Mechanical Properties of σ-Phase and Its Effect on the Mechanical Properties of Austenitic Stainless Steel

Abstract

:1. Introduction

2. Experimental Details

2.1. Material and Metallographic Structure

2.2. Microhardness Test

2.3. Mechanical Properties Tests

2.4. Nano-Indentation Tests

3. Results

3.1. Metallographic Structure

3.2. Room Temperature Mechanical Properties

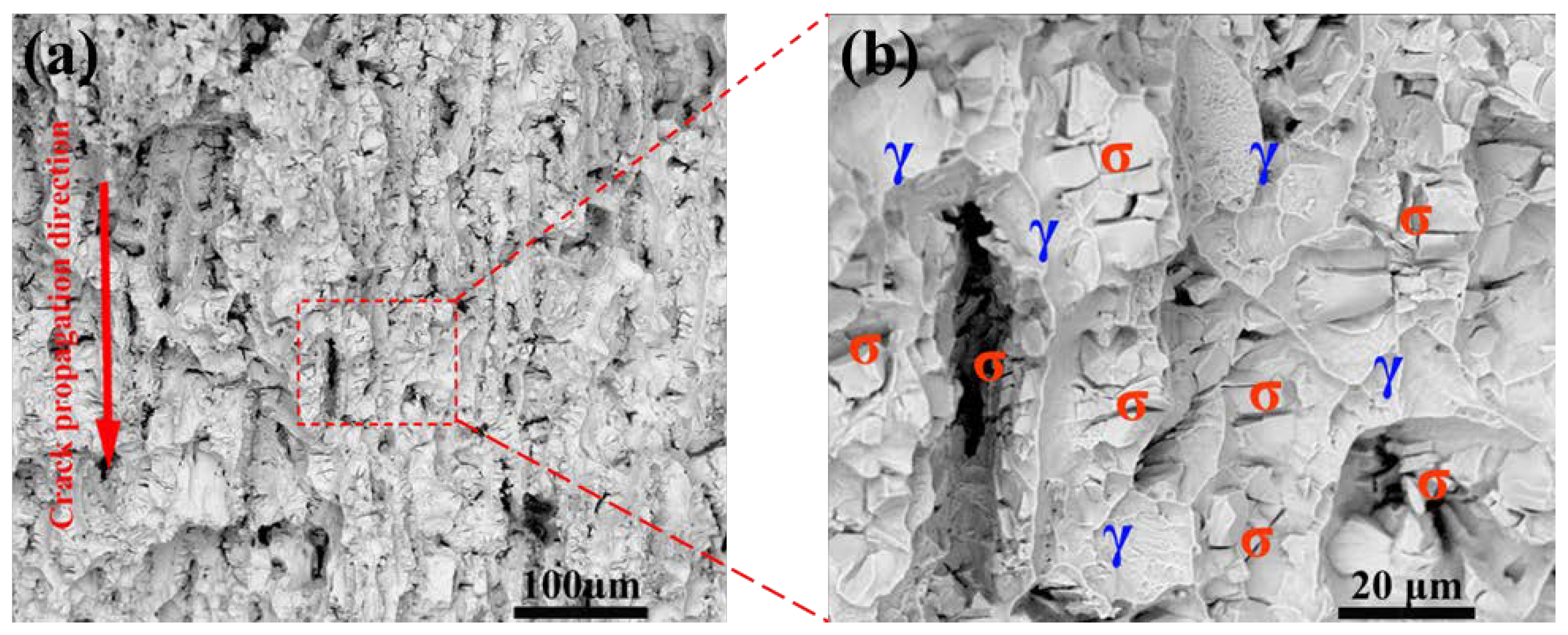

3.3. Nano-Indentation Test Results

4. Discussion

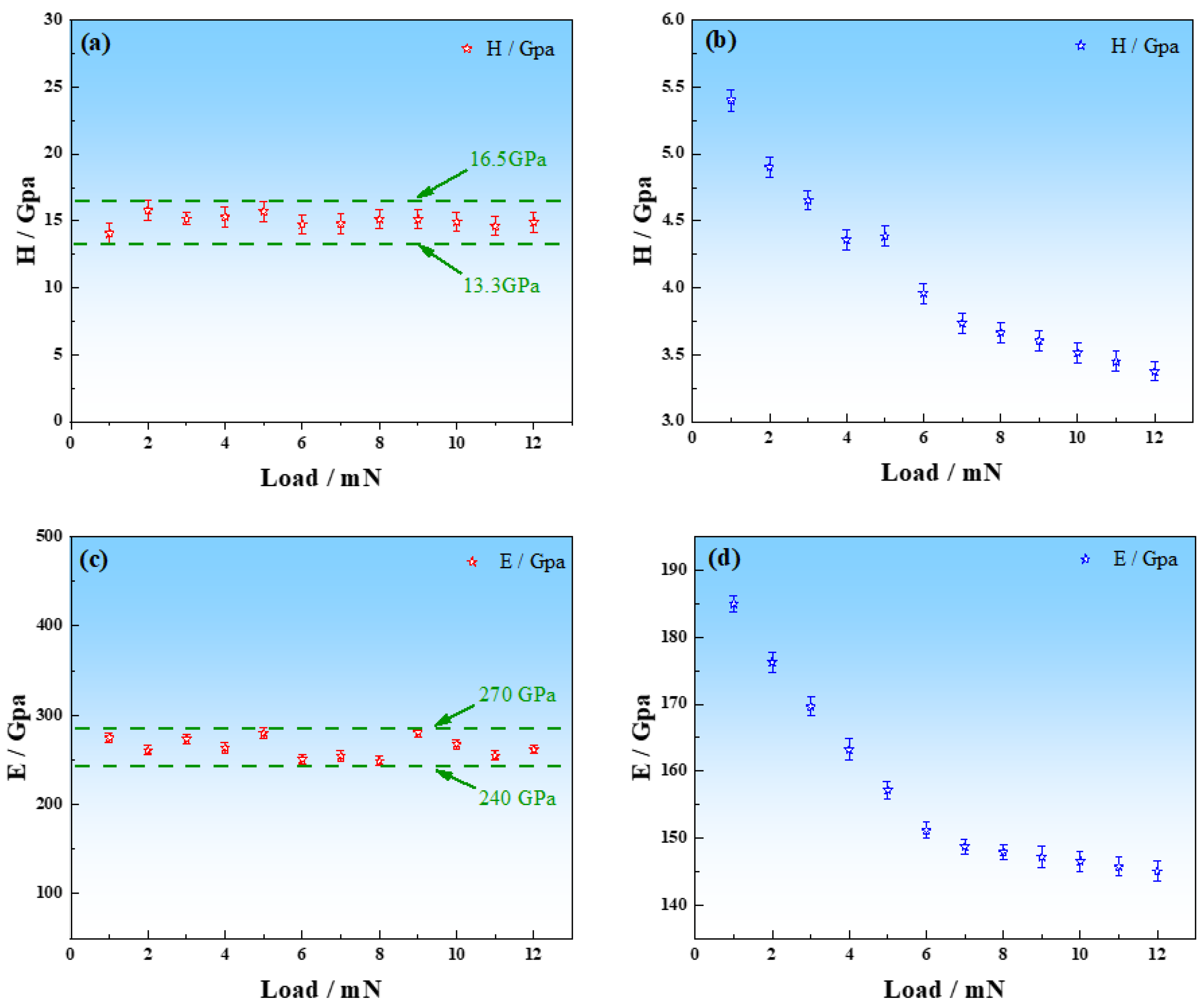

4.1. Credibility of Mechanical Properties Obtained by Nano-Indentation Test

4.2. Mechanical Properties’ Fluctuation of σ-Phase in the Nano-Indentation Test

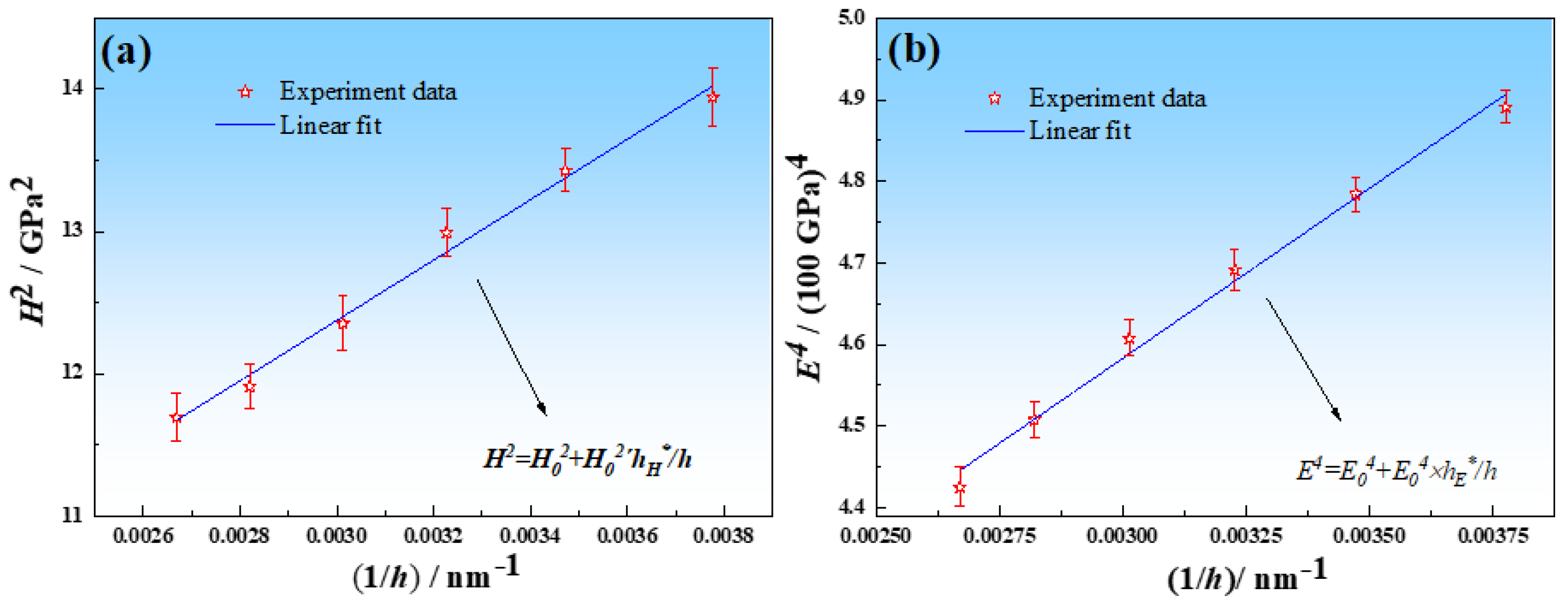

4.3. Analysis of Size Effect in Nano-Indentation

