The Influence of the Coating on the Saw Blade on the Energy Intensity of Cross-Cutting of Wood

Abstract

:1. Introduction

2. Materials and Methods

- made of tool steel without SK blades with a diameter of ø 600 × 3.5 × 30 with 56 evenly spaced teeth and a cutting-edge angle of 20° (referred to as HSS);

- with SK blades with a diameter of ø 600 × 3.5 × 30 with 54 evenly spaced teeth and a cutting-edge angle of 20° (marked as SK).

2.1. Coating Maximizer AlTiN

2.2. Coating CRONAL I

2.3. Coating KTRN I

2.4. Analysis of the Coated Samples

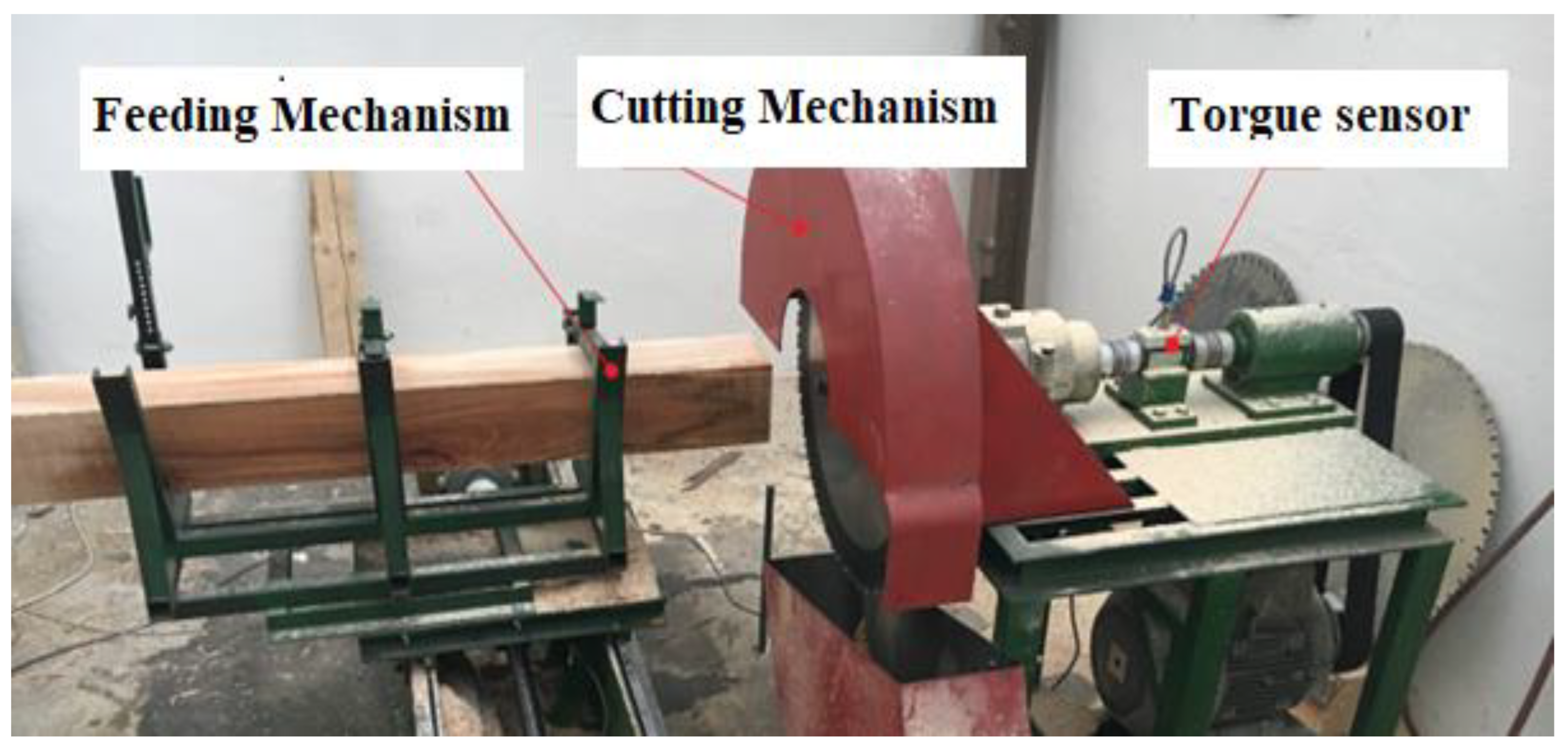

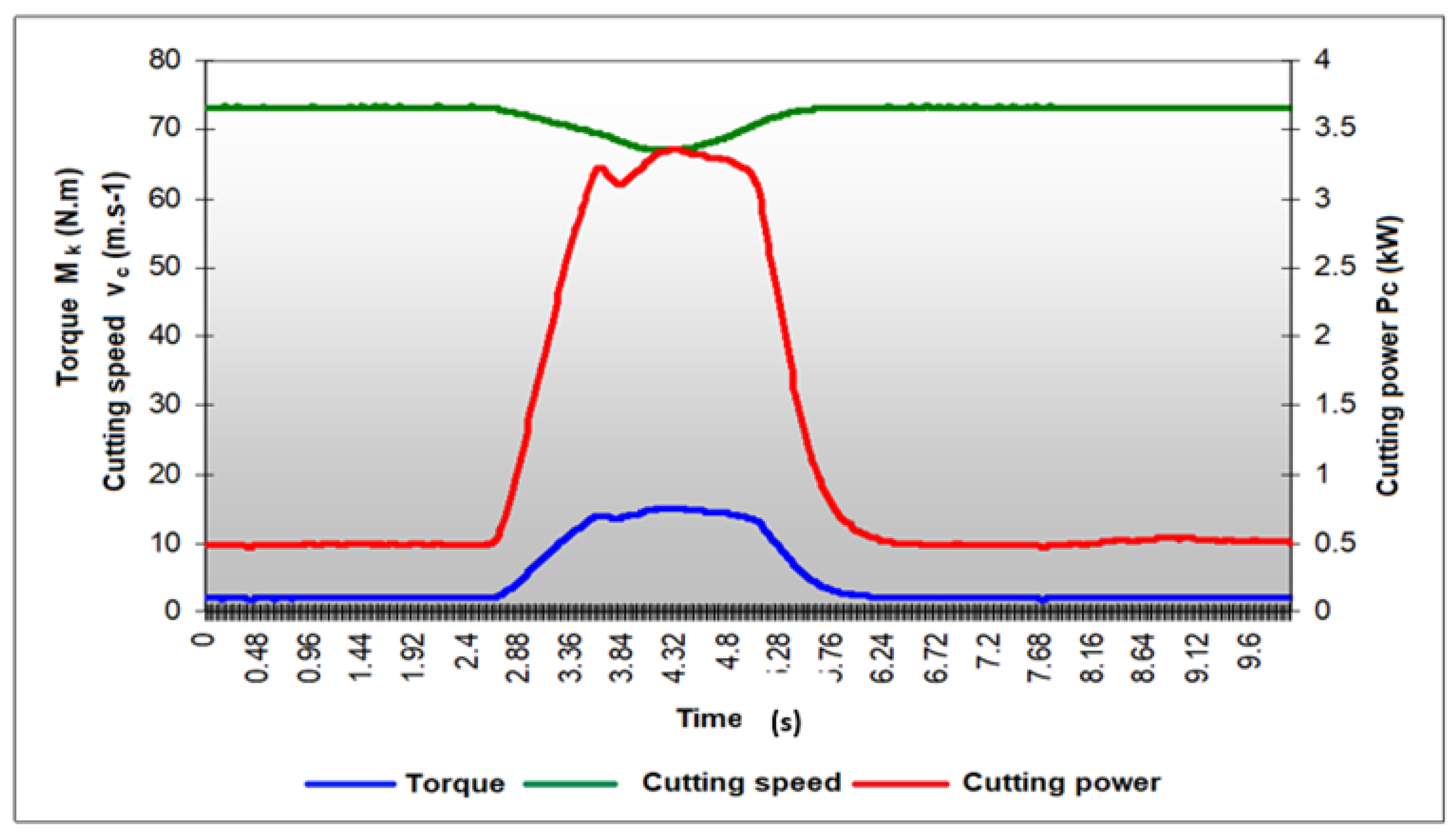

2.5. Experimental Transverse Cutting

