Effect of TiC Content and TaC Addition in Substrates on Properties and Wear Behavior of TiAlN-Coated Tools

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

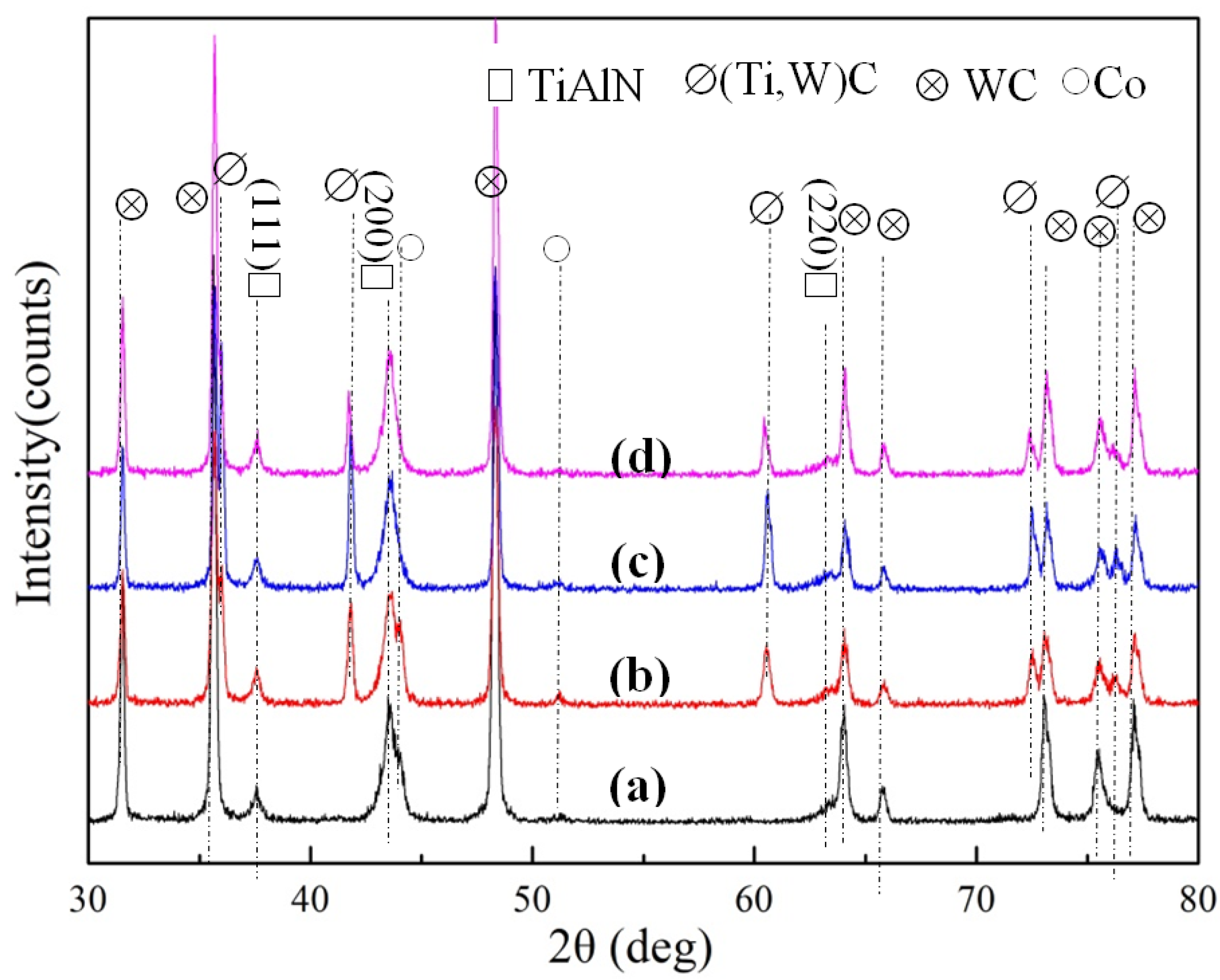

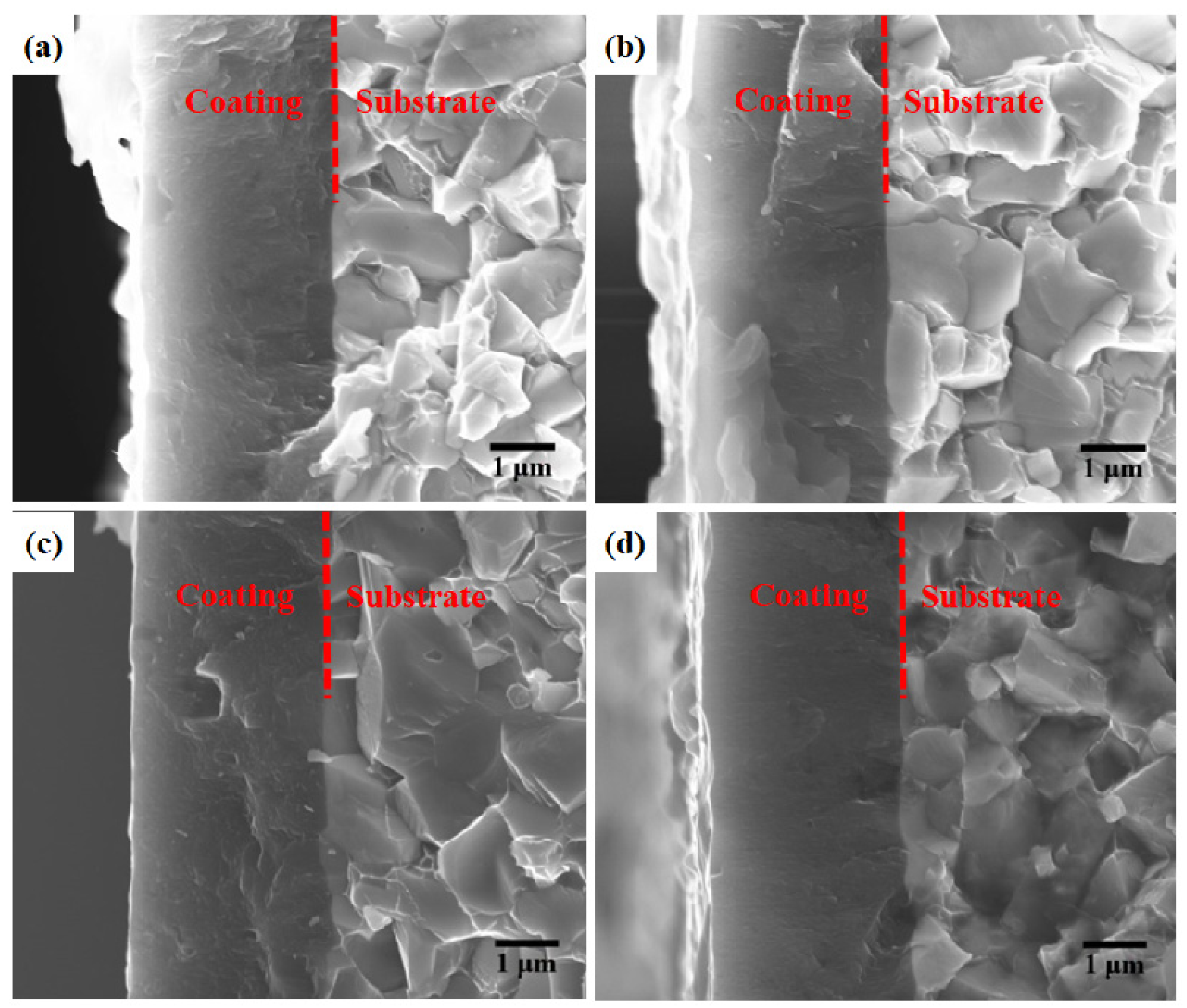

3.1. Microstructure

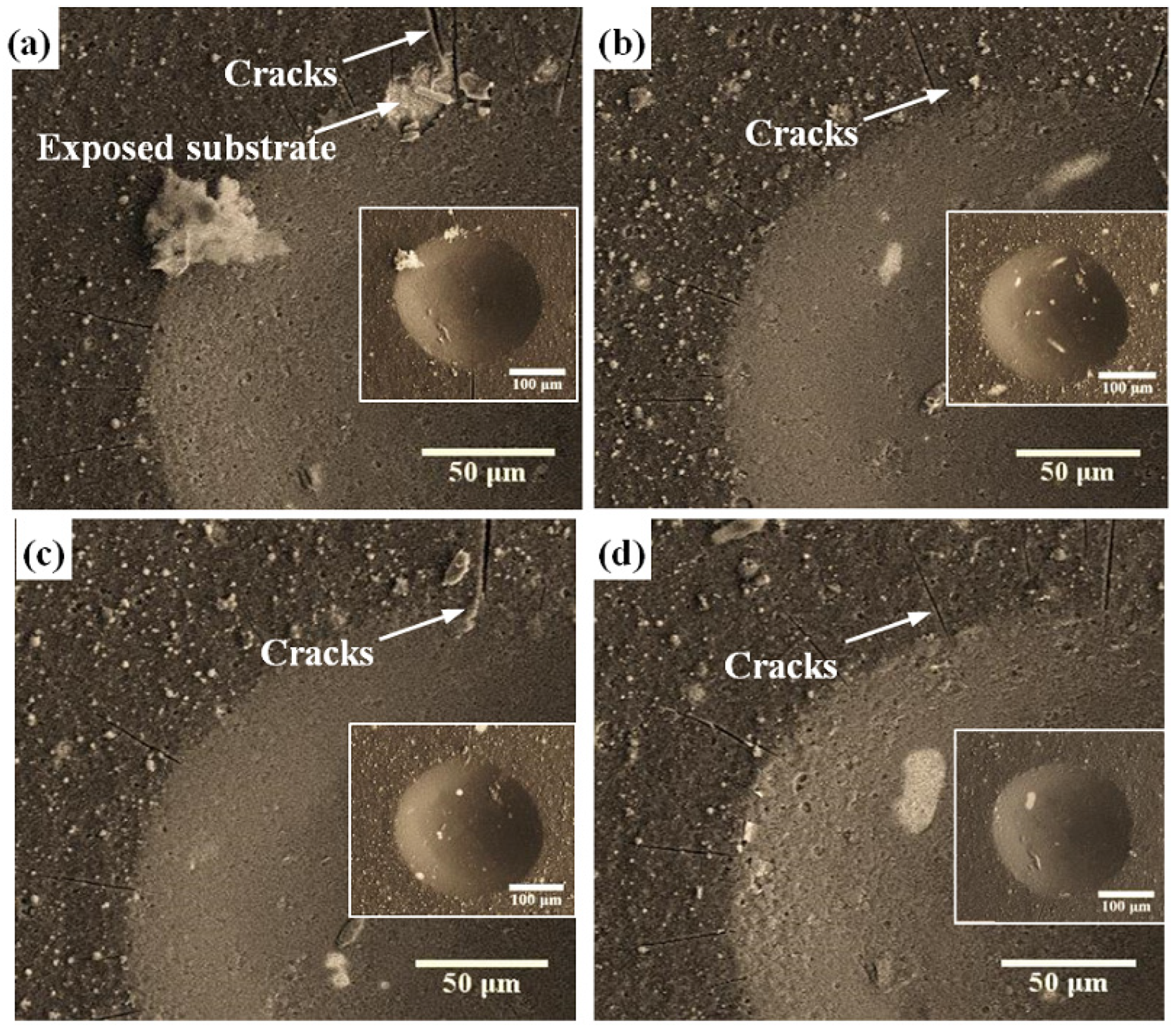

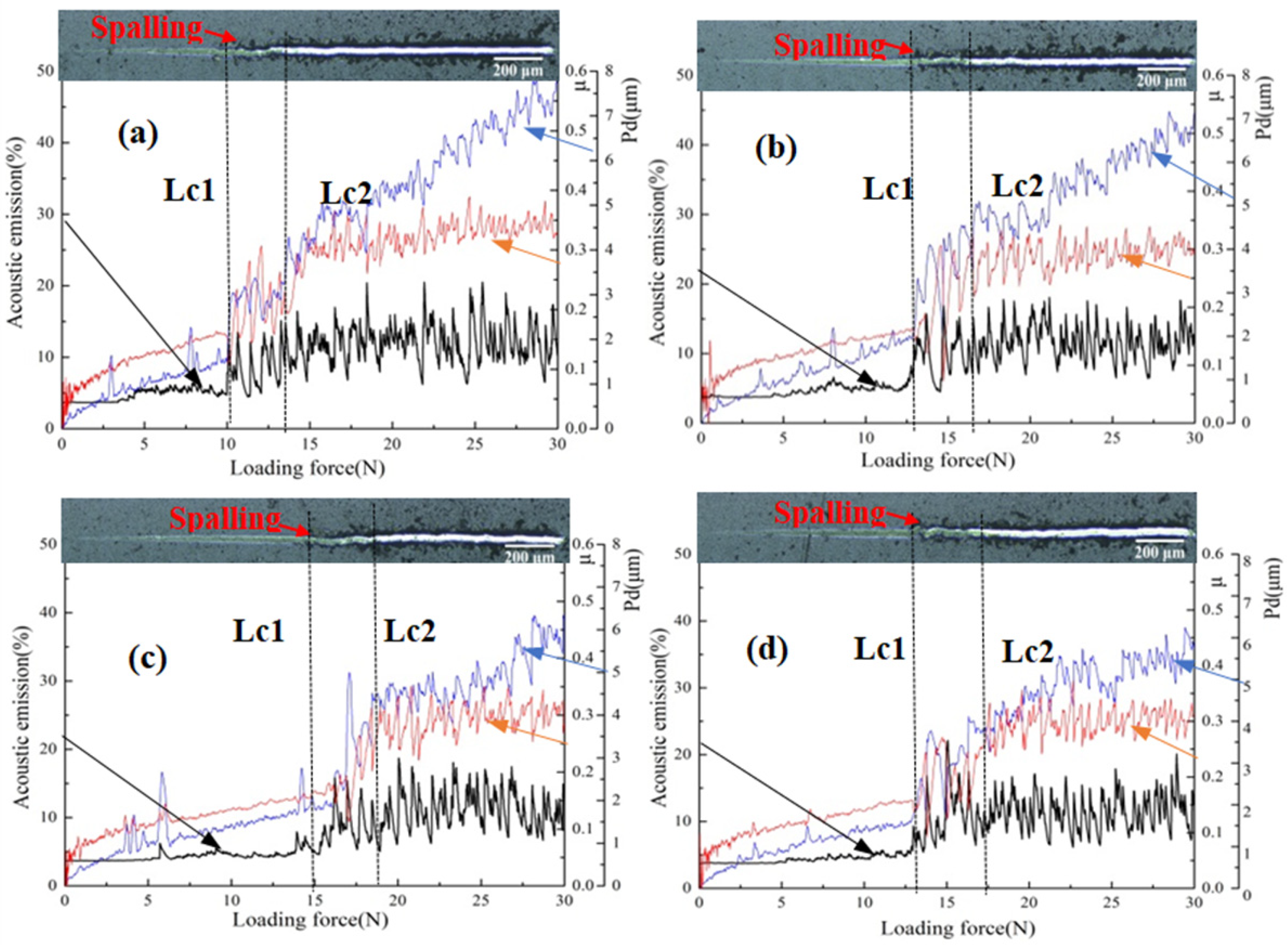

3.2. Mechanical Properties

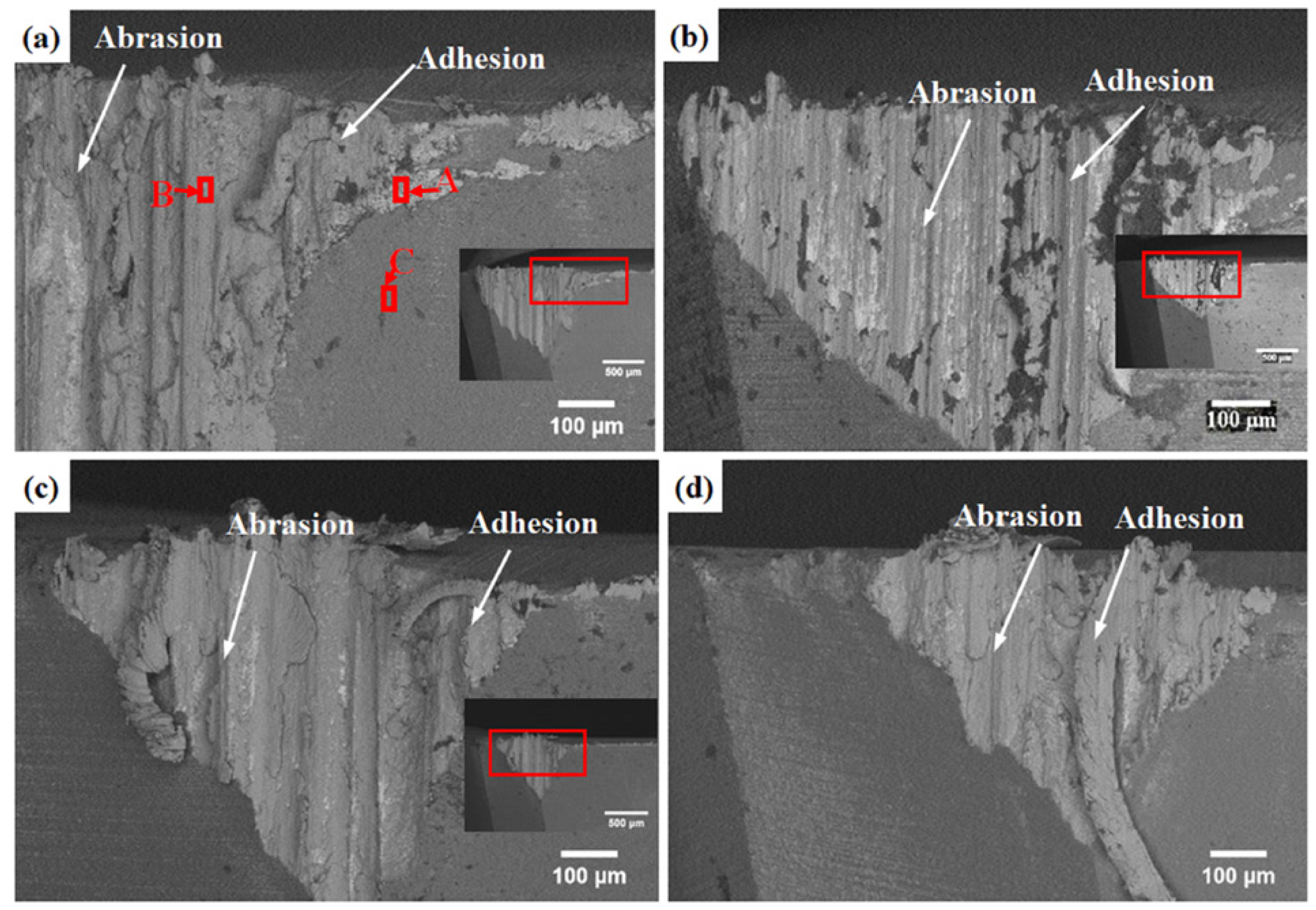

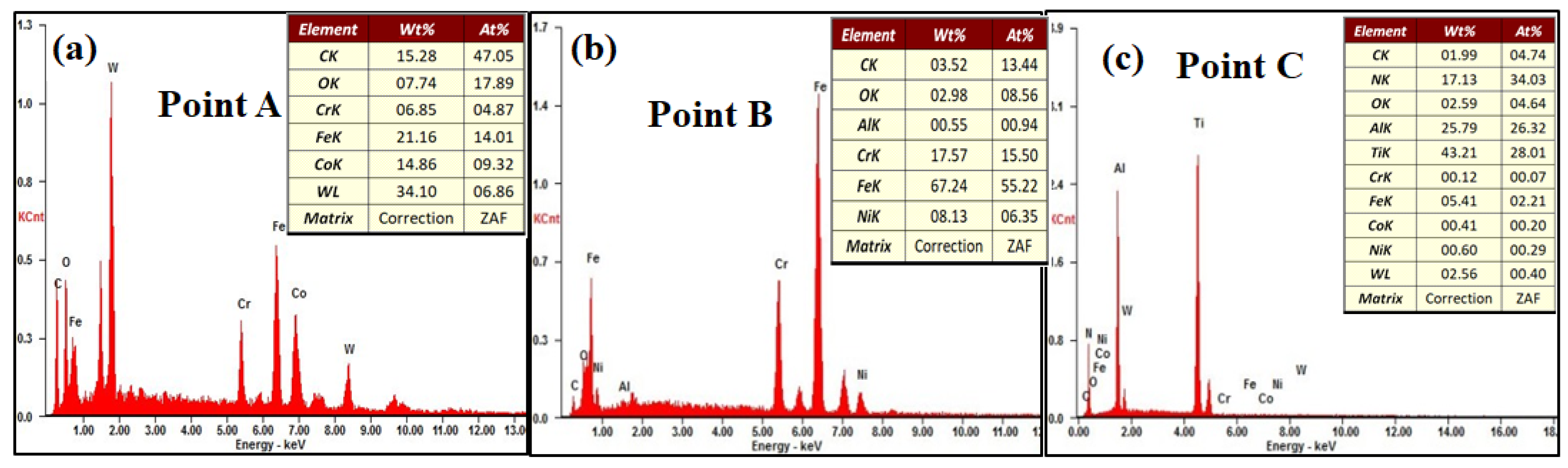

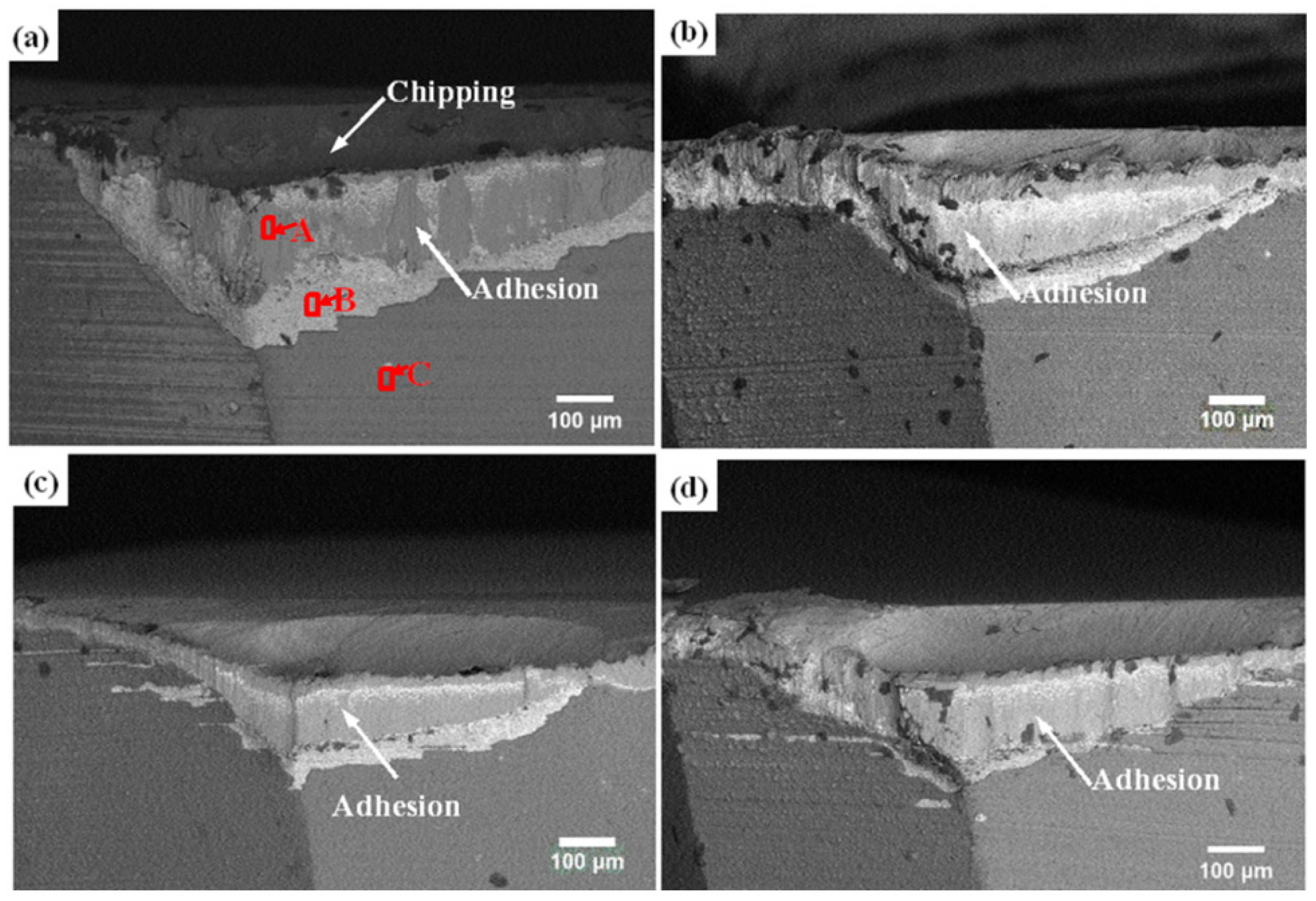

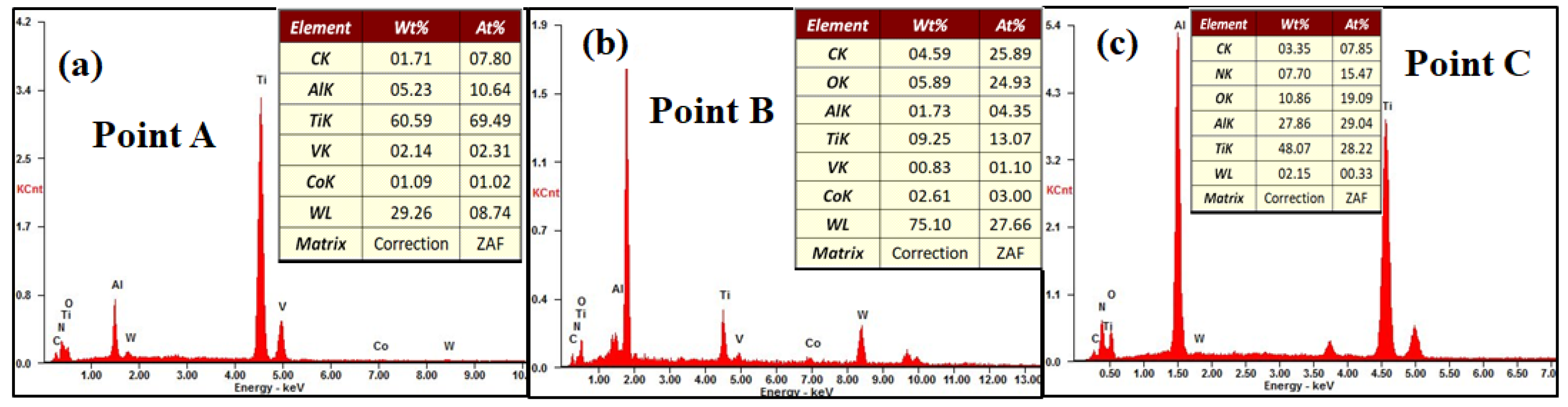

