About Gas Barrier Performance and Recyclability of Waterborne Coatings on Paperboard

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Coating Prepration

2.3. Coating Characterization

2.4. Single Gas Barrier Performance

2.5. Water Vapor Transmission Rate (WVTR)

2.6. Oxygen Transmission Rate (OTR)

2.7. Coating Removal

3. Results and Discussion

3.1. Gas Barrier Performance

3.1.1. Characterization of the Waterborne Coating on Paperboard

3.1.2. Oxygen and Water Vapor Barrier Properties

3.1.3. Carbon Dioxide and Nitrogen Barrier Properties

3.2. Recyclability of Coated Paperboard

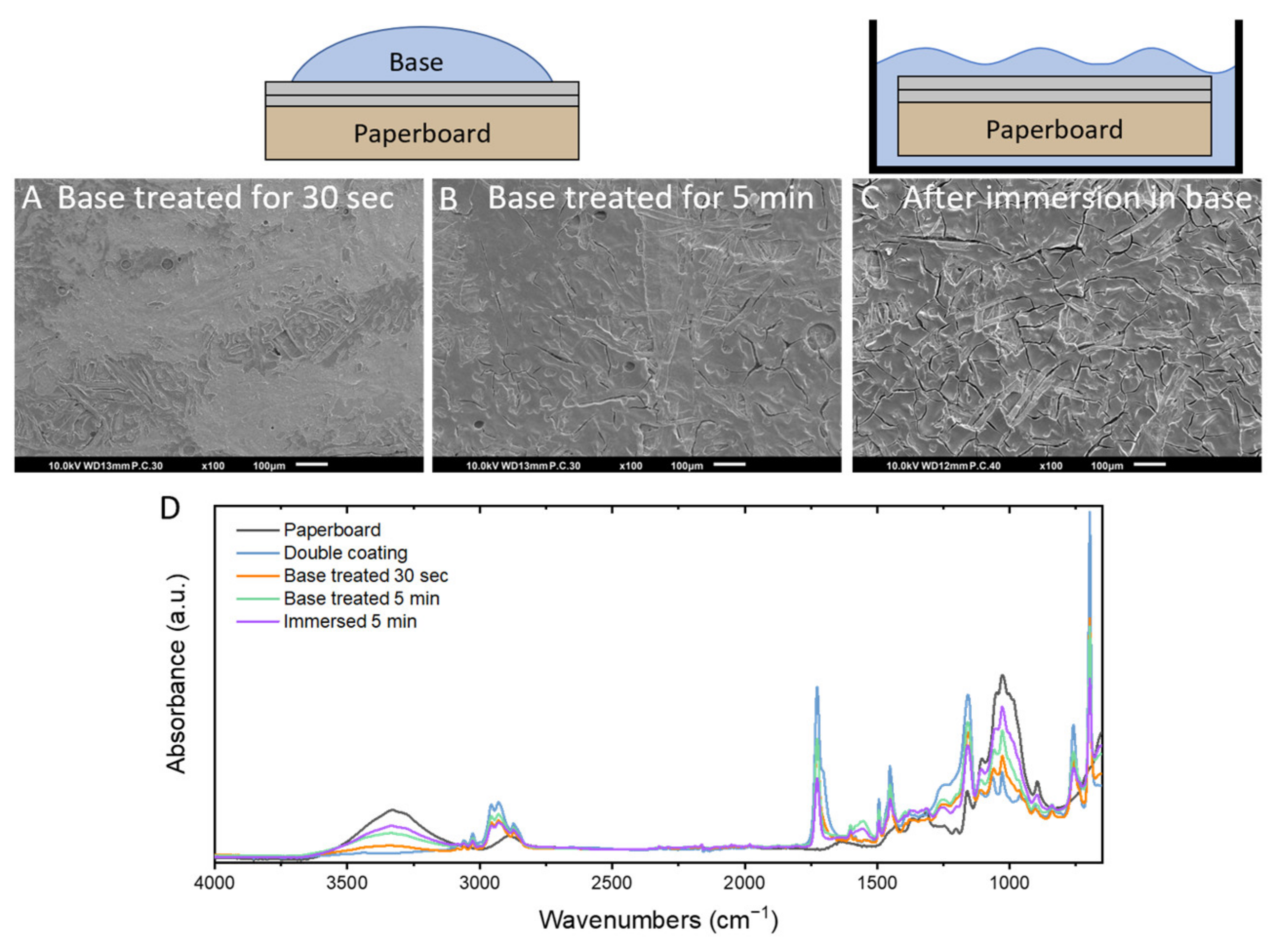

3.2.1. Influence of Individual Base Treatments on Paperboard and Coating Material

3.2.2. Influence of Base Treatment of Coated Paperboard

3.2.3. Re-Using Paperboard

3.2.4. Multilayer Barrier Coatings

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cichello, S.A. Oxygen Absorbers in Food Preservation: A Review. J. Food Sci. Technol. 2015, 52, 1889–1895. [Google Scholar] [CrossRef] [PubMed]

- M Rangaraj, V.; Rambabu, K.; Banat, F.; Mittal, V. Natural Antioxidants-Based Edible Active Food Packaging: An Overview of Current Advancements. Food Biosci. 2021, 43, 101251. [Google Scholar] [CrossRef]

- Pittia, P.; Sacchetti, G. Antiplasticization Effect of Water in Amorphous Foods. A Review. Food Chem. 2008, 106, 1417–1427. [Google Scholar] [CrossRef]

- Embleni, A. Modified Atmosphere Packaging and Other Active Packaging Systems for Food, Beverages and Other Fast-Moving Consumer Goods. In Trends in Packaging of Food, Beverages and Other Fast-Moving Consumer Goods (FMCG); Woodhead Publishing Limited: Philadelphia, PA USA, 2013; pp. 22–34. ISBN 9780857095039. [Google Scholar]

