A Staged Approach to Erosion Analysis of Wind Turbine Blade Coatings

Abstract

1. Introduction

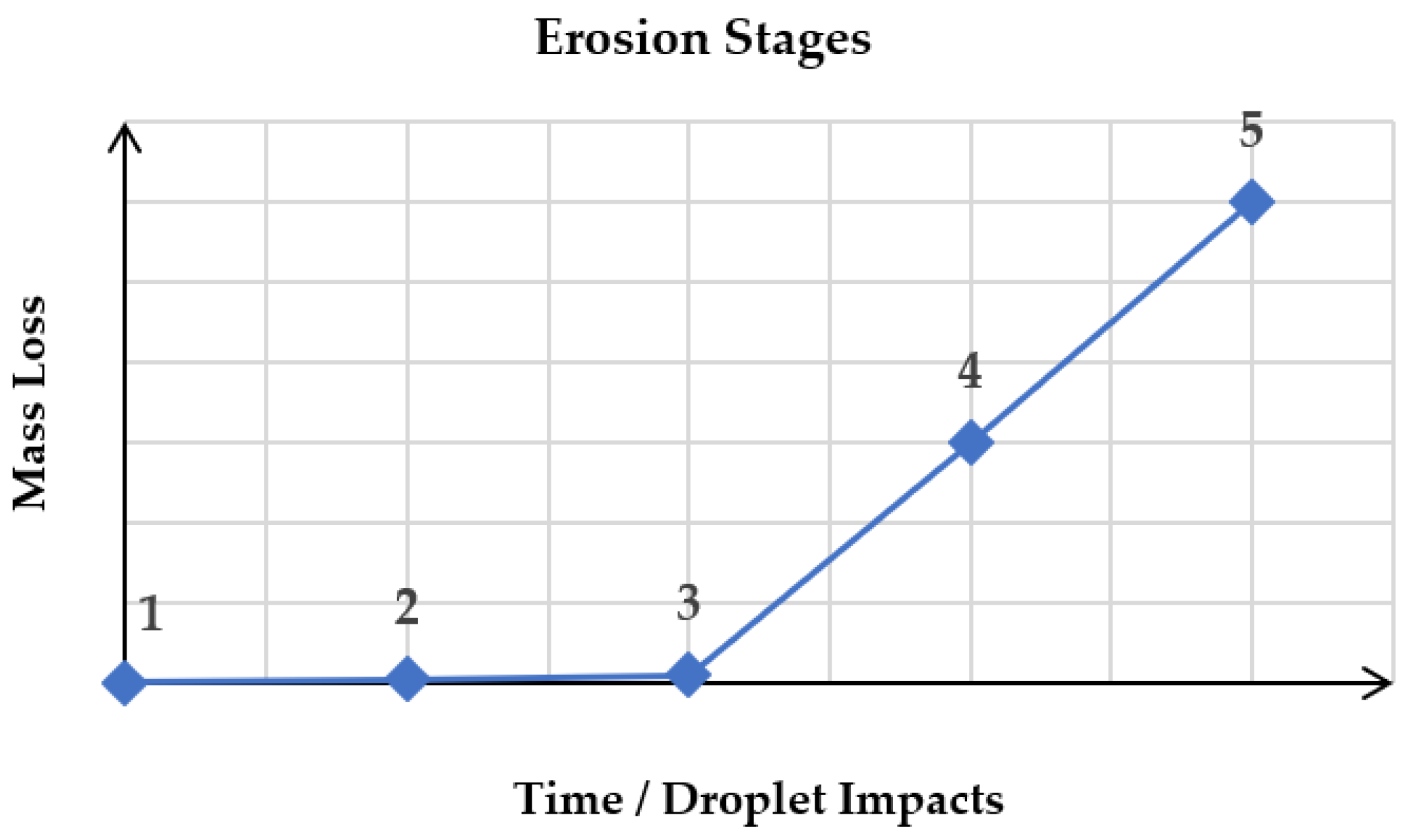

2. Stages of Erosion

3. Experimental Methodology

4. Results

4.1. Photographs of Samples at Five Stages of Erosion

4.2. Microscopy of Samples at Five Stages of Erosion

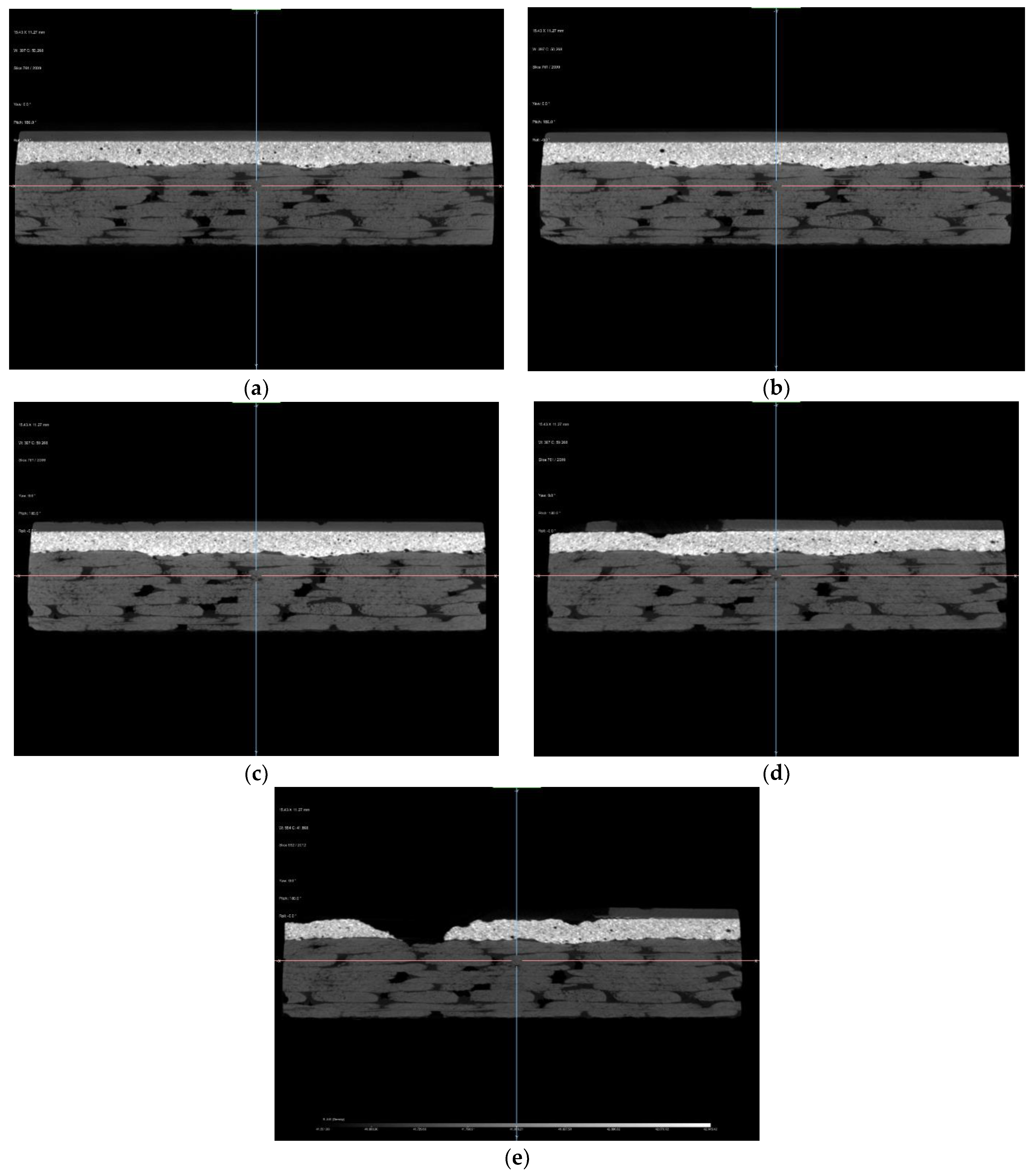

4.3. X-ray Computed Tomography (XCT)

4.4. Mass Loss during RET

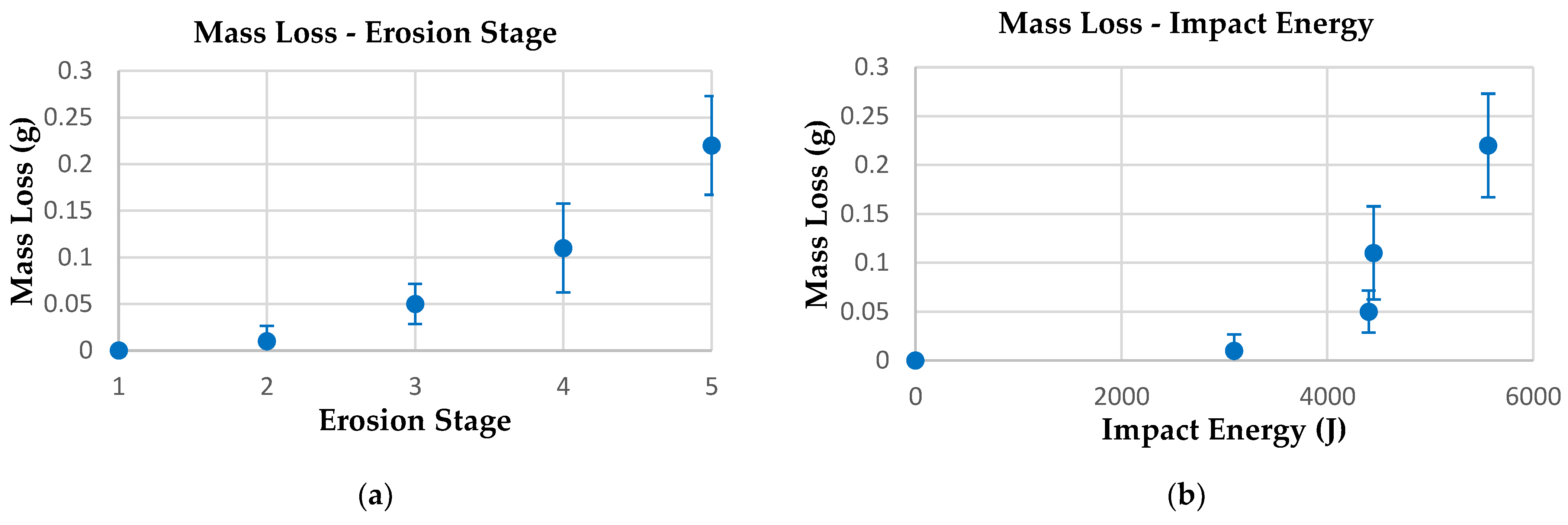

4.5. Results Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Keegan, M.; Nash, D.; Stack, M. On erosion issues associated with the leading edge of wind turbine blades. J. Phys. D Appl. Phys. 2013, 46, 383001. [Google Scholar] [CrossRef]