3.3. Wear Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti,Al)N: A review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Pramanik, A. Problems and solutions in machining of titanium alloys. Int. J. Adv. Manuf. Technol. 2014, 70, 919–928. [Google Scholar] [CrossRef]

- Li, G.J.; Lü, W.Z.; Liu, S.Y.; Li, C.; Zhou, Y.Y.; Wang, Q. Multilayer-growth of TiAlN/WS self-lubricating composite coatings with high adhesion and their cutting performance on titanium alloy. Compos. Part B 2021, 211, 108620. [Google Scholar] [CrossRef]

- Xiao, B.J.; Zhang, T.F.; Guo, Z.; Li, Z.; Fan, B.; Chen, G.X.; Xiong, Z.H.; Wang, Q.M. Mechanical, oxidation, and cutting properties of AlCrN/AlTiSiN nano-multilayer. Surf. Coat. Technol. 2022, 433, 128094. [Google Scholar] [CrossRef]

- Pei, F.; Liu, H.J.; Chen, L.; Xu, Y.X.; Du, Y. Improved properties of TiAlN coating by combined Si-addition and multilayer architecture. J. Alloys Compd. 2019, 790, 909–916. [Google Scholar] [CrossRef]

- Chen, L.; Du, Y.; Xiong, X.; Chang, K.K.; Wu, M.J. Improved properties of Ti-Al-N coating by multilayer structure. Int. J. Refract. Met. Hard Mater. 2011, 29, 681–685. