Smart Food Packaging: An Umbrella Review of Scientific Publications

Abstract

:1. Introduction

2. Methodology: Bibliometric Analysis

3. Results and Discussion

3.1. Annual Trend of Publications

3.2. Subject Categories

3.3. Most Prolific Countries and Institutions

3.4. Most Prolific Institutions

3.5. Key Actors

3.6. Most Prolific Journals

3.7. Keywords Analysis

- Turquoise is the main cluster with “smart packaging” as the main keyword. This cluster contains works, such as “bacterial cellulose” and “biosensors”.

- Orange covers keywords related to intelligent packaging with words, such as “nanomaterials”, “smart material”, “food spoilage”, and “food quality”.

- Blue is closely related to the turquoise and orange clusters and includes keywords, such as “indicator”, “freshness indicator”, “electrospinning”, “curcumin”, and “shelf life”.

- Purple focuses on polymers and biopolymers related to food waste, sustainability, controlled release, and antimicrobial packaging.

- Green focuses on mechanisms of smart packaging and their safety with words, such as “quality”, “safety”, “spoilage”, “sensors”, and radio-frequency identification “RFID”.

- Yellow had nanotechnology as a central nod. This cluster contained words, such as “nano sensors”, “food preservation”, “safety”, “food additives”, and “processing”. This reflects the interest in this technology in nanomaterials for developing intelligent packaging.

- Red consisted of words related to packaging biomaterials with keywords, including “chitosan”, “starch”, “gelatin”, and their properties (i.e., antioxidant and antibacterial).

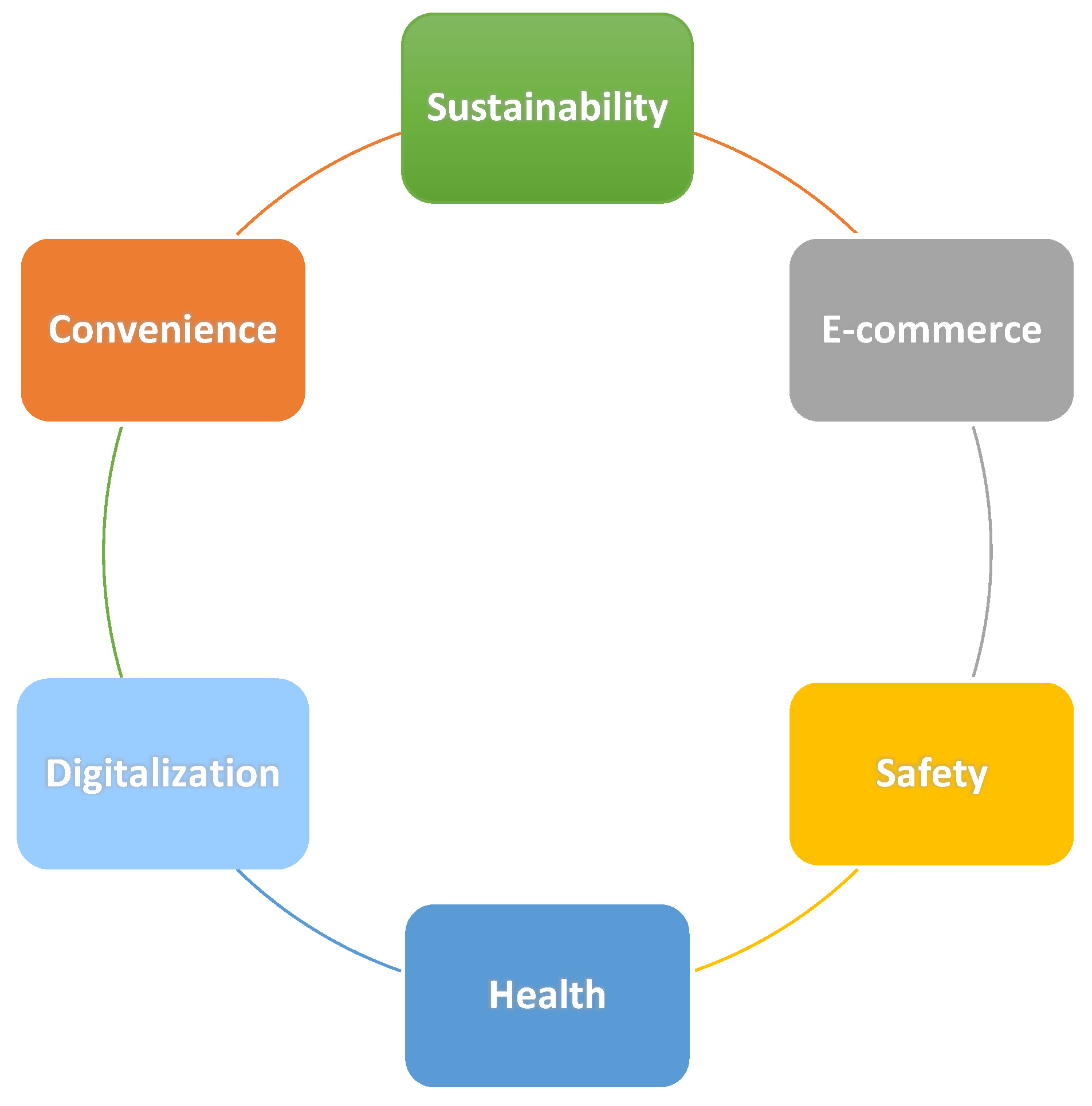

3.8. Impact of COVID-19 on Research Topics

3.9. Challenges and Opportunities

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pascall, M.A.; DeAngelo, K.; Richards, J.; Arensberg, M.B. Role and Importance of Functional Food Packaging in Specialized Products for Vulnerable Populations: Implications for Innovation and Policy Development for Sustainability. Foods 2022, 11, 3043. [Google Scholar] [CrossRef] [PubMed]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. An Overview of Plastic Waste Generation and Management in Food Packaging Industries. Recycling 2021, 6, 12. [Google Scholar] [CrossRef]

