Effect of Polymer Shell Structure of a Gamma-ray Shielding Film Prepared Using Composite Material on Shielding Performance

Abstract

:1. Introduction

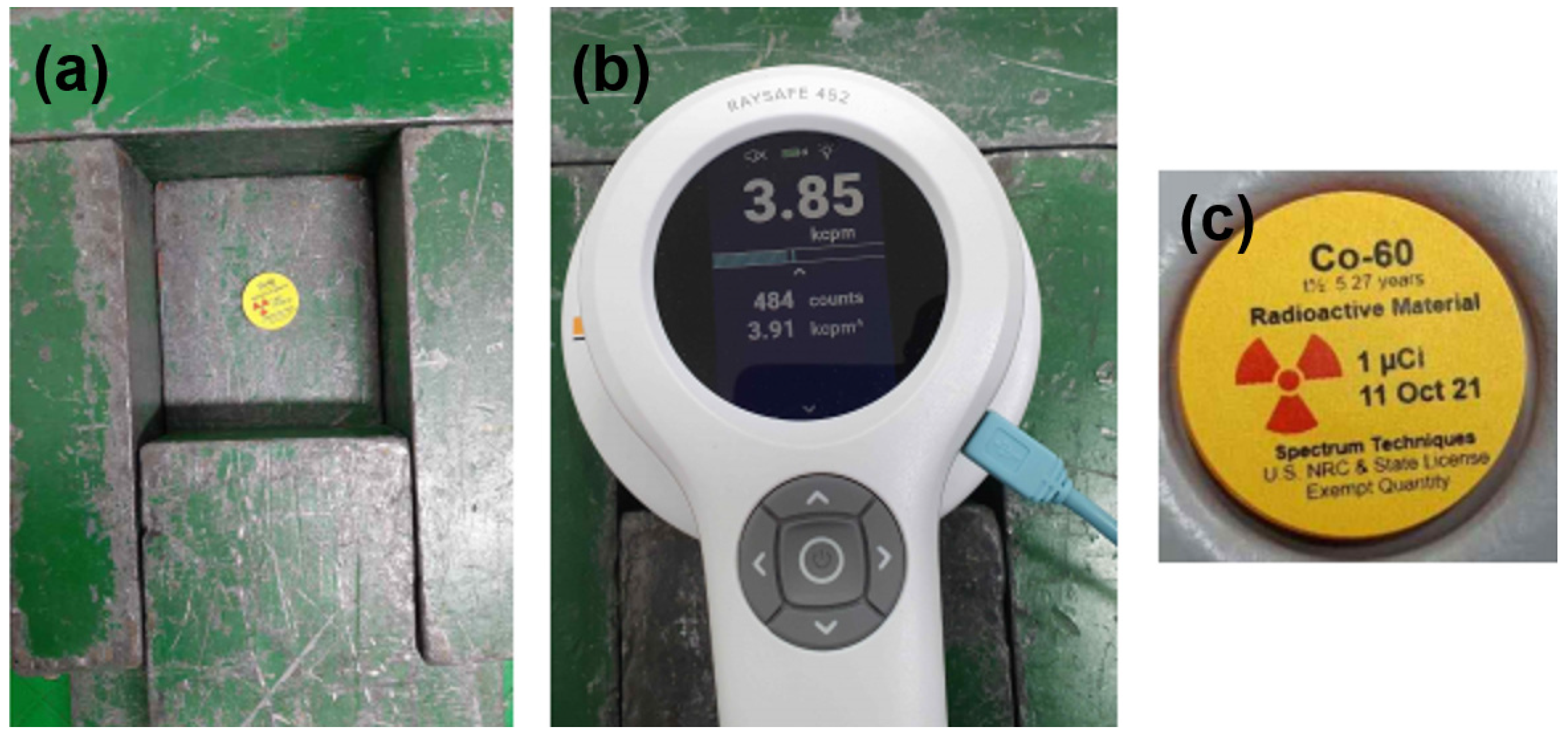

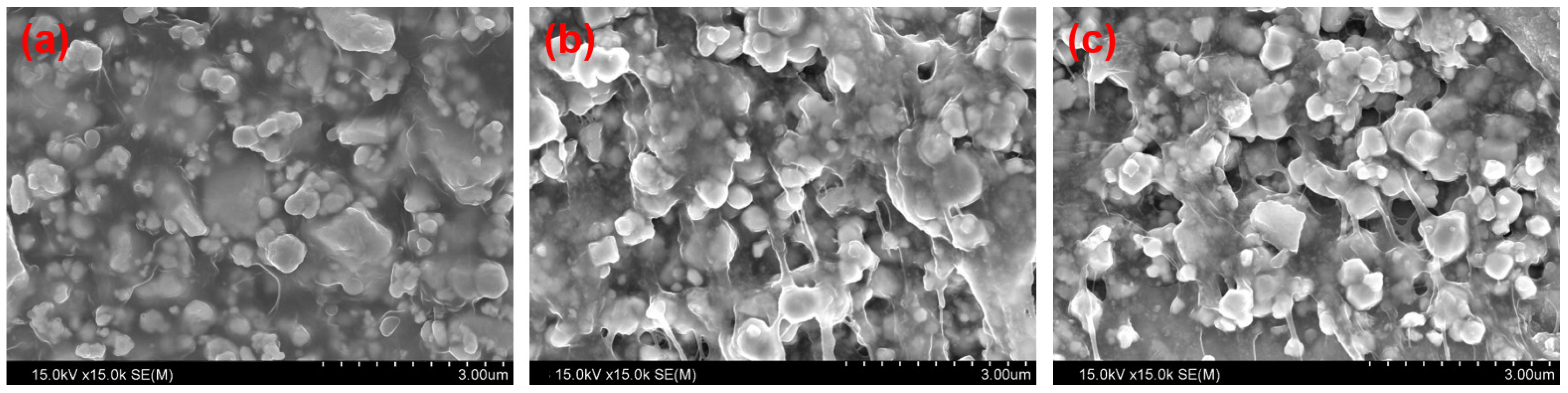

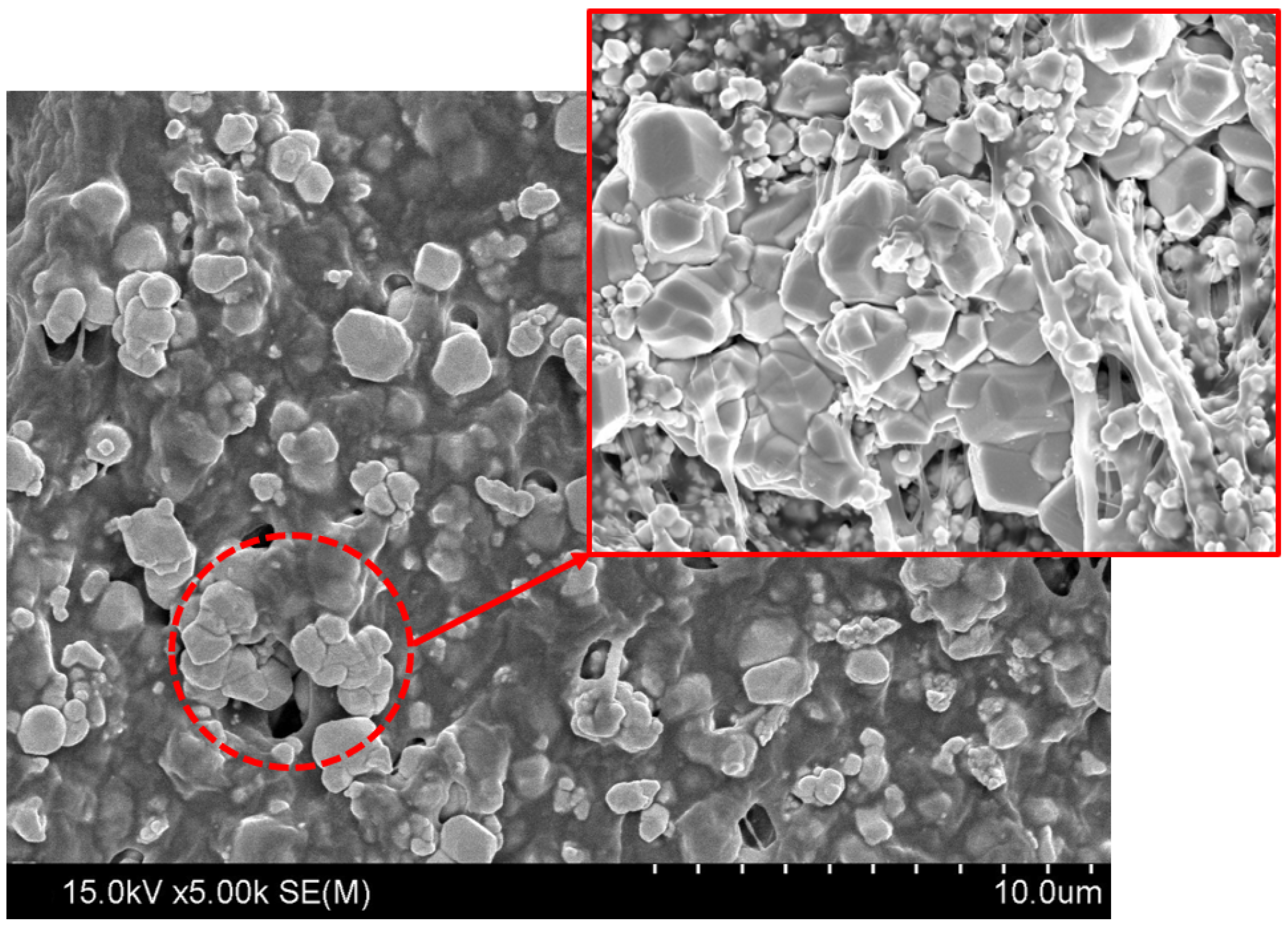

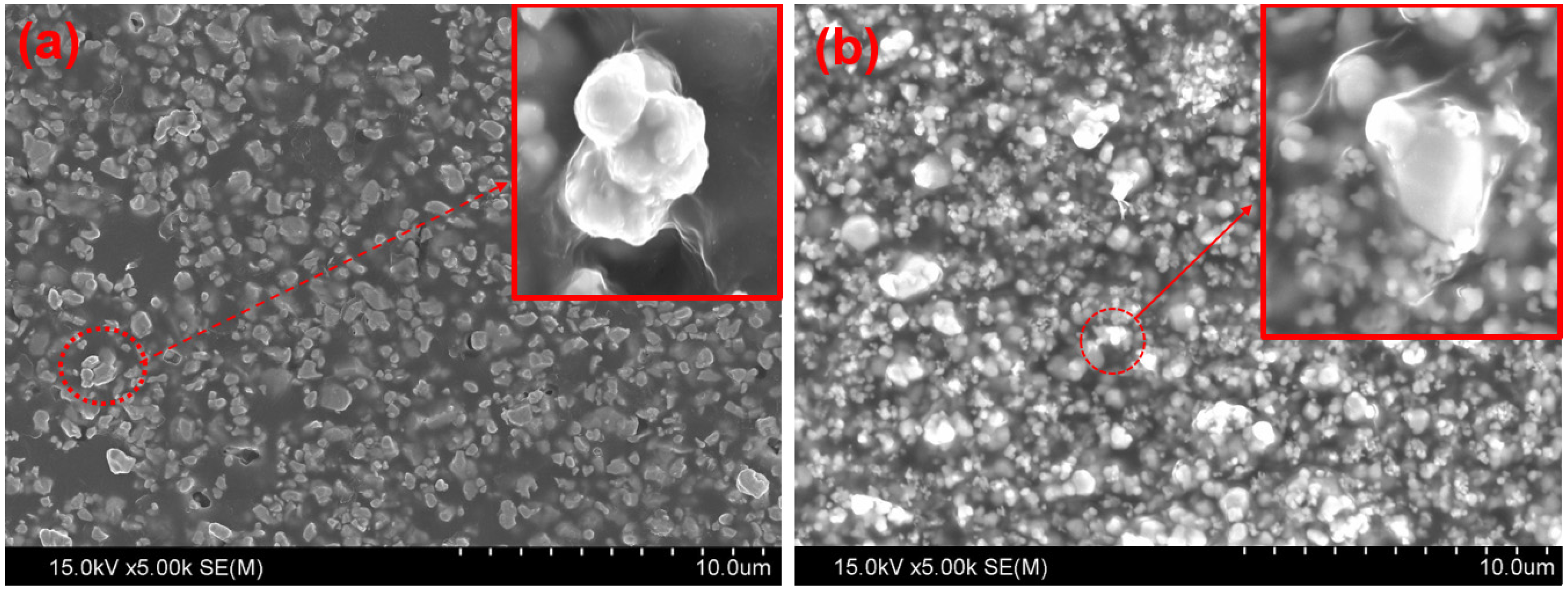

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Skopljak-Beganović, A.; Čiva, L.M.; Ðedović, E.; Hrelja, S.Z.; Gazibegović-Busuladžić, A.; Beganović, A. Evaluation of the Effectiveness of Protective Aprons in the Primary and Scattered Radiation X-ray Beam. Int. Conf. Med. Biol. Eng. 2021, 84, 817–825. [Google Scholar] [CrossRef]

