Study on Modified Liquid Polysulfide Rubber Bimetallic Salt-Spray-Resistant Epoxy Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Method

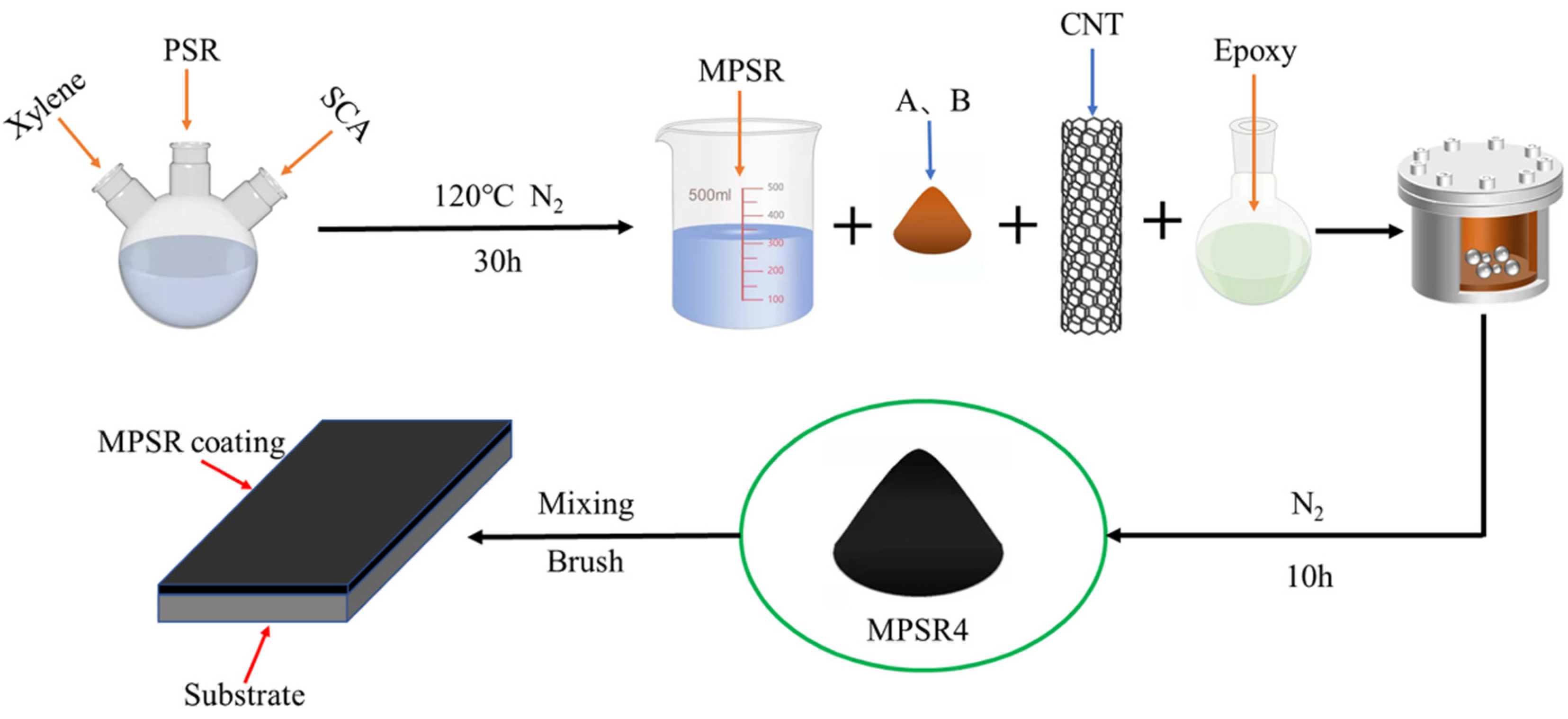