- Bala, A.; Laso, J.; Abejón, R.; Margallo, M.; Fullana-i-Palmer, P.; Aldaco, R. Environmental Assessment of the Food Packaging Waste Management System in Spain: Understanding the Present to Improve the Future. Sci. Total Environ. 2020, 702, 134603. [Google Scholar] [CrossRef] [PubMed]

- Arunan, I.; Crawford, R.H. Greenhouse Gas Emissions Associated with Food Packaging for Online Food Delivery Services in Australia. Resour. Conserv. Recycl. 2021, 168, 105299. [Google Scholar] [CrossRef]

- Galanakis, C.M. The Food Systems in the Era of the Coronavirus (COVID-19) Pandemic Crisis. Foods 2020, 9, 523. [Google Scholar] [CrossRef] [Green Version]

- Iftekhar, A.; Cui, X. Blockchain-Based Traceability System That Ensures Food Safety Measures to Protect Consumer Safety and COVID-19 Free Supply Chains. Foods 2021, 10, 1289. [Google Scholar] [CrossRef]

- Pascuta, M.S.; Vodnar, D.C. Nanocarriers for Sustainable Active Packaging: An Overview during and Post COVID-19. Coatings 2022, 12, 102. [Google Scholar] [CrossRef]

- Kitz, R.; Walker, T.; Charlebois, S.; Music, J. Food Packaging during the COVID-19 Pandemic: Consumer Perceptions. Int. J. Consum. Stud. 2022, 46, 434–448. [Google Scholar] [CrossRef]

- Echegaray, F. What POST-COVID-19 Lifestyles May Look like? Identifying Scenarios and Their Implications for Sustainability. Sustain. Prod. Consum. 2021, 27, 567. [Google Scholar] [CrossRef]

- Schaefer, D.; Cheung, W.M. Smart Packaging: Opportunities and Challenges. Procedia CIRP 2018, 72, 1022–1027. [Google Scholar] [CrossRef]

- Kamer, D.D.A.; Kaynarca, G.B.; Yücel, E.; Gümüş, T. Development of Gelatin/PVA Based Colorimetric Films with a Wide PH Sensing Range Winery Solid by-Product (Vinasse) for Monitor Shrimp Freshness. Int. J. Biol. Macromol. 2022, 220, 627–637. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Brahma, S.; Mackay, J.; Cao, C.; Aliakbarian, B. The Role of Smart Packaging System in Food Supply Chain. J. Food Sci. 2020, 85, 517–525. [Google Scholar] [CrossRef] [Green Version]

- Allied Market Research Smart Packaging Market Size, Growth and Forecast to 2030. Available online: https://www.alliedmarketresearch.com/smart-packaging-market (accessed on 17 November 2022).

- European Parliament Commission Regulation (EC) No 450/2009 of 29 May 2009 on Active and Intelligent Materials and Articles Intended to Come into Contact with Food. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32009R0450&from=EN (accessed on 9 December 2022).

- Flores, Y.; Pelegrín, C.J.; Ramos, M.; Jiménez, A.; Garrigós, M.C. Use of Herbs and Their Bioactive Compounds in Active Food Packaging. Aromat. Herbs Food Bioact. Compd. Process. Appl. 2021, 5, 323–365. [Google Scholar] [CrossRef]

- Lamri, M.; Bhattacharya, T.; Boukid, F.; Chentir, I.; Dib, A.L.; Das, D.; Djenane, D.; Gagaoua, M. Nanotechnology as a Processing and Packaging Tool to Improve Meat Quality and Safety. Foods 2021, 10, 2633. [Google Scholar] [CrossRef] [PubMed]

- Song, T.; Qian, S.; Lan, T.; Wu, Y.; Liu, J.; Zhang, H. Recent Advances in Bio-Based Smart Active Packaging Materials. Foods 2022, 11, 2228. [Google Scholar] [CrossRef] [PubMed]

- EFSA. Guidelines on Submission of a Dossier for Safety Evaluation by the EFSA of Active or Intelligent Substances Present in Active and Intelligent Materials and Articles Intended to Come into Contact with Food. EFSA J. 2009, 7, 1–10. [Google Scholar] [CrossRef]

- Pou, K.R.J.; Raghavan, V.; Packirisamy, M. Microfluidics in Smart Packaging of Foods. Food Res. Int. 2022, 161, 111873. [Google Scholar] [CrossRef]

- Müller, P.; Schmid, M. Intelligent Packaging in the Food Sector: A Brief Overview. Foods 2019, 8, 16. [Google Scholar] [CrossRef] [Green Version]