2.6. Test Samples

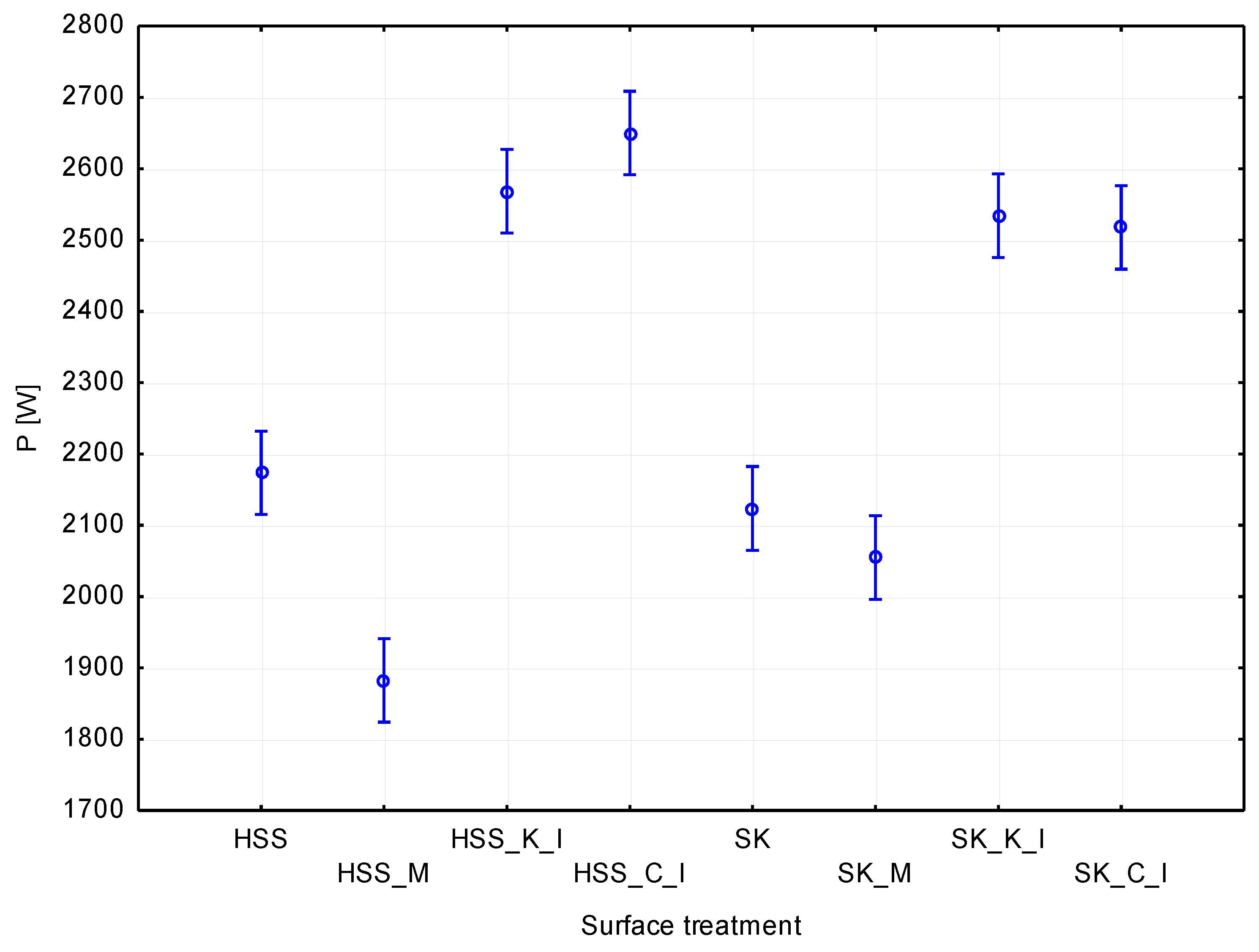

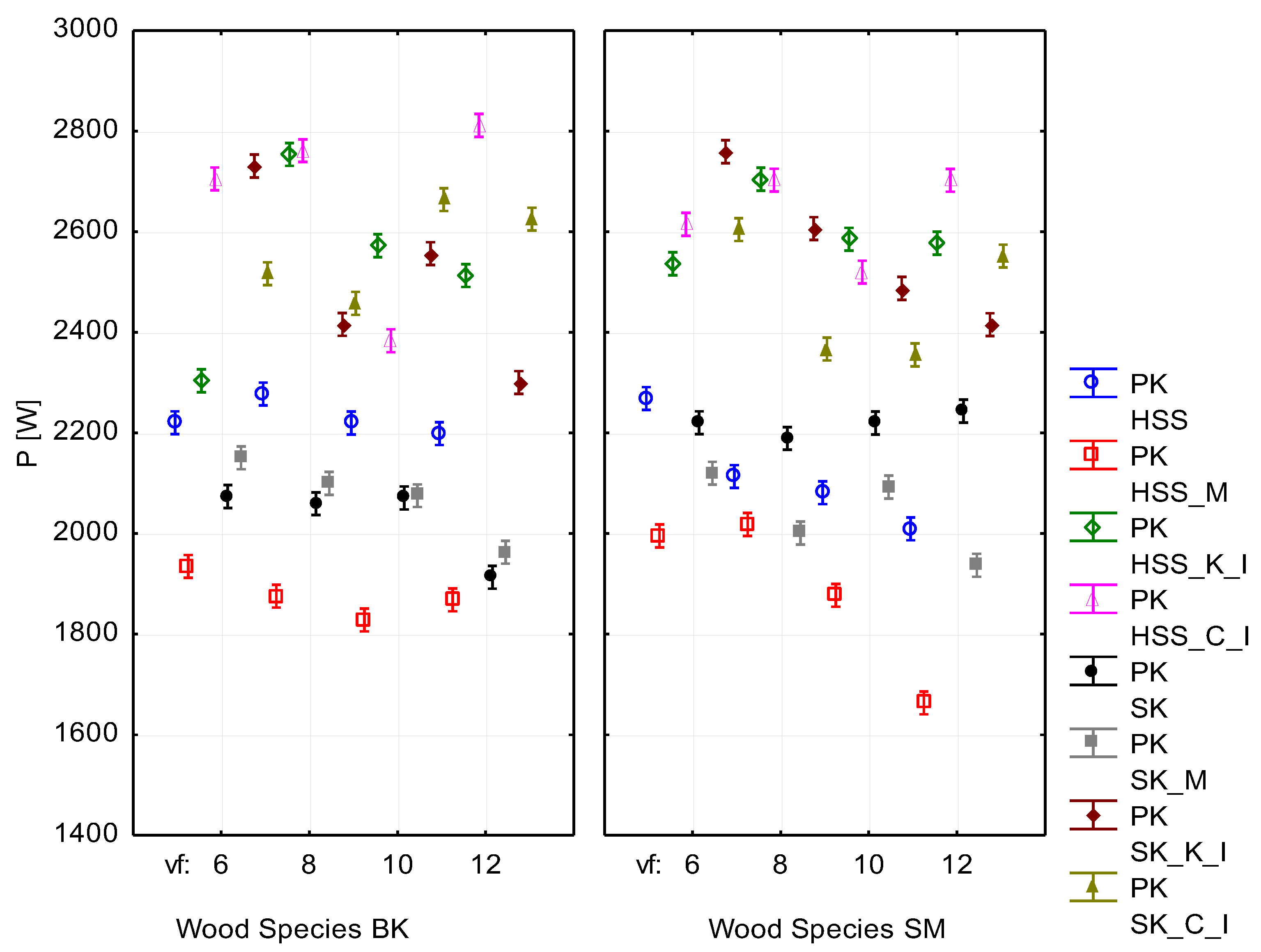

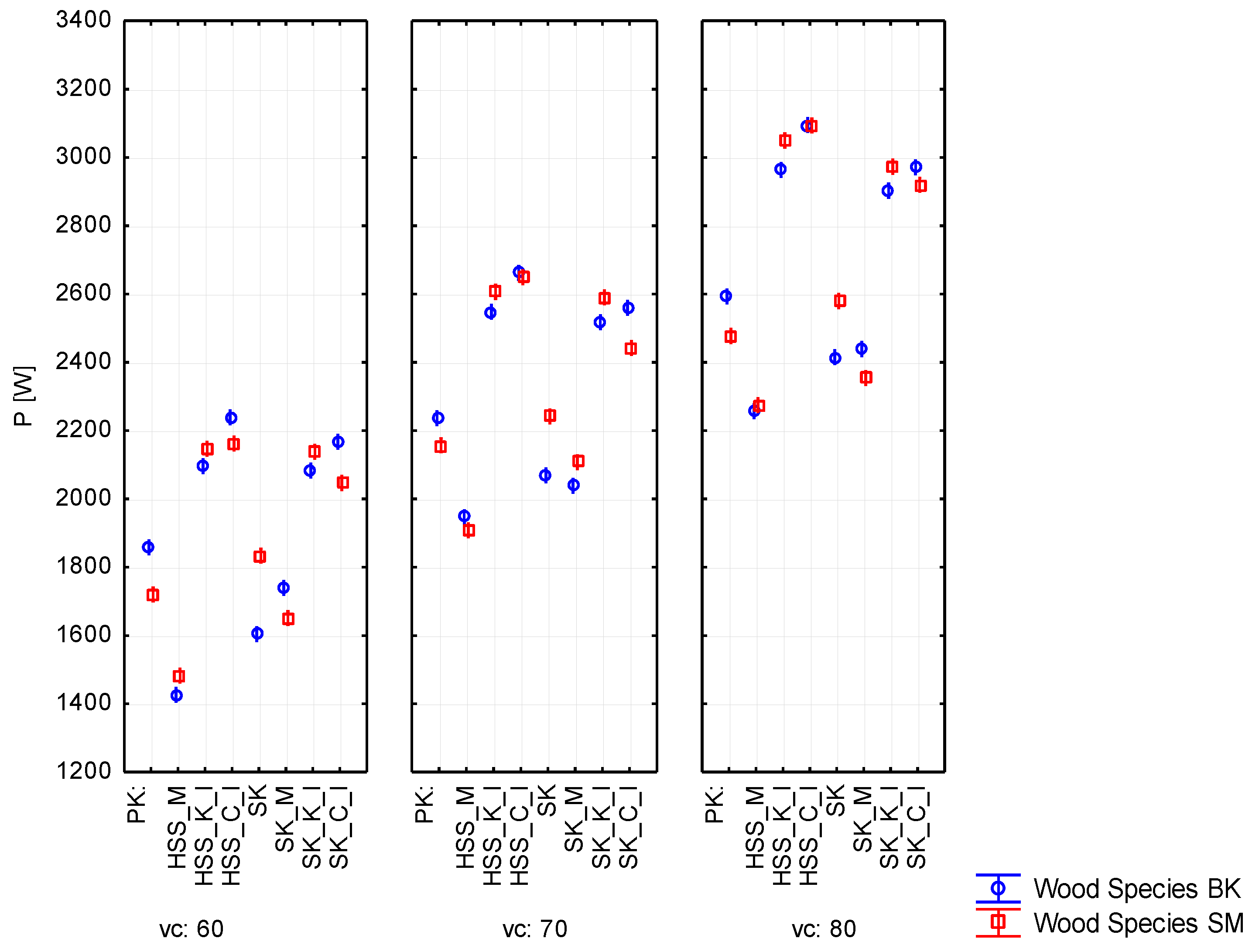

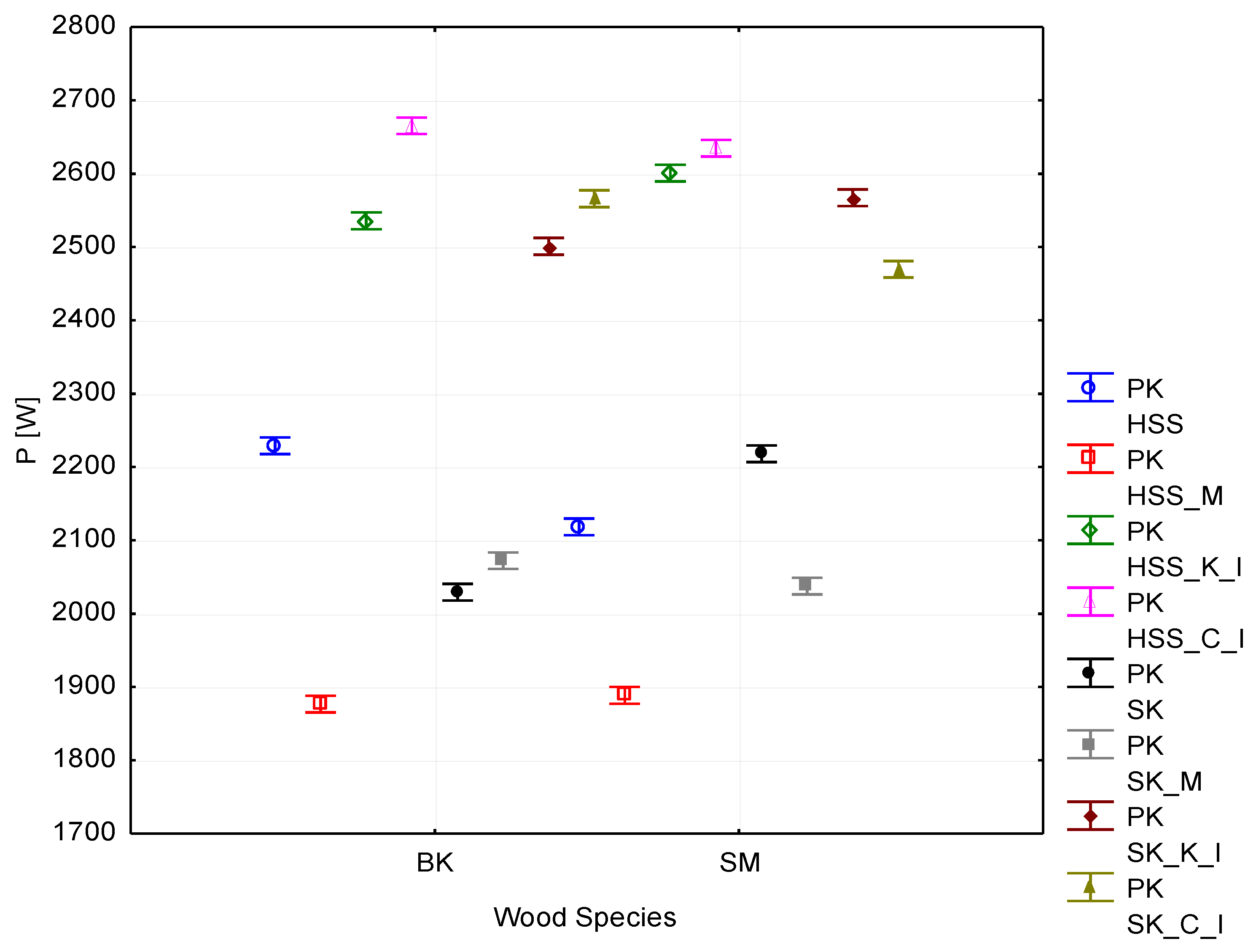

3. Results and Discussion

- H0: = 0 versus H1: ≠ 0

- H0: = 0 versus H1: ≠ 0

- H0: = 0 versus H1: ≠ 0

- H0: = 0 versus H1: ≠ 0

- H0: = 0 versus H1: ≠ 0

- ...

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Detvaj, J. Technológia Piliarskej Výroby; Vydavateľstvo TU vo Zvolene: Zvolen, Slovakia, 2003; ISBN 80-228-1248-X. [Google Scholar]

- Kováč, J.; Mikleš, M. Vplyv Vybraných Parametrov Na Energetickú Náročnosť Procesu Rezania Dreva Pílovými Kotúčmi. 