Chemical Vapor Deposition of Graphene on Cu-Ni Alloys: The Impact of Carbon Solubility

Abstract

:1. Introduction

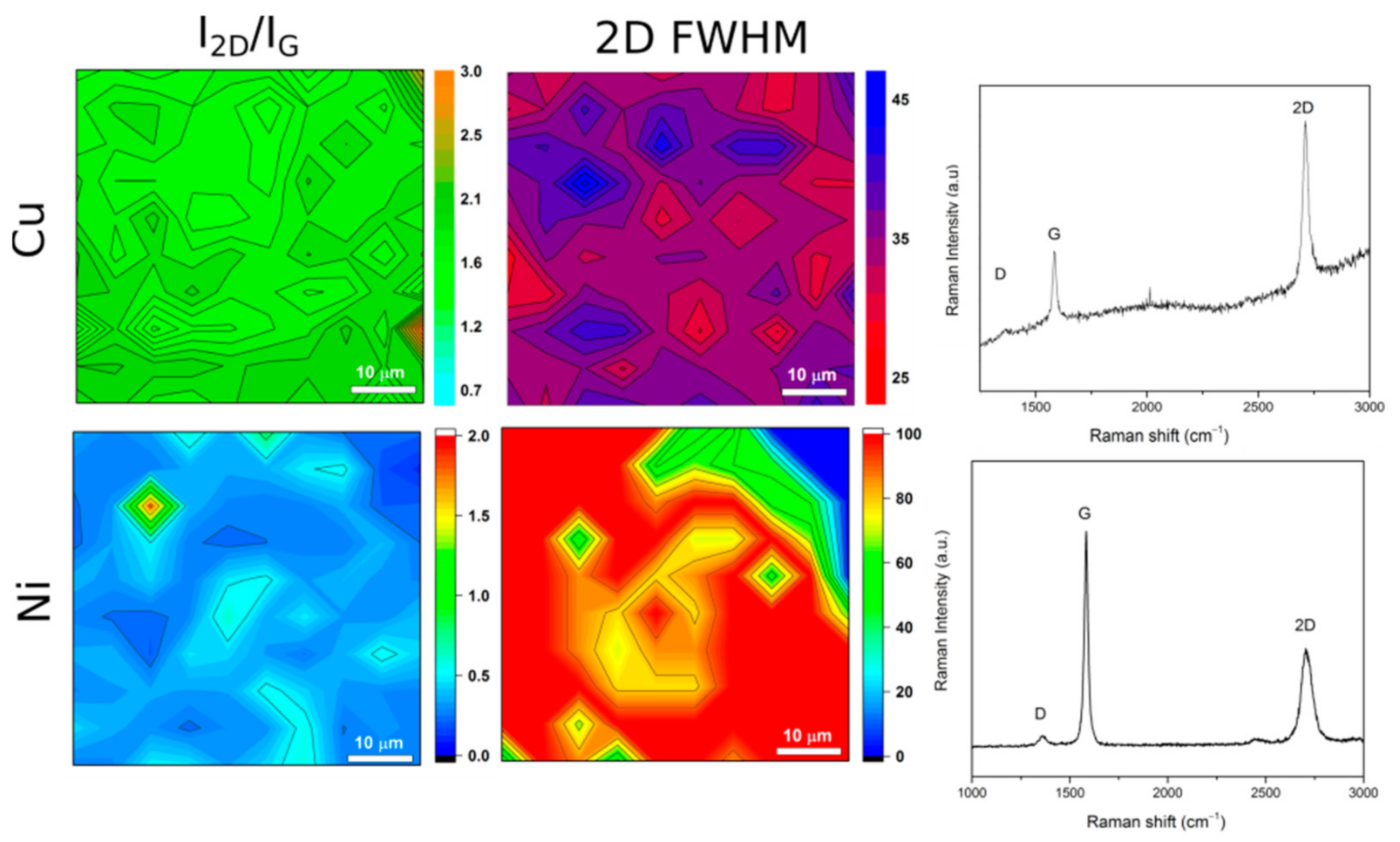

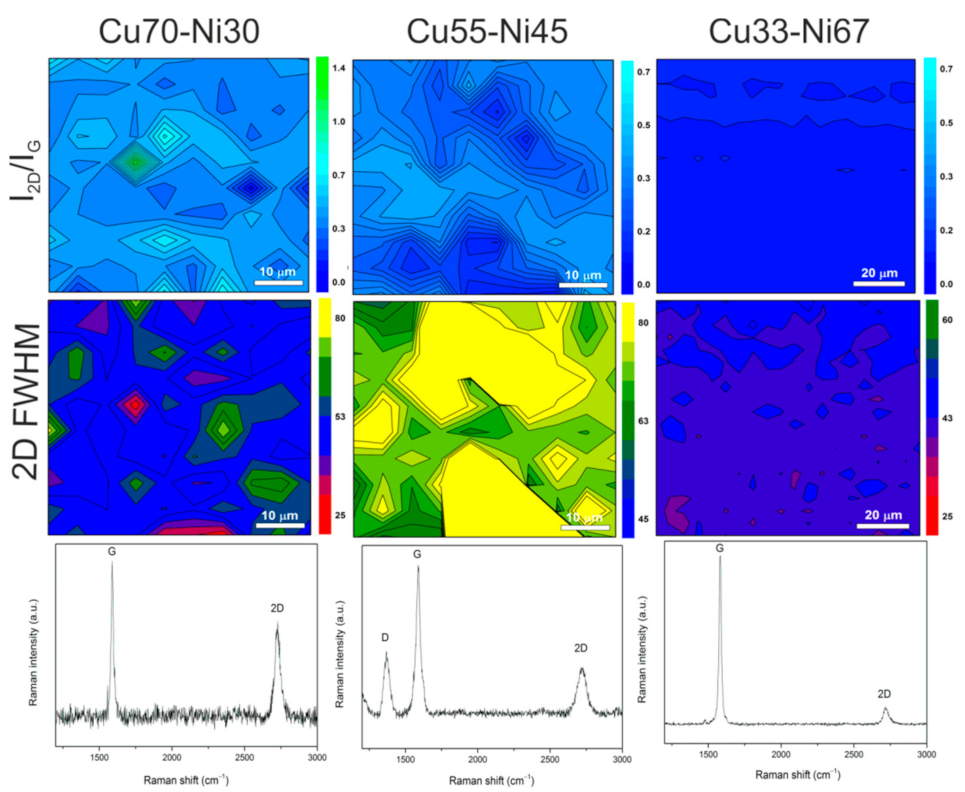

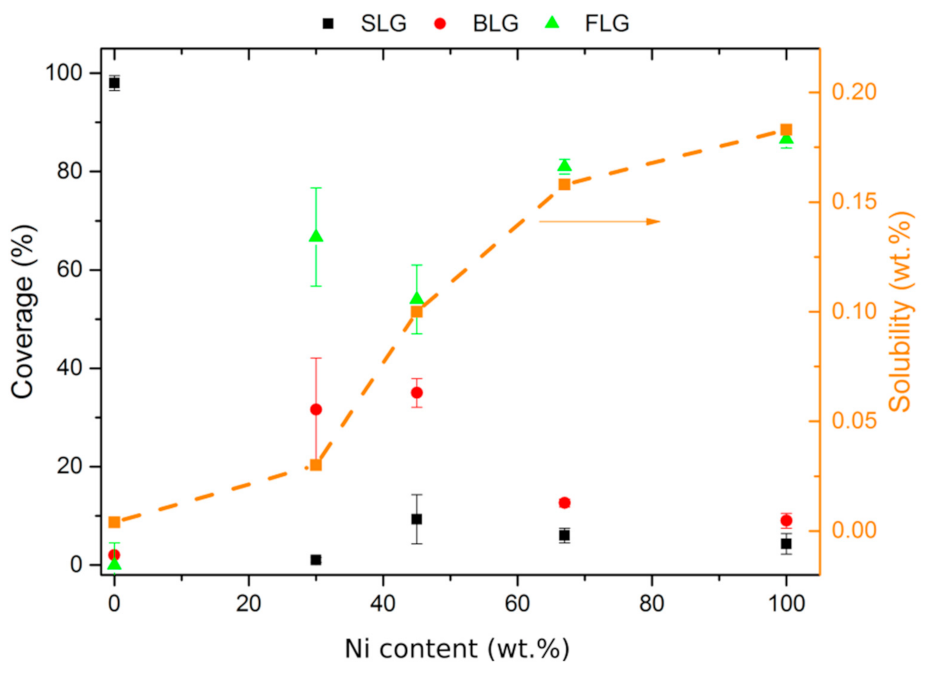

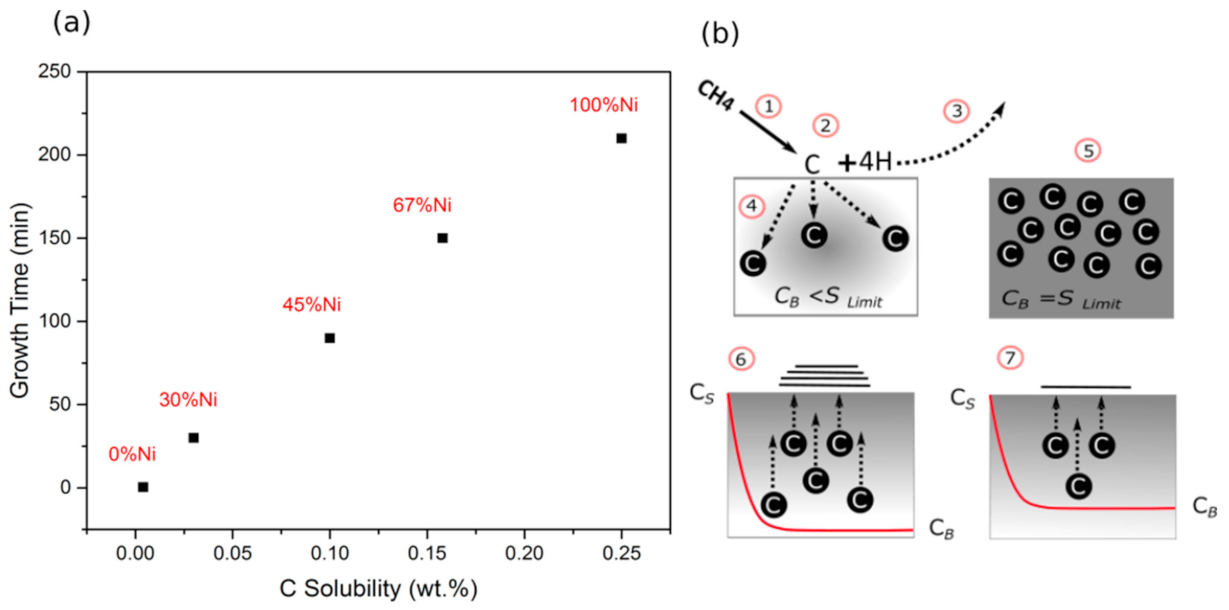

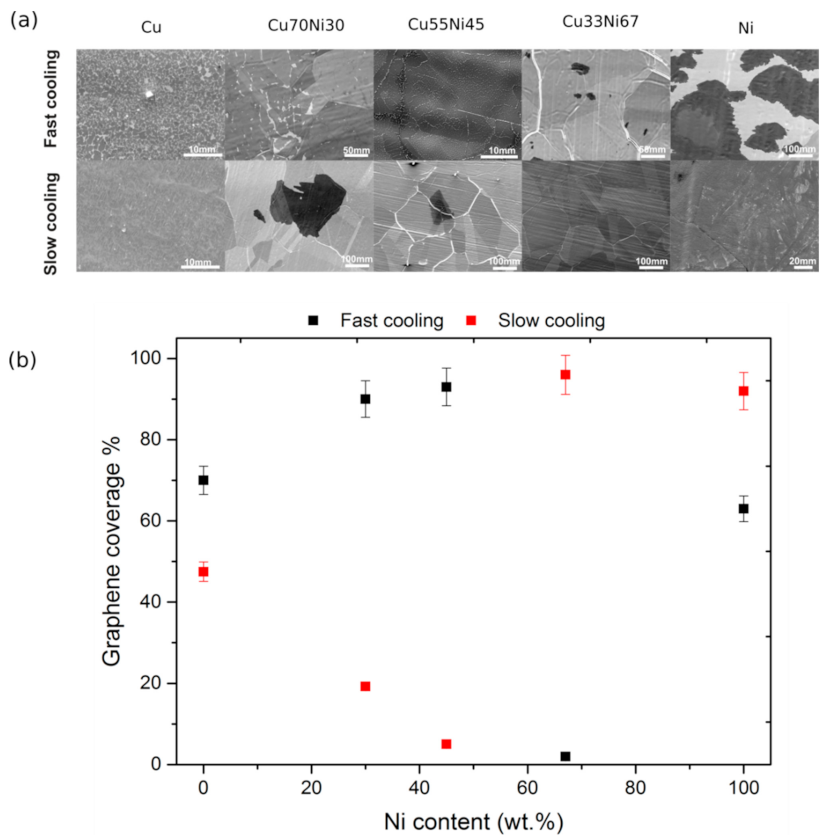

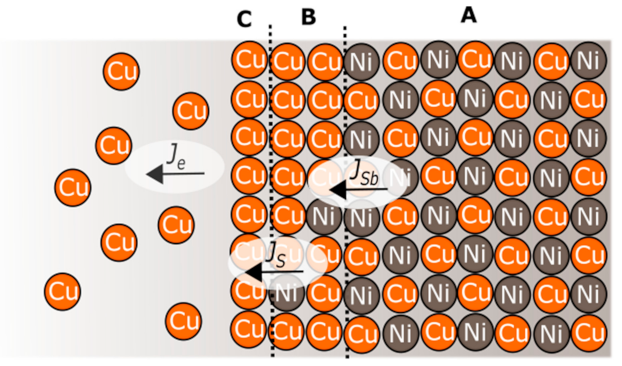

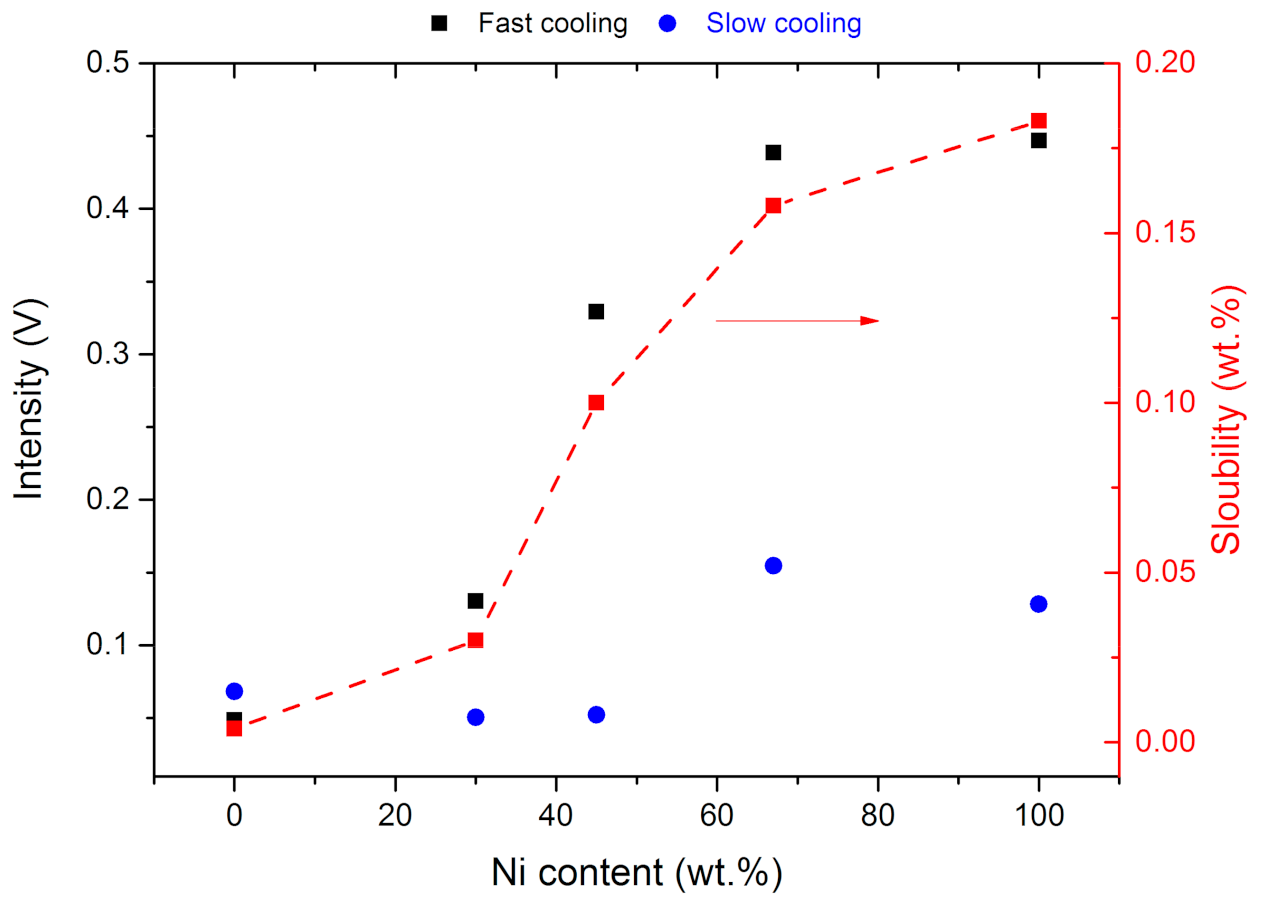

