Dynamic Coupling Analysis on Thermo–Chemo–Mechanical Field and Fluid–Structure Interaction for Aero-Engine Turbine Blade with Functional Gradient Thermal Barrier Coatings

Abstract

1. Introduction

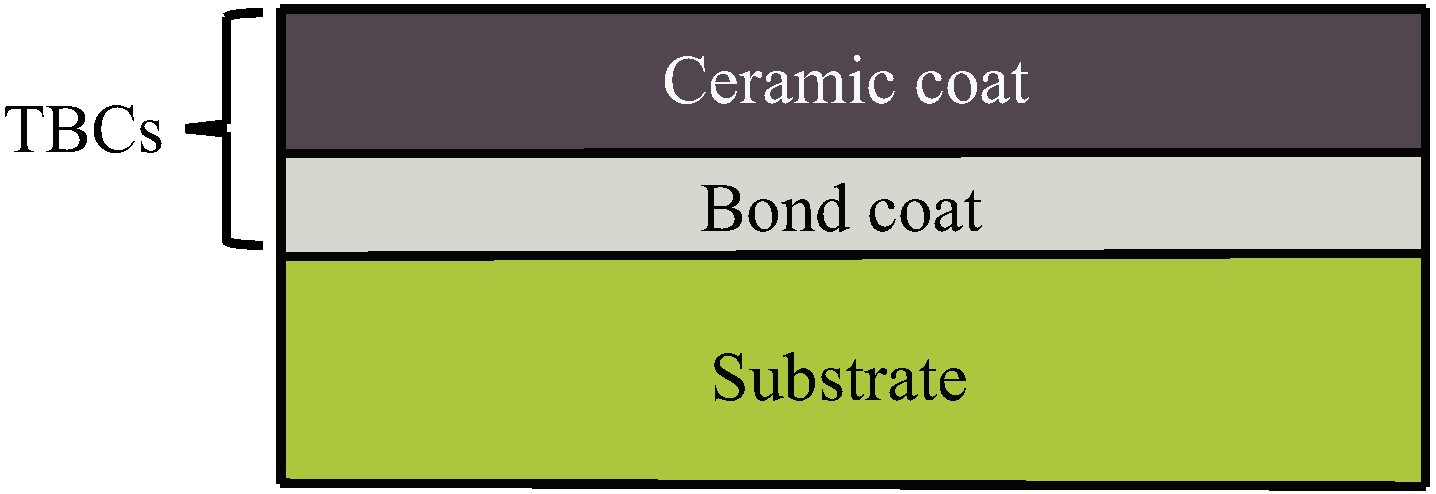

2. Thermo–Chemo–Mechanical Solid-Element Method for Substrate Structure

2.1. Thermo–Chemo–Mechanical Variational Theorem

2.2. Solid-Element Method for Thermo–Chemo–Mechanical Coupling Problem of Substrate Structure

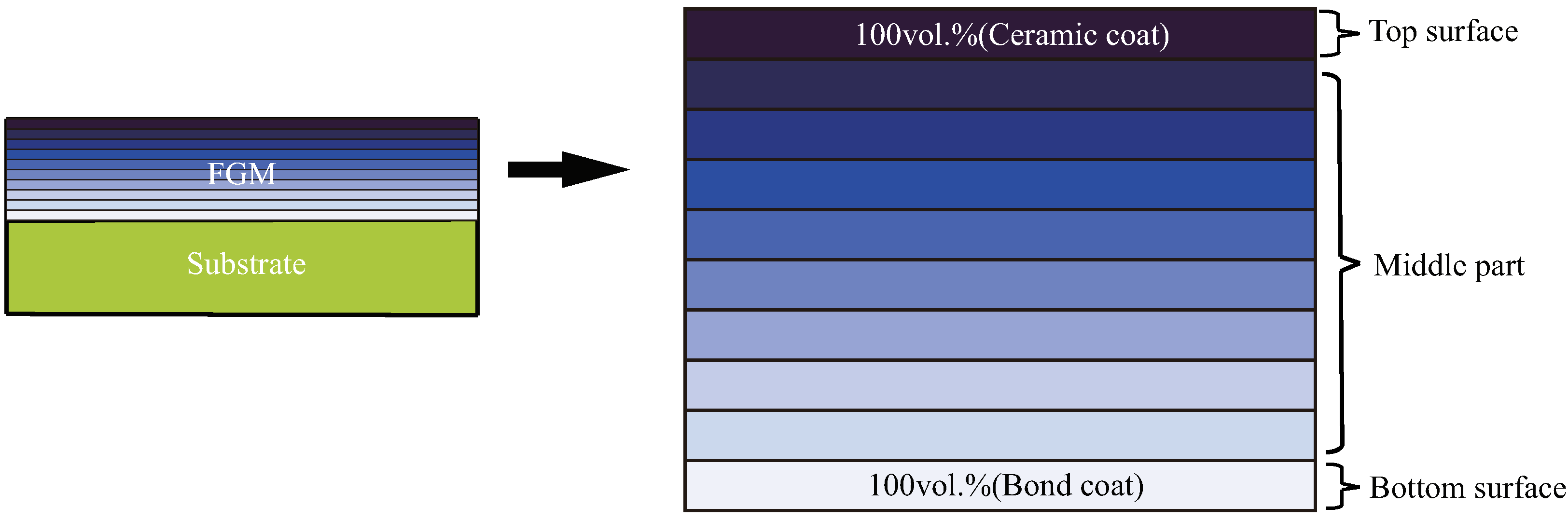

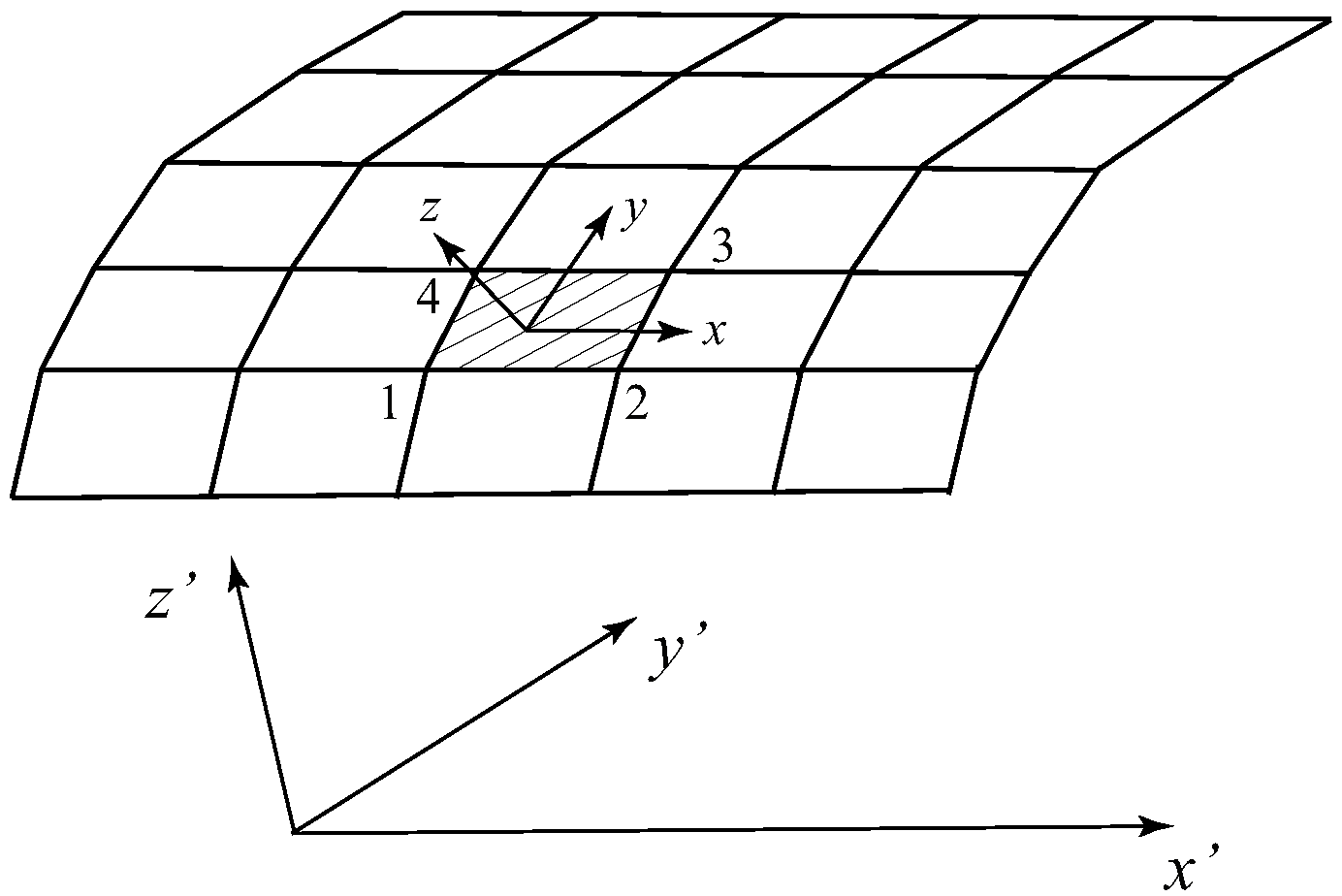

3. Thermo–Chemo–Mechanical Extended Layerwise Method for TBCs Structure

3.1. Functionally Gradient Material Structure

3.2. Thermo–Chemo–Mechanical Extended Layerwise Method of TBCs Structure

3.3. Transformation of Coordinate System

