Analysis of Rotor–Stator Interaction on the Aerothermal and TBC Insulation Performance of a Turbine Stage under Hot Streak Inlet Condition

Abstract

:1. Introduction

2. Numerical Methods

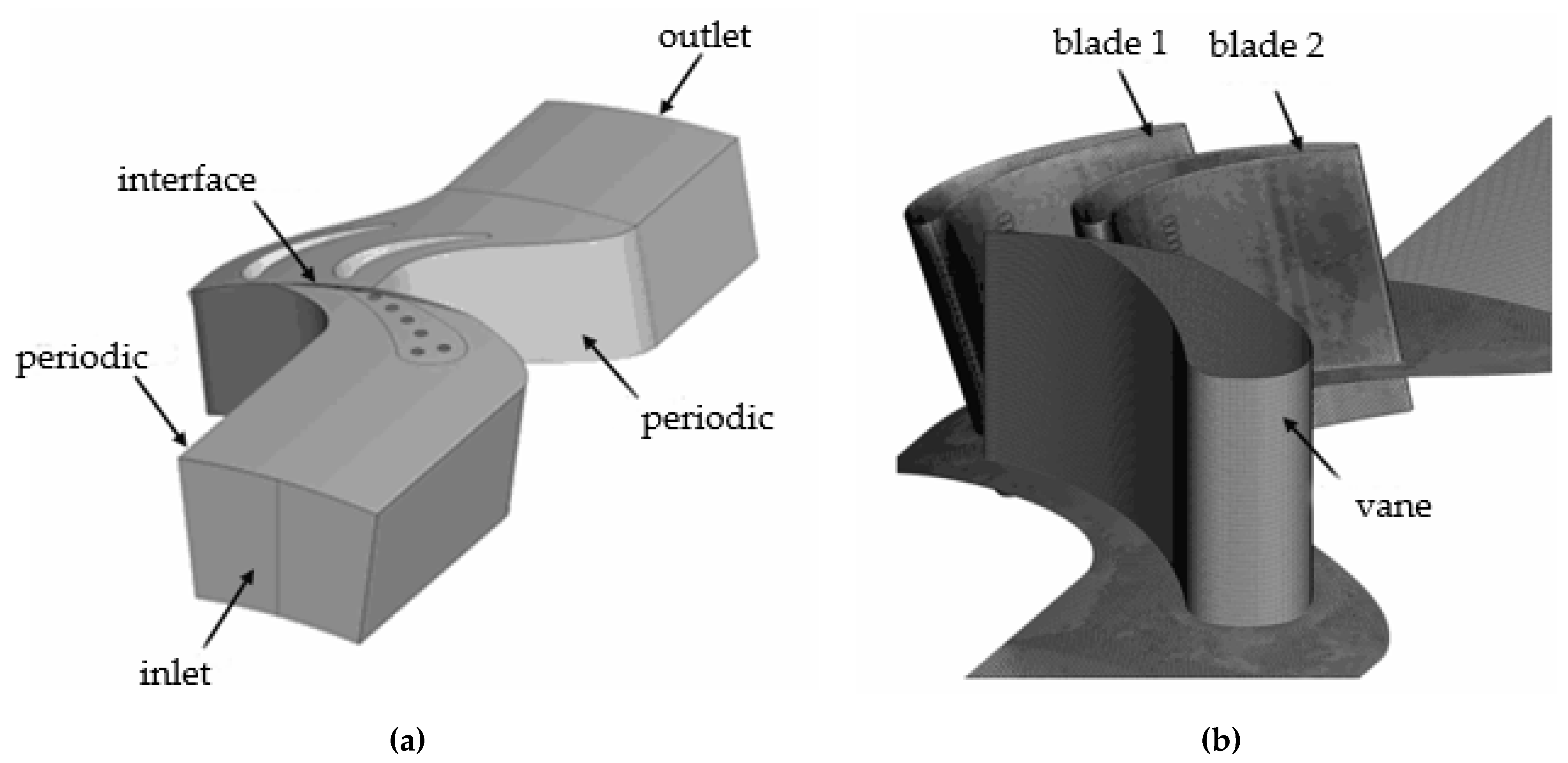

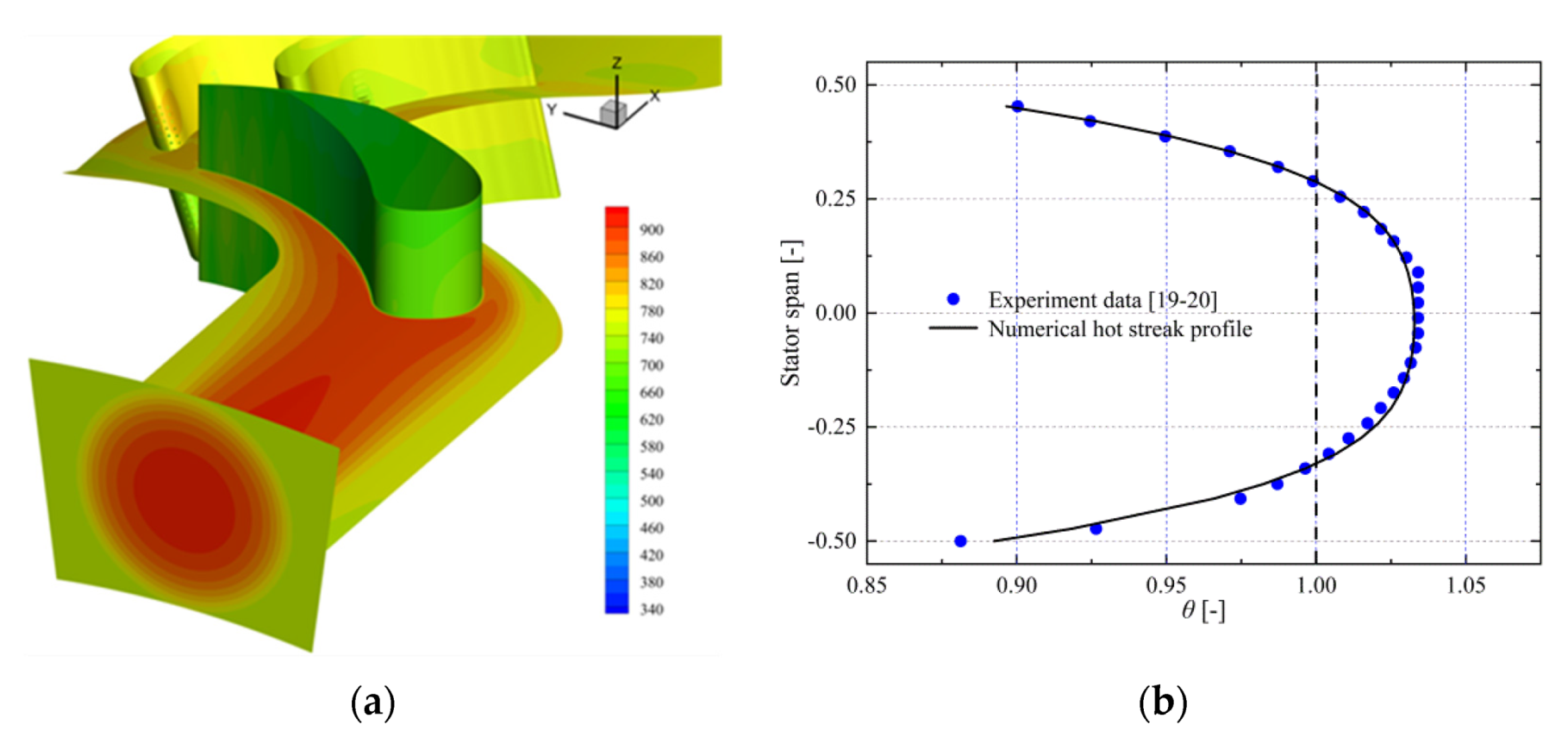