- Mujtaba, M.; Lipponen, J.; Ojanen, M.; Puttonen, S.; Vaittinen, H. Trends and Challenges in the Development of Bio-Based Barrier Coating Materials for Paper/Cardboard Food Packaging; a Review. Sci. Total Environ. 2022, 851, 158328. [Google Scholar] [CrossRef] [PubMed]

- Tiseo, I. Packaging Market in the Netherlands in 2020, by Type of Material. Available online: https://www.statista.com/statistics/712415/packaging-market-in-the-netherlands-by-type-of-material/ (accessed on 5 August 2022).

- Tiseo, I. Containerboard Consumption Worldwide from 2020 to 2031. Available online: https://www.statista.com/statistics/1090439/global-containerboard-demand/ (accessed on 1 August 2022).

- Tiseo, I. Market Size of Paperboard Packaging Worldwide in 2021 and 2026. Available online: https://www.statista.com/statistics/1030199/market-value-of-paper-worldwide/ (accessed on 5 August 2022).

- Tyagi, P.; Samaher, K.; Hubbe, M.A.; Pal, L. Advances in Barrier Coatings and Film Technologies for Achieving Sustainable Packaging of Food Products–A Review. Trends Food Sci. Technol. 2021, 115, 461–485. [Google Scholar] [CrossRef]

- Anukiruthika, T.; Sethupathy, P.; Wilson, A.; Kashampur, K.; Moses, J.A.; Anandharamakrishnan, C. Multilayer Packaging: Advances in Preparation Techniques and Emerging Food Applications. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1156–1186. [Google Scholar] [CrossRef] [PubMed]

- Tiseo, I. Recycling Rate of Paper and Cardboard Packaging Waste in the European Union from 2005 to 2019. Available online: https://www.statista.com/statistics/974705/recycling-rate-of-paper-and-cardboard-packaging-waste-in-the-eu/ (accessed on 6 September 2022).

