Effect of Nitrogen Flow Rate on Microstructure and Optical Properties of Ta2O5 Coatings

Abstract

1. Introduction

2. Materials and Methods

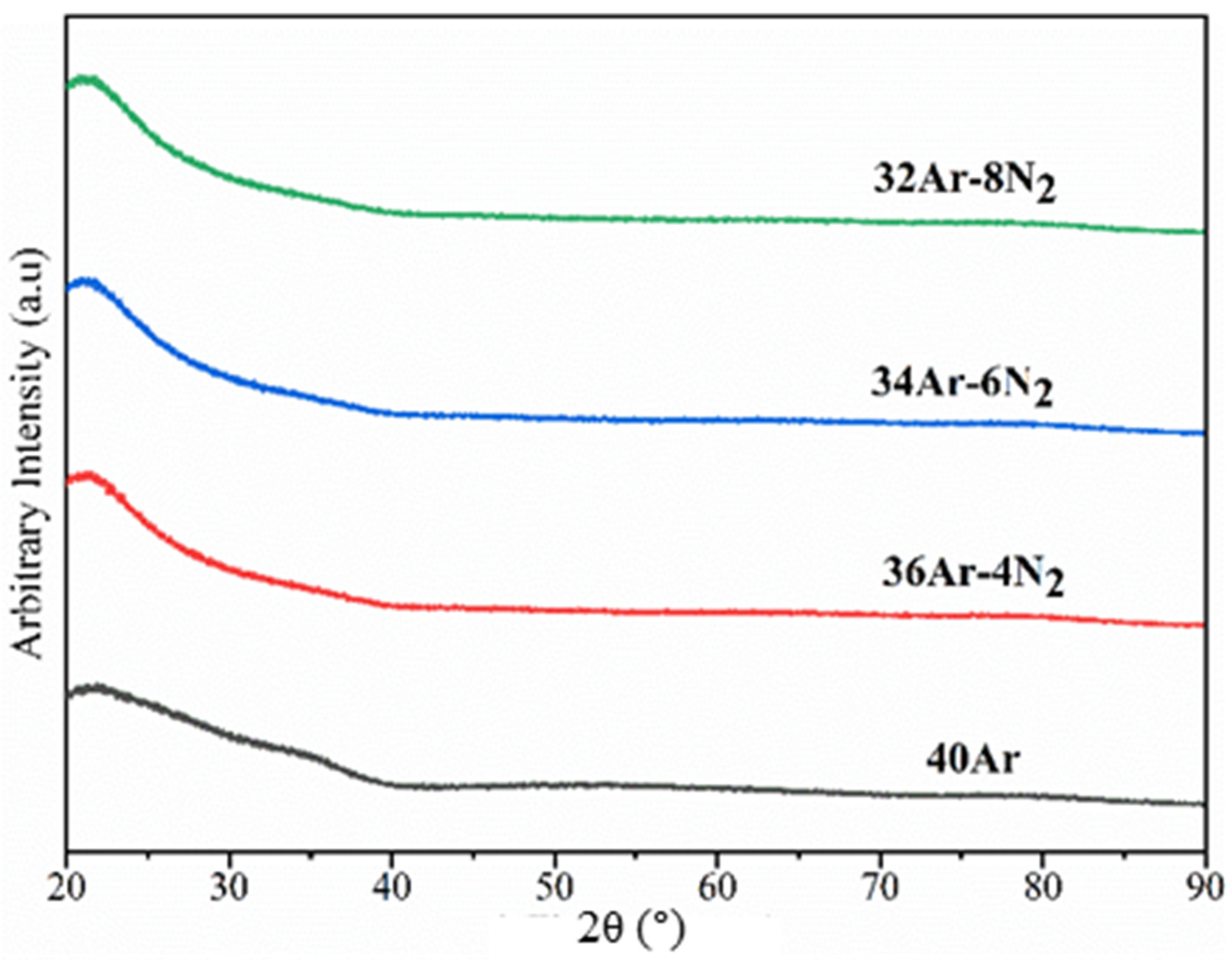