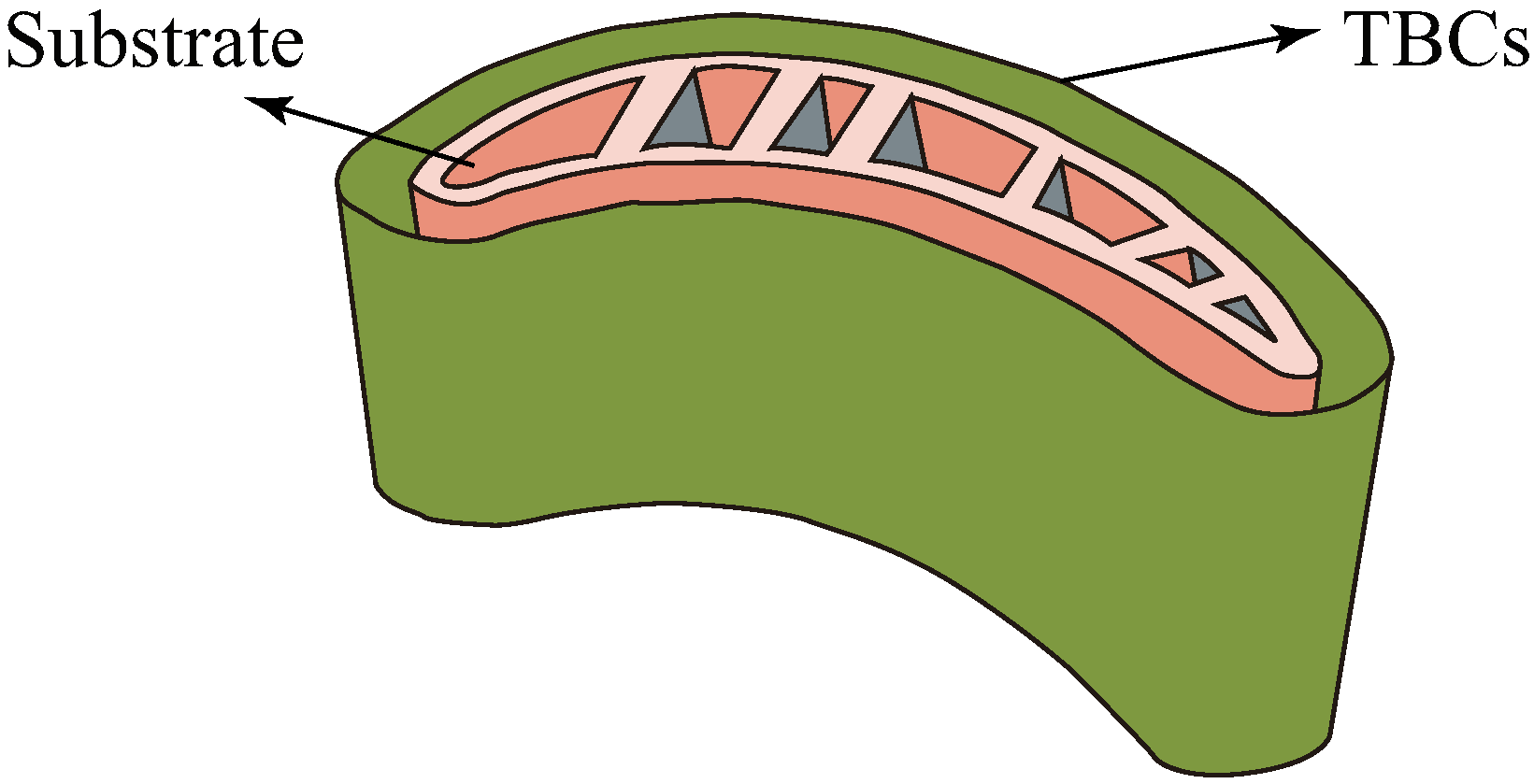

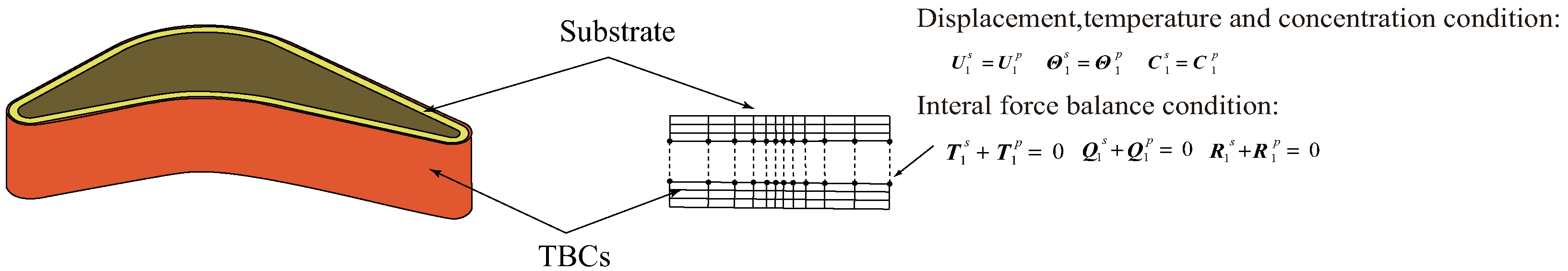

4. Extended-Layerwise/Solid-Element Method for Aero-Engine Turbine Blade with TBCs

4.1. Modeling of Aero-Engine Turbine Blade with TBCs

4.2. Governing Equations of Aero-Engine Turbine Blade with TBCs

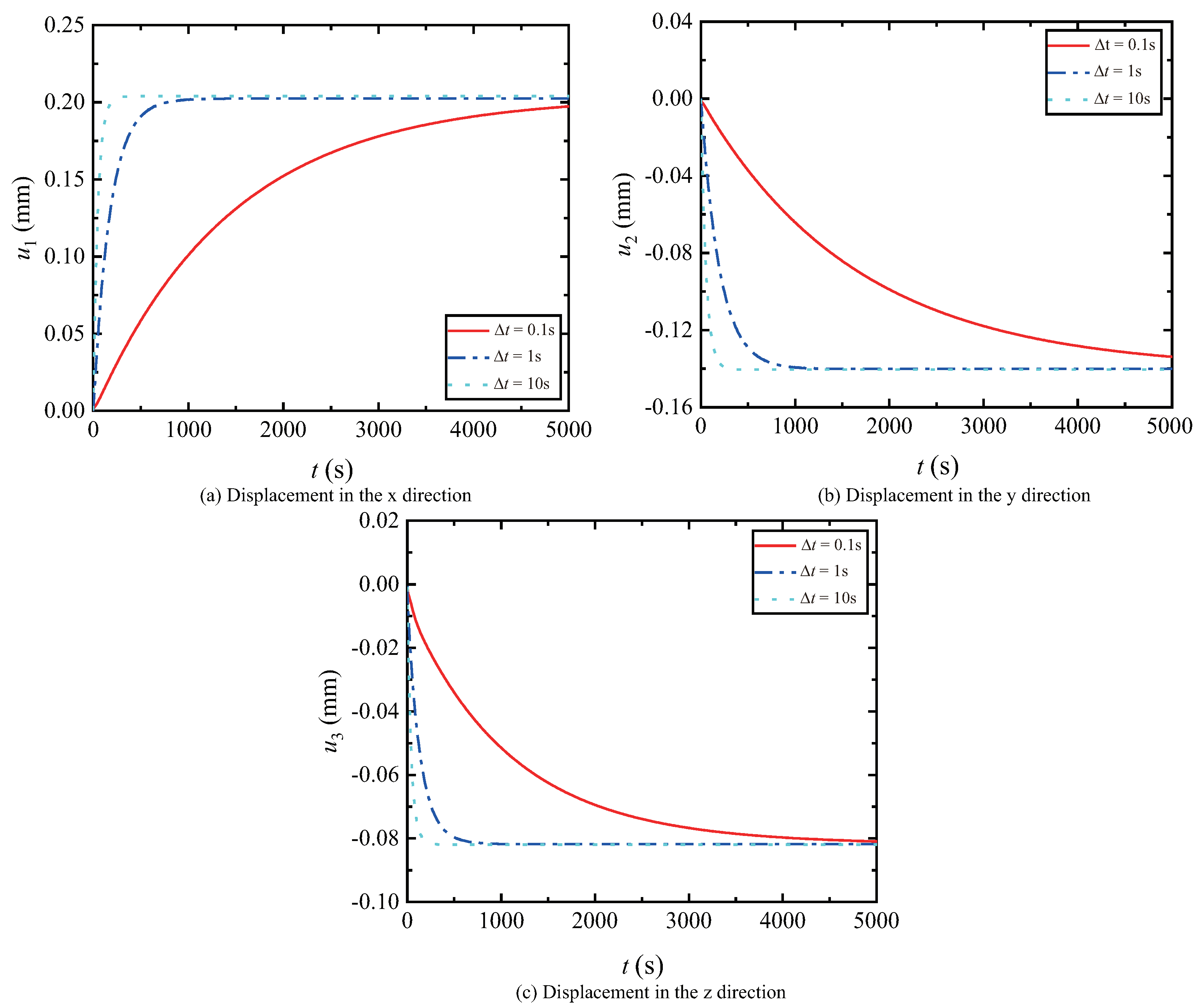

4.3. Time Integration of Thermo–Chemo–Mechanical Responses

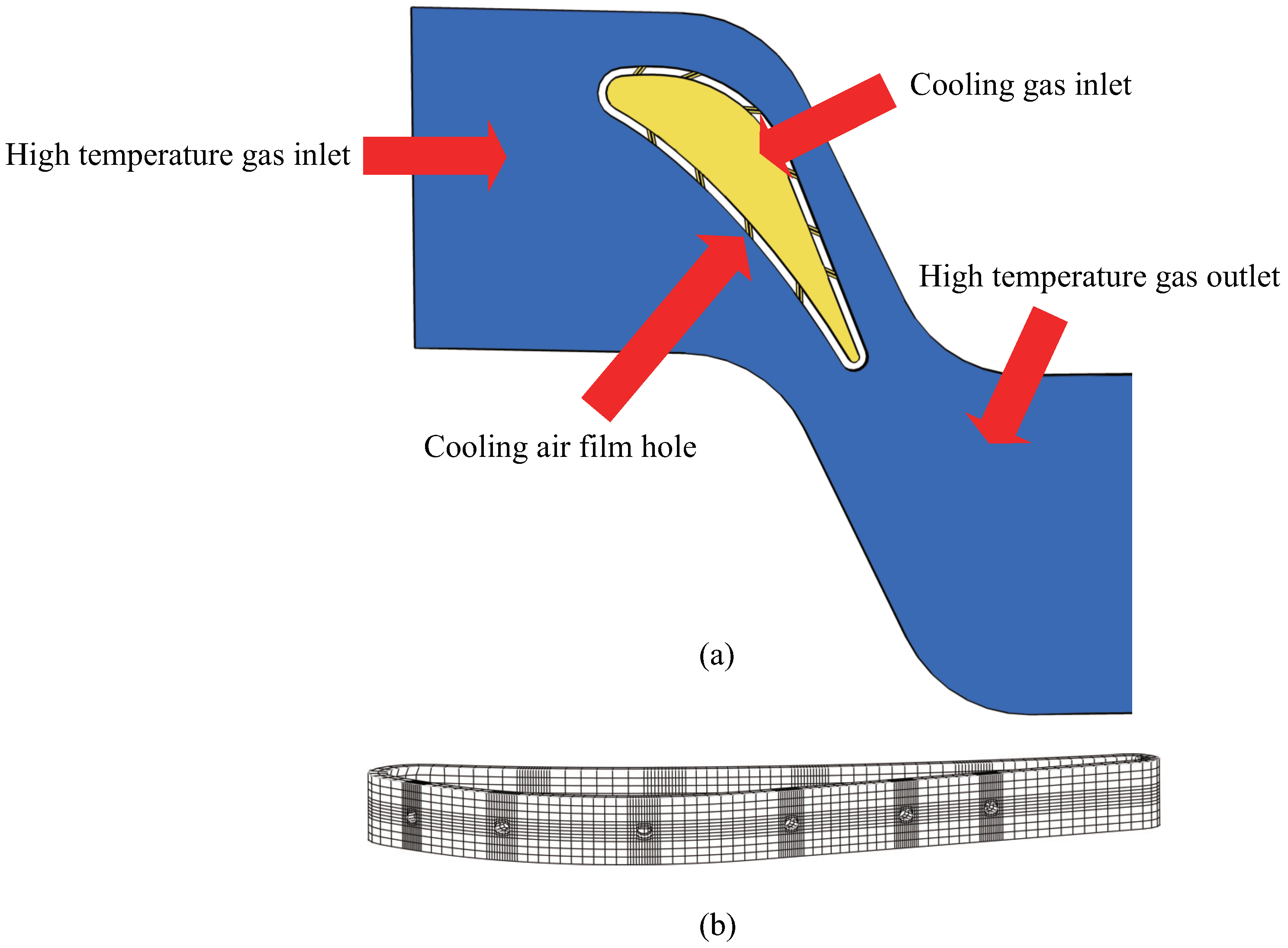

5. Fluid-Structure Analysis for Aero-Engine Turbine Blade with Cooling Structure

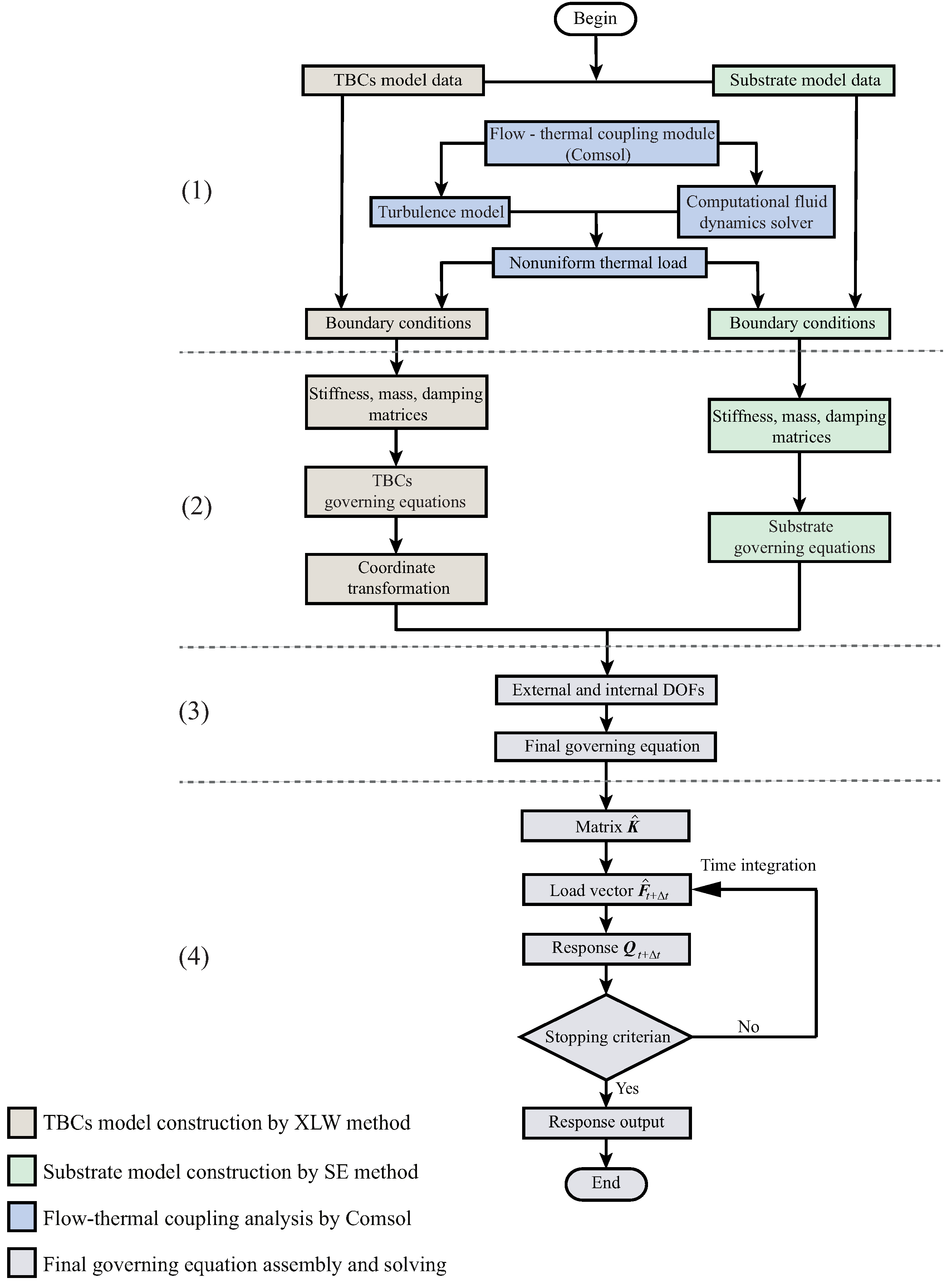

6. Computational Framework of Extended-Layerwise/Solid-Element Method

7. Numerical Examples

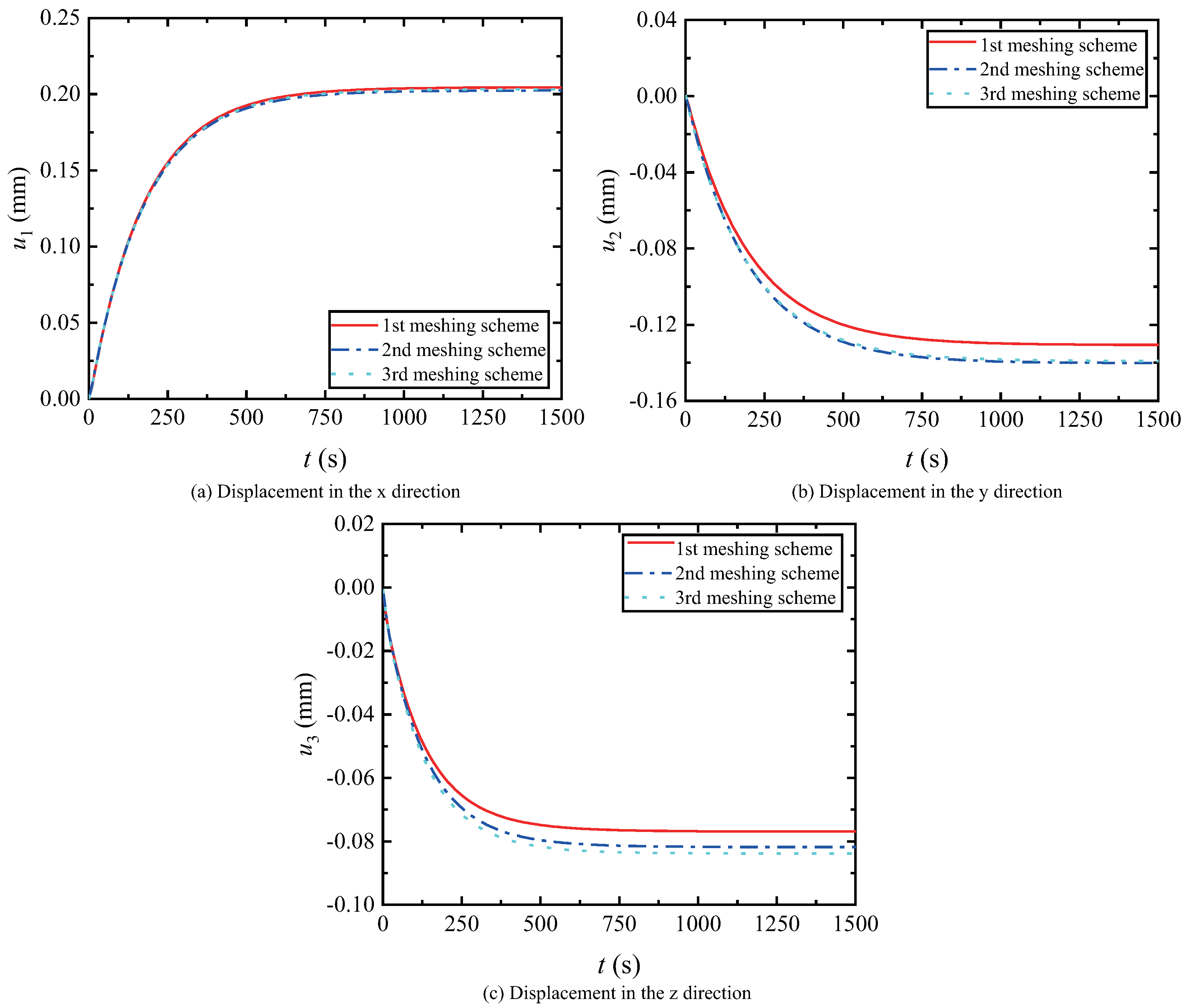

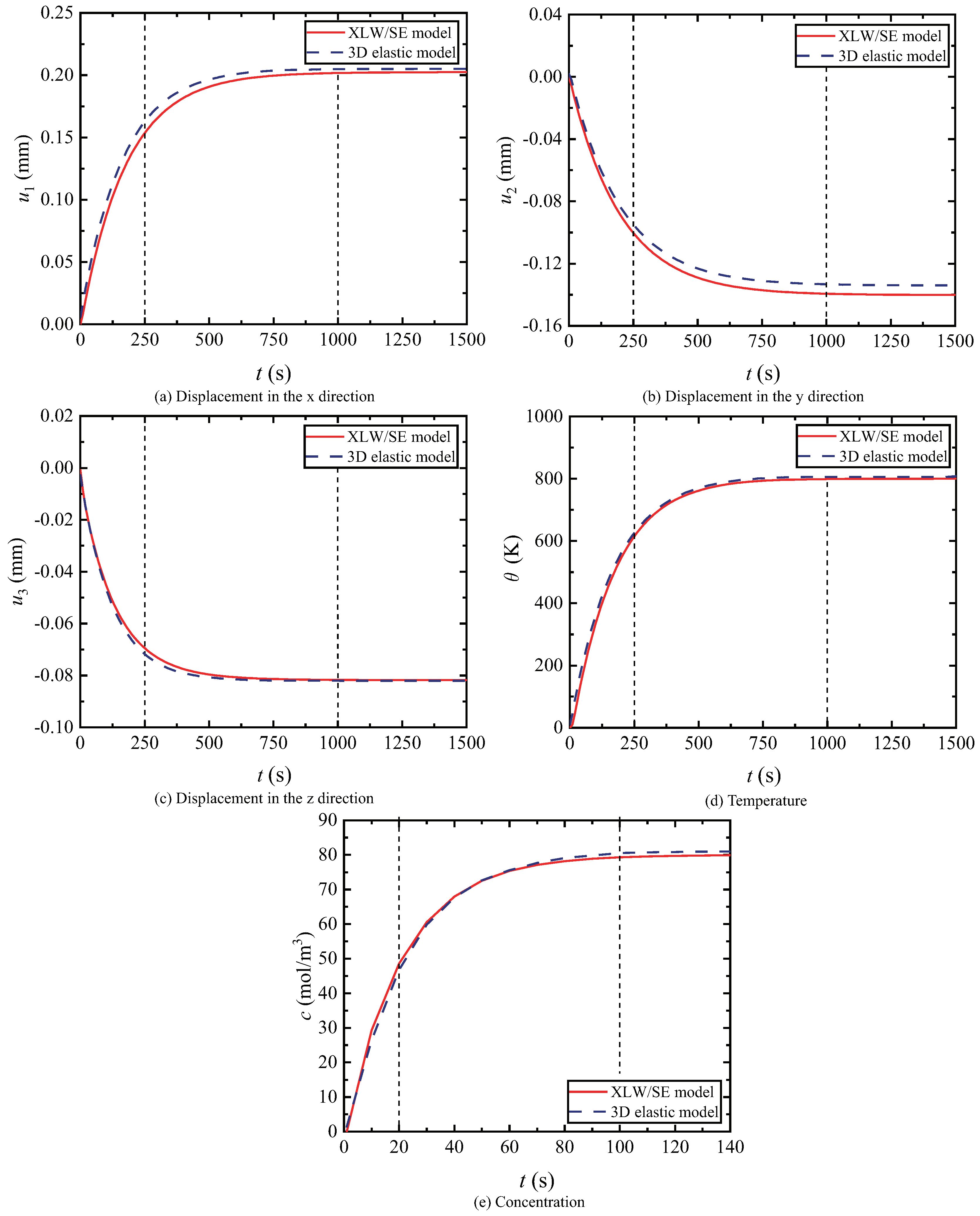

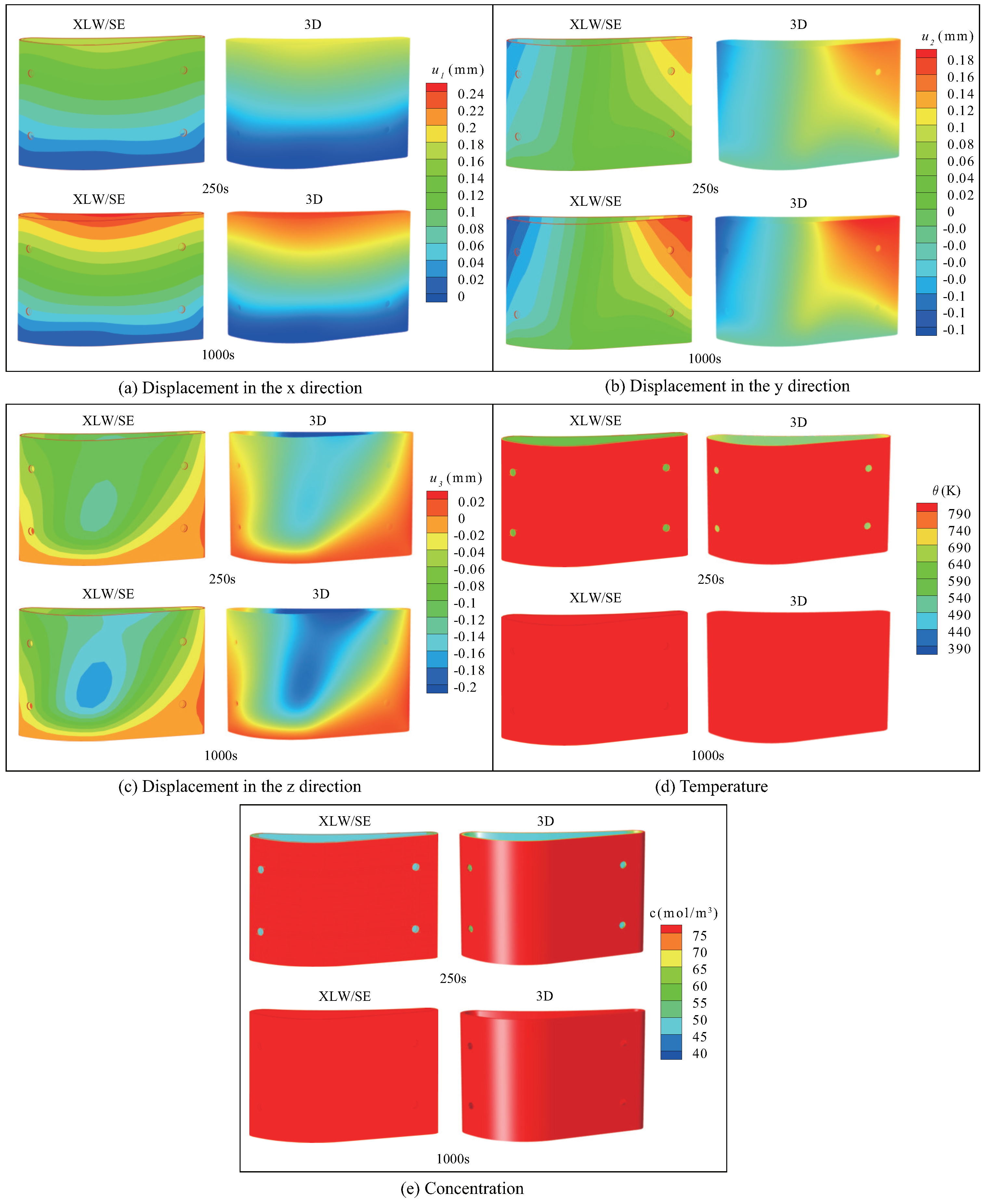

