Surface Modification and Parametric Optimization of Tensile Strength of Al6082/SiC/Waste Material Surface Composite Produced by Friction Stir Processing

Abstract

:1. Introduction

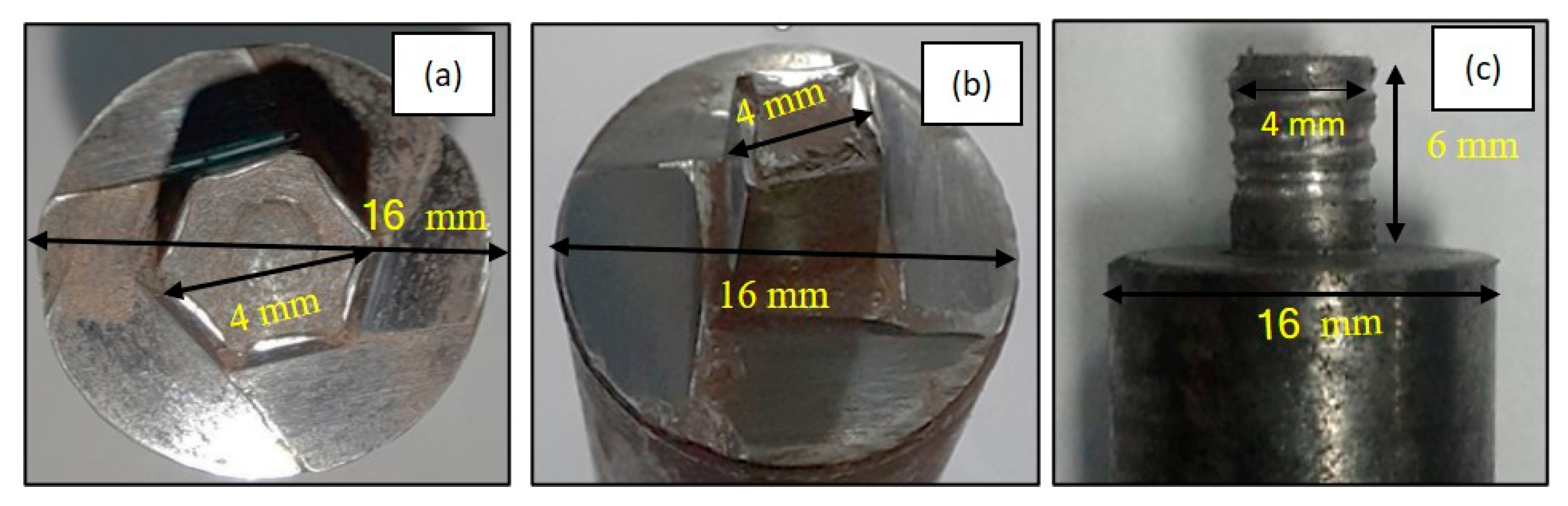

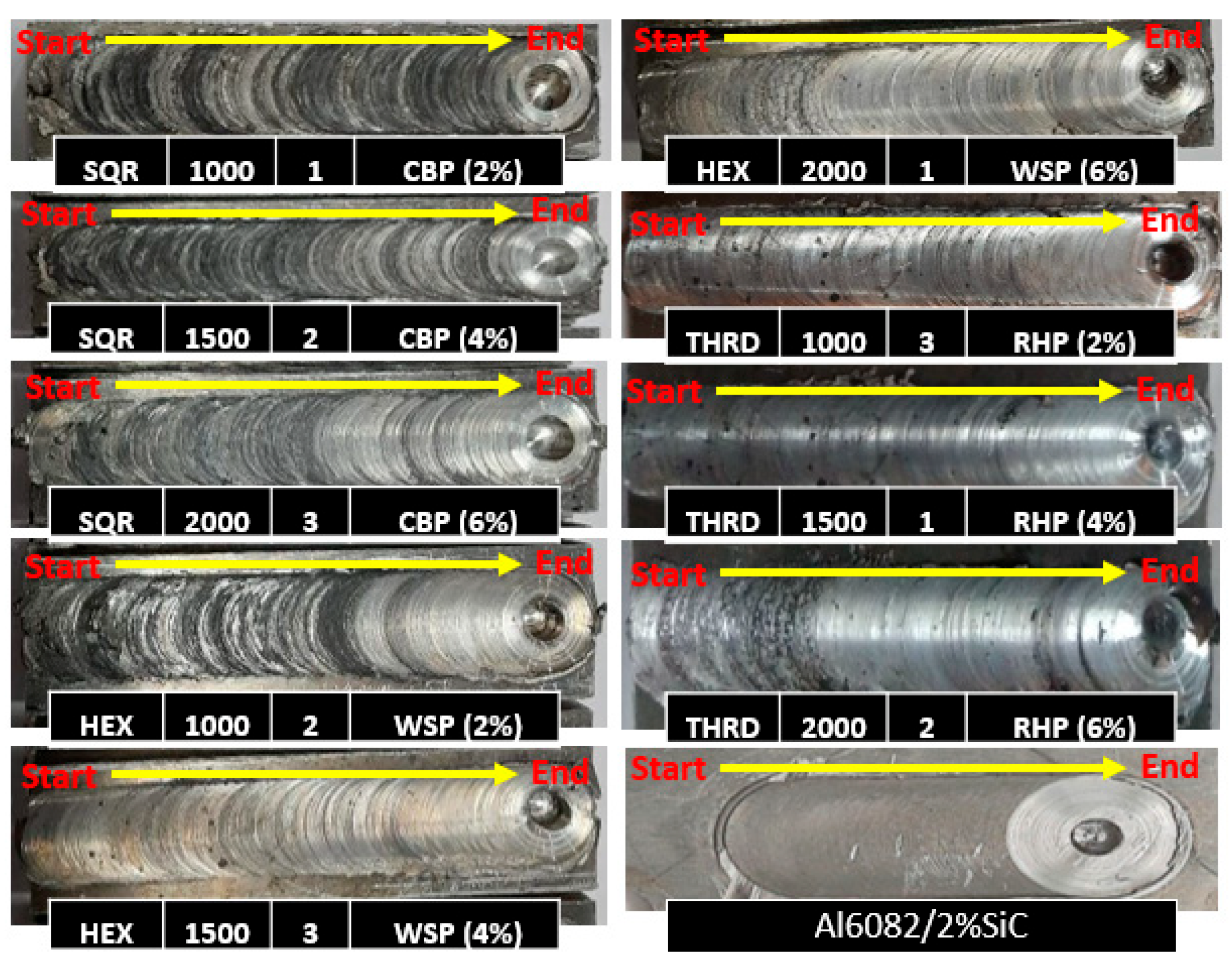

2. Experimental Procedure

3. Result and Discussion

4. Conclusions