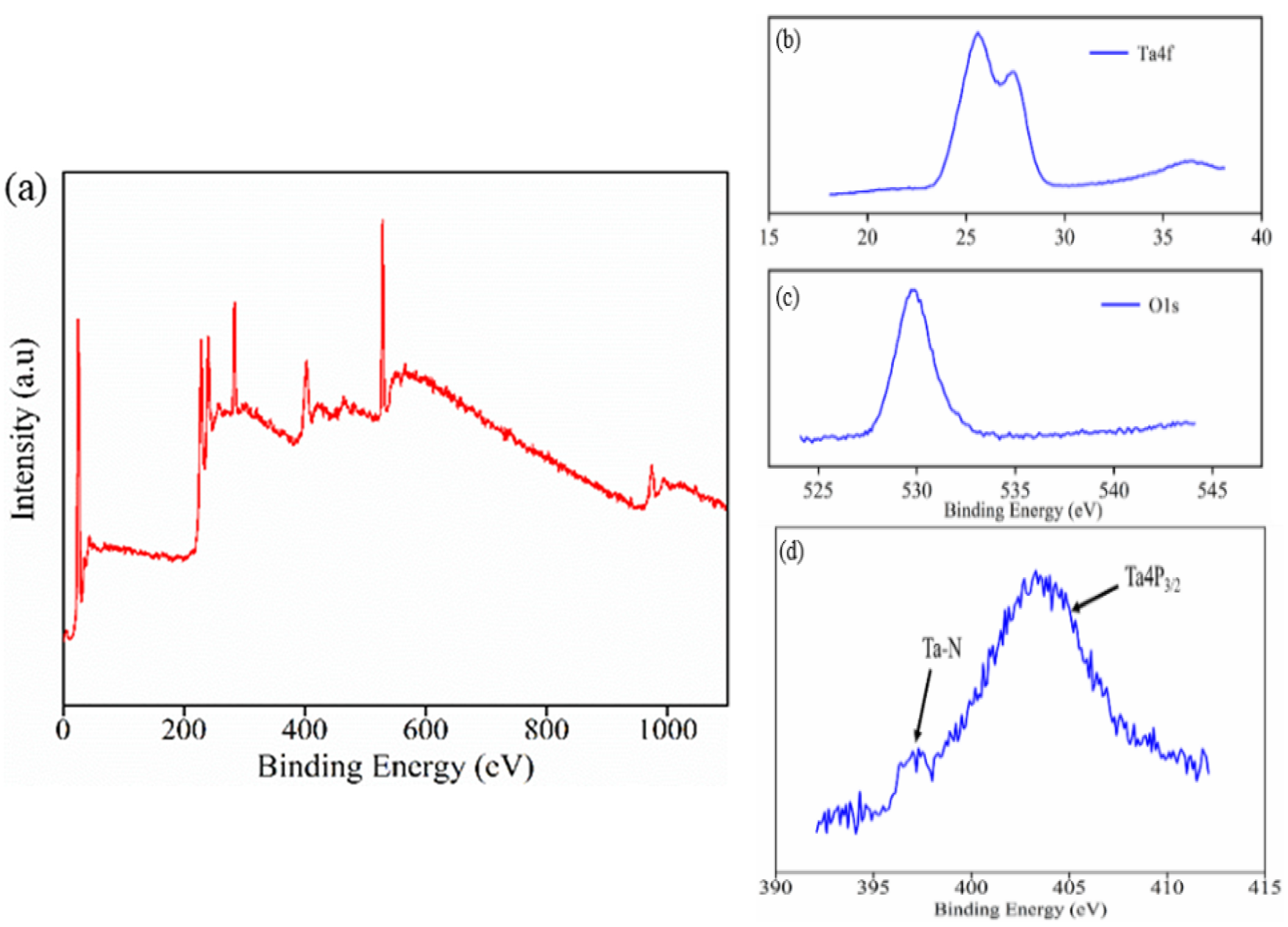

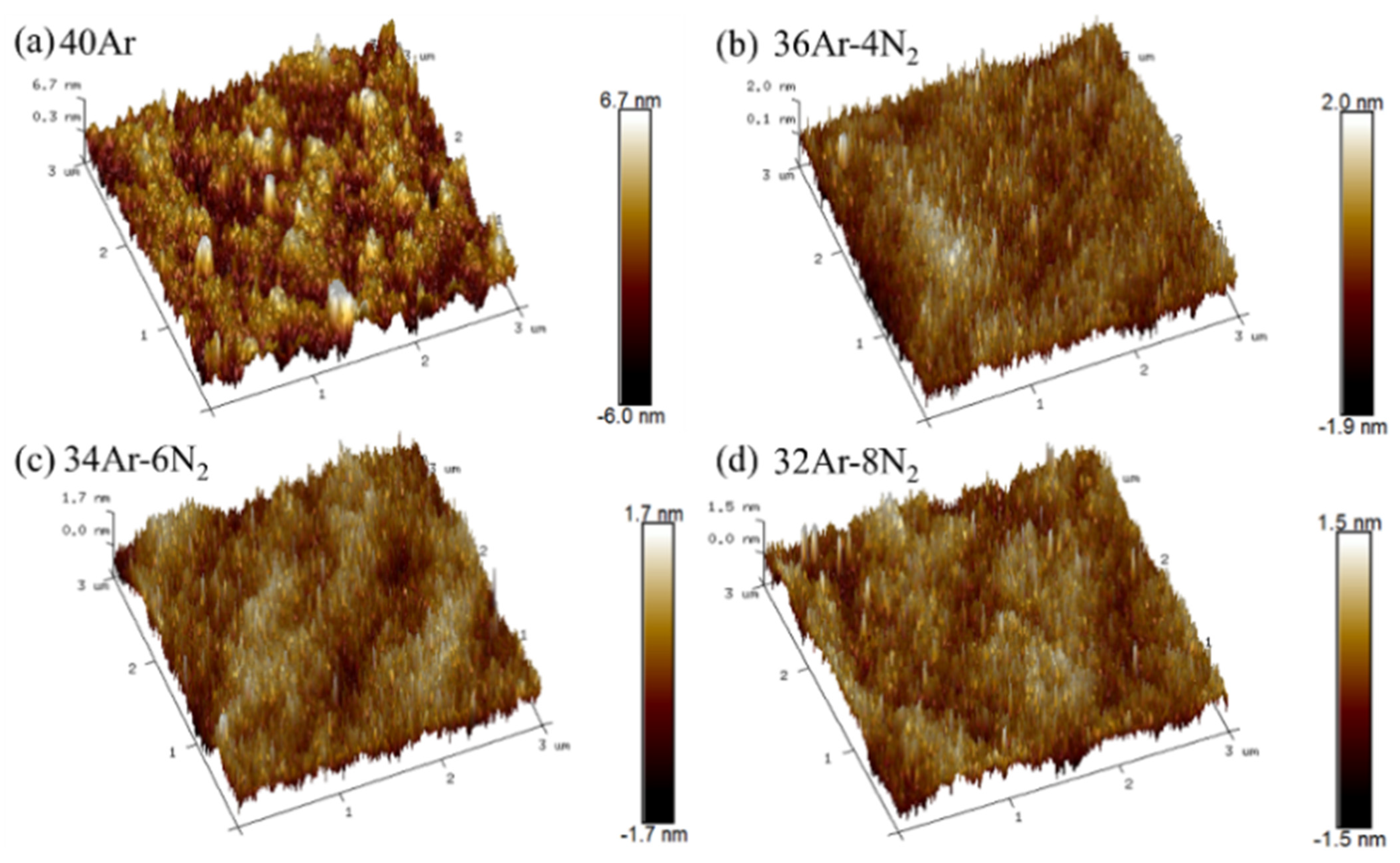

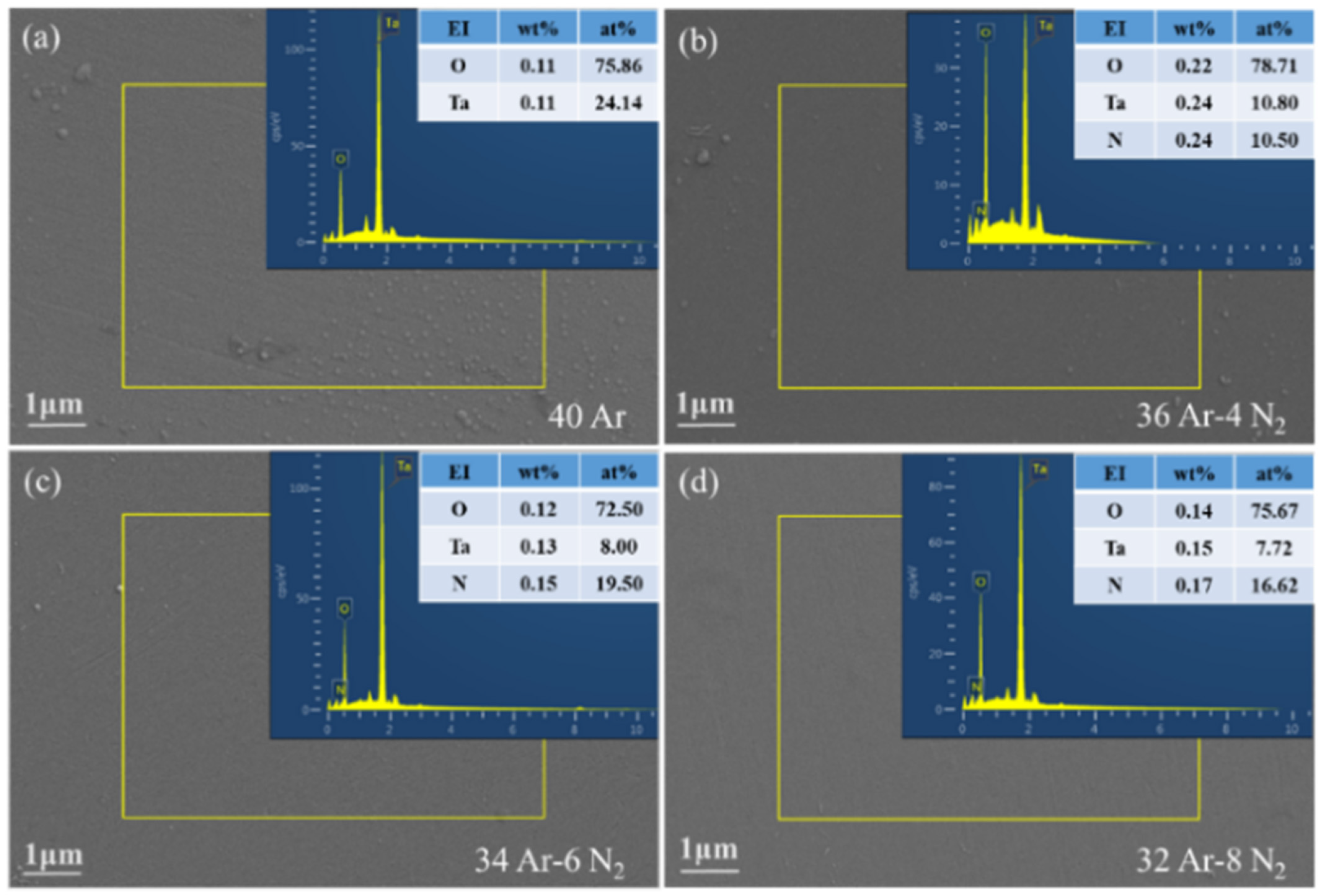

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameters | Gas Flow (sccm) | ||||

