Wetting Patterns of Liquid-Repellent Femtosecond Laser Textured Aluminum Surfaces

Abstract

:1. Introduction

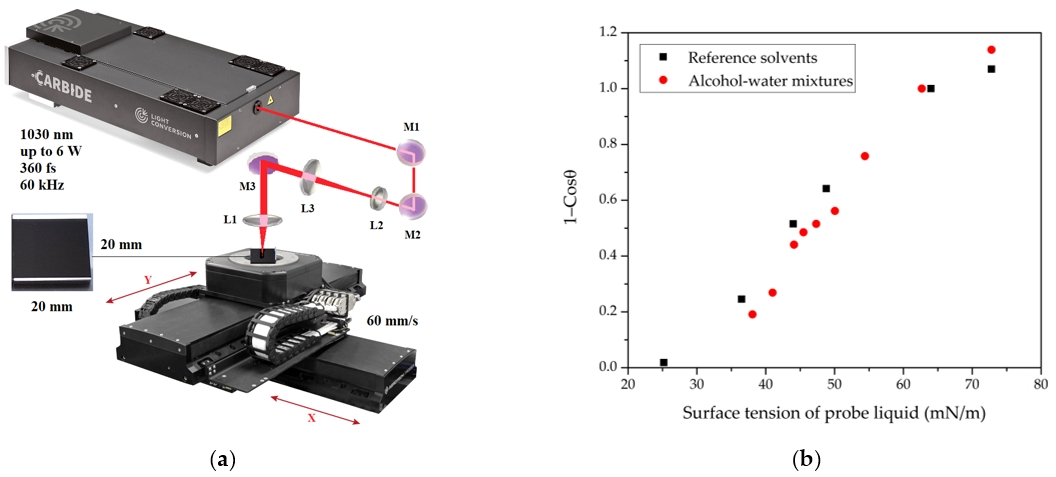

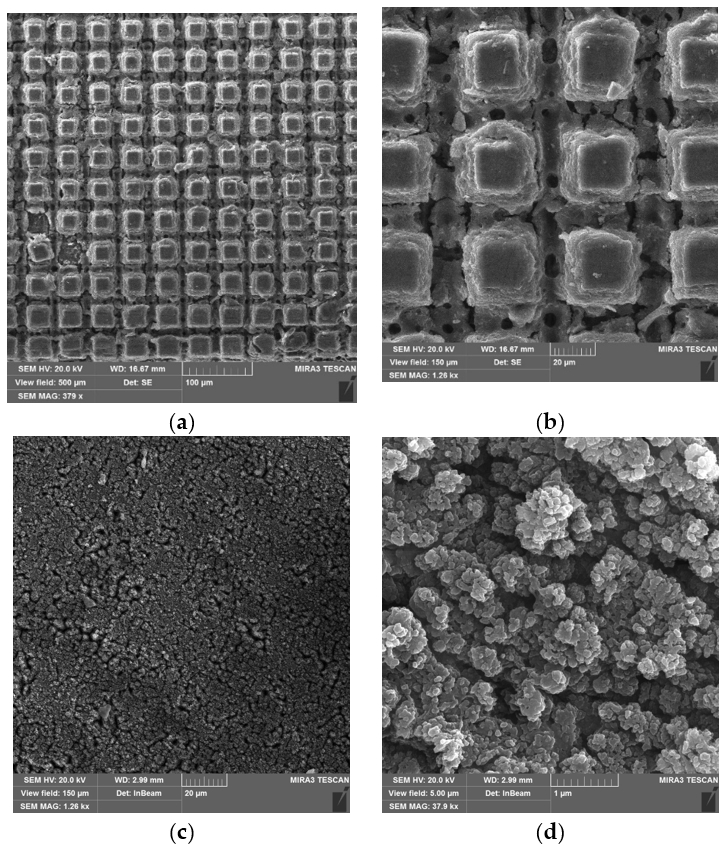

2. Materials and Methods

- 1H,1H,2H,2H-Perfluorooctyltriethoxysilane (POTS);

- n-Octyltriethoxysilane (OCTEO);

- Oleic acid (OA).

