Design and Optimization of the Antireflective Coating Properties of Silicon Solar Cells by Using Response Surface Methodology

Abstract

1. Introduction

2. Materials and Methods

2.1. 2D Model Simulation and Analysis

2.2. Operational Parameter Statistical Analysis

2.3. Continuous Factors

2.4. Categorical Factors

3. Results and Discussion

3.1. Interpretation of Regression Model and Analysis

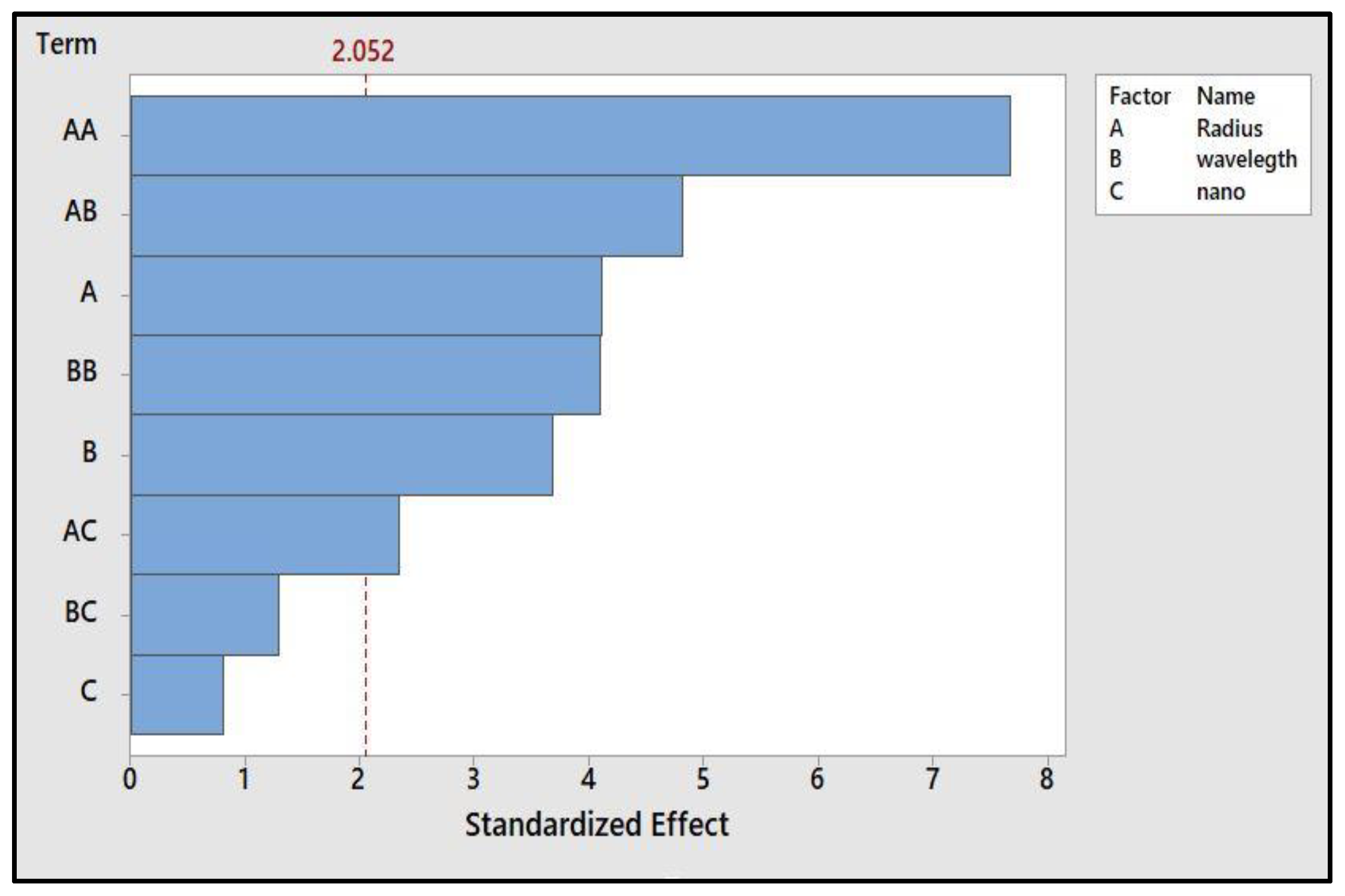

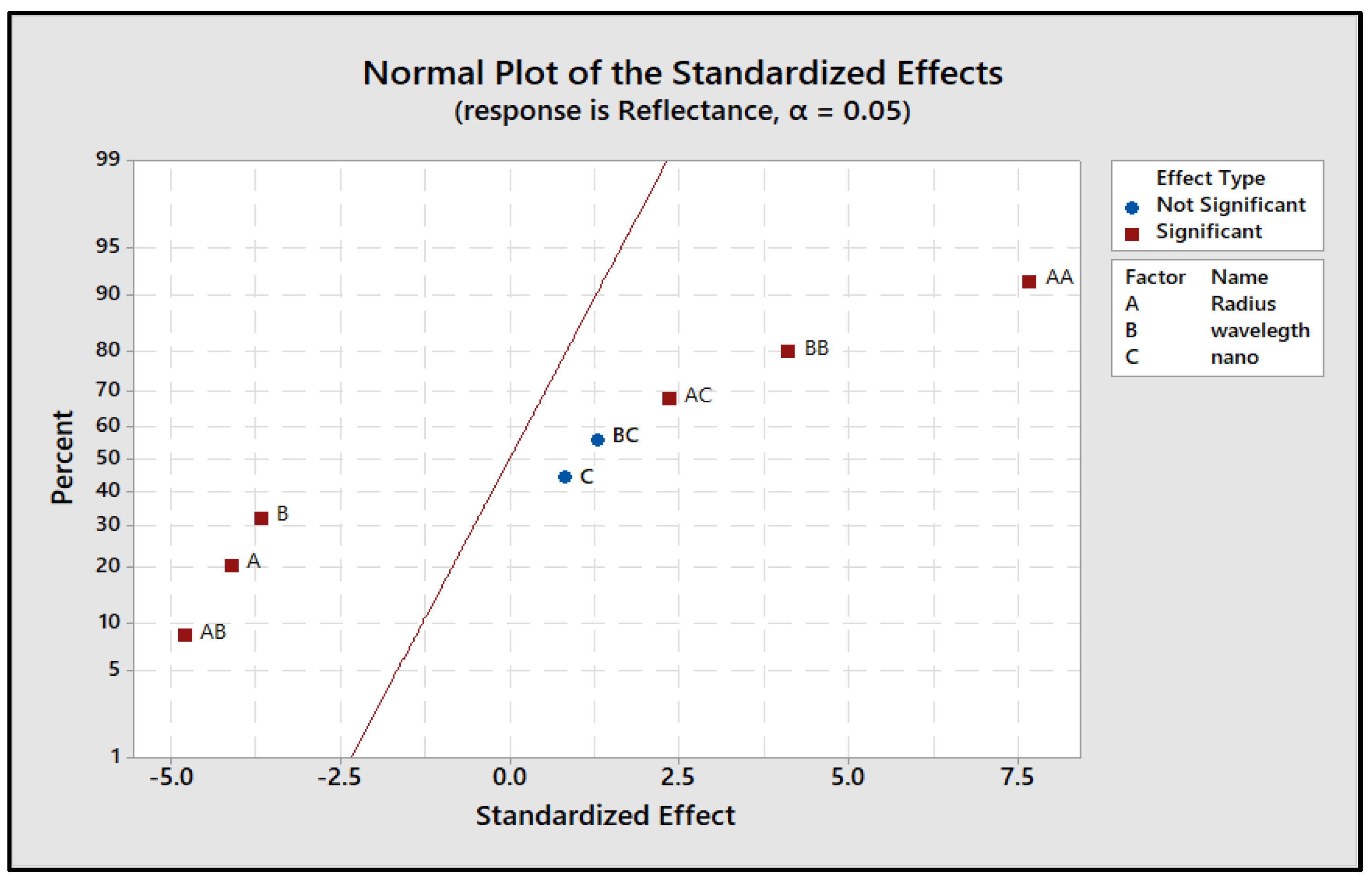

3.2. Estimation of Factor Effects

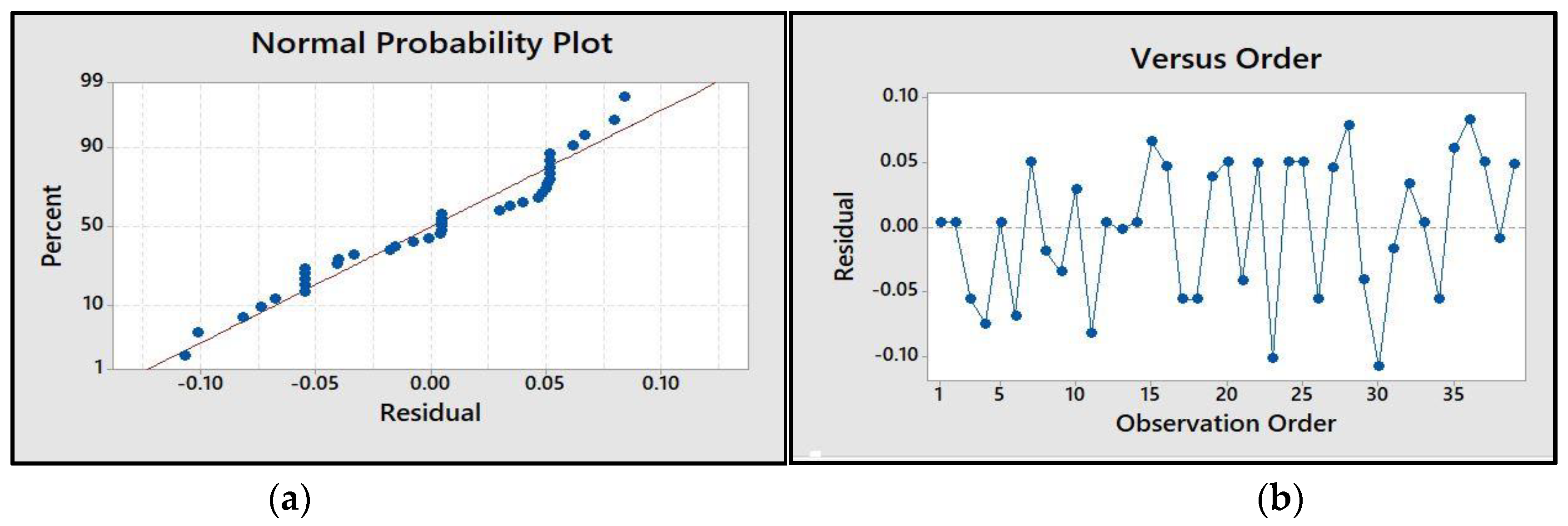