2015. Available online: http://www.fvt.tuke.sk/journal/pdf09/3-str−23−26.pdf (accessed on 14 October 2018).

- Krilek, J.; Ťavodová, M.; Kováč, J.; Tichý, B. Impact of irregular tooth pitch of circular saw blades in power for wood cross-cutting. Drv. Ind. Znan. Časopis Za Pitanja Drv. Technol. 2020, 71, 3–11. [Google Scholar] [CrossRef]

- Siklienka, M.; Mišura, Ľ. Influence of the clearance of saw blade over the work piece on tool-wear. In Proceedings of the New Technologies and Materials in Industries based on the Forestry Sector, Croatia, Zagreb, 19 October 2007; pp. 113–117. [Google Scholar]

- Argay, F. Effect of the saw blade teeth number on transverse cutting process noise when cutting beechwood. Acta Fac. Xylologiae Zvolen 2014, 56, 77–85. [Google Scholar]

- Konov, V.N. Research of the temperature field on the circular saw blades in the wood cutting process. In Working Machines, Tools in Machining of the Wood; University Textbook of the Scientific Works: Leningrad, Russia, 1982; Volume 9, pp. 3–6. [Google Scholar]

- Martinez, H.V.; Hankele, M. Simulation of the circular sawing process. In Proceedings of the 10th European LS-DYNA Conference, Würzburg, Germany, 15–17 June 2015. [Google Scholar]

- Ratnasingam, J.; Ma, T.P.; Ramasamy, G. Tool temperature and cutting forces during the machining of