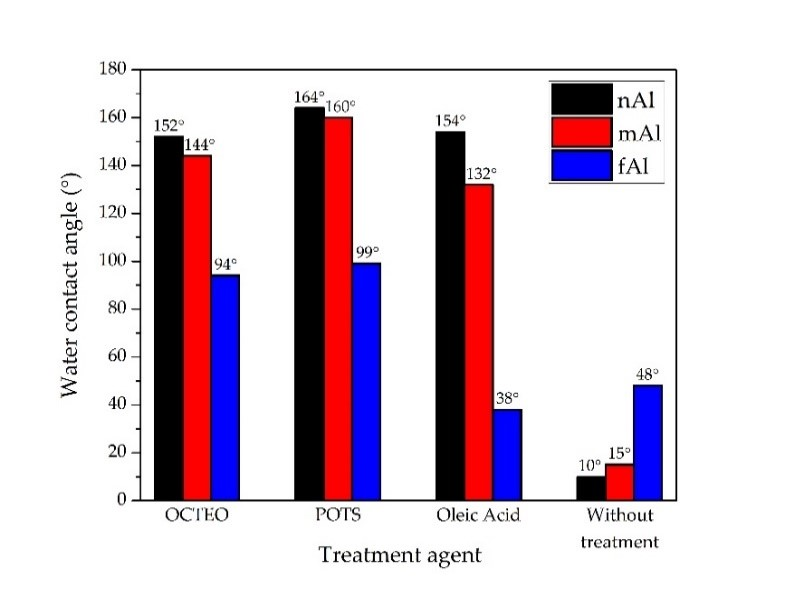

3. Results

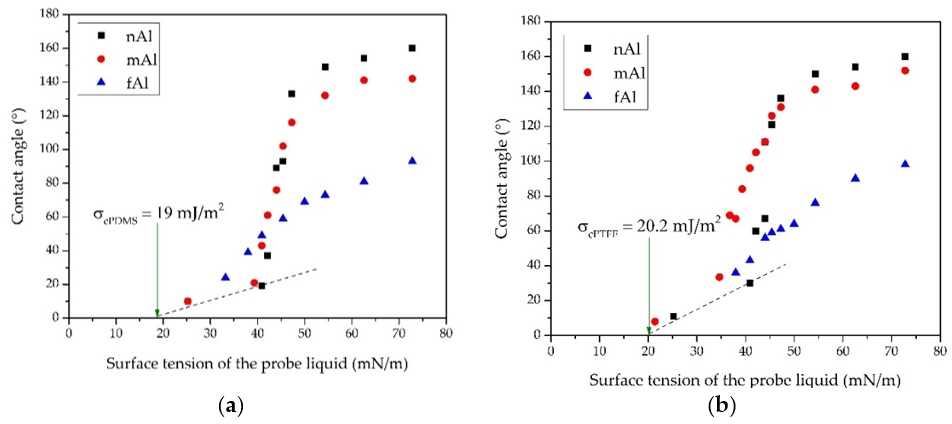

4. Discussion

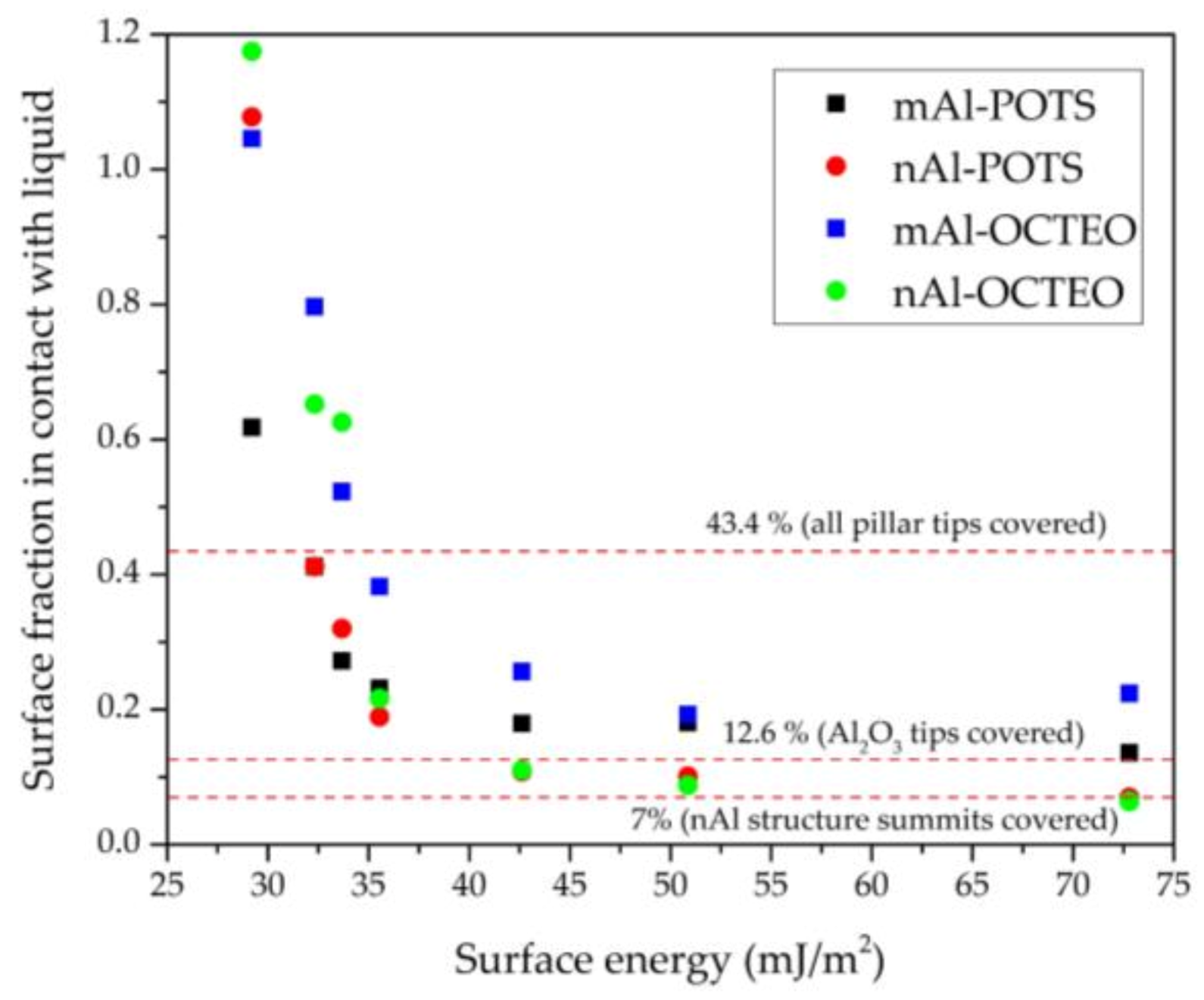

4.1. Determining the Distribution of the Liquid Contact Surface

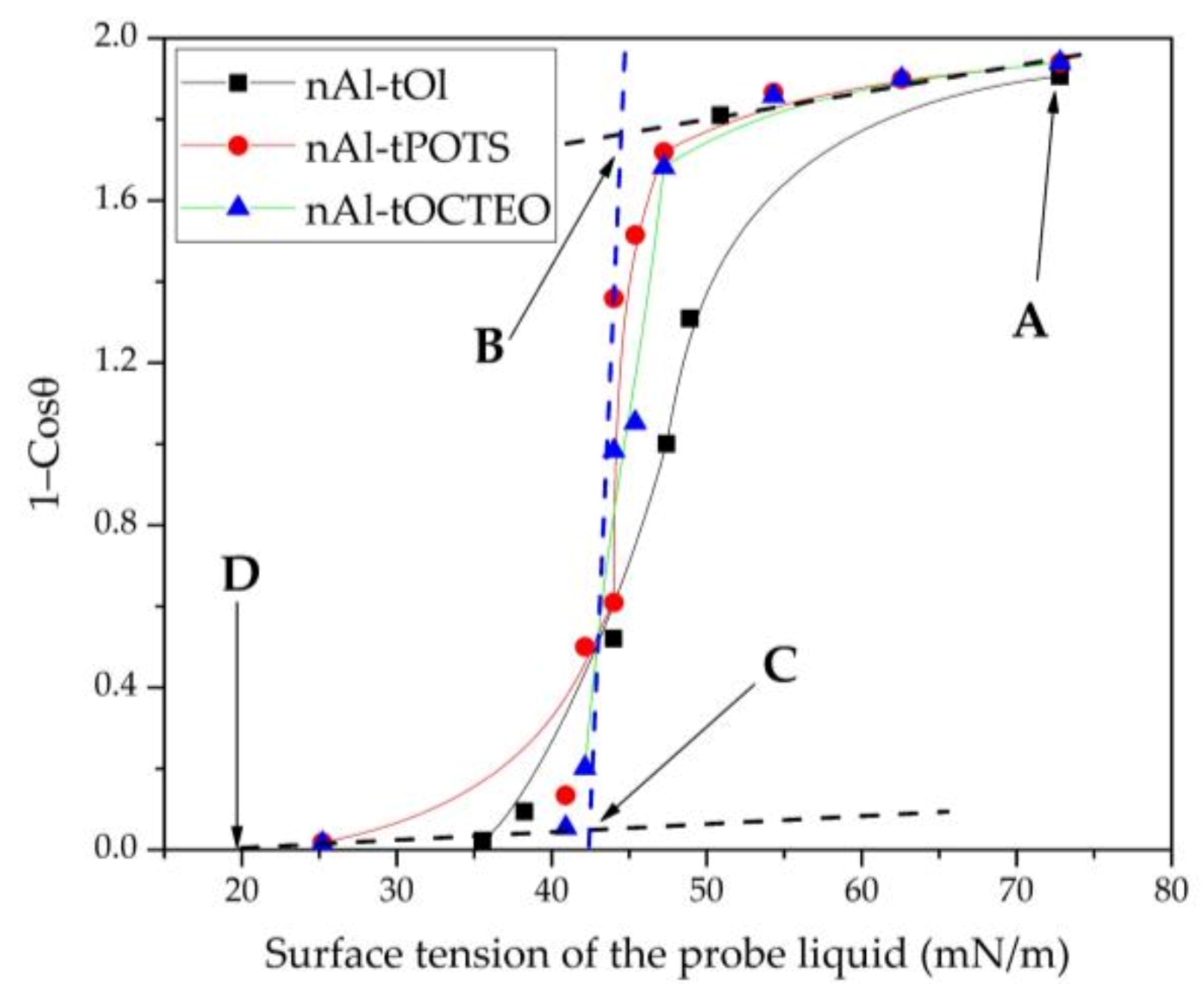

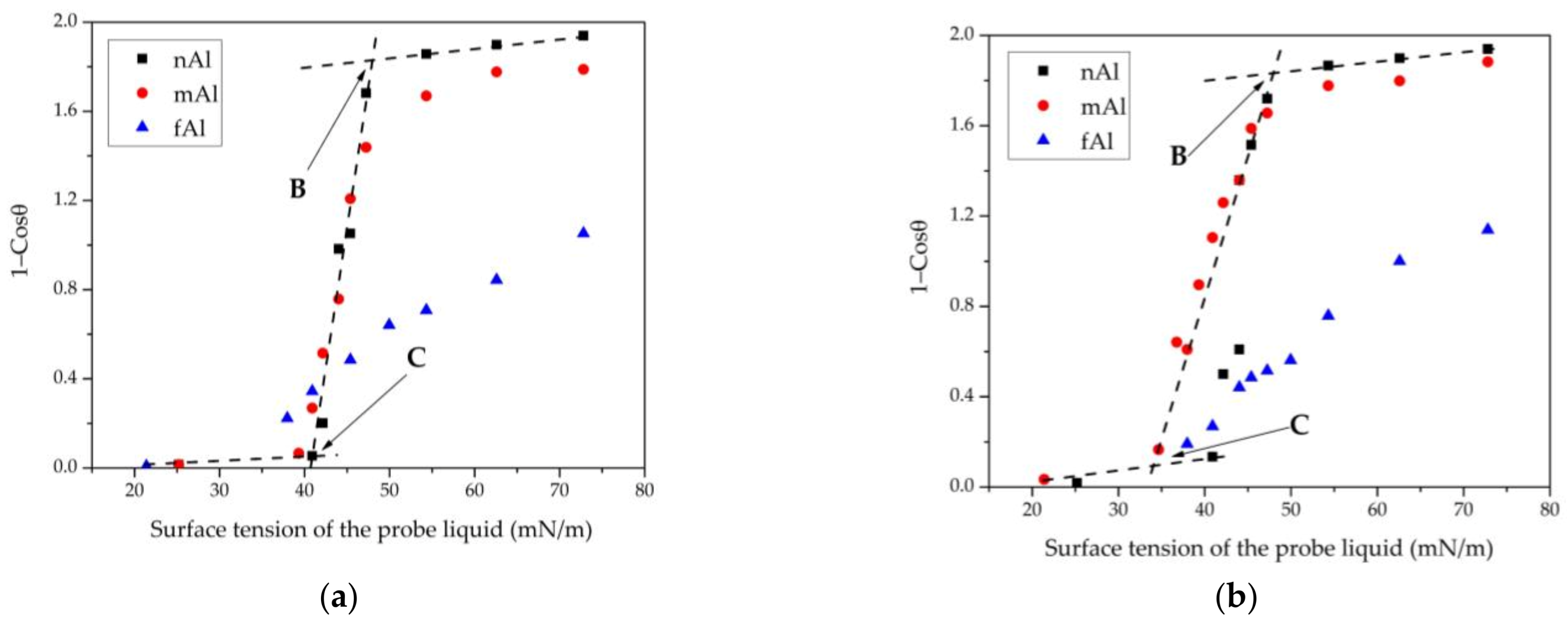

4.2. General Shape of the Zisman Plot for Textured Hydrophobized Surfaces

4.3. Point A Position

