The degradation rate of magnesium alloy in the human body is too fast, which will cause the generation of hydrogen. The reaction Equations are shown in (2) and (3). The hydrogen evolution reaction will lead to an increase in the pH value around the bone tissue, which will seriously affect the living environment of bone cells [

59]. Therefore, detecting the pH change of the simulated body fluid during the immersion process can reflect the hydrogen evolution rate of the magnesium alloy.

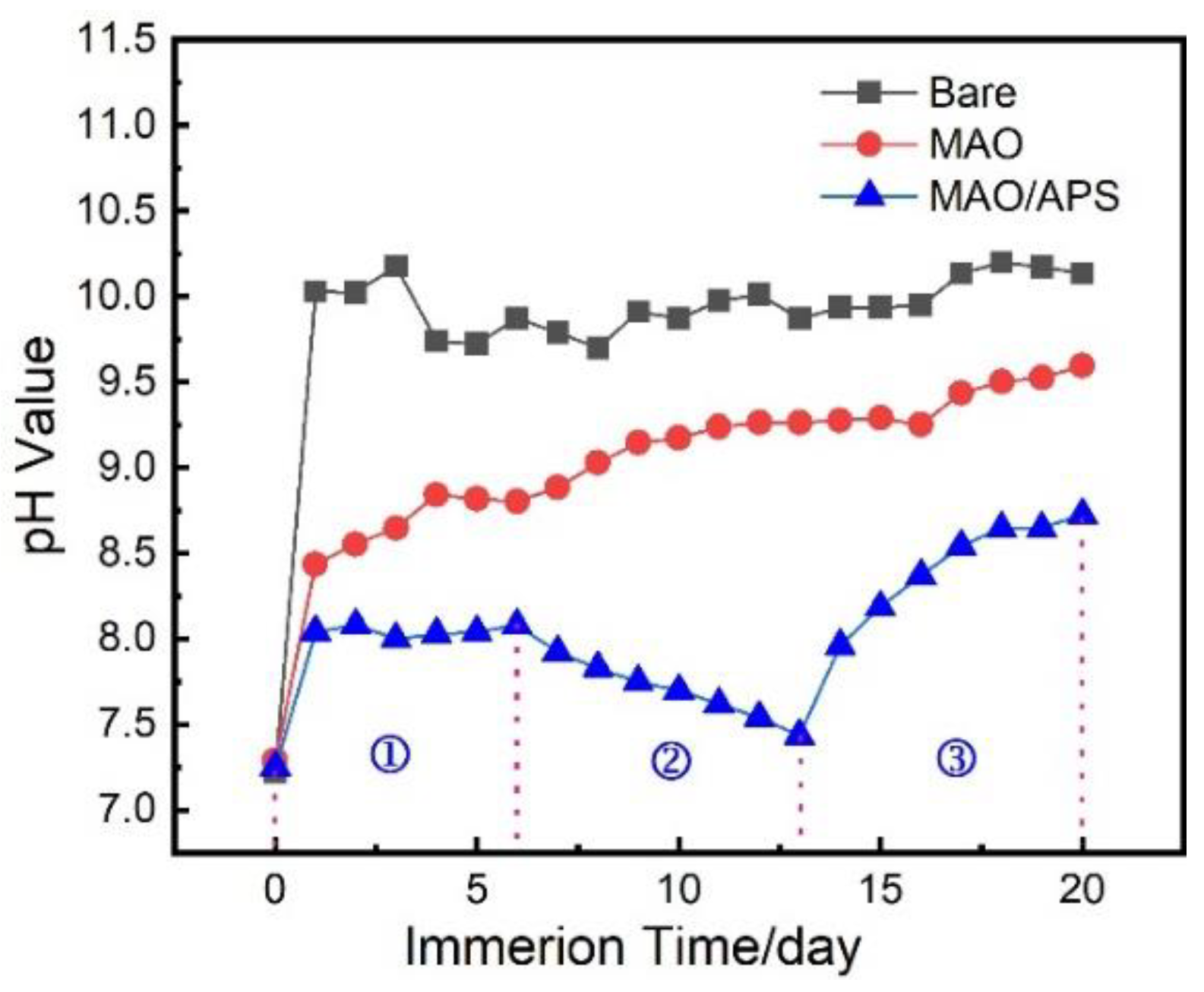

Figure 7 shows the pH of SBF as a function of immersion time. It can be seen from the figure that the pH values of the SBF immersed with the bare sample and the MAO sample are always higher than those of the MAO/APS sample during immersion for 20 days.

For the composite coatings, the pH value during the immersion process is always at a relatively low level, and the change over time shows a “V” shape. The change process consists of three parts. As shown in the figure, the pH value of the SBF solution in the first stage is at a stable stage; it is basically unchanged. The second stage has a certain decrease. After 15 days, it enters the third stage, and the pH value of SBF begins to rise gradually. At the initial stage of immersion, the composite coating may only dissolve part of the amorphous phase in the simulated body fluid. Since the amorphous structure in the local area of the composite coating cannot be fully crystallized, it will dissolve faster during the immersion process [

17,

61,

62]. Therefore, in the initial immersion process, the coating mainly locally dissolves, and the pH value of SBF is almost unchanged. The dissolution of the amorphous structure produces the Ca

2+ and PO

43− in the SBF solution. As time goes by, calcium and phosphorus compounds may be deposited on the local area of the composite coating. During the experiment, it is found that the surface of the coating is white. The production of corrosion products consumes OH– in the SBF during this process; hence, the pH value of the SBF drops. With the prolongation of the immersion time (the third stage), the surface of the composite coating has undergone local dissolution and deposition, and the coating becomes loose. At this moment, the corrosive medium in the SBF enters the coating, causing a corrosion reaction; hence, the pH value of the system begins to gradually rise.