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Michailidis, N.; Skordaris, G.; Tsouknidas, A.; Makrimallakis, S.; Bouzakis, E. Grain size effect of pre- and post-coating treated cementedcarbides on PVD films’ adhesion and mechanical properties. Mater. Sci. Eng. Technol. 2013, 44, 697–703. [Google Scholar]

- Lü, W.Z.; Li, G.J.; Zhou, Y.Y.; Liu, S.Y.; Wang, K.; Wang, Q. Effect of high hardness and adhesion of gradient TiAlSiN coating on cutting performance of titanium alloy. J. Alloys Compd. 2020, 820, 153137. [Google Scholar] [CrossRef]

- Sprute, T.; Tillmann, W.; Grisales, D.; Selvadurai, U.; Fischer, G. Influence of substrate pre-treatments on residual stresses and tribo-mechanical properties of TiAlN-based PVD coatings. Surf. Coat. Technol. 2014, 260, 369–379. [Google Scholar] [CrossRef]

- Xian, G.; Xiong, J.; Zhao, H.B.; Xian, L.J.; Fan, H.Y.; Li, Z.X.; Du, H. Study on the growth and wear behavior of the TiAlN-based composite coating deposited on TiCN-based cermets with different binder phase. Wear 2020, 460–461, 203460. [Google Scholar] [CrossRef]

- Xian, L.J.; Zhao, H.B.; Xian, G.; Xiong, J.; Fan, H.Y.; Du, H. Effect of TiC addition and Co binder content in cemented carbide substrates on the microstructure and mechanical properties of the TiAlN-based composite films. Vacuum 2020, 182, 109787. [Google Scholar] [CrossRef]

- Hogmark, S.; Jacobson, S.; Larsson, M.; Wiklund, U. Mechanical and tribological requirements and evaluation of coating composites. In Modern Tribology Handbook; Bhushan, B., Ed.; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Zhang, X.; Tian, X.B.; Zhao, Z.W.; Gao, J.B.; Zhou, Y.W.; Gao, P.; Guo, Y.Y.; Zhe, L. Evaluation of the adhesion and failure mechanism of the hard CrN coatings on different substrates. Surf. Coat. Technol. 2019, 364, 135–143. [Google Scholar] [CrossRef]

