Adhesion in Bitumen/Aggregate System: Adhesion Mechanism and Test Methods

Abstract

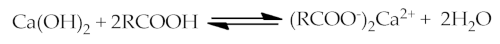

1. Introduction

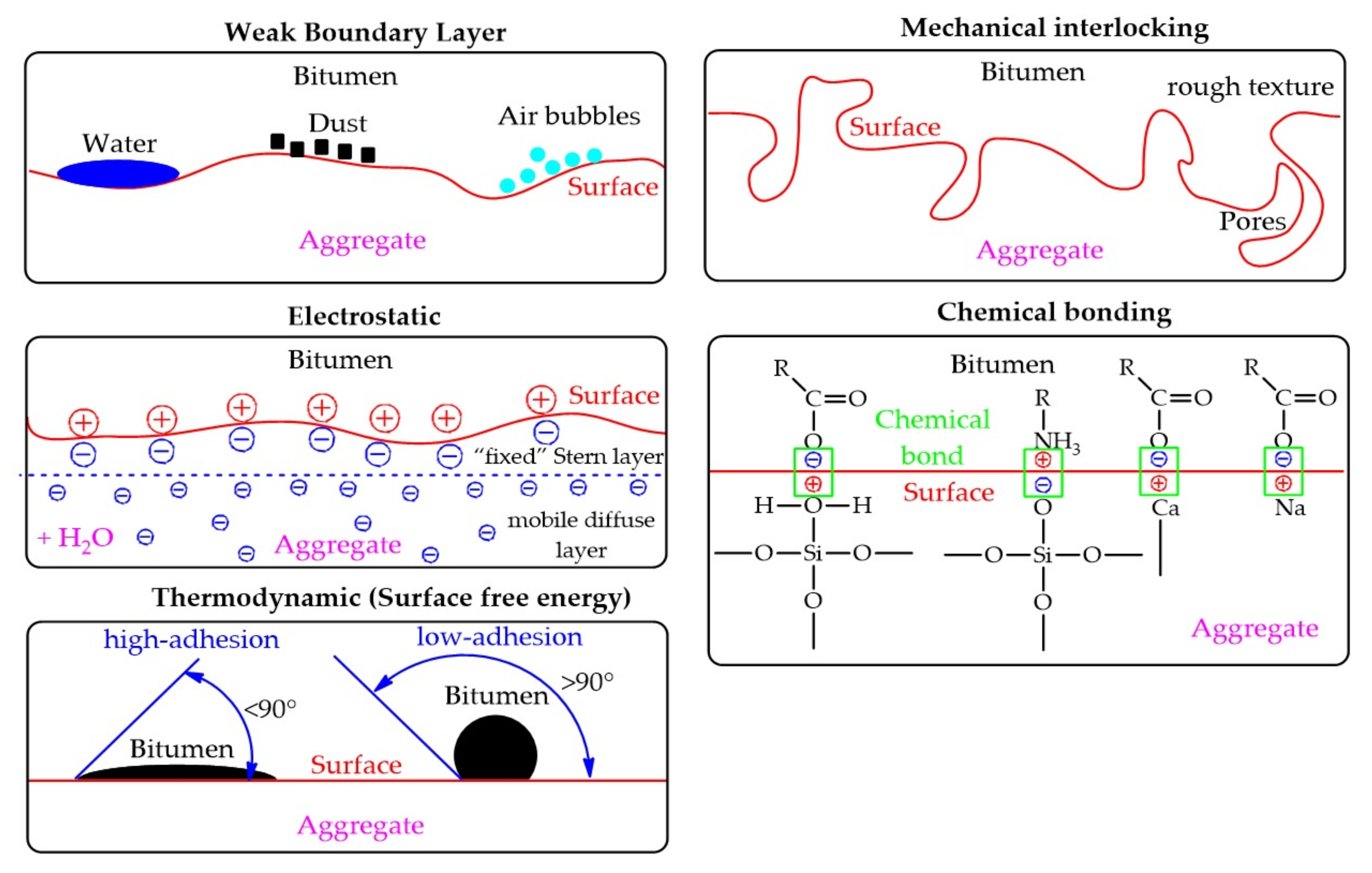

2. Adhesion Mechanism in Bitumen/Aggregate System

2.1. Theory of Weak Boundary Layers

2.2. Theory of Mechanical Interlocking

2.3. Electrostatic Theory

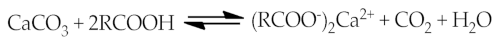

2.4. Chemical Bonding Theory

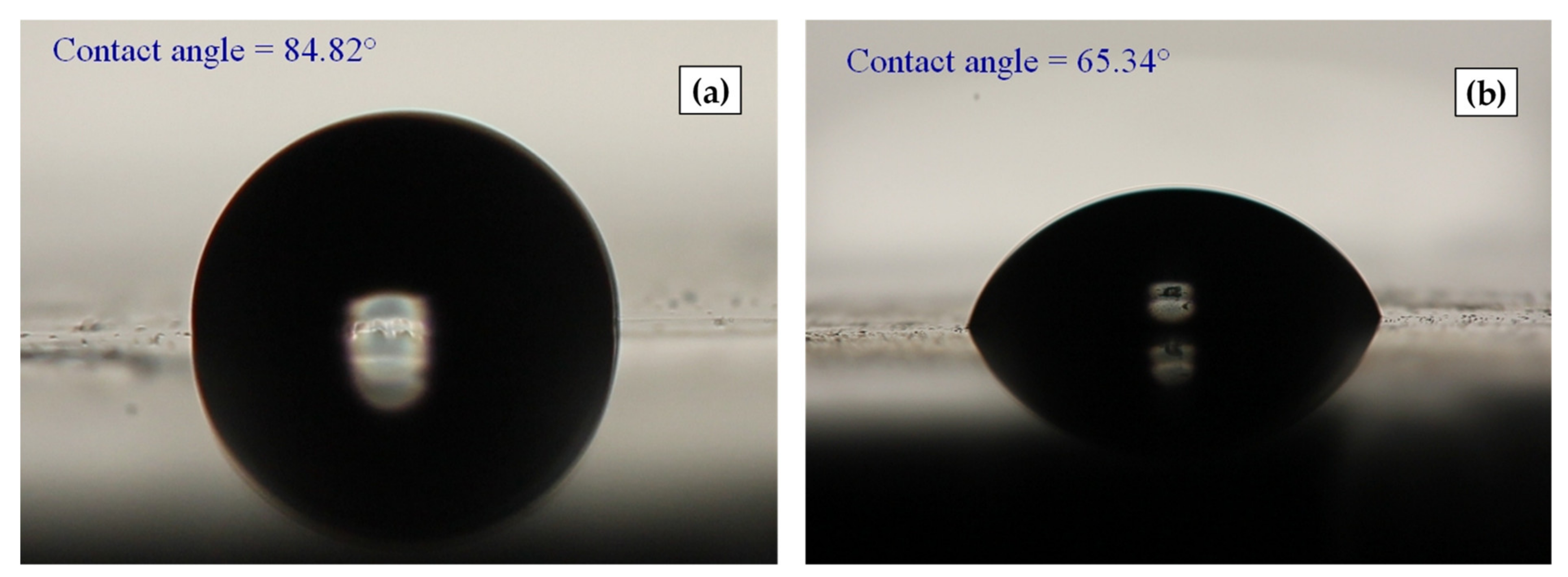

2.5. Thermodynamic Theory (Surface Free Energy)

3. Test Methods for Adhesions

- Determination of adhesion forces for bitumen with different materials;

- Determination of bitumen resistance to the exfoliating action of water with different materials;

- Determination of adhesion as a fundamental value (contact angle measurements, interfacial fracture energy, adsorption capacity and others).

3.1. Determination of Adhesion Forces for Bitumen with Different Materials

3.2. Determination of Bitumen Resistance to Exfoliating Action of Water with Different Materials

- Easy implementation;

- No additional special equipment;

- Short test time in most methods (when boiling in water the test time does not exceed 1.0–1.5 h);

- Due to the use of grains of stone material of the same size it is possible to assess the influence on the adhesion value the bitumen film thickness on the surface of the grains.