4.4. Point B Position

4.5. Positions of Points C and D

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mohamed, A.M.A.; Abdullah, A.M.; Younan, N.A. Corrosion behavior of superhydrophobic surfaces: A review. Arab. J. Chem. 2015, 8, 749–765. [Google Scholar] [CrossRef] [Green Version]

- Cao, L.; Jones, A.K.; Sikka, V.K.; Wu, J.; Gao, D. Anti-Icing Superhydrophobic Coatings. Langmuir 2009, 25, 12444–12448. [Google Scholar] [CrossRef]

- Manoharan, K.; Bhattacharya, S. Superhydrophobic surfaces review: Functional application, fabrication techniques and limitations. J. Micromanuf. 2019, 2, 59–78. [Google Scholar] [CrossRef]

- Jung, Y.C.; Bhushan, B. Dynamic Effects of Bouncing Water Droplets on Superhydrophobic Surfaces. Langmuir 2008, 24, 6262–6269. [Google Scholar] [CrossRef]

- Li, H.; Zhang, K. Dynamic behavior of water droplets impacting on the superhydrophobic surface: Both experimental study and molecular dynamics simulation study. Appl. Surf. Sci. 2019, 498, 143793. [Google Scholar] [CrossRef]

- Mirmohammadi, S.M.; Hoshian, S.; Jokinen, V.P.; Franssila, S. Fabrication of elastic, conductive, wear-resistant superhydrophobic composite material. Sci. Rep. 2021, 11, 1–10. [Google Scholar] [CrossRef]