2. Results and Discussion

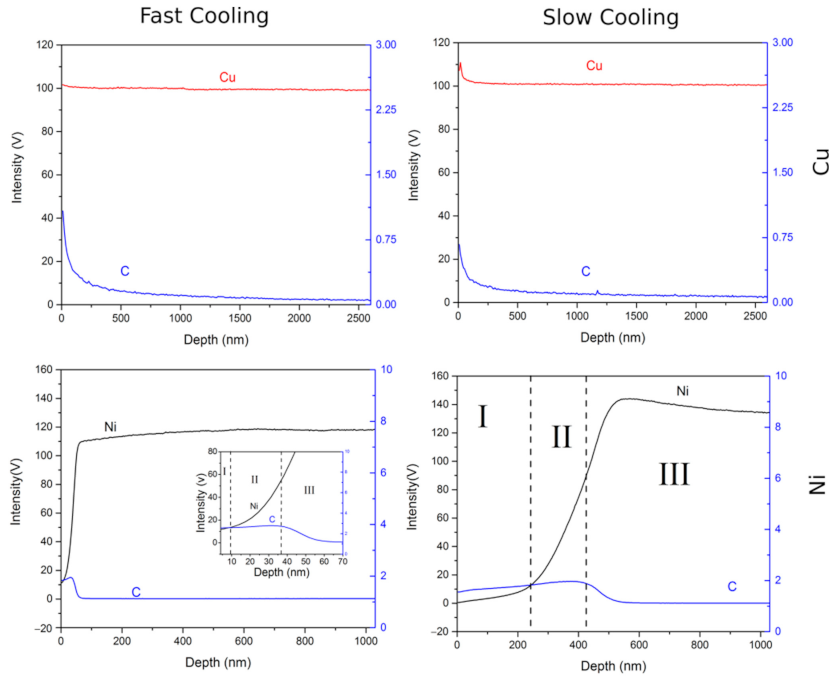

- The plasma intensity of Cu and Ni at the surface is always higher than the bulk (the flat intensity region), regardless of the cooling rate.

- After fast cooling rates, the plasma intensity profile is smooth and flat for both the Cu and Ni signal.

- The slowly cooled samples exhibit disturbances in Cu and Ni intensity at the surface and