- Visual evaluation of results, leads to significant errors;

- Results dependence on the size and surface of stone materials grains;

- In some methods, low sensitivity to the presence of modifying additives;

- Inability to compare the results obtained by different methods.

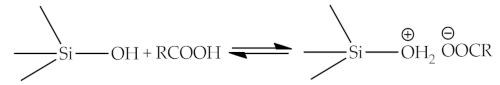

3.2.1. Tests on Loose Mixtures

- Static

- Dynamic

- Bitumen/aggregate ratio;

- Aggregate size;

- Methods of bitumen and aggregate preparation and mixing (for example, mixing Temperature, cooling time and other);

- Water conditioning (test temperature from room to boiling; it should also be noted that as the water temperature increases, the test time decreases significantly; adding different amounts of Na2CO3 to distilled water during chemical immersion test [57];

- Coating degree assessment (it’s usually a visual estimation of the coating, but digital image processing is possible [61].

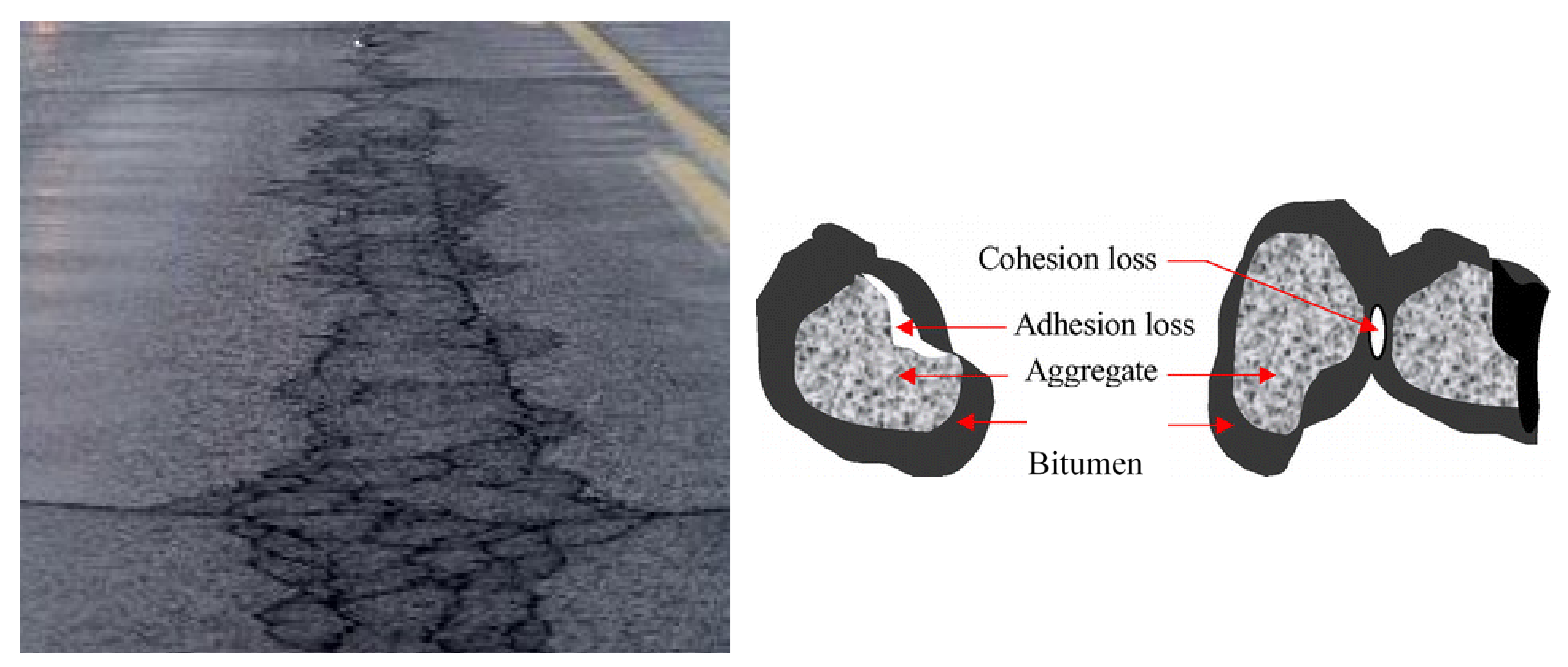

3.2.2. Tests on Loose Mixtures

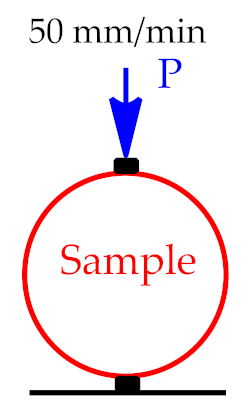

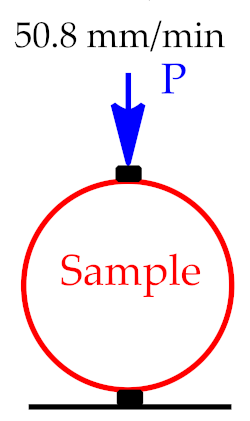

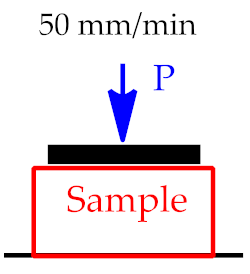

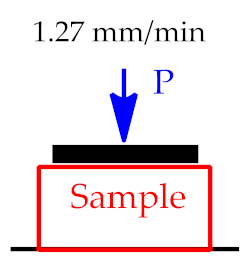

- Size samples;

- Preparation the dry and wet samples;

- Determination of the different performance indicators for dry and wet samples (indirect tensile strength;

- Compressive strength;

- Marshall stability and other.

