Structure, Phase Composition, and Properties of Ti3AlC2—Nano-Cu Powder Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples Preparation

2.2. Samples Investigation

3. Results and Discussion

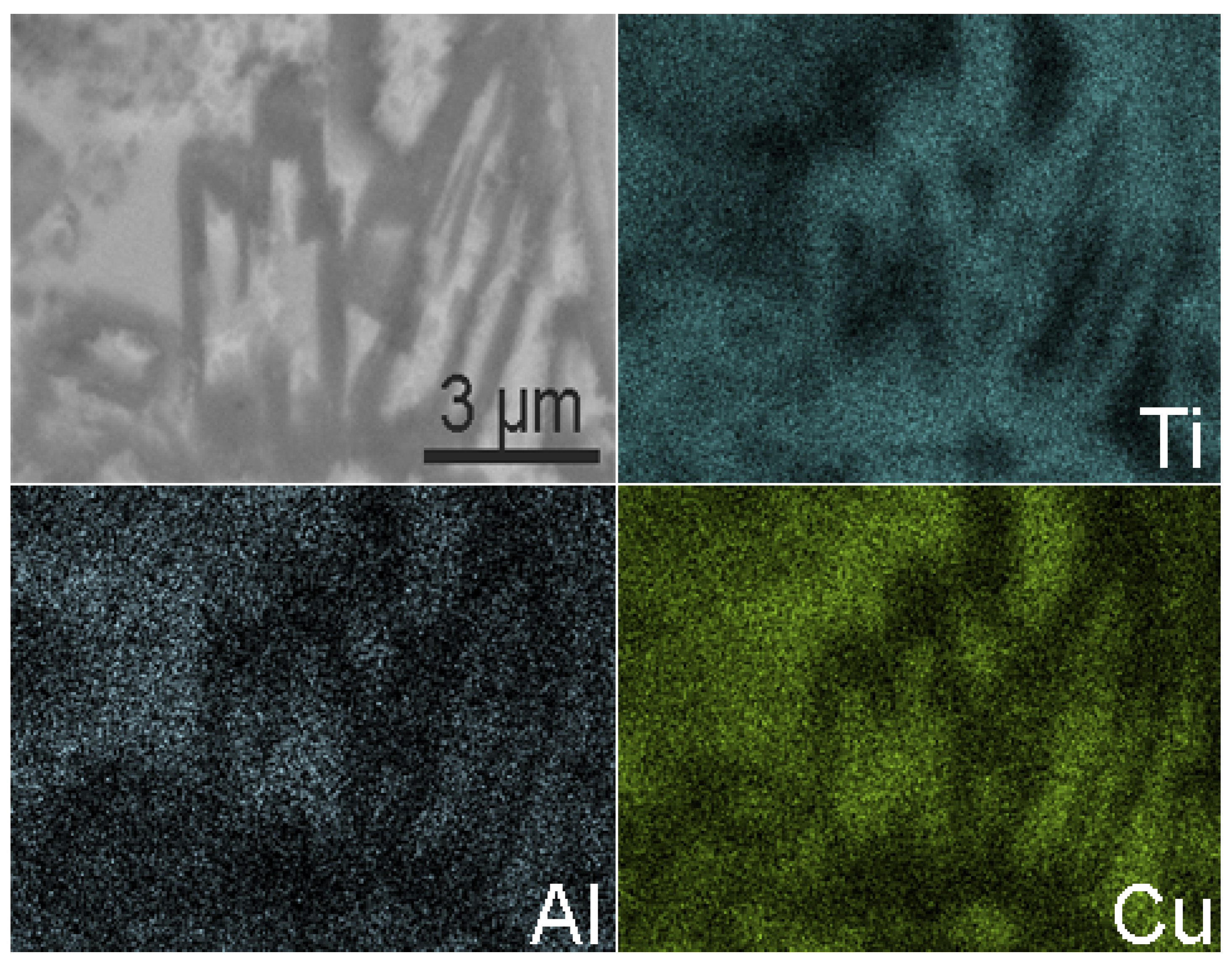

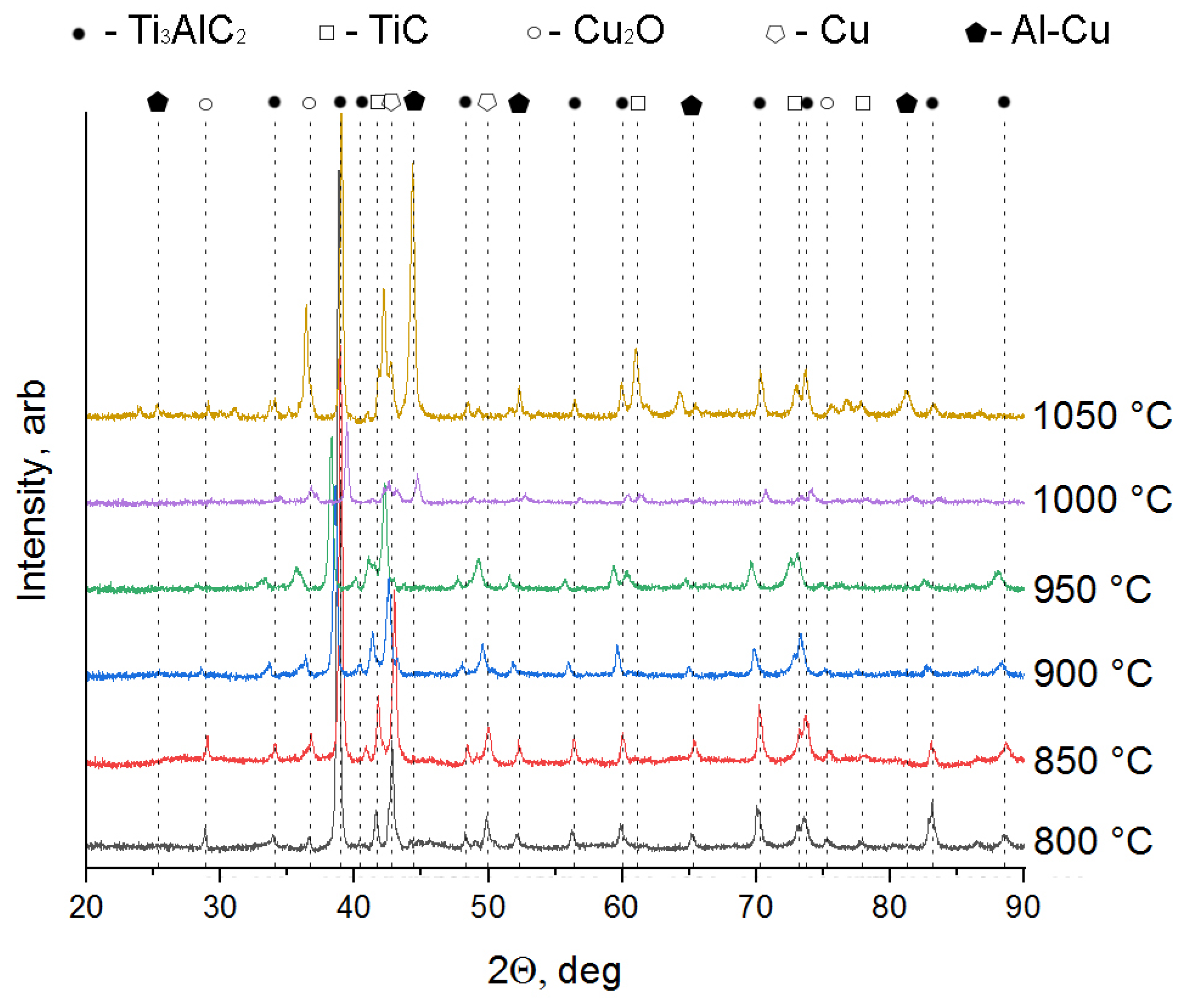

3.1. Microstructure and Phase Composition

3.2. Porosity

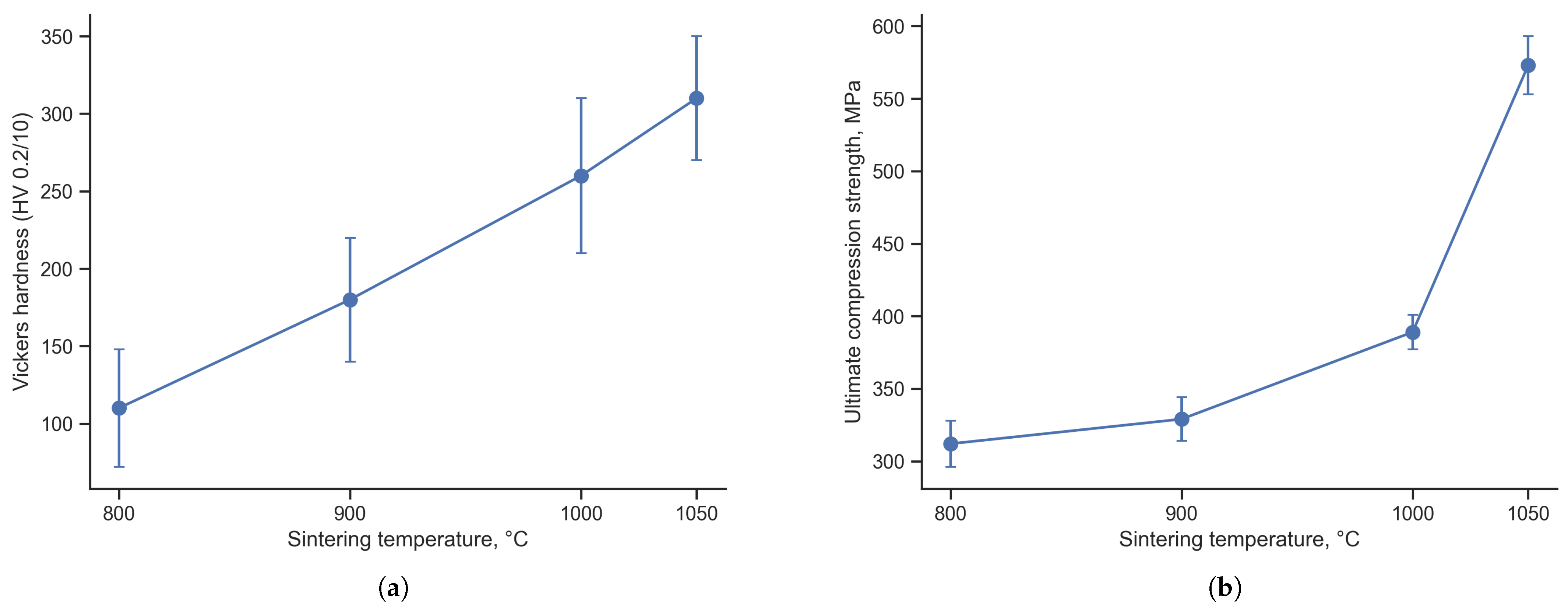

3.3. Electrical and Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barsoum, M.W. The MN+1AXN phases: A new class of solids: Thermodynamically stable nanolaminates. Prog. Solid State Chem. 2000, 28, 201–281. [Google Scholar] [CrossRef]

- Mateen, A.; Ansari, M.Z.; Abbas, Q.; Muneeb, A.; Hussain, A.; Eldin, E.T.; Alzahrani, F.M.; Alsaiari, N.S.; Ali, S.; Javed, M.S. In