- Biji, K.B.; Ravishankar, C.N.; Mohan, C.O.; Srinivasa Gopal, T.K. Smart Packaging Systems for Food Applications: A Review. J. Food Sci. Technol. 2015, 52, 6125. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Jafari, S.M.; Salehabadi, A.; Nafchi, A.M.; Uthaya Kumar, U.S.; Khalil, H.P.S.A. Biodegradable Green Packaging with Antimicrobial Functions Based on the Bioactive Compounds from Tropical Plants and Their By-Products. Trends Food Sci. Technol. 2020, 100, 262–277. [Google Scholar] [CrossRef]

- Zhong, Y.; Godwin, P.; Jin, Y.; Xiao, H. Biodegradable Polymers and Green-Based Antimicrobial Packaging Materials: A Mini-Review. Adv. Ind. Eng. Polym. Res. 2020, 3, 27–35. [Google Scholar] [CrossRef]

- Brandelli, A. The Interaction of Nanostructured Antimicrobials with Biological Systems: Cellular Uptake, Trafficking and Potential Toxicity. Food Sci. Hum. Wellness 2020, 9, 8–20. [Google Scholar] [CrossRef]

- Tunger, D.; Eulerich, M. Bibliometric Analysis of Corporate Governance Research in German-Speaking Countries: Applying Bibliometrics to Business Research Using a Custom-Made Database. Scientometrics 2018, 117, 2041–2059. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Pandey, N. A Retrospective Evaluation of Marketing Intelligence and Planning: 1983–2019. Mark. Intell. Plan. 2021, 39, 48–73. [Google Scholar] [CrossRef]

- Boukid, F.; Sogari, G.; Rosell, C.M. Edible Insects as Foods: Mapping Scientific Publications and Product Launches in the Global Market (1996–2021). J. Insects Food Feed 2022, 1–16. [Google Scholar] [CrossRef]

- Villaró, S.; Ciardi, M.; Morillas-España, A.; Sánchez-Zurano, A.; Acién-Fernández, G.; Lafarga, T. Microalgae Derived Astaxanthin: Research and Consumer Trends and Industrial Use as Food. Foods 2021, 10, 2303. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Cortés-García, F.J.; Camacho-Ferre, F. Agricultural Waste: Review of the Evolution, Approaches and Perspectives on Alternative Uses. Glob. Ecol. Conserv. 2020, 22, e00902. [Google Scholar] [CrossRef]

- Mishra, H.G.; Pandita, S.; Bhat, A.A.; Mishra, R.K.; Sharma, S. Tourism and Carbon Emissions: A Bibliometric Review of the Last Three Decades: 1990–2021. Tour. Rev. 2022, 77, 636–658. [Google Scholar] [CrossRef]

- Montoya-Torres, J.R.; Muñoz-Villamizar, A.; Mejia-Argueta, C. Mapping Research in Logistics and Supply Chain Management during COVID-19 Pandemic. Int. J. Logist. Res. 2021, 1–21. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Macé, S.; Cornet, J.; Chevalier, F.; Cardinal, M.; Pilet, M.F.; Dousset, X.; Joffraud, J.J. Characterisation of the Spoilage Microbiota in Raw Salmon (Salmo Salar) Steaks Stored under Vacuum or Modified Atmosphere Packaging Combining Conventional Methods and PCR–TTGE. Food Microbiol. 2012, 30, 164–172. [Google Scholar] [CrossRef] [Green Version]

- Nychas, G.J.E.; Skandamis, P.N. Fresh Meat Spoilage and Modified Atmosphere Packaging (MAP). Improv. Saf. Fresh Meat 2005, 461–502. [Google Scholar] [CrossRef]

- O’Grady, M.N.; Kerry, J.P. Smart Packaging Technologies and Their Application in Conventional Meat Packaging Systems. Meat Biotechnol. 2008, 425–451. [Google Scholar] [CrossRef]

- Kerry, J.P.; O’Grady, M.N.; Hogan, S.A. Past, Current and Potential Utilisation of Active and Intelligent Packaging Systems for Meat and Muscle-Based Products: A Review. Meat Sci. 2006, 74, 113–130. [Google Scholar] [CrossRef] [PubMed]

- Silvestre, C.; Duraccio, D.; Cimmino, S. Food Packaging Based on Polymer Nanomaterials. Prog. Polym. Sci. 2011, 36, 1766–1782. [Google Scholar] [CrossRef]

- Singh Sekhon, B. Nanotechnology in Agri-Food Production: An Overview. Nanotechnol. Sci. Appl. 2014, 7, 31–53. [Google Scholar] [CrossRef] [Green Version]

- Rhim, J.W.; Park, H.M.; Ha, C.S. Bio-Nanocomposites for Food Packaging Applications. Prog. Polym. Sci. 2013, 38, 1629–1652. [Google Scholar] [CrossRef]

- Vanderroost, M.; Ragaert, P.; Devlieghere, F.; De Meulenaer, B. Intelligent Food Packaging: The next Generation. Trends Food Sci. Technol. 2014, 39, 47–62. [Google Scholar] [CrossRef]

- Salgado, P.R.; Di Giorgio, L.; Musso, Y.S.; Mauri, A.N. Recent Developments in Smart Food Packaging Focused on Biobased and Biodegradable Polymers. Front. Sustain. Food Syst. 2021, 5, 125. [Google Scholar] [CrossRef]