- Bartolomé, L.; Teuwen, J. Prospective challenges in the experimentation of the rain erosion on the leading edge of wind turbine blades. Wind Energy 2018, 22, 140–151. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Hasager, C.; Bak, C.; Tilg, A.; Bech, J.; Doagou Rad, S.; Fæster, S. Leading edge erosion of wind turbine blades: Understanding, prevention and protection. Renew. Energy 2021, 169, 953–969. [Google Scholar] [CrossRef]

- Han, W.; Kim, J.; Kim, B. Effects of contamination and erosion at the leading edge of blade tip airfoils on the annual energy production of wind turbines. Renew. Energy 2018, 115, 817–823. [Google Scholar] [CrossRef]

- Koodly Ravishankara, A.; Özdemir, H.; van der Weide, E. Analysis of leading edge erosion effects on turbulent flow over airfoils. Renew. Energy 2021, 172, 765–779. [Google Scholar] [CrossRef]

- ISO/TS 19392-1:2018. Paints and Varnishes—Coating Systems for Wind-Turbine Rotor Blades; BSI Standards Publication: London, UK, 2018. [Google Scholar]

- ASTM G73-10. Standard Test Method for Liquid Impingement Erosion Using Rotating Apparatus; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- DNVGL-RP-0171. Testing of Rotor Blade Erosion Protection Systems; DNVGL: Bærum, Norway, 2018. [Google Scholar]

- Elhadi Ibrahim, M.; Medraj, M. Water Droplet Erosion of Wind Turbine Blades: Mechanics, Testing, Modeling and Future Perspectives. Materials 2019, 13, 157. [Google Scholar] [CrossRef] [PubMed]

