (mm) | Experimental Validation | References |

|---|---|---|---|---|---|---|---|

| Cu | 17 | 30 | 2.2 | 80–440 | 4.4, 6.22, 7.62 | N | [34] |

| Cu | 8 | 10 | 2 | 40 | 2, 3, 4, 5, 6, 7, 8 | Y | [35] |

| 316L stainless | 18.2 | 54 | 2.7, 5.4 | 67.6, 120, 270 | 10.4-12.4 | Y | [36] |

| Polymer | 9.8 | 4.44 | 2.66 | 133.68 | 6.3 | Y | [37] |

| N/A | 14 | 20 | 2.7 | 59.9, 69.9, 79.9, 89.9 | 8.36 | N | [38] |

| Al | N/A | 17, 22, 27, 32, 42, 57 | 2.7 | 42, 57, 67, 72, 77, 82 | 4.32, 5.58, 6.84, 8.5 | N | [39] |

| Al | N/A | N/A | 0.5 | 20 | 1 | N | [40] |

| Al | N/A | N/A | 0.5 | 20 | 1 | Y | [41] |

| Ti | 10 | 5 | 0.8 | 25 | 1.5 | Y | [42] |

| Ti | N/A | 43.6 | 2.7 | 129 | 6.6 | Y | [43] |

| Ti | 10 | 15.5, 20, 30 | 1, 1.34 | 180, 190 | 3, 4 | Y | [44] |

| Material | Density (kg/m3) | Thermal Conductivity (W/m/K) | Heat Capacity (J/kg/K) | Melting Point (°C) | Yield Strength (MPa) | Ultimate Strength (MPa) | Critical Velocity for CSAM (m/s) |

|---|---|---|---|---|---|---|---|

| Cu | 8880 | 398 | 386 | 660 | 90 | 210 | 451 |

| Al | 2688 | 237 | 905 | 933 | 44 | 80 | 482 |

| Ti | 4506 | 21.9 | 522 | 1680 | 140 | 220 | 712 |

| Ti6Al4V | 4420 | 7.6 | 537 | 1660 | 880 | 950 | 1013 |

| Type | Di (mm) | Lc (mm) | Dt (mm) | Ld (mm) | De (mm) | Total Length (mm) |

|---|---|---|---|---|---|---|

| 1.5–30 | 20 | 30 | 1.5 | 170 | 3.6 | 200 |

| 1.5–65 | 65 | 235 | ||||

| 2.7–30 | 30 | 2.7 | 210 | 6 | 240 | |

| 2.7–40 | 40 | 250 | ||||

| 2.7–90 | 90 | 300 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, C.; Li, W.; Zhang, Z.; Yang, X.; Xu, Y. Cold Spray Additive Manufacturing of Ti6Al4V: Special Nozzle Design Using Numerical Simulation and Experimental Validation. Coatings 2022, 12, 210. https://doi.org/10.3390/coatings12020210

Cao C, Li W, Zhang Z, Yang X, Xu Y. Cold Spray Additive Manufacturing of Ti6Al4V: Special Nozzle Design Using Numerical Simulation and Experimental Validation. Coatings. 2022; 12(2):210. https://doi.org/10.3390/coatings12020210

Chicago/Turabian StyleCao, Congcong, Wenya Li, Zhengmao Zhang, Xiawei Yang, and Yaxin Xu. 2022. "Cold Spray Additive Manufacturing of Ti6Al4V: Special Nozzle Design Using Numerical Simulation and Experimental Validation" Coatings 12, no. 2: 210. https://doi.org/10.3390/coatings12020210

APA StyleCao, C., Li, W., Zhang, Z., Yang, X., & Xu, Y. (2022). Cold Spray Additive Manufacturing of Ti6Al4V: Special Nozzle Design Using Numerical Simulation and Experimental Validation. Coatings, 12(2), 210. https://doi.org/10.3390/coatings12020210