- Forghani, S.; Almasi, H.; Moradi, M. Electrospun Nanofibers as Food Freshness and Time-Temperature Indicators: A New Approach in Food Intelligent Packaging. Innov. Food Sci. Emerg. Technol. 2021, 73, 102804. [Google Scholar] [CrossRef]

- Youssef, A.M.; El-Sayed, S.M. Bionanocomposites Materials for Food Packaging Applications: Concepts and Future Outlook. Carbohydr. Polym. 2018, 193, 19–27. [Google Scholar] [CrossRef] [PubMed]

- Chausali, N.; Saxena, J.; Prasad, R. Recent Trends in Nanotechnology Applications of Bio-Based Packaging. J. Agric. Food Res. 2022, 7, 100257. [Google Scholar] [CrossRef]

- Madhusudan, P.; Chellukuri, N.; Shivakumar, N. Smart Packaging of Food for the 21st Century - A Review with Futuristic Trends, Their Feasibility and Economics. Mater. Today Proc. 2018, 5, 21018–21022. [Google Scholar] [CrossRef]

- Tyuftin, A.A.; Kerry, J.P. Review of Surface Treatment Methods for Polyamide Films for Potential Application as Smart Packaging Materials: Surface Structure, Antimicrobial and Spectral Properties. Food Packag. Shelf Life 2020, 24, 100475. [Google Scholar] [CrossRef]

- Moradi, M.; Kousheh, S.A.; Razavi, R.; Rasouli, Y.; Ghorbani, M.; Divsalar, E.; Tajik, H.; Guimarães, J.T.; Ibrahim, S.A. Review of Microbiological Methods for Testing Protein and Carbohydrate-Based Antimicrobial Food Packaging. Trends Food Sci. Technol. 2021, 111, 595–609. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.W. Anthocyanin Food Colorant and Its Application in PH-Responsive Color Change Indicator Films. Crit. Rev. Food Sci. Nutr. 2021, 61, 2297–2325. [Google Scholar] [CrossRef]

- Yong, H.; Liu, J. Recent Advances in the Preparation, Physical and Functional Properties, and Applications of Anthocyanins-Based Active and Intelligent Packaging Films. Food Packag. Shelf Life 2020, 26, 100550. [Google Scholar] [CrossRef]

- Jin, K.; Tang, Y.; Liu, J.; Wang, J.; Ye, C. Nanofibrillated Cellulose as Coating Agent for Food Packaging Paper. Int. J. Biol. Macromol. 2021, 168, 331–338. [Google Scholar] [CrossRef]

- McClements, D.J.; Xiao, H. Is Nano Safe in Foods? Establishing the Factors Impacting the Gastrointestinal Fate and Toxicity of Organic and Inorganic Food-Grade Nanoparticles. NPJ Sci. Food 2017, 1, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Cheng, H.; Chen, L.; McClements, D.J.; Yang, T.; Zhang, Z.; Ren, F.; Miao, M.; Tian, Y.; Jin, Z. Starch-Based Biodegradable Packaging Materials: A Review of Their Preparation, Characterization and Diverse Applications in the Food Industry. Trends Food Sci. Technol. 2021, 114, 70–82. [Google Scholar] [CrossRef]

- Bhargava, N.; Sharanagat, V.S.; Mor, R.S.; Kumar, K. Active and Intelligent Biodegradable Packaging Films Using Food and Food Waste-Derived Bioactive Compounds: A Review. Trends Food Sci. Technol. 2020, 105, 385–401. [Google Scholar] [CrossRef]

- Roohi, S.P.; Bano, K.; Zaheer, M.R.; Kuddus, M. Biodegradable Smart Biopolymers for Food Packaging: Sustainable Approach toward Green Environment. In Bio-Based Materials for Food Packaging: Green and Sustainable Advanced Packaging Materials; Springer: Singapore, 2018; pp. 197–216. ISBN 9789811319099. [Google Scholar]

- Abelti, A.L.; Abera Teka, T.; Fikreyesus Forsedo, S.; Tamiru, M.; Bultosa, G.; Alkhtib, A.; Burton, E. Bio-Based Smart Materials for Fish Product Packaging: A Review. Int. J. Food Prop. 2022, 25, 857–871. [Google Scholar] [CrossRef]

- Ahmed, I.; Lin, H.; Zou, L.; Li, Z.; Brody, A.L.; Qazi, I.M.; Lv, L.; Pavase, T.R.; Khan, M.U.; Khan, S.; et al. An Overview of Smart Packaging Technologies for Monitoring Safety and Quality of Meat and Meat Products. Packag. Technol. Sci. 2018, 31, 449–471. [Google Scholar] [CrossRef]

- Atta, O.M.; Manan, S.; Shahzad, A.; Ul-Islam, M.; Ullah, M.W.; Yang, G. Biobased Materials for Active Food Packaging: A Review. Food Hydrocoll. 2022, 125, 107419. [Google Scholar] [CrossRef]

- Perez Espitia, P.J.; Du, W.X.; Avena-Bustillos, R.d.J.; Ferreira Soares, N.d.F.; McHugh, T.H. Edible Films from Pectin: Physical-Mechanical and Antimicrobial Properties—A Review. Food Hydrocoll. 2014, 35, 287–296. [Google Scholar] [CrossRef]

- Kovačević, K.; Karadžić, M.; Banjac, K.; Yan, M.R.; Hsieh, S.; Ricacho, N. Innovative Food Packaging, Food Quality and Safety, and Consumer Perspectives. Processes 2022, 10, 747. [Google Scholar] [CrossRef]

