Assessment of Defects under Insulation Using K-Medoids Clustering Algorithm-Based Microwave Nondestructive Testing

Abstract

:1. Introduction

2. Materials and Methods

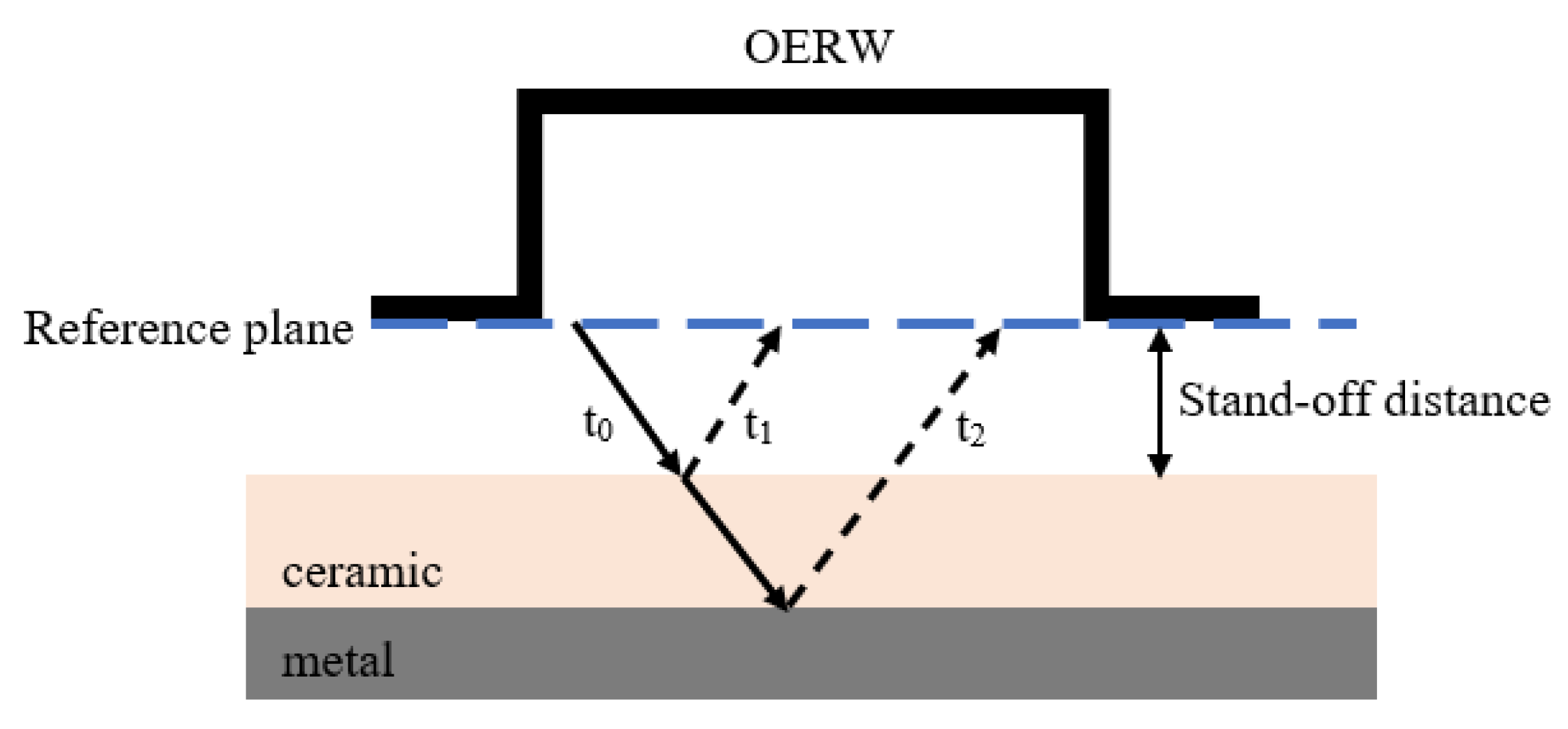

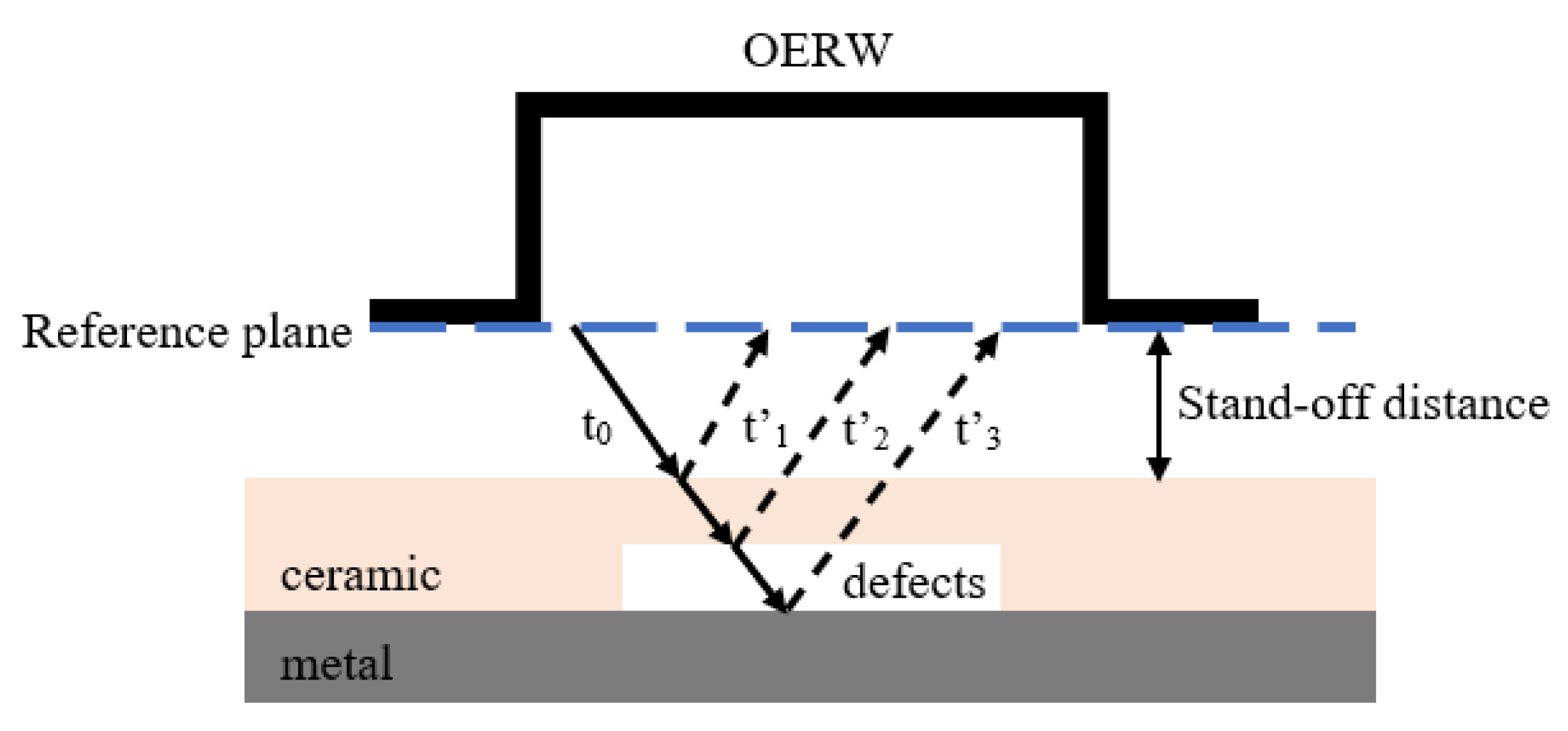

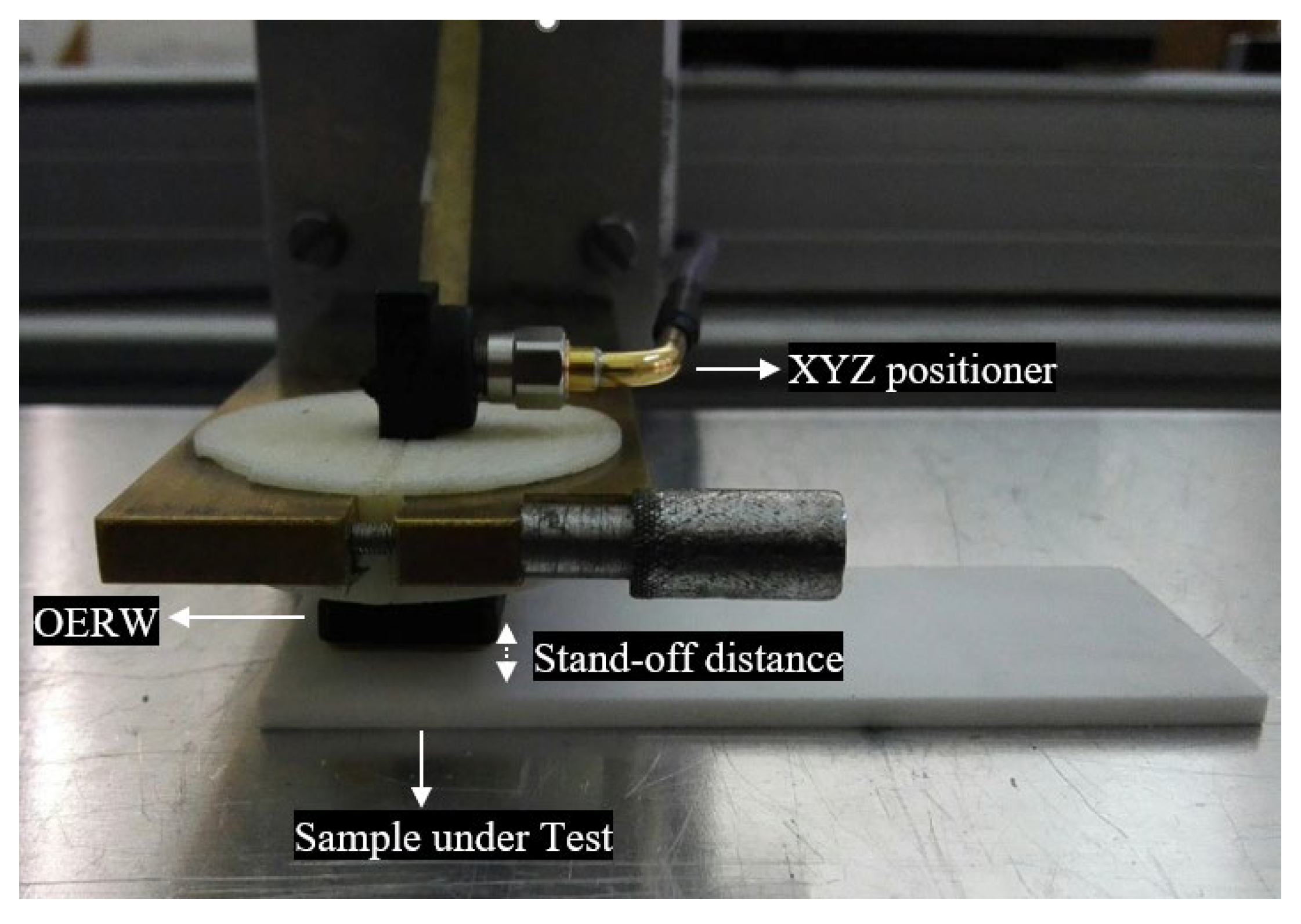

2.1. Open-Ended Rectangular Waveguide (OERW)

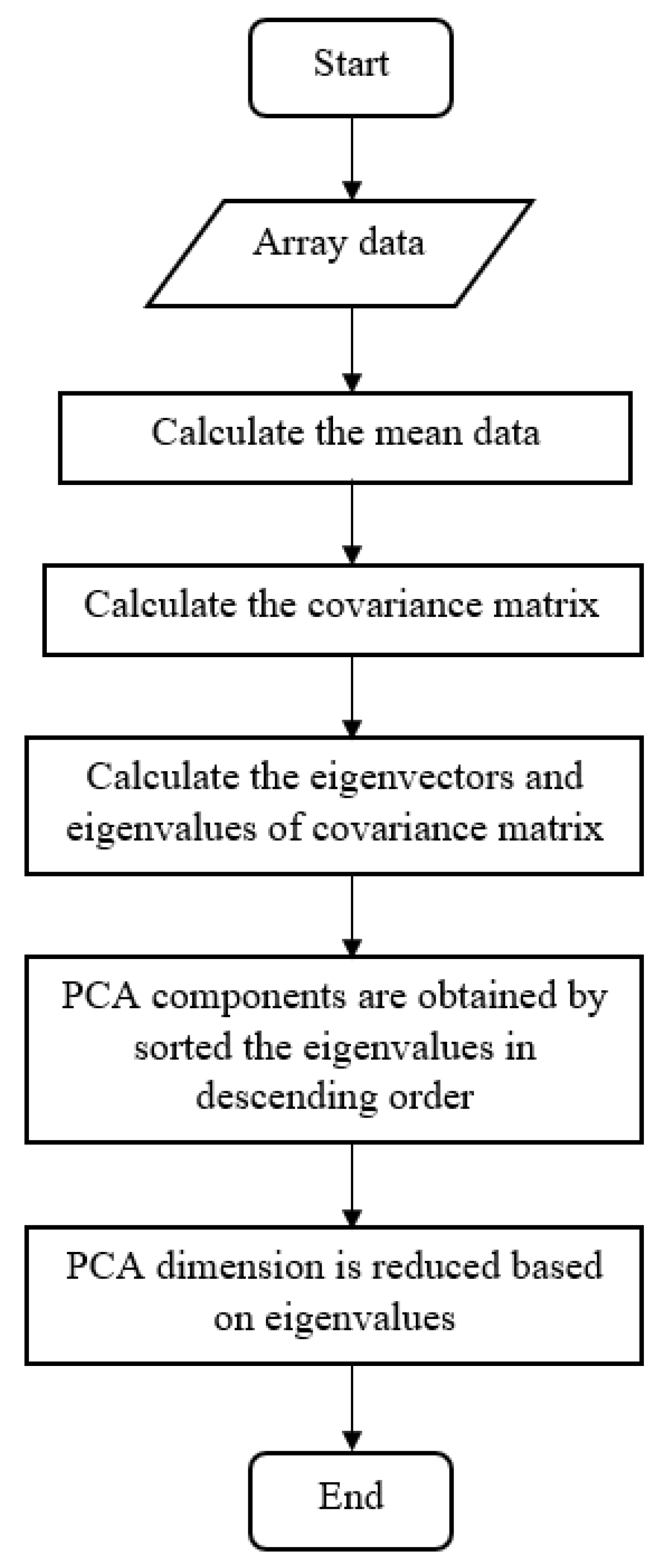

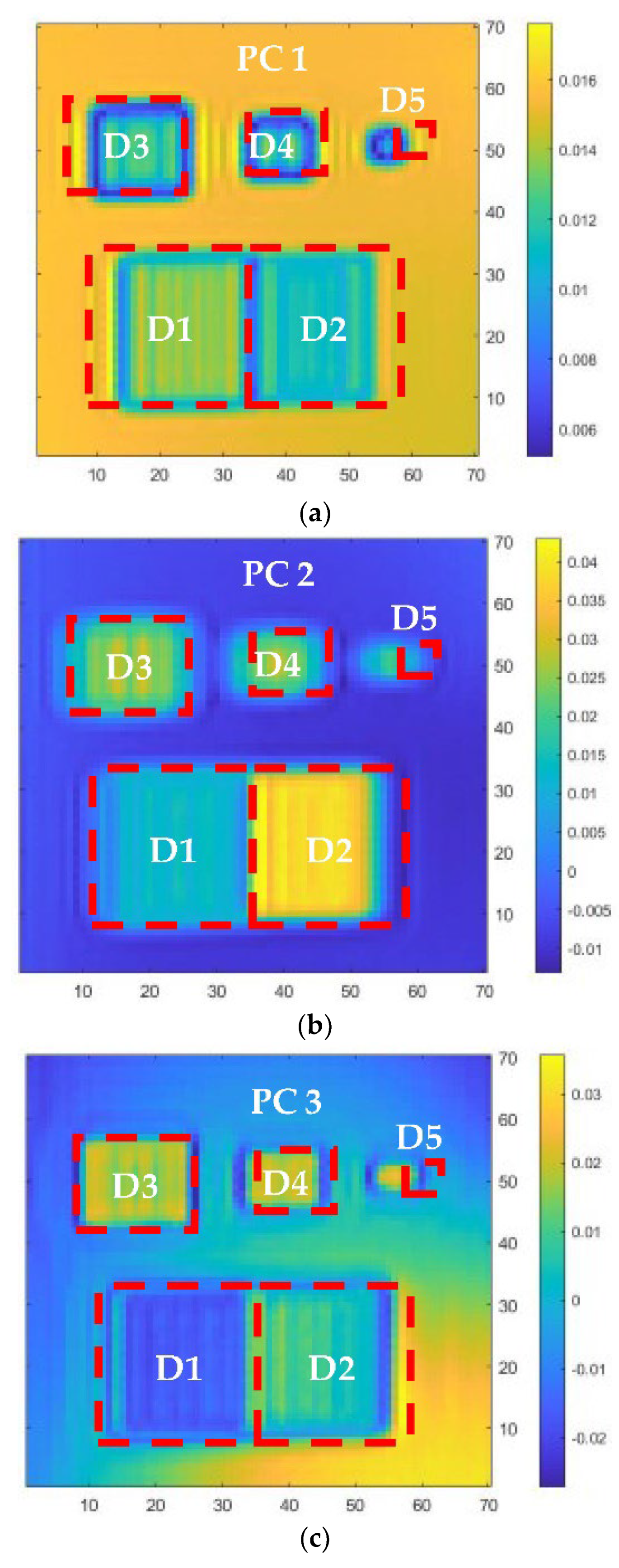

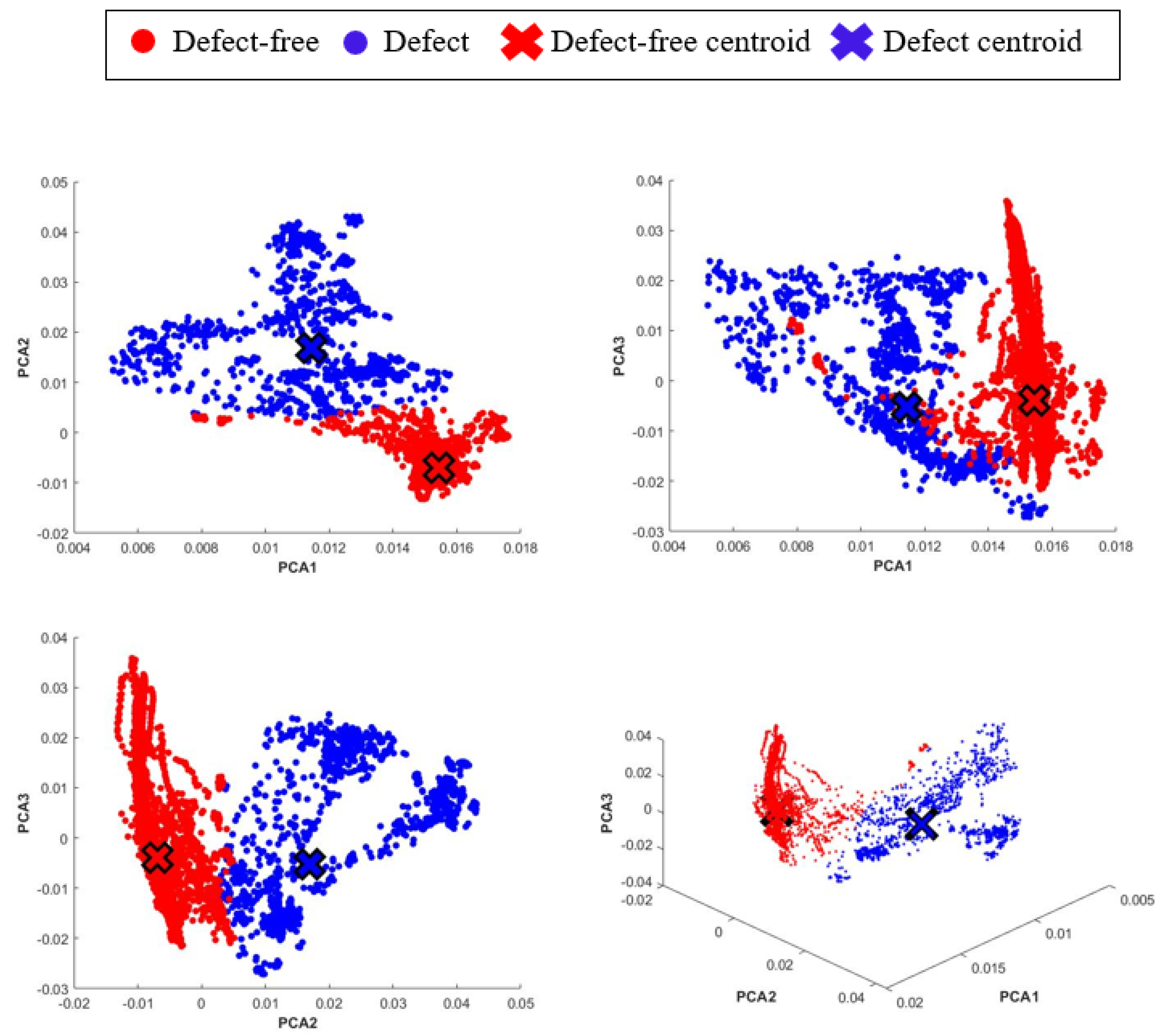

2.2. Principal Component Analysis (PCA)

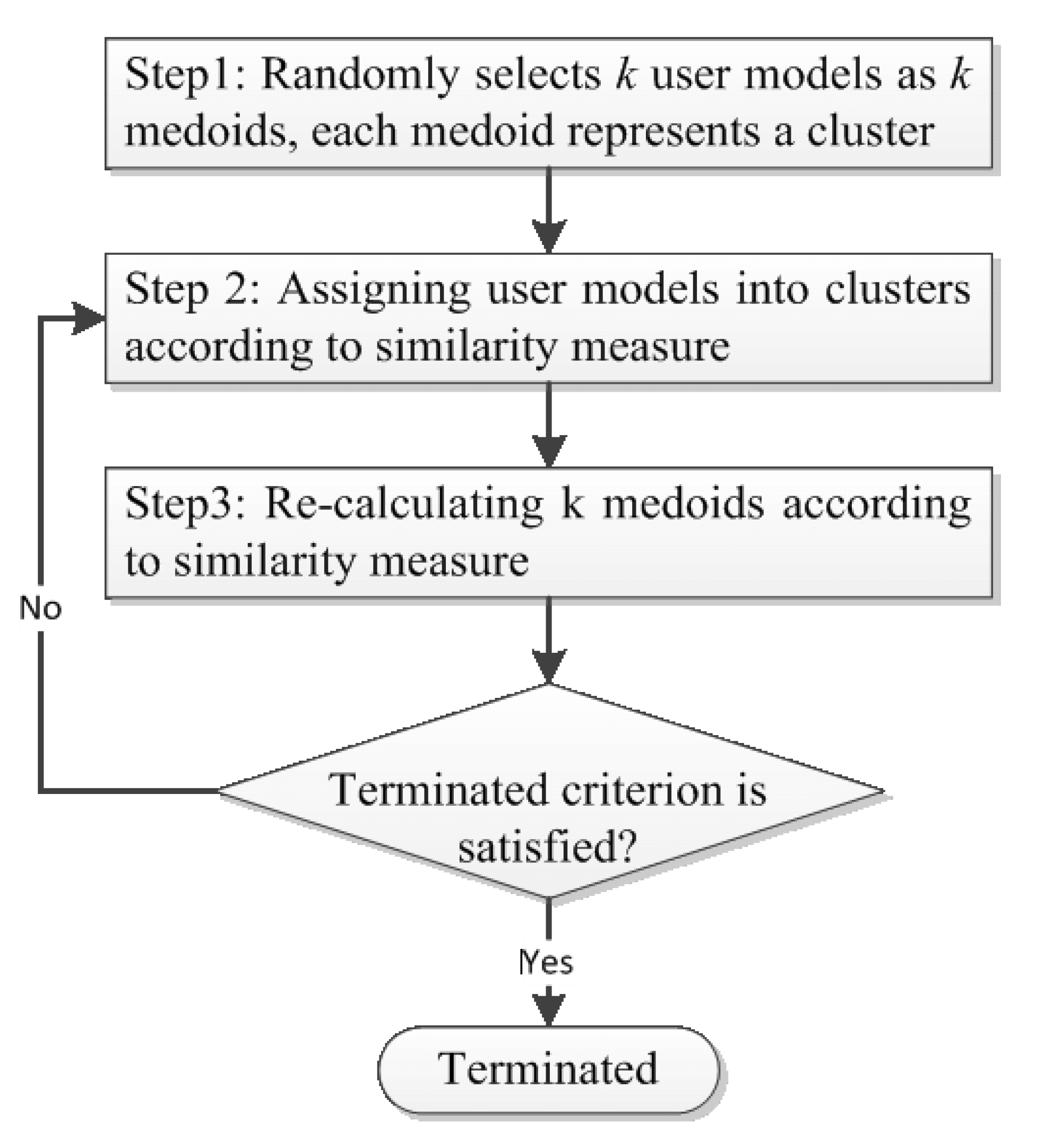

2.3. K-Medoids Clustering Algorithm

2.4. Methods

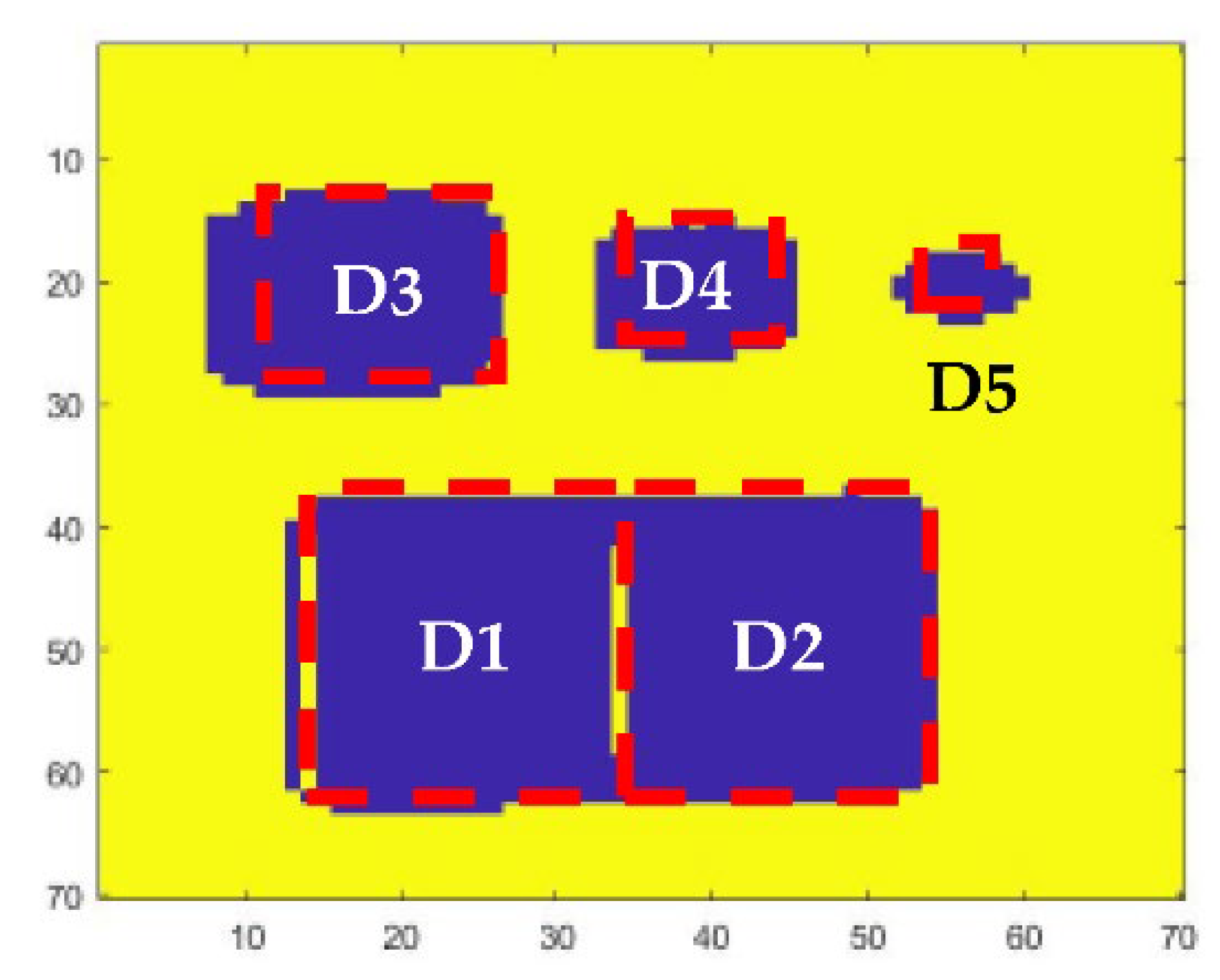

2.4.1. Macor Sample

2.4.2. Inspection Technique