3.3. Definition of Adhesion as a Fundamental Value

4. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, L.; Varveri, A.; Jing, R.; Erkens, S. Comprehensive review on the transport and reaction of oxygen and moisture towards coupled oxidative ageing and moisture damage of bitumen. Constr. Build. Mater. 2021, 283, 122632. [Google Scholar] [CrossRef]

- Oliviero Rossi, C.; Teltayev, B.; Angelico, R. Adhesion promoters in bituminous road materials: A review. Appl. Sci. 2017, 7, 524. [Google Scholar] [CrossRef]

- Tarefder, R.A.; Zaman, A.M. Nanoscale evaluation of moisture damage in polymer modified asphalts. J. Mater. Civ. Eng. 2010, 22, 714–725. [Google Scholar] [CrossRef]

- Cihlářová, D.; Fencl, I.; Cápayová, S.; Pospíšil, P. Use of adhesion promoters in asphalt mixtures. Slovak J. Civ. Eng. 2018, 26, 19–24. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Effect of filler on the bitumen-aggregate adhesion in asphalt mix. Int. J. Pavement Eng. 2020, 21, 1482–1490. [Google Scholar] [CrossRef]

- Gardner, D.J.; Blumentritt, M.; Wang, L.; Yildirim, N. Adhesion Theories in Wood Adhesive Bonding. Prog. Adhes. Adhes. 2015, 2, 125–168. [Google Scholar] [CrossRef]

- Hefer, A.W.; Little, D.N.; Lytton, R.L. A synthesis of theories and mechanisms of bitumen-aggregate adhesion including recent advances in quantifying the effects of water. J. Assoc. Asph. Paving Technol. 2005, 74, 139–196. [Google Scholar]

- Omar, H.A.; Yusoff, N.I.M.; Mubaraki, M.; Ceylan, H. Effects of moisture damage on asphalt mixtures. J. Traffic Transp. Eng. (Engl. Ed.) 2020, 7, 600–628. [Google Scholar] [CrossRef]

- Nardin; Schultz, J.M. Theories and mechanisms of adhesion. In Handbook of Adhesive Technology; Marcel Dekker, Inc.: New York, NY, USA, 1994. [Google Scholar] [CrossRef]

- Shi, N. Interface Bonding Mechanism of Recycled Asphalt Mixture. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 300, p. 032052. [Google Scholar] [CrossRef]

- Little, D.N.; Jones, D.R. Chemical and mechanical processes of moisture damage in hot-mix asphalt pavements. In Moisture Sensitivity of Asphalt Pavements; The National Academies Press: Washington, DC, USA, 2003; pp. 43–76. [Google Scholar] [CrossRef]

- McBain, J.; Hopkins, D. On adhesives and adhesive action. J. Phys. Chem. 1925, 29, 188–204. [Google Scholar] [CrossRef]

- Plancher, H.; Dorrence, S.M.; Petersen, J.C. Identification of Chemical Types in Asphalts Strongly Adsorbed at the Asphalt-Aggregate Interface and Their Relative Displacement by Water [Moisture Damage to Roads]; No. CONF-770216-1; Energy Research and Development Administration: Washington, DC, USA, 1977. [Google Scholar]

- Curtis, C.W.; Ensley, K.; Epps, J. Fundamental Properties of Asphalt-Aggregate Interactions Including Adhesion and Absorption; No. SHRP-A-341; Strategic Highway Research Program: Washington, DC, USA, 1993. [Google Scholar]

- Park, S.; Jo, M.C.; Park, J.B. Adsorption and thermal desorption behaviour of asphalt-like functionalities on silica. Adsorpt. Sci. Technol. 2000, 18, 675–684. [Google Scholar] [CrossRef]

- Wistuba, M.P.; Grothe, H.; Grönniger, J.; Handle, F. Adhesion of bitumen: Screening and evaluating laboratory testing techniques. In Proceedings of the 5th Eurasphalt & Eurobitume Congress, Istanbul, Turkey, 13–15 June 2012. [Google Scholar]

- Taylor, M.A.; Khosla, N.P. Stripping of Asphalt Pavements: State of the Art (Discussion, Closure); No. 911; Transportation Research Board: Washington, DC, USA, 1983. [Google Scholar]