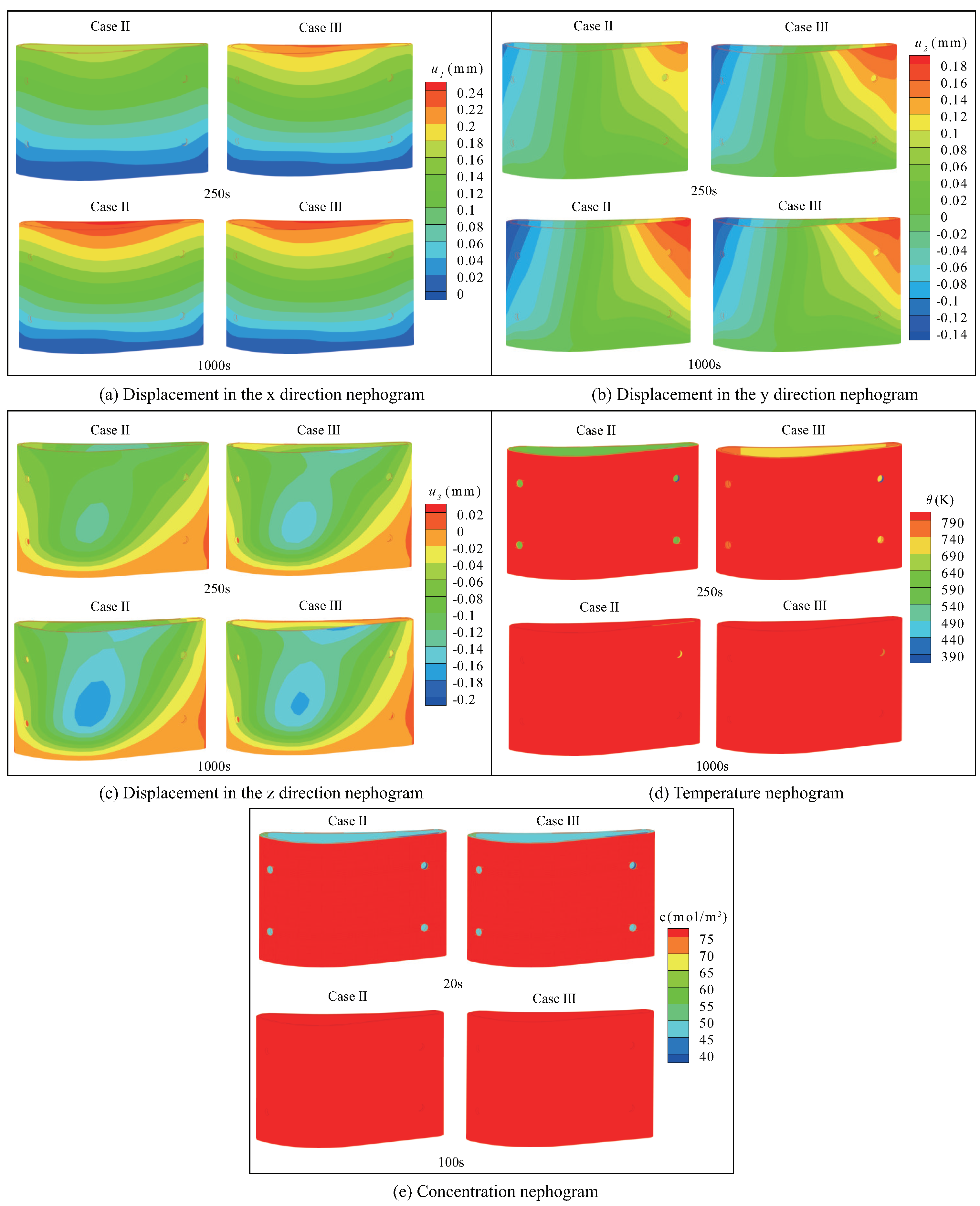

7.1. Validation of Extended-Layerwise/Solid-Element Method

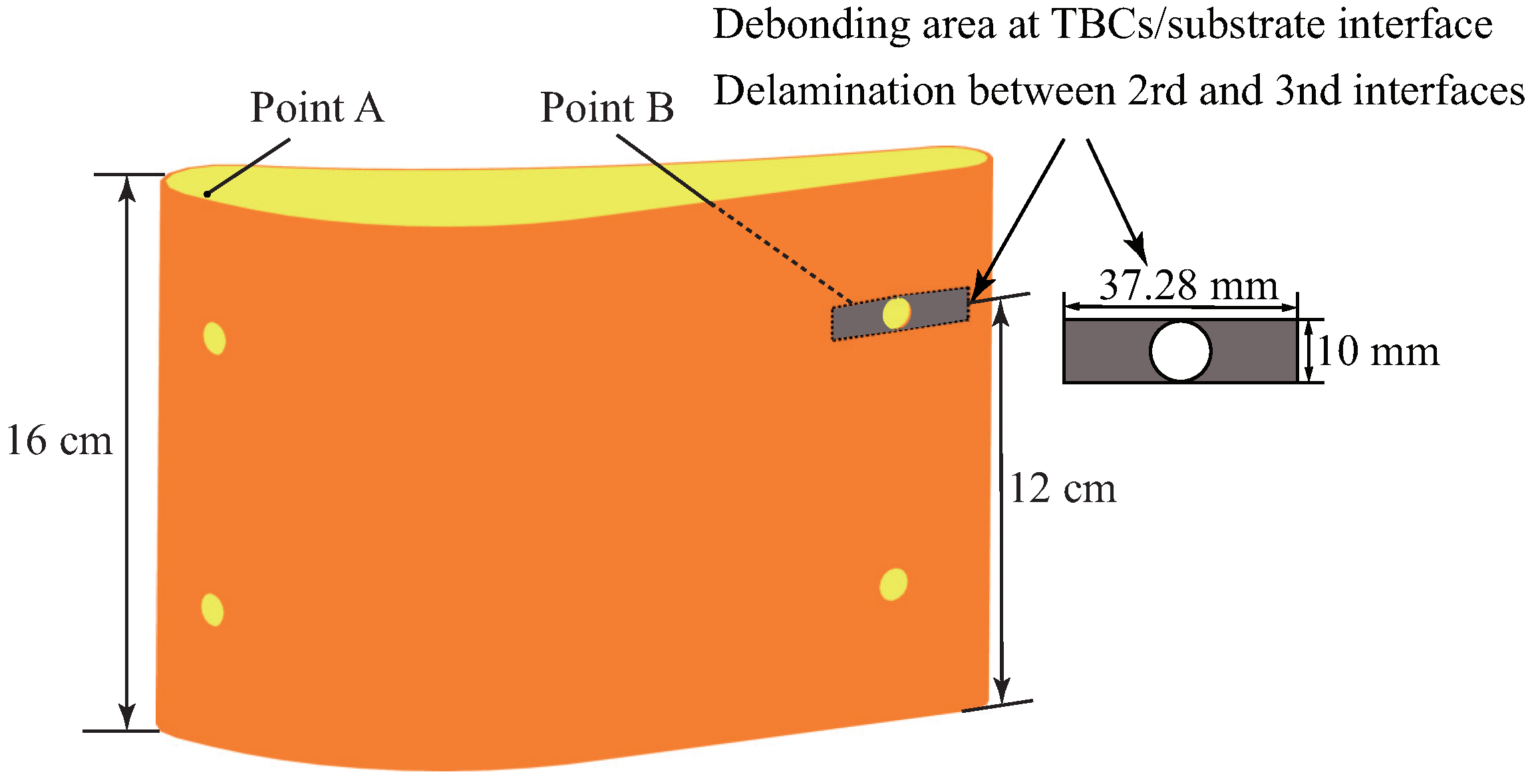

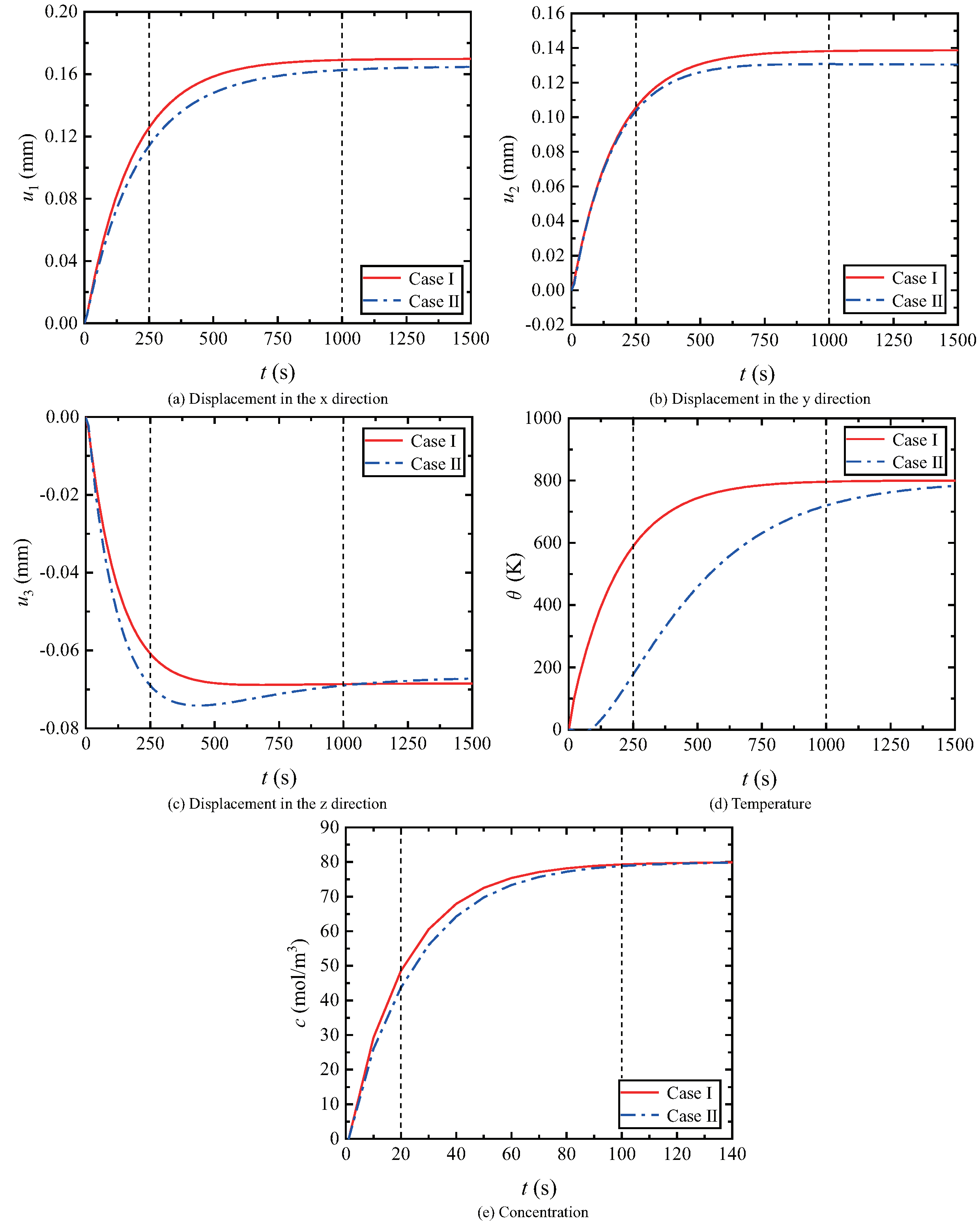

7.2. TBCs with Debonding at Interface

7.3. TBCs with Delamination and Interfacial Debonding

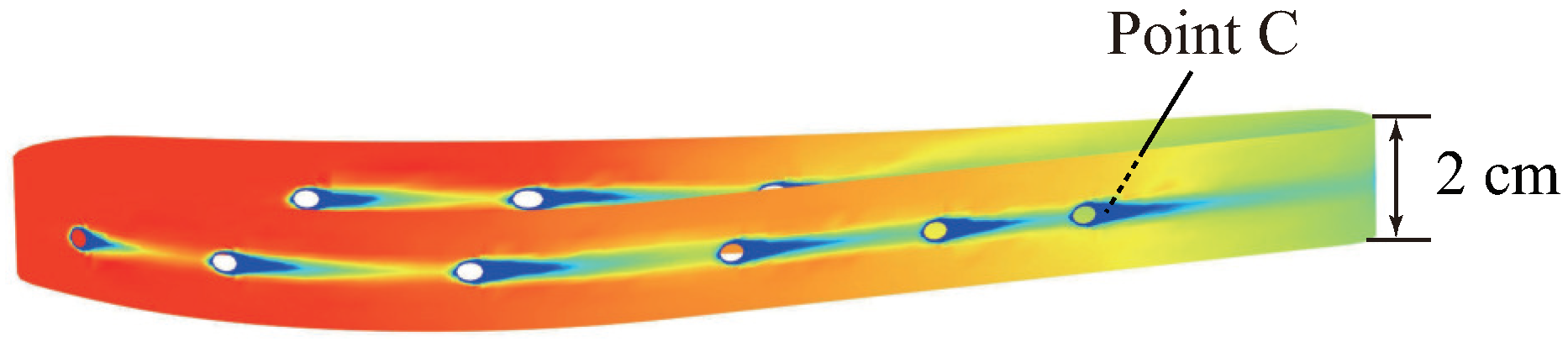

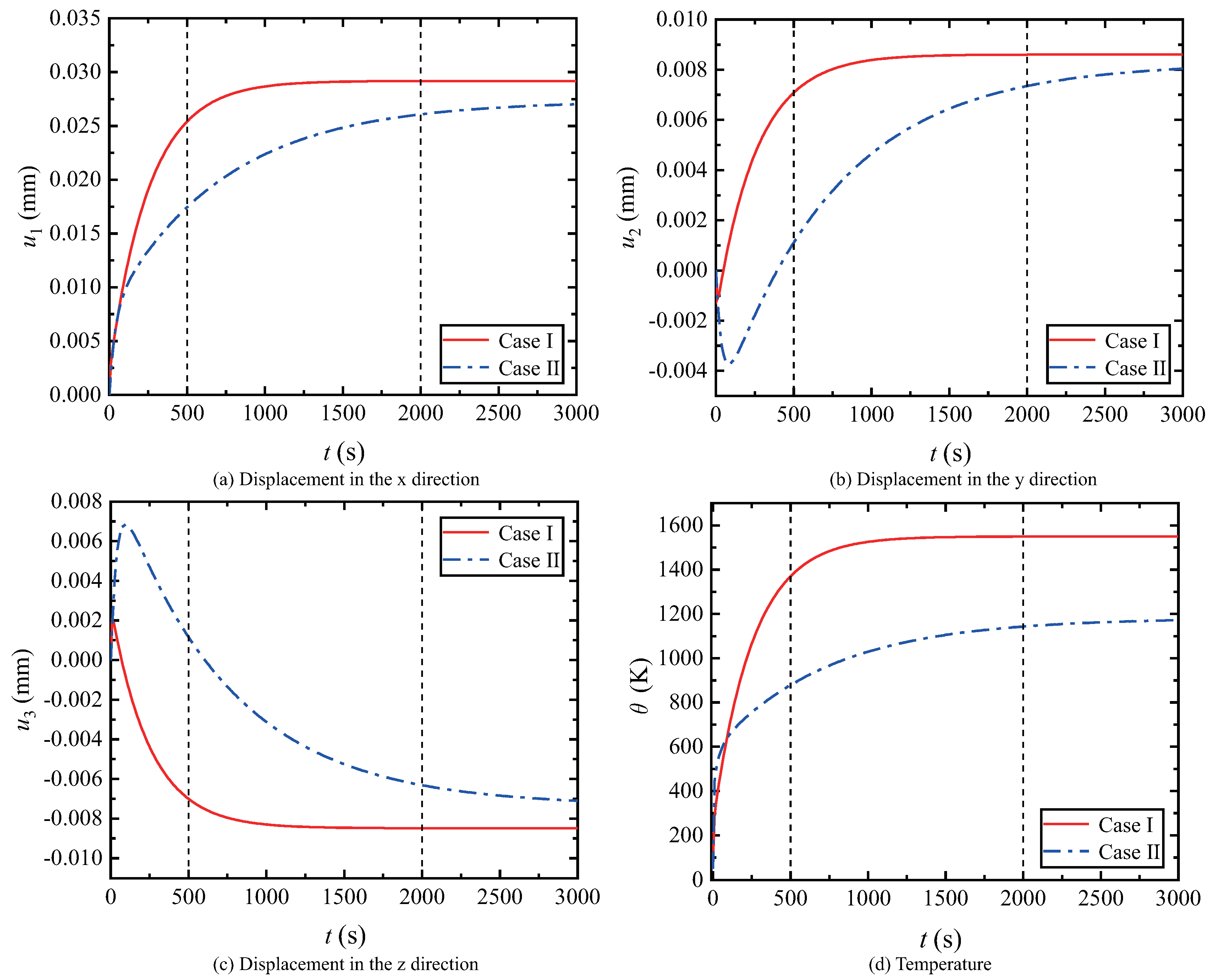

7.4. Coupling Analysis of Thermo–Chemo–Mechanical Field and Fluid-Structure Interaction

8. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Zhang, D.; Cheng, Y.; Jiang, R. Turbine Blade Investment Casting Die Technology; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Yu, Z.Q.; Liu, J.; Li, C.; An, B. Experimental investigation of film cooling performance on blade endwall with diffusion slot holes and stator-rotor purge flow. J. Turbomach. 2021, 84171, V07BT12A015. [Google Scholar] [CrossRef]