- Bajpai, P. Process Steps in Recycled Fibre Processing. In Recycling and Deinking of Recovered Paper; Elsevier: Waltham, MA, USA, 2014; pp. 55–83. ISBN 9780124169982. [Google Scholar]

- Nazhad, M.M. Recycled Fiber Quality- A Review. J. Ind. Eng. Chem. 2005, 11, 314–329. [Google Scholar]

- Han, N.; Zhang, J.; Hoang, M.; Gray, S.; Xie, Z. A Review of Process and Wastewater Reuse in the Recycled Paper Industry. Environ. Technol. Innov. 2021, 24, 101860. [Google Scholar] [CrossRef]

- Pivnenko, K.; Eriksson, E.; Astrup, T.F. Waste Paper for Recycling: Overview and Identification of Potentially Critical Substances. Waste Manag. 2015, 45, 134–142. [Google Scholar] [CrossRef]

- Geueke, B.; Groh, K.; Muncke, J. Food Packaging in the Circular Economy: Overview of Chemical Safety Aspects for Commonly Used Materials. J. Clean. Prod. 2018, 193, 491–505. [Google Scholar] [CrossRef]

- Suciu, N.A.; Tiberto, F.; Vasileiadis, S.; Lamastra, L.; Trevisan, M. Recycled Paper-Paperboard for Food Contact Materials: Contaminants Suspected and Migration into Foods and Food Simulant. Food Chem. 2013, 141, 4146–4151. [Google Scholar] [CrossRef]

- Koivula, H.M.; Jalkanen, L.; Saukkonen, E.; Ovaska, S.-S.; Lahti, J.; Christophliemk, H.; Mikkonen, K.S. Machine-Coated Starch-Based Dispersion Coatings Prevent Mineral Oil Migration from Paperboard. Prog. Org. Coat. 2016, 99, 173–181. [Google Scholar] [CrossRef]

- Christophliemk, H.; Johansson, C.; Ullsten, H.; Järnström, L. Oxygen and Water Vapor Transmission Rates of Starch-Poly(Vinyl Alcohol) Barrier Coatings for Flexible Packaging Paper. Prog. Org. Coat. 2017, 113, 218–224. [Google Scholar] [CrossRef]

- Tayeb, A.H.; Tajvidi, M.; Bousfield, D. Paper-Based Oil Barrier Packaging Using Lignin-Containing Cellulose Nanofibrils. Molecules 2020, 25, 1344. [Google Scholar] [CrossRef] [PubMed]

- Türe, H.; Gällstedt, M.; Johansson, E.; Hedenqvist, M.S. Wheat-Gluten/Montmorillonite Clay Multilayer-Coated Paperboards with High Barrier Properties. Ind. Crops Prod. 2013, 51, 1–6. [Google Scholar] [CrossRef]

- Aulin, C.; Gällstedt, M.; Lindström, T. Oxygen and Oil Barrier Properties of Microfibrillated Cellulose Films and Coatings. Cellulose 2010, 17, 559–574. [Google Scholar] [CrossRef]

- Galizia, M.; Chi, W.S.; Smith, Z.P.; Merkel, T.C.; Baker, R.W.; Freeman, B.D. 50th Anniversary Perspective: Polymers and Mixed Matrix Membranes for Gas and Vapor Separation: A Review and Prospective Opportunities. Macromolecules 2017, 50, 7809–7843. [Google Scholar] [CrossRef]

- Andersson, C.; Ernstsson, M.; Järnström, L. Barrier Properties and Heat Sealability/Failure Mechanisms of Dispersion-Coated Paperboard. Packag. Technol. Sci. 2002, 15, 209–224. [Google Scholar] [CrossRef]

- Zhu, Y.D.; Allen, G.C.; Adams, J.M.; Gittins, D.I.; Hooper, J.J.; Skuse, D.R. Barrier Properties of Latex/Kaolin Coatings. Polym. Chem. 2013, 4, 4386. [Google Scholar] [CrossRef]

- Vähä-Nissi, M.; Kervinen, K.; Savolainen, A.; Egolf, S.; Lau, W. Hydrophobic Polymers as Barrier Dispersion Coatings. J. Appl. Polym. Sci. 2006, 101, 1958–1962. [Google Scholar] [CrossRef]

- Zhu, Y.; Bousfield, D.; Gramlich, W.M. The Influence of Pigment Type and Loading on Water Vapor Barrier Properties of Paper Coatings before and after Folding. Prog. Org. Coat. 2019, 132, 201–210. [Google Scholar] [CrossRef]

- Al-Gharrawi, M.; Ollier, R.; Wang, J.; Bousfield, D.W. The Influence of Barrier Pigments in Waterborne Barrier Coatings on Cellulose Nanofiber Layers. J. Coat. Technol. Res. 2022, 19, 3–14. [Google Scholar] [CrossRef]