2.2.1. Preparation of Modified Liquid Polysulfide Rubber

2.2.2. Preparation of the Coatings

2.3. Characterization

2.3.1. Characterization of Modified Liquid Polysulfide Rubber

2.3.2. Characterization of the Coatings Layer

3. Results and Discussion

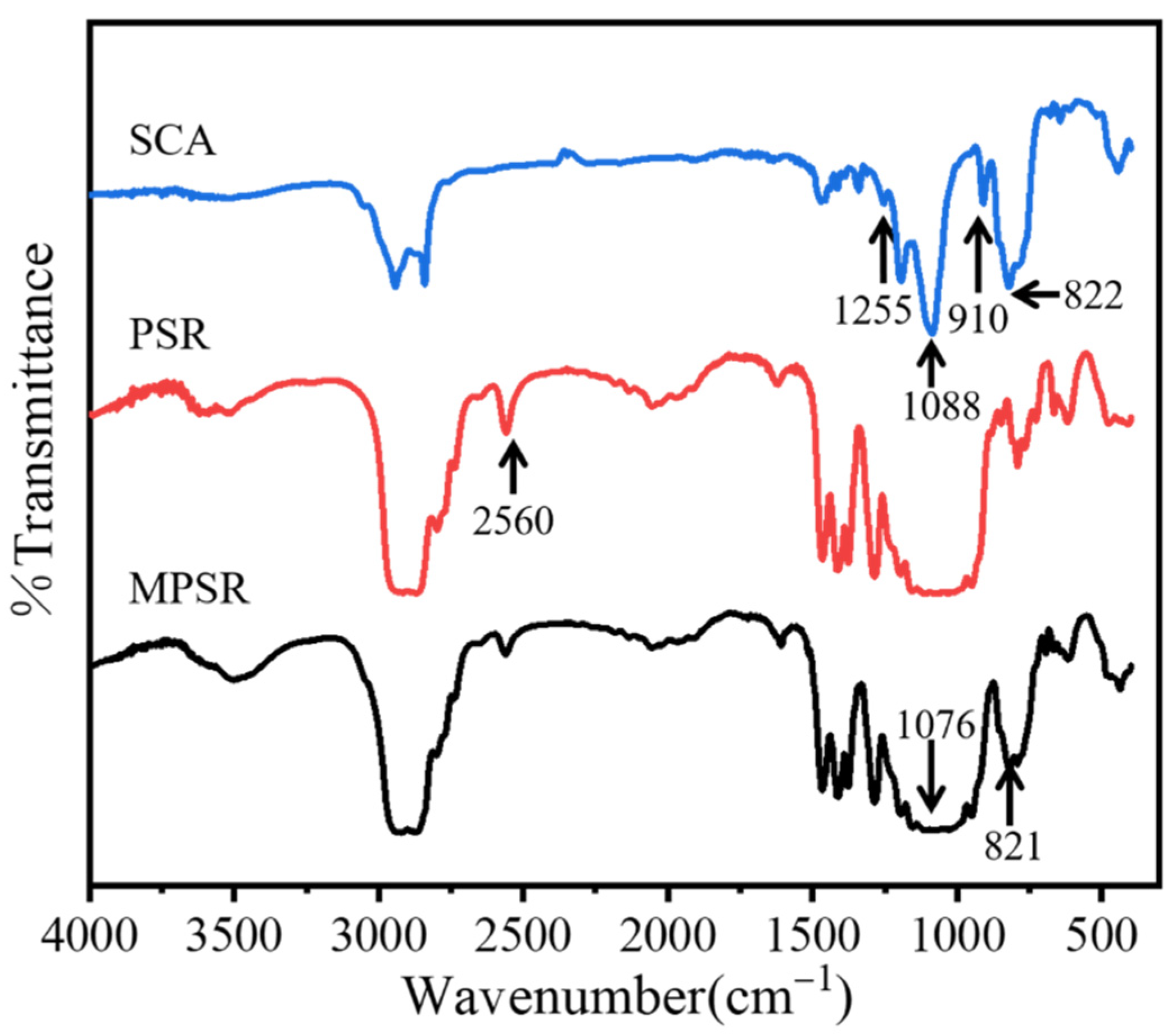

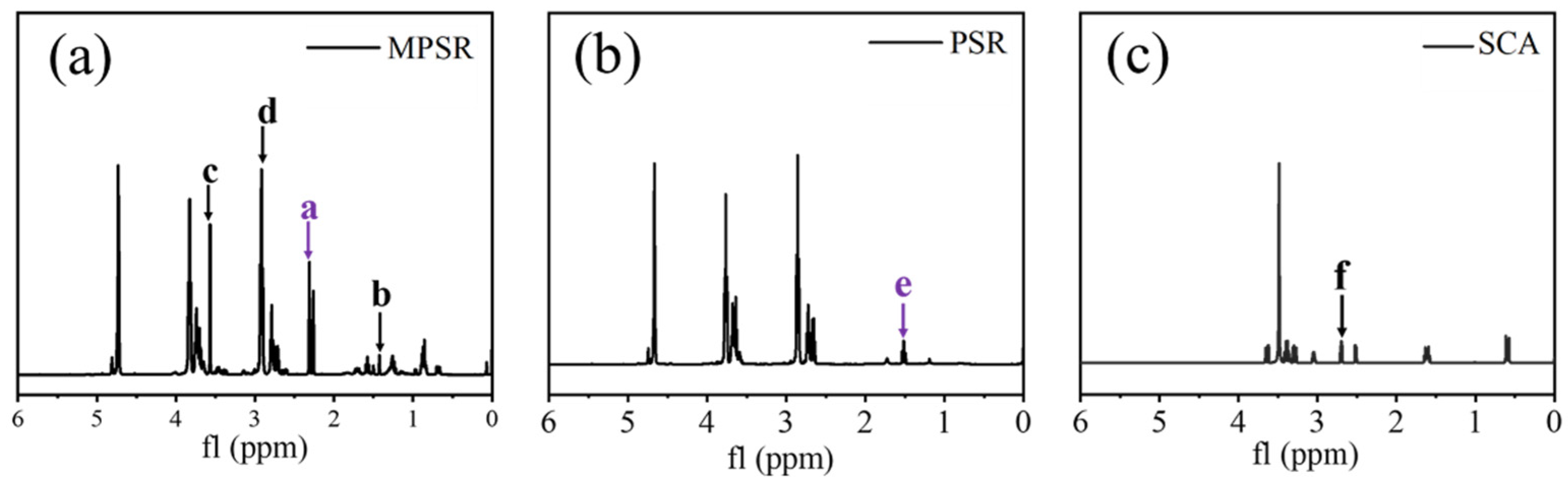

3.1. Characterization of Modified Liquid Polysulfide Rubber

3.2. Characterization of Coatings