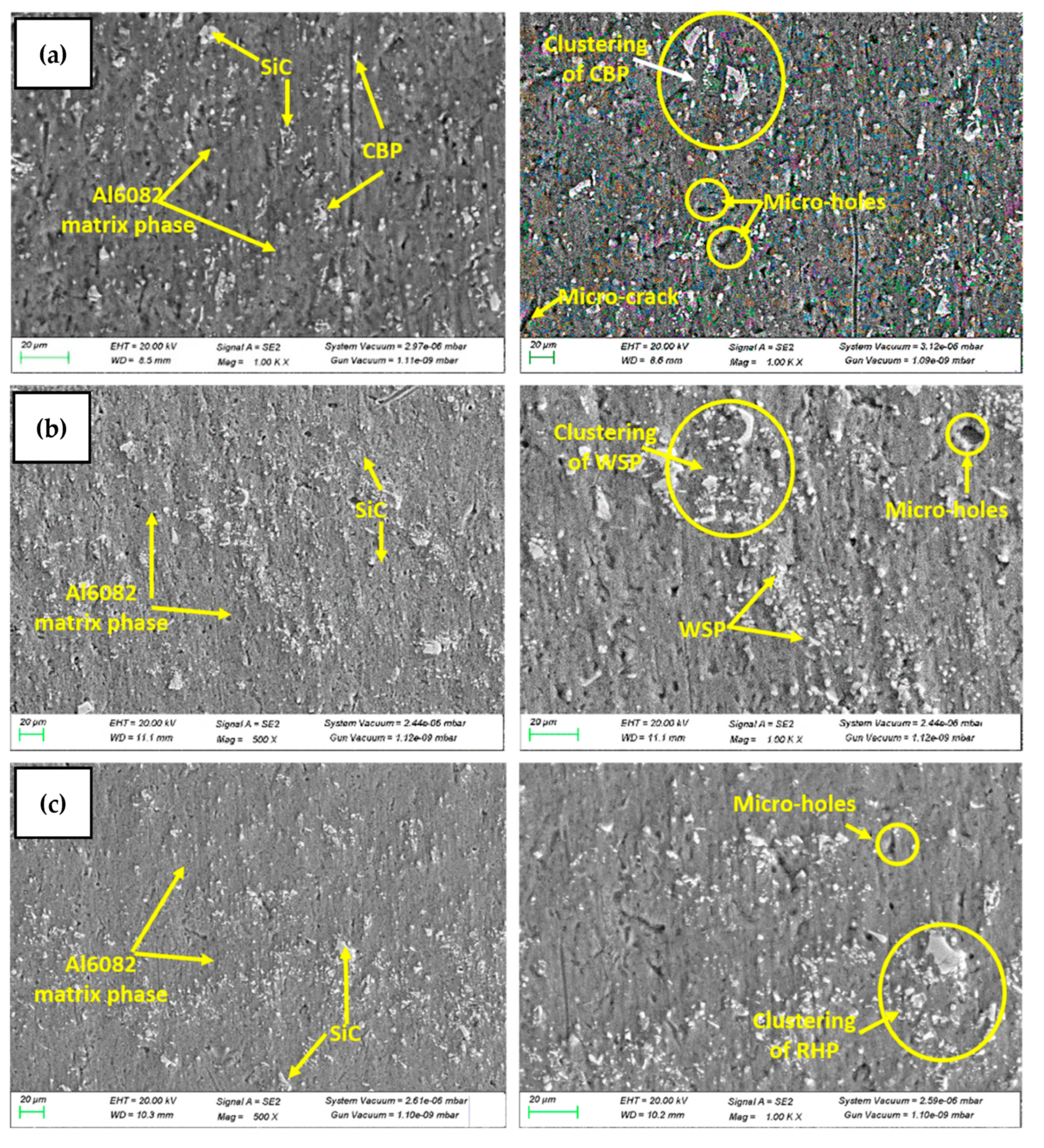

- FESEM images show the uniform distribution of both SiC and secondary reinforcement CBP, WSP, and RHP into the stir zone of the matrix material. The average grain size of the developed specimens varies in the range of 20 to 35 µm for all three types of composites. The minimum grain size of 6 µm is observed for Al6082/2%SiC/2%WSP.