2.1. Mesh Generation and Calculation Techniques

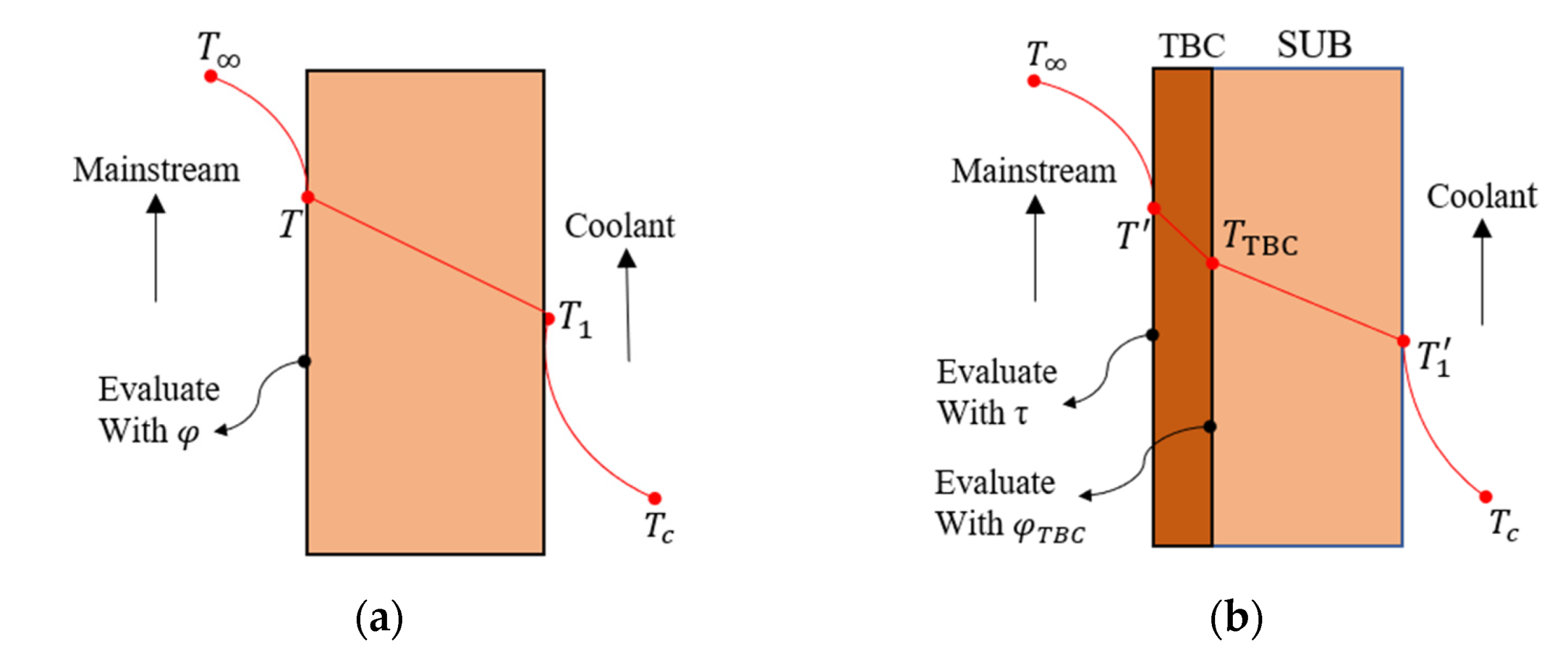

2.2. Thermal Parameter Definition

3. Discussion

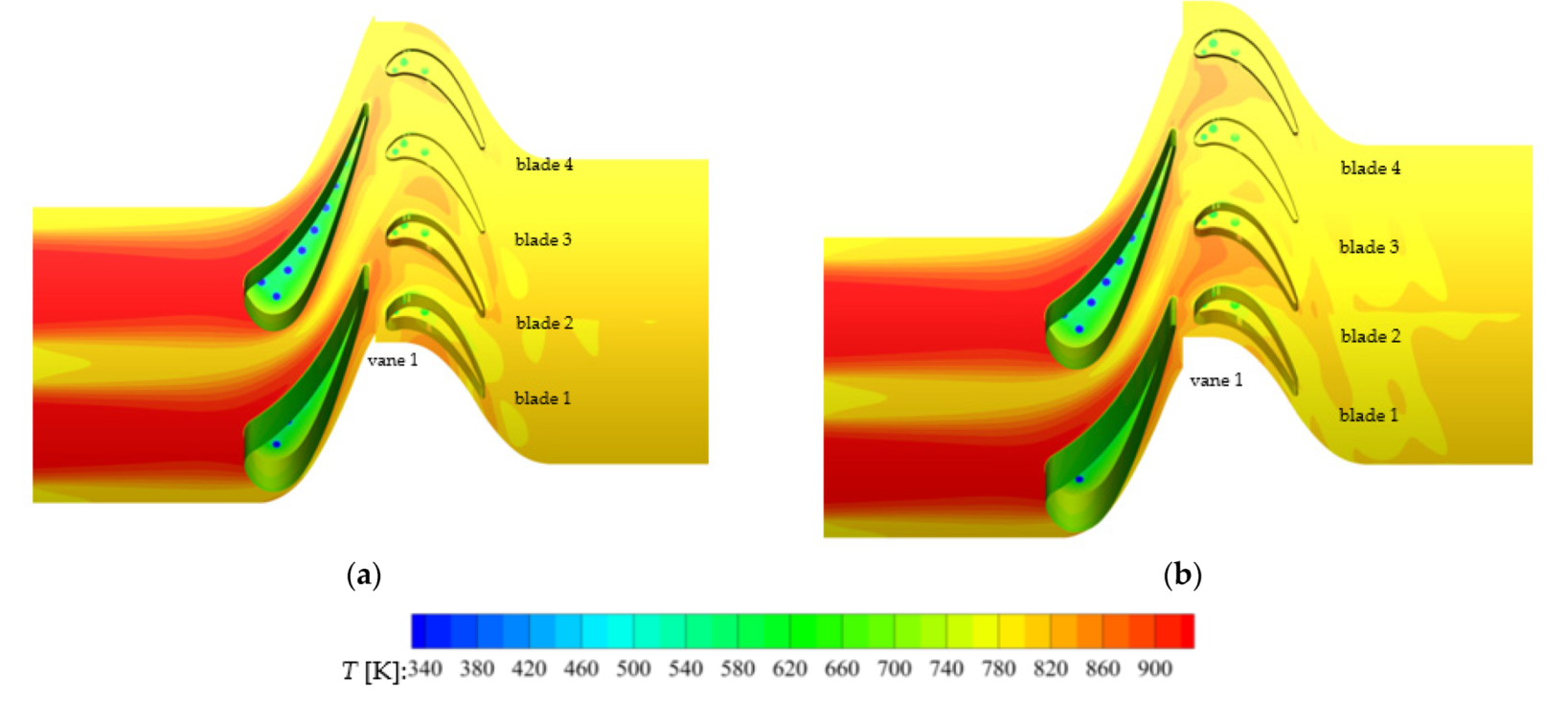

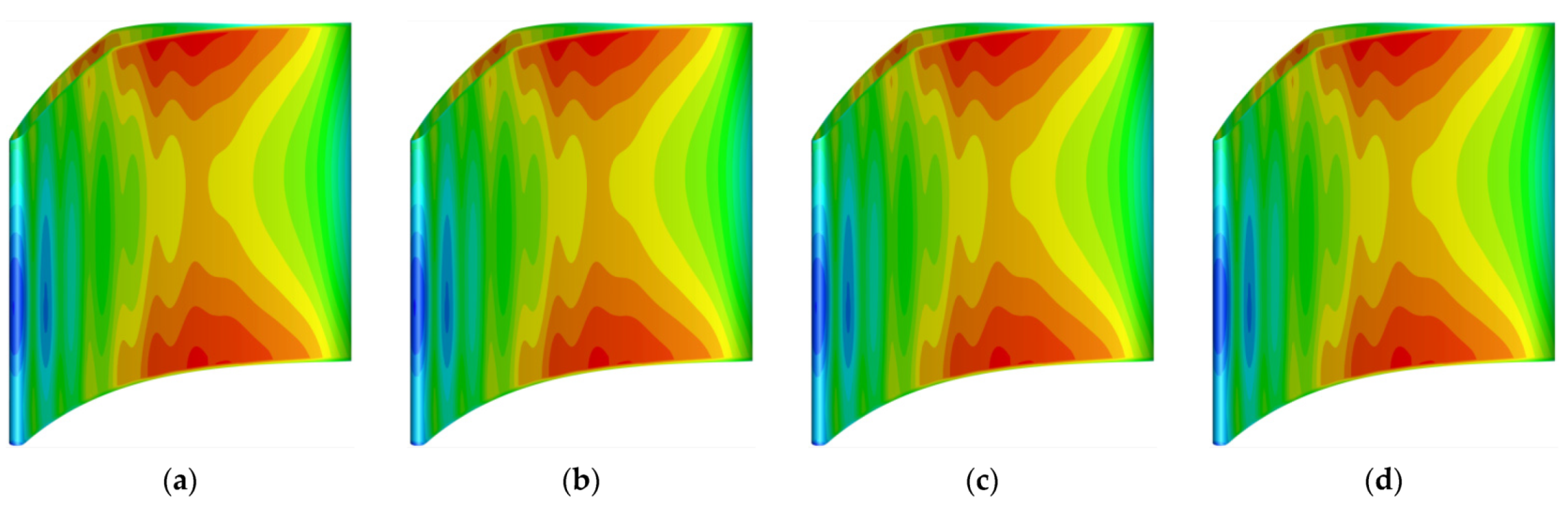

3.1. Influence on the Cooling Performance of the Uncoated Stator Vane