- Rämänen, P.; Pitkänen, P.; Jämsä, S.; Maunu, S.L. Natural Oil-Based Alkyd-Acrylic Copolymers: New Candidates for Barrier Materials. J. Polym. Environ. 2012, 20, 950–958. [Google Scholar] [CrossRef]

- Lopes, C.M.A.; Felisberti, M.I. Composite of Low-Density Polyethylene and Aluminum Obtained from the Recycling of Postconsumer Aseptic Packaging. J. Appl. Polym. Sci. 2006, 101, 3183–3191. [Google Scholar] [CrossRef]

- Şahin, G.G.; Karaboyacı, M. Process and Machinery Design for the Recycling of Tetra Pak Components. J. Clean. Prod. 2021, 323, 129186. [Google Scholar] [CrossRef]

- Del Curto, B.; Barelli, N.; Profaizer, M.; Farè, S.; Tanzi, M.C.; Cigada, A.; Ognibene, G.; Recca, G.; Cicala, G. Poly-Paper: A Sustainable Material for Packaging, Based on Recycled Paper and Recyclable with Paper. J. Appl. Biomater. Funct. Mater. 2016, 14, 490–495. [Google Scholar] [CrossRef] [PubMed]

- Bakker, S.; Bosveld, L.; Metselaar, G.A.; Esteves, A.C.C.; Schenning, A.P.H.J. Understanding and Improving the Oil and Water Barrier Performance of a Waterborne Coating on Paperboard. ACS Appl. Polym. Mater. 2022, 4, 6148–6155. [Google Scholar] [CrossRef] [PubMed]

- Bakker, S.; Aarts, J.; Esteves, A.C.C.; Metselaar, G.A.; Schenning, A.P.H.J. Water Barrier Properties of Resin-Stabilized Waterborne Coatings for Paperboard. Macromol. Mater. Eng. 2022, 307, 2100829. [Google Scholar] [CrossRef]

- Siddiq, M.; Tam, K.C.; Jenkins, R.D. Dissolution Behaviour of Model Alkali-Soluble Emulsion Polymers: Effects of Molecular Weights and Ionic Strength. Colloid Polym. Sci. 1999, 277, 1172–1178. [Google Scholar] [CrossRef]

- Lopes Brito, E.; Ballard, N. Film Formation of Alkali Soluble Resin (ASR) Stabilized Latexes. Prog. Org. Coat. 2021, 159, 106444. [Google Scholar] [CrossRef]

- Steward, P.A.; Hearn, J.; Wilkinson, M.C. An Overview of Polymer Latex Film Formation and Properties. Adv. Colloid Interface Sci. 2000, 86, 195–267. [Google Scholar] [CrossRef] [PubMed]

- Keddie, J.L. Film Formation of Latex. Mater. Sci. Eng. R Rep. 1997, 21, 101–170. [Google Scholar] [CrossRef]

- Winnik, M.A. Latex Film Formation. Curr. Opin. Colloid Interface Sci. 1997, 2, 192–199. [Google Scholar] [CrossRef]

- Routh, A.F.; Russel, W.B. Process Model for Latex Film Formation: Limiting Regimes for Individual Driving Forces. Langmuir 1999, 15, 7762–7773. [Google Scholar] [CrossRef]

- Badía, A.; Barandiaran, M.J.; Leiza, J.R. Biobased Alkali Soluble Resins Promoting Supramolecular Interactions in Sustainable Waterborne Pressure-Sensitive Adhesives: High Performance and Removability. Eur. Polym. J. 2021, 144, 110244. [Google Scholar] [CrossRef]

- Helmenstine, A.M. The Chemical Composition of Air. Available online: https://www.thoughtco.com/chemical-composition-of-air-604288 (accessed on 21 October 2022).