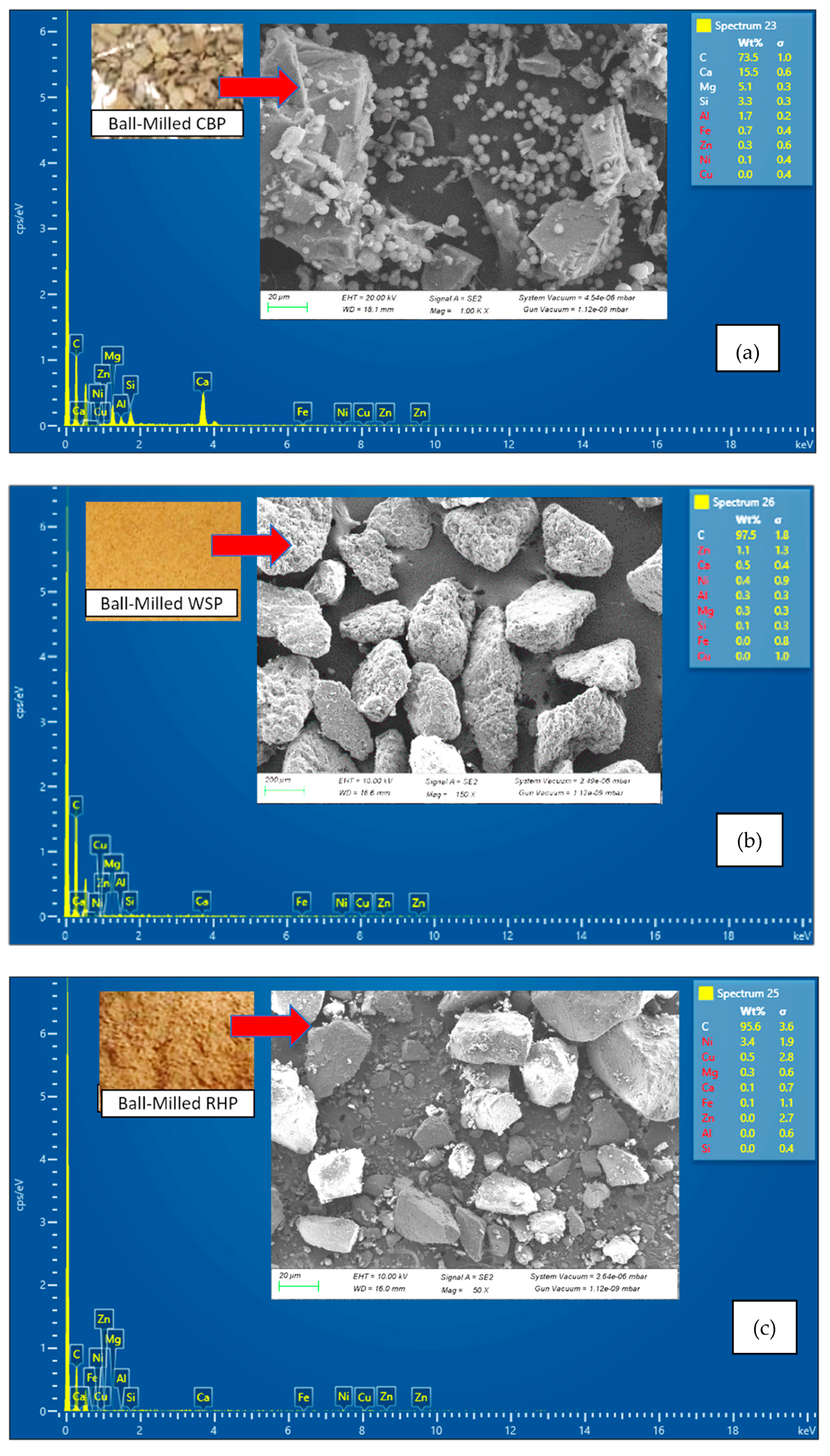

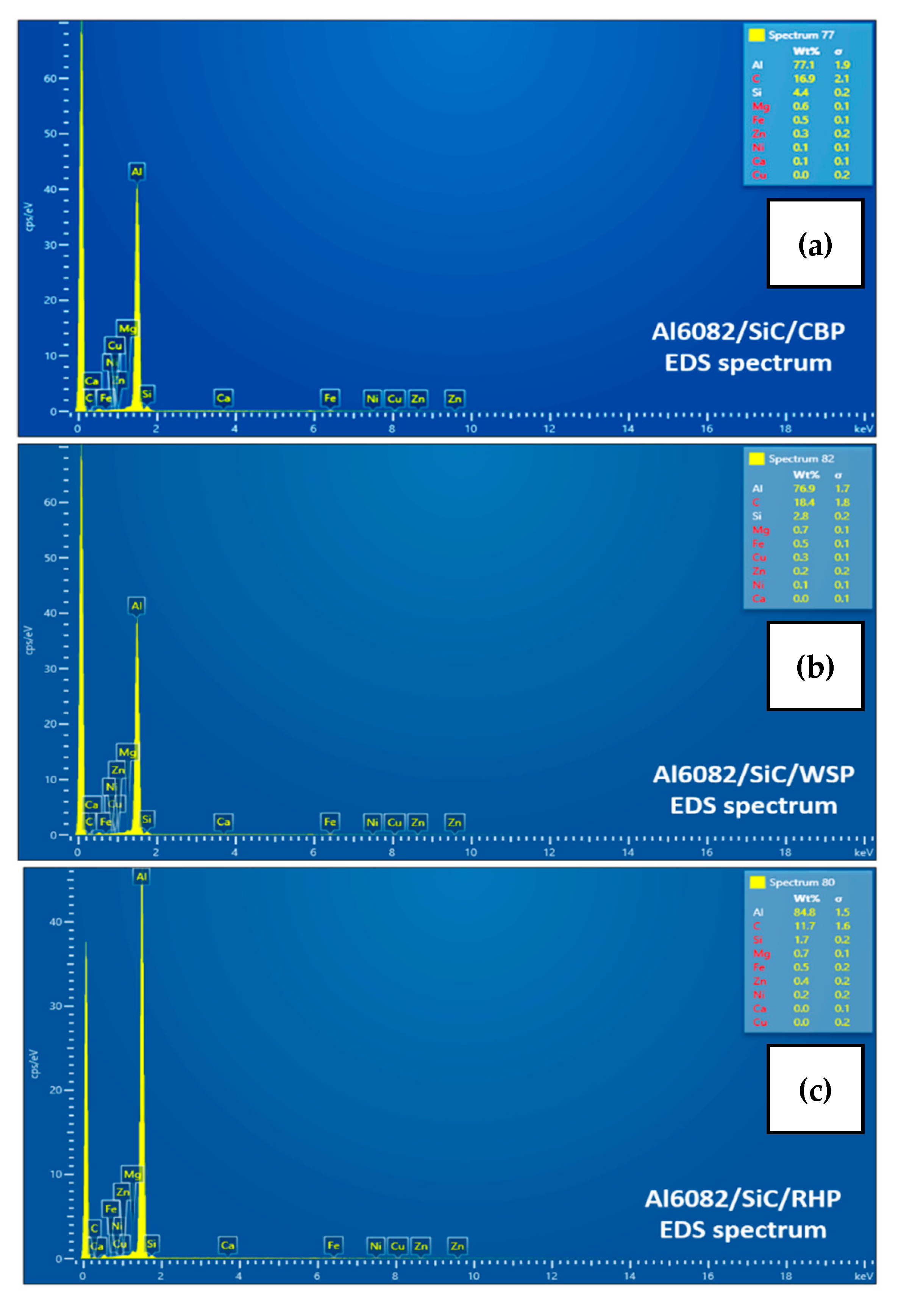

- Phase mapping and EDS spectrum of the developed Al6082/2% SiC/2% (CBP/WSP/RHP) show the presence of major constituents of the matrix and alloy phase. It is evident from the study that the reinforcement phase is completely diffused into the matrix material.