4.4. Effect of σ-Phase Precipitation on Mechanical Properties

5. Conclusions

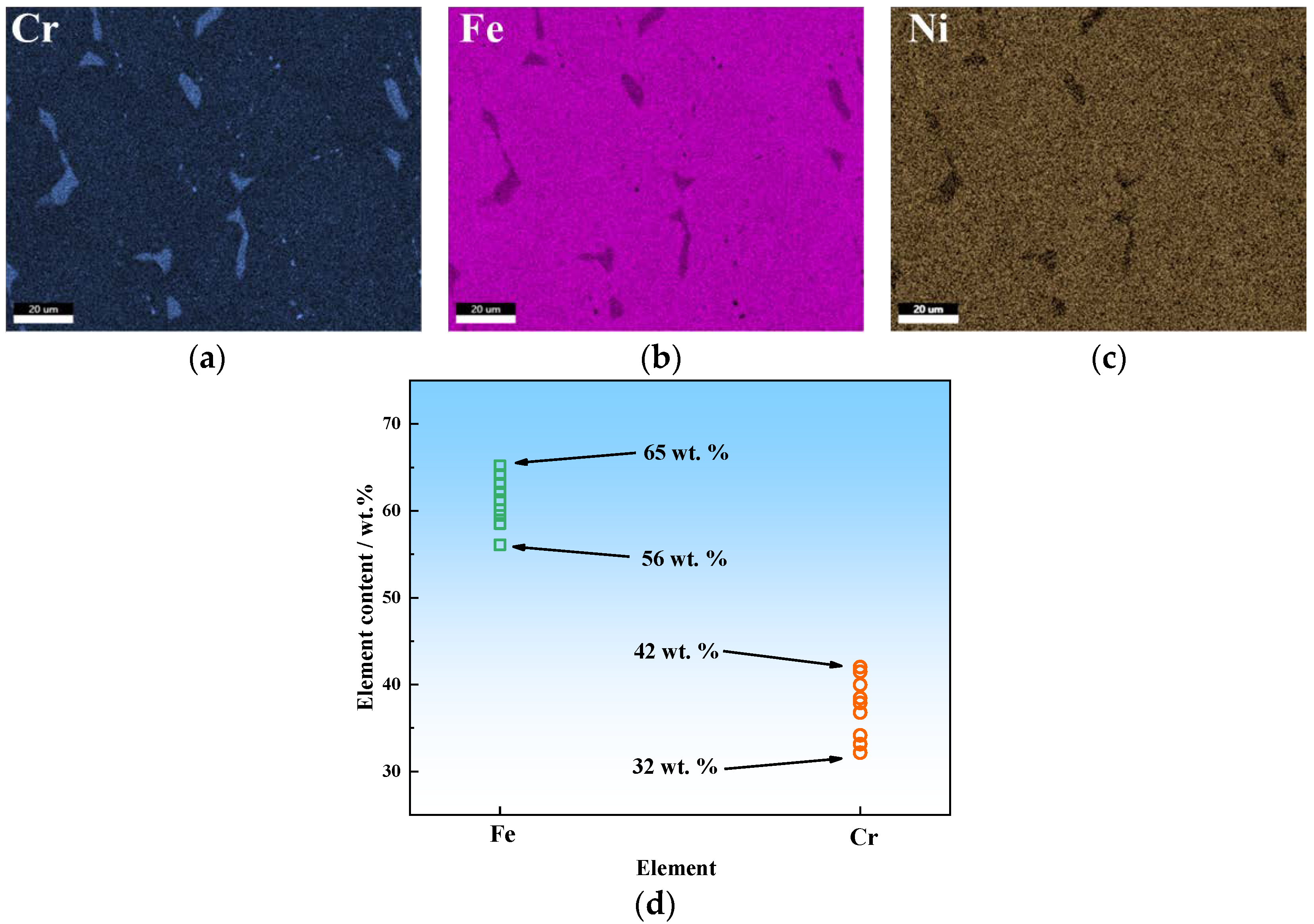

- σ-phase in 304H is a kind of Fe-Cr intermetallic. In different σ-phases, the Cr and Fe element content is not constant, but varies from ≈32 to 42 wt. % and ≈56 to 65 wt. %, respectively.

- Because of the high hardness of σ-phases (13.3 to 16.5 GPa), no obvious size effect is observed in the nano-indentation test of σ-phase. The average true hardness H0, elastic modulus E0, strain hardening exponent n, and yield strength σy of σ-phases are 14.95 GPa, 263 GPa, 0.78, and 2.42 GPa, respectively.

- Because of precipitation hardening effects, σ-phase leads to the improvement in Vickers hardness, yield strength, and tensile strength of 304H. However, the elongation and impact toughness of 304H are reduced greatly owing to the brittleness of σ-phase.