- He, X.; Zhao, R.; Rong, L.; Yao, K.; Chen, S.; Wei, B. Answers to if the Lead Aprons are Really Helpful in Nuclear Medicine from the Perspective of Spectroscopy. Radiat. Prot. Dosim. 2017, 174, 558–564. [Google Scholar] [CrossRef] [PubMed]

- Livingstone, R.S.; Varghese, A.; Keshava, S.N. A study on the use of radiation-protective apron among interventionists in radiology. J. Clin. Imaging Sci. 2018, 8, 34. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, W.; Zhang, X.; Gao, Y.; Guo, S. High-efficiency, flexibility and lead-free X-ray shielding multilayered polymer composites: Layered structure design and shielding mechanism. Sci. Rep. 2021, 11, 4384. [Google Scholar] [CrossRef] [PubMed]

- Kaewjang, S.; Maghanemi, U.; Kothan, S.; Kim, H.J.; Limkitjaroenporn, P.; Kaewkhao, J. New gadolinium based glasses for gamma-rays shielding materials. Nucl. Eng. Des. 2014, 280, 21–26. [Google Scholar] [CrossRef]

- Jayakumar, S.; Mani, V.; Saravanan, T.; Rajamanickam, K.; Prabhu, A.D.; Philip, J. Multifiller nanocomposites containing gadolinium oxide and bismuth nanoparticles with enhanced X-ray attenuation property. J. Appl. Polym. Sci. 2021, 138, 51252. [Google Scholar] [CrossRef]

- Kaur, P.; Singh, K.J.; Thakur, S.; Kurudirek, M.; Rafiei, M.M. Structural investigations and nuclear radiation shielding ability of bismuth lithium antimony borate glasses. J. Phys. Chem. Solids 2020, 150, 109812. [Google Scholar] [CrossRef]

- Mehnati, P.; Malekzadeh, R.; Sooteh, M.Y. Application of Personal Non-Lead Nano-Composite Shields for Radiation Protection in Diagnostic Radiology: A Systematic Review and Meta-Analysis. Nanomed. J. 2020, 7, 170–182. [Google Scholar] [CrossRef]