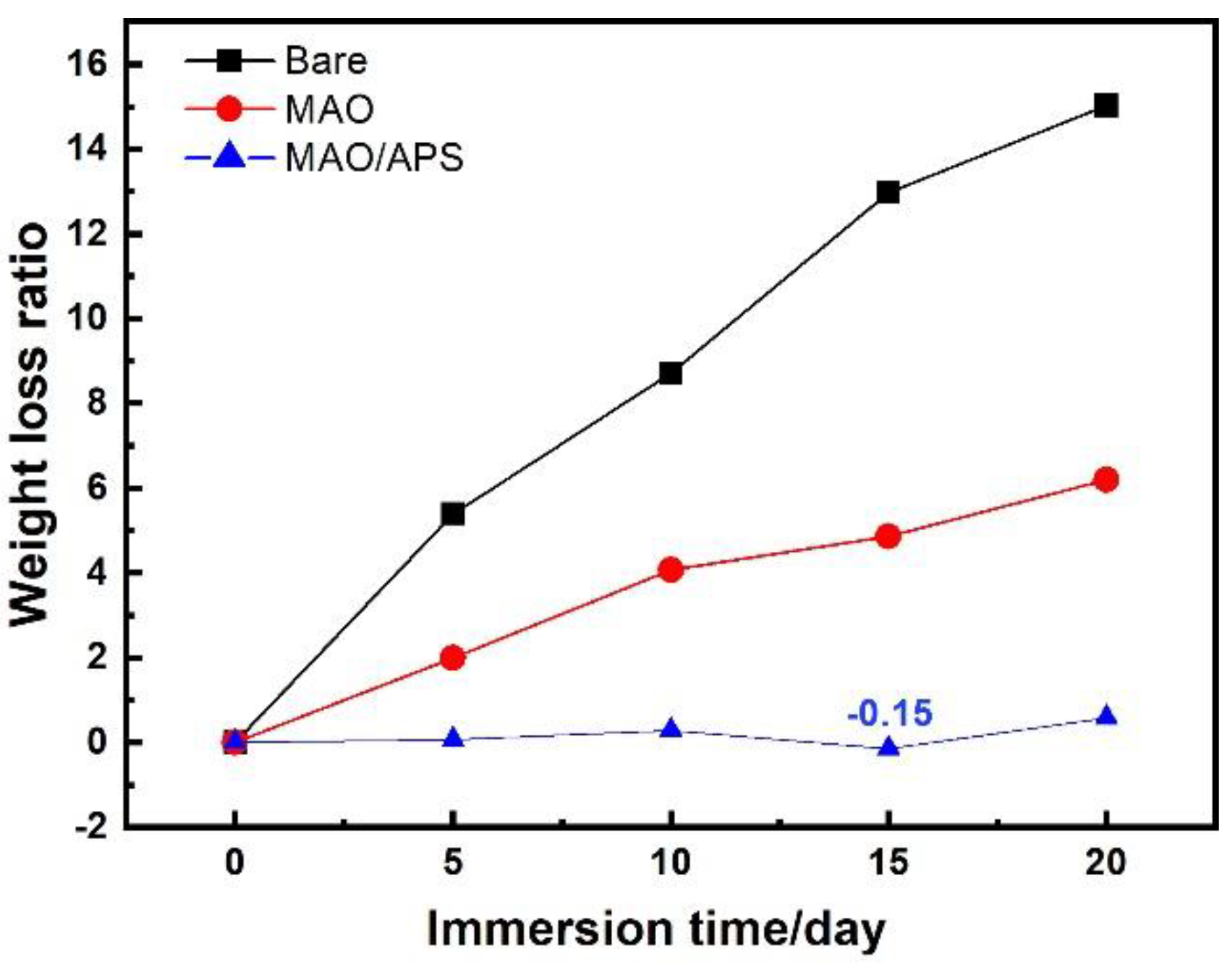

Figure 8 shows the weight loss of the sample during immersion in simulated body fluid. It can be seen from

Figure 8 that the weight loss rates of bare samples, MAO samples and MAO/APS samples decrease in the SBF. For bare samples and MAO samples, as the immersion time increases, the substrate or coating is gradually corroded and degraded; hence, the weight loss rates of the samples gradually increase. As for the MAO/APS sample, there is the dissolution of the amorphous phase and the deposition of corrosion products during the immersion. Therefore, the weight loss rate of the MAO/APS sample gradually increases in the initial stage.

When the immersion was carried out for 15 days, the weight loss ratio of the sample showed a negative value for the first time. It could be indicated that the deposited amount of the corrosion products on the surface was greater than the dissolved amount of the coating. The degradation process of the composite coating in the immersion test becomes more complicated.

The surface coating of HA coating is beneficial in terms of inducing the accumulation of corrosion products containing Ca–P in the solution during the immersion process, the inner coating of MAO and the outer coating of HA, under the joint action of the coating. For this reason, the substrate is significantly protected from corrosion by corrosive media. Comparing the bare sample and the MAO sample, it can be seen that the corrosion resistance of the MAO/APS sample is greatly improved. During the 20-day simulated body fluid immersion process, the total weight loss rate is only 0.58%.