- According to this study, the nano-indentation test is a feasible method to study the mechanical properties of small-scale precipitates, such as σ-phase.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hsieh, C.C.; Wu, W. Overview of intermetallic sigma (σ) phase precipitation in stainless steels. Int. Sch. Res. Not. 2012, 2012, 732471. [Google Scholar] [CrossRef]

- Bergman, G.; Shoemaker, D.P. The determination of the crystal structure of the σ phase in the iron–chromium and iron–molybdenum systems. Acta Crystallogr. 1954, 7, 857–865. [Google Scholar] [CrossRef]

- Kasper, J.S.; Decker, B.F.; Belanger, J.R. The Crystal Structure of the Sigma-Phase in the Co-Cr System. J. Appl. Phys. 1951, 22, 361–362. [Google Scholar] [CrossRef]

- Berne, C.; Sluiter, M.; Kawazoe, Y.; Hansen, T.; Pasturel, A. Site occupancy in the Re-W sigma phase. Phys. Rev. B 2001, 64, 144103. [Google Scholar] [CrossRef]

- Silva, C.C.; Farias, J.P.; Miranda, H.C.; Guimaraes, R.F.; Menezes, J.W.; Neto, M.A. Microstructural characterization of the HAZ in AISI 444 ferritic stainless steel welds. Mater. Charact. 2008, 59, 528–533. [Google Scholar] [CrossRef]

- Park, C.J.; Ahn, M.K.; Kwon, H.S. Influences of Mo substitution by W on the precipitation kinetics of secondary phases and the associated localized corrosion and embrittlement in 29% Cr ferritic stainless steels. Mater. Sci. Eng. A 2006, 418, 211–217. [Google Scholar] [CrossRef]