Situ Nitrogen Functionalization of 2D-Ti3C2Tx-MXenes for High-Performance Zn-Ion Supercapacitor. Molecules 2022, 27, 7446. [Google Scholar] [CrossRef] [PubMed]

- Shuck, C.E.; Han, M.; Maleski, K.; Hantanasirisakul, K.; Kim, S.J.; Choi, J.; Reil, W.E.; Gogotsi, Y. Effect of Ti3AlC2 MAX phase on structure and properties of resultant Ti3C2Tx MXene. ACS Appl. Nano Mater. 2019, 2, 3368–3376. [Google Scholar] [CrossRef]

- Gogotsi, Y.; Anasori, B. The rise of MXenes. ACS Nano 2019, 13, 8491–8494. [Google Scholar] [CrossRef] [Green Version]

- Naguib, M.; Barsoum, M.W.; Gogotsi, Y. Ten years of progress in the synthesis and development of MXenes. Adv. Mater. 2021, 33, 2103393. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, S.; Cheng, J.; Qiao, Z.; Yang, J.; Liu, W. Microstructural, mechanical and tribological properties of Al matrix composites reinforced with Cu coated Ti3AlC2. J. Alloys Compd. 2017, 690, 612–620. [Google Scholar] [CrossRef]

- Cui, K.; Mao, H.; Zhang, Y.; Wang, J.; Wang, H.; Tan, T.; Fu, T. Microstructure, mechanical properties, and reinforcement mechanism of carbide toughened ZrC-based ultra-high temperature ceramics: A review. Compos. Interfaces 2022, 29, 1–20. [Google Scholar] [CrossRef]

- Mao, H.; Shen, F.; Zhang, Y.; Wang, J.; Cui, K.; Wang, H.; Lv, T.; Fu, T.; Tan, T. Microstructure and mechanical properties of carbide reinforced tic-based ultra-high temperature ceramics: A review. Coatings 2021, 11, 1444. [Google Scholar] [CrossRef]