- Jung, K.K.; Jung, Y.; Park, B.-G.; Choi, C.J.; Ko, J.S. Super Wear Resistant Nanostructured Superhydrophobic Surface. Int. J. Precis. Eng. Manuf. Technol. 2021, 9, 1177–1189. [Google Scholar] [CrossRef]

- Myronyuk, O.; Dudko, V.; Baklan, D.; Melnyk, L. Study of structure influence on wear resistance of hierarchial superhydrophobic coatings. East.-Eur. J. Enterp. Technol. 2017, 3, 44–49. [Google Scholar] [CrossRef] [Green Version]

- Fan, X.; Chen, L.; Wong, C.; Chu, H.-W.; Zhang, G. Effects of Vapor Pressure and Super-Hydrophobic Nanocomposite Coating on Microelectronics Reliability. Engineering 2015, 1, 384–390. [Google Scholar] [CrossRef] [Green Version]

- Murakami, D.; Jinnai, H.; Takahara, A. Wetting Transition from the Cassie–Baxter State to the Wenzel State on Textured Polymer Surfaces. Langmuir 2014, 30, 2061–2067. [Google Scholar] [CrossRef]

- Kim, H.; Saha, J.K.; Jang, J. Drying Transition of Water Confined between Hydrophobic Pillars. J. Phys. Chem. C 2012, 116, 19233–19239. [Google Scholar] [CrossRef]

- Kwon, T.W.; Jang, J.; Sim, G.H.; Park, S.H.; Ha, M.Y. Wetting Behavior of a Surface with Dual-Scale Structures. Langmuir 2021, 37, 7995–8006. [Google Scholar] [CrossRef]

- Ai, Y.; Yu, L.; Huang, Y.; Liu, X. The investigation of molten pool dynamic behaviors during the “∞” shaped oscillating laser welding of aluminum alloy. Int. J. Therm. Sci. 2022, 173, 107350. [Google Scholar] [CrossRef]

- Sun, H.; Li, J.; Liu, M.; Yang, D.; Li, F. A Review of Effects of Femtosecond Laser Parameters on Metal Surface Properties. Coatings 2022, 12, 1596. [Google Scholar] [CrossRef]

- Yokoi, N.; Manabe, K.; Tenjimbayashi, M.; Shiratori, S. Optically Transparent Superhydrophobic Surfaces with Enhanced Mechanical Abrasion Resistance Enabled by Mesh Structure. ACS Appl. Mater. Interfaces 2015, 7, 4809–4816. [Google Scholar] [CrossRef]

- Çakır, M. Investigation of Coating Performance of UV-Curable Hybrid Polymers Containing 1H,1H,2H,2H-Perfluorooctyltriethoxysilane Coated on Aluminum Substrates. Coatings 2017, 7, 37. [Google Scholar] [CrossRef] [Green Version]

- Salazar-Hernández, C.; Salazar-Hernández, M.; Mendoza-Miranda, J.M.; Miranda-Avilés, R.; Elorza-Rodríguez, E.; Carrera-Rodríguez, R.; Puy-Alquiza, M.J. Organic modified silica obtained from DBTL polycondensation catalyst for anticorrosive coating. J. Sol-Gel Sci. Technol. 2018, 87, 299–309. [Google Scholar] [CrossRef]

- Sabry, R.S.; Fahad, N.K. Oleic acid-modified superhydrophobic ZnO nanostructures via double hydrothermal method. J. Adhes. Sci. Technol. 2019, 33, 1558–1571. [Google Scholar] [CrossRef]

- Chevalier, N.R. Super-hydrophobic powders obtained by froth flotation: Properties and applications. RSC Adv. 2017, 7, 45335–45343. [Google Scholar] [CrossRef] [Green Version]

- Hu, Z.; Deng, Y. Superhydrophobic Surface Fabricated from Fatty Acid-Modified Precipitated Calcium Carbonate. Ind. Eng. Chem. Res. 2010, 49, 5625–5630. [Google Scholar] [CrossRef]