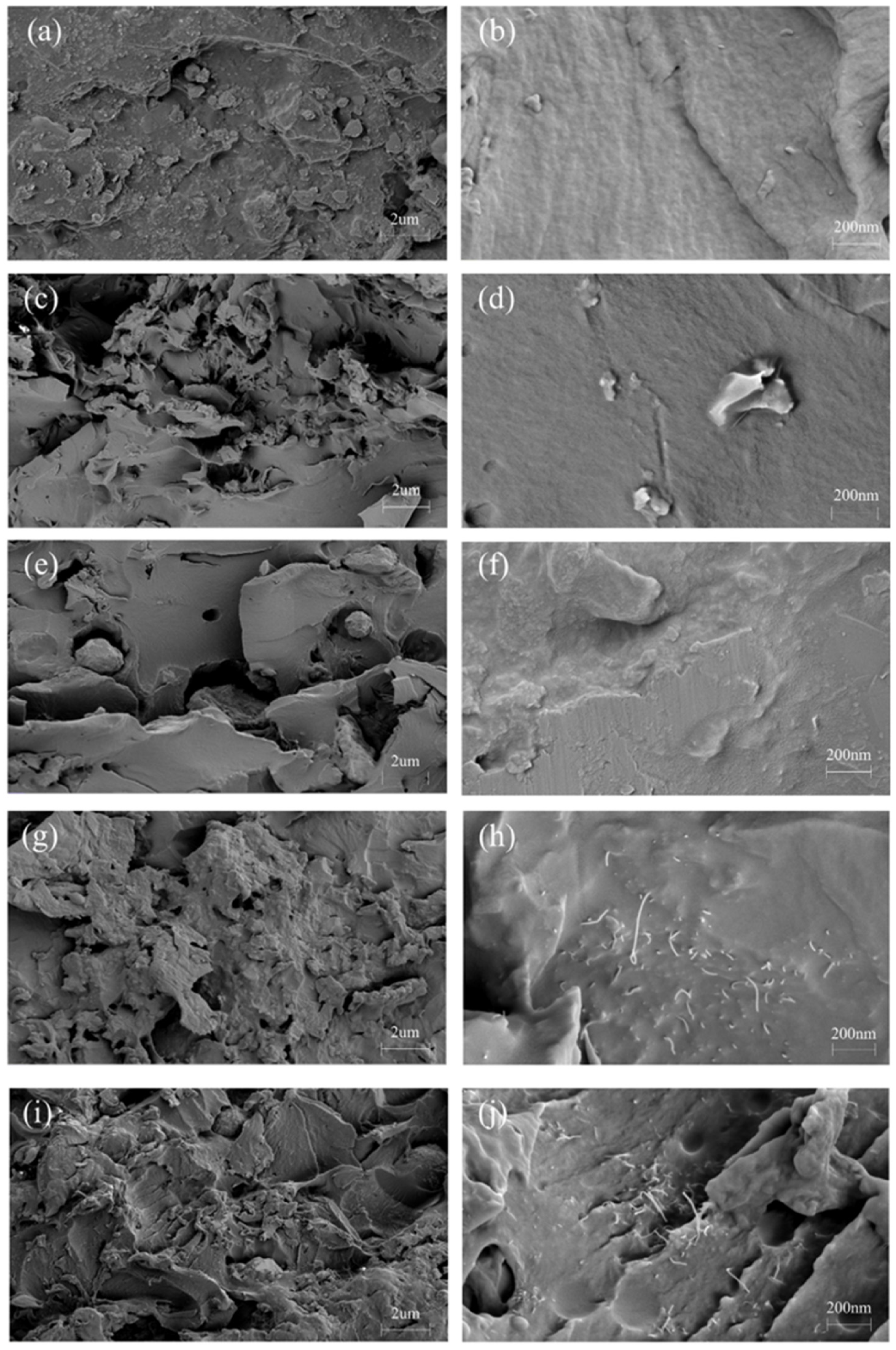

3.2.1. Section Morphology of the Coatings

3.2.2. The Weight Gain Rate of the Coatings

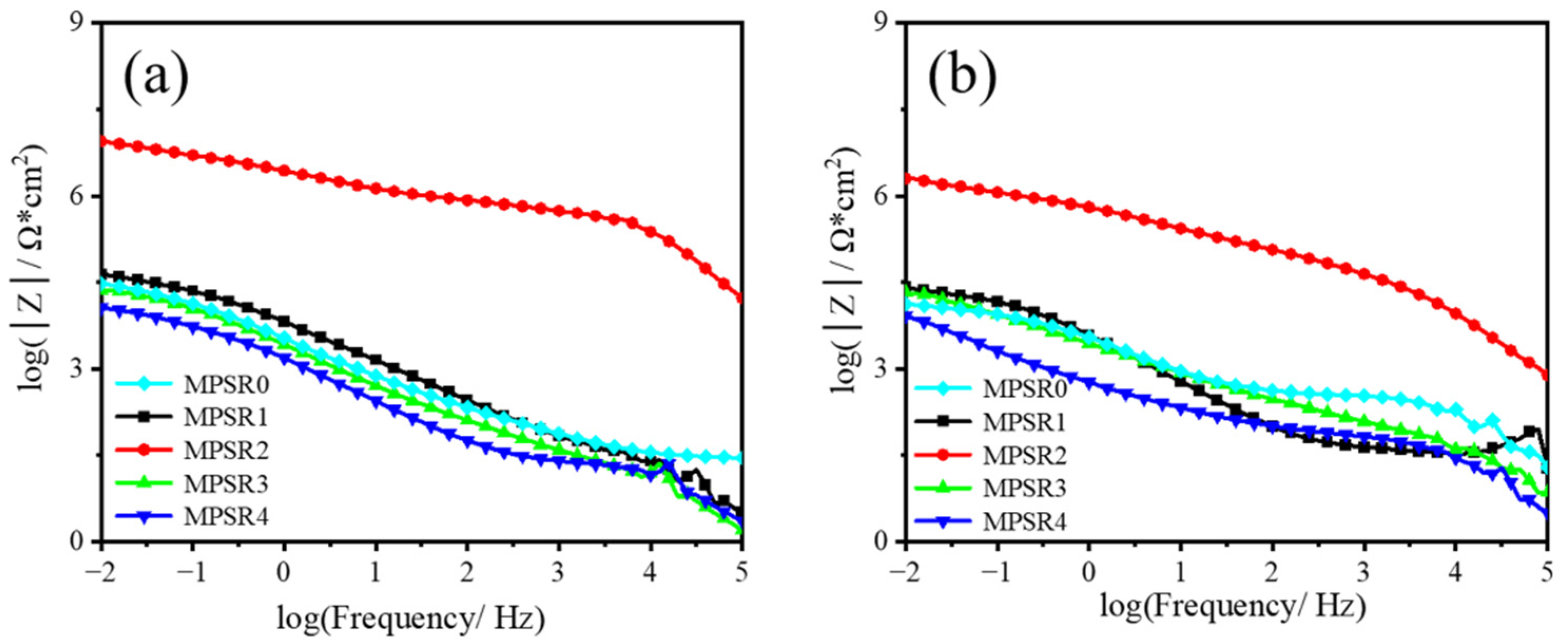

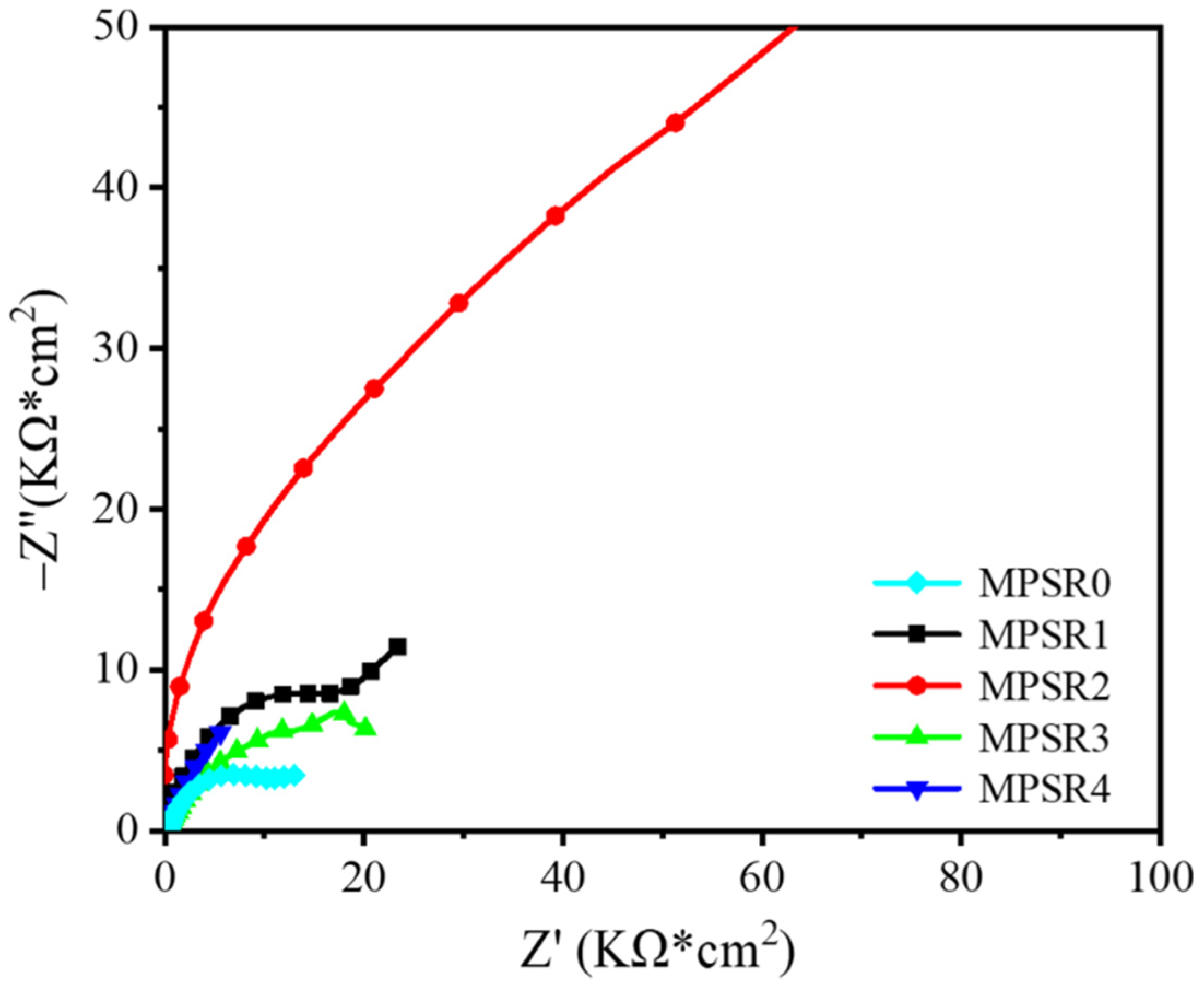