- Luchese, C.L.; Abdalla, V.F.; Spada, J.C.; Tessaro, I.C. Evaluation of Blueberry Residue Incorporated Cassava Starch Film as PH Indicator in Different Simulants and Foodstuffs. Food Hydrocoll. 2018, 82, 209–218. [Google Scholar] [CrossRef]

- Yoon, S.D.; Park, M.H.; Byun, H.S. Mechanical and Water Barrier Properties of Starch/PVA Composite Films by Adding Nano-Sized Poly(Methyl Methacrylate-Co-Acrylamide) Particles. Carbohydr. Polym. 2012, 87, 676–686. [Google Scholar] [CrossRef]

- Li, S.; Jiang, Y.; Zhou, Y.; Li, R.; Jiang, Y.; Alomgir Hossen, M.; Dai, J.; Qin, W.; Liu, Y. Facile Fabrication of Sandwich-like Anthocyanin/Chitosan/Lemongrass Essential Oil Films via 3D Printing for Intelligent Evaluation of Pork Freshness. Food Chem. 2022, 370, 131082. [Google Scholar] [CrossRef]

- Fernández-Marín, R.; Fernandes, S.C.M.; Sánchez, M.Á.A.; Labidi, J. Halochromic and Antioxidant Capacity of Smart Films of Chitosan/Chitin Nanocrystals with Curcuma Oil and Anthocyanins. Food Hydrocoll. 2022, 123, 107119. [Google Scholar] [CrossRef]

- Gasti, T.; Dixit, S.; D’souza, O.J.; Hiremani, V.D.; Vootla, S.K.; Masti, S.P.; Chougale, R.B.; Malabadi, R.B. Smart Biodegradable Films Based on Chitosan/Methylcellulose Containing Phyllanthus Reticulatus Anthocyanin for Monitoring the Freshness of Fish Fillet. Int. J. Biol. Macromol. 2021, 187, 451–461. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Huang, T.S.; Yan, H.; Hu, X.; Ren, T. Novel PH-Sensitive Films Based on Starch/Polyvinyl Alcohol and Food Anthocyanins as a Visual Indicator of Shrimp Deterioration. Int. J. Biol. Macromol. 2020, 145, 768–776. [Google Scholar] [CrossRef] [PubMed]

- Luchese, C.L.; Frick, J.M.; Patzer, V.L.; Spada, J.C.; Tessaro, I.C. Synthesis and Characterization of Biofilms Using Native and Modified Pinhão Starch. Food Hydrocoll. 2015, 45, 203–210. [Google Scholar] [CrossRef]

- Chen, S.; Wu, M.; Lu, P.; Gao, L.; Yan, S.; Wang, S. Development of PH Indicator and Antimicrobial Cellulose Nanofibre Packaging Film Based on Purple Sweet Potato Anthocyanin and Oregano Essential Oil. Int. J. Biol. Macromol. 2020, 149, 271–280. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, Y.; Bai, R.; Zhang, X.; Yuan, L.; Liu, J. Preparation of PH-Sensitive and Antioxidant Packaging Films Based on κ-Carrageenan and Mulberry Polyphenolic Extract. Int. J. Biol. Macromol. 2019, 134, 993–1001. [Google Scholar] [CrossRef]

- Santos, L.G.; Alves-Silva, G.F.; Martins, V.G. Active-Intelligent and Biodegradable Sodium Alginate Films Loaded with Clitoria Ternatea Anthocyanin-Rich Extract to Preserve and Monitor Food Freshness. Int. J. Biol. Macromol. 2022, 220, 866–877. [Google Scholar] [CrossRef]

- da Silva, H.M.; Mageste, A.B.; e Silva, S.J.B.; Dias Ferreira, G.M.; Ferreira, G.M.D. Anthocyanin Immobilization in Carboxymethylcellulose/Starch Films: A Sustainable Sensor for the Detection of Al(III) Ions in Aqueous Matrices. Carbohydr. Polym. 2020, 230, 115679. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Y.; Zhao, L.; Wang, Y. Anthocyanin-Based PH-Sensitive Smart Packaging Films for Monitoring Food Freshness. J. Agric. Food Res. 2022, 9, 100340. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Ezati, P.; Rhim, J.W. Recent Advances in Intelligent Food Packaging Applications Using Natural Food Colorants. ACS Food Sci. Technol. 2021, 1, 124–138. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Mohammadian, E.; Rhim, J.W.; Jafari, S.M. PH-Sensitive (Halochromic) Smart Packaging Films Based on Natural Food Colorants for the Monitoring of Food Quality and Safety. Trends Food Sci. Technol. 2020, 105, 93–144. [Google Scholar] [CrossRef]

- Ravichandran, R. Nanotechnology Applications in Food and Food Processing: Innovative Green Approaches, Opportunities and Uncertainties for Global Market. Int. J. Green Nanotechnol. Phys. Chem. 2010, 1, P72–P96. [Google Scholar] [CrossRef] [Green Version]