- Li, H.-W.; Zhang, D.-W. Han Feng: Experimental investigation on the effect of hole diameter on the leading edge region film cooling of a twist turbine blade under rotation conditions. Appl. Therm. Eng. 2021, 184, 116386. [Google Scholar] [CrossRef]

- Pu, J.; Wang, F.Q.; Wang, J. Numerical investigation of effects of blockage, inclination angle, and hole-size on film cooling effectiveness at concave surface. J. Turbomach. 2021, 143, 1–59. [Google Scholar] [CrossRef]

- Zhu, R.; Zhang, G.; Li, S.; Xie, G. Combined-hole film cooling designs based on the construction of anti-kidney vortex structure. A review. J. Heat Transf. 2020, 143, 030801. [Google Scholar] [CrossRef]

- Jiang, J.; Jiang, L.; Cai, Z. Numerical stress analysis of the TBC-film cooling system under operating conditions considering the effects of thermal gradient and tgo growth. Surf. Coatings Technol. 2019, 357, 433–444. [Google Scholar] [CrossRef]

- Yugeswaran, S.; Amarnath, P.; Ananthapadmanabhan, P.V. Thermal conductivity and oxidation behavior of porous inconel 625 coating interface prepared by dual-injection plasma spraying. Surf. Coatings Technol. 2021, 411, 126990. [Google Scholar] [CrossRef]

- Elumalai, P.V.; Parthasarathy, M. Effect of Cerium Oxide Nanoparticles to Improve the Combustion Characteristics of Palm Oil Nano Water Emulsion using Low Heat Rejection Engine. Int. J. Green Energy 2021, 18, 1482–1496. [Google Scholar] [CrossRef]