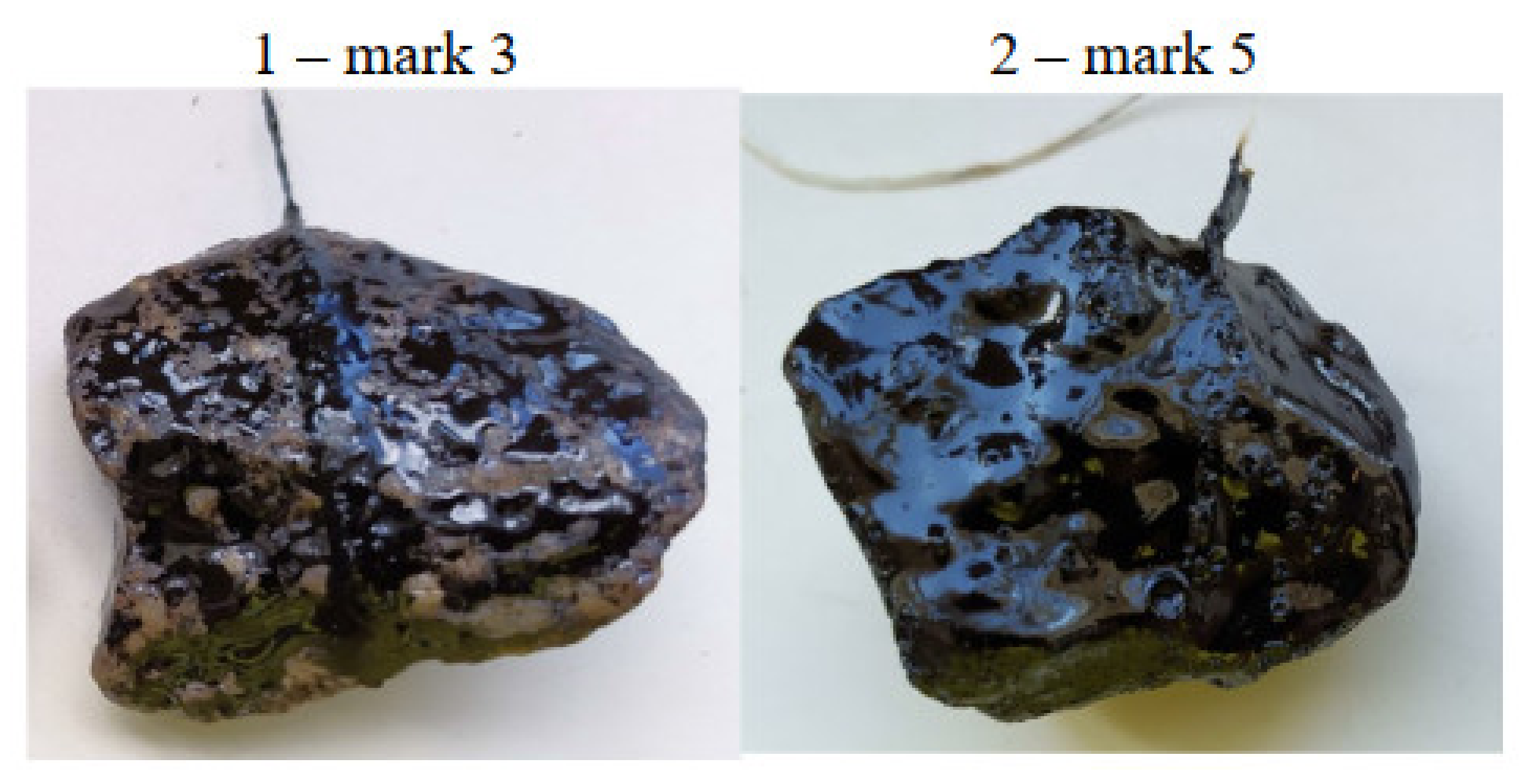

- Pyrig, Y.; Galkin, A. Comparative evaluation of the bitumen binders adhesion by the methods normalized by national standards of Ukraine. Bull. Kharkov Natl. Automob. Highw. Univ. 2019, 86, 202–212. [Google Scholar] [CrossRef]

- Pyrig, Y. State of the art of methods for assessing the adhesion of bitumen to mineral aggregates. Bull. Kharkiv Natl. Automob. Highw. Univ. 2019, 85, 73–82. [Google Scholar] [CrossRef]

- Liu, Y.; Apeagyei, A.; Ahmad, N.; Grenfell, J.; Airey, G. Examination of moisture sensitivity of aggregate-bitumen bonding strength using loose asphalt mixture and physico-chemical surface energy property tests. Int. J. Pavement Eng. 2014, 15, 657–670. [Google Scholar] [CrossRef]

- Aranowski, R.; Wojewódka, P.; Błażejowski, K. Determination of binder-aggregate adhesion by contact angle measurement. In Asphalt Pavements; CRC Press: Boca Raton, FL, USA, 2014; pp. 617–624. [Google Scholar] [CrossRef]

- Fini, E.H.; Al-Qadi, I.L. Development of a pressurized blister test for interface characterization of aggregate highly polymerized bituminous materials. J. Mater. Civ. Eng. 2011, 23, 656–663. [Google Scholar] [CrossRef]

- Airey, G.D.; Choi, Y.K. State of the art report on moisture sensitivity test methods for bituminous pavement materials. Road Mater. Pavement Des. 2002, 3, 355–372. [Google Scholar] [CrossRef]

- AASHTO TP 91; Standard Method of Test for Determining Asphalt Binder Bond Strength by Means of the Binder Bond Strength (BBS) Test. AASHTO: Washington, DC, USA, 2015.

- Ahmed, T.A.; Williams, R.C. Using a modified asphalt bond strength test to investigate the properties of asphalt binders with poly ethylene wax-based warm mix asphalt additive. Int. J. Pavement Res. Technol. 2018, 11, 28–37. [Google Scholar] [CrossRef]

- Canestrari, F.; Cardone, F.; Graziani, A.; Santagata, F.A.; Bahia, H.U. Adhesive and Cohesive Properties of Asphalt-Aggregate Systems Subjected to Moisture Damage. Road Mater. Pavement Des. 2010, 11, 11–32. [Google Scholar] [CrossRef]

- Blackman, B.R.; Cui, S.; Kinloch, A.J.; Taylor, A.C. The development of a novel test method to assess the durability of asphalt road–pavement materials. Int. J. Adhes. Adhes. 2013, 42, 1–10. [Google Scholar] [CrossRef]

- EN 12272-3; Surface Dressing—Test Methods—Part 3: Determination of Binder Aggregate Adhesivity by the Vialit Plate Shock Test Method. European Standard: Pilsen, Czech Republic, 2021.

- Sidun, I.; Solodkyy, S.; Vollis, O.; Stanchak, S.; Bidos, V. Adhesion of bituminous binders with aggregates in the context of surface dressing technology for road pavements treatment. Theory Build. Pract. 2021, 3, 92–99. [Google Scholar] [CrossRef]

- Zolotarev, V.A.; Ageeva, E.N.; Zinchenko, V.N. Quantitative evaluation of bitumen’s adhesion by the method of its displacement by water. In Mechanical Tests for Bituminous Materials–Recent Improvements and Future Prospects; A.A. Balkema: Rotterdam, The Netherlands, 1997. [Google Scholar]

- Gunka, V.; Demchuk, Y.; Sidun, I.; Miroshnichenko, D.; Nyakuma, B.B.; Pyshyev, S. Application of phenol-cresol-formaldehyde resin as an adhesion promoter for bitumen and asphalt concrete. Road Mater. Pavement Des. 2021, 22, 2906–2918. [Google Scholar] [CrossRef]

- DSTU B V.2.7-81-98; Viscous Petroleum Road Bitumens. Method for Determination of Adhesion to the Surface of the Glass and Stone Materials. State Committee of Building, Architecture and Housing Policy of Ukraine: Kyiv, Ukraine, 1999.