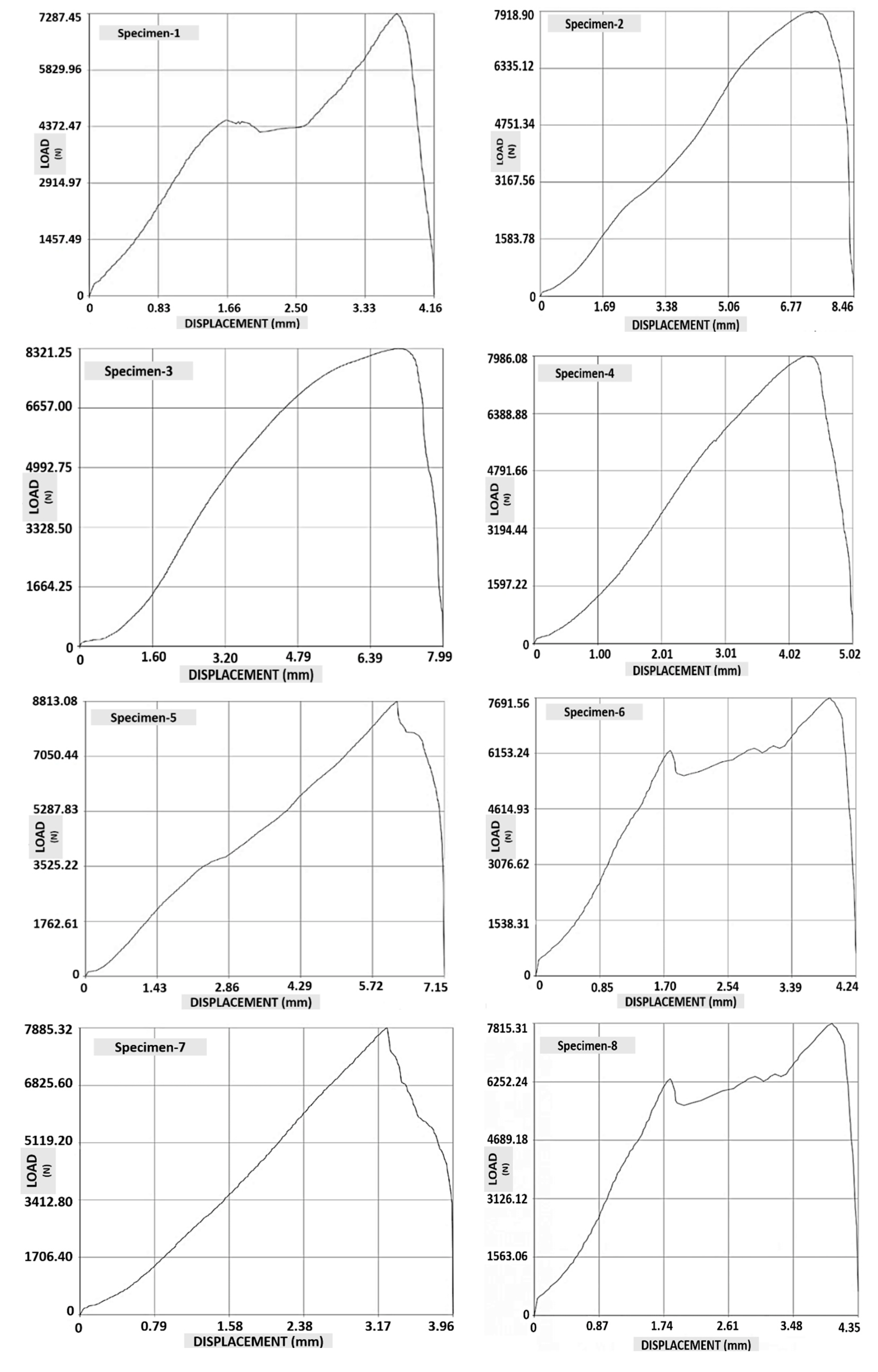

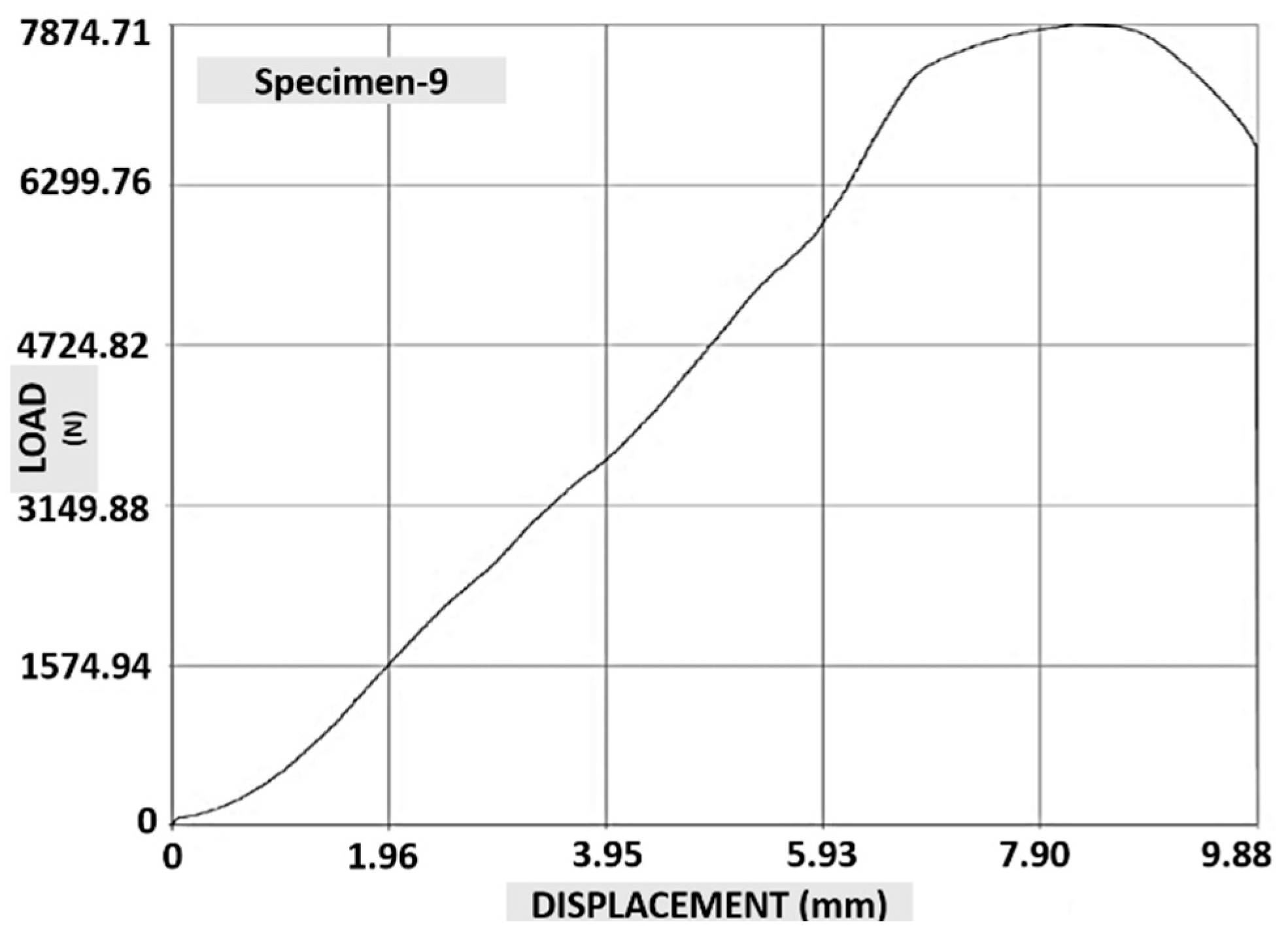

- As an outcome, the tensile strength of each specimen has been evaluated and found significant increment of around 20% to 35% of tensile strength compared to base alloy Al6082.

