Properties of the YbF3 Films Prepared by Ion-Assisted Deposition

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Characterization of Thin Films

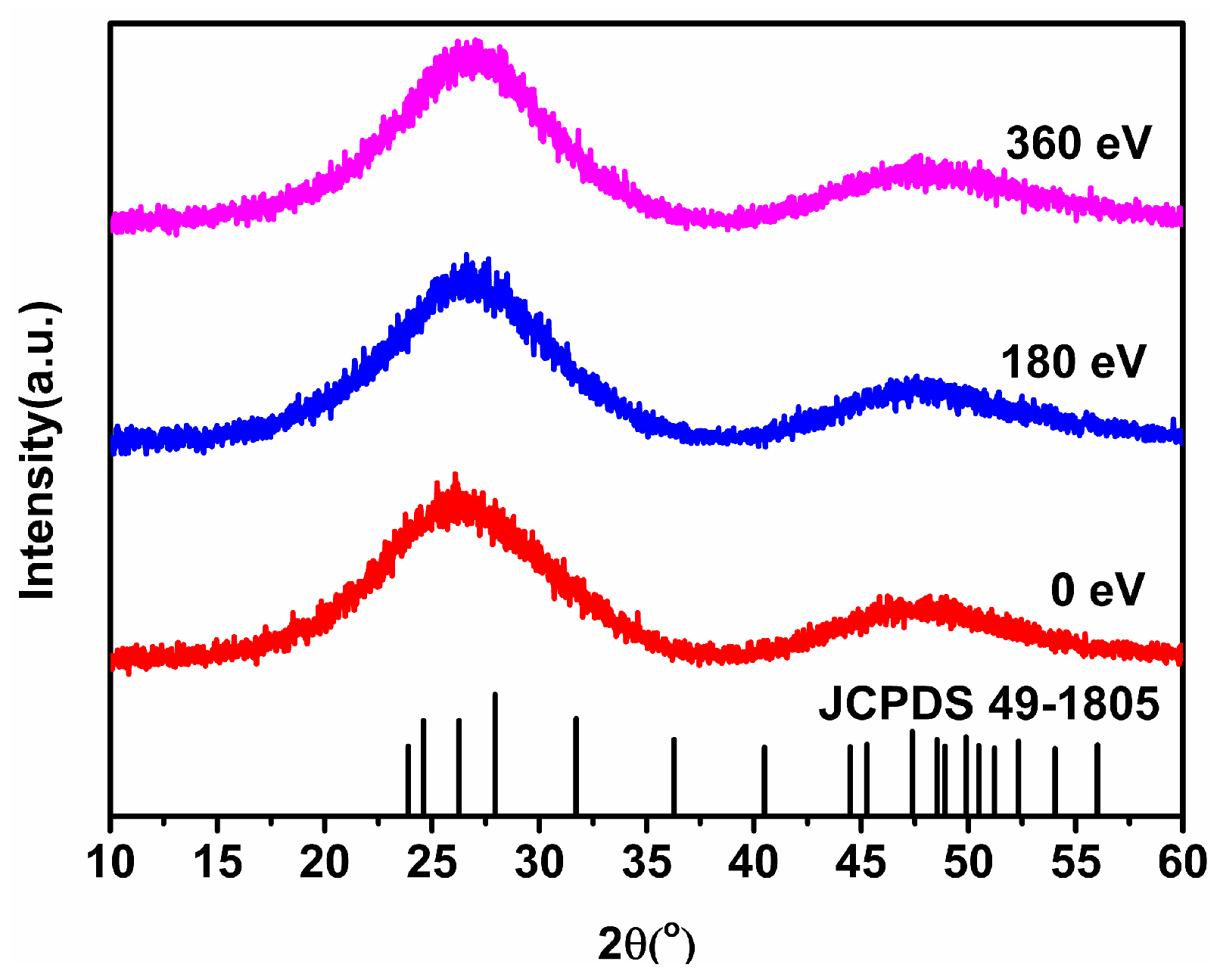

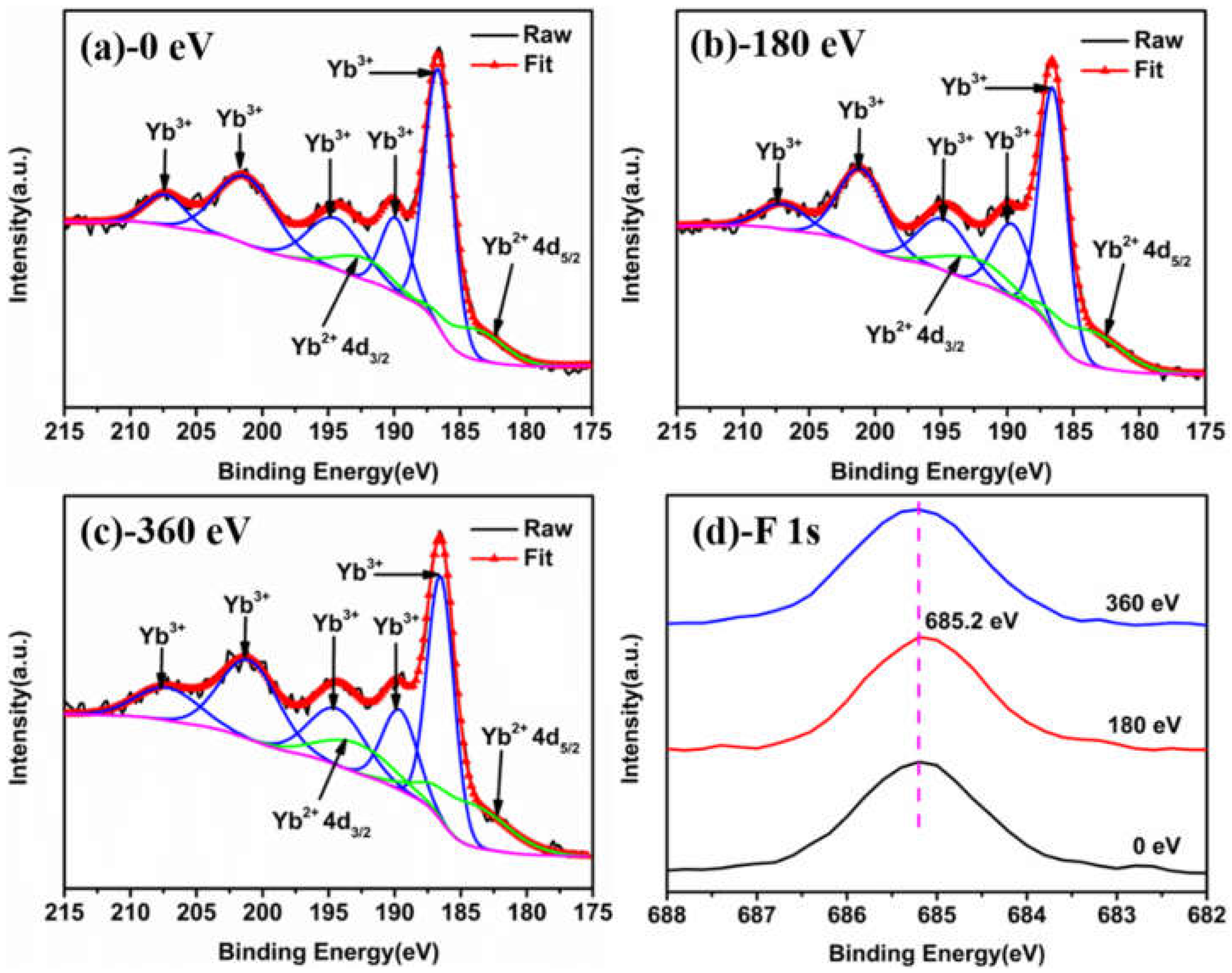

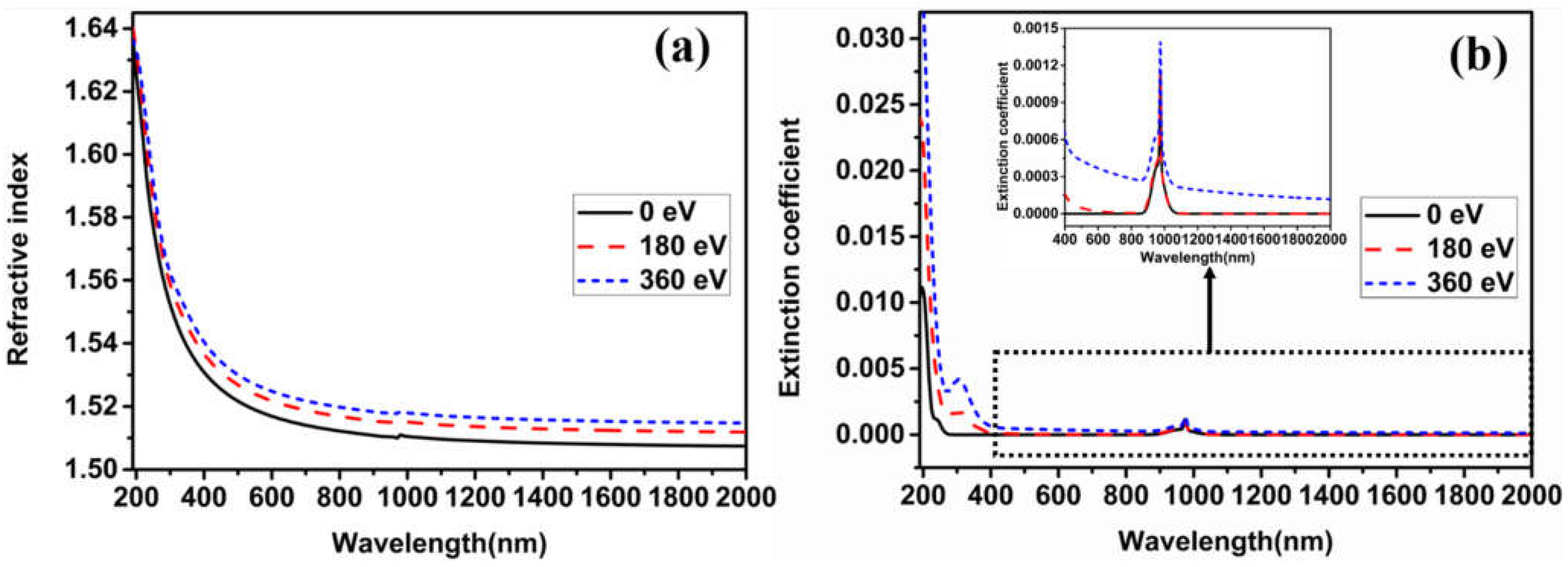

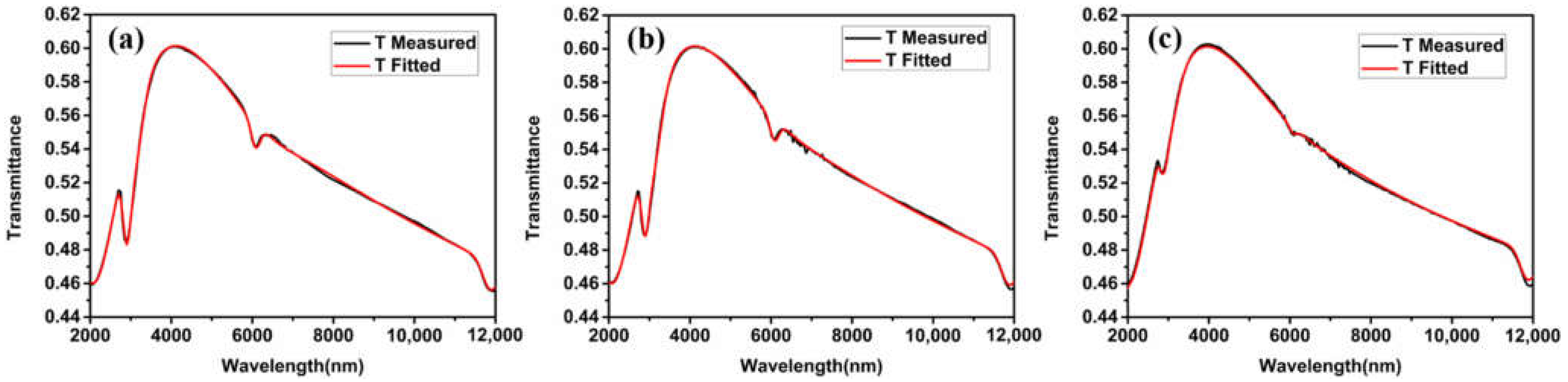