- Demchuk, Y.; Sidun, I.; Gunka, V.; Pyshyev, S.; Solodkyy, S. Effect of phenol-cresol-formaldehyde resin on adhesive and physico-mechanical properties of road bitumen. Chem. Chem. Technol. 2018, 12, 456–461. [Google Scholar] [CrossRef]

- Pyshyev, S.; Demchuk, Y.; Poliuzhyn, I.; Kochubei, V. Obtaining and use adhesive promoters to bitumen from the phenolic fraction of coal tar. Int. J. Adhes. Adhes. 2022, 118, 103191. [Google Scholar] [CrossRef]

- Demchuk, Y.; Gunka, V.; Sidun, I.; Solodkyy, S. Comparison of Bitumen Modified by Phenol Formaldehyde Resins Synthesized from Different Raw Materials. In International Scientific Conference EcoComfort and Current Issues of Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2020; pp. 95–102. [Google Scholar] [CrossRef]

- Pyshyev, S.; Gunka, V.; Grytsenko, Y.; Bratychak, M. Polymer Modified Bitumen: Review. Chem. Chem. Technol. 2016, 10, 631–636. [Google Scholar] [CrossRef]

- Pyshyev, S.; Gunka, V.; Grytsenko, Y.; Shved, M.; Kochubei, V. Oil and gas processing products to obtain polymers modified bitumen. Int. J. Pavement Res. Technol. 2017, 10, 289–296. [Google Scholar] [CrossRef]

- Pyshyev, S.; Demchuk, Y.; Gunka, V.; Sidun, I.; Shved, M.; Bilushchak, H.; Obshta, A. Development of mathematical model and Identification of optimal conditions to obtain phenol-cresol-formaldehyde resin. Chem. Chem. Technol. 2019, 13, 212–217. [Google Scholar] [CrossRef]

- Gunka, V.; Demchuk, Y.; Sidun, I.; Kochubei, V.; Shved, M.; Romanchuk, V.; Korchak, B. Chemical modification of road oil bitumens by formaldehyde. Pet. Coal 2020, 62, 420–429. [Google Scholar]

- Wręczycki, J.; Demchuk, Y.; Bieliński, D.M.; Bratychak, M.; Gunka, V.; Anyszka, R.; Gozdek, T. Bitumen Binders Modified with Sulfur/Organic Copolymers. Materials 2022, 15, 1774. [Google Scholar] [CrossRef]

- Pstrowska, K.; Gunka, V.; Prysiazhnyi, Y.; Demchuk, Y.; Hrynchuk, Y.; Sidun, I.; . Kułażyński, M.; Bratychak, M. Obtaining of Formaldehyde Modified Tars and Road Materials on Their Basis. Materials 2022, 15, 5693. [Google Scholar] [CrossRef]

- Bratychak, M.; Gunka, V.; Prysiazhnyi, Y.; Hrynchuk, Y.; Sidun, I.; Demchuk, Y.; Shyshchak, O. Production of Bitumen Modified with Low-Molecular Organic Compounds from Petroleum Residues. 1. Effect of Solvent Nature on the Properties of Petroleum Residues Modified with Folmaldehyde. Chem. Chem. Technol. 2021, 15, 274–283. [Google Scholar] [CrossRef]

- Gunka, V.; Prysiazhnyi, Y.; Hrynchuk, Y.; Sidun, I.; Demchuk, Y.; Shyshchak, O.; Bratychak, M. Production of Bitumen Modified with Low-Molecular Organic Compounds from Petroleum Residues. 2. Bitumen Modified with Maleic Anhydride. Chem. Chem. Technol. 2021, 15, 443–449. [Google Scholar] [CrossRef]

- Gunka, V.; Prysiazhnyi, Y.; Hrynchuk, Y.; Sidun, I.; Demchuk, Y.; Shyshchak, O.; Poliak, O.; Bratychak, M. Production of Bitumen Modified with Low-Molecular Organic Compounds from Petroleum Residues. 3. Tar Modified with Formaldehyde. Chem. Chem. Technol. 2022, 15, 608–620. [Google Scholar] [CrossRef]

- Gunka, V.; Bilushchak, H.; Prysiazhnyi, Y.; Demchuk, Y.; Hrynchuk, Y.; Sidun, I.; Shyshchak, O.; Bratychak, M. Production of Bitumen Modified with Low-Molecular Organic Compounds from Petroleum Residues.4. Determining the Optimal Condi-tions for Tar Modification with Formaldehyde and Properties of the Modified Products. Chem. Chem. Technol. 2022, 16, 142–149. [Google Scholar] [CrossRef]

- Gunka, V.; Prysiazhnyi, Y.; Demchuk, Y.; Hrynchuk, Y.; Sidun, I.; Reutskyy, V.; Bratychak, M. Production of Bitumen Modified with Low-Molecular Organic Compounds from Petroleum Residues. 5. Use of Maleic Anhydride for Foaming Bitumens. Chem. Chem. Technol. 2022, 16, 295–302. [Google Scholar] [CrossRef]

- Gunka, V.; Hrynchuk, Y.; Sidun, I.; Demchuk, Y.; Prysiazhnyi, Y.; Bratychak, M. Production of Bitumen Modified with Low-Molecular Organic Compounds from Petroleum Residues. 6. Temperature Effect on the Chemical Modification of Bitumen with Maleic Anhydride. Chem. Chem. Technol. 2022, 16, 475–483. [Google Scholar] [CrossRef]

- DSTU 8787:2018; Bitumen and Bituminous Binders. Determination of Adhesion with Crushed Stone. DerzhdorNDI: Kyiv, Ukraine, 2018.

- Solaimanian, M.; Harvey, J.; Tahmoressi, M.; Tandon, V. Test methods to predict moisture sensitivity of hot-mix asphalt pavements. In Transportation Research Board National Seminar; Materials Science: San Diego, CA, USA, 2003; pp. 77–110. [Google Scholar]

- Williams, R.C.; Breakah, T.M. Evaluation of Hot Mix Asphalt Moisture Sensitivity Using the Nottingham Asphalt Test Equipment; InTrans Project Reports; Iowa. Dept. of Transportation: Ames, IA, USA, 2010; pp. 12–15. [Google Scholar]

- Taib, A.; Jakarni, F.M.; Rosli, M.F.; Yusoff, N.I.M.; Abd Aziz, M. Comparative study of moisture damage performance test. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 512, p. 012008. [Google Scholar] [CrossRef]

- EN 12697-11; Bituminous Mixtures—Test Methods—Part 11: Determination of the Affinity between Aggregate and Bitumen. European Standard: Pilsen, Czech Republic, 2020.