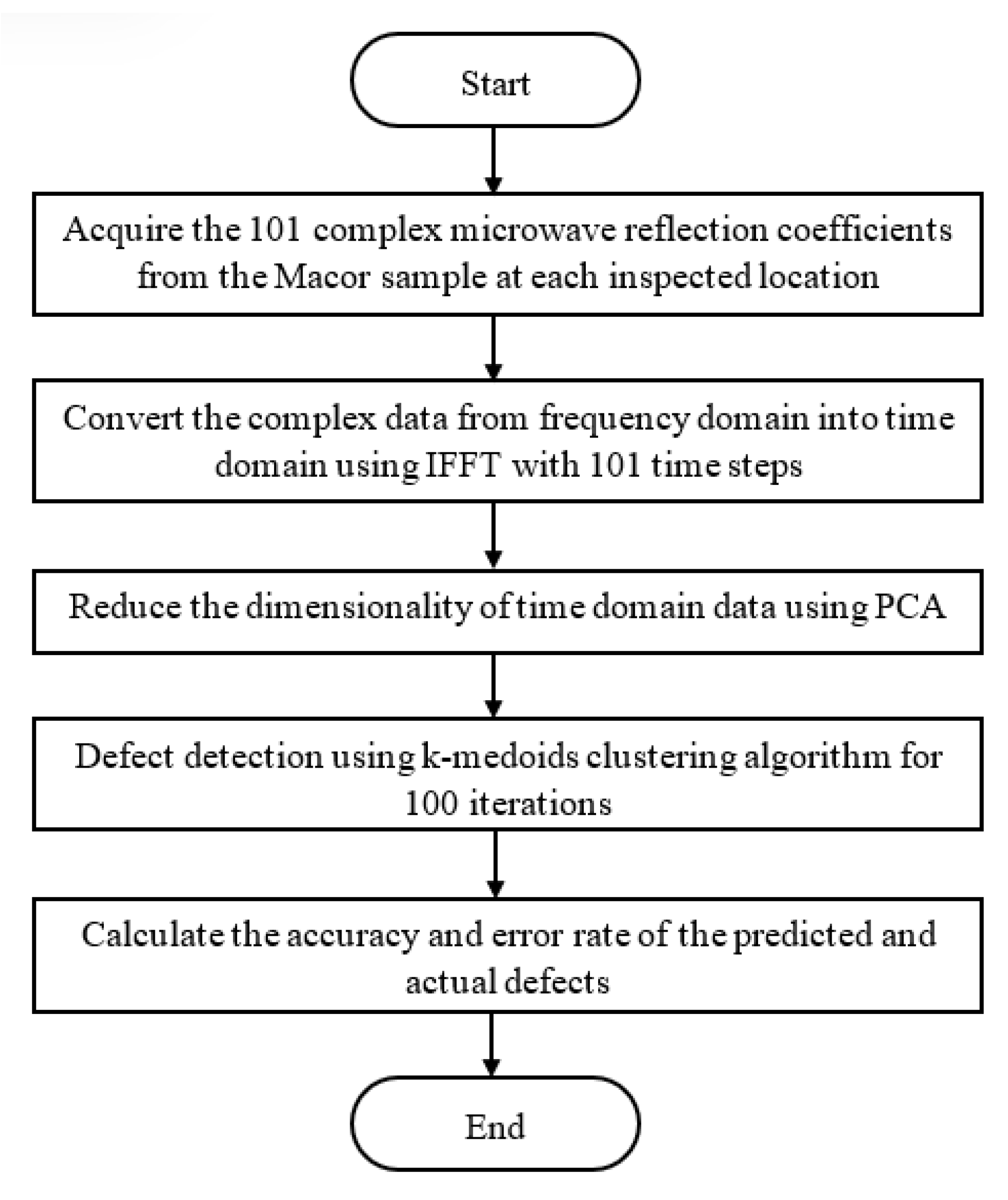

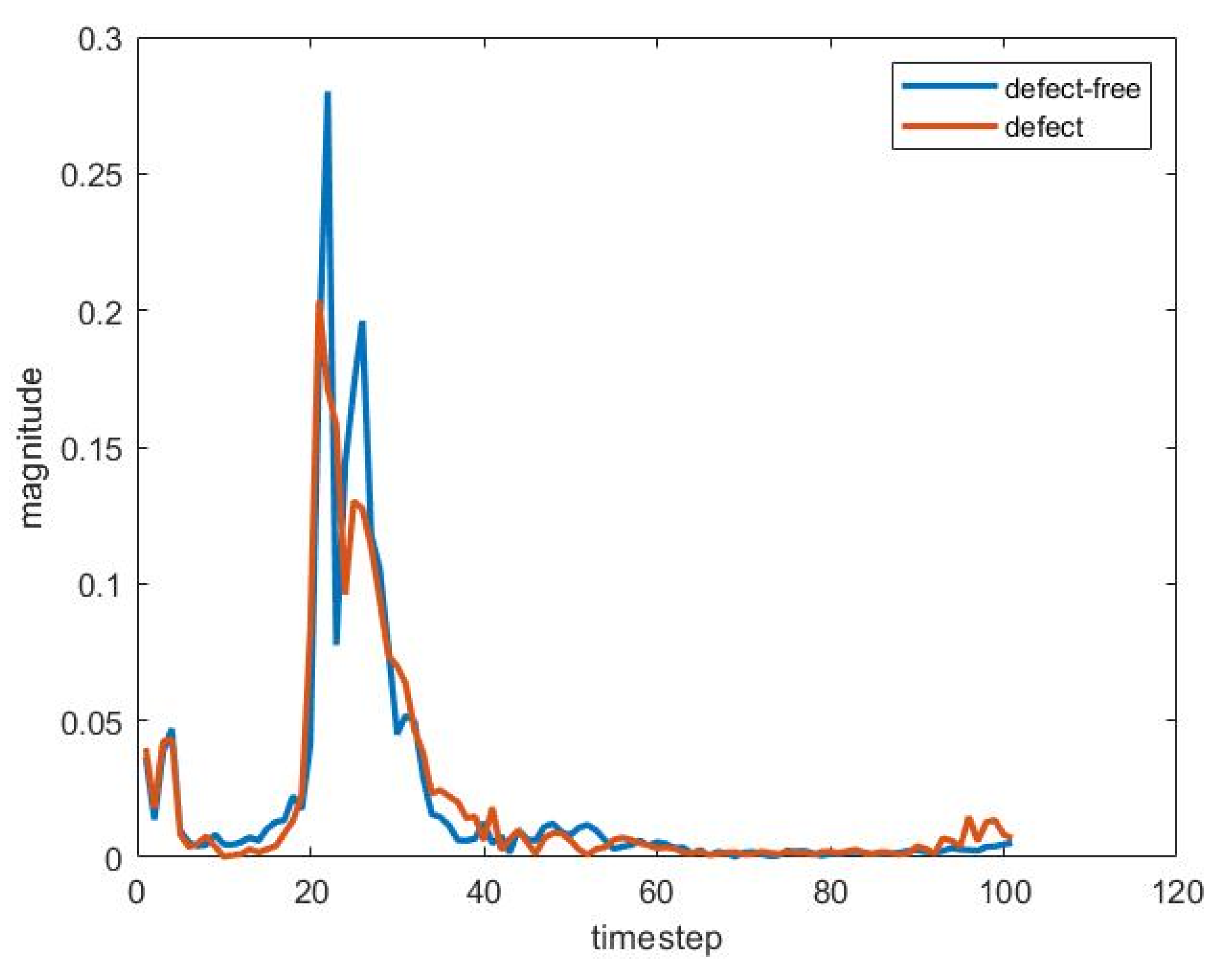

2.4.3. Microwave Signal Processing

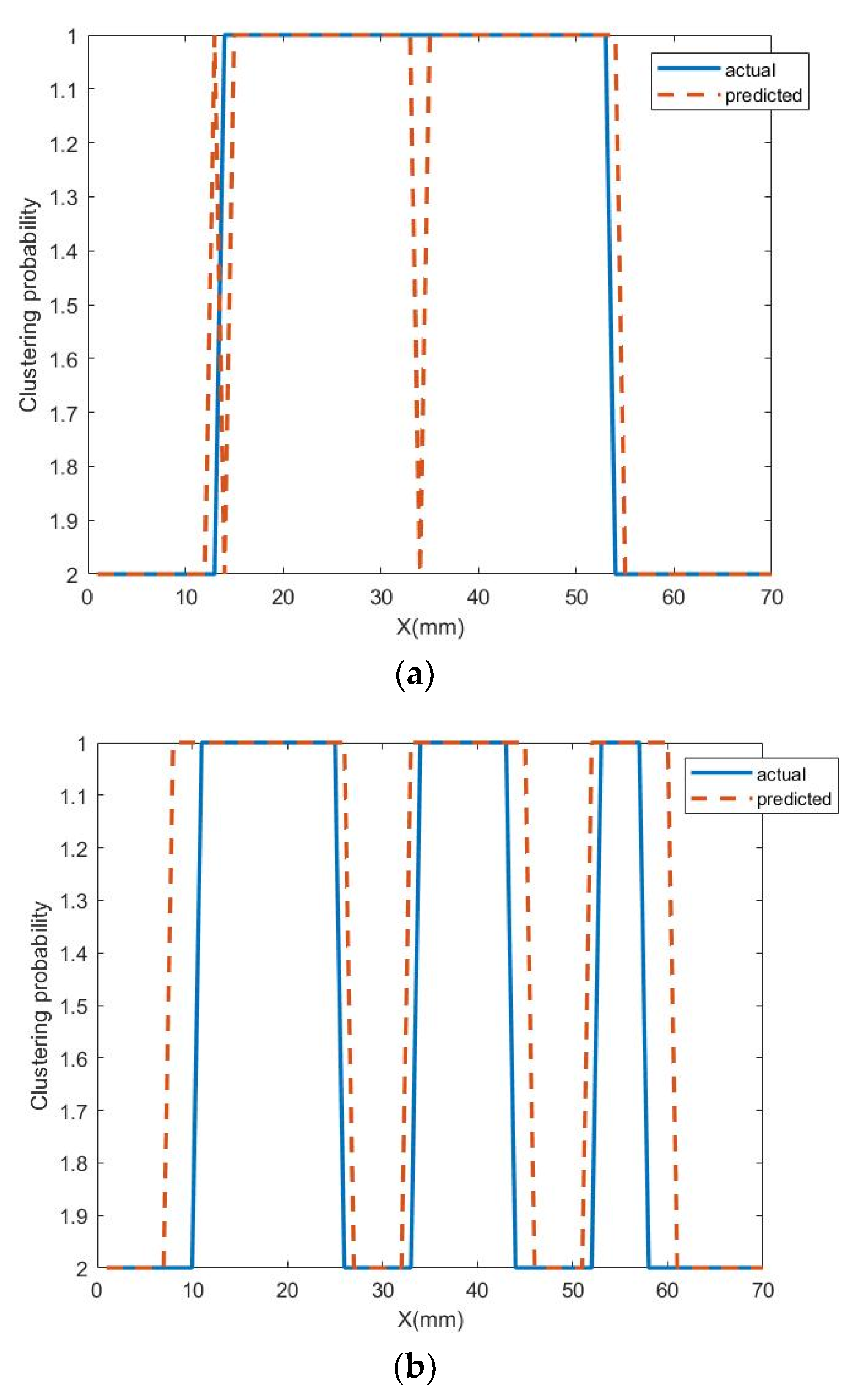

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Z. Review of Non-Destructive Testing Methods for Defect Detection of Ceramics. Ceram. Int. 2021, 47, 4389–4397. [Google Scholar] [CrossRef]

- Akbar, M.F.; Jawad, G.N.; Duff, C.I.; Sloan, R. Porosity Evaluation of In-Service Thermal Barrier Coated Turbine Blades Using a Microwave Nondestructive Technique. NDT E Int. 2018, 93, 64–77. [Google Scholar] [CrossRef]

- Akbar, M.F.; Jawad, G.N.; Danoon, L.R.; Sloan, R. Delamination Detection in Glass-Fibre Reinforced Polymer (GFRP) Using Microwave Time