3.2.3. Characterization of Electrochemistry

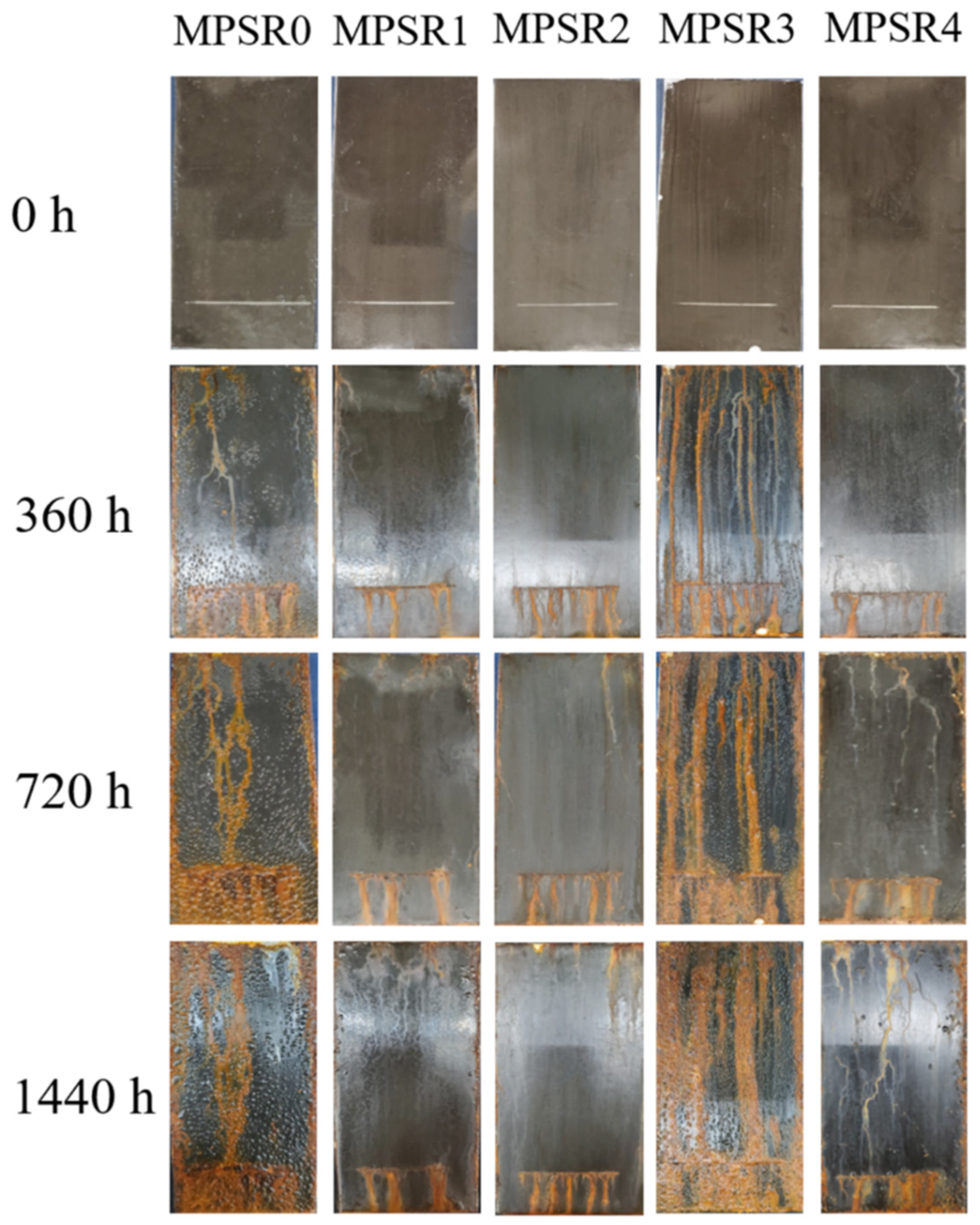

3.2.4. Characterization of Coating Salt Spray Test

3.2.5. Adhesion of Coatings

3.3. Coating Immersion Test

4. Conclusions

- (1)