particleboard and solid wood. J. Appl. Sci. 2010, 10, 2881–2886. [Google Scholar] [CrossRef] [Green Version]

- Kalincová, D.; Barborák, O.; Andrejčák, I. Quality of the chrome layer of coining dies and its impact on their reliability and durability in operation. Kov. Mater. 2011, 49, 457–461. [Google Scholar]

- Hrubec, J. Špeciálna Technológia II; Edičné stredisko SVŠT: Bratislava, Slovakia, 1990; ISBN 80-227-0465-2. [Google Scholar]

- Janáč, A.; Lipa, Z.; Peterka, J. Teória Obrábania; Vydavateľstvo STU: Bratislava, Slovakia, 1999. [Google Scholar]

- Peterka, J.; Jančovič, R. Pvd coatings on the cutting tools. In Zborník Prednášok: Medzinárodná Vedecká Konferencia Matar ’04; MATAR Praha: Czech Republic, 2004; pp. 207–211. [Google Scholar]

- Orlicz, T. Wood Machining with Cutting Tools; Script SGGW-AR, SGGW-AR: Warsaw, Poland, 1998. [Google Scholar]

- Naylor, A.; Hackney, P.; Perera, N.; Clahr, E. A predictive model for the cutting force in wood machining developed using mechanical properties. Bioresources 2012, 7, 2883–2894. [Google Scholar] [CrossRef]

- Zdravecká, E.; Ondáč, M. Charakteristika Procesov Abrazívneho Opotrebenia. 2014. Available online: http://www.engineering.sk/clanky2/tribologia-a-tribotechnika/1628-charakterizacia-procesov-abrazivneho-opotrebenia (accessed on 22 February 2018).