Domain Reflectometry. In Proceedings of the 15th European Radar Conference (EuRAD), Madrid, Spain, 26–28 September 2018; pp. 253–256. [Google Scholar] [CrossRef]

- Yee, T.S.; Akbar, M.F.; Ghazali, N.A.; Mohamed, M.F.P. Defects Detection Using Complementary Split Ring Resonator with Microstrip Patch Antenna. In Lecture Notes in Electrical Engineering, Proceedings of the 11th International Conference on Robotics, Vision, Signal Processing and Power Applications, Malaysia, 11 February 2022; Mahyuddin, M.N., Norr, M.R.N., Sakim, M.A.H., Eds.; Springer: Berlin/Heidelberg, Germany, 2022; pp. 625–631. [Google Scholar] [CrossRef]

- Akbar, M.F. Material Characterisation and Nondestructive Testing Using Microwave Technique. Ph.D. Thesis, University of Manchester, Manchester, UK, 2018. [Google Scholar]

- Taheri, H.; Hassen, A.A. Nondestructive Ultrasonic Inspection of Composite Materials: A Comparative Advantage of Phased Array Ultrasonic. Appl. Sci. 2019, 9, 1628. [Google Scholar] [CrossRef]

- Shi, L.; Long, Y.; Wang, Y.; Chen, X.; Zhao, Q. On-Line Detection of Porosity Change of High Temperature Blade Coating for Gas Turbine. Infrared Phys. Technol. 2020, 110, 103415. [Google Scholar] [CrossRef]

- Akbar, M.F.; Sloan, R.; Duff, C.; Wielgat, M.; Knowles, J. Nondestructive Testing of Thermal Barrier Coated Turbine Blades Using Microwave Techniques. Mater. Eval. 2016, 74, 543–551. [Google Scholar]