- Park, S.H.C.; Sato, Y.S.; Kokawa, H.; Okamoto, K.; Inagaki, M. Rapid formation of the sigma phase in 304 stainless steel during friction stir welding. Scr. Mater. 2003, 49, 1175–1180. [Google Scholar] [CrossRef]

- Vach, M.; Kuníková, T.; Dománková, M.; Ševc, P.; Čaplovič, L.; Gogola, P.; Janovec, J. Evolution of secondary phases in austenitic stainless steels during long-term exposures at 600, 650 and 800 °C. Mater. Charact. 2008, 59, 1792–1798. [Google Scholar] [CrossRef]

- Sieurin, H.; Sandström, R. Sigma phase precipitation in duplex stainless steel 2205. Mater. Sci. Eng. A 2007, 444, 271–276. [Google Scholar] [CrossRef]

- Magnabosco, R. Kinetics of sigma phase formation in a duplex stainless steel. Mater. Res. 2009, 12, 321–327. [Google Scholar] [CrossRef]

- Chen, T.H.; Yang, J.R. Effects of solution treatment and continuous cooling on σ-phase precipitation in a 2205 duplex stainless steel. Mater. Sci. Eng. A 2001, 311, 28–41. [Google Scholar] [CrossRef]

- Duprez, L.; De Cooman, B.C.; Akdut, N. Redistribution of the substitutional elements during σ and χ phase formation in a duplex stainless steel. Steel Res. 2001, 72, 311–316. [Google Scholar] [CrossRef]

- Chiu, L.H.; Hsieh, W.C.; Wu, C.H. Cooling rate effect on vacuum brazed joint properties for 2205 duplex stainless steels. Mater. Sci. Eng. A 2003, 354, 82–91. [Google Scholar] [CrossRef]

- Chen, T.H.; Weng, K.L.; Yang, J.R. The effect of high-temperature exposure on the microstructural stability and toughness property in a 2205 duplex stainless steel. Mater. Sci. Eng. A 2002, 338, 259–270. [Google Scholar] [CrossRef]

- Bain, E.C.; Griffiths, W.E. An introduction to the iron-chromium-nickel alloys. Trans. Aime 1927, 75, 166–211. [Google Scholar]

- You, D.; Yang, G.; Choa, Y.H.; Kim, J.K. Crack-resistant σ/FCC interfaces in the Fe40Mn40Co10Cr10 high entropy alloy with the dispersed σ-phase. Mater. Sci. Eng. A 2022, 831, 142039. [Google Scholar] [CrossRef]

- Minami, Y.; Kimura, H.; Ihara, Y. Microstructural changes in austenitic stainless steels during long-term aging. Mater. Sci. Technol. 1986, 2, 795–806. [Google Scholar] [CrossRef]

- Kington, A.V.; Noble, F.W. σ phase embrittlement of a type 310 stainless steel. Mater. Sci. Eng. A 1991, 138, 259–266. [Google Scholar] [CrossRef]

- Acevedo, F.; Sáenz, L. Estudio de la fragilización de un acero inoxidable austenítico AISI 304h con 15 años de servicio expuesto a elevada temperatura. DYNA-Ing. E Ind. 2018, 93, 428–434. [Google Scholar] [CrossRef] [Green Version]

- Morris, D. The influence of sigma phase on creep ductility in type 316 stainless steel. Scr. Metall. 1979, 13, 1195–1196. [Google Scholar] [CrossRef]

- Babakr, A.M.; Al-Ahmari, A.; Al-Jumayiah, K.; Habiby, F. Sigma phase formation and embrittlement of cast iron-chromium-nickel (Fe-Cr-Ni) alloys. J. Miner. Mater. Charact. Eng. 2008, 7, 127. [Google Scholar] [CrossRef]

- Liu, F.; Hwang, Y.H.; Nam, S.W. Precipitation of σ-phase and creep-fatigue behavior of 308L steel weldment. Mater. Sci. Eng. A 2008, 483, 418–421. [Google Scholar] [CrossRef]

- Conejero, O.; Palacios, M.; Rivera, S. Premature corrosion failure of a 316L stainless steel plate due to the presence of sigma phase. Eng. Fail. Anal. 2009, 16, 699–704. [Google Scholar] [CrossRef]

- Perren, R.; Suter, T.; Uggowitzer, P.; Weber, L.; Magdowski, R.; Böhni, H.; Speidel, M. Corrosion resistance of super duplex stainless steels in chloride ion containing environments: Investigations by means of a new microelectrochemical method: I. Precipitation-free states. Corros. Sci. 2001, 43, 707–726. [Google Scholar] [CrossRef]