- He, X.; Deng, H.; Hwang, H. min The Current Application of Nanotechnology in Food and Agriculture. J. Food Drug Anal. 2019, 27, 1–21. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Muncke, J.; Backhaus, T.; Geueke, B.; Maffini, M.V.; Martin, O.V.; Myers, J.P.; Soto, A.M.; Trasande, L.; Trier, X.; Scheringer, M. Scientific Challenges in the Risk Assessment of Food Contact Materials. Environ. Health Perspect. 2017, 125, 095001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karmaus, A.L.; Osborn, R.; Krishan, M. Scientific Advances and Challenges in Safety Evaluation of Food Packaging Materials: Workshop Proceedings. Regul. Toxicol. Pharmacol. 2018, 98, 80–87. [Google Scholar] [CrossRef] [PubMed]

- Magnuson, B.; Munro, I.; Abbot, P.; Baldwin, N.; Lopez-Garcia, R.; Ly, K.; McGirr, L.; Roberts, A.; Socolovsky, S. Review of the Regulation and Safety Assessment of Food Substances in Various Countries and Jurisdictions. Food Addit. Contam. Part A Chem. Anal. Control. Expo. Risk Assess. 2013, 30, 1147. [Google Scholar] [CrossRef] [PubMed]

- EFSA Active and Intelligent Packaging Substances | EFSA. Available online: https://www.efsa.europa.eu/en/topics/topic/active-and-intelligent-packaging-substances (accessed on 23 November 2022).

- Janssen, M.; Chang, B.P.I.; Hristov, H.; Pravst, I.; Profeta, A.; Millard, J. Changes in Food Consumption During the COVID-19 Pandemic: Analysis of Consumer Survey Data from the First Lockdown Period in Denmark, Germany, and Slovenia. Front. Nutr. 2021, 8, 60. [Google Scholar] [CrossRef]

- Hassoun, A.; Bekhit, A.E.D.; Jambrak, A.R.; Regenstein, J.M.; Chemat, F.; Morton, J.D.; Gudjónsdóttir, M.; Carpena, M.; Prieto, M.A.; Varela, P.; et al. The Fourth Industrial Revolution in the Food Industry—Part II: Emerging Food Trends. Crit. Rev. Food Sci. Nutr. 2022, 1–31. [Google Scholar] [CrossRef]

- Bender, K.E.; Badiger, A.; Roe, B.E.; Shu, Y.; Qi, D. Consumer Behavior during the COVID-19 Pandemic: An Analysis of Food Purchasing and Management Behaviors in U.S. Households through the Lens of Food System Resilience. Socioecon. Plann. Sci. 2022, 82, 101107. [Google Scholar] [CrossRef]

- Kabadurmus, O.; Kayikci, Y.; Demir, S.; Koc, B. A Data-Driven Decision Support System with Smart Packaging in Grocery Store Supply Chains during Outbreaks. Socioecon. Plann. Sci. 2022, 101417. [Google Scholar] [CrossRef]

- Thirumalai, A.; Harini, K.; Pallavi, P.; Gowtham, P.; Girigoswami, K.; Girigoswami, A. Nanotechnology Driven Improvement of Smart Food Packaging. Mater. Res. Innov. 2022. [Google Scholar] [CrossRef]

- Liu, J.; Li, K.; Chen, Y.; Ding, H.; Wu, H.; Gao, Y.; Huang, S.; Wu, H.; Kong, D.; Yang, Z.; et al. Active and Smart Biomass Film Containing Cinnamon Oil and Curcumin for Meat Preservation and Freshness Indicator. Food Hydrocoll. 2022, 133, 107979. [Google Scholar] [CrossRef]

- Dirpan, A.; Djalal, M.; Kamaruddin, I. Application of an Intelligent Sensor and Active Packaging System Based on the Bacterial Cellulose of Acetobacter Xylinum to Meat Products. Sensors 2022, 22, 544. [Google Scholar] [CrossRef] [PubMed]

- Tahir, H.E.; Hashim, S.B.H.; Komla Mahunu, G.; Arslan, M.; Jiyong, S.; Adam Mariod, A.; Zhang, J.; El-Seedi, H.R.; Zhai, X.; Musa, T.H.; et al. Smart Films Fabricated from Natural Pigments for Measurement of Total Volatile Basic Nitrogen (TVB-N) Content of Meat for Freshness Evaluation: A Systematic Review. Food Chem. 2022, 396, 133674. [Google Scholar] [CrossRef] [PubMed]

- Raimondi, S.; Nappi, M.R.; Sirangelo, T.M.; Leonardi, A.; Amaretti, A.; Ulrici, A.; Magnani, R.; Montanari, C.; Tabanelli, G.; Gardini, F.; et al. Bacterial Community of Industrial Raw Sausage Packaged in Modified Atmosphere throughout the Shelf Life. Int. J. Food Microbiol. 2018, 280, 78–86. [Google Scholar] [CrossRef] [PubMed]

- Alizadeh-Sani, M.; Tavassoli, M.; Mohammadian, E.; Ehsani, A.; Khaniki, G.J.; Priyadarshi, R.; Rhim, J.W. PH-Responsive Color Indicator Films Based on Methylcellulose/Chitosan Nanofiber and Barberry Anthocyanins for Real-Time Monitoring of Meat Freshness. Int. J. Biol. Macromol. 2021, 166, 741–750. [Google Scholar] [CrossRef]

- Dirpan, A.; Djalal, M.; Ainani, A.F. A Simple Combination of Active and Intelligent Packaging Based on Garlic Extract and Indicator Solution in Extending and Monitoring the Meat Quality Stored at Cold Temperature. Foods 2022, 11, 1495. [Google Scholar] [CrossRef]