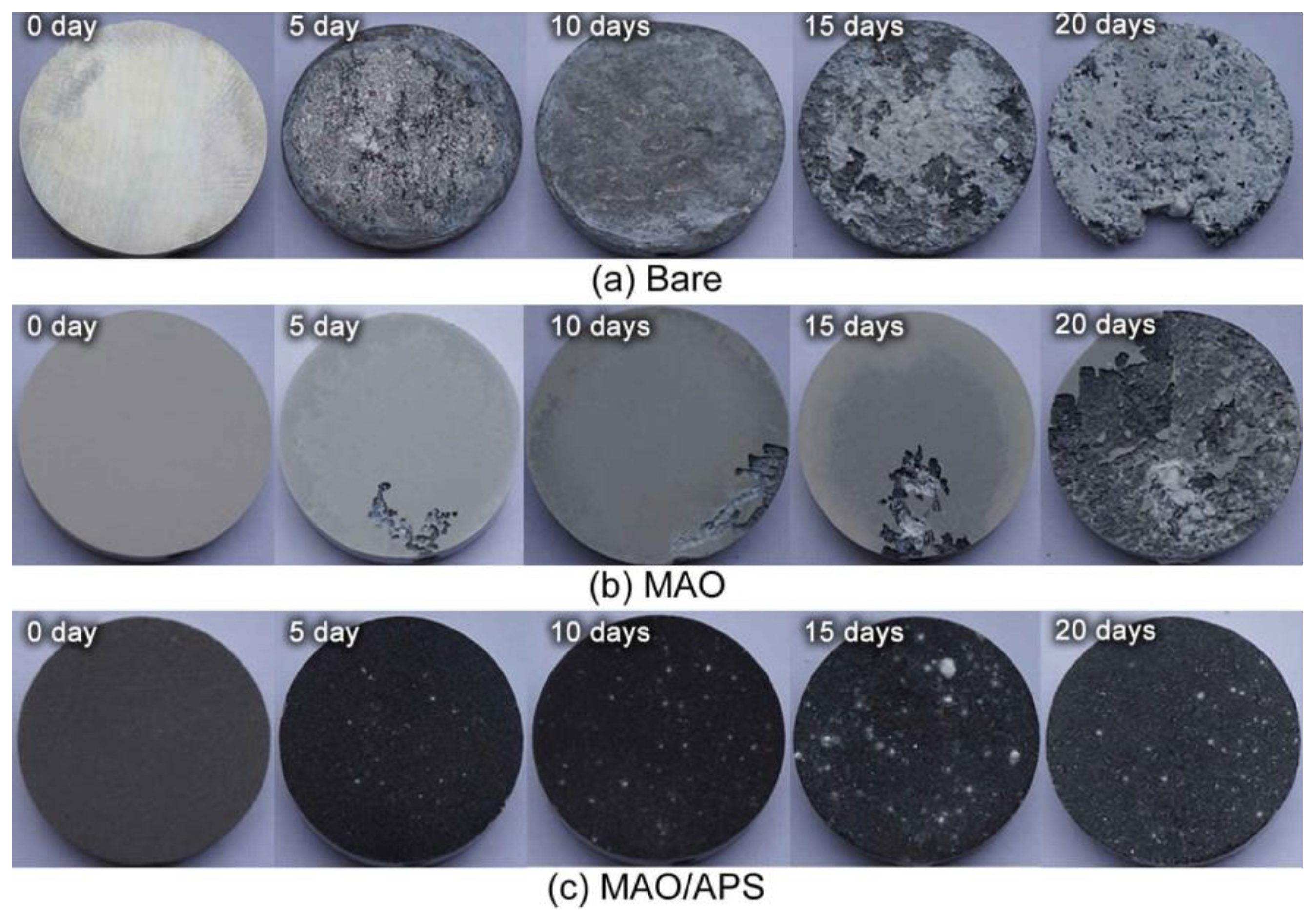

3.4.2. Changes in the Macroscopic Corrosion Morphology of the Sample

Figure 9 shows the comparison of the morphology of the bare sample, MAO sample, and MAO/APS sample after immersion in SBF solution for different numbers of days. It can be seen that during the degradation process of the bare sample in the SBF solution, uniform corrosion and local corrosion take place, and the local corrosion always takes precedence over the uniform corrosion (

Figure 9a). With the extension of the immersion time, the corrosive medium gradually enters from the corrosion pit and/or from the corners to the center. On the 20th day, the corner area begins to fall off, and the surface is extremely rough.

The degradation of the MAO sample in the SBF solution is stable (

Figure 9b). In the long-term immersion process, the corrosion mainly takes place at the corners of the sample and finally leads to the peeling off of the MAO coating. On the 20th day, a small amount of the MAO coating on the surface of the sample is still present.