- Saida, K. Prediction of sigma-phase embrittlement and its influence on repair weldability for type 316FR stainless steel weld metals with different solidification modes. J. Nucl. Mater. 2018, 505, 212–226. [Google Scholar] [CrossRef]

- Kumar, S.; Krisam, S.; Jacob, A.; Kiraly, F.; Keplinger, A.; Abart, R.; Povoden-Karadeniz, E. Microstructures and element distributions in an aged hyper duplex stainless steel and corresponding hardness variation. Mater. Des. 2020, 194, 108951. [Google Scholar] [CrossRef]

- Ohmura, T.; Tsuzaki, K.; Sawada, K.; Kimura, K. Inhomogeneous nano-mechanical properties in the multi-phase microstructure of long-term aged type 316 stainless steel. J. Mater. Res. 2006, 21, 1229–1236. [Google Scholar] [CrossRef]

- Badji, R.; Cheniti, B.; Kahloun, C.; Chauveau, T.; Hadji, M.; Bacroix, B. Microstructure, mechanical behavior, and crystallographic texture in a hot forged dual-phase stainless steel. Int. J. Adv. Manuf. Technol. 2021, 116, 1115–1132. [Google Scholar] [CrossRef]

- ASTM A. 370; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM International: California, USA, 2017.

- Jiang, Y.; Li, Y.; Jia, Y.F.; Zhang, X.C.; Gong, J.M. Gradient elastic–plastic properties of expanded austenite layer in 316L stainless steel. Acta Metall. Sin. (Engl. Lett.) 2018, 31, 831–841. [Google Scholar] [CrossRef] [Green Version]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Schneider, C.; Fayette, L.; Zacharie-Aubrun, I.; Blay, T.; Sercombe, J.; Favergeon, J.; Chevalier, S. Study of the hardness and Young’s modulus at the fuel-cladding interface of a high-burnup PWR fuel rod by nanoindentation measurements. J. Nucl. Mater. 2022, 560, 153511. [Google Scholar] [CrossRef]

- Sadiq, M.; Lecomte, J.S.; Cherkaoui, M. Individual phase mechanical properties at different temperatures of Sn–Ag–Cu lead-free solders incorporating special pileup effects using nanoindentation. J. Electron. Packag. 2015, 137, 031005. [Google Scholar] [CrossRef]

- Swadener, J.G.; George, E.P.; Pharr, G.M. The correlation of the indentation size effect measured with indenters of various shapes. J. Mech. Phys. Solids 2002, 50, 681–694. [Google Scholar] [CrossRef]

- Ma, Z.S.; Zhou, Y.C.; Long, S.G.; Lu, S.C. An inverse approach for extracting elastic–plastic properties of thin films from small scale sharp indentation. J. Mater. Sci. Technol. 2012, 28, 626–635. [Google Scholar] [CrossRef]

- Xiao, X.; Terentyev, D.; Chen, Q.; Yu, L.; Chen, L. The depth dependent hardness of bicrystals with dislocation transmission through grain boundaries: A theoretical model. Int. J. Plast. 2017, 90, 212–230. [Google Scholar] [CrossRef]

- Cheng, Y.T.; Cheng, C.M. Relationships between hardness, elastic modulus, and the work of indentation. Appl. Phys. Lett. 1998, 73, 614–616. [Google Scholar] [CrossRef]

- Ma, Z.S. Characterization of Mechanical Properties of Metallic Film by Nanoindentation Method. Ph.D. Thesis, Xiangtan University, Xiangtan, China, 2011. [Google Scholar]

- Zhao, Y.R.; Wang, L.; Dong, Y.Y. Micromechanical Properties of Steel-Fiber-Reinforced Cementitious Composites Characterized with Nanoindentation. Adv. Civ. Eng. 2021, 2021, 6673283. [Google Scholar] [CrossRef]

- Wang, X.H.; Jacobsen, S.; He, J.Y.; Zhang, Z.L.; Lee, S.F.; Lein, H.L. Application of nanoindentation testing to study of the interfacial transition zone in steel fiber reinforced mortar. Cem. Concr. Res. 2009, 39, 701–715. [Google Scholar] [CrossRef]