- The polysulfide liquid rubber is successfully modified by the silane coupling agent. Compared with the epoxy resin coating, the modified polysulfide liquid rubber-epoxy monometallic coating showed better corrosion resistance, and the salt spray foam resistance of the coatings was greatly improved. Blistering time with coatings increased from 72 h to 720 h, and the adhesion of the coatings was greatly improved from 6.543 MPa to 9.729 MPa, with an increase of 48.7%. The corrosion spread of the coating salt spray system has been greatly reduced, from 7.0 mm to 1.7 mm.

- (2)

- Bimetal combination with different potential parameters (Ti and Zn) could improve the corrosion resistance and blistering resistance of the coatings, and the bimetal epoxy coating could achieve corrosion resistance of 1440 h. As a result, the impedance could be two orders of magnitude higher than that of a single-metal epoxy coating.

- (3)

- Compared with the single metal epoxy coating, the modified polysulfide liquid rubber bimetal anti-salt spray epoxy coating showed higher impedance, low surface exudation, long-term resistance to saltwater immersion, and no change in the surface of the coating, the added zinc content was only 28.6%. The coating had a high initial weight gain rate, and a dense long-term protective coating was obtained. It is a long-term anti-corrosion coating that can be used for a long time in both saline atmosphere and underwater environments. It is expected to be widely used in marine engineering.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hou, B.-R.; Zhang, J.; Duan, J.; Li, Y. Corrosion of thermally sprayed zinc and aluminium coatings in simulated splash and tidal zone conditions. Corros. Eng. Sci. Technol. 2003, 38, 157–160. [Google Scholar] [CrossRef]

- Schumacher, M. Sea Water Corrosion Handbook; Noyes Data: Park Ridge, NJ, USA, 1979. [Google Scholar]

- Yang, S.; Lee, K.W.; Lu, C.; Mirville, M.; Parham, A. Adhesion Evaluation of Duplex Paint System for Sustainable Infrastructure. J. Mater. Civ. Eng. 2017, 29, 04017134. [Google Scholar] [CrossRef]

- Zhang, S.H.; Li, M.X.; Yoon, J.H.; Cho, T.Y.; He, Y.Z.; Lee, C.G. Microstructure and corrosion resistance of Ni-based alloy laser coatings with nanosize CeO2 addition. Sci. Technol. Adv. Mater. 2008, 9, 035002. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-S.; Jeong, Y.-S.; Dao, D.K.; Kim, I.-T. An approach for evaluating tensile strength of painted steel plates from the surface rusting grade. Corros. Eng. Sci. Technol. 2018, 53, 510–516. [Google Scholar] [CrossRef]

- Jalili, M.; Rostami, M.; Ramezanzadeh, B. An investigation of the electrochemical action of the epoxy zinc-rich coatings containing surface modified aluminum nanoparticle. Appl. Surf. Sci. 2015, 328, 95–108. [Google Scholar] [CrossRef]

- Lu, X.; Zuo, Y.; Zhao, X.; Tang, Y. The influence of aluminum tri-polyphosphate on the protective behavior of Mg-rich epoxy coating on AZ91D magnesium alloy. Electrochim. Acta 2013, 93, 53–64. [Google Scholar] [CrossRef]

- Reedy, M.W.; Eden, T.J.; Potter, J.K.; Wolfe, D.E. Erosion performance and characterization of nanolayer (Ti, Cr) N hard coatings for gas turbine engine compressor blade applications. Surf. Coat. Technol. 2011, 206, 464–472. [Google Scholar] [CrossRef]

- Luo, X.; Zhong, J.; Zhou, Q.; Du, S.; Yuan, S.; Liu, Y. Cationic Reduced Graphene Oxide as Self-Aligned Nanofiller in the Epoxy Nanocomposite Coating with Excellent Anticorrosive Performance and Its High Antibacterial Activity. ACS Appl. Mater. Interfaces 2018, 10, 18400–18415. [Google Scholar] [CrossRef] [PubMed]

- Wen, J.-G.; Geng, W.; Geng, H.-Z.; Zhao, H.; Jing, L.-C.; Yuan, X.-T.; Tian, Y.; Wang, T.; Ning, Y.-J.; Wu, L. Improvement of Corrosion Resistance of Waterborne Polyurethane Coatings by Covalent and Noncovalent Grafted Graphene Oxide Nanosheets. ACS Omega 2019, 4, 20265–20274. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Wu, Y.; Zhao, W.; Yu, J.; Jiang, F.; Wu, Y.; Ma, L. Designing reduced graphene oxide/zinc rich epoxy composite coatings for improving the anticorrosion performance of carbon steel substrate. Mater. Des. 2019, 169, 107694. [Google Scholar] [CrossRef]