- Anvar, A.A.; Ahari, H.; Ataee, M. Antimicrobial Properties of Food Nanopackaging: A New Focus on Foodborne Pathogens. Front. Microbiol. 2021, 12, 690706. [Google Scholar] [CrossRef]

- Parashar, N.; Hait, S. Plastics in the Time of COVID-19 Pandemic: Protector or Polluter? Sci. Total Environ. 2021, 759, 144274. [Google Scholar] [CrossRef]

- Amorim, A.; Barbosa, A.d.H.; do Amaral Sobral, P.J. Hunger, Obesity, Public Policies, and Food-Based Dietary Guidelines: A Reflection Considering the Socio-Environmental World Context. Front. Nutr. 2022, 8, 805569. [Google Scholar] [CrossRef]

- O’Callaghan, K.A.M.; Kerry, J.P. Consumer Attitudes towards the Application of Smart Packaging Technologies to Cheese Products. Food Packag. Shelf Life 2016, 9, 1–9. [Google Scholar] [CrossRef]

- Kuswandi, B.; Moradi, M. Improvement of Food Packaging Based on Functional Nanomaterial. In Nanotechnology: Applications in Energy, Drug and Food; Springer: Cham, Switzerland, 2019; pp. 309–344. [Google Scholar] [CrossRef]

- Escursell, S.; Llorach-Massana, P.; Roncero, M.B. Sustainability in E-Commerce Packaging: A Review. J. Clean. Prod. 2021, 280, 124314. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Rhim, J.W. Chitosan-Based Biodegradable Functional Films for Food Packaging Applications. Innov. Food Sci. Emerg. Technol. 2020, 62, 102346. [Google Scholar] [CrossRef]

- Pirola, F.; Boucher, X.; Wiesner, S.; Pezzotta, G. Digital Technologies in Product-Service Systems: A Literature Review and a Research Agenda. Comput. Ind. 2020, 123, 103301. [Google Scholar] [CrossRef]

- Lenka, S.; Parida, V.; Wincent, J. Digitalization Capabilities as Enablers of Value Co-Creation in Servitizing Firms. Psychol. Mark. 2017, 34, 92–100. [Google Scholar] [CrossRef] [Green Version]

- Chong, W.J.; Shen, S.; Li, Y.; Trinchi, A.; Pejak, D.; Kyratzis, I.L.; Sola, A.; Wen, C. Additive Manufacturing of Antibacterial PLA-ZnO Nanocomposites: Benefits, Limitations and Open Challenges. J. Mater. Sci. Technol. 2022, 111, 120–151. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, W.; Xia, Y.; Xue, W.; Wu, H.; Li, Z.; Zhang, F.; Qiu, B.; Fu, C. Properties and Applications of Intelligent Packaging Indicators for Food Spoilage. Membranes 2022, 12, 477. [Google Scholar] [CrossRef]

| Rank | Subject Area | Documents | Record (%) |

|---|---|---|---|

| 1 | Engineering | 320 | 36.4% |

| 2 | Agricultural and Biological Sciences | 313 | 35.6% |

| 3 | Materials Science | 248 | 28.2% |

| 4 | Chemistry | 181 | 20.6% |

| 5 | Biochemistry, Genetics and Molecular Biology | 177 | 20.2% |

| 6 | Chemical Engineering | 119 | 13.6% |

| 7 | Physics and Astronomy | 102 | 11.6% |

| 8 | Medicine | 79 | 9.0% |

| 9 | Environmental Science | 70 | 8.0% |

| 10 | Computer Science | 58 | 6.6% |

| 11 | Energy | 48 | 5.5% |

| 12 | Economics, Econometrics and Finance | 39 | 4.4% |

| 13 | Pharmacology, Toxicology and Pharmaceutics | 32 | 3.6% |

| 14 | Business, Management and Accounting | 31 | 3.5% |

| 15 | Social Sciences | 31 | 3.5% |

| 16 | Immunology and Microbiology | 28 | 3.2% |

| 17 | Nursing | 17 | 1.9% |

| 18 | Earth and Planetary Sciences | 15 | 1.7% |

| 19 | Mathematics | 13 | 1.5% |

| 20 | Health Professions | 12 | 1.4% |

| Rank | Country/Territory | Documents | Record (%) |

|---|---|---|---|

| 1 | India | 119 | 13.6% |

| 2 | USA | 112 | 12.8% |

| 3 | China | 94 | 10.7% |

| 4 | Italy | 56 | 6.4% |

| 5 | Iran | 54 | 6.2% |

| 6 | Spain | 45 | 5.1% |

| 7 | United Kingdom | 44 | 5.0% |

| 8 | South Korea | 42 | 4.8% |

| 9 | Brazil | 37 | 4.2% |

| 10 | Indonesia | 33 | 3.8% |

| 11 | Ireland | 30 | 3.4% |

| 12 | Portugal | 28 | 3.2% |

| 13 | Turkey | 27 | 3.1% |

| 14 | Canada | 23 | 2.6% |

| 15 | Greece | 23 | 2.6% |

| 16 | Australia | 21 | 2.4% |

| 17 | Malaysia | 20 | 2.3% |

| 18 | Egypt | 15 | 1.7% |

| 19 | Germany | 15 | 1.7% |

| 20 | Thailand | 14 | 1.6% |

| Institution | Country | Documents | Record (%) | |

|---|---|---|---|---|

| 1 | Urmia University | Iran | 28 | 3.2% |

| 2 | Tabriz University of Medical Sciences | Iran | 19 | 2.3% |

| 3 | University College Cork | Ireland | 16 | 1.8% |

| 4 | Kyung Hee University | Republic of Korea | 13 | 1.5% |

| 5 | University of Massachusetts Amherst | USA | 13 | 1.5% |

| 6 | Consiglio Nazionale delle Ricerche | Italy | 13 | 1.5% |

| 7 | Ministry of Education China | China | 11 | 1.3% |

| 8 | CSIC–Instituto de Agroquímica y Tecnología de los Alimentos IATA | Spain | 11 | 1.3% |