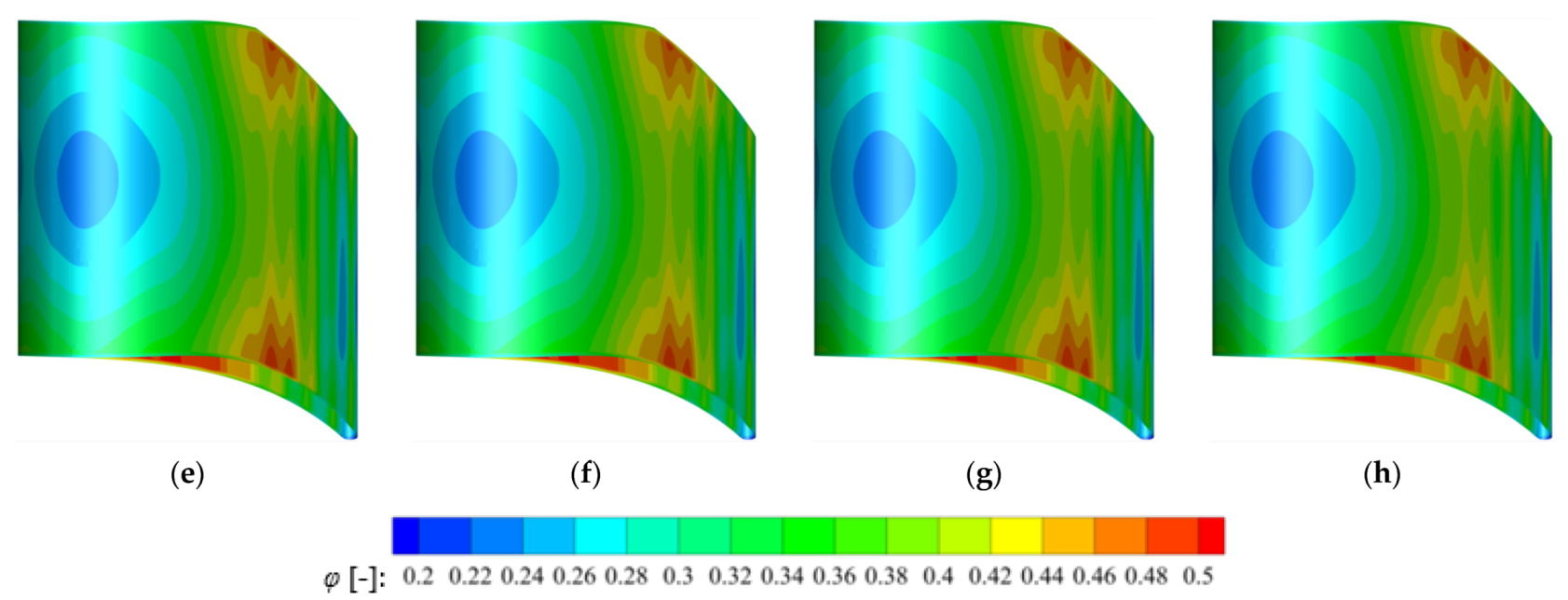

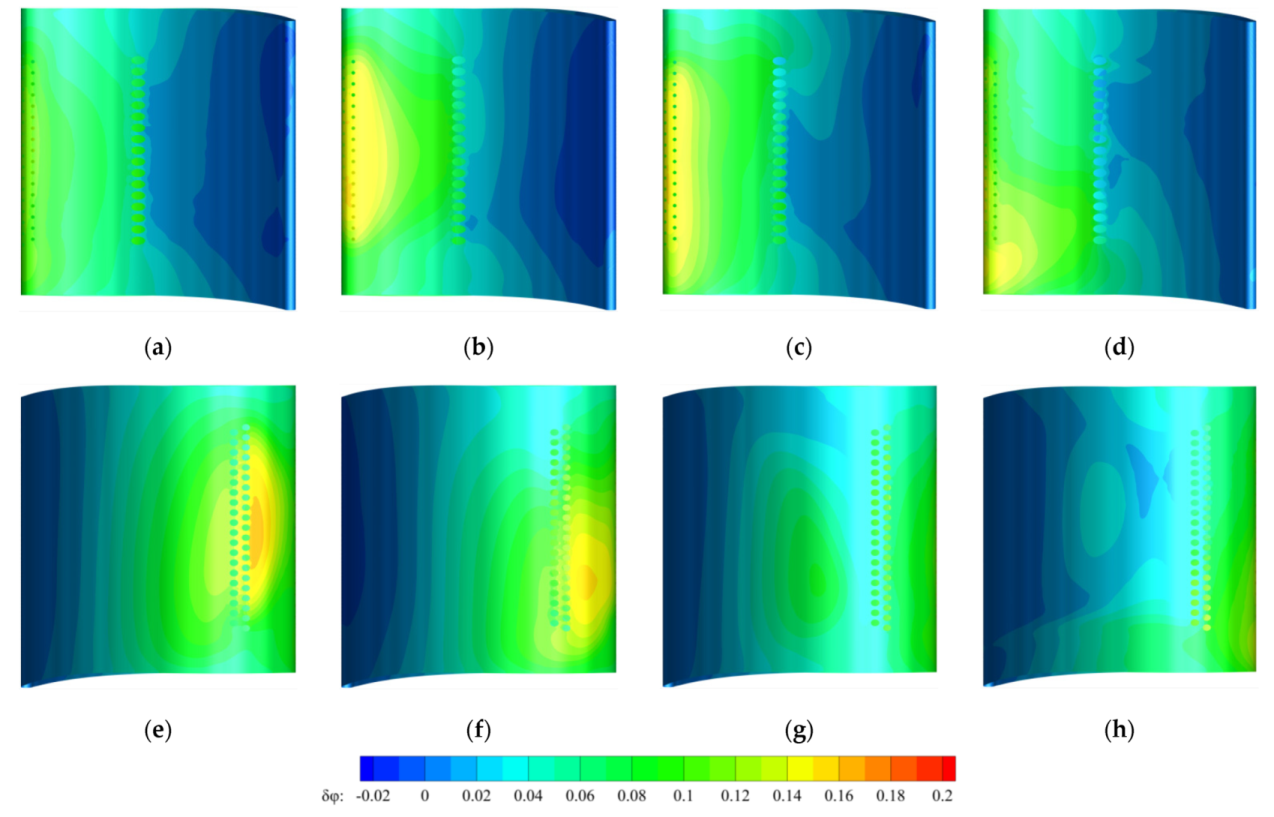

3.2. Influence on the Cooling Performance of the Uncoated Rotor Blade

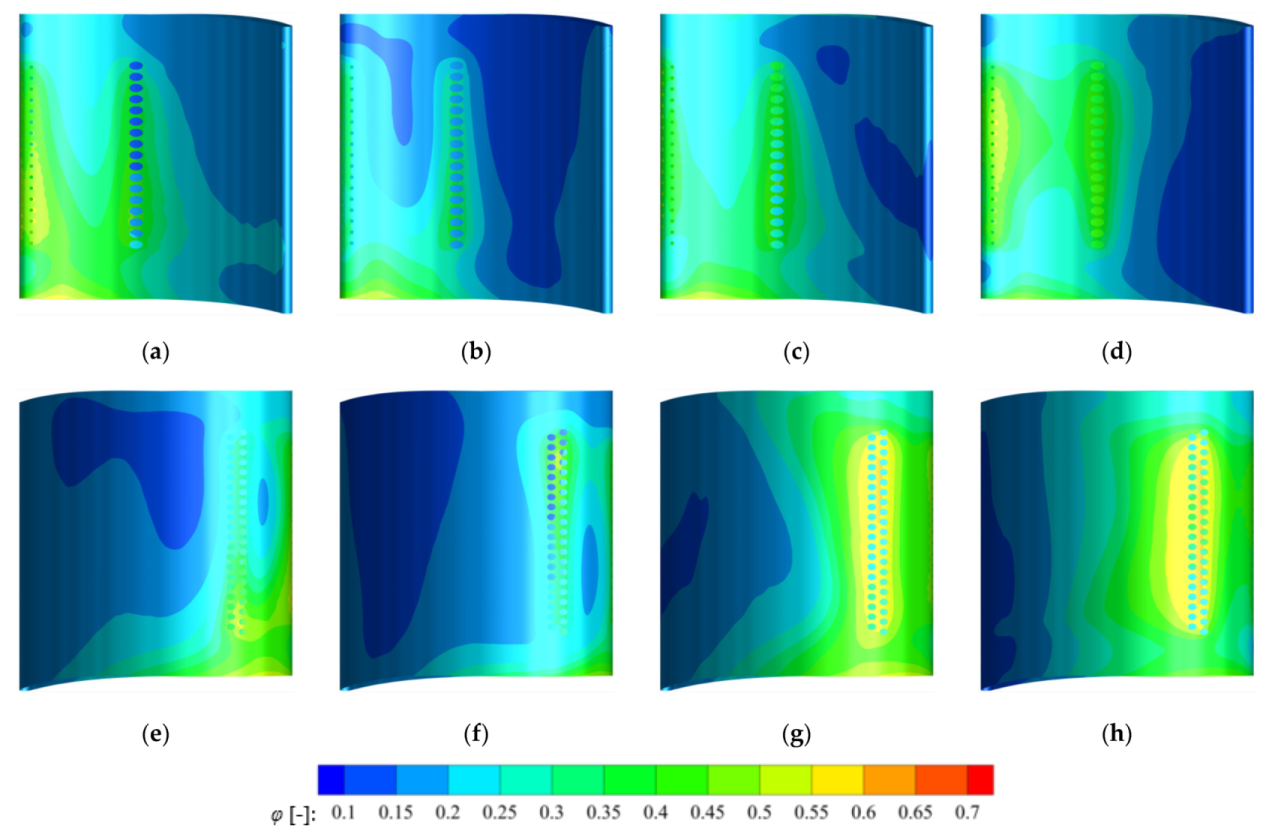

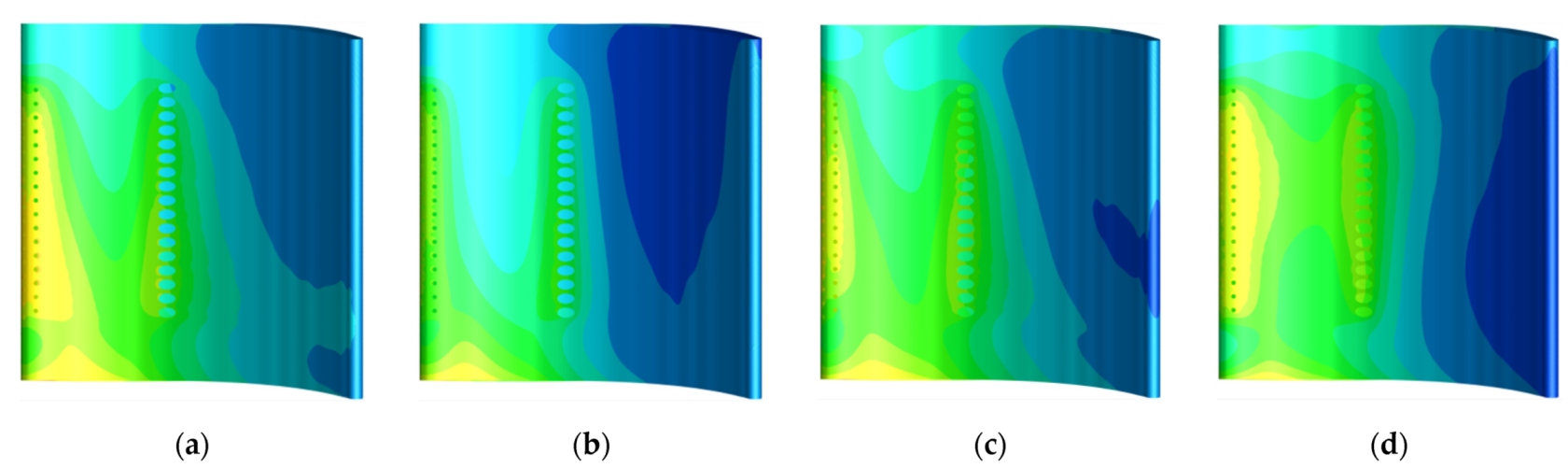

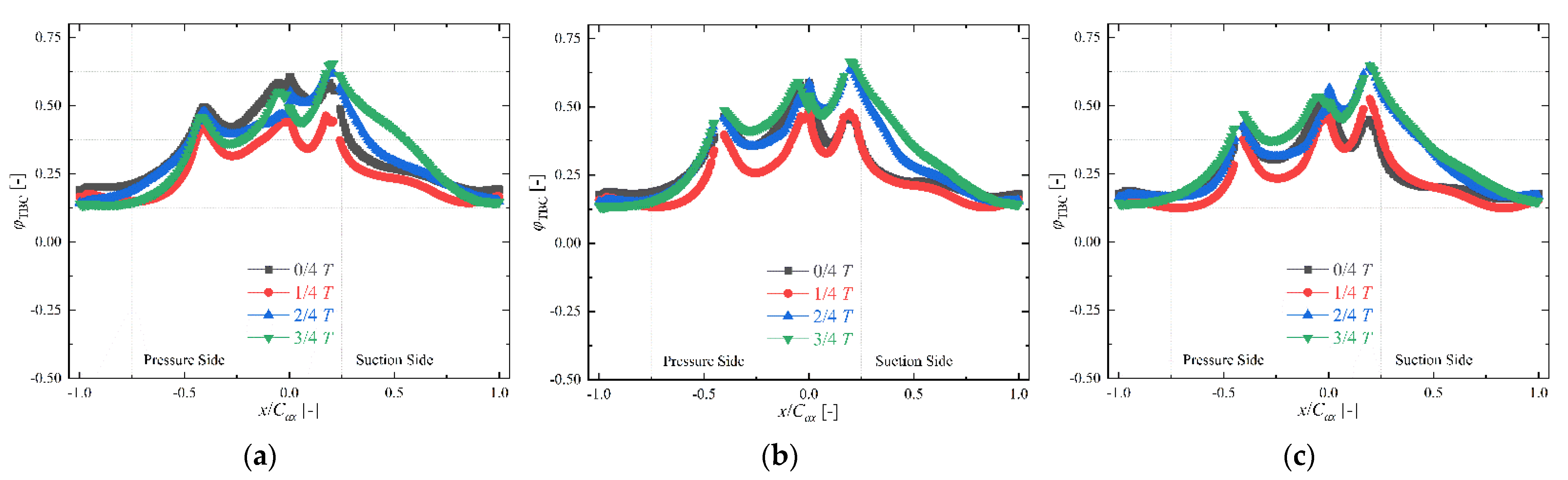

3.3. Influence on the Cooling Performance of the Coated Rotor Blade

4. Conclusions

- (1)

- Under the hot streak inlet conditions, the rotor–stator interaction basically does not affect the overall cooling effectiveness distribution on the stator vane surface. In comparison, it exerts a significant impact on the cooling performance of the rotor blades. Within one stator period, relatively lower cooling effectiveness of the blade can be observed in the 2/4 stator period. Then, the overall cooling effectiveness begins to increase, where relatively higher values can be observed in the 3/4 stator period. For the uncoated blade, the over cooling effectiveness values are 0.407, 0.309, 0.398, and 0.424 for different relative stator–rotor locations near the relative chord length of −0.40 Cax on 50% span.