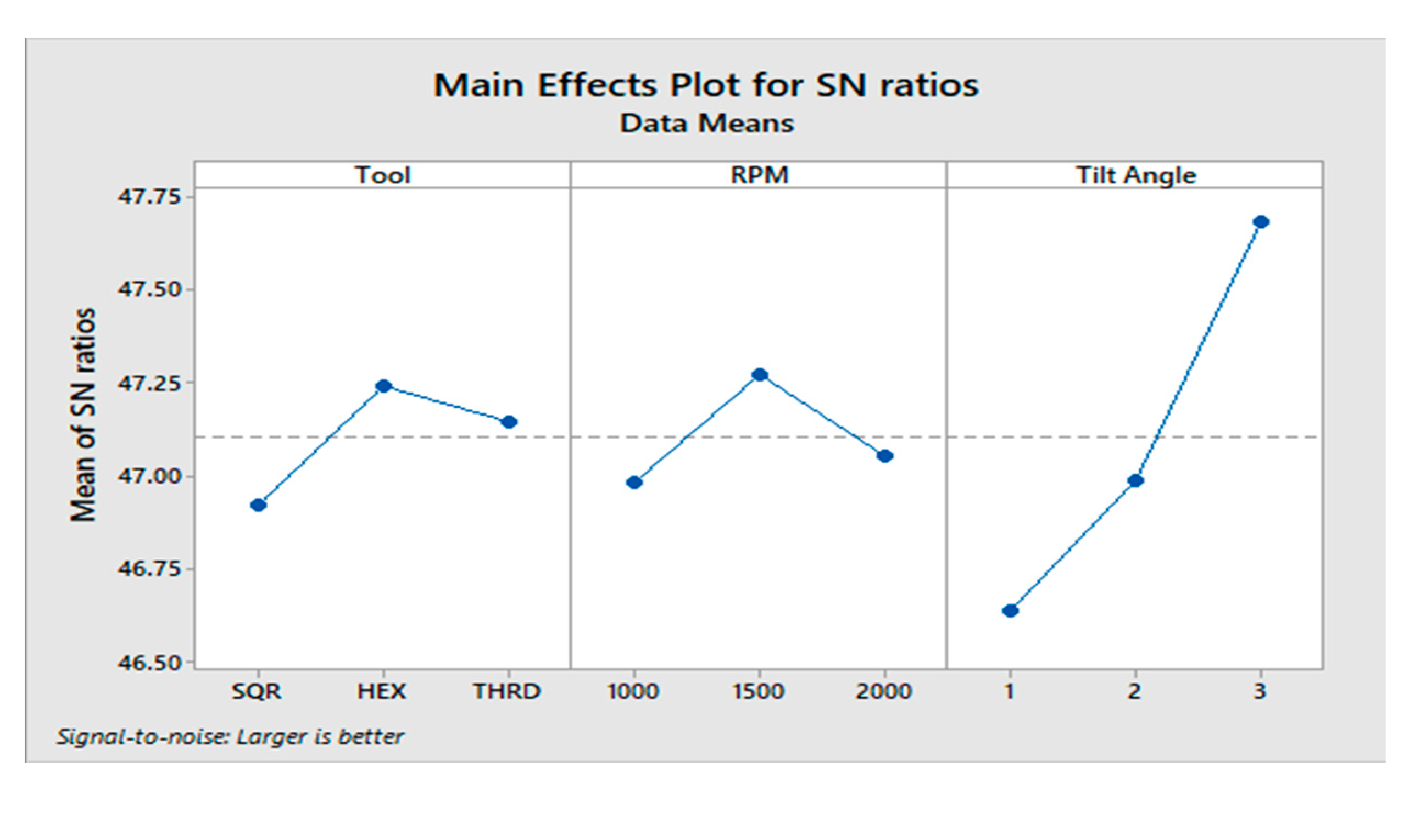

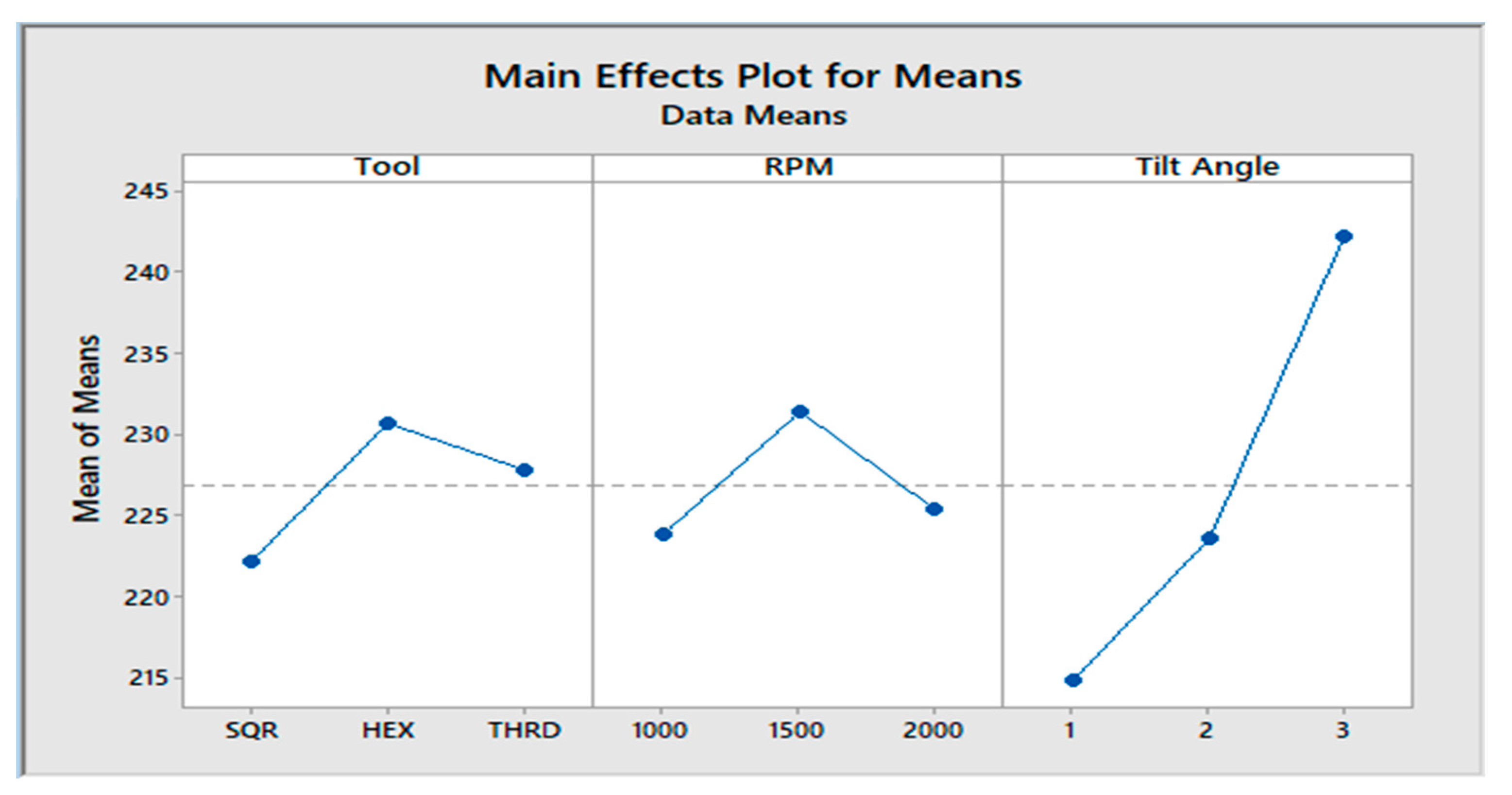

- Taguchi’s L9 optimization approach and ANOVA response show the significance of the rotational speed and tool tilt angle and selected tool pin profile. It is concluded from the study that the tensile strength of processed samples is increased with using the hexagonal pin profile tool due to better stirring action as a result proper material flow takes place.

- Tool tilt angle also plays a vital role in increasing tensile strength. These values are increased after increasing the tilt angle. It is attributed to the thrusting effect and also due to contact between the shoulder and workpiece.

- The optimized value for tensile strength is in the range of (247.32–253.96) MPa with a hexagonal (HEX) tool pin profile, 1500 rpm, and 3° tilt angle.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Srivastava, A.K.; Dixit, A.R.; Maurya, M.; Saxena, A.; Maurya, N.K.; Dwivedi, S.P.; Bajaj, R. 20th century uninterrupted growth in friction stir processing of lightweight composites and alloys. Mater. Chem. Phys. 2021, 266, 124572. [Google Scholar] [CrossRef]

- Dwivedi, R.; Singh, R.K.; Kumar, S.; Srivastva, A.K. Parametric optimization of process parameters during the friction stir processing of Al7075/SiC/waste eggshell composite. Mater. Today Proc. 2021, 47, 3884–3890. [Google Scholar] [CrossRef]

- Kumar, S.; Srivastava, A.K.; Singh, R.K. Fabrication of AA7075 hybrid green metal matrix composites by friction stir processing technique. Ann. Chim.-Sci. MatÉRiaux 2020, 44, 295–300. [Google Scholar] [CrossRef]