- Elumalai, P.V.; Annamalai, K.; Dhinesh, B. Effects of thermal barrier coating on the performance, combustion and emission of DI diesel engine powered by biofuel oil–water emulsion. J. Therm. Anal. Calorim. 2019, 137, 593–605. [Google Scholar] [CrossRef]

- Xu, H.; Guo, H. Thermal Barrier Coatings; Woodhead Publishing Limited: Sawston, UK, 2011. [Google Scholar]

- Liu, J.H.; Liu, Y.B.; Liu, L.; He, X. Numerical simulation of thermal stress of thermal barrier coating on gas film cooled turbine guide vane. China Surf. Eng. 2018, 31, 11. [Google Scholar]

- Wang, L.P.; Zhang, J.Z.; Yao, Y. Numerical study on temperature distribution of air-cooled blades with thermal barrier coating. J. Aerosp. Power 2012, 27, 8. [Google Scholar]

- Zhou, Y.C.; Hashida, T. Coupled effects of temperature gradient and oxidation on thermal stress in thermal barrier coating system. Int. J. Solids Struct. 2001, 38, 4235–4264. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, J.; Wang, H.; Lou, W.; Liu, X. Influences of cr and co on the growth of thermally grown oxide in thermal barrier coating during high-temperature exposure. Coatings 2018, 8, 195. [Google Scholar] [CrossRef]

- Tawancy, H.M.; Mohammad, A.I.; Al-Hadhrami, L.M. On the performance and failure mechanism of thermal barrier coating systems used in gas turbine blade applications: Influence of bond coat/superalloy combination. Eng. Fail. Anal. 2015, 57, 1–20. [Google Scholar] [CrossRef]

- Chen, P.-W.; Wang, S.-M.; Wang, F.-H. Fracture analysis of thermal barrier coating delamination under thermal shock. Procedia Eng. 2015, 99, 344–348. [Google Scholar] [CrossRef]