|---|---|---|---|---|---|

| 40 Ar | 36 Ar-4 N2 | 34 Ar-6 N2 | 32 Ar-8 N2 | ||

| Coating thickness (nm) | 685.4 | 437.6 | 433.8 | 337.8 | |

| Average roughness (nm) | 1.140 | 0.429 | 0.382 | 0.347 | |

| EDS (at%) | O | 75.86 | 78.71 | 72.50 | 75.67 |

| Ta | 24.14 | 10.80 | 8.00 | 7.72 | |

| N | - | 10.50 | 19.50 | 16.62 | |

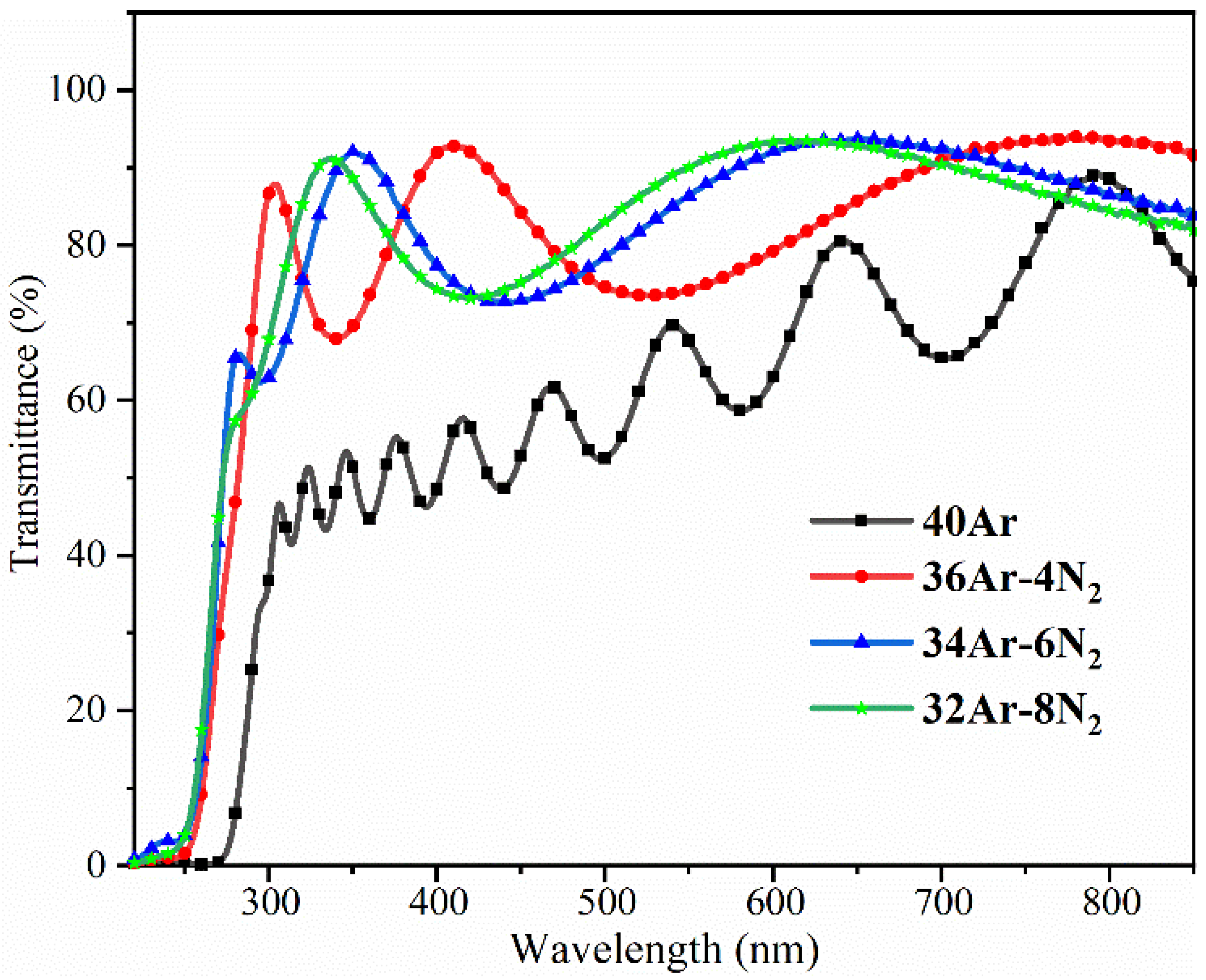

| Average transmittance (%) | 57.36 | 76.56 | 77.79 | 78.03 | |

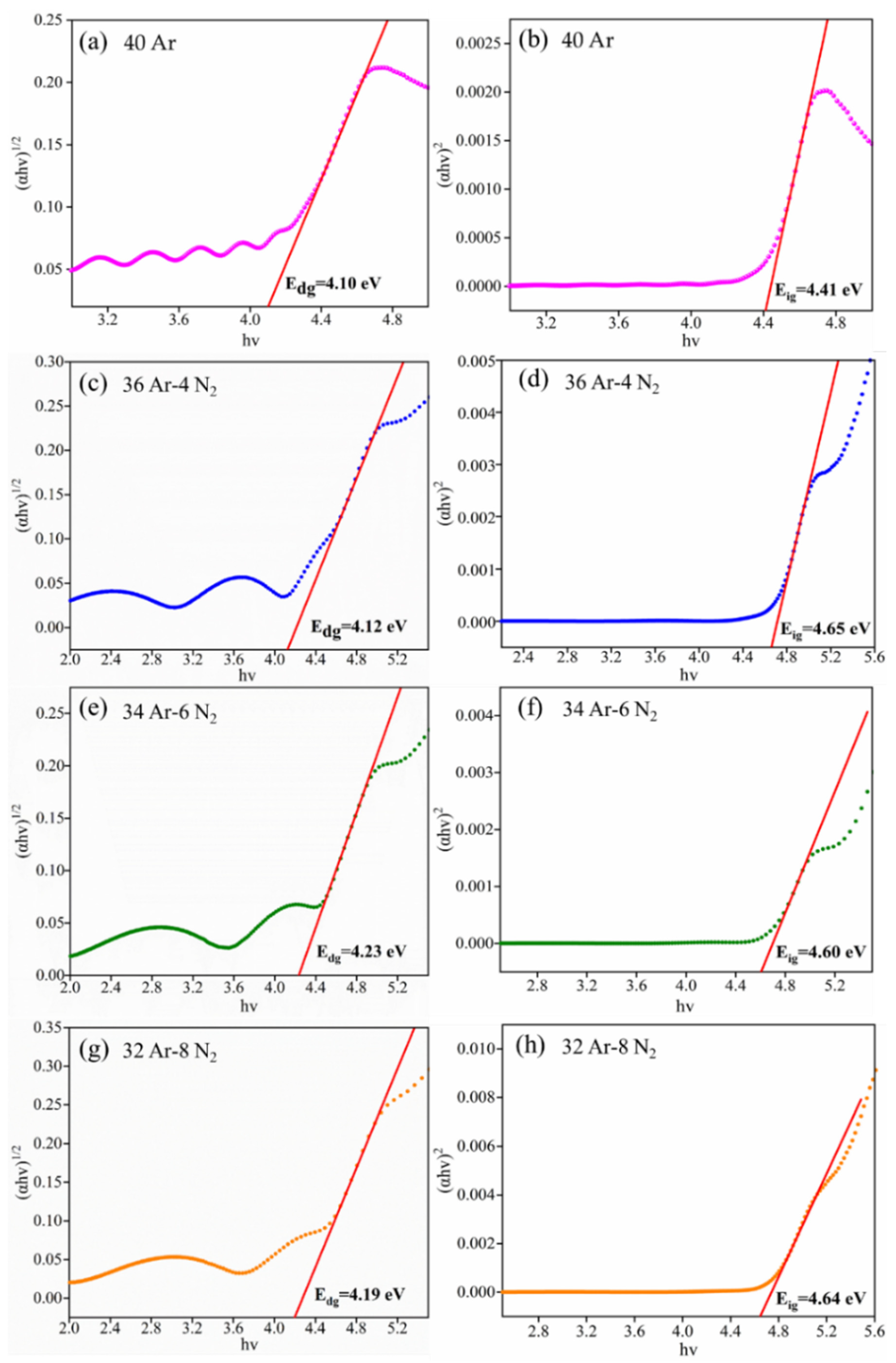

| Optical band gap (eV) | Edg | 4.10 | 4.12 | 4.23 | 4.19 |

| Eig | 4.41 | 4.65 | 4.60 | 4.64 | |

| Absorption coefficient (k) l = 600 nm | 4.34 × 10−3 | 2.35 × 10−3 | 2.23 × 10−3 | 2.17 × 10−3 | |

References

- Das, U.K.; Tey, K.S.; Seyedmahmoudian, M.; Mekhilef, S.; Idris, M.Y.I.; Van Deventer, W.; Horan, B.; Stojcevski, A. Forecasting of photovoltaic power generation and model optimization: A review. Renew. Sustain. Energy Rev. 2018, 81, 912–928. [Google Scholar] [CrossRef]