- Gaudern, N. A practical study of the aerodynamic impact of wind turbine blade leading edge erosion. J. Phys. Conf. Ser. 2014, 524, 012031. [Google Scholar] [CrossRef]

- Herring, R.; Dyer, K.; Martin, F.; Ward, C. The increasing importance of leading edge erosion and a review of existing protection solutions. Renew. Sustain. Energy Rev. 2019, 115, 109382. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Fæster, S.; Mikkelsen, L.; Kusano, Y.; Bech, J. Micromechanisms of leading edge erosion of wind turbine blades: X-ray tomography analysis and computational studies. Wind Energy 2019, 23, 547–562. [Google Scholar] [CrossRef]

- Mackie, C.; Nash, D.; Boyce, D.; Wright, M.; Dyer, K. Characterisation of a Whirling Arm Erosion Test Rig. In Proceedings of the 2018 Asian Conference on Energy, Power and Transportation Electrification (ACEPT), Singapore, 30 October–November 2018. [Google Scholar]

- Dragonfly 2020.2 [Computer Software]; Object Research Systems (ORS) Inc.: Montreal, QC, Canada, 2020; Available online: http://www.theobjects.com/dragonfly (accessed on 23 February 2021).

- Mishnaevsky, L.; Sütterlin, J. Micromechanical model of surface erosion of polyurethane coatings on wind turbine blades. Polym. Degrad. Stab. 2019, 166, 283–289. [Google Scholar] [CrossRef]

| Rotation Speed (RPM) | Linear Speed (m/s) |

|---|---|

| 700 | 75.1 |

| 800 | 85.9 |

| 900 | 96.6 |

| 1000 | 107.3 |

| 1100 | 118.1 |

| 1200 | 128.8 |

| 1300 | 139.5 |

| 1400 | 150.3 |

| Erosion Stage | A007 | A010 | A030 | A035 | A038 |

|---|---|---|---|---|---|

| Stage 2 | - | 60 min | 60 min | 80 min | 60 min |

| Stage 3 | - | 100 min | 90 min | 120 min | 100 min |

| Stage 4 | 60 min | 110 min | 115 min | 140 min | 120 min |

| Stage 5 | - | 120 min | 120 min | 145 min | 130 min |

| Title | A010 | A030 | A035 | A038 |

|---|---|---|---|---|

| Stage 1 | 0.38% | 0.36% | 0.71% | 0.27% |

| Stage 2 | 1.64% | 2.75% | 2.99% | 2.84% |

| Stage 3 | 1.37% | 6.30% | 4.81% | 3.44% |

| Stage 4 | 6.30% | 11.09% | 6.97% | 7.62% |

| Stage 5 | 30.66% | 36.78% | 12.78% | 56.10% |

| Title | A010 | A030 | A035 | A038 |

|---|---|---|---|---|

| Stage 1 | 0.63% | 0.92% | 0.69% | 0.52% |

| Stage 2 | 0.84% | 0.94% | 0.76% | 0.93% |

| Stage 3 | 1.83% | 1.14% | 1.31% | 1.03% |

| Stage 4 | 1.40% | 1.77% | 1.29% | 1.00% |

| Stage 5 | 4.52% | 4.65% | 3.11% | 8.22% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nash, D.; Leishman, G.; Mackie, C.; Dyer, K.; Yang, L. A Staged Approach to Erosion Analysis of Wind Turbine Blade Coatings. Coatings 2021, 11, 681. https://doi.org/10.3390/coatings11060681

Nash D, Leishman G, Mackie C, Dyer K, Yang L. A Staged Approach to Erosion Analysis of Wind Turbine Blade Coatings. Coatings. 2021; 11(6):681. https://doi.org/10.3390/coatings11060681

Chicago/Turabian StyleNash, David, Grant Leishman, Cameron Mackie, Kirsten Dyer, and Liu Yang. 2021. "A Staged Approach to Erosion Analysis of Wind Turbine Blade Coatings" Coatings 11, no. 6: 681. https://doi.org/10.3390/coatings11060681

APA StyleNash, D., Leishman, G., Mackie, C., Dyer, K., & Yang, L. (2021). A Staged Approach to Erosion Analysis of Wind Turbine Blade Coatings. Coatings, 11(6), 681. https://doi.org/10.3390/coatings11060681