- (2)

- In the initial state (the 0/4 stator period), the unsteady wake transportation exerts a significant impact on the cooling air flow field close to the pressure side of the leading edge. In the 3/4 stator period, it exerts a significant impact on the cooling air close to the suction side of the leading edge, which induces the cooling air to “lift off” and thus decreases the mass flow of the cooling air, which leads to the film cooling over the blade surface. The unsteady wake exerts a relatively weak impact on the film cooling on the suction side due to a relatively higher velocity of the mainstream.

- (3)

- Within one stator period, a relatively lower increment in the overall cooling effectiveness of the coated rotor blade can be observed in the 3/4 stator period. Regions with negative values can be observed at the trailing edge. In the 1/4 stator period, negative values can be observed between −0.8 and −1.0 Cax on the pressure side of the mid-span. On the suction side, negative values are located between 0.9 and 1.0 Cax on the mid-span. Therefore, the internal heat transfer must be enhanced in those regions in the cooling arrangement design process to maximize the insulation performance of TBCs for the coated rotor blade.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| x, y, z | Cartesian coordinates (mm) |

| Cax | Axial chord (mm) |

| x/Cax | Relative chord length |

| p | Pressure (Pa) |

| Inlet temperature (K) | |

| Tc | Temperature of the cooling gas in the cooling channel (K) |

| Tw | Temperature of the coupling surface (K) |

| TTBC | Metal surface temperature with a TBC (K) |

| Tw | Vane local wall temperature (K) |

| T∞ | Inlet temperature of the mainstream (K) |

| T′ | Surface temperature outside the coating (K) |

| T | The stator period |

| Uniform turbulence intensity | |

| φ | Overall cooling effectiveness |

| φTBC | Overall cooling effectiveness of the coated blade |

| Δφ | Overall cooling effectiveness increment due to coating |

| Greek letters | |

| φ | Temperature ratio |

| Abbreviations | |

| NGV | Nozzle stator vane |

| TBC | Thermal barrier coating |

| HS | Hot streak |

| CHT | Conjugate heat transfer |

| LE | Leading edge |

| PS | Pressure side |

| SS | Suction side |

References

- Qureshi, I.; Smith, A.D.; Povey, T. HP vane aerodynamics and heat transfer in the presence of aggressive inlet swirl. J. Turbomach. 2013, 135, 021040. [Google Scholar] [CrossRef]

- Laskowski, G.M.; Tolpadi, A.K.; Ostrowski, M.C. Heat transfer predictions of film cooled stationary turbine airfoils[C]//Turbo Expo: Power for Land, Sea, and Air. Turbo Expo 2007, 47934, 475–485. [Google Scholar]

- Gomes, R.A.; Niehuis, R. Film cooling effectiveness measurements with periodic unsteady inflow on highly loaded blades with main flow separation. J. Turbomach. 2011, 133, 021019. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef]

- Feuerstein, A.; Knapp, J.; Taylor, T.; Ashary, A.; Bolcavage, A.; Hitchman, N. Technical and economical aspects of current thermal barrier coating systems for gas turbine engines by thermal spray and EBPVD: A review. J. Therm. Spray Technol. 2008, 17, 199–213. [Google Scholar] [CrossRef]

- Prapamonthon, P.; Xu, H.; Yang, W. Numerical study of the effects of thermal barrier coating and turbulence intensity on cooling performances of a nozzle guide vane. Energies 2017, 10, 362. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, W. Numerical study on unsteady film cooling performance of turbine rotor considering influences of inlet non-uniformities and upstream coolant. Aerosp. Sci. Technol. 2021, 119, 107089. [Google Scholar] [CrossRef]

- Liu, J.H.; Liu, Y.B.; He, X.; Liu, L. Study on TBCs insulation characteristics of a turbine blade under serving conditions. Case Stud. Therm. Eng. 2016, 8, 250–259. [Google Scholar] [CrossRef] [Green Version]

- Prasert, P.; Soemsak, Y.; Suwin, S.; Daniele, D.; Huazhao, X.; Jianhua, W. Investigation of cooling performances of a non-film-cooled turbine vane coated with a thermal barrier coating using conjugate heat transfer. Energies 2018, 11, 1000. [Google Scholar]

- Tang, W.Z.; Yang, L.; Zhu, W. Numerical simulation of temperature distribution and thermal-stress field in a turbine blade with multilayer-structure TBCs by a fluid–solid coupling method. J. Mater. Sci. Technol. 2016, 32, 452–458. [Google Scholar] [CrossRef]

- Shi, L.; Sun, Z.Y.; Lu, Y.F. The Combined influences of film cooling and thermal barrier coatings on the cooling performances of a film and internal cooled vane. Coatings 2020, 10, 861. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D.; Wang, Z.; Feng, Z. Heat transfer analyses of film-cooled HP turbine vane considering effects of swirl and hot streak. Appl. Therm. Eng. 2018, 142, 815–829. [Google Scholar] [CrossRef]

- Wang, J.; Ge, N.; Sheng, C. Analysis of swirling flow effects on the characteristics of unsteady hot-streak migration. Chin. J. Aeronaut 2016, 29, 1469–1476. [Google Scholar] [CrossRef] [Green Version]

- Mansouri, Z.; Belamadi, R. The influence of inlet swirl intensity and hot-streak on aerodynamics and thermal characteristics of a high pressure turbine vane. Chin. J. Aeronaut 2021, 34, 66–78. [Google Scholar] [CrossRef]

- Basol, A.M.; Jenny, P.; Ibrahim, M. Hot streak migration in a turbine stage: Integrated design to improve aerothermal performance. J. Eng. Gas Turb. Power 2011, 133, 44–53. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Z.; Feng, Z. Influence of mainstream turbulence intensity on heat transfer characteristics of a HP turbine Stage with inlet hot streak[C]//Turbo Expo: Power for Land, Sea, and Air. Am. Soc. Mech. Eng. 2015, 56727, V05BT13A010. [Google Scholar]