- AASHTO T182; Standard Specification for Coating and Stripping of Bitumen-Aggregate Mixtures. AASHTO: Washington, DC, USA, 1984.

- Kennedy, T.W.; Roberts, F.L.; Anagnos, J.N. Texas Boiling Test for Evaluating Moisture Susceptibility of Asphalt Mixtures; Center for Transportation Research, Bureau of Engineering Research, University of Texas at Austin: Austin, TX, USA, 1984. [Google Scholar]

- ASTM D3625; Standard Practice for Effect of Water on Bituminous-Coated Aggregate Using Boiling Water. ASTM International Committee: West Conshohocken, PA, USA, 2012.

- Cuciniello, G.; Bahia, H.U. Using the boiling test to evaluate effects of mixing temperatures on quality of aggregate coating. In Proceedings of the 3rd Middle East Society of Asphalt Technologists (MESAT), Conference American University, Dubai, United Arab Emirates, 6–8 April 2015; pp. 119–133. [Google Scholar]

- Method B11; The Determination of the Adhesion of Bituminous Binder to Stone Aggregate by Means of the Chemical Immersion Test (Riedel Weber). Road Research Laboratory, Bituminous Materials in Road Construction: Crowthorne, UK, 1986.

- Solaimanian, M.C., Jr.; Manke, P.G.; O’bannon, C.E. Quantitative evaluation of stripping by the surface reaction test. In Proceedings of the 53rd Annual Meeting of the Highway Research Board, Washington, DC, USA, 21–25 January 1974; Transportation Research Record; No. 517. 1974; pp. 40–54. [Google Scholar]

- Lantieri, C.; Lamperti, R.; Simone, A.; Vignali, V.; Sangiorgi, C.; Dondi, G.; Magnani, V. Use of image analysis for the evaluation of rolling bottle tests results. Int. J. Pavement Res. Technol. 2017, 10, 45–53. [Google Scholar] [CrossRef]

- Isacsson, U.; Jörgensen, T. Laboratory Methods for Determination of the Water Susceptibility of Bituminous Pavements; Experience Gained in the Nordic Countries; VTI rapport 324 A; Swedish National Road and Transport Research Institute (VTI): Linköping, Sweden, 1987. [Google Scholar]

- Grönniger, J.; Wistuba, M.P.; Renken, P. Adhesion in bitumen-aggregate-systems: New technique for automated interpretation of rolling bottle tests. Road Mater. Pavement Des. 2010, 11, 881–898. [Google Scholar] [CrossRef]

- Paliukaitė, M.; Vorobjovas, V.; Bulevičius, M.; Andrejevas, V. Evaluation of different test methods for bitumen adhesion properties. Transp. Res. Procedia 2016, 14, 724–731. [Google Scholar] [CrossRef]

- California Test 302; Method of Test for Film Stripping. Department of Transportation Division of Engineering Services: Sacramento, CA, USA, 2014.

- Son, J.T.; Lee, J.W.; Rhee, S.K.; Hwang, S.D.; Im, J.H. Evaluation of results of dynamic immersion test using digital image analysis. Int. J. Highw. Eng. 2016, 18, 47–53. [Google Scholar] [CrossRef]

- EN 12697-12; Bituminous Mixtures—Test Methods—Part 12: Determination of the Water Sensitivity of Bituminous Specimens. European Standard: Pilsen, Czech Republic, 2018.

- Lottman, R.P. Laboratory Test Methods for Predicting Moisture-Induced Damage to Asphalt Concrete; Transportation Research Record: Washington, DC, USA, 1982. [Google Scholar]

- AASHTO T 283-14; Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. AASHTO: Washington, DC, USA, 2015.

- Tahmoressi, M. Prediction of moisture-induced damage to bituminous paving materials using molded specimens. In Evaluation of Test Method TEX-531-C; DHT-38; Texas Department of Transportation: Austin, TX, USA, 1996. [Google Scholar]

- Tunnicliff, D.G.; Root, R.E. Use of Antistripping Additives in Asphaltic Concrete Mixtures Laboratory Phase; Transportation Research Board, Laboratory Phase: Washington, DC, USA, 1984. [Google Scholar]

- ASTM D4867/D4867M-09; Standard Test Method for Effect of Moisture on Asphalt Concrete Paving Mixtures. ASTM International Committee: West Conshohocken, PA, USA, 2014.

- ASTM D 1075; Standard Test Method for Effect of Water on Compressive Strength of Compacted Bituminous Mixtures. ASTM International Committee: West Conshohocken, PA, USA, 2007.

- AASHTO T165-02; Standard Method of Test for Effect of Water on Compressive Strength of Compacted Bituminous Mixtures. AASHTO: Washington, DC, USA, 2002.

- Ali, N. The experimental study on the resistance of asphalt concrete with Butonic bitumen against water saturation. Int. J. Eng. Technol. 2013, 3, 508–516. [Google Scholar]

- Kennedy, T.W.; Roberts, F.L.; Lee, K.W.; Anagnos, J.N. Texas Freeze-Thaw Pedestal Test for Evaluating Moisture Susceptibility for Asphalt Mixtures; Center for Highway Research, University of Texas at Austin: Austin, TX, USA, 1982. [Google Scholar]

- Plancher, H.; Miyake, G.; Venable, R.L.; Petersen, J.C. A Simple Laboratory Test to Indicate the Susceptibility of Asphalt-Aggregate Mixtures to Moisture Damage during Repeated Freeze-Thaw Cycling; Canadian Technical Asphalt Association: West Kelowna, BC, Canada, 1980; Volume 25, pp. 246–262. [Google Scholar]

- Nicholls, J.C.; Prime, J.; Meitei, B.; Lowe, A. Review of Saturation Ageing Tensile Stiffness (SATS) test for use in Ireland; PPR 547; TRL: Berkshire, UK, 2011. [Google Scholar]

- EN 12697-45; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 45: Saturation Ageing Tensile Stiffness (SATS) Conditioning Test. European Standard: Pilsen, Czech Republic, 2020.