- Comello, S.; Reichelstein, S.; Sahoo, A. The road ahead for solar PV power. Renew. Sustain. Energy Rev. 2018, 92, 744–756. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Ali, H.; Khaled, M.M.; Al-Aqeeli, N.; Abu-Dheir, N.; Varanasi, K.K. Influence of dust and mud on the optical, chemical and mechanical properties of a pv protective glass. Sci. Rep. 2015, 5, 15833. [Google Scholar] [CrossRef] [PubMed]

- Said, S.A.; Al-Aqeeli, N.; Walwil, H.M. The potential of using textured and anti-reflective coated glasses in minimizing dust fouling. Sol. Energy 2015, 113, 295–302. [Google Scholar] [CrossRef]

- Quan, Y.-Y.; Zhang, L.-Z. Experimental investigation of the anti-dust effect of transparent hydrophobic coatings applied for solar cell covering glass. Sol. Energy Mater. Sol. Cells 2017, 160, 382–389. [Google Scholar] [CrossRef]

- Xu, L.; Li, S.; Jiang, J.; Liu, T.; Wu, H.; Wang, J.; Li, X. The influence of dust deposition on the temperature of soiling photovoltaic glass under lighting and windy conditions. Sol. Energy 2020, 199, 491–496. [Google Scholar] [CrossRef]