- Han, J.H.; Hwang, S.S.; Lee, D.; Park, S.W. Synthesis and mechanical properties of Ti3AlC2 by hot pressing TiCx/Al powder mixture. J. Eur. Ceram. Soc. 2008, 28, 979–988. [Google Scholar] [CrossRef]

- Li, S.B.; Zhai, H.X.; Bei, G.P.; Zhou, Y.; Zhang, Z.L. Synthesis and microstructure of Ti3AlC2 by mechanically activated sintering of elemental powders. Ceram. Int. 2007, 33, 169–173. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, Y. Stability and selective oxidation of aluminum in nano-laminate Ti3AlC2 upon heating in argon. Chem. Mater. 2003, 15, 3716–3720. [Google Scholar] [CrossRef]

- Pang, W.K.; Low, I.M.; Sun, Z.M. In situ high-temperature diffraction study of the thermal dissociation of Ti3AlC2 in vacuum. J. Am. Ceram. Soc. 2010, 93, 2871–2876. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Zhou, Y. Structure stability of Ti3AlC2 in Cu and microstructure evolution of Cu–Ti3AlC2 composites. Acta Mater. 2007, 55, 4381–4390. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, Y. Microstructure, mechanical, and electrical properties of Cu–Ti3AlC2 and in situ Cu–TiCx composites. J. Mater. Res. 2008, 23, 924–932. [Google Scholar] [CrossRef]

- Wang, W.; Zhai, H.; Chen, L.; Zhou, Y.; Huang, Z.; Bei, G.; Greil, P. Sintering and properties of mechanical alloyed Ti3AlC2-Cu composites. Mater. Sci. Eng. A 2017, 685, 154–158. [Google Scholar] [CrossRef]

- Wu, G.; Dong, K.; Xu, Z.; Xiao, S.; Wei, W.; Chen, H.; Li, J.; Huang, Z.; Li, J.; Gao, G.; et al. Pantograph–catenary electrical contact system of high-speed railways: Recent progress, challenges, and outlooks. Railw. Eng. Sci. 2022, 30, 437–467. [Google Scholar] [CrossRef]

- Zhao, H.; Feng, Y.; Zhou, Z.; Qian, G.; Zhang, J.; Huang, X.; Zhang, X. Effect of electrical current density, apparent contact pressure, and sliding velocity on the electrical sliding wear behavior of Cu–Ti3AlC2 composites. Wear 2020, 444, 203156. [Google Scholar] [CrossRef]

- Pervikov, A.; Lerner, M.; Krukovskii, K. Structural characteristics of copper nanoparticles produced by the electric explosion of wires with different structures of metal grains. Curr. Appl. Phys. 2017, 17, 201–206. [Google Scholar] [CrossRef]

- Bakina, O.; Glazkova, E.; Pervikov, A.; Lozhkomoev, A.; Rodkevich, N.; Svarovskaya, N.; Lerner, M.; Naumova, L.; Varnakova, E.; Chjou, V. Design and Preparation of Silver–Copper Nanoalloys for Antibacterial Applications. J. Clust. Sci. 2021, 32, 779–786. [Google Scholar] [CrossRef]

- Cverna, F. ASM Ready Reference: Thermal Properties of Metals; ASM International: Materials Park, OH, USA, 2002. [Google Scholar]

- Yeshchenko, O.A.; Dmitruk, I.M.; Alexeenko, A.A.; Dmytruk, A.M. Size-dependent melting of spherical copper nanoparticles embedded in a silica matrix. Phys. Rev. B 2007, 75, 085434. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Zhu, Y.; Shi, T.; Tang, Z.; Li, M.; Liao, G. Molecular dynamics simulation of the melting behavior of copper nanorod. Comput. Mater. Sci. 2018, 143, 248–254. [Google Scholar] [CrossRef]

- Magdassi, S.; Grouchko, M.; Kamyshny, A. Copper nanoparticles for printed electronics: Routes towards achieving oxidation stability. Materials 2010, 3, 4626–4638. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Singh, J.; Kaur, G.; Rawat, M. A brief review on synthesis and characterization of copper oxide nanoparticles and its applications. J. Bioelectron. Nanotechnol. 2016, 1, 9. [Google Scholar]

- Siddiqi, K.S.; Husen, A. Current status of plant metabolite-based fabrication of copper/copper oxide nanoparticles and their applications: A review. Biomater. Res. 2020, 24, 1–15. [Google Scholar] [CrossRef]

- Rai, A.; Park, K.; Zhou, L.; Zachariah, M. Understanding the mechanism of aluminium nanoparticle oxidation. Combust. Theory Model. 2006, 10, 843–859. [Google Scholar] [CrossRef]