- Almurayshid, M.; Alssalim, Y.; Aksouh, F.; Almsalam, R.; ALQahtani, M.; Sayyed, M.I.; Almasoud, F. Development of New Lead-Free Composite Materials as Potential Radiation Shields. Materials 2021, 14, 4957. [Google Scholar] [CrossRef]

- Adlienė, D.; Gilys, L.; Griškonis, E. Development and characterization of new tungsten and tantalum containing composites for radiation shielding in medicine. Nucl. Instruments Methods Phys. Res. B 2020, 467, 21–26. [Google Scholar] [CrossRef]

- Soylu, H.M.; Lambrecht, F.Y.; Ersöz, O.A. Gamma radiation shielding efficiency of a new lead-free composite material. J. Radioanal. Nucl. Chem. 2015, 305, 529–534. [Google Scholar] [CrossRef]

- Günther, K.; Mahltig, B.; Askani, A.; Bohnet, F.; Brinkert, N.; Kyosev, Y.; Weide, T.; Krieg, M.; Leisegang, T. X-ray-protective organic/inorganic fiber—along the textile chain from fiber production to clothing application. J. Text. Inst. 2017, 108, 1975–1984. [Google Scholar] [CrossRef]

- AbuAlRoos, N.J.; Amin, N.A.B.; Zainon, R. Conventional and new lead-free radiation shielding materials for radiation protection in nuclear medicine: A review. Radiat. Phys. Chem. 2019, 165, 108439. [Google Scholar] [CrossRef]

- Lopresti, M.; Alberto, G.; Cantamessa, S.; Cantino, G.; Conterosito, E.; Palin, L.; Milanesio, M. Light Weight, Easy Formable and Non-Toxic Polymer-Based Composites for Hard X-ray Shielding: A Theoretical and Experimental Study. Int. J. Mol. Sci. 2020, 21, 833. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, J.W.; Kweon, D.C. Evaluation of radiation dose reduction by barium composite shielding in an angiography system. Radiat. Eff. Defects Solids 2020, 176, 368–381. [Google Scholar] [CrossRef]

- Uthoff, H.; Benenati, M.J.; Katzen, B.T.; Peña, C.; Gandhi, R.; Staub, D.; Schernthaner, M. Lightweight bilayer barium sulfate-bismuth oxide composite thyroid collars for superior radiation protection in fluoroscopy-guided interventions: A prospective randomized controlled trial. Radiology 2014, 270, 601–606. [Google Scholar] [CrossRef]

- Schueler, B.A.; Balter, S.; Miller, D.L. Radiation Protection Tools in Interventional Radiology. J. Am. Coll. Radiol. 2012, 9, 844–845. [Google Scholar] [CrossRef]

- Li, Q.; Wei, Q.; Zheng, W.; Zheng, Y.; Okosi, N.; Wang, Z.; Su, M. Enhanced Radiation Shielding with Conformal Light-Weight Nanoparticle–Polymer Composite. ACS Appl. Mater. Interfaces 2018, 10, 35510–35515. [Google Scholar] [CrossRef]

- Kim, J.W.; Seo, D.B.; Lee, B.C.; Seo, Y.S.; William, H.M. Nano-W dispersed gamma radiation shielding materials. Adv. Eng. Mater. 2014, 16, 1083–1089. [Google Scholar] [CrossRef]

- Kim, J.W.; Lee, B.C.; Uhm, Y.R.; Miller, W.H. Enhancement of thermal neutron attenuation of nano-B4C, -BN dispersed neutron shielding polymer nanocomposites. J. Nucl. Mater. 2014, 453, 48–53. [Google Scholar] [CrossRef]

- Asgari, M.; Afarideh, H.; Ghafoorifard, H.; Amirabadi, E.A. Comparison of nano/micro lead, bismuth and tungsten on the gamma shielding properties of the flexible composites against photon in wide energy range (40 keV–662 keV). Nucl. Eng. Technol. 2021, 53, 4142–4149. [Google Scholar] [CrossRef]