- Fountoukis, C.; Figgis, B.; Ackermann, L.; Ayoub, M.A. Effects of atmospheric dust deposition on solar PV energy production in a desert environment. Sol. Energy 2018, 164, 94–100. [Google Scholar] [CrossRef]

- Lu, H.; Zhao, W. Effects of particle sizes and tilt angles on dust deposition characteristics of a ground-mounted solar photovoltaic system. Appl. Energy 2018, 220, 514–526. [Google Scholar] [CrossRef]

- Hong, G.; Shen, Z.; He, R.; Liu, G. Material requirements for China’s future lunar exploration missions. Aerosp. Mater. Technol. 2021, 51, 15–25. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=YHCG202105004&DbName=CJFQ2021 (accessed on 10 August 2022).

- Pan, A.; Lu, H.; Zhang, L.-Z. Experimental investigation of dust deposition reduction on solar cell covering glass by different self-cleaning coatings. Energy 2019, 181, 645–653. [Google Scholar] [CrossRef]

- Shang, P.; Xiong, S.; Li, L.; Tian, D.; Ai, W. Investigation on thermal stability of Ta2O5, TiO2 and Al2O3 coatings for application at high temperature. Appl. Surf. Sci. 2013, 285, 713–720. [Google Scholar] [CrossRef]

- Farhan, M.S.; Zalnezhad, E.; Bushroa, A. Properties of Ta2O5 thin films prepared by ion-assisted deposition. Mater. Res. Bull. 2013, 48, 4206–4209. [Google Scholar] [CrossRef]

- Ren, W.; Yang, G.-D.; Feng, A.-L.; Miao, R.-X.; Xia, J.-B.; Wang, Y.-G. Annealing effects on the optical and electrochemical properties of tantalum pentoxide films. J. Adv. Ceram. 2021, 10, 704–713. [Google Scholar] [CrossRef]

- Shakoury, R.; Rezaee, S.; Mwema, F.; Luna, C.; Ghosh, K.; Jurečka, S.; Ţălu, Ş.; Arman, A.; Korpi, A.G. Multifractal and optical bandgap characterization of Ta2O5 thin films deposited by electron gun method. Opt. Quantum Electron. 2020, 52, 95. [Google Scholar] [CrossRef]

- Qiao, Z.; Pu, Y.; Liu, H.; Luo, K.; Wang, G.; Liu, Z.; Ma, P. Residual stress and laser-induced damage of ion-beam sputtered Ta2O5/SiO2 mixture coatings. Thin Solid Films 2015, 592, 221–224. [Google Scholar] [CrossRef]

- Lv, Q.; Huang, M.; Zhang, S.; Deng, S.; Gong, F.; Wang, F.; Pan, Y.; Li, G.; Jin, Y. Effects of Annealing on Residual Stress in Ta2O5 Films Deposited by Dual Ion Beam Sputtering. Coatings 2018, 8, 150. [Google Scholar] [CrossRef]

- Huang, H.-L.; Chang, Y.-Y.; Chen, H.-J.; Chou, Y.-K.; Lai, C.-H.; Chen, M.Y.C. Antibacterial properties and cytocompatibility of tantalum oxide coatings with different silver content. J. Vac. Sci. Technol. A Vac. Surf. Film. 2014, 32, 02B117. [Google Scholar] [CrossRef]

- Horandghadim, N.; Khalil-Allafi, J.; Urgen, M. Influence of tantalum pentoxide secondary phase on surface features and mechanical properties of hydroxyapatite coating on NiTi alloy produced by electrophoretic deposition. Surf. Coatings Technol. 2020, 386, 125458. [Google Scholar] [CrossRef]

- Zaman, A.; Meletis, E.I. Microstructure and Mechanical Properties of TaN Thin Films Prepared by Reactive Magnetron Sputtering. Coatings 2017, 7, 209. [Google Scholar] [CrossRef]

- Riekkinen, T.; Molarius, J.; Laurila, T.; Nurmela, A.; Suni, I.; Kivilahti, J. Reactive sputter deposition and properties of TaxN thin films. Microelectron. Eng. 2002, 64, 289–297. [Google Scholar] [CrossRef]