- Wang, Z.; Wang, D.; Liu, Z. Numerical analysis on effects of inlet pressure and temperature non-uniformities on aero-thermal performance of a HP turbine. Int. J. Heat Mass Tran. 2017, 104, 83–97. [Google Scholar] [CrossRef]

- Xie, G.; Tao, Z.; Zhou, Z. Hole arrangement effect to film cooling performance on leading edge region of rotating blade. Int. J. Therm. Sci. 2021, 169, 107034. [Google Scholar] [CrossRef]

- Zhao, W.; Chi, Z.; Zang, S. Scaling criteria accuracy for turbine blade film cooling effectiveness at unmatched temperature ratio conditions. Appl. Therm. Eng. 2021, 197, 117363. [Google Scholar] [CrossRef]

- Shi, L.; Huang, H.; Lu, Y.F. The combined influences of hot streak and swirl on the cooling performances of C3X stator vane with or without TBCs. Coatings 2021, 11, 688. [Google Scholar] [CrossRef]

- Hylton, L.D.; Mihelc, M.S.; Turner, E.R.; Nealy, D.A.; York, R.E. Analytical and Experimental Evaluation of the Heat Transfer Distribution over the Surfaces of Turbine Vanes; NASA Technical Report; NASA-CR-168015; NASA Lewis Research Center: Cleveland, OH, USA, 1982.

- Hylton, L.D.; Nirmalan, V.; Sultanian, B.K.; Kauffman, R.M. The Effects of Leading Edge and Downstream Film Cooling on Turbine Vane Heat Transfer; NASA Technical Report; NASA-CR-182133; NASA: Washington, DC, USA, 1988.

- Ke, Z.; Wang, J.-H. Conjugate heat transfer simulations of pulsed film cooling on an entire turbine vane. Appl. Therm. Eng. 2016, 109, 600–609. [Google Scholar] [CrossRef]

- Wang, T.; Xuan, Y.; Han, X. Analysis of transient radiation-convection coupled effects on the HP turbine blade heat load with hot streak inlet. Appl. Therm. Eng. 2018, 138, 705–721. [Google Scholar] [CrossRef]

- Camci, C.; Arts, T. An Experimetal convective heat transfer investigation around a film cooled gas turbine blade. J. Turbomach. 1990, 112, 497–503. [Google Scholar] [CrossRef]

- Li, Y.; Su, X.; Yuan, X. The effect of mismatching between combustor and HP vanes on the aerodynamics and heat load in a 1-1/2 stages turbine. Aerosp. Sci. Technol. 2020, 86, 78–92. [Google Scholar] [CrossRef]

| Cooling Channel | Diameter (mm) | Film Cooling Hole Count |

|---|---|---|

| Leading edge | 4.5 | 17 + 18 + 18 (52 cylindrical) |

| Suction side | 6 | 21 + 20 (41 shaped) |

| Pressure side | 6 | 17 (17 shaped) |

| Material | Parameter | Value |

|---|---|---|

| Gas | Density (kg∙m−3) | Ideal gas assumption |

| Specific heat capacity (J∙kg−1∙k−1) | 938 + 0.196 T | |

| Thermal conductivity (W∙m−1∙K−1) | 0.0102 + 5.8 × 10−5 T | |

| Substrate metal | Density (kg∙m−3) | 8055 |

| Specific heat capacity (J∙kg−1∙k−1) | 438.5 + 0.177 T | |

| Thermal conductivity (W∙m−1∙K−1) | 11.2 + 0.0144 T | |

| TBCs | Density (kg∙m−3) | 5500 |

| Specific heat capacity (J∙kg−1∙k−1) | 418 | |

| Thermal conductivity (W∙m−1∙K−1) | 1.04 |

| Parameter | Value |

|---|---|

| Inlet total temperature of the mainstream (K) | 818 |

| Inlet total pressure of the mainstream (kPa) | 213.28 |

| Turbulence intensity of the mainstream (%) | 8.0 |

| Mass–weight ratio of the LE cooling air (%) | 40 |

| Mass–weight ratio of the PS cooling air (%) | 35 |

| Mass–weight ratio of the SS cooling air (%) | 25 |

| Inlet total temperature of the cooling air (K) | 414 |

| Turbulence intensity of the cooling air (%) | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, L.; Lu, Y.; Huang, H. Analysis of Rotor–Stator Interaction on the Aerothermal and TBC Insulation Performance of a Turbine Stage under Hot Streak Inlet Condition. Coatings 2022, 12, 25. https://doi.org/10.3390/coatings12010025

Shi L, Lu Y, Huang H. Analysis of Rotor–Stator Interaction on the Aerothermal and TBC Insulation Performance of a Turbine Stage under Hot Streak Inlet Condition. Coatings. 2022; 12(1):25. https://doi.org/10.3390/coatings12010025

Chicago/Turabian StyleShi, Li, Yuanfeng Lu, and Hanze Huang. 2022. "Analysis of Rotor–Stator Interaction on the Aerothermal and TBC Insulation Performance of a Turbine Stage under Hot Streak Inlet Condition" Coatings 12, no. 1: 25. https://doi.org/10.3390/coatings12010025

APA StyleShi, L., Lu, Y., & Huang, H. (2022). Analysis of Rotor–Stator Interaction on the Aerothermal and TBC Insulation Performance of a Turbine Stage under Hot Streak Inlet Condition. Coatings, 12(1), 25. https://doi.org/10.3390/coatings12010025