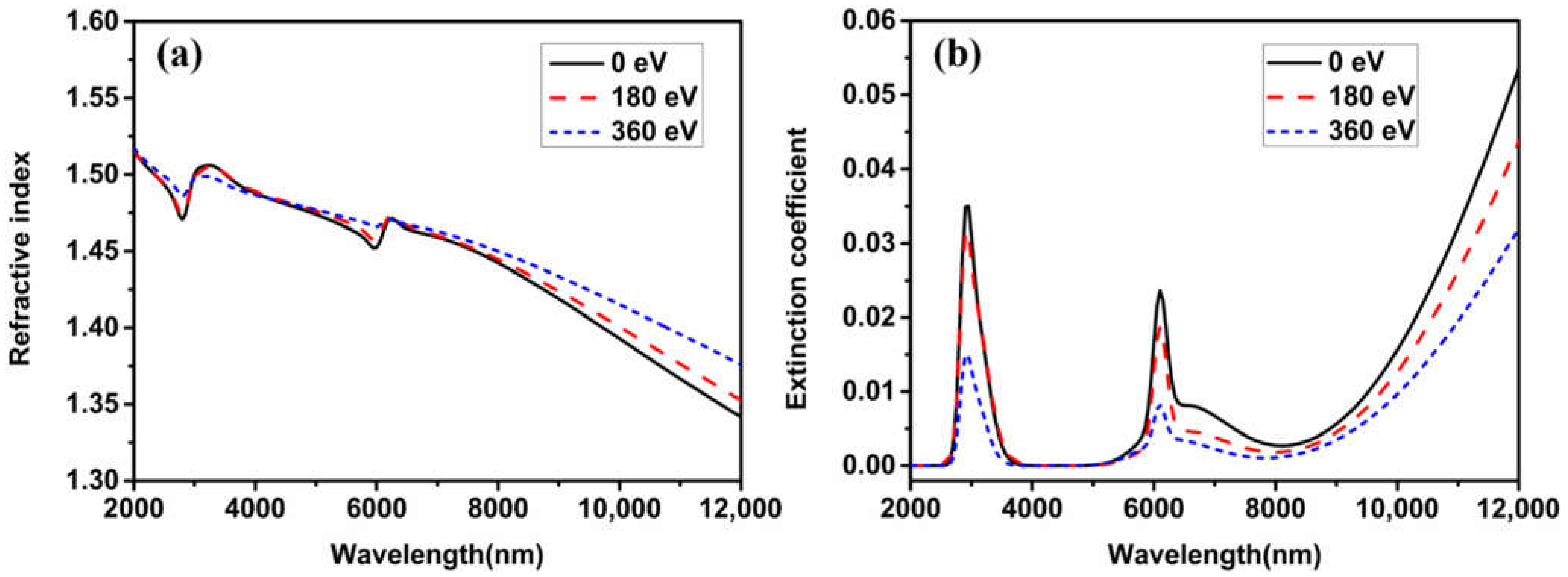

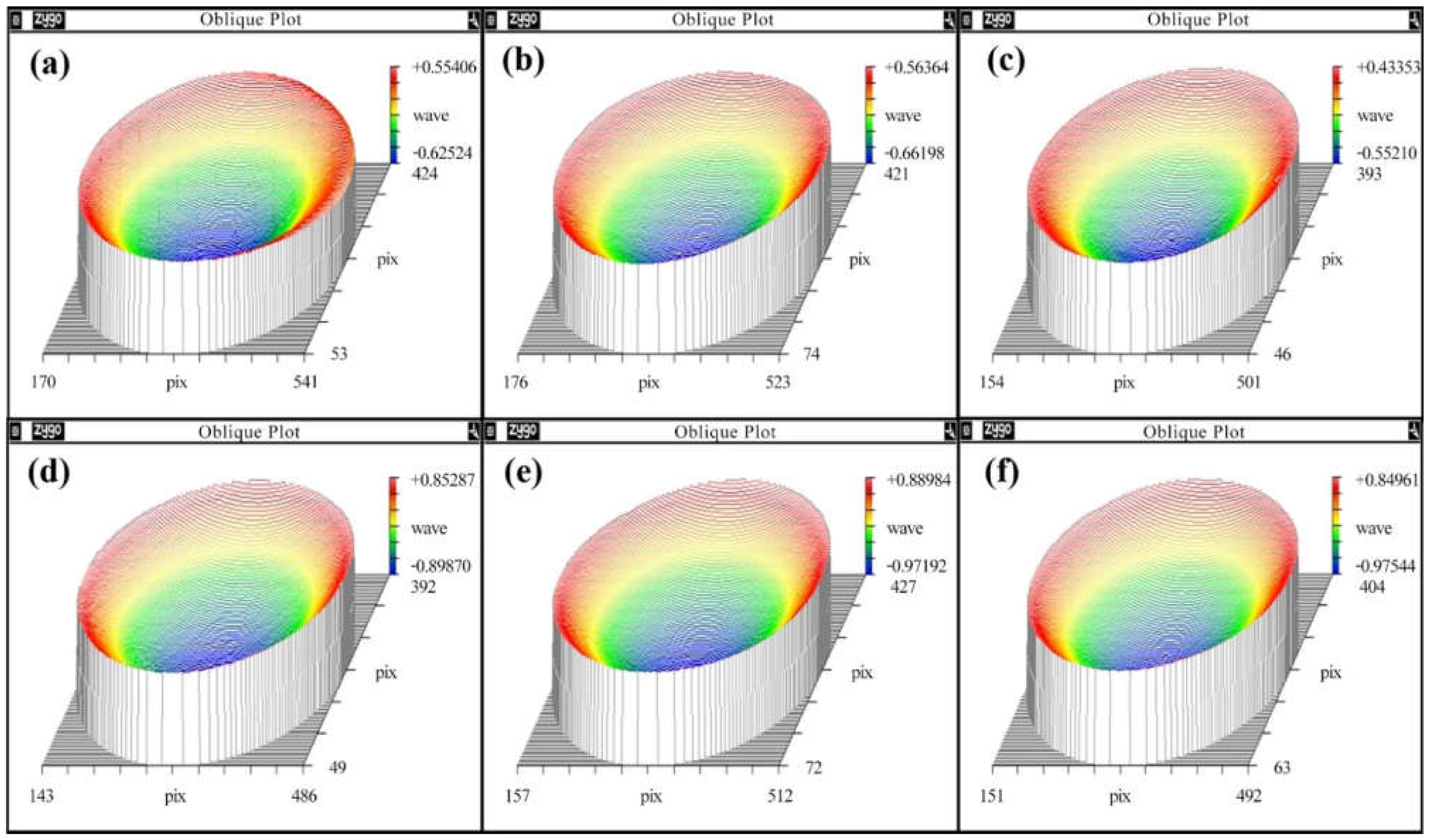

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stolze, M.; Neff, J.; Waibel, F. Rare earth-based low-index films for IR and multispectral thin film solutions. Proc. SPIE 2017, 10448, 104481S. [Google Scholar]

- Zhang, Y.H.; Xiong, S.M.; Huang, W.; Zhang, K.P.; Tian, X.X. Six-spectral antireflection coating on zinc sulfide simultaneously effective for the visible, near-IR, and long wavelength IR regions. Surf. Coat. Tech. 2019, 359, 1–5. [Google Scholar] [CrossRef]

- Liu, W.; Tu, H.L.; Gao, M.; Su, X.P.; Zhang, S.Y.; Huo, C.S.; Yang, H. High performance DLC/BP and ZnS/YbF3 double-layer protective and antireflective coatings. J. Alloys Compd. 2013, 581, 526–529. [Google Scholar] [CrossRef]

- Zhupanov, V.; Fedoseev, V.; Trubetskov, M.; Amotchkina, T.; Tikhonravov, A. Design and production of three line antireflection coating for visible-far infrared spectral regions. Proc. SPIE. 2015, 9627, 962706. [Google Scholar]

- Fu, X.H.; Dong, L.H.; Lu, P.; Fu, X.H.; Duan, W.B.; Li, X.M.; Yin, R.J. Study of Infrared AR and Protection Coating On MgF2. Proc. SPIE 2006, 6034, 603415. [Google Scholar]