- Xu, L.; Yu, H.; Chi, Y.; Deng, F.; Hu, J. Nano-indentation character of interfacial transition zone between steel fiber and cement paste. J. Chin. Ceram. Soc. 2016, 44, 1134–1146. [Google Scholar] [CrossRef]

- Giannakopoulos, A.E.; Suresh, S. Theory of indentation of piezoelectric materials. Acta Mater. 1999, 47, 2153–2164. [Google Scholar] [CrossRef]

- Xiao, G.; Ma, Y.; Ji, X.; Wang, T.; Shu, X.; Liu, E. Effective acquisition of elastoplastic and creep parameters of lead-free solder alloy from high-temperature micro-indentation eliminating the size effect. Mech. Mater. 2021, 160, 103985. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, F.; Hwang, K.C.; Nix, W.D.; Pharr, G.M.; Feng, G. A model of size effects in nano-indentation. J. Mech. Phys. Solids 2006, 54, 1668–1686. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Jiang, Y.; Wu, Q.; Li, Y.; Peng, Y.W.; Gong, J.M. Mechanical properties of low-temperature gaseous carburizated layer in 316L stainless steel based on nano-indentation and four-point bending tests. Surf. Coat. Technol. 2020, 387, 125501. [Google Scholar] [CrossRef]

- Fei, H.; Pan, B.; Zhang, C.; Jiang, Y.; Xu, Q.; Lu, Y.; Gong, J. Study on the mechanical properties gradient in surface oxygen diffusion hardened layer of Ti6Al4V alloy. J. Mater. Res. Technol. 2022, 18, 3173–3183. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Ding, Z.; Su, C.; Yan, T.; Song, Y.; Cheng, Y. A correlation between micro-and nano-indentation on materials irradiated by high-energy heavy ions. J. Nucl. Mater. 2018, 498, 129–136. [Google Scholar] [CrossRef]

- ISO 14577-1; Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1. International Organization for Standardization: Geneva, Switzerland, 2002.

- Zieliński, A.; Golański, G.; Sroka, M. Evolution of the microstructure and mechanical properties of HR3C austenitic stainless steel after ageing for up to 30,000 h at 650–750 °C. Mater. Sci. Eng. A 2020, 796, 139944. [Google Scholar] [CrossRef]

- Stelmashenko, N.A.; Walls, M.G.; Brown, L.M.; Milman, Y.V. STM study of micro-indentations on oriented metallic single crystals. In Mechanical Properties and Deformation Behavior of Materials Having Ultra-Fine Microstructures; Springer: Dordrecht, The Netherlands, 1993; pp. 605–610. [Google Scholar] [CrossRef]

- De Guzman, M.S.; Neubauer, G.; Flinn, P.; Nix, W.D. The Role of Indentation Depth on the Measured Hardness of Materials. MRS Online Proc. Libr. 1993, 308, 613–618. [Google Scholar] [CrossRef]

- Fleck, N.A.; Muller, G.M.; Ashby, M.F.; Hutchinson, J.W. Strain gradient plasticity: Theory and experiment. Acta Metall. Et Mater. 1994, 42, 475–487. [Google Scholar] [CrossRef]

- Tanaka, H.; Murata, M.; Abe, F.; Irie, H. Microstructural evolution and change in hardness in type 304H stainless steel during long-term creep. Mater. Sci. Eng. A 2001, 319, 788–791. [Google Scholar] [CrossRef]

- Zhang, L.; Huo, X.; Wang, A.; Du, X.H.; Zhang, L.; Li, W.P.; Zou, N.; Wan, G.; Duan, G.; Wu, B. A ductile high entropy alloy strengthened by nano sigma phase. Intermetallics 2020, 122, 106813. [Google Scholar] [CrossRef]

- Yamagishi, T.; Akita, M.; Nakajima, M.; Uematsu, Y.; Tokaji, K. Effect of σ-phase embrittlement on fatigue behaviour in high-chromium ferritic stainless steel. Procedia Eng. 2010, 2, 275–281. [Google Scholar] [CrossRef] [Green Version]

- Golański, G.; Lachowicz, M.M. Failure cause analysis for the suspension element of boiler superheater. Eng. Fail. Anal. 2019, 105, 490–495. [Google Scholar] [CrossRef]

- Ibrahim, O.H.; Ibrahim, I.S.; Khalifa, T.A.F. Effect of aging on the toughness of austenitic and duplex stainless steel weldments. J. Mater. Sci. Technol. 2010, 26, 810–816. [Google Scholar] [CrossRef]