3.3. Interpretation of Residual Plots

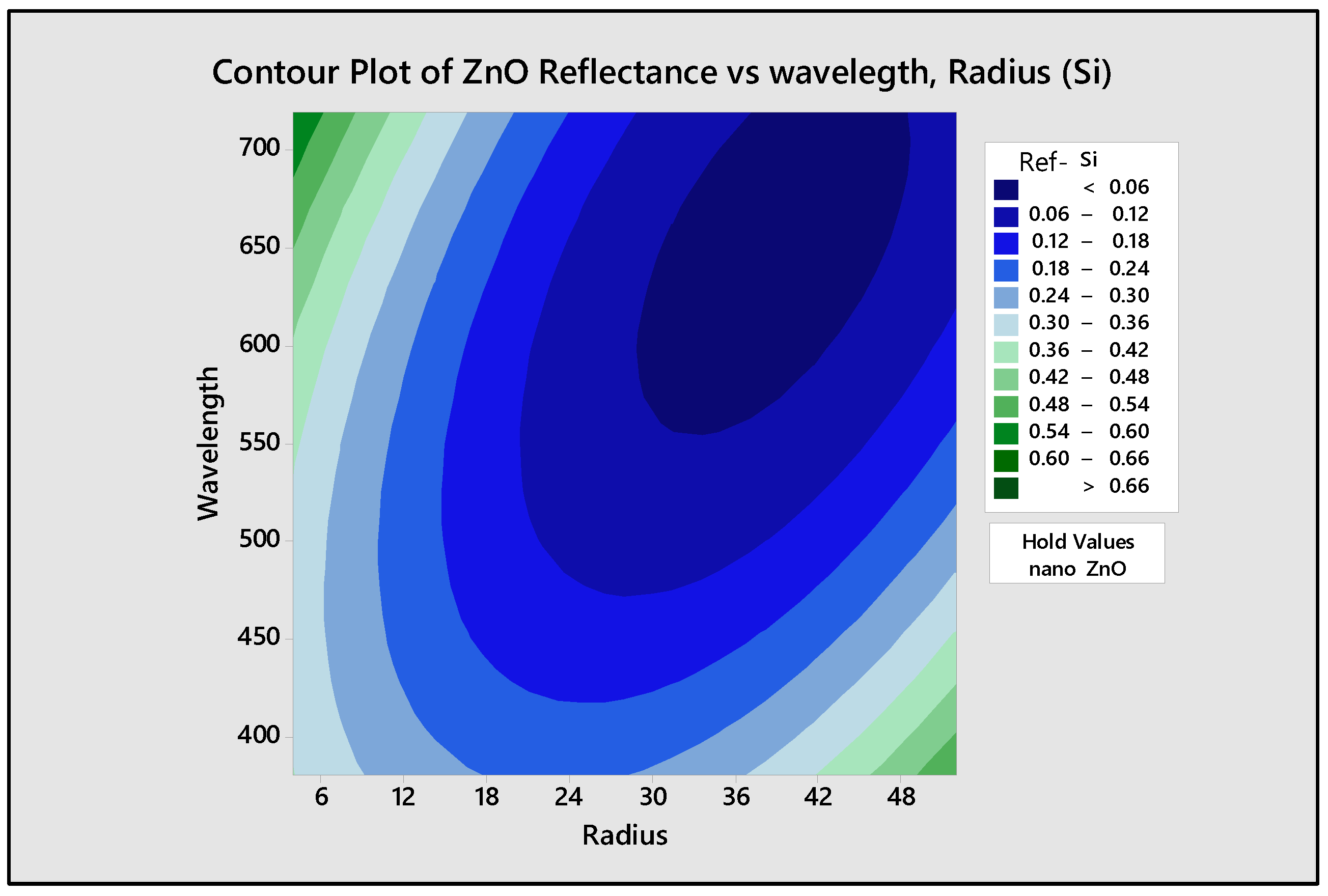

3.4. Response Surface Methodology—Interpretation of Contour Plots

3.4.1. Aluminum Dioxide ARC Results

3.4.2. Titanium Dioxide ARC Results

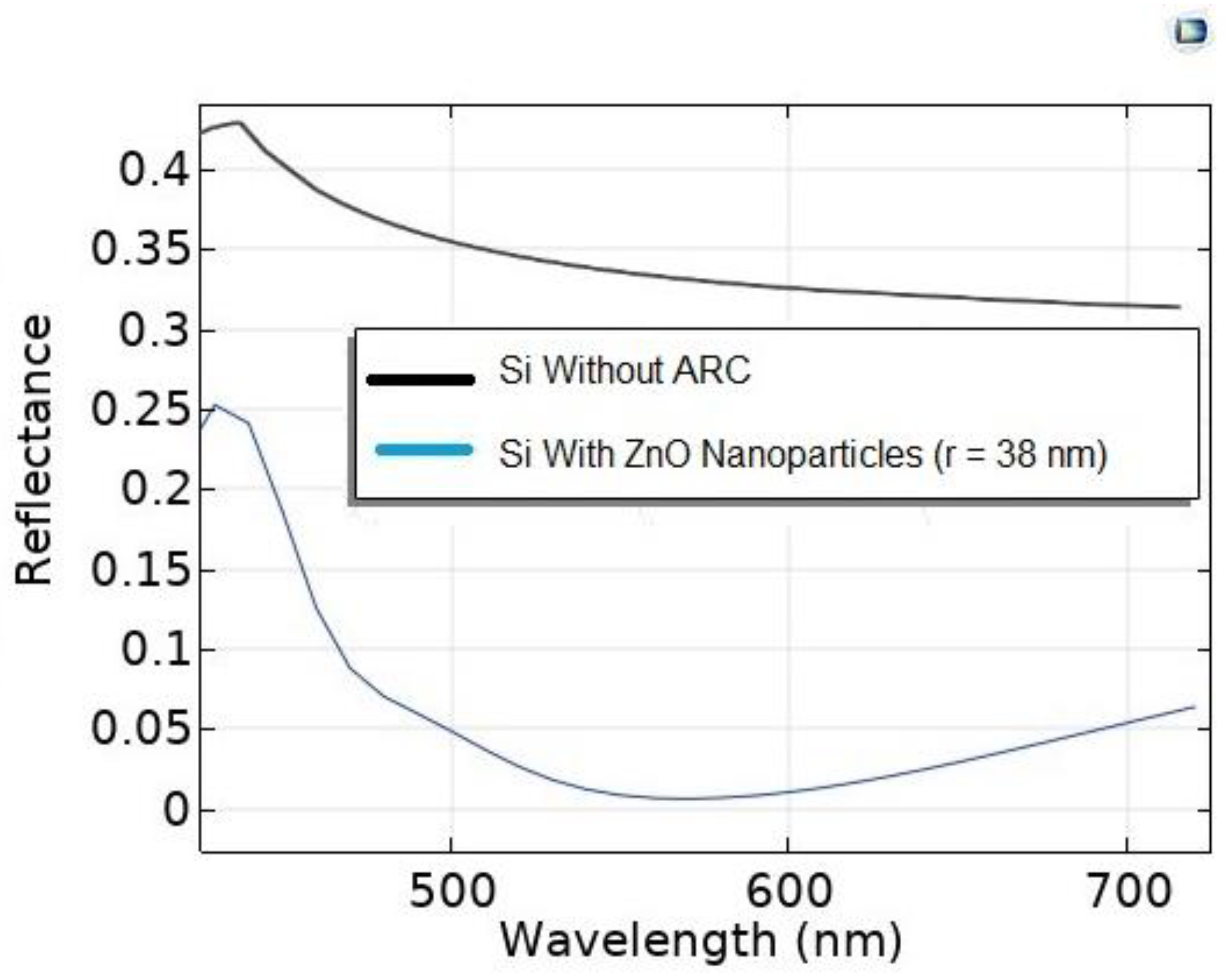

3.4.3. Zinc Oxide ARC Results

3.5. COMSOL Multiphysics Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, X.; Streimikiene, D.; Balezentis, T.; Mardani, A.; Cavallaro, F.; Liao, H. A review of greenhouse gas emission profiles, dynamics, and climate change mitigation efforts across the key climate change players. J. Clean. Prod. 2019, 234, 1113–1133. [Google Scholar] [CrossRef]