- Ma, Z.Y. Friction stir processing technology: A review. Metall. Mater. Trans. A 2008, 39, 642–658. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Maurya, N.K.; Dixit, A.R.; Dwivedi, S.P.; Saxena, A.; Maurya, M. Experimental investigation of A359/Si3N4 composite produced by multi-pass friction stir processing. Mater. Chem. Phys. 2021, 257, 123717. [Google Scholar] [CrossRef]

- Kumar, S.; Srivastava, A.K.; Singh, R.K.; Dwivedi, S.P. Experimental study on hardness and fatigue behavior in joining of AA5083 and AA6063 by friction stir welding. Mater. Today Proc. 2020, 25, 646–648. [Google Scholar] [CrossRef]

- Rathee, S.; Maheshwari, S.; Siddiquee, A.N.; Srivastava, M. Investigating the effects of SiC particle sizes on the microstructural and mechanical properties of AA5059/SiC composites during multi pass FSP. Silicon 2019, 11, 797–805. [Google Scholar] [CrossRef]

- Dwivedi, R.; Kumar Singh, R.; Kumar Srivastava, A.; Anand, A.; Kumar, S.; Pal, A. Statistical optimization of process parameters during the friction stir processing of Al7075/Al2O3/waste eggshell surface composite. In Recent Trends in Industrial and Production Engineering; Lecture Notes in Mechanical Engineering, Dvivedi, A., Sachdeva, A., Sindhwani, R., Sahu, R., Eds.; Springer: Singapore, Singapore, 2022. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Saxena, A.; Dixit, A.R. Investigation on the thermal behaviour of AZ31B/waste eggshell composites produced by friction stir processing. Compos. Commun. 2021, 28, 100912. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Kumar, N.; Dixit, A.R. Friction stir additive manufacturing—An innovative tool to enhance mechanical and microstructural properties. Mater. Sci. Eng. B 2021, 263, 114832. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Kumar, N.; Saxena, A.; Tiwari, S. Effect of friction stir processing on microstructural and mechanical properties of lightweight composites and cast metal alloys—A review. Int. J. Cast Met. Res. 2021, 34, 169–195. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Maurya, M.; Saxena, A.; Maurya, N.K.; Dwivedi, S.P.; Dixit, A.R. Microstructural and fractographic analysis of A359/Si3N4 composite produced by friction stir processing. Int. J. Mater. Res. 2021, 112, 68–77. [Google Scholar] [CrossRef]

- Pei, J.; Wu, Z.; Hu, Y.; Fu, X.; Wang, J.; Song, X.; Sun, Z.; Wang, M. Molecular dynamic simulations and experimental study on pBAMO-b-GAP copolymer/energetic plasticizer mixed systems. FirePhysChem 2022, 2, 67–71. [Google Scholar] [CrossRef]

- Rathee, S.; Maheshwari, S.; Siddiquee, A.N.; Srivastava, M.; Sharma, S.K. Process parameters optimization for enhanced microhardness of AA 6061/ SiC surface composites fabricated via Friction Stir Processing (FSP). Mater. Today: Proc. 2016, 3, 4151–4156. [Google Scholar] [CrossRef]

- Awasthi, S.; Gupta, P.; Pachuri, P.; Tyagi, M. Optimization of magnesium ZK60A/SiC/B4C hybrid composite fabricated by friction stir processing. Mater. Today Proc. 2022, 62, 191–197. [Google Scholar] [CrossRef]

- Taghiabadi, R.; Moharami, A. Mechanical properties enhancement of Mg–4Si in-situ composites by friction stir processing. Mater. Sci. Technol. 2021, 37, 66–77. [Google Scholar] [CrossRef]

- Moharami, A.; Razaghian, A. Corrosion behaviour of friction stir processed Al–Mg2Si composites. Mater. Sci. Technol. 2020, 36, 1922–1929. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Dwivedi, S.; Saxena, A.; Kumar, D.; Dixit, A.R.; Singh, G.K.; Bhutto, J.K.; Verma, R. Tribological characteristics of Al359/Si3N4/eggshell surface composite produced by friction stir processing. Coatings 2022, 12, 1362. [Google Scholar] [CrossRef]

- Dwivedi, R.; Srivastava, A.K.; Singh, R.K. Effect of eggshell waste and B4C particles on the mechanical and tribological properties of Al7075 alloy developed by friction stir processing. Metall. Res. Technol. 2022, 119, 508. [Google Scholar] [CrossRef]

| Elements | Aluminum (Al) | Silicon (Si) | Magnesium (Mg) | Manganese (Mn) | Iron (Fe) | Chromium (Cr) | Zinc (Zn) | Titanium (Ti) | Copper (Cu) |

|---|---|---|---|---|---|---|---|---|---|

| wt. % | 95.2 | 1.3 | 1.2 | 1.0 | 0.5 | 0.25 | 0.2 | 0.1 | 0.1 |

| Mechanical Properties | Values |

|---|---|

| Tensile Strength | 180 MPa |

| Hardness Value (BHN) | 49 BHN |

| Levels | 1 | 2 | 3 | |

|---|---|---|---|---|

| Factors | ||||

| Tool | SQR | HEX | THRD | |

| Tool Rotation Speed (RPM) | 1000 | 1500 | 2000 | |

| Tilt Angle (°) | 1 | 2 | 3 | |

| Secondary Reinforcement | CBP | WSP | RHP | |

| % of Secondary Reinforcement (%) | 2 | 4 | 6 | |

| Experimental Run | Tool Pin Profile | Tool Rotation Speed (RPM) | Tool Tilt Angle (°) | Hybrid Reinforcement (By Wt.%) SiC (2%) + |

|---|---|---|---|---|

| 1 | SQR | 1000 | 1 | CBP (2%) |

| 2 | SQR | 1500 | 2 | CBP (4%) |

| 3 | SQR | 2000 | 3 | CBP (6%) |

| 4 | HEX | 1000 | 2 | WSP (2%) |

| 5 | HEX | 1500 | 3 | WSP (4%) |

| 6 | HEX | 2000 | 1 | WSP (6%) |

| 7 | THRD | 1000 | 3 | RHP (2%) |

| 8 | THRD | 1500 | 1 | RHP (4%) |

| 9 | THRD | 2000 | 2 | RHP (6%) |

| Experimental Run | Tool Pin Profile | Rotation Speed (RPM) | Tilt Angle (°) | Tensile Strength (Avg. of 3 Readings) (MPa) |