subsurface, indicating a local change in the alloy composition.

- The intensity (composition) changes with the Ni content are more evident for the Cu70–Ni30 substrate alloy than for Cu33-Ni67.

3. Conclusions

4. Methods

4.1. Graphene Growth

4.2. Sample Characterisation

4.3. Experiment Parameters

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Falcao, E.H.L.; Wudl, F. Carbon allotropes: Beyond graphite and diamond. J. Chem. Technol. Biotechnol. 2007, 82, 524–531. [Google Scholar] [CrossRef]

- Inagaki, M.; Kang, F. Graphene derivatives: Graphane, fluorographene, graphene oxide, graphyne and graphdiyne. J. Mater. Chem. A 2014, 2, 13193–13206. [Google Scholar] [CrossRef]

- Georgakilas, V.; Perman, J.A.; Tucek, J.; Zboril, R. Broad family of carbon nanoallotropes: Classification, chemistry, and applications of fullerenes, carbon dots, nanotubes, graphene, nanodiamonds, and combined superstructures. Chem. Rev. 2015, 115, 4744–4822. [Google Scholar] [CrossRef]

- Yang, D.-C.; Jia, R.; Wang, Y.; Kong, C.-P.; Wang, J.; Ma, Y.; Eglitis, R.I.; Zhang, H.-X. Novel carbon nanotubes rolled from 6,6,12-graphyne: Double dirac points in 1d material. J. Phys. Chem. C 2017, 121, 14835–14844. [Google Scholar] [CrossRef]