For the MAO/APS sample, there was no obvious change during the 20-day immersion process. On the 20th day, the sample still maintained the original integrity, and no obvious corrosion degradation on the surface is found.

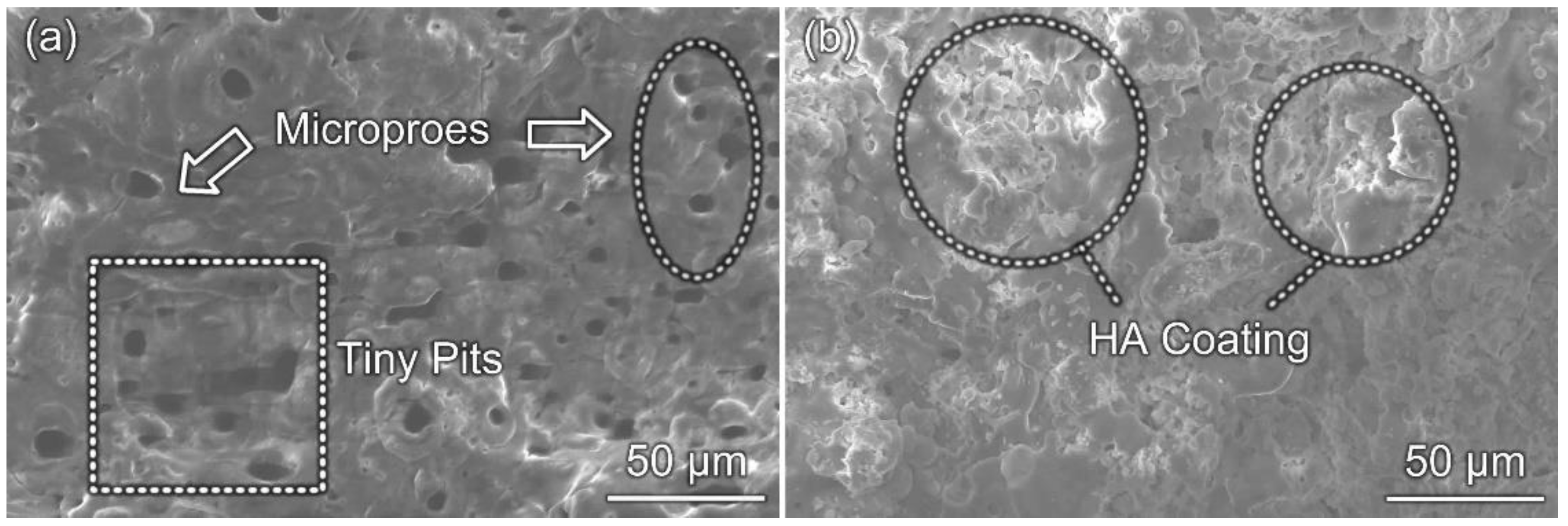

Figure 10 shows the surface micro-topography of MAO/APS samples with immersion time. The surface of the MAO/APS sample before immersion is rough and uneven. At the initial stage of immersion, the surface of the sample is formed by a considerable number of ellipsoidal particles. As the immersion time is prolonged, the phenomenon of the accumulation of clumps can be observed in local areas. The cracks gradually spread, which divide the surface into a large number of irregular tiny polygonal shapes. Because the HA coating on the surface of the composite coating is not completely crystallized, it contains the amorphous structure and decomposition phases produced during the spraying. The decomposition phases that follow the immersion time are speculated to be hydroxy-carbonate-apatite (HCA) [

63]. These decomposition products degrade in SBF solution. The rate is much higher than the degradation rate of HA crystals [

64]. Therefore, in the initial stage of immersion, the ACP and decomposition phase in the coating preferentially dissolve. Due to the production of ACP and decomposition phases, supersaturated Ca

2+ and PO

43+ are produced in the SBF solution, and the deposition of Ca–P compounds is prone to take place with the extension of the immersion time, as shown in

Figure 10c.