- Zhang, B.; Zeng, Y.; Wang, J.; Sun, Y.; Zhang, J.; Li, Y. Superamphiphobic aluminum alloy with low sliding angles and acid-alkali liquids repellency. Mater. Des. 2020, 188, 108479. [Google Scholar] [CrossRef]

- Noor, M.Z.M.; Sollahunddin, N.A.; Irawan, S. Surface Modification of Aluminium Oxide (Al2O3) Nanoparticles (NPs) on Detection of Crude Oil Production. Environ. Green Technol. Eng. Int. Conf. 2018, 2, 1273. [Google Scholar] [CrossRef] [Green Version]

- Weng, M.; Shen, Q. Solid surface tension components and their error limits induced by contact angle measurement in application of the van Oss–Chaudhury–Good approach. J. Adhes. Sci. Technol. 2013, 27, 2571–2591. [Google Scholar] [CrossRef]

- Gómez-Díaz, D.; Mejuto, J.C.; Navaza, J.M.; Rodríguez-Álvarez, A. Viscosities, Densities, Surface Tensions, and Refractive Indexes of 2,2,4-Trimethylpentane + Cyclohexane + Decane Ternary Liquid Systems at 298.15 K. J. Chem. Eng. Data 2002, 47, 872–875. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, W.; Korpacz, A.N.; Dufour, C.R.; Weiland, Z.J.; Lambert, C.R.; Timko, M.T. Binary Liquid Mixture Contact-Angle Measurements for Precise Estimation of Surface Free Energy. Langmuir 2019, 35, 12317–12325. [Google Scholar] [CrossRef]

- Milne, A.; Amirfazli, A. The Cassie equation: How it is meant to be used. Adv. Colloid Interface Sci. 2012, 170, 48–55. [Google Scholar] [CrossRef]

- Shi, S.; Lv, C.; Zheng, Q. Temperature-regulated adhesion of impacting drops on nano/microtextured monostable superrepellent surfaces. Soft Matter 2020, 16, 5388–5397. [Google Scholar] [CrossRef]

- Raja, R.S.S.; Selvakumar, P.; Babu, P.D.; Rubasingh, B.J.; Suresh, K. Influence of laser parameters on superhydrophobicity- A review. Eng. Res. Express 2021, 3, 022001. [Google Scholar] [CrossRef]

- Hsiao, M.; Chen, K.-Y.; Chen, C.-Y. Tailoring the robust superhydrophobic silicon textures with stable photodetection properties. Sci. Rep. 2019, 9, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Fowkes, F.M. Contact Angle, Wettability and Adhesion; American Chemical Society: New York, NY, USA, 1964; ISBN 9780841222120. [Google Scholar]

- Parvate, S.; Dixit, P.; Chattopadhyay, S. Superhydrophobic Surfaces: Insights from Theory and Experiment. J. Phys. Chem. B 2020, 124, 1323–1360. [Google Scholar] [CrossRef] [PubMed]

- Prydatko, A.; Myronyuk, O.; Svidersky, V. Analysis of approaches to mathematical description of the characteristics of materials with high hydrophobicity. East.-Eur. J. Enterp. Technol. 2015, 5, 30. [Google Scholar] [CrossRef] [Green Version]

- Bico, J.; Thiele, U.; Quéré, D. Wetting of textured surfaces. Colloids Surf. A Physicochem. Eng. Asp. 2002, 206, 41–46. [Google Scholar] [CrossRef]

- Fedorova, N.; Ottinger, B.; Jovicic, V.; Zbogar-Rasic, A.; Delgado, A.; Virtanen, S. Static Wettability of Differently Mechanically Treated and Amphiphobic-Coated Aluminium Surfaces. Materials 2020, 13, 2240. [Google Scholar] [CrossRef]

- Tuteja, A.; Choi, W.; Mabry, J.M.; McKinley, G.H.; Cohen, R.E. Robust omniphobic surfaces. Proc. Natl. Acad. Sci. 2008, 105, 18200–18205. [Google Scholar] [CrossRef] [Green Version]