- Huang, H.; Shi, H.; Das, P.; Qin, J.; Li, Y.; Wang, X.; Su, F.; Wen, P.; Li, S.; Lu, P.; et al. The chemistry and promising applications of graphene and porous graphene materials. Adv. Funct. Mater. 2020, 30, 1909035. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, J.; Zhang, X.; Li, K.; Du, Y.; Yu, G.; Jia, Y.; Zhang, Y. Recent advances on graphene microstructure engineering for propellant-related applications. J. Appl. Polym. Sci. 2021, 138, 50474. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Somani, P.R.; Somani, S.P.; Umeno, M. Planer nano-graphenes from camphor by CVD. Chem. Phys. Lett. 2006, 430, 56–59. [Google Scholar] [CrossRef]

- Li, X.; Cai, W.; An, J.; Kim, S.; Nah, J.; Yang, D.; Piner, R.; Velamakanni, A.; Jung, I.; Tutuc, E.; et al. Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 2009, 324, 1312–1314. [Google Scholar] [CrossRef] [Green Version]

- Al-Hilfi, S.H.; Derby, B.; Martin, P.A.; Whitehead, J.C. Chemical vapour deposition of graphene on copper–nickel alloys: The simulation of a thermodynamic and kinetic approach. Nanoscale 2020, 12, 15283–15294. [Google Scholar] [CrossRef]

- Li, X.; Cai, W.; Colombo, L.; Ruoff, R.S. Evolution of graphene growth on Ni and Cu by carbon isotope labeling. Nano Lett. 2009, 9, 4268–4272. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Lin, L.; Jia, K.; Sun, L.; Peng, H.; Liu, Z. Controlled growth of single-Crystal graphene films. Adv. Mater. 2020, 32, 1903266. [Google Scholar] [CrossRef] [Green Version]

- Huang, M.; Ruoff, R.S. Growth of single-layer and multilayer graphene on Cu/Ni alloy substrates. Acc. Chem. Res. 2020, 53, 800–811. [Google Scholar] [CrossRef]

- Uddin, S.; Song, Y.-W. Directly synthesized graphene-based photonics and optoelectronics devices. Appl. Sci. 2021, 11, 2768. [Google Scholar] [CrossRef]

- Fazi, A.; Nylander, A.; Zehri, A.; Sun, J.; Malmberg, P.; Ye, L.; Liu, J.; Fu, Y. Multiple growth of graphene from a pre-dissolved carbon source. Nanotechnology 2020, 31, 345601. [Google Scholar] [CrossRef] [PubMed]

- Reina, A.; Jia, X.; Ho, J.; Nezich, D.; Son, H.; Bulovic, V.; Dresselhaus, M.S.; Jing, K. Large area, few-layer graphene films on arbitrary substrates by chemical vapor deposition. Nano Lett. 2009, 9, 30–35. [Google Scholar] [CrossRef]

- Nicholson, M.E. The solubility of carbon in nickel-copper alloys at 1000 °C. Transcation Metall. Soc. AIME 1962, 224, 533. [Google Scholar]

- Yang, C.; Wu, T.; Wang, H.; Zhang, G.; Sun, J.; Lu, G.; Niu, T.; Li, A.; Xie, X.; Jiang, M. Copper-vapor-assisted rapid synthesis of large AB-stacked bilayer graphene domains on Cu-Ni Alloy. Small 2016, 12, 2009–2013. [Google Scholar] [CrossRef]

- Liu, X.; Fu, L.; Liu, N.; Gao, T.; Zhang, Y.; Liao, L.; Liu, Z. Segregation growth of graphene on Cu-Ni alloy for precise layer control. J. Phys. Chem. C 2011, 115, 11976–11982. [Google Scholar] [CrossRef]

- Chen, S.; Cai, W.; Piner, R.D.; Suk, J.W.; Wu, Y.; Ren, Y.; Kang, J.; Ruoff, R.S. Synthesis and characterization of large-area graphene and graphite films on commercial Cu-Ni alloy foils. Nano Lett. 2011, 11, 3519–3525. [Google Scholar] [CrossRef]