|---|---|---|---|---|

| 1 | SQR | 1000 | 1 | 206.55 ± 2 |

| 2 | SQR | 1500 | 2 | 223.34 ± 7 |

| 3 | SQR | 2000 | 3 | 236.62 ± 5 |

| 4 | HEX | 1000 | 2 | 224.98 ± 4 |

| 5 | HEX | 1500 | 3 | 249.91 ± 3 |

| 6 | HEX | 2000 | 1 | 217.07 ± 6 |

| 7 | THRD | 1000 | 3 | 240.09 ± 5 |

| 8 | THRD | 1500 | 1 | 220.81 ± 4 |

| 9 | THRD | 2000 | 2 | 222.09 ± 10 |

| Mean | 226.83 ± 5 |

| Term | Coef | SE Coef | T | p |

|---|---|---|---|---|

| Constant | 47.1028 | 0.01954 | 2410.254 | 0.000 |

| Tool SQR | −0.1825 | 0.02764 | −6.603 | 0.022 |

| Tool HEX | 0.1407 | 0.02764 | 5.092 | 0.036 |

| RPM 1000 | −0.1192 | 0.02764 | −4.312 | 0.050 |

| RPM 1500 | 0.1690 | 0.02764 | 6.115 | 0.026 |

| Tilt Ang 1 | −0.4652 | 0.02764 | −16.831 | 0.004 |

| Tilt Ang 2 S = 0.5863 | −0.1134 R-Sq = 99.7% | 0.02764 R-Sq(adj) = 98.6% | −4.105 | 0.055 |

| Term | Coef | SE Coef | T | p |

|---|---|---|---|---|

| Constant | 226.872 | 0.3345 | 678.311 | 0.000 |

| Tool SQR | −4.702 | 0.4730 | −9.941 | 0.010 |

| Tool HEX | 3.781 | 0.4730 | 7.944 | 0.015 |

| RPM 1000 | −2.999 | 0.4730 | −6.340 | 0.024 |

| RPM 1500 | 4.481 | 0.4730 | 9.474 | 0.011 |

| Tilt Ang 1 | −12.062 | 0.4730 | −25.501 | 0.002 |

| Tilt Ang 2 S = 1.003 | −3.272 R-Sq = 99.9% | 0.4730 R-Sq(adj) = 99.4% | −6.918 | 0.020 |

| Source | DF | Seq SS | Adj SS | Adj MS | F | p | PC (%) |

|---|---|---|---|---|---|---|---|

| Tool | 2 | 0.16457 | 0.16457 | 0.082283 | 23.94 | 0.040 | 8.23 |

| RPM | 2 | 0.13574 | 0.13574 | 0.067871 | 19.75 | 0.048 | 6.79 |

| Tilt Angle | 2 | 1.69210 | 1.69210 | 0.846048 | 246.14 | 0.004 | 84.64 |

| Residual Error | 2 | 0.00687 | 0.00687 | 0.003437 | |||

| Total | 8 | 1.99928 |

| Source | DF | Seq SS | Adj SS | Adj MS | F | p | PC (%) |

|---|---|---|---|---|---|---|---|

| Tool | 2 | 111.77 | 111.77 | 55.884 | 55.51 | 0.018 | 8.09 |

| RPM | 2 | 93.81 | 93.81 | 46.906 | 46.59 | 0.021 | 6.79 |

| Tilt Angle | 2 | 1174.05 | 1174.05 | 587.025 | 583.05 | 0.002 | 84.97 |

| Residual Error | 2 | 2.01 | 2.01 | 1.007 | |||

| Total | 8 | 1381.64 |

| Level | Tool | RPM | Tilt Angle |

|---|---|---|---|

| 1 | 46.92 | 46.98 | 46.64 |

| 2 | 47.24 | 47.27 | 46.98 |

| 3 | 47.14 | 47.05 | 47.68 |

| Delta | 0.32 | 0.29 | 1.04 |

| Rank | 2 | 3 | 1 |

| Larger is better |

| Level | Tool | RPM | Tilt Angle |

|---|---|---|---|

| 1 | 222.2 | 223.9 | 214.8 |

| 2 | 230.7 | 231.4 | 223.5 |

| 3 | 227.7 | 225.3 | 242.2 |

| Delta | 8.5 | 7.5 | 27.4 |

| Rank | 2 | 3 | 1 |

| Larger is better |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, N.; Singh, R.K.; Srivastava, A.K.; Nag, A.; Petru, J.; Hloch, S. Surface Modification and Parametric Optimization of Tensile Strength of Al6082/SiC/Waste Material Surface Composite Produced by Friction Stir Processing. Coatings 2022, 12, 1909. https://doi.org/10.3390/coatings12121909

Kumar N, Singh RK, Srivastava AK, Nag A, Petru J, Hloch S. Surface Modification and Parametric Optimization of Tensile Strength of Al6082/SiC/Waste Material Surface Composite Produced by Friction Stir Processing. Coatings. 2022; 12(12):1909. https://doi.org/10.3390/coatings12121909

Chicago/Turabian StyleKumar, Nitesh, Rakesh Kumar Singh, Ashish Kumar Srivastava, Akash Nag, Jana Petru, and Sergej Hloch. 2022. "Surface Modification and Parametric Optimization of Tensile Strength of Al6082/SiC/Waste Material Surface Composite Produced by Friction Stir Processing" Coatings 12, no. 12: 1909. https://doi.org/10.3390/coatings12121909

APA StyleKumar, N., Singh, R. K., Srivastava, A. K., Nag, A., Petru, J., & Hloch, S. (2022). Surface Modification and Parametric Optimization of Tensile Strength of Al6082/SiC/Waste Material Surface Composite Produced by Friction Stir Processing. Coatings, 12(12), 1909. https://doi.org/10.3390/coatings12121909