In

Figure 10b–d, the existence of cracks (yellow dotted line position) can be clearly observed. As the immersion time increases, the cracks gradually spread from scattered small shapes to continuous thick and deep shapes. Li et al. [

65,

66,

67] reported that cracks are produced as a result of the volume shrinkage effect caused by the loss of moisture in the coating during the drying process. Apparently, such a statement cannot fully explain this phenomenon. The occurrence of the spreading of cracks may be related to the phenomenon of local corrosion [

68]. Due to the inhomogeneity of the surface HA coating composition, the degradation rate of the local area is inconsistent; hence, corrosion is easily introduced at the interface position. As the immersion time increases, the corrosion gradually spreads, causing the cracks to expand. The coating is gradually divided into small pieces when the cracks are connected, which eventually causes the coating to fail.

3.4.3. Corrosion Products on the Surface of Coatings

Table 7 shows the changes of element content on the surface of the coating under different immersion times. It can be found that the contents of Ca and P elements increase with the immersion time, which reaches the maximum value after 15 days of immersion. The weight loss ratios of the samples can also show that the MAO/APS sample has a slight increase in weight on the 15th day, indicating that the amount of Ca–P compound deposited is greater than the local dissolution of the coating. In the later stage of immersion, Si is presented in the coating, and this element is a constituent element of the MAO coating, indicating that the composite coating, at this time, has begun to gradually fall off the HA coating.

