Acoustic Emission Assessment of Corroded RC Columns Jointly Reinforced with Concrete Canvas and CFRP

Abstract

:1. Introduction

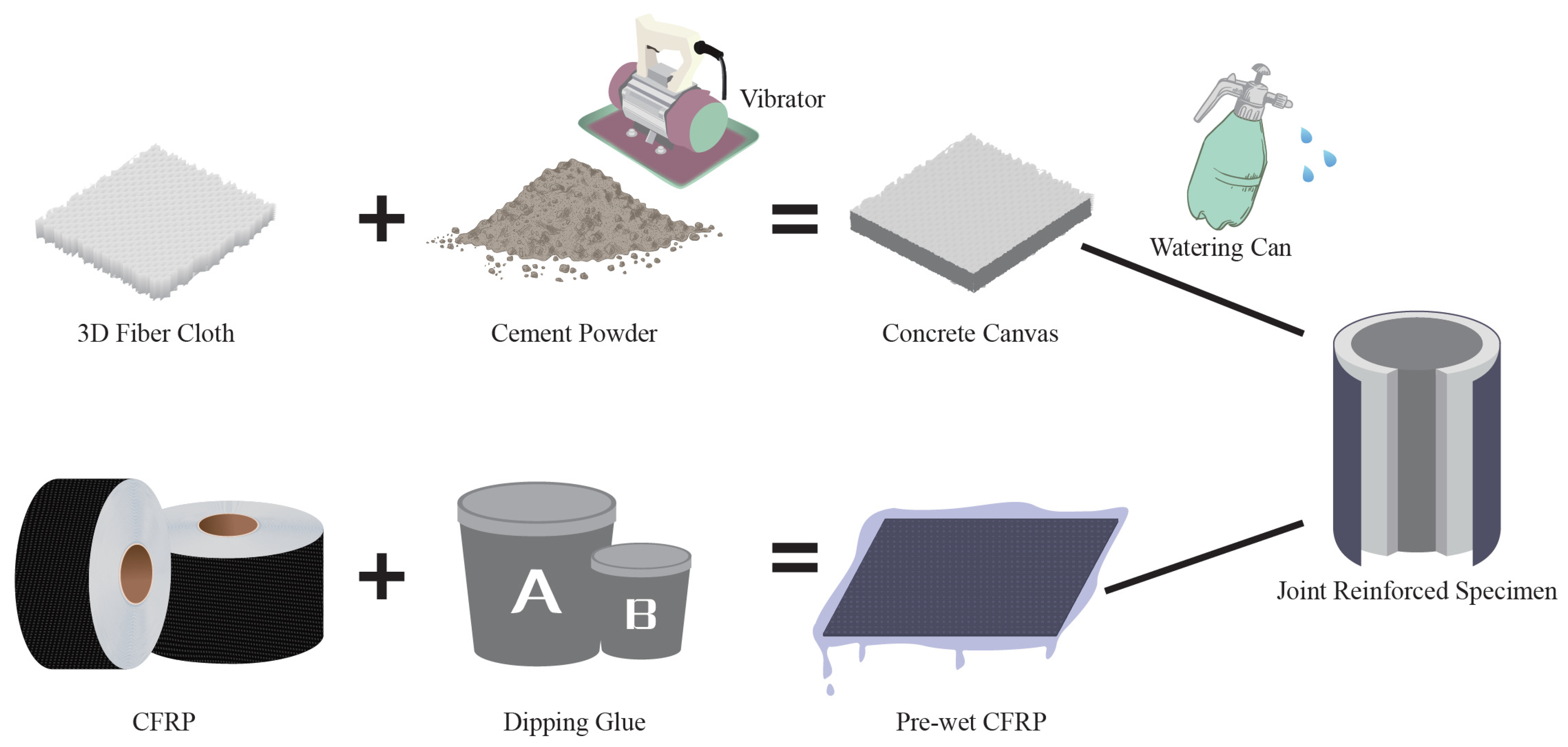

2. Experimental Program

2.1. Specimen Details

2.2. Reinforcement and Corrosion Induction Methodology

2.3. Measurement Systems

3. Results and Discussion

3.1. Failure Pattern

3.2. AE Characteristic Parameters

3.3. Rise Time/Amplitude (RA) and Average Frequency (AF)

3.4. B Value

3.5. AE Event Spatial Location Map

4. Conclusions

- The added CC remedies better the stress concentration of the specimen due to local failure during the loading process, makes the failure more complete, changes the failure mode of CFRP from “flaky” to “velvet”, and makes the sound of fiber failure duller.