- Teng, S.; Gao, Y.; Cao, F.; Kong, D.; Zheng, X.; Ma, X.; Zhi, L. Zinc-reduced graphene oxide for enhanced corrosion protection of zinc-rich epoxy coatings. Prog. Org. Coat. 2018, 123, 185–189. [Google Scholar] [CrossRef]

- Shirehjini, F.T.; Danaee, I.; Eskandari, H.; Zarei, D. Effect of Nano Clay on Corrosion Protection of Zinc-rich Epoxy Coatings on Steel 37. J. Mater. Sci. Technol. 2016, 32, 1152–1160. [Google Scholar] [CrossRef]

- Luo, X.; Yin, H.; Ren, J.; Yan, H.; Huang, X.; Yang, D.; He, L. Enhanced mixing of binary droplets induced by capillary pressure. J. Colloid Interface Sci. 2019, 545, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Ding, R.; Zheng, Y.; Yu, H.; Li, W.; Wang, X.; Gui, T. Study of water permeation dynamics and anti-corrosion mechanism of graphene/zinc coatings. J. Alloys Compd. 2018, 748, 481–495. [Google Scholar] [CrossRef]

- Hu, H.; He, Y.; Long, Z.; Zhan, Y. Synergistic effect of functional carbon nanotubes and graphene oxide on the anti-corrosion performance of epoxy coating. Polym. Adv. Technol. 2017, 28, 754–762. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, W.; Qiang, Y.; Chen, Z.; Wang, L.; Gao, X.; Fang, Z. π-π interaction between fluorinated reduced graphene oxide and acridizinium ionic liquid: Synthesis and anti-corrosion application. Carbon 2020, 159, 292–302. [Google Scholar] [CrossRef]

- Shen, L.; Li, Y.; Zhao, W.; Miao, L.; Xie, W.; Lu, H.; Wang, K. Corrosion Protection of Graphene-Modified Zinc-Rich Epoxy Coatings in Dilute NaCl Solution. ACS Appl. Nano Mater. 2018, 2, 180–190. [Google Scholar] [CrossRef]

- Modesti, L.A.; de Vargas, A.S.; Schneider, E.L. Repairing concrete with epoxy adhesives. Int. J. Adhes. Adhes. 2020, 101, 102645. [Google Scholar] [CrossRef]

- Yeon, J. Deformability of Bisphenol A-Type Epoxy Resin-Based Polymer Concrete with Different Hardeners and Fillers. Appl. Sci. 2020, 10, 1336. [Google Scholar] [CrossRef]

- Giv, A.N.; Ayatollahi, M.R.; Ghaffari, S.H.; da Silva, L. Effect of reinforcements at different scales on mechanical properties of epoxy adhesives and adhesive joints: A review. J. Adhes. 2018, 94, 1082–1121. [Google Scholar] [CrossRef]

- Sun, M.; Ma, Z.; Li, A.; Zhu, G.; Zhang, Y. Anticorrosive performance of polyaniline/waterborne epoxy/poly (methylhydrosiloxane) composite coatings. Prog. Org. Coat. 2019, 139, 105462. [Google Scholar] [CrossRef]

- Zubielewicz, M.; Langer, E.; Królikowska, A.; Komorowski, L.; Wanner, M.; Krawczyk, K.; Aktas, L.; Hilt, M. Concepts of steel protection by coatings with a reduced content of zinc pigments. Prog. Org. Coat. 2021, 161, 106471. [Google Scholar] [CrossRef]

- Wang, S.; Chia, P.-J.; Chua, L.-L.; Zhao, L.-H.; Png, R.-Q.; Sivaramakrishnan, S.; Zhou, M.; Goh, R.G.-S.; Friend, R.H.; Wee, A.T.-S.; et al. Band-like Transport in Surface-Functionalized Highly Solution-Processable Graphene Nanosheets. Adv. Mater. 2008, 20, 3440–3446. [Google Scholar] [CrossRef]

- Pourhashem, S.; Vaezi, M.R.; Rashidi, A.; Bagherzadeh, M.R. Distinctive roles of silane coupling agents on the corrosion inhibition performance of graphene oxide in epoxy coatings. Prog. Org. Coat. 2017, 111, 47–56. [Google Scholar] [CrossRef]

- Matsui, T.; Nakajima, M.; Nonaka, T.; Dokoshi, N. New liquid polysulfide polymer terminated with silyl group. J. Appl. Polym. Sci. 2004, 93, 2642–2649. [Google Scholar] [CrossRef]

- Kurbangaleeva, A.R.; Kurkin, A.I.; Khakimullin, Y.N. Structure and properties of thiokol sealants modified with organosilanes. Russ. J. Appl. Chem. 2012, 85, 432–436. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y. A novel design for water-based modified epoxy coating with anti-corrosive application properties. Prog. Org. Coat. 2014, 77, 219–224. [Google Scholar] [CrossRef]

- Zhan, Y.; Zhang, J.; Wan, X.; Long, Z.; He, S.; He, Y. Epoxy composites coating with Fe3O4 decorated graphene oxide: Modified bio-inspired surface chemistry, synergistic effect and improved anti-corrosion performance. Appl. Surf. Sci. 2018, 436, 756–767. [Google Scholar] [CrossRef]