- Li, Z.; Wang, P.; Haigh, A.; Soutis, C.; Gibson, A. Review of Microwave Techniques Used in the Manufacture and Fault Detection of Aircraft Composites. Aeronaut. J. 2021, 125, 151–179. [Google Scholar] [CrossRef]

- Viegas, C.; Alderman, B.; Huggard, P.G.; Powell, J.; Parow-Souchon, K.; Firdaus, M.; Liu, H.; Duff, C.I.; Sloan, R. Active Millimeter-Wave Radiometry for Nondestructive Testing/Evaluation of Composites-Glass Fiber Reinforced Polymer. IEEE Trans. Microw. Theory Tech. 2017, 65, 641–650. [Google Scholar] [CrossRef]

- Teng, W.S.; Akbar, M.F.; Jawad, G.N.; Tan, S.Y.; Sazali, M.I.S.M. A Past, Present, and Prospective Review on Microwave Nondestructive Evaluation of Composite Coatings. Coatings 2021, 11, 913. [Google Scholar] [CrossRef]

- Yee, T.S.; Akbar, M.F. Under Insulation Microwave Non-Destructive Testing Using Dual-Ridges Open-Ended Rectangular Waveguide. In Lecture Notes in Electrical Engineering, Proceedings of the 11th International Conference on Robotics, Vision, Signal Processing and Power Applications, Malaysia, 11 February 2022; Mahyuddin, M.N., Norr, M.R.N., Sakim, M.A.H., Eds.; Springer: Berlin/Heidelberg, Germany, 2022; pp. 684–689. [Google Scholar] [CrossRef]

- Shrifan, N.H.M.M.; Akbar, M.F.; Isa, N.A.M. Prospect of Using Artificial Intelligence for Microwave Nondestructive Testing Technique: A Review. IEEE Access 2019, 7, 110628–110650. [Google Scholar] [CrossRef]