- Zhang, Y.H.; Xiong, S.M.; Huang, W. Study on defects in ZnS/YbF3 infrared coatings on silicon substrates. Surf. Coat. Tech. 2017, 320, 3–6. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Zhang, Y.D. Defect study on several fluoride coatings. Proc. SPIE 2009, 7283, 72832Q. [Google Scholar]

- Wang, G.; Ling, X.L.; Liu, X.F.; Fan, Z.X. Effects of deposition temperature on characterization and laser-induced damage threshold of YbF3 films. Opt. Laser. Technol. 2013, 49, 274–278. [Google Scholar] [CrossRef]

- Rahe, M.; Ristau, D.; Schmidt, H. The effect of hydrogen concentration in conventional and IAD coatings on the absorption and laser induced damage at 10.6 µm. Proc. SPIE 1992, 1848, 335–348. [Google Scholar]

- Amotchkina, T.; Trubetskov, M.; Schulz, M.; Pervak, V. Comparative study of NIR-MIR beamsplitters based on ZnS/YbF3 and Ge/YbF3. Opt. Express. 2019, 27, 5557–5569. [Google Scholar] [CrossRef]

- Xiong, S.M.; Zhang, Y.D. The optical coatings of the 3.8µm reflecting and visible transmitting. Proc. SPIE 1998, 3557, 71–76. [Google Scholar]

- Lisitsyn, V.M.; Lisitsyna, L.A.; Popov, A.I.; Kotomin, E.A.; Abuova, F.U.; Akilbekov, A.; Maier, J. Stabilization of primary mobile radiation defects in MgF2 crystals. Nucl. Instrum. Meth. B 2016, 374, 24–28. [Google Scholar] [CrossRef]

- Schnellbügel, A.; Hagedorn, H.; Anton, R. Ion assisted deposition of non-toxic coatings for high power CO2 laser optics. Proc. SPIE 1994, 2253, 839–848. [Google Scholar]

- Zhang, Y.P.; FAN, J.Q.; Long, G.Y. Influence of deposition parameters on residual stress of YbF3 thin film. Proc. SPIE 2016, 9796, 97960N. [Google Scholar]

- Zhang, Y.H.; Xiong, S.M.; Huang, W.; Zhang, K.P. Determination of refractive index and thickness of YbF3 thin films deposited at different bias voltages of APS ion source from spectrophotometric methods. Adv. Opt. Techn. 2018, 7, 33–37. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.G.; Chen, W.L.; Shen, W.D.; Liu, X.; Gu, P.F. Optical properties and residual stress of YbF3 thin films deposited at different temperatures. Appl. Optics. 2008, 47, C319–C323. [Google Scholar] [CrossRef] [PubMed]

- Su, W.T.; Li, B.; Liu, D.Q.; Zhang, F.S. The determination of infrared optical constants of rare earth fluorides by classical Lorentz oscillator model. J. Phys. D Appl. Phys. 2007, 40, 3343–3347. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Zhang, K.P.; Huang, W.; Xiong, S.M. Determination of infrared refractive index of ZnS and YbF3 thin films by spectroscopy. Optik 2018, 170, 321–327. [Google Scholar] [CrossRef]

- Ferlauto, A.S.; Ferreira, G.M.; Pearce, J.M.; Wronski, C.R.; Collins, R.W. Analytical model for the optical functions of amorphous semiconductors from the near-infrared to ultraviolet: Applications in thin film photovoltaics. J. Appl. Phys. 2002, 92, 2424–2436. [Google Scholar] [CrossRef]

- Wang, L.S.; Liu, H.S.; Jiang, Y.G.; Yang, X.; Liu, D.D.; Ji, Y.Q.; Zhang, F.; Chen, D.Y. Effects of hot-isostatic pressing and annealing post-treatment on HfO2 and Ta2O5 films prepared by ion beam sputtering. Optik 2017, 142, 33–41. [Google Scholar] [CrossRef]

- Liu, D.D.; Liu, H.S.; Ji, Y.Q.; Jiang, Y.G.; Xing, Y.Z.; Leng, J.; Zhuang, K.W. Research VIS-NIR optical constants of Si films deposited by different techniques. Proc. SPIE 2018, 10691, 106910P. [Google Scholar]