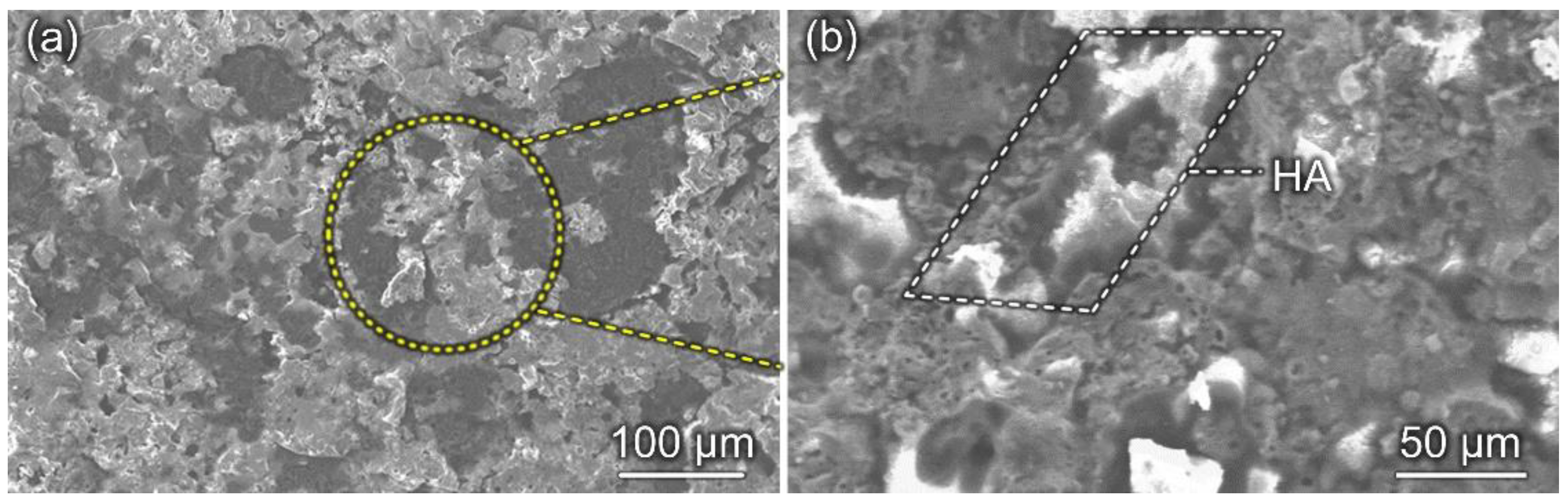