- Wu, Y.; Chou, H.; Ji, H.; Wu, Q.; Chen, S.; Jiang, W.; Hao, Y.; Kang, J.; Ren, Y.; Piner, R.D.; et al. Growth mechanism and controlled synthesis of AB-stacked bilayer graphene on Cu-Ni alloy foils. ACS Nano 2012, 6, 7731–7738. [Google Scholar] [CrossRef]

- Choi, H.; Lim, Y.; Park, M.; Lee, S.; Kang, Y.; Kim, M.S.; Kim, J.; Jeon, M. Precise control of chemical vapor deposition graphene layer thickness using NixCu1−x alloys. J. Mater. Chem. C 2015, 3, 1463–1467. [Google Scholar] [CrossRef]

- Madito, M.J.; Manyala, N.; Bello, A.; Dangbegnon, J.K.; Masikhwa, T.M.; Momodu, D.Y. A wafer-scale Bernal-stacked bilayer graphene film obtained on a dilute Cu (0.61 at.% Ni) foil using atmospheric pressure chemical vapour deposition. RSC Adv. 2016, 6, 28370–28378. [Google Scholar] [CrossRef] [Green Version]

- Robinson, Z.R.; Tyagi, P.; Murray, T.M.; Ventrice, C.A., Jr.; Chen, S.; Munson, A.; Magnuson, C.W.; Ruoff, R.S. Substrate grain size and orientation of Cu and Cu–Ni foils used for the growth of graphene films. J. Vac. Sci. Technol. A 2012, 30, 011401. [Google Scholar] [CrossRef] [Green Version]

- Lee, W.G.; Kim, E.; Jung, J. Fast and simultaneous growth of graphene, intermetallic compounds, and silicate on Cu-Ni alloy foils. Mater. Chem. Phys. 2014, 147, 452–460. [Google Scholar] [CrossRef]

- Wu, T.; Liu, Z.; Chen, G.; Dai, D.; Sun, H.; Dai, W.; Jiang, N.; Jiang, Y.H.; Lin, C.-T. A study of the growth-time effect on graphene layer number based on a Cu-Ni bilayer catalyst system. RSC Adv. 2016, 6, 23956–23960. [Google Scholar] [CrossRef]

- Tyagi, P.; Robinson, Z.R.; Munson, A.; Magnuson, C.W.; Chen, S.; McNeilan, J.D.; Moore, R.L.; Piner, R.D.; Ruoff, R.S.; Ventrice, C.A. Characterization of graphene films grown on CuNi foil substrates. Surf. Sci. 2015, 634, 16–24. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, T.; Jiang, Q.; Wang, H.; Zhu, H.; Chen, Z.; Jiang, R.; Niu, T.; Li, Z.; Zhang, Y.; et al. Epitaxial Growth of 6 in. Single-Crystalline Graphene on a Cu/Ni (111) Film at 750 °C via Chemical Vapor Deposition. Small 2019, 15, 1805395. [Google Scholar] [CrossRef]

- Wu, T.; Zhang, X.; Yuan, Q.; Xue, J.; Lu, G.; Liu, Z.; Wang, H.; Wang, H.; Ding, F.; Yu, Q.; et al. Fast growth of inch-sized single-crystalline graphene from a controlled single nucleus on Cu–Ni alloys. Nat. Mater. 2015, 15, 43–47. [Google Scholar] [CrossRef]

- Ferrari, A.C. Raman spectroscopy of graphene and graphite: Disorder, electron–phonon coupling, doping and nonadiabatic effects. Solid State Commun. 2007, 143, 47–57. [Google Scholar] [CrossRef]

- Bernardo, C.A.; Alstrup, I.; Rostrup-Nielsen, J.R. Carbon deposition and methane steam reforming on silica-supported NiCu catalysts. J. Catal. 1985, 96, 517–534. [Google Scholar] [CrossRef]

- Reynolds, P.W. 57. Heterogeneous catalysis. Part II. Hydrogenation by binary alloys. J. Chem. Soc. 1950, 265–271. [Google Scholar] [CrossRef]

- Weatherup, R.S.; Bayer, B.C.; Blume, R.; Ducati, C.; Baehtz, C.; Schlögl, R.; Hofmann, S. In situ characterization of alloy catalysts for low-temperature graphene growth. Nano Lett. 2011, 11, 4154–4160. [Google Scholar] [CrossRef]