- Sveen, S.; Andersson, J.M.; M’Saoubi, R.; Olsson, M. Scratch adhesion characteristics of PVD TiAlN deposited on high speed steel, cemented carbide and PCBN substrates. Wear 2013, 308, 133–141. [Google Scholar] [CrossRef]

- Tillmann, W.; Dildrop, M. Influence of Si content on mechanical and tribological properties of TiAlSiN PVD coatings at elevated temperatures. Surf. Coat. Technol. 2017, 321, 448–454. [Google Scholar] [CrossRef]

- Chen, L.; Wang, S.Q.; Du, Y.; Zhou, S.Z.; Gang, T.; Fen, J.C.; Chang, K.K.; Li, Y.W.; Xiong, X. Machining performance of Ti-Al-Si-N coated inserts. Surf. Coat. Technol. 2010, 205, 582–586.e3. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Weng, S.Y.; Chen, C.H.; Fu, F.X. High temperature oxidation and cutting performance of AlCrN, TiVN and multilayered AlCrN/TiVN hard coatings. Surf. Coat. Technol. 2017, 332, 494–503. [Google Scholar] [CrossRef]

- Li, W.; Liu, P.; Wang, J.T.; Ma, F.C.; Liu, X.K.; Chen, X.H.; He, D.H. Investigation on microstructure and mechanical properties of reactively synthesized TiAlN/AlON nanomultilayers. Vacuum 2012, 86, 1300–1304. [Google Scholar] [CrossRef]

- Zhang, K.D.; Deng, J.X.; Sun, J.L.; Jiang, C.; Liu, Y.Y.; Chen, S. Effect of micro/nano-scale textures on anti-adhesive wear properties of WC/Co-based TiAlN coated tools in AISI 316 austenitic stainless steel cutting. Appl. Surf. Sci. 2015, 355, 602–624. [Google Scholar] [CrossRef]

- Wang, B.X.; Wang, Z.H.; Yuan, J.T.; Yin, Z.B.; Huang, L.; Zheng, K. High temperature fracture mechanism of ultrafine WC-Co cemented carbides containing (Ti,W)C. Int. J. Refract. Met. Hard Mater. 2021, 95, 105428. [Google Scholar] [CrossRef]

- Su, W.; Sun, Y.X.; Yang, X.Q.; Zhang, X.Q.; Ruan, J.M. Effects of TaC on microstructure and mechanical properties of coarse grained WC-9Co cemented carbides. Trans. Nonferrous Met. Soc. China 2015, 25, 1194–1199. [Google Scholar] [CrossRef]

- Merwe, R.; Sacks, N. Effect of TaC and TiC on the friction and dry sliding wear of WC-6 wt.%Co cemented carbides against steel counterfaces. Int. J. Refract. Met. Hard Mater. 2013, 41, 94–102. [Google Scholar] [CrossRef]

- Yi, J.Y.; Chen, S.Y.; Chen, K.H.; Xu, Y.C.; Chen, Q.; Zhu, C.J.; Liu, L. Effects of Ni content on microstructure, mechanical properties and Inconel 718 cutting performance of AlTiN-Ni nanocomposite coatings. Ceram. Int. 2019, 45, 474–480. [Google Scholar] [CrossRef]

- Kagnaya, T.; Boher, C.; Lambert, L.; Lazard, M.; Cutard, T. Wear mechanisms of WC-Co cutting tools from high-speed tribological tests. Wear 2009, 267, 890–897. [Google Scholar] [CrossRef]

- Kennedy, F.E.; Lu, Y.; Baker, I. Contact temperatures and their influence on wear during pin-on-disk tribotesting. Tribol. Int. 2015, 82, 534–542. [Google Scholar]

- Liu, K.; Wang, Z.H.; Yin, Z.B.; Cao, L.Y.; Yuan, J.T. Effect of Co content on microstructure and mechanical properties of ultrafine grained WC-Co cemented carbide sintered by spark plasma sintering. Ceram. Int. 2018, 44, 18711–18718. [Google Scholar] [CrossRef]

- Chen, L.; Chang, K.K.; Du, Y.; Li, J.R.; Wu, M.J. A comparative research on magnetron sputtering and arc evaporation deposition of Ti-Al-N coatings. Thin Solid Films 2011, 519, 3762–3767. [Google Scholar] [CrossRef]

- Lin, N.; He, Y.H.; Wu, C.H.; Liu, S.F.; Xiao, X.H.; Jiao, Y. Influence of TiC additions on the corrosion behaviour of WC-Co hardmetals in alkaline solution. Int. J. Refract. Met. Hard Mater. 2014, 46, 52–57. [Google Scholar] [CrossRef]

- Chen, H.; Chen, K.H.; Xu, Y.C.; Pan, C.X.; Yi, J.Y.; Zhu, C.J. Microstructure, mechanical properties, and milling performance of arc-PVD AlTiN–Cu and AlTiN/AlTiN–Cu coatings. J. Cent. South. Univ. 2018, 25, 506–515. [Google Scholar] [CrossRef]

- Xiao, Y.; Xiong, J.; Guo, Z.X.; Liu, J.B.; Zhou, L.M.; Ye, J.L.; Zhao, W. Microstructures and properties of PVD TiAlN coating deposited on cermets with different Ti(C,N) grain size. J. Cent. South. Univ. 2020, 27, 721–735. [Google Scholar] [CrossRef]