- Ovchinnikov, S.; Kalashnikov, M.J.S.; Technology, C. Structure and tribological properties of gradient-layered coatings (Ti, Al, Si, Cr, Mo, S) O, N. Surf. Coat. Technol. 2021, 408, 126807. [Google Scholar] [CrossRef]

- Jiao, X.; Wang, C.; Gong, Z.; Wang, G.; Sun, H.; Yang, H. Effect of Ti on T15M composite coating fabricated by laser cladding technology. Surf. Coat. Technol. 2017, 325, 643–649. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Z.; Zhao, S.; Wang, Y.; Chen, H.; Lin, X. Effect of a small addition of Ti on the Fe-based coating by laser cladding. Surf. Coat. Technol. 2016, 291, 423–429. [Google Scholar] [CrossRef]

- Ramezanzadeh, B.; Mohamadzadeh Moghadam, M.H.; Shohani, N.; Mahdavian, M. Effects of highly crystalline and conductive polyaniline/graphene oxide composites on the corrosion protection performance of a zinc-rich epoxy coating. Chem. Eng. J. 2017, 320, 363–375. [Google Scholar] [CrossRef]

- Fatemi, D.J.; Harris, V.G.; Browning, V.M.; Kirkland, J.P. Processing and cation redistribution of MnZn ferrites via high-energy ball milling. J. Appl. Phys. 1998, 83, 6867–6869. [Google Scholar] [CrossRef]

- Arcos, D.; Valenzuela, R.; Vázquez, M.; Vallet-Regí, M. Chemical Homogeneity of Nanocrystalline Zn–Mn Spinel Ferrites Obtained by High-Energy Ball Milling. J. Solid State Chem. 1998, 141, 10–16. [Google Scholar] [CrossRef]

- Arcos, D.; Valenzuela, R.; Vázquez, M.; Vallet-Regí, M. Frequency behaviour of Zn–Mn ferrites nanoparticles obtained by high-energy ball milling. J. Magn. Magn. Mater. 1999, 203, 319–321. [Google Scholar] [CrossRef]

- Yang, F.; Ma, W.; Wang, F. Preparation and Characterization of KH-560 Modified Liquid Polysulfide Rubber. High Perform. Polym. 2013, 29, 156–159. [Google Scholar]

- Fang, Z.; Wang, G.; Xiong, Y.; Li, J.; Yang, Y.; Huang, L.; Wang, P.; Liao, J.; Wang, A. Anti-Corrosion Performance of Polyaniline Coated Basalt Rockwool Wastes/Epoxy Resin Coatings. Coatings 2021, 11, 463. [Google Scholar] [CrossRef]

| Sample | icoor10−6 (A/cm2) | Ecoor (mV) |

|---|---|---|

| MPSR0 | 0.08059 | −168.9 |

| MPSR1 | 0.1006 | −295.7 |

| MPSR2 | 0.1669 | −27.40 |

| MPSR3 | 0.2788 | −147.7 |

| MPSR4 | 0.5177 | −125.3 |

| Sample | MPSR0 | MPSR1 | MPSR2 | MPSR3 | MPSR4 |

|---|---|---|---|---|---|

| Width | 7.0 mm | 2.0 mm | 1.7 mm | 5.0 mm | 2.5 mm |

| Sample | EP(g) | MPSR(g) | Ti(g) | Zn(g) | CNTs(g) |

|---|---|---|---|---|---|

| MPSR0 | 20 | - | 20 | - | - |

| MPSR1 | 20 | 10 | 20 | - | - |

| MPSR2 | 20 | 10 | 20 | 20 | - |

| MPSR3 | 20 | 10 | 20 | - | 0.6 |

| MPSR4 | 20 | 10 | 20 | 20 | 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, Q.; Liu, S.; Jiang, H.; Sun, H.; Xiong, Y.; Fang, Z.; Li, J.; Wang, G. Study on Modified Liquid Polysulfide Rubber Bimetallic Salt-Spray-Resistant Epoxy Coatings. Coatings 2022, 12, 1418. https://doi.org/10.3390/coatings12101418

Mao Q, Liu S, Jiang H, Sun H, Xiong Y, Fang Z, Li J, Wang G. Study on Modified Liquid Polysulfide Rubber Bimetallic Salt-Spray-Resistant Epoxy Coatings. Coatings. 2022; 12(10):1418. https://doi.org/10.3390/coatings12101418

Chicago/Turabian StyleMao, Qitong, Siqi Liu, Hao Jiang, Hua Sun, Yangkai Xiong, Zhiqiang Fang, Jiang Li, and Guoqing Wang. 2022. "Study on Modified Liquid Polysulfide Rubber Bimetallic Salt-Spray-Resistant Epoxy Coatings" Coatings 12, no. 10: 1418. https://doi.org/10.3390/coatings12101418

APA StyleMao, Q., Liu, S., Jiang, H., Sun, H., Xiong, Y., Fang, Z., Li, J., & Wang, G. (2022). Study on Modified Liquid Polysulfide Rubber Bimetallic Salt-Spray-Resistant Epoxy Coatings. Coatings, 12(10), 1418. https://doi.org/10.3390/coatings12101418