- Snoeck, J.-W.; Froment, G.F.; Fowles, M. Filamentous carbon formation and gasification: Thermodynamics, driving force, nucleation, and steady-state growth. J. Catal. 1997, 169, 240–249. [Google Scholar] [CrossRef]

- Weiss, Z. Calibration methods in glow discharge optical emission spectroscopy: A tutorial review. J. Anal. At. Spectrom. 2015, 30, 1038–1049. [Google Scholar] [CrossRef]

- Weatherup, R.S.; Amara, H.; Blume, R.; Dlubak, B.; Bayer, B.C.; Diarra, M.; Bahri, M.; Cabrero-Vilatela, A.; Caneva, S.; Kidambi, P.R.; et al. Interdependency of subsurface carbon distribution and graphene-catalyst interaction. J. Am. Chem. Soc. 2014, 136, 13698–13708. [Google Scholar] [CrossRef]

- Wagatsuma, K.; Hirokawa, K. Analysis of binary alloy surfaces by low wattage glow discharge emission spectrometry. Anal. Chem. 1984, 56, 412–416. [Google Scholar] [CrossRef]

- Wagatsuma, K.; Hirokawa, K. Observation of Cu-Ni alloy surfaces by low wattage glow discharge emission spectrometry. Surf. Interface Anal. 1984, 6, 167–170. [Google Scholar] [CrossRef]

- Kuijers, F.J.; Ponec, V. The surface composition of the nickel-copper alloy system as determined by Auger electron spectroscopy. Surf. Sci. 1977, 68, 294–304. [Google Scholar] [CrossRef]

- Foiles, S.M. Calculation of the surface segregation of Ni-Cu alloys with the use of the embedded-atom method. Phys. Rev. B 1985, 32, 7685–7693. [Google Scholar] [CrossRef] [PubMed]

- Good, B.; Bozzolo, G.; Ferrante, J. Surface segregation in Cu-Ni alloys. Phys. Rev. B 1993, 48, 18284–18287. [Google Scholar] [CrossRef] [Green Version]

- Lea, C.; Seah, M.P. Kinetics of surface segregation. Philos. Mag. A J. Theor. Exp. Appl. Phys. 1977, 35, 213–228. [Google Scholar] [CrossRef]

- Wang, B.; Meng, F.; Zheng, L.; Wang, M.; Meng, Y.; Cui, F.; Liang, X.; Gao, Y.; Yang, S.; Zhao, Y. Surface segregation modeling in the case of evaporation. J. Alloys Compd. 2019, 797, 640–651. [Google Scholar] [CrossRef]

- Webber, P.R.; Chadwick, D. Evaporation limited segregation of Cu Ni. Surf. Sci. 1980, 94, L151–L156. [Google Scholar] [CrossRef]

- Zhao, P.; Hou, B.; Chen, X.; Kim, S.; Chiashi, S.; Einarsson, E.; Maruyama, S. Investigation of non-segregation graphene growth on Ni via isotope-labeled alcohol catalytic chemical vapor deposition. Nanoscale 2013, 5, 6530. [Google Scholar] [CrossRef]

- Peng, Z.; Yan, Z.; Sun, Z.; Tour, J.M. Direct growth of bilayer graphene on SiO2 substrates by carbon diffusion through nickel. ACS Nano 2011, 5, 8241–8247. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Hilfi, S.H.; Kinloch, I.A.; Derby, B. Chemical Vapor Deposition of Graphene on Cu-Ni Alloys: The Impact of Carbon Solubility. Coatings 2021, 11, 892. https://doi.org/10.3390/coatings11080892

Al-Hilfi SH, Kinloch IA, Derby B. Chemical Vapor Deposition of Graphene on Cu-Ni Alloys: The Impact of Carbon Solubility. Coatings. 2021; 11(8):892. https://doi.org/10.3390/coatings11080892

Chicago/Turabian StyleAl-Hilfi, Samir H., Ian A. Kinloch, and Brian Derby. 2021. "Chemical Vapor Deposition of Graphene on Cu-Ni Alloys: The Impact of Carbon Solubility" Coatings 11, no. 8: 892. https://doi.org/10.3390/coatings11080892

APA StyleAl-Hilfi, S. H., Kinloch, I. A., & Derby, B. (2021). Chemical Vapor Deposition of Graphene on Cu-Ni Alloys: The Impact of Carbon Solubility. Coatings, 11(8), 892. https://doi.org/10.3390/coatings11080892