- Shrifan, N.H.M.M.; Akbar, M.F.; Isa, N.A.M. An Adaptive Outlier Removal Aided K-Means Clustering Algorithm. J. King Saud Univ. Comput. Inf. Sci. 2021, 34, 1–12. [Google Scholar] [CrossRef]

- Shrifan, N.H.M.M.; Jawad, G.N.; Isa, N.A.M.; Akbar, M.F. Microwave Nondestructive Testing for Defect Detection in Composites Based on K-Means Clustering Algorithm. IEEE Access 2021, 9, 4820–4828. [Google Scholar] [CrossRef]

- Case, J.T.; Kenderian, S. Microwave NDT: An Inspection Method. Mater. Eval. 2017, 75, 339–346. [Google Scholar]

- Rahman, M.S.U.; Yassin, A.; Abou-Khousa, M.A. Microwave Imaging of Thick Composite Structures Using Circular Aperture Probe. Meas. Sci. Technol. 2018, 29, 095403. [Google Scholar] [CrossRef]

- Akbar, M.F.; Shrifan, N.H.M.M.; Jawad, G.N.; Isa, N.A.M. Assessment of Delamination Under Insulation Using Ridge Waveguide. IEEE Access 2022, 10, 36177–36187. [Google Scholar] [CrossRef]

- Savin, A.; Novy, F.; Fintova, S.; Steigmann, R. Evaluation of Thin Discontinuities in Planar Conducting Materials Using the Diffraction of Electromagnetic Field. In IOP Conference Series: Materials Science and Engineering, Proceedings of the ModTech International Conference-Modern Technologies in Industrial Engineering V, Sibiu, Romania 14–17 June 2017; IOP Publishing Ltd.: Bristol, UK, 2017. [Google Scholar] [CrossRef]

- Li, Z.; Haigh, A.; Soutis, C.; Gibson, A.; Sloan, R. A Simulation-Assisted Non-Destructive Approach for Permittivity Measurement Using an Open-Ended Microwave Waveguide. J. Nondestr. Eval. 2018, 37, 1–10. [Google Scholar] [CrossRef]

- Ghasr, M.T.; Horst, M.J.; Lechuga, M.; Rapoza, R.; Renoud, C.J.; Zoughi, R. Accurate One-Sided Microwave Thickness Evaluation of Lined-Fiberglass Composites. IEEE Trans. Instrum. Meas. 2015, 64, 2802–2812. [Google Scholar] [CrossRef]

- Zoughi, R.; Gallion, J.R.; Ghasr, M.T. Accurate Microwave Measurement of Coating Thickness on Carbon Composite Substrates. IEEE Trans. Instrum. Meas. 2016, 65, 951–953. [Google Scholar] [CrossRef]

- Akbar, M.F.; Jawad, G.N.; Rashid, L.D.; Sloan, R. Nondestructive Evaluation of Coatings Delamination Using Microwave Time Domain Reflectometry Technique. IEEE Access 2020, 8, 114833–114841. [Google Scholar] [CrossRef]

- Akbar, M.F.; Sloan, R.; Duff, C.I.; Wielgat, M.; Knowles, J.F. Microwave Nondestructive Evaluation of Thermal Barrier Coated Turbine Blades Using Correlation Analysis. In Proceedings of the 46th European Microwave Week 2016: “Microwaves Everywhere”, European Microwave Conference, EuMC 2016, London, UK, 3–7 October 2016; pp. 520–523. [Google Scholar] [CrossRef]

- Shrifan, N.H.M.M.; Akbar, M.F.; Isa, N.A.M. Maximal Overlap Discrete Wavelet-Packet Transform Aided Microwave Nondestructive Testing. NDT E Int. 2021, 119, 102414. [Google Scholar] [CrossRef]

- Edis, E.; Flores-Colen, I.; de Brito, J. Time-Dependent Passive Building Thermography for Detecting Delamination of Adhered Ceramic Cladding. J. Nondestruct. Eval. 2015, 34, 1–16. [Google Scholar] [CrossRef]

- Qin, B.; Hu, C.; Huang, S. Target/Background Classification Regularized Nonnegative Matrix Factorization for Fluorescence Unmixing. IEEE Trans. Instrum. Meas. 2016, 65, 874–889. [Google Scholar] [CrossRef]

- Sanchez-Suarez, R.M.; Choquehuanca-Zevallos, J.J.; Huamán-Mamani, F.A.; Mayta-Ponce, D.L.; Ludeña-Choez, J. A Method Based on RF Spectral Featuresfor Evaluating the Porosity Degree in Ceramic Materials. In Proceedings of the 2018 IEEE MTT-S Latin America Microwave Conference, LAMC, Arequipa, Peru, 12–14 December 2018. [Google Scholar] [CrossRef]

- Kraljevski, I.; Duckhorn, F.; Tschope, C.; Wolff, M. Machine Learning for Anomaly Assessment in Sensor Networks for NDT in Aerospace. IEEE Sens. J. 2021, 21, 11000–11008. [Google Scholar] [CrossRef]

- Agarwal, S.; Singh, D. Optimal Non-Invasive Fault Classification Model for Packaged Ceramic Tile Quality Monitoring Using MMW Imaging. J. Infrared Millim. Terahertz Waves 2016, 37, 394–413. [Google Scholar] [CrossRef]

- James, R.; Kim, T.H.; Narayanan, R.M. Prognostic Investigation of Galvanic Corrosion Precursors in Aircraft Structures and Their Detection Strategy. In SPIE Conference on Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, and Civil Infrastructure, and Transportation XI, Portland, Oregon, USA, 26–29 March 2017; Shull, J.P., Gyekenyesi, L.A., Wu, F.H., Eds.; SPIE: Bellingham, WA, USA, 2017; pp. 91–102. [Google Scholar] [CrossRef]

- Martinez, J.A.; Belenguer, A.; Esteban, H. Fast Frequency Sweep Technique Based on Segmentation for the Acceleration of the Electromagnetic Analysis of Microwave Devices. Appl. Sci. 2019, 9, 1118. [Google Scholar] [CrossRef]

- Jawad, G.N.; Akbar, M.F. IFFT-Based Microwave Non-Destructive Testing for Delamination Detection and Thickness Estimation. IEEE Access 2021, 9, 98561–98572. [Google Scholar] [CrossRef]

- Alkandari, A.; Aljaber, S.J. Principle Component Analysis Algorithm (PCA) for Image Recognition. In Proceedings of the 2015 2nd International Conference on Computing Technology and Information Management, ICCTIM, Johor, Malaysia, 21–23 April 2015; pp. 76–80. [Google Scholar] [CrossRef]

- Yin, Y.; Liu, F.; Zhou, X.; Li, Q. An Efficient Data Compression Model Based on Spatial Clustering and Principal Component Analysis in Wireless Sensor Networks. Sensors 2015, 15, 19443–19465. [Google Scholar] [CrossRef]

- Ba, A.; Bui, H.-K.; Berthiau, G.; Yi, Q.; Zhu, J.; Tian, G.Y. Eddy-Current Pulsed Thermography for the Detection of Impact Damage on CFRP. In Proceedings of the 11th International Symposium on NDT in Aerospace, Paris-Saclay, France, 13–15 November 2019. [Google Scholar]

- Adiwijaya, K.; Wisesty, U.N.; Aditsania, A.; Kusumo, D. Dimensionality Reduction Using Principal Component Analysis for Cancer Detection Based on Microarray Data Classification Analysis of Watermaking Using SVD Based on DWT and DCT View Project. Artic. J. Comput. Sci. 2018, 14, 1521–1530. [Google Scholar] [CrossRef]