- Vereschaka, A.; Aksenenko, A.; Sitnikov, N.; Migranov, M.; Shevchenko, S.; Sotova, C.; Batako, A.; Andreev, N. Effect of adhesion and tribological properties of modified composite nano-structured multi-layer nitride coatings on WC-Co tools life. Tribol. Int. 2018, 128, 313–327. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, L.; Zhu, J.J.; Zhang, H.D.; Zhou, L.; Xiao, Q.P.; Luo, G.K. Phase interfaces between AlTiN and WC/Mo2C in WC-Mo2C substrate and the related characteristics. Int. J. Refract. Met. Hard Mater. 2018, 72, 323–331. [Google Scholar] [CrossRef]

- Soleimany, J.; Ghayour, H.; Amini, K.; Gharavi, F. The effect of deep cryogenic treatment on microstructure and wear behavior of H11 tool steel. Phys. Met. Metallogr. 2019, 120, 888–897. [Google Scholar] [CrossRef]

- Yang, W.; Xiong, J.; Guo, Z.X.; Du, H.; Yang, T.E.; Tang, J.; Wen, B. Structure and properties of PVD TiAlN and TiAlN/CrAlN coated Ti(C,N)-based cermets. Ceram. Int. 2017, 43, 1911–1915. [Google Scholar] [CrossRef]

- Wei, M.X.; Chen, K.M.; Wang, S.Q.; Cui, X.H. Analysis for Wear Behaviors of Oxidative Wear. Tribol. Lett. 2011, 42, 1–7. [Google Scholar] [CrossRef]

- Sui, X.D.; Li, G.J.; Qin, X.S.; Yu, H.D.; Zhou, X.K.; Wang, K.; Wang, Q. Relationship of microstructure, mechanical properties and titanium cutting performance of TiAlN/TiAlSiN composite coated tool. Ceram. Int. 2016, 42, 7524–7532. [Google Scholar] [CrossRef]

- Li, G.J.; Sui, X.D.; Jiang, C.J.; Gao, Y.; Wang, K.; Wang, Q.; Liu, D. Low adhesion effect of TaO functional composite coating on the titanium cutting performance of coated cemented carbide insert. Mater. Des. 2016, 110, 105–111. [Google Scholar] [CrossRef]

| Chemical Composition (wt.%) | Vicker Hardness (HV30) | Elastic Modulus (GPa) | ||||

|---|---|---|---|---|---|---|

| WC | Co | TiC | TaC | |||

| WT1 | 92 | 8 | - | - | 1380 ± 85 | 605 ± 20.7 |

| WT2 | 85 | 10 | 5 | - | 1400 ± 101 | 596 ± 18.4 |

| WT3 | 78 | 8 | 14 | - | 1530 ± 94 | 534 ± 25.3 |

| WT4 | 82 | 8 | 6 | 4 | 1650 ± 104 | 575 ± 23.7 |

| Machining Operation | Tool Substrate | Workpiece Material | Speed m/min | Feed, mm/rev | Depth of Cut, mm | Cooling Mode |

|---|---|---|---|---|---|---|

| turning | 4160511 | TC4 | 80 | 0.2 | 0.5 | Dry |

| 304 stainless steel | 160 | 0.2 | 0.5 | Dry |

| Sample | Coating Hardness (GPa) | Coating Elastic Modulus (GPa) | Adhesion Strength | |

|---|---|---|---|---|

| Lc1 (N) | Lc2 (N) | |||

| TiAlN/WT1 | 27.9 ± 1.1 | 303.8 ± 19.5 | 10.1 | 14.0 |

| TiAlN/WT2 | 24.6 ± 0.9 | 286.8 ± 23.7 | 13.1 | 16.7 |

| TiAlN/WT3 | 22.9 ± 1.5 | 264.7 ± 20.1 | 13.8 | 18.3 |

| TiAlN/WT4 | 30.1 ± 1.2 | 378.5 ± 21.3 | 13.2 | 17.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, J.; Xu, Y.; Liu, Z.; Xiao, L. Effect of TiC Content and TaC Addition in Substrates on Properties and Wear Behavior of TiAlN-Coated Tools. Coatings 2022, 12, 1911. https://doi.org/10.3390/coatings12121911

Yi J, Xu Y, Liu Z, Xiao L. Effect of TiC Content and TaC Addition in Substrates on Properties and Wear Behavior of TiAlN-Coated Tools. Coatings. 2022; 12(12):1911. https://doi.org/10.3390/coatings12121911

Chicago/Turabian StyleYi, Jiyong, Yinchao Xu, Zhixiong Liu, and Lijuan Xiao. 2022. "Effect of TiC Content and TaC Addition in Substrates on Properties and Wear Behavior of TiAlN-Coated Tools" Coatings 12, no. 12: 1911. https://doi.org/10.3390/coatings12121911

APA StyleYi, J., Xu, Y., Liu, Z., & Xiao, L. (2022). Effect of TiC Content and TaC Addition in Substrates on Properties and Wear Behavior of TiAlN-Coated Tools. Coatings, 12(12), 1911. https://doi.org/10.3390/coatings12121911