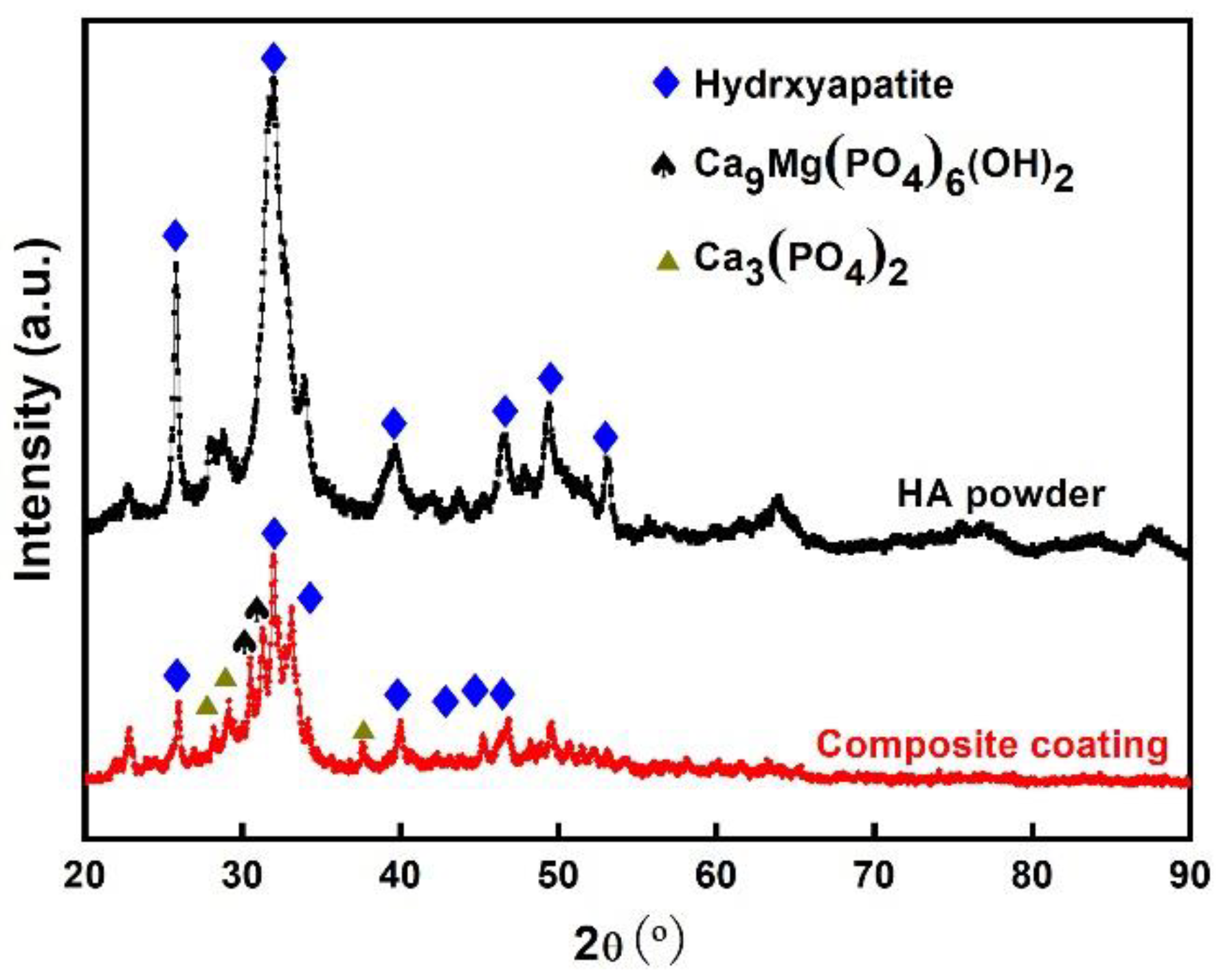