- Rai, A.; Lee, D.; Park, K.; Zachariah, M.R. Importance of phase change of aluminum in oxidation of aluminum nanoparticles. J. Phys. Chem. B 2004, 108, 14793–14795. [Google Scholar] [CrossRef]

- Wang, W.; Gauthier-Brunet, V.; Bei, G.; Laplanche, G.; Bonneville, J.; Joulain, A.; Dubois, S. Powder metallurgy processing and compressive properties of Ti3AlC2/Al composites. Mater. Sci. Eng. A 2011, 530, 168–173. [Google Scholar] [CrossRef]

- Ai, T.; Wang, F.; Feng, X.; Ruan, M. Microstructural and mechanical properties of dual Ti3AlC2–Ti2AlC reinforced TiAl composites fabricated by reaction hot pressing. Ceram. Int. 2014, 40, 9947–9953. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, L.; Li, B.; Song, Q.; Wu, P. Structural, elastic, and electronic properties of Al-Cu intermetallics from first-principles calculations. J. Electron. Mater. 2009, 38, 356–364. [Google Scholar] [CrossRef]

- Plevachuk, Y.; Sklyarchuk, V.; Yakymovych, A.; Eckert, S.; Willers, B.; Eigenfeld, K. Density, viscosity, and electrical conductivity of hypoeutectic Al-Cu liquid alloys. Metall. Mater. Trans. A 2008, 39, 3040–3045. [Google Scholar] [CrossRef]

- Buytoz, S.; Dagdelen, F.; Islak, S.; Kok, M.; Kir, D.; Ercan, E. Effect of the TiC content on microstructure and thermal properties of Cu–TiC composites prepared by powder metallurgy. J. Therm. Anal. Calorim. 2014, 117, 1277–1283. [Google Scholar] [CrossRef]

- Viet, N.H.; Oanh, N.T.H. Microstructure and Electrical Property of Ex-Situ and In-Situ Copper Titanium Carbide Nanocomposites. Metals 2020, 10, 735. [Google Scholar] [CrossRef]

- Du, X.; Liu, R.; Xiong, X.; Liu, H. Effects of sintering time on the microstructure and properties of an Al-Cu-Mg alloy. J. Mater. Res. Technol. 2020, 9, 9657–9666. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, L.; Wang, J.; Mao, H.; Cui, K. Microstructure and mechanical properties of high strength porous ceramics with high sewage sludge content. J. Clean. Prod. 2022, 380, 135084. [Google Scholar] [CrossRef]

- Cui, K.; Fu, T.; Zhang, Y.; Wang, J.; Mao, H.; Tan, T. Microstructure and mechanical properties of CaAl12O19 reinforced Al2O3-Cr2O3 composites. J. Eur. Ceram. Soc. 2021, 41, 7935–7945. [Google Scholar] [CrossRef]

- Yehia, H.M.; Nouh, F.; El-Kady, O. Effect of graphene nano-sheets content and sintering time on the microstructure, coefficient of thermal expansion, and mechanical properties of (Cu/WC–TiC-Co) nano-composites. J. Alloys Compd. 2018, 764, 36–43. [Google Scholar] [CrossRef]

- Xu, X.; Li, W.; Wang, Y.; Dong, G.; Jing, S.; Wang, Q.; Feng, Y.; Fan, X.; Ding, H. Study of the preparation of Cu-TiC composites by reaction of soluble Ti and ball-milled carbon coating TiC. Results Phys. 2018, 9, 486–492. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krinitcyn, M.; Toropkov, N. Structure, Phase Composition, and Properties of Ti3AlC2—Nano-Cu Powder Composites. Coatings 2022, 12, 1928. https://doi.org/10.3390/coatings12121928

Krinitcyn M, Toropkov N. Structure, Phase Composition, and Properties of Ti3AlC2—Nano-Cu Powder Composites. Coatings. 2022; 12(12):1928. https://doi.org/10.3390/coatings12121928

Chicago/Turabian StyleKrinitcyn, Maksim, and Nikita Toropkov. 2022. "Structure, Phase Composition, and Properties of Ti3AlC2—Nano-Cu Powder Composites" Coatings 12, no. 12: 1928. https://doi.org/10.3390/coatings12121928

APA StyleKrinitcyn, M., & Toropkov, N. (2022). Structure, Phase Composition, and Properties of Ti3AlC2—Nano-Cu Powder Composites. Coatings, 12(12), 1928. https://doi.org/10.3390/coatings12121928