- Xing, Y.; Han, P.; Wang, S.; Liang, P.; Lou, S.; Zhang, Y.; Hu, S.; Zhu, H.; Zhao, C.; Mi, Y. A review of concentrator silicon solar cells. Renew. Sustain. Energy Rev. 2015, 51, 1697–1708. [Google Scholar] [CrossRef]

- Deshpande, R.A. Advances in Solar Cell Technology: An Overview. J. Sci. Res. 2021, 65, 72–75. [Google Scholar] [CrossRef]

- Jiang, T.; Xu, X.; Chen, G.Z. Silicon prepared by electro-reduction in molten salts as new energy materials. J. Energy Chem. 2020, 47, 46–61. [Google Scholar] [CrossRef]

- Lindroos, J.; Savin, H. Review of light-induced degradation in crystalline silicon solar cells. Sol. Energy Mater. Sol. Cells 2016, 147, 115–126. [Google Scholar] [CrossRef]

- Zarmai, M.T.; Ekere, P.N.N.; Oduoza, C.; Amalu, E.H. A review of interconnection technologies for improved crystalline silicon solar cell photovoltaic module assembly. Appl. Energy 2015, 154, 173–182. [Google Scholar] [CrossRef]

- Arduca, E.; Perego, M. Doping of silicon nanocrystals. Mater. Sci. Semicond. Process. 2017, 62, 156–170. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, T.; Chen, W. Polyoxometalate modified all-weather solar cells for energy harvesting. Electrochim. Acta 2020, 330, 135215. [Google Scholar] [CrossRef]

- Diop, M.M.; Diaw, A.; Mbengue, N.; Ba, O.; Diagne, M.; Niasse, O.A.; Ba, B.; Sarr, J. Optimization and Modeling of Antireflective Layers for Silicon Solar Cells: In Search of Optimal Materials. Mater. Sci. Appl. 2018, 9, 705–722. [Google Scholar] [CrossRef]

- Singh, G. Solar power generation by PV (photovoltaic) technology: A review. Energy 2013, 53, 1–13. [Google Scholar] [CrossRef]