- When the ultimate strength is reached, the AE signals of the JRC group specimen are widely distributed, and the number is large, while the CRC group specimen is narrow.

- From the AE characteristic parameters, it is observed that the CC addition can ensure an efficient accumulation and release of energy throughout the loading stage. The change range of the energy rate of the specimen increases due to corrosion in the late loading stage.

- The crack mode of the jointly reinforced specimens undergoes multiple transformations between tensile cracks and shear cracks, resulting in the final crush failure. The corrosion will reduce the probability of shear cracks in the core concrete.

- The fluctuations in both amplitude and frequency of the b values of the jointly reinforced specimens increase significantly with time. The crack activity of concrete is more intense in this period, which proves that the jointly reinforced method ensures a more complete failure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Siddika, A.; Mamun, M.d.A.A.; Alyousef, R.; Amran, Y.H.M. Strengthening of Reinforced Concrete Beams by Using Fiber-Reinforced Polymer Composites: A Review. J. Build. Eng. 2019, 25, 100798. [Google Scholar] [CrossRef]

- Soares, S.; Sena-Cruz, J.; Cruz, J.R.; Fernandes, P. Influence of Surface Preparation Method on the Bond Behavior of Externally Bonded CFRP Reinforcements in Concrete. Materials 2019, 12, 414. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zou, X.; Lin, H.; Feng, P.; Bao, Y.; Wang, J. A Review on FRP-Concrete Hybrid Sections for Bridge Applications. Compos. Struct. 2021, 262, 113336. [Google Scholar] [CrossRef]

- Naser, M.Z.; Hawileh, R.A.; Abdalla, J.A. Fiber-Reinforced Polymer Composites in Strengthening Reinforced Concrete Structures: A Critical Review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Xiang, Z.; Zhou, J.; Niu, J. Compressive Behavior of CFRP-Confined Steel Fiber-Reinforced Self-Compacting Lightweight Aggregate Concrete in Square Columns. J. Build. Eng. 2022, 105118. [Google Scholar] [CrossRef]

- Liang, H.; Li, S.; Lu, Y.; Yang, T. Reliability Analysis of Bond Behaviour of CFRP-Concrete Interface under Wet-Dry Cycles. Materials 2018, 11, 741. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, X.; Zhang, W.; Cui, W.; Wittmann, F.H. Bond Strength of Corroded Steel Bars in Reinforced Concrete Structural Elements Strengthened with CFRP Sheets. Cem. Concr. Compos. 2011, 33, 513–519. [Google Scholar] [CrossRef]

- Al-Saidy, A.H.; Al-Jabri, K.S. Effect of Damaged Concrete Cover on the Behavior of Corroded Concrete Beams Repaired with CFRP Sheets. Compos. Struct. 2011, 93, 1775–1786. [Google Scholar] [CrossRef]

- Cheng, L.; Karbhari, V.M. New Bridge Systems Using FRP Composites and Concrete: A State-of-the-Art Review. Prog. Struct. Eng. Mater. 2006, 8, 143–154. [Google Scholar] [CrossRef]

- Ramirez, R.; Maljaee, H.; Ghiassi, B.; Lourenço, P.B.; Oliveira, D.V. Bond Behavior Degradation between FRP and Masonry under Aggressive Environmental Conditions. Mech. Adv. Mater. Struct. 2019, 26, 6–14. [Google Scholar] [CrossRef]

- Li, H.; Chen, H.; Liu, L.; Zhang, F.; Han, F.; Lv, T.; Zhang, W.; Yang, Y. Application Design of Concrete Canvas (CC) in Soil Reinforced Structure. Geotext. Geomembr. 2016, 44, 557–567. [Google Scholar] [CrossRef]

- Jun, Z.; Wei, X.; Xingzhong, W.; Peiwei, G.; Zhihua, Y.; Lihai, S.; Jiang, W. Application and Research Status of Concrete Canvas and Its Application Prospect in Emergency Engineering. J. Eng. Fibers Fabr. 2020, 15, 155892502097575. [Google Scholar] [CrossRef]

- Joint Strengthening Effect of Concrete Canvas and Carbon Fiber Reinforced Plastic on Mechanical Properties of Reinforced Concrete Square Columns. Available online: http://www-webofscience-com-s.webvpn.imust.edu.cn:8118/wos/alldb/full-record/CSCD:6800919 (accessed on 6 September 2022).