| 9 | Tehran University of Medical Sciences | Iran | 11 | 1.3% |

| 10 | Universidade do Minho | Portugal | 9 | 1.1% |

| 11 | Hasanuddin University | Indonesia | 9 | 1.0% |

| 12 | Yonsei University Mirae Campus | Republic of Korea | 9 | 1.0% |

| 13 | Rutgers University–New Brunswick | USA | 9 | 1.0% |

| 14 | School of Public Health | USA | 9 | 1.0% |

| 15 | Consejo Nacional de Investigaciones Científicas y Técnicas | Spain | 8 | 1.0% |

| 16 | Gorgan University of Agricultural Sciences and Natural Resources | Iran | 8 | 0.9% |

| 17 | Universidade de Vigo | Spain | 8 | 0.9% |

| 18 | Clemson University | USA | 8 | 0.9% |

| 19 | Universitas Jember | Indonesia | 8 | 0.9% |

| 20 | National Technical University of Athens | Greece | 7 | 0.8% |

| Authors | Affiliation | Documents |

|---|---|---|

| Kerry, J. | Department of Food and Nutritional Sciences, University College Cork, National University of Ireland, Cork, Ireland | 15 |

| Rhim, J.W. | Department of Food and Nutrition, BioNanocomposite Research Center, Kyung Hee University, 26 Kyungheedae-ro, Dongdaemun-gu, Seoul 02447, South Korea | 12 |

| Moradi, M. | Department of Food Hygiene and Quality Control, Faculty of Veterinary Medicine, Urmia University, Urmia, Iran | 11 |

| Liu, J. | College of Food Science and Engineering, Yangzhou University, Yangzhou 225127, PR China | 10 |

| McClements, D.J. | Department of Food Science, University of Massachusetts Amherst, Amherst, MA 01003, USA | 10 |

| Rank | Source | Publisher, Country | Documents | Record (%) |

|---|---|---|---|---|

| 1 | International Journal Of Biological Macromolecules | Elsevier (Netherlands) | 40 | 4.6% |

| 2 | Food Packaging And Shelf Life | Elsevier (Netherlands) | 16 | 1.8% |

| 3 | Trends In Food Science And Technology | Elsevier (Netherlands) | 16 | 1.8% |

| 4 | Food Hydrocolloids | Elsevier (Netherlands) | 15 | 1.7% |

| 5 | Food Control | Elsevier (Netherlands) | 14 | 1.6% |

| 6 | Iop Conference Series Earth And Environmental Science | IOP Publishing (UK) | 13 | 1.5% |

| 7 | Food Chemistry | Elsevier (Netherlands) | 12 | 1.4% |

| 8 | Critical Reviews In Food Science And Nutrition | Taylor and Francis Ltd. (USA) | 11 | 1.3% |

| 9 | Sensors And Actuators B: Chemical | Elsevier (Netherlands) | 11 | 1.3% |

| 10 | Carbohydrate Polymers | Elsevier (Netherlands) | 10 | 1.1% |

| 11 | Polymers | MDPI (Switzerland) | 10 | 1.1% |

| 12 | Food Research International | Elsevier (Netherlands) | 9 | 1.0% |

| 13 | Foods | MDPI (Switzerland) | 9 | 1.0% |

| 14 | Nanomaterials | MDPI (Switzerland) | 9 | 1.0% |

| 15 | Packaging Technology And Science | Wiley (USA) | 9 | 1.0% |

| 16 | Materials | MDPI (Switzerland) | 8 | 0.9% |

| 17 | Acta Horticulturae | International Society for Horticultural Science (Belgium) | 7 | 0.8% |

| 18 | Diabetes Self Management | SAGE Publications Inc. (USA) | 7 | 0.8% |

| 19 | Food And Bioprocess Technology | Springer Nature (Switzerland) | 7 | 0.8% |

| 20 | Molecules | MDPI (Switzerland) | 7 | 0.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boukid, F. Smart Food Packaging: An Umbrella Review of Scientific Publications. Coatings 2022, 12, 1949. https://doi.org/10.3390/coatings12121949

Boukid F. Smart Food Packaging: An Umbrella Review of Scientific Publications. Coatings. 2022; 12(12):1949. https://doi.org/10.3390/coatings12121949

Chicago/Turabian StyleBoukid, Fatma. 2022. "Smart Food Packaging: An Umbrella Review of Scientific Publications" Coatings 12, no. 12: 1949. https://doi.org/10.3390/coatings12121949

APA StyleBoukid, F. (2022). Smart Food Packaging: An Umbrella Review of Scientific Publications. Coatings, 12(12), 1949. https://doi.org/10.3390/coatings12121949