- Salman, K.A. Effect of surface texturing processes on the performance of crystalline silicon solar cell. Sol. Energy 2017, 147, 228–231. [Google Scholar] [CrossRef]

- Yin, Y.; Bu, Y.; Wang, X. PDMS-based subwavelength structures for broadband and wide-angle anti-reflection. Phys. B Condens. Matter 2020, 580, 411943. [Google Scholar] [CrossRef]

- Pillai, S.; Green, M. Plasmonics for photovoltaic applications. Sol. Energy Mater. Sol. Cells 2010, 94, 1481–1486. [Google Scholar] [CrossRef]

- Rehman, A.U.; Iqbal, M.Z.; Bhopal, M.F.; Khan, M.F.; Hussain, F.; Iqbal, J.; Khan, M.; Lee, S.H. Development and prospects of surface passivation schemes for high-efficiency c-Si solar cells. Sol. Energy 2018, 166, 90–97. [Google Scholar] [CrossRef]

- Shinen, M.H.; AlSaati, S.A.A.; Razooqi, F.Z. Preparation of high transmittance TiO2 thin films by sol-gel technique as antireflection coating. J. Phys. Conf. Ser. 2018, 1032, 012018. [Google Scholar] [CrossRef]

- Han, S.-Y.; Paul, B.K.; Chang, C.-H. Nanostructured ZnO as biomimetic anti-reflective coatings on textured silicon using a continuous solution process. J. Mater. Chem. 2012, 22, 22906–22912. [Google Scholar] [CrossRef]

- Oh, S.J.; Chhajed, S.; Poxson, D.J.; Cho, J.; Schubert, E.F.; Tark, S.J.; Kim, D.; Kim, J.K. Enhanced broadband and omni-directional performance of polycrystalline Si solar cells by using discrete multilayer antireflection coatings. Opt. Express 2012, 21, A157–A166. [Google Scholar] [CrossRef]

- Jung, J.; Jannat, A.; Akhtar, M.S.; Yang, O.-B. Sol–Gel Deposited Double Layer TiO2 and Al2O3 Anti-Reflection Coating for Silicon Solar Cell. J. Nanosci. Nanotechnol. 2018, 18, 1274–1278. [Google Scholar] [CrossRef] [PubMed]

- Makableh, Y.F.; Al-Fandi, M.; Khasawneh, M.; Tavares, C.J. Comprehensive design analysis of ZnO anti-reflection nanostructures for Si solar cells. Superlattices Microstruct. 2018, 124, 1–9. [Google Scholar] [CrossRef]

- Hocine, D.; Belkaid, M.; Pasquinelli, M.; Escoubas, L.; Simon, J.; Rivière, G.; Moussi, A. Improved efficiency of multicrystalline silicon solar cells by TiO2 antireflection coatings derived by APCVD process. Mater. Sci. Semicond. Process. 2013, 16, 113–117. [Google Scholar] [CrossRef]

- Lin, J.-Y.; Zheng, Q.; Hu, C.-S.; Lin, Y.-A. Reduction of silicon surface reflection with micro-sphere texturing. In Proceedings of the 2017 International Conference on Applied System Innovation (ICASI), Sapporo, Japan, 13–17 May 2017; Volume 2017, pp. 509–511. [Google Scholar] [CrossRef]

- Jo, H.-J.; Shim, B.-H. Efficiency enhancement of Cu(In,Ga)Se2 thin film solar cells by employing onmi-directional ZnO nanostructure with MgF2 anti-reflection-coating layer. Microw. Opt. Technol. Lett. 2018, 60, 2634–2639. [Google Scholar] [CrossRef]

- Ramelan, A.H.; Wahyuningsih, S.; Munawaroh, H.; Narayan, R. ZnO wide bandgap semiconductors preparation for optoelectronic devices. IOP Conf. Ser. Mater. Sci. Eng. 2017, 176, 012008. [Google Scholar] [CrossRef]

- Ahmad, A.A.; Al-Bataineh, Q.M.; Alsaad, A.M.; Samara, T.O.; Al-Izzy, K.A. Optical properties of hydrophobic ZnO nano-structure based on antireflective coatings of ZnO/TiO/SiO thin films. Phys. B Condens. Matter 2020, 593, 412263. [Google Scholar] [CrossRef]