- Aschenbrener, T.; McGennis, R.B.; Terrel, R.L. Comparison of several moisture susceptibility tests to pavements of known field performance (with discussion and closure). J. Assoc. Asph. Paving Technol. 1996, 64, 163–208. [Google Scholar]

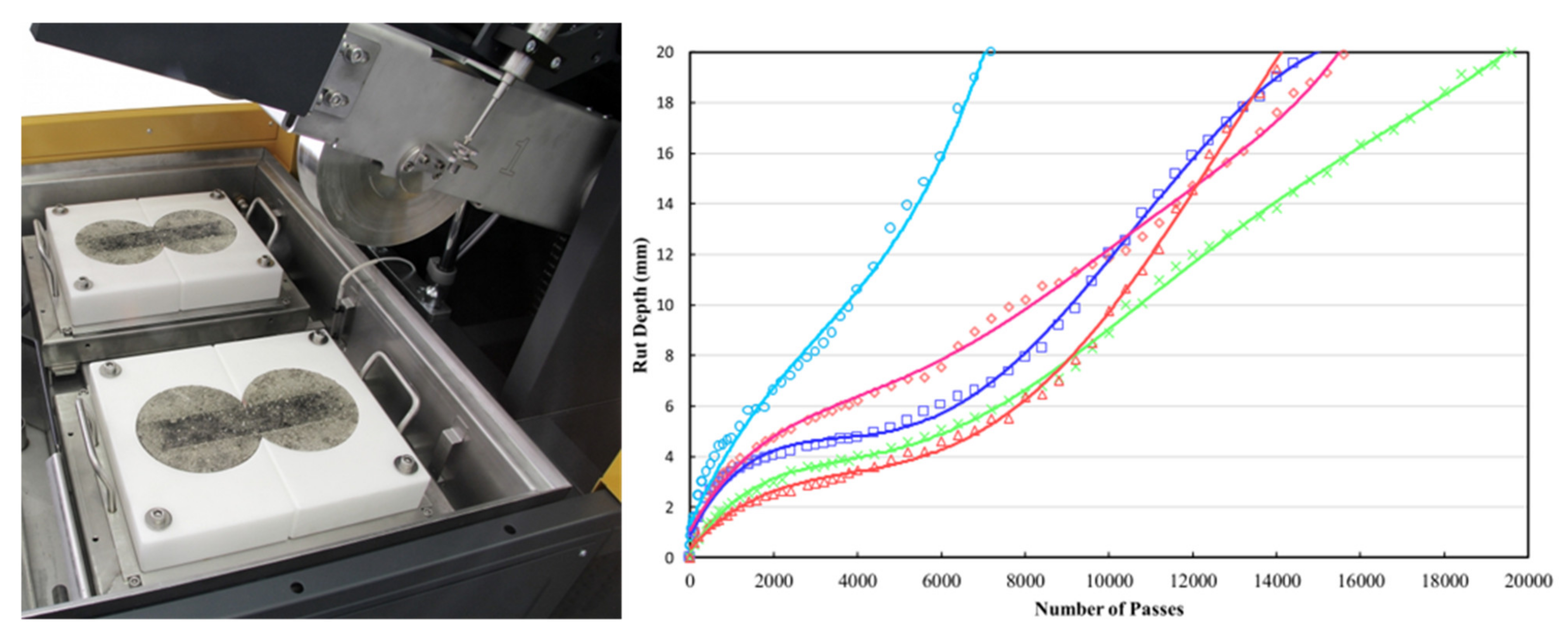

- Lv, Q.; Huang, W.; Sadek, H.; Xiao, F.; Yan, C. Investigation of the rutting performance of various modified asphalt mixtures using the Hamburg Wheel-Tracking Device test and Multiple Stress Creep Recovery test. Constr. Build. Mater. 2019, 206, 62–70. [Google Scholar] [CrossRef]

- Lu, Q.; Harvey, J.T. Evaluation of Hamburg wheel-tracking device test with laboratory and field performance data. Transp. Res. Rec. 2006, 1970, 25–44. [Google Scholar] [CrossRef]

- AASHTO T324; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. AASHTO: Washington, DC, USA, 2019.

- EN 12697-22; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 22: Wheel Tracking. European Standard: Pilsen, Czech Republic, 2020.

- Martínez-Rodríguez, M.; Esquena, J. Wetting and interfacial properties of bitumen at room temperature, and the role of naturally present ionic molecules. Colloids Surf. A Physicochem. Eng. Asp. 2021, 609, 125575. [Google Scholar] [CrossRef]

- Molina, R.; Esquena, J.; Erra, P. Interfacial processes in textile materials: Relevance to adhesion. J. Adhes. Sci. Technol. 2010, 24, 7–33. [Google Scholar] [CrossRef]

- Salou, M.; Siffert, B.; Jada, A. Study of the stability of bitumen emulsions by application of DLVO theory. Colloids Surf. A Physicochem. Eng. Asp. 1998, 142, 9–16. [Google Scholar] [CrossRef]

- Cantin, S.; Bouteau, M.; Benhabib, F.; Perrot, F. Surface free energy evaluation of well-ordered Langmuir–Blodgett surfaces: Comparison of different approaches. Colloids Surf. A Physicochem. Eng. Asp. 2006, 276, 107–115. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Guo, F.; Pei, J.; Zhang, J.; Xue, B.; Sun, G.; Li, R. Study on the adhesion property between asphalt binder and aggregate: A state-of-the-art review. Constr. Build. Mater. 2020, 256, 119474. [Google Scholar] [CrossRef]

- Stalder, A.F.; Melchior, T.; Müller, M.; Sage, D.; Blu, T.; Unser, M. Low-bond axisymmetric drop shape analysis for surface tension and contact angle measurements of sessile drops. Colloids Surf. A Physicochem. Eng. Asp. 2010, 364, 72–81. [Google Scholar] [CrossRef]

- Williams, D.L.; Kuhn, A.T.; Amann, M.A.; Hausinger, M.B.; Konarik, M.M.; Nesselrode, E.I. Computerised measurement of contact angles. Galvanotechnik 2010, 101, 2502. [Google Scholar]

- Labib, M.E.; Hefer, A.W.; Little, D.N. Surface chemistry at the bitumen-aggregate interface. In Proceedings of the International Conference on Advanced Characterisation of Pavement and Soil Engineering Material, Athens, Greece, 20–22 June 2007. [Google Scholar]

- Nomlala, B.; Mthembu, Z.; Mturi, G.; Hefer, A. Bitumen-aggregate adhesion: A predictive study based on zeta potential analysis using the streaming potential technique. In Proceedings of the 40th Annual Southern African Transport Conference, Pretoria, South Africa, 4–7 July 2022. [Google Scholar]