- Guo, Y.H.; Li, S.C.; Wang, G.S.; Ma, W.; Huang, Z. Waterborne Polyurethane/Poly(n-Butyl Acrylate-Styrene) Hybrid Emulsions: Particle Formation, Film Properties, and Application. Prog. Org. Coat. 2012, 74, 248–256. [Google Scholar] [CrossRef]

- Wang, H.; Fan, J.; Fei, G.; Lan, J.; Zhao, Z. Preparation and Property of Waterborne UV-Curable Chain-Extended Polyurethane Surface Sizing Agent: Strengthening and Waterproofing Mechanism for Cellulose Fiber Paper. J. Appl. Polym. Sci. 2015, 132, 1–11. [Google Scholar] [CrossRef]

- Yook, S.; Park, H.; Park, H.; Lee, S.Y.; Kwon, J.; Youn, H.J. Barrier Coatings with Various Types of Cellulose Nanofibrils and Their Barrier Properties. Cellulose 2020, 27, 4509–4523. [Google Scholar] [CrossRef]

- Yan, X.; Ji, Y.; He, T. Synthesis of Fiber Crosslinking Cationic Latex and Its Effect on Surface Properties of Paper. Prog. Org. Coat. 2013, 76, 11–16. [Google Scholar] [CrossRef]

- Parry, R.T. (Ed.) Principles and Applications of Modified Atmosphere Packaging of Foods; Springer: New York, NY, USA, 1993; ISBN 978-1-4613-5892-3. [Google Scholar]

- Kloos, J.; Jansen, N.; Houben, M.; Casimiro, A.; Lub, J.; Borneman, Z.; Schenning, A.P.H.J.; Nijmeijer, K. On the Order and Orientation in Liquid Crystalline Polymer Membranes for Gas Separation. Chem. Mater. 2021, 33, 8323–8333. [Google Scholar] [CrossRef] [PubMed]

- Ismail, A.F.; Khulbe, K.C.; Matsuura, T. Gas Seperation Membranes-Polymeric and Inorganic; Springer: New York, NY, USA, 2015; ISBN 9783319010946. [Google Scholar]

- Wijmand, J.G.; Baker, R.W. The Solution-Diffusion Model: A Review. J. Memb. Sci. 1993, 107, 1–21. [Google Scholar] [CrossRef]

- Koros, W.J.; Fleming, G.K. Membrane-Based Gas Separation. J. Memb. Sci. 1993, 83, 1–80. [Google Scholar] [CrossRef]

- Proniewicz, L.M.; Paluszkiewicz, C.; Wesełucha-Birczyńska, A.; Majcherczyk, H.; Barański, A.; Konieczna, A. FT-IR and FT-Raman Study of Hydrothermally Degradated Cellulose. J. Mol. Struct. 2001, 596, 163–169. [Google Scholar] [CrossRef]

- Oh, S.Y.; Yoo, D.I.; Shin, Y.; Seo, G. FTIR Analysis of Cellulose Treated with Sodium Hydroxide and Carbon Dioxide. Carbohydr. Res. 2005, 340, 417–428. [Google Scholar] [CrossRef] [PubMed]

| Gas | Kinetic Diameter (nm) | Critical Temperature (°C) |

|---|---|---|

| He | 0.26 | −268 |

| CO2 | 0.33 | 31 |

| O2 | 0.35 | −119 |

| N2 | 0.36 | −147 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bakker, S.; Kloos, J.; Metselaar, G.A.; Esteves, A.C.C.; Schenning, A.P.H.J. About Gas Barrier Performance and Recyclability of Waterborne Coatings on Paperboard. Coatings 2022, 12, 1841. https://doi.org/10.3390/coatings12121841

Bakker S, Kloos J, Metselaar GA, Esteves ACC, Schenning APHJ. About Gas Barrier Performance and Recyclability of Waterborne Coatings on Paperboard. Coatings. 2022; 12(12):1841. https://doi.org/10.3390/coatings12121841

Chicago/Turabian StyleBakker, Sterre, Joey Kloos, Gerald A. Metselaar, A. Catarina C. Esteves, and Albert P. H. J. Schenning. 2022. "About Gas Barrier Performance and Recyclability of Waterborne Coatings on Paperboard" Coatings 12, no. 12: 1841. https://doi.org/10.3390/coatings12121841

APA StyleBakker, S., Kloos, J., Metselaar, G. A., Esteves, A. C. C., & Schenning, A. P. H. J. (2022). About Gas Barrier Performance and Recyclability of Waterborne Coatings on Paperboard. Coatings, 12(12), 1841. https://doi.org/10.3390/coatings12121841