- Jamil, M.; Hazlan, M.H.; Ramli, R.M.; NoorAzman, N.Z. Study of Electrospun PVA-Based Concentrations Nanofibre Filled with Bi2O3 or WO3 as Potential X-ray Shielding Material. Radiat. Phys. Chem. 2019, 156, 272–282. [Google Scholar] [CrossRef]

- Pavlenko, V.I.; Cherkashina, N.I.; Yastrebinsky, R.N. Synthesis and radiation shielding properties of polyimide/Bi2O3 composites. Heliyon 2019, 5, e01703. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Uhm, Y.R.; Kim, J.W.; Son, K.J.; Kim, C.S. Effect of particle size, dispersion, and particle-matrix adhesion on W reinforced polymer composites. Res. Chem. Intermed. 2014, 40, 2145–2153. [Google Scholar] [CrossRef]

- Intom, S.; Kalkornsurapranee, E.; Johns, J.; Kaewjaeng, S.; Kothan, S.; Hongtong, W.; Chaiphaksa, W.; Kaewkhao, J. Mechanical and radiation shielding properties of flexible material based on natural rubber/Bi2O3 composites. Radiat. Phys. Chem. 2020, 172, 108772. [Google Scholar] [CrossRef]

- Fakher Alfashed, R.K.; Mohammad, K.K.; Majeed, M.S.; Ali Badran, H.; Ali, K.M.; Yahya Kadem, B. Preparation, morphological, and mechanical characterization of titanium dioxide (TiO2)/polyvinyl alcohol (PVA) composite for gamma-rays radiation shielding. J. Phys. Conf. Ser. 2019, 1279, 012019. [Google Scholar] [CrossRef]

- Kim, H.; Lim, J.; Kim, J.; Lee, J.; Seo, Y. Multilayer Structuring of Nonleaded Metal (BiSn)/Polymer/Tungsten Composites for Enhanced γ-ray Shielding. Adv. Eng. Mater. 2020, 22, 1901448. [Google Scholar] [CrossRef]

- Cheewasukhanont, W.; Limkitjaroenporn, P.; Kothan, S.; Kedkaew, C.; Kaewkhao, J. The effect of particle size on radiation shielding properties for bismuth borosilicate glass. Radiat. Phys. Chem. 2020, 172, 108791. [Google Scholar] [CrossRef]

- Hubbell, J.H. Photon mass attenuation and energy absorption coefficients from 1 keV to 20 MeV. Int. J. Appl. Radiat. Isot. 1982, 33, 1269–1290. [Google Scholar] [CrossRef]

- Habashi, F. Tungsten and the Mining Industry. J. Powder Metall. Min. 2017, 6, 1000166. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, X.; Tsarkova, L.; Pich, A.; Möller, M. All-Silica Colloidosomes with a Particle-Bilayer Shell. ACS Nano 2011, 5, 3937–3942. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.C. Research on performance improvement measures for medical radiation shielding film through removal of air bubbles and pinholes. Radiat. Eff. Defects Solids 2021, 176, 718–730. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D256-10; Standard Test Methods for Determining the Izod Pendulum Impact Strength of Plastics. ASTM International: West Conshohocken, PA, USA, 2018.

- Oberer, R.B.; Gunn, C.A.; Chiang, L.G. Small-angle Compton scattering used to determine the depth of a radioactive source in material and to estimate gamma-ray attenuation. Nucl. Instruments Methods Phys. Res. Sect. A 2013, 722, 65–70. [Google Scholar] [CrossRef]

- Verma, V.; Ryan, K.M.; Padrela, L. Production and isolation of pharmaceutical drug nanoparticles. Int. J. Pharm. 2021, 603, 120708. [Google Scholar] [CrossRef]

- Chai, H.; Tang, X.; Ni, M.; Chen, F.; Zhang, Y.; Chen, D.; Qiu, Y. Preparation and properties of novel, flexible, lead-free X-ray-shielding materials containing tungsten and bismuth(III) oxide. J. Appl. Polym. Sci. 2015, 133, 43012. [Google Scholar] [CrossRef]