- Nairn, J.J.; Forster, W.A. Methods for evaluating leaf surface free energy and polarity having accounted for surface roughness. Pest Manag. Sci. 2017, 73, 1854–1865. [Google Scholar] [CrossRef]

- Ebnesajjad, S.; Ebnesajjad, C.F. Surface Treatment of Materials for Adhesion Bonding, 2nd ed.; William Andrew: Oxford, UK, 2014; ISBN 978-0-323-26435-8. [Google Scholar]

- Vudayagiri, S.; Junker, M.D.; Skov, A.L. Factors affecting the surface and release properties of thin polydimethylsiloxane films. Polym. J. 2013, 45, 871–878. [Google Scholar] [CrossRef] [Green Version]

- Mańko, D.; Zdziennicka, A.; Jańczuk, B. Surface tension of polytetrafluoroethylene and its wetting by aqueous solution of some surfactants and their mixtures. Appl. Surf. Sci. 2017, 392, 117–125. [Google Scholar] [CrossRef]

- Pocius, A.V.; Dillard, D.A.; Chaudhury, M.K. Adhesion Science and Engineering; Elsevier: Amsterdam, The Netherlands, 2002; ISBN 978-0-444-51140-9. [Google Scholar]

- Galet, L.; Patry, S.; Dodds, J. Determination of the wettability of powders by the Washburn capillary rise method with bed preparation by a centrifugal packing technique. J. Colloid Interface Sci. 2010, 346, 470–475. [Google Scholar] [CrossRef]

| Liquid (CAS) | Surface Tension, mN/m (25 °C) |

|---|---|

| Water (7732-18-5) | 72.1 |

| Glycerol (56-81-5) | 64.0 |

| Ethylene glycol (107-21-1) | 48.0 |

| Dimethyl sulfoxide (67-68-5) | 44.0 |

| Formamide (75-12-7) | 58.0 |

| Cyclohexane (110-82-7) | 25.2 |

| Modifier | Water Contact Angle, Deg | Wetted Surface Percentage | |||

|---|---|---|---|---|---|

| fAl | mAl | nAl | mAl | nAl | |

| OCTEO | 94 | 144 | 152 | 0.21 | 0.07 |

| POTS | 99 | 160 | 164 | 0.14 | 0.07 |

| % Wet Surface Area of the Pillar Tip | f2 | f1 | r | θc (Equation (1)) | θc Experimental |

|---|---|---|---|---|---|

| 100 | 0.52 | 0.48 | 1.77 | 113 | 93–98 |

| 26 | 0.87 | 0.13 | 1.39 | 133 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Myronyuk, O.; Baklan, D.; Vasilyev, G.S.; Rodin, A.M.; Vanagas, E. Wetting Patterns of Liquid-Repellent Femtosecond Laser Textured Aluminum Surfaces. Coatings 2022, 12, 1852. https://doi.org/10.3390/coatings12121852

Myronyuk O, Baklan D, Vasilyev GS, Rodin AM, Vanagas E. Wetting Patterns of Liquid-Repellent Femtosecond Laser Textured Aluminum Surfaces. Coatings. 2022; 12(12):1852. https://doi.org/10.3390/coatings12121852

Chicago/Turabian StyleMyronyuk, Oleksiy, Denys Baklan, Georgii S. Vasilyev, Aleksej M. Rodin, and Egidijus Vanagas. 2022. "Wetting Patterns of Liquid-Repellent Femtosecond Laser Textured Aluminum Surfaces" Coatings 12, no. 12: 1852. https://doi.org/10.3390/coatings12121852

APA StyleMyronyuk, O., Baklan, D., Vasilyev, G. S., Rodin, A. M., & Vanagas, E. (2022). Wetting Patterns of Liquid-Repellent Femtosecond Laser Textured Aluminum Surfaces. Coatings, 12(12), 1852. https://doi.org/10.3390/coatings12121852