- Liu, D.D.; Liu, H.S.; Jiang, C.H.; Leng, J.; Zhang, Y.M.; Zhao, Z.H.; Zhuang, K.W.; Jiang, Y.G.; Ji, Y.Q. Temperature dependence of the infrared optical constants of germanium films. Thin Solid Films 2015, 592, 292–295. [Google Scholar] [CrossRef]

- Ji, Y.Q.; Jiang, Y.G.; Liu, H.S.; Wang, L.S.; Liu, D.D.; Jiang, C.H.; Fan, R.W.; Chen, D.Y. Effects of thermal treatment on infrared optical properties of SiO2 films on Si Substrates. Thin Solid Films 2013, 545, 111–115. [Google Scholar] [CrossRef]

- Thielsch, R.; Gatto, A.; Kaiser, N. Mechanical stress and thermal-elastic properties of oxide coatings for use in the deep-ultraviolet spectral region. Appl. Opt. 2002, 41, 3211–3217. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, R.Z.; Xiao, S.G.; Qu, M.H.; Li, K.Y.; Liu, C.X.; Wang, X.F.; Yan, X.H.; Yan, H. Efficient ultraviolet and near-infrared conversion amorphous YbF3: Er film. J. Lumin. 2014, 145, 351–356. [Google Scholar] [CrossRef]

- Schnellbügel, A.; Selle, B.; Anton, R. Determination of the Stoichiometry and the Yb2+/Yb3+ Ratio in YbFx Optical IAD Films by RBS and in situ XPS Analysis. Microchim Acta. 1997, 125, 239–243. [Google Scholar] [CrossRef]

- Schmidt, S.; Hüfner, S. X-ray photoemission of YbInCu4. Phys. Rev. B 2005, 71, 195110. [Google Scholar] [CrossRef]

- Ohno, Y. XPS studies of the intermediate valence state of Yb in (YbS)1.25CrS2. J. Electron. Spectrosc. 2008, 165, 1–4. [Google Scholar] [CrossRef]

- Suga, S.; Ogawa, S.; Namatame, H.; Taniguchi, M.; Kakizaki, A.; Ishii, T.; Fujimori, A.; Oh, S.J.; Kato, H.; Miyahara, T.; et al. XPS and UPS Studies of Valence Fluctuation and Surface States of Yb4As3, Yb4Sb3 and Yb4Bi3. J. Phys. Soc. Jpn. 1989, 58, 4534–4543. [Google Scholar] [CrossRef]

- Kaczmarek, S.M.; Tsuboi, T.; Ito, M.; Boulon, G.; Leniec, G. Optical study of Yb3+/Yb2+ conversion in CaF2 crystals. J. Phys. Condens. Matter. 2005, 17, 3771–3786. [Google Scholar] [CrossRef]

- Nicoara, I.; Lighezan, L.; Enculescu, M.; Enculescu, I. Optical spectroscopy of Yb2+ ions in YbF3-doped CaF2 crystals. J. Cryst. Growth 2008, 310, 2026–2032. [Google Scholar] [CrossRef]

- Hirsch, E.H. Stress in porous thin films through adsorption of polar molecules. J. Phys. D 1980, 13, 2081–2094. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, P.; Bai, J.; He, J.; Yang, M.; Su, J.; Ji, Y.; Liu, H. Properties of the YbF3 Films Prepared by Ion-Assisted Deposition. Coatings 2022, 12, 1693. https://doi.org/10.3390/coatings12111693

Sun P, Bai J, He J, Yang M, Su J, Ji Y, Liu H. Properties of the YbF3 Films Prepared by Ion-Assisted Deposition. Coatings. 2022; 12(11):1693. https://doi.org/10.3390/coatings12111693

Chicago/Turabian StyleSun, Peng, Jinlin Bai, Jiahuan He, Ming Yang, Jianzhong Su, Yiqin Ji, and Huasong Liu. 2022. "Properties of the YbF3 Films Prepared by Ion-Assisted Deposition" Coatings 12, no. 11: 1693. https://doi.org/10.3390/coatings12111693

APA StyleSun, P., Bai, J., He, J., Yang, M., Su, J., Ji, Y., & Liu, H. (2022). Properties of the YbF3 Films Prepared by Ion-Assisted Deposition. Coatings, 12(11), 1693. https://doi.org/10.3390/coatings12111693