- Bashirpour, M.; Forouzmehr, M.; Hosseininejad, S.E.; Kolahdouz, M.; Neshat, M. Improvement of Terahertz Photoconductive Antenna using Optical Antenna Array of ZnO Nanorods. Sci. Rep. 2019, 9, 1–8. [Google Scholar] [CrossRef] [PubMed]

- BashirKhanabc, S.; Zhangd, Z.; Lee, S.L. Single component: Bilayer TiO2 as a durable antireflective coating. J. Alloy. Compd. 2020, 834, 155137. [Google Scholar] [CrossRef]

- Юрпалoв, В.Л.; Федoрoва, Е.Д.; Дрoздoв, В.А.; Лавренoв, А.В. Оценка кислoтных свoйств систем B2O3–Al2O3и Pt/B2O3–Al2O3метoдoм зoндoвoй ЭПР-спектрoскoпии и их кoрреляция с прoтеканием сoвместнoй гидрoизoмеризации гептана и бензoла. Кинетика и Катализ 2016, 57, 548–553. [Google Scholar] [CrossRef]

- Chaya, B.M.; Sharon Prarthna, C.; Vinith Kumar, G.P.; Krishnaswamy, N. Modeling and Analysis of Double Layer Motheye Anti Reflective Coatings on Organic Light Emitting Diode. In Proceedings of the 7th International Conference on Photonics, Prague, Czech Republic, 25–27 February 2019; pp. 190–195. [Google Scholar]

- Refinery, N.P.; Braimah, M.N.; Odejobi, O.J. Utilization of Response Surface Methodology (RSM) in the Optimization of Crude Oil Refinery. J. Multidiscip. Eng. Sci. Technol. 2016, 3, 4361–4369. [Google Scholar]

- Paulo, F.; Santos, L. Design of experiments for microencapsulation applications: A review. Mater. Sci. Eng. C 2017, 77, 1327–1340. [Google Scholar] [CrossRef]

- Cao, B.; Adutwum, L.A.; Oliynyk, A.O.; Luber, E.J.; Olsen, B.C.; Mar, A.; Buriak, J.M. How to Optimize Materials and Devices via Design of Experiments and Machine Learning: Demonstration Using Organic Photovoltaics. ACS Nano 2018, 12, 7434–7444. [Google Scholar] [CrossRef]

- Wang, Y.; Hang, L. Study on transmission spectrum and electric field distribution of graded-index anti-reflection coatings. In Proceedings of the 9th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Meta-Surface-Wave and Planar Optics, Chengdu, China, 26–29 June 2019; Volume 10841, p. 1084112. [Google Scholar]

- Sivakumar, R.; Gopalakrishnan, P.; Razak, M.S.A. Comparative analysis of anti-reflection coatings on solar PV cells through TiO2 and SiO2 nanoparticles. Pigment. Resin Technol. 2021. [CrossRef]

- Mousavi, B.K.; Mousavu, A.K.; Busani, T.; Zadeh, M.H.; Brueck, S.R.J. Nanostructured Anti-Reflection Coatings for Enhancing Transmission of Light. J. Appl. Math. Phys. 2019, 7, 3083–3100. [Google Scholar] [CrossRef][Green Version]

- Al-Fandi, M.; Makableh, Y.F.; Khasawneh, M.; Rabady, R. Near zero reflection by nanostructured anti-reflection coating design for Si substrates. Superlattices Microstruct. 2018, 117, 115–120. [Google Scholar] [CrossRef]

- Kazanskiy, N.; Butt, M.; Khonina, S. Silicon photonic devices realized on refractive index engineered subwavelength grating waveguides-A review. Opt. Laser Technol. 2021, 138, 106863. [Google Scholar] [CrossRef]

- Elshorbagy, M.H.; Abdel-Hady, K.; Kamal, H.; Alda, J. Broadband anti-reflection coating using dielectric Si3N4 nanostructures. Application to amorphous-Si-H solar cells. Opt. Commun. 2017, 390, 130–136. [Google Scholar] [CrossRef]

- Rezaei, N.; Isabella, O.; Vroon, Z.; Zeman, M. Optical optimization of a multi-layer wideband anti-reflection coating using porous MgF2 for sub-micron-thick CIGS solar cells. Sol. Energy 2019, 177, 59–67. [Google Scholar] [CrossRef]

- Montgomery, D. C.; Runger, G.C. Applied Statistics and Probability for Engineers. Eur. J. Eng. Educ. 1994, 19, 383. [Google Scholar] [CrossRef]