- Tsukimoto, S.; Moriyama, M.; Murakami, M. Microstructure of amorphous tantalum nitride thin films. Thin Solid Films 2004, 460, 222–226. [Google Scholar] [CrossRef]

- Chen, S.-F.; Wang, S.-J.; Yang, T.-H.; Yang, Z.-D.; Bor, H.-Y.; Wei, C.-N. Effect of nitrogen flow rate on TaN diffusion barrier layer deposited between a Cu layer and a Si-based substrate. Ceram. Int. 2017, 43, 12505–12510. [Google Scholar] [CrossRef]

- Grilli, M.L.; Yilmaz, M.; Aydogan, S.; Cirak, B.B. Room temperature deposition of XRD-amorphous TiO2 thin films: Investigation of device performance as a function of temperature. Ceram. Int. 2018, 44, 11582–11590. [Google Scholar] [CrossRef]

- Li, K.; Xiong, Y.Q.; Wang, H.; He, Y.C.; Wang, L.X.; Zhou, C.; Zhou, H. Effects of Process Parameters on Optical Properties and Crystallization Characteristics of Zinc Sulfide Films. Surf. Technol. 2021, 50, 184–192. [Google Scholar]

- Li, K.P.; Wang, D.S.; Li, C.; Wang, J.; Dong, M.; Zhang, L. Study on optical thin film parameters measurement method. Infrared Laser Eng. 2015, 44, 1048–1052. [Google Scholar]

- Chen, X.; Bai, R.; Huang, M. Optical properties of amorphous Ta2O5 thin films deposited by RF magnetron sputtering. Opt. Mater. 2019, 97, 109404. [Google Scholar] [CrossRef]

- Pai, Y.-H.; Chou, C.-C.; Shieu, F.-S. Preparation and optical properties of Ta2O5−x thin films. Mater. Chem. Phys. 2008, 107, 524–527. [Google Scholar] [CrossRef]

- Minkov, D.; Gavrilov, G.; Angelov, G.; Moreno, J.; Vazquez, C.; Ruano, S.; Marquez, E. Optimisation of the envelope method for characterisation of optical thin film on substrate specimens from their normal incidence transmittance spectrum. Thin Solid Films 2018, 645, 370–378. [Google Scholar] [CrossRef]

- Ghobadi, N.; Arman, A.; Sadeghi, M.; Luna, C.; Mirzaei, S.; Zelati, A.; Shakoury, R. Optical transitions and photocatalytic activity of NiSe films prepared by the chemical solution deposition method. Eur. Phys. J. Plus 2022, 137, 661. [Google Scholar] [CrossRef]

- Wang, L.; Yang, X.; Liu, D.; Jiang, C.; Liu, H.; Ji, Y.; Zhang, F.; Fan, R.; Chen, D. Heat treatment effect on the optical properties of ion beam sputtered tantalum oxide thin films. Infrared Laser Eng. 2018, 47, 184–190. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=HWYJ201803025&DbName=CJFQ2018 (accessed on 10 August 2022).

- Xu, C.; Yang, S.; Wang, J.-F.; Niu, J.; Ma, H.; Qiang, Y.-H.; Liu, J.-T.; Li, D.-W.; Tao, C.-X. Effect of Oxygen Vacancy on the Band Gap and Nanosecond Laser-Induced Damage Threshold of Ta2O5 Films. Chin. Phys. Lett. 2012, 29, 084207. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chao, R.; Cai, H.; Li, H.; Xue, Y. Effect of Nitrogen Flow Rate on Microstructure and Optical Properties of Ta2O5 Coatings. Coatings 2022, 12, 1745. https://doi.org/10.3390/coatings12111745

Chao R, Cai H, Li H, Xue Y. Effect of Nitrogen Flow Rate on Microstructure and Optical Properties of Ta2O5 Coatings. Coatings. 2022; 12(11):1745. https://doi.org/10.3390/coatings12111745

Chicago/Turabian StyleChao, Rui, Haichao Cai, Hang Li, and Yujun Xue. 2022. "Effect of Nitrogen Flow Rate on Microstructure and Optical Properties of Ta2O5 Coatings" Coatings 12, no. 11: 1745. https://doi.org/10.3390/coatings12111745

APA StyleChao, R., Cai, H., Li, H., & Xue, Y. (2022). Effect of Nitrogen Flow Rate on Microstructure and Optical Properties of Ta2O5 Coatings. Coatings, 12(11), 1745. https://doi.org/10.3390/coatings12111745