- Orlowski, K.A.; Ochrymiuk, T.; Atkins, A.; Chuchala, D. Application of fracture mechanics for energetic effects predictions while wood sawing. Wood Sci. Technol. 2013, 47, 949–963. [Google Scholar] [CrossRef] [Green Version]

- Krilek, J.; Kovac, J.; Kučera, M. Wood Crosscutting Process Analysis for Circular Saws. BioResources 2013, 9, 1417–1429. [Google Scholar] [CrossRef]

- Gaff, M.; Sarvašová-Kvietková, M.; Gašparík, M.; Slávik, M. Dependence of roughness change and crack formation on parameters of wood surface embossing. Wood Res. 2016, 61, 163–174. [Google Scholar]

- Kminiak, R.; Kubš, J. Cutting power during cross-cutting of selected wood species with a circular saw. BioResources 2016, 11, 10528–10539. [Google Scholar] [CrossRef] [Green Version]

- Orlowski, A.K.; Ochrymiuk, T.; Hlaskova, L.; Chuchala, D.; Kopecky, Z. Revisiting the estimation of cutting power with different energetic methods while sawing soft and hard woods on the circular sawing machine: A central european case. Wood Sci. Technol. 2020, 54, 457–477. [Google Scholar] [CrossRef] [Green Version]

- Pilana. Technické Informace Pro Pilové Kotouče Z Nástrojové Oceli. Česká Republika—Hulín: Pilana a.s. 2017. Available online: https://www.pilanamarket.cz/pilove-kotouce−2/ (accessed on 14 October 2018).

- Kováč, J.; Harvánek, P.; Krilek, J.; Kuvik, T.; Melicherčík, J. Analysis of cutting conditions in the process of cross-cutting wood by circular saws. BioResources 2021, 16, 102–1041. [Google Scholar] [CrossRef]

- Schmidtová, J.; Vacek, V. Applied Statistics; Technical University in Zvolen: Zvolen, Slovakia, 2013; ISBN 978-80-228-2496-5. [Google Scholar]

- Kminiak, R. Vplyv konštrukcie pílového kotúča na kvalitu vytvoreného povrchu pri priečnom pílení smrekového reziva na kapovacej pokosovej píle (effect of the saw blade construction on the surface quality when transverse sawing spruce lumber on crosscut miter saw). Acta Fac. Xilologice Zvolen 2014, 56, 87–96. [Google Scholar]

- Siklienka, M.; Kminiak, R.; Argay, F. Influence of angular geometry of saw blade on cutting performance at cross-cutting beech wood. Vplyv uhlovej geometrie pílového kotúča na rezný výkon pri priečnom pílení bukového dreva. Acta Fac. Xylologiae 2013, 1, 91–99. [Google Scholar]

- Myna, R.; Hellmayr, R.; Georgiades, M.; Leiter, M.L.; Frömel-Frybort, S.; Wimmer, R.; Liebner, F. Môže povrchová úprava kotúčových pílových kotúčov potenciálne znížiť tvorbu prachu? Materiály 2021, 14, 5123. [Google Scholar]

- Kubovský, I.; Krišťák, Ľ.; Suja, J.; Gajtanská, M.; Igaz, R.; Ružiak, I.; Réh, R. Optimalizácia parametrov rezania materiálov na báze dreva CO2 laserom. Appl. Sci. 2020, 10, 8113. [Google Scholar] [CrossRef]

| Coating Composition | Al Ti N |

|---|---|

| Operational temperature | 850 °C |

| Coating temperature | 450–550 °C |

| Hardness HV 0.05 | 3500 |

| Color | blue/black |

| Coating Composition | Al Ti Cr Si N |

|---|---|

| Operational temperature | 1000 °C |

| Coating temperature | 500 °C |

| Hardness HV 0.05 | 1200 |

| Color | blue/black |

| Coating Composition | Al Ti Cr N |

|---|---|

| Operational temperature | 1000 °C |

| Coating temperature | 500 °C |

| Hardness HV 0.05 | 1200 |

| Colour | blue/black |

| Saw Blades | Feed Speed [m·min−1] | Cutting Speed [m·s−1] | Power [W] (Average) |