- Walsh, G.; Jamieson, I.; Thornton, J.; O’Mahony, M. A modified SHRP net adsorption test. In Proceedings of the Eurasphalt & Eurobitume Congress, Strasbourg, France, 7–10 May 1996; Volume 2. [Google Scholar]

| Theory | Interaction | References |

|---|---|---|

| Weak Boundary Layer | layering | Bikerman, 1961 [6] and other [7,8,9,10,11] |

| Mechanical interlocking | interlock | McBain and Hopkins, 1925 [12] and other [6,7,8,9,10,11] |

| Electrostatic | potential | Deryaguin and other, 1948 [7] and other [6,8,9,10,11] |

| Chemical bonding | covalent and ionic bonds | [6,7,8,9,10,11,13,14,15,16] |

| Thermodynamic (Surface free energy) | surface free energy | [6,7,8,9,10,11] |

| Parameter | Test | |||||

|---|---|---|---|---|---|---|

| Static | Static Immersion | Texas Boiling | Boiling Water Stripping | Rolling Bottle | Film Stripping | |

| Aggregate Coating | ||||||

| Binder amount | 4% (±x·0.5%) | 5.5 g (5.2%) | 2.3%–8% | 30 g (2.0%) | 16 g (3.0%) | 3.6% |

| Aggregate (size) | 150 particles (8/11.2 or 6/10 mm) | 100 g (6.3/9.5 mm) | 300 or 100 g (3/8 in) | 1500 g (8/11.2 or 6/10 mm) | 510 g for 3 sets (8/11.2 (5.6/8, 6.3/10) mm) | 60 g (3/8 in) |

| Amount for testing | ||||||

| Loose Mixtures | 150 particles | 100 g | 300 or 100 g | 200 g | 150 g | − |

| Water | full cover | 600 mL | 500 mL | 600 mL | 500 mL * | − |

| Water conditioning | ||||||

| Conditioning type | static | static | static | static | dynamic | dynamic |

| Water temperature | 19 ± 1°C | 25 °C | boiling water | 20 ± 5 °C | 25 °C | |

| Conditioning time | 48 ± 1 h | 16–18 h | 10 and 13 min | 10 min | 6 h and 24 h if necessary 48 h and 72 h | 15 min |

| Assessment of the coating degree | ||||||

| Validation of the result | number of not completely coated aggregates (visual) | visual estimation of the coating, less than or greater than 95% | visual estimation of the coating | visual estimation of the coating | visual estimation of the coating | validation of the result |

| Parameter | Test | |||||

|---|---|---|---|---|---|---|

| Indirect Tensile Strength | Modified Lottman Indirect Tension | Compression Strength | Immersion-Compression | Marshall Immersion | Texas Freeze-Thaw Pedestal | |

| Sample Size | ||||||

| Diameter | 80, 100, 120, 150 and 160 mm | 63.5 and 150 mm | 80, 100, 120, 150 and 160 mm | 101.6 mm | 100 mm (cylinder height 75 mm) | 41.3 mm (cylinder height 19.5 mm) |

| Preparation of dry samples | ||||||

| 20 °C (air) | 25 °C, 2 h (in plastic film, water) | 18 °C (air) | 25 °C, 4 h (air) | 25 °C, 4 h (air) | - | |

| Preparation of wet samples | ||||||

| Water saturation | (1) 30 min(vacuum) | (1) 10 min (water, vacuum) | (1) 60 min (vacuum) | (1) 60 °C, 24 h or 49 °C, 4 days (water) | (1) 60 °C, 24 h (water) | (1) 3 days (air) |

| (2) 40 °C, 68–72 h (water) | (2) 18 °C, 16 h (in plastic film, freezer) | (2) 120 min (water, vacuum) | - | - | (2) freeze-thaw cycles bottle (−12 °C, 24 h (freezer); 49 °C, 9 h (water)) | |

| - | (3) 60 °C, 24 h (in plastic film, water) | (3) 18 °C, 7 days (water) | - | - | - | |

| Testing | ||||||

| Cooling | 2–4 h (water) | 2 h (in plastic film, water) | - | 2 h (water) | 2 h (water) | - |

| Temperature | 25 °C | 25 °C | 18 °C | 25 °C | 25 °C | - |

| Method | Indirect tensile strength (ITS; kPa) | Indirect tensile strength (ITS, kPa) | Compressive strength (CS; kPa) | Compressive strength (CS; kPa) | Marshall stability (MS; kN) | After each freeze-thaw cycle, the briquette surface is checked for cracks |

|  |  |  |  |  | |

| Result | ||||||

| Index | indirect tensile strength ratio (ITSR) | tensile strength ration (TSR) | index of retained strength (IRS) | retained compression strength (RCS) | retaining strength index (RSI) | the number of cycles required to induce cracking is a measure of water susceptibility (typically 10 freeze-thaw cycles) |

| Calculation | (%) | (%) | (%) | (%) | (%) | - |

| Liquid | (mJ/m2) | (mJ/m2) | (mJ/m2) |

|---|---|---|---|

| Water | 21.80 | 51.00 | 72.80 |

| Ethylene glycol | 29.00 | 19.00 | 48.00 |

| Contact Angle (°) | Surface Energy Components (mJ/m2) | Total Surface Energy (mJ/m2) | ||

|---|---|---|---|---|

| Water | Ethylene glycol | |||

| 84.82 | 65.34 | 14.90 | 9.21 | 24.11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pstrowska, K.; Gunka, V.; Sidun, I.; Demchuk, Y.; Vytrykush, N.; Kułażyński, M.; Bratychak, M. Adhesion in Bitumen/Aggregate System: Adhesion Mechanism and Test Methods. Coatings 2022, 12, 1934. https://doi.org/10.3390/coatings12121934

Pstrowska K, Gunka V, Sidun I, Demchuk Y, Vytrykush N, Kułażyński M, Bratychak M. Adhesion in Bitumen/Aggregate System: Adhesion Mechanism and Test Methods. Coatings. 2022; 12(12):1934. https://doi.org/10.3390/coatings12121934

Chicago/Turabian StylePstrowska, Katarzyna, Volodymyr Gunka, Iurii Sidun, Yuriy Demchuk, Nataliya Vytrykush, Marek Kułażyński, and Michael Bratychak. 2022. "Adhesion in Bitumen/Aggregate System: Adhesion Mechanism and Test Methods" Coatings 12, no. 12: 1934. https://doi.org/10.3390/coatings12121934

APA StylePstrowska, K., Gunka, V., Sidun, I., Demchuk, Y., Vytrykush, N., Kułażyński, M., & Bratychak, M. (2022). Adhesion in Bitumen/Aggregate System: Adhesion Mechanism and Test Methods. Coatings, 12(12), 1934. https://doi.org/10.3390/coatings12121934