- Guan, K.; Xu, X.; Xu, H.; Wang, Z.W. Effect of aging at 700 °C on precipitation and toughness of AISI 321 and AISI 347 austenitic stainless steel welds. Nucl. Eng. Des. 2005, 235, 2485–2494. [Google Scholar] [CrossRef]

- Hong, H.U.; Rho, B.S.; Nam, S.W. A study on the crack initiation and growth from δ-ferrite/γ phase interface under continuous fatigue and creep-fatigue conditions in type 304L stainless steels. Int. J. Fatigue 2002, 24, 1063–1070. [Google Scholar] [CrossRef]

- Rho, B.S.; Hong, H.U.; Nam, S.W. The effect of δ-ferrite on fatigue cracks in 304L steels. Int. J. Fatigue 2000, 22, 683–690. [Google Scholar] [CrossRef]

- Curry, D.A.; Knott, J.F. Effect of microstructure on cleavage fracture toughness of quenched and tempered steels. Met. Sci. 1979, 13, 341–345. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, N.; Li, D.; Zhang, J.; Luo, Y.; Zhang, R. Effect of microstructure evolution on strength and impact toughness of G18CrMo2-6 heat-resistant steel during tempering. Mater. Sci. Eng. A 2014, 604, 103–110. [Google Scholar] [CrossRef]

- Curry, D.A.; Knott, J.F. Effects of microstructure on cleavage fracture stress in steel. Met. Sci. 1978, 12, 511–514. [Google Scholar] [CrossRef]

- Pohl, M.; Storz, O.; Glogowski, T. σ-phase morphologies and their effect on mechanical properties of duplex stainless steels. Int. J. Mater. Res. 2008, 99, 1163–1170. [Google Scholar] [CrossRef]

| Material | Yield Strength (σ0.2)/MPa | Tensile Strength (σs)/MPa | Elongation (δ)/% | Young’s Modulus (E) GPa | Impact Energy (Akv)/J | Hardness (HV200) |

|---|---|---|---|---|---|---|

| Average | 320 ± 5 | 710 ± 8 | 39 ± 2 | 160 ± 10 | 25 ± 3 | 245 ± 12 |

| Data on warranty | 280 | 620 | 59 | - | 258 | 190 (HB180) |

| ASME A213 standard | ≥220 | ≥520 | ≥35 | - | - | ≤200 |

| σ-Phase | Pmax/μN | 7000 | 8000 | 9000 | 10,000 | 11,000 | 12,000 |

| σy/MPa | 2.96 | 2.63 | 2.1 | 2.26 | 2.67 | 1.88 | |

| n | 0.57 | 0.67 | 0.75 | 0.74 | 0.64 | 0.87 | |

| Austenite | Pmax/μN | 7000 | 8000 | 9000 | 10,000 | 11,000 | 12,000 |

| σy/GPa | 575.31 | 559.26 | 543.57 | 519.59 | 500.47 | 495.02 | |

| n | 0.36 | 0.37 | 0.36 | 0.36 | 0.37 | 0.37 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, P.; Xie, J.; Jiang, Y.; Tang, P.; Liang, B.; Lu, Y.; Gong, J. Mechanical Properties of σ-Phase and Its Effect on the Mechanical Properties of Austenitic Stainless Steel. Coatings 2022, 12, 1917. https://doi.org/10.3390/coatings12121917

Qiao P, Xie J, Jiang Y, Tang P, Liang B, Lu Y, Gong J. Mechanical Properties of σ-Phase and Its Effect on the Mechanical Properties of Austenitic Stainless Steel. Coatings. 2022; 12(12):1917. https://doi.org/10.3390/coatings12121917

Chicago/Turabian StyleQiao, Peiheng, Jinyang Xie, Yong Jiang, Pengjie Tang, Bin Liang, Yilan Lu, and Jianming Gong. 2022. "Mechanical Properties of σ-Phase and Its Effect on the Mechanical Properties of Austenitic Stainless Steel" Coatings 12, no. 12: 1917. https://doi.org/10.3390/coatings12121917

APA StyleQiao, P., Xie, J., Jiang, Y., Tang, P., Liang, B., Lu, Y., & Gong, J. (2022). Mechanical Properties of σ-Phase and Its Effect on the Mechanical Properties of Austenitic Stainless Steel. Coatings, 12(12), 1917. https://doi.org/10.3390/coatings12121917