- Niu, J.; Xu, W.; Li, J.; Liang, J. Influence of Cross-Sectional Shape on the Mechanical Properties of Concrete Canvas and CFRP-Reinforced Columns. Adv. Mater. Sci. Eng. 2021, 2021, 5541587. [Google Scholar] [CrossRef]

- Kim, B.; Weiss, W.J. Using Acoustic Emission to Quantify Damage in Restrained Fiber-Reinforced Cement Mortars. Cem. Concr. Res. 2003, 33, 207–214. [Google Scholar] [CrossRef]

- Effect of Aggregate Saturation Degree on the Freeze-Thaw Resistance of High Performance Polypropylene Fiber Lightweight Aggregate Concrete. Available online: http://www-webofscience-com-s.webvpn.imust.edu.cn:8118/wos/alldb/full-record/WOS:000401876800039 (accessed on 6 September 2022).

- Aslan, M. Investigation of Damage Mechanism of Flax Fibre LPET Commingled Composites by Acoustic Emission. Compos. Part B Eng. 2013, 54, 289–297. [Google Scholar] [CrossRef]

- Dev, A.; Chellapandian, M.; Prakash, S.S.; Kawasaki, Y. Failure-Mode Analysis of Macro-Synthetic and Hybrid Fibre-Reinforced Concrete Beams with GFRP Bars Using Acoustic Emission Technique. Constr. Build. Mater. 2020, 249, 118737. [Google Scholar] [CrossRef]

- Du, F.; Li, D.; Li, Y. Fracture Mechanism and Damage Evaluation of FRP/Steel–Concrete Hybrid Girder Using Acoustic Emission Technique. J. Mater. Civ. Eng. 2019, 31, 04019111. [Google Scholar] [CrossRef]

- Proverbio, E. Evaluation of Deterioration in Reinforced Concrete Structures by AE Technique. Mater. Corros. 2011, 62, 161–169. [Google Scholar] [CrossRef]

- Degala, S.; Rizzo, P.; Ramanathan, K.; Harries, K.A. Acoustic Emission Monitoring of CFRP Reinforced Concrete Slabs. Constr. Build. Mater. 2009, 23, 2016–2026. [Google Scholar] [CrossRef]

- Golewski, P.; Sadowski, T. Technological and Strength Aspects of Layers Made of Different Powders Laminated on a Polymer Matrix Composite Substrate. Molecules 2022, 27, 1168. [Google Scholar] [CrossRef]

- Van Steen, C.; Nasser, H.; Verstrynge, E.; Wevers, M. Acoustic Emission Source Characterisation of Chloride-Induced Corrosion Damage in Reinforced Concrete. Struct. Health Monit. 2022, 21, 1266–1286. [Google Scholar] [CrossRef]

- El Maaddawy, T.A.; Soudki, K.A. Effectiveness of Impressed Current Technique to Simulate Corrosion of Steel Reinforcement in Concrete. J. Mater. Civ. Eng. 2003, 15, 41–47. [Google Scholar] [CrossRef]

- Ma, G.; Li, H.; Duan, Z. Repair Effects and Acoustic Emission Technique–Based Fracture Evaluation for Predamaged Concrete Columns Confined with Fiber-Reinforced Polymers. J. Compos. Constr. 2012, 16, 626–639. [Google Scholar] [CrossRef]

- Analysis of B-Value and Improved b-Value of Acoustic Emissions Accompanying Rock Fracture. Available online: http://www-webofscience-com-s.webvpn.imust.edu.cn:8118/wos/alldb/full-record/WOS:000233351600030 (accessed on 6 September 2022).