- Azarsa, E.; Mostafapour, A. On the feasibility of producing polymer–metal composites via novel variant of friction stir processing. J. Manuf. Process. 2013, 15, 682–688. [Google Scholar] [CrossRef]

- Maghrabi, H.A.; Vijayan, A.; Deb, P.; Wang, L. Bismuth oxide-coated fabrics for X-ray shielding. Text. Res. J. 2015, 86, 649–658. [Google Scholar] [CrossRef]

- Özkalaycı, F.; Kaçal, M.R.; Polat, H.; Agar, O.; Almousa, N.; Akman, F. Lead-free Sb-based polymer composite for γ-ray shielding purposes. Radiochim. Acta 2022, 110, 393–402. [Google Scholar] [CrossRef]

| wt% | Density (g/cm³) | Tensile Strength (MPa) | Impact Strength (J/m) | Thickness (mm) | ||||

|---|---|---|---|---|---|---|---|---|

| E-P | P-P | E-P | P-P | E-P | P-P | E-P | P-P | |

| 80 | 9.8 ± 0.05 | 12.2 ± 0.05 | 50.4 | 50.1 | 41.8 | 42.6 | 3.01 | 2.69 |

| 85 | 10.2 ± 0.03 | 13.6 ± 0.03 | 48.5 | 48.4 | 43.5 | 43.5 | 3.01 | 2.70 |

| 90 | 10.6 ± 0.01 | 13.1 ± 0.01 | 43.2 | 46.2 | 39.5 | 41.2 | 3.00 | 2.72 |

| 95 | 11.2 ± 0.01 | 14.5 ± 0.01 | 40.9 | 45.6 | 38.4 | 40.9 | 3.00 | 2.74 |

| Background 1 | Radioactive Source Count Rate | Net Counting Rate 1 | Background 2 | Radioactive Source Count Rate after Shielding | Net Counting Rate 2 | Attenuation Rate (%) | ||

|---|---|---|---|---|---|---|---|---|

| E-P | 80 | 40.04 | 3975.36 | 3935.32 | 43.60 | 1190.70 | 1147.11 | 70.85 |

| P-P | 1052.27 | 1095.87 | 72.15 | |||||

| E-P | 85 | 44.93 | 3950.77 | 3905.83 | 46.68 | 1049.45 | 1096.13 | 71.94 |

| P-P | 1012.34 | 1059.02 | 72.89 | |||||

| E-P | 90 | 45.37 | 3960.40 | 3915.03 | 51.93 | 894.89 | 946.82 | 75.82 |

| P-P | 796.66 | 848.59 | 78.32 | |||||

| E-P | 95 | 47.13 | 3998.91 | 3951.78 | 45.04 | 668.23 | 713.27 | 81.95 |

| P-P | 625.01 | 670.05 | 83.04 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-C. Effect of Polymer Shell Structure of a Gamma-ray Shielding Film Prepared Using Composite Material on Shielding Performance. Coatings 2022, 12, 1846. https://doi.org/10.3390/coatings12121846

Kim S-C. Effect of Polymer Shell Structure of a Gamma-ray Shielding Film Prepared Using Composite Material on Shielding Performance. Coatings. 2022; 12(12):1846. https://doi.org/10.3390/coatings12121846

Chicago/Turabian StyleKim, Seon-Chil. 2022. "Effect of Polymer Shell Structure of a Gamma-ray Shielding Film Prepared Using Composite Material on Shielding Performance" Coatings 12, no. 12: 1846. https://doi.org/10.3390/coatings12121846

APA StyleKim, S.-C. (2022). Effect of Polymer Shell Structure of a Gamma-ray Shielding Film Prepared Using Composite Material on Shielding Performance. Coatings, 12(12), 1846. https://doi.org/10.3390/coatings12121846