|---|---|---|---|

| HSS | 12 | 60 | 1820.61 |

| HSS_M | 12 | 60 | 1310.63 |

| HSS_K_I | 6 | 60 | 1826.08 |

| HSS_C_I | 10 | 60 | 1969.01 |

| SK | 12 | 60 | 1529.77 |

| SK_M | 12 | 60 | 1628.19 |

| SK_K_I | 12 | 60 | 1866.39 |

| SK_C_I | 6 | 60 | 2079.32 |

| Saw Blades | Feed Speed [m·min−1] | Cutting Speed [m·s−1] | Power [W] (Average) |

|---|---|---|---|

| HSS | 8 | 60 | 1621.13 |

| HSS_M | 12 | 60 | 1251.54 |

| HSS_K_I | 12 | 60 | 2113.56 |

| HSS_C_I | 10 | 60 | 2098.21 |

| SK | 6 | 60 | 1797.48 |

| SK_M | 12 | 60 | 1509.93 |

| SK_K_I | 12 | 60 | 2013.19 |

| SK_C_I | 10 | 60 | 1913.99 |

| Source of Variability | Sum of Squares | Degrees of Freedom | Variance | F-Test | p-Level of Significance |

|---|---|---|---|---|---|

| Abs. member | 6.164104 × 10−9 | 1 | 6.164104 × 10−9 | 2,559,047 | 0.000000 |

| St | 8.304495 × 10−7 | 7 | 1.186356 × 10−7 | 4925 | 0.000000 |

| WS | 1.617926 × 10−4 | 1 | 1.617926 × 10−4 | 7 | 0.009696 |

| vf | 1.573577 × 10−6 | 3 | 5.245258 × 10−5 | 218 | 0.000000 |

| vc | 1.262143 × 10−8 | 2 | 6.310716 × 10−7 | 26,199 | 0.000000 |

| St·WS | 2.437381 × 10−6 | 7 | 3.481973 × 10−5 | 145 | 0.000000 |

| St·vf | 7.711793 × 10−6 | 21 | 3.672282 × 10−5 | 152 | 0.000000 |

| WS·vf | 2.829735 × 10−5 | 3 | 9.432451 × 10−4 | 39 | 0.000000 |

| St·vc | 9.134908 × 10−5 | 14 | 6.524935 × 10−4 | 27 | 0.000000 |

| WS·vc | 1.975272 × 10−4 | 2 | 9.876362 × 10−3 | 4 | 0.016860 |

| vf·vc | 7.944500 × 10−4 | 6 | 1.324083 × 10−4 | 5 | 0.000013 |

| St·WS·vf | 2.741593 × 10−6 | 21 | 1.305520 × 10−5 | 54 | 0.000000 |

| St·WS·vc | 3.697694 × 10−5 | 14 | 2.641210 × 10−4 | 11 | 0.000000 |

| St·vf·vc | 1.012590 × 10−6 | 42 | 2.410928 × 10−4 | 10 | 0.000000 |

| WS·vf·vc | 1.490149 × 10−5 | 6 | 2.483582 × 10−4 | 10 | 0.000000 |

| St·WS·vf·vc | 8.469191 × 10−5 | 42 | 2.016474 × 10−4 | 8 | 0.000000 |

| Error | 2.312400 × 10−6 | 960 | 2.408750 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kováč, J.; Kuvik, T.; Melicherčík, J.; Krilek, J. The Influence of the Coating on the Saw Blade on the Energy Intensity of Cross-Cutting of Wood. Coatings 2022, 12, 1803. https://doi.org/10.3390/coatings12121803

Kováč J, Kuvik T, Melicherčík J, Krilek J. The Influence of the Coating on the Saw Blade on the Energy Intensity of Cross-Cutting of Wood. Coatings. 2022; 12(12):1803. https://doi.org/10.3390/coatings12121803

Chicago/Turabian StyleKováč, Ján, Tomáš Kuvik, Ján Melicherčík, and Jozef Krilek. 2022. "The Influence of the Coating on the Saw Blade on the Energy Intensity of Cross-Cutting of Wood" Coatings 12, no. 12: 1803. https://doi.org/10.3390/coatings12121803

APA StyleKováč, J., Kuvik, T., Melicherčík, J., & Krilek, J. (2022). The Influence of the Coating on the Saw Blade on the Energy Intensity of Cross-Cutting of Wood. Coatings, 12(12), 1803. https://doi.org/10.3390/coatings12121803