- Wu, Y.-F.; Zhou, Y.-W. Unified Strength Model Based on Hoek-Brown Failure Criterion for Circular and Square Concrete Columns Confined by FRP. J. Compos. Constr. 2010, 14, 175–184. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Soulioti, D.V.; Sapouridis, N.; Barkoula, N.M.; Paipetis, A.S.; Matikas, T.E. Acoustic Emission Characterization of the Fracture Process in Fibre Reinforced Concrete. Constr. Build. Mater. 2011, 25, 4126–4131. [Google Scholar] [CrossRef]

- Ma, G.; Wu, C.; Hwang, H.-J.; Li, B. Crack Monitoring and Damage Assessment of BFRP-Jacketed Concrete Cylinders under Compression Load Based on Acoustic Emission Techniques. Constr. Build. Mater. 2021, 272, 121936. [Google Scholar] [CrossRef]

- Alver, N.; Tanarslan, H.M.; Tayfur, S. Monitoring Fracture Processes of CFRP-Strengthened RC Beam by Acoustic Emission. J. Infrastruct. Syst. 2017, 23, B4016002. [Google Scholar] [CrossRef]

- Ma, G.; Li, H.; Zhou, W.; Xian, G. Acoustic Emission Monitoring of Concrete Columns and Beams Strengthened with Fiber Reinforced Polymer Sheets. In Proceedings of the SPIE International Society for Optical Engineering, San Diego, CA, USA, 26 April 2012; p. 83472F. [Google Scholar]

- Ma, G.; Li, H. Acoustic Emission Monitoring and Damage Assessment of FRP-Strengthened Reinforced Concrete Columns under Cyclic Loading. Constr. Build. Mater. 2017, 144, 86–98. [Google Scholar] [CrossRef]

- Sagar, R.V.; Prasad, B.K.R.; Kumar, S.S. An Experimental Study on Cracking Evolution in Concrete and Cement Mortar by the B-Value Analysis of Acoustic Emission Technique. Cem. Concr. Res. 2012, 42, 1094–1104. [Google Scholar] [CrossRef]

- Yue, J.; Xia, Y.; Fang, H. Experimental Study on Fracture Mechanism and Tension Damage Constitutive Relationship of Steel Fiber Reinforced Concrete. China Civ. Eng. J. 2021, 54, 93–106. [Google Scholar]

| Material Type | Strain at Ultimate Strength (×10−6) | Yield Strength (MPa) | Ultimate Strength (MPa) | Elastic Modulus (MPa) |

|---|---|---|---|---|

| 6 mm hoop | 2019 | 422 | 528 | 209,014 |

| 10 mm rebar | 2622 | 527 | 646 | 200,991 |

| CFRP | 162 | - | 1848 | 233,077 |

| Specimen Type | Specimen Code | Theoretical Corrosion Rate (%) | CC Layers | CFRP Layers |

|---|---|---|---|---|

| URC group | URC-0 | 0 | 0 | 0 |

| URC-5 | 5 | 0 | 0 | |

| CRC group | CRC-5 | 5 | 0 | 2 |

| JRC group | JRC-0 | 0 | 1 | 2 |

| JRC-5 | 5 | 1 | 2 | |

| JRC-10 | 10 | 1 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Niu, J.; Xiang, Z.; Zhou, J.; Wang, J. Acoustic Emission Assessment of Corroded RC Columns Jointly Reinforced with Concrete Canvas and CFRP. Coatings 2022, 12, 1843. https://doi.org/10.3390/coatings12121843

Wang J, Niu J, Xiang Z, Zhou J, Wang J. Acoustic Emission Assessment of Corroded RC Columns Jointly Reinforced with Concrete Canvas and CFRP. Coatings. 2022; 12(12):1843. https://doi.org/10.3390/coatings12121843

Chicago/Turabian StyleWang, Jingsong, Jiangang Niu, Zehui Xiang, Jie Zhou, and Jun Wang. 2022. "Acoustic Emission Assessment of Corroded RC Columns Jointly Reinforced with Concrete Canvas and CFRP" Coatings 12, no. 12: 1843. https://doi.org/10.3390/coatings12121843

APA StyleWang, J., Niu, J., Xiang, Z., Zhou, J., & Wang, J. (2022). Acoustic Emission Assessment of Corroded RC Columns Jointly Reinforced with Concrete Canvas and CFRP. Coatings, 12(12), 1843. https://doi.org/10.3390/coatings12121843