- Visser, D.; Chen, D.Y.; Désières, Y.; Ravishankar, A.P.; Anand, S. Embossed Mie resonator arrays composed of compacted TiO2 nanoparticles for broadband anti-reflection in solar cells. Sci. Rep. 2020, 10, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Minemoto, T.; Mizuta, T.; Takakura, H.; Hamakawa, Y. Antireflective coating fabricated by chemical deposition of ZnO for spherical Si solar cells. Sol. Energy Mater. Sol. Cells 2007, 91, 191–194. [Google Scholar] [CrossRef]

- Ilican, S.; Caglar, Y.; Caglar, M. Preparation and characterization of ZnO thin films deposited by sol-gel spin coating method. J. Optoelectron. Adv. Mater. 2008, 10, 2578–2583. [Google Scholar]

- Lee, Y.-J.; Ruby, D.S.; Peters, D.W.; McKenzie, B.B.; Hsu, J.W.P. ZnO Nanostructures as Efficient Antireflection Layers in Solar Cells. Nano Lett. 2008, 8, 1501–1505. [Google Scholar] [CrossRef] [PubMed]

| Symbol | Process Parameter | Unit | Range |

|---|---|---|---|

| A | Radius (R) | nm | 5–50 |

| B | Wavelength (λ) | nm | 380–720 |

| C | Nanomaterial type | - | Al2O3, ZnO, TiO2 |

| Source | DF | Adj SS | Adj MS | F-Value | p Value |

|---|---|---|---|---|---|

| Model | 11 | 0.535781 | 0.048707 | 12.33 | 0.0002 |

| Linear | |||||

| A, Radius (R) | 1 | 0.066718 | 0.066718 | 16.88 | 0.001 |

| B, Wavelength (λ) | 1 | 0.053480 | 0.053480 | 13.53 | 0.003 |

| C, Nanomaterial type | 2 | 0.006938 | 0.003469 | 0.88 | 0.427 |

| Square | |||||

| AA | 1 | 0.232468 | 0.232468 | 58.83 | >0.001 |

| BB | 1 | 0.066449 | 0.066449 | 16.82 | >0.001 |

| 2-Way Interaction | |||||

| AB | 1 | 0.091424 | 0.091424 | 23.14 | 0.011 |

| AC | 2 | 0.032866 | 0.016433 | 4.16 | 0.027 |

| BC | 2 | 0.013248 | 0.006624 | 1.68 | 0.206 |

| Input Parameters | Details |

|---|---|

| Geometry | Nanoparticle size range: 5–50 nm |

| Nanoparticles Materials | Al2O3, TiO2, and ZnO |

| Model Physics | Electromagnetic wave frequency domain (emwf), with the following boundary conditions: - Top and bottom surfaces: Periodic - Left and right sides: Floquet periodicity |

| Mesh size | Physics-controlled mesh with element size (Fine) |

| Study | ● Type: Wavelength domain ● Unit: nm ● Range: 380–720 nm, with resolution: 10 nm |

| Interval (nm) | Reflectance |

|---|---|

| 380–720 | 5.5% |

| 500–720 | 2.3% |

| 550–600 | ~0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makableh, Y.F.; Alzubi, H.; Tashtoush, G. Design and Optimization of the Antireflective Coating Properties of Silicon Solar Cells by Using Response Surface Methodology. Coatings 2021, 11, 721. https://doi.org/10.3390/coatings11060721

Makableh YF, Alzubi H, Tashtoush G. Design and Optimization of the Antireflective Coating Properties of Silicon Solar Cells by Using Response Surface Methodology. Coatings. 2021; 11(6):721. https://doi.org/10.3390/coatings11060721

Chicago/Turabian StyleMakableh, Yahia F., Hani Alzubi, and Ghassan Tashtoush. 2021. "Design and Optimization of the Antireflective Coating Properties of Silicon Solar Cells by Using Response Surface Methodology" Coatings 11, no. 6: 721. https://doi.org/10.3390/coatings11060721

APA StyleMakableh, Y. F., Alzubi, H., & Tashtoush, G. (2021). Design and Optimization of the Antireflective Coating Properties of Silicon Solar Cells by Using Response Surface Methodology. Coatings, 11(6), 721. https://doi.org/10.3390/coatings11060721