- Sun, Y.; Tao, X.; Li, Y.; Lu, J. Robust 2D Principal Component Analysis: A Structured Sparsity Regularized Approach. IEEE Trans. Image Process. 2015, 24, 2515–2526. [Google Scholar] [CrossRef]

- Xu, C.; Zhou, N.; Xie, J.; Gong, X.; Chen, G.; Song, G. Investigation on Eddy Current Pulsed Thermography to Detect Hidden Cracks on Corroded Metal Surface. NDT E Int. 2016, 84, 27–35. [Google Scholar] [CrossRef]

- Reddy, G.T.; Reddy, M.P.K.; Lakshmanna, K.; Kaluri, R.; Rajput, D.S.; Srivastava, G.; Baker, T. Analysis of Dimensionality Reduction Techniques on Big Data. IEEE Access 2020, 8, 54776–54788. [Google Scholar] [CrossRef]

- Allegretta, I.; Marangoni, B.; Manzari, P.; Porfido, C.; Terzano, R.; de Pascale, O.; Senesi, G.S. Macro-Classification of Meteorites by Portable Energy Dispersive X-Ray Fluorescence Spectroscopy (PED-XRF), Principal Component Analysis (PCA) and Machine Learning Algorithms. Talanta 2020, 212, 120785. [Google Scholar] [CrossRef] [PubMed]

- MacHidon, A.L.; MacHidon, O.M.; Ogrutan, P.L. Face Recognition Using Eigenfaces, Geometrical PCA Approximation and Neural Networks. In Proceedings of the 2019 42nd International Conference on Telecommunications and Signal Processing, TSP 2019, Budapest, Hungary, 1–3 July 2019; pp. 80–83. [Google Scholar] [CrossRef]

- Onan, A. A K-Medoids Based Clustering Scheme with an Application to Document Clustering. In Proceedings of the 2nd International Conference on Computer Science and Engineering, UBMK, Antalya, Turkey, 5–8 October 2017; pp. 354–359. [Google Scholar] [CrossRef]

- Yu, D.; Liu, G.; Guo, M.; Liu, X. An Improved K-Medoids Algorithm Based on Step Increasing and Optimizing Medoids. Expert Syst. Appl. 2018, 92, 464–473. [Google Scholar] [CrossRef]

- Martino, A.; Rizzi, A.; Massimo, F.; Mascioli, F. Efficient Approaches for Solving the Large-Scale k-Medoids Problem. In Proceedings of the 9th International Joint Conference on Computational Intelligence, International Joint Conference on Computational Intelligence, Funchal-Madeira, Portugal, 1–3 November 2017; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, L.; Wu, R.; Simm, A. Sweep Frequency Microwave NDT for Subsurface Defect Detection in GFRP. nsight Non-Destr. Test. Cond. Monit. 2018, 65, 123–129. [Google Scholar] [CrossRef]

| Ref. No. | Technique | Concept of Use | Advantages | Disadvantages |

|---|---|---|---|---|

| [17] | Microwave GSG probe | Delamination evaluation in metal with TBCs coating | Able to detect delamination and sizes. | Unable to detect delamination next to the sloping edges. |

| [18] | Ridge waveguide | Delamination evaluation in ceramic-coated metal | Able to detect delamination depth and size. Lower error rate. | Low-resolution imaging. |

| [19] | Electromagnetic sensor with metamaterials | Delamination evaluation in stainless steel with ceramic zirconia coating | Able to detect and characterize defects. Higher spatial resolution of defects. | Unable to detect small delamination. Lower accuracy rate. |

| [5] | OERW | Delamination evaluation in ceramic-coated metal | Able to detect very small delamination. | Low spatial image quality. Larger defect size prediction than the actual defect. |

| Techniques | Concept of Use | Advantages | Disadvantages | |

|---|---|---|---|---|

| [23] | TDR-IDFT | Delamination evaluation in ceramic-coated metal | Able to characterize defect and defect-free areas. | Delay in signal propagation. |

| [24] | Correlation analysis | Delamination evaluation in ceramic-coated metal | Able to distinguish types of defects. Lag in time does not affect the results of defect inspection. | Inconsistent correlation values caused by sample’s edge. Requires non-defective sample as a point of comparison. |

| [25] | PCA | Delamination evaluation in ceramic-coated metal | Does not require pre-existing data. | Unable to predict minor defects. Blur margin around defects. |

| [26] | NMF | Defect evaluation in adhered ceramic claddings | Able to distinguish defect and defect-free areas. | Accuracy affected by spectral resolution. |

| [28] | SVM | Porosity detection in ceramics | Able to categorize degree of porosity of ceramics. | Categorization inaccuracy affected by data noise. Training samples are limited. |

| [30] | PCA-ANN | Crack categorization in ceramic tiles | Able to detect cracks. | Training samples are limited. Unable to anticipate the depth of the defect. |

| [15] | k-means | Delamination detection in GFRP | Does not require training samples. Able to sharply separate the edges of defect and defect-free areas. Able to identify delamination size. | Identified defect size is larger than actual defect size. |

| Macor Sample | Defect 1 (D1) | Defect 2 (D2) | Defect 3 (D3) | Defect 4 (D4) | Defect 5 (D5) |

|---|---|---|---|---|---|

| Delamination size | 20 × 25 mm | 20 × 25 mm | 15 × 15 mm | 10 × 10 mm | 5 × 5 mm |

| Delamination depth | 2 mm | 1 mm | 1.5 mm | 1.5 mm | 1.5 mm |

| Defects | Actual Defect Size (mm × mm) | Predicted Defect Size (mm2) | Actual Defect Area (mm × mm) | Predicted Defect Area (mm2) | Error Rate (%) | Accuracy (%) |

|---|---|---|---|---|---|---|

| D1 | 20 × 25 | 20 × 26 | 500 | 486 | 2.8 | 95.3878 |

| D2 | 20 × 25 | 22 × 25 | 500 | 528 | 5.6 | |

| D3 | 15 × 15 | 19 × 17 | 225 | 301 | 33.78 | |

| D4 | 10 × 10 | 13 × 12 | 100 | 136 | 36 | |

| D5 | 5 × 5 | 9 × 6 | 25 | 41 | 64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, S.Y.; Akbar, M.F.; Shrifan, N.H.M.M.; Nihad Jawad, G.; Ab Wahab, M.N. Assessment of Defects under Insulation Using K-Medoids Clustering Algorithm-Based Microwave Nondestructive Testing. Coatings 2022, 12, 1440. https://doi.org/10.3390/coatings12101440

Tan SY, Akbar MF, Shrifan NHMM, Nihad Jawad G, Ab Wahab MN. Assessment of Defects under Insulation Using K-Medoids Clustering Algorithm-Based Microwave Nondestructive Testing. Coatings. 2022; 12(10):1440. https://doi.org/10.3390/coatings12101440

Chicago/Turabian StyleTan, Shin Yee, Muhammad Firdaus Akbar, Nawaf H. M. M. Shrifan, Ghassan Nihad Jawad, and Mohd Nadhir Ab Wahab. 2022. "Assessment of Defects under Insulation Using K-Medoids Clustering Algorithm-Based Microwave Nondestructive Testing" Coatings 12, no. 10: 1440. https://doi.org/10.3390/coatings12101440

APA StyleTan, S. Y., Akbar, M. F., Shrifan, N. H. M. M., Nihad Jawad, G., & Ab Wahab, M. N. (2022). Assessment of Defects under Insulation Using K-Medoids Clustering Algorithm-Based Microwave Nondestructive Testing. Coatings, 12(10), 1440. https://doi.org/10.3390/coatings12101440