- Bhatnagar, H.; Ghosh, S.; Walter, M.E. Parametric studies of failure mechanisms in elastic eb-pvd thermal barrier coatings using fem. Int. J. Solids Struct. 2006, 43, 4384–4406. [Google Scholar] [CrossRef]

- Yildirim, B.; Erdogan, F. Edge crack problems in homogenous and functionally graded material thermal barrier coatings under uniform thermal loading. J. Therm. Stress. 2004, 27, 311–329. [Google Scholar] [CrossRef]

- Ueda, S.; Nakano, Y. An axisymmetric crack in a functionally graded thermal barrier coating bonded to a homogeneous elastic substrate under transient thermal loading. J. Therm. Stress. 2018, 43, 940–961. [Google Scholar] [CrossRef]

- Ueda, S.; Nakano, Y. A normal crack in a functionally graded thermal barrier coating bonded to a homogeneous elastic substrate under transient thermal loading. J. Therm. Stress. 2018, 41, 1487–1500. [Google Scholar] [CrossRef]

- Xiao, Y.Q.; Yang, L.; Zhu, W.; Zhou, Y.C. Delamination mechanism of thermal barrier coatings induced by thermal cycling and growth stresses. Eng. Fail. Anal. 2021, 121, 105202. [Google Scholar] [CrossRef]

- Shan, W.K.; Li, D.H. Thermo-mechanic-chemical coupling fracture analysis for thermal barrier coating based on extended layerwise method. Surf. Coat. Technol. 2021, 405, 126520. [Google Scholar] [CrossRef]

- Li, D.H. Layerwise theories of laminated composite structures and their applications. A review. Arch. Comput. Methods Eng. 2021, 28, 577–600. [Google Scholar] [CrossRef]

- Li, D.H.; Zhang, F. Full extended layerwise method for the simulation of laminated composite plates and shells. Comput. Struct. 2017, 187, 101–113. [Google Scholar] [CrossRef]

- Li, D.H. Extended layerwise method of laminated composite shells. Compos. Struct. 2016, 136, 313–344. [Google Scholar] [CrossRef]

- Li, D.H. Delamination and transverse crack growth prediction for laminated composite plates and shells. Comput. Struct. 2016, 177, 39–55. [Google Scholar] [CrossRef]

- Li, D.H.; Zhang, X.; Sze, K.Y.; Liu, Y. Extended layerwise method for laminated composite plates with multiple delaminations and transverse cracks. Comput. Mech. 2016, 58, 657–679. [Google Scholar] [CrossRef]

- Li, D.H.; Zhang, F.; Xu, J.X. Incompatible extended layerwise method for laminated composite shells. Int. J. Mech. Sci. 2016, 119, 243–252. [Google Scholar] [CrossRef]

- Li, D.H.; Liu, Y.; Zhang, X. An extended layerwise method for composite laminated beams with multiple delaminations and matrix cracks. Int. J. Numer. Methods Eng. 2015, 101, 407–434. [Google Scholar] [CrossRef]

- Lu, X.; Yang, J.Y.; Xu, D.; Wu, Y.G.; Li, D.H. Extended layerwise/solid-element method of composite sandwich plates with damage. Mech. Adv. Mater. Struct. 2019, 26, 1376–1389. [Google Scholar] [CrossRef]

- Lu, X.; Yang, J.Y.; Wu, Y.G.; Zhang, F.; Li, D.H. An extended layerwise/solid-element method of stiffened composite plates with delaminations and transverse crack. Int. J. Mech. Mater. Des. 2018, 14, 345–358. [Google Scholar] [CrossRef]

- Li, D.H.; Wang, R.P.; Qian, R.L.; Liu, Y.; Qing, G. Static response and free vibration analysis of the composite sandwich structures with multi-layer cores. Int. J. Mech. Sci. 2016, 111–112, 101–115. [Google Scholar] [CrossRef]

- Li, D.H.; Liu, Y.; Zhang, X. A layerwise/solid-element method of the linear static and free vibration analysis for the composite sandwich plates. Compos. Part B Eng. 2013, 52, 187–198. [Google Scholar] [CrossRef]

- Li, D.H.; Liu, Y.; Zhang, X. Linear statics and free vibration sensitivity analysis of the composite sandwich plates based on a layerwise/solid-element method. Compos. Struct. 2013, 106, 175–200. [Google Scholar] [CrossRef]

- Li, D.H.; Liu, Y.; Zhang, X. Low-velocity impact responses of the stiffened composite laminated plates based on the progressive failure model and the layerwise/solid-elements method. Compos. Struct. 2014, 110, 249–275. [Google Scholar] [CrossRef]

- Li, D.H.; Qing, G.H.; Liu, Y. A layerwise/solid-element method for the composite stiffened laminated cylindrical shell structures. Compos. Struct. 2013, 98, 215–227. [Google Scholar] [CrossRef]

- Li, D.H.; Liu, Y. Three-dimensional semi-analytical model for the static response and sensitivity analysis of the composite stiffened laminated plate with interfacial imperfections. Compos. Struct. 2012, 94, 1943–1958. [Google Scholar] [CrossRef]

- Li, D.H.; Fish, J. Thermomechanical extended layerwise method for laminated composite plates with multiple delaminations and transverse cracks. Compos. Struct. 2017, 185, 665–683. [Google Scholar] [CrossRef]

- Li, D.H.; Shan, W.K.; Zhang, F. Steady-state thermomechanical analysis of composite laminated plate with damage based on extended layerwise method. Arch. Appl. Mech. 2020, 90, 415–435. [Google Scholar] [CrossRef]

- Li, D.H.; Shan, W.K. Numerical fracture analysis for chemo-mechanical coupling problems in multilayered porous media. Int. J. Mech. Sci. 2019, 172, 105412. [Google Scholar] [CrossRef]

- Hass, D. Thermal Barrier Coatings via Directed Vapor Deposition; University of Virginia: Charlottesville, VA, USA, 2001; Volume 62, p. 470. [Google Scholar]

| Elastic | Poisson | Mass | Thermal Expansion | Heat Conduction | Specific Heat | Diffusion | |

|---|---|---|---|---|---|---|---|

| Materials | Modulus | Ratio | Density | Coefficient | Coefficient | Capacity | Coefficients |

| (kg/m3) | (10 K−1) | (W/m·K) | c (J/kg·K) | (10 m2/s) | |||

| 34 | 0.12 | 5600 | 8.657 | 2.09 | 460 | 2.5 | |

| 214.5 | 0.3 | 7320 | 11.6 | 16.1 | 501 | 2.5 | |

| 160 | 0.35 | 8240 | 17 | 23.6 | 615 | 2.5 |

| Meshing Schemes | Elements | Nodes |

|---|---|---|

| 1st meshing | 13,312 | 20,928 |

| 2nd meshing | 23,808 | 36,792 |

| 3rd meshing | 32,256 | 49,728 |

| Displacements | 3D Elastic Model (×10 m) | Proposed XLW/SE Model (×10 m) | Error (%) |

|---|---|---|---|

| 0.24028 | 0.24456 | 1.78% | |

| 0.18776 | 0.19395 | 3.29% | |

| 0.03062 | 0.03098 | 1.18% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Yuan, H.; Ma, S.; Yang, J. Dynamic Coupling Analysis on Thermo–Chemo–Mechanical Field and Fluid–Structure Interaction for Aero-Engine Turbine Blade with Functional Gradient Thermal Barrier Coatings. Coatings 2022, 12, 1498. https://doi.org/10.3390/coatings12101498

Li D, Yuan H, Ma S, Yang J. Dynamic Coupling Analysis on Thermo–Chemo–Mechanical Field and Fluid–Structure Interaction for Aero-Engine Turbine Blade with Functional Gradient Thermal Barrier Coatings. Coatings. 2022; 12(10):1498. https://doi.org/10.3390/coatings12101498

Chicago/Turabian StyleLi, Dinghe, Hang Yuan, Shuo Ma, and Jimeng Yang. 2022. "Dynamic Coupling Analysis on Thermo–Chemo–Mechanical Field and Fluid–Structure Interaction for Aero-Engine Turbine Blade with Functional Gradient Thermal Barrier Coatings" Coatings 12, no. 10: 1498. https://doi.org/10.3390/coatings12101498

APA StyleLi, D., Yuan, H., Ma, S., & Yang, J. (2022). Dynamic Coupling Analysis on Thermo–Chemo–Mechanical Field and Fluid–Structure Interaction for Aero-Engine Turbine Blade with Functional Gradient Thermal Barrier Coatings. Coatings, 12(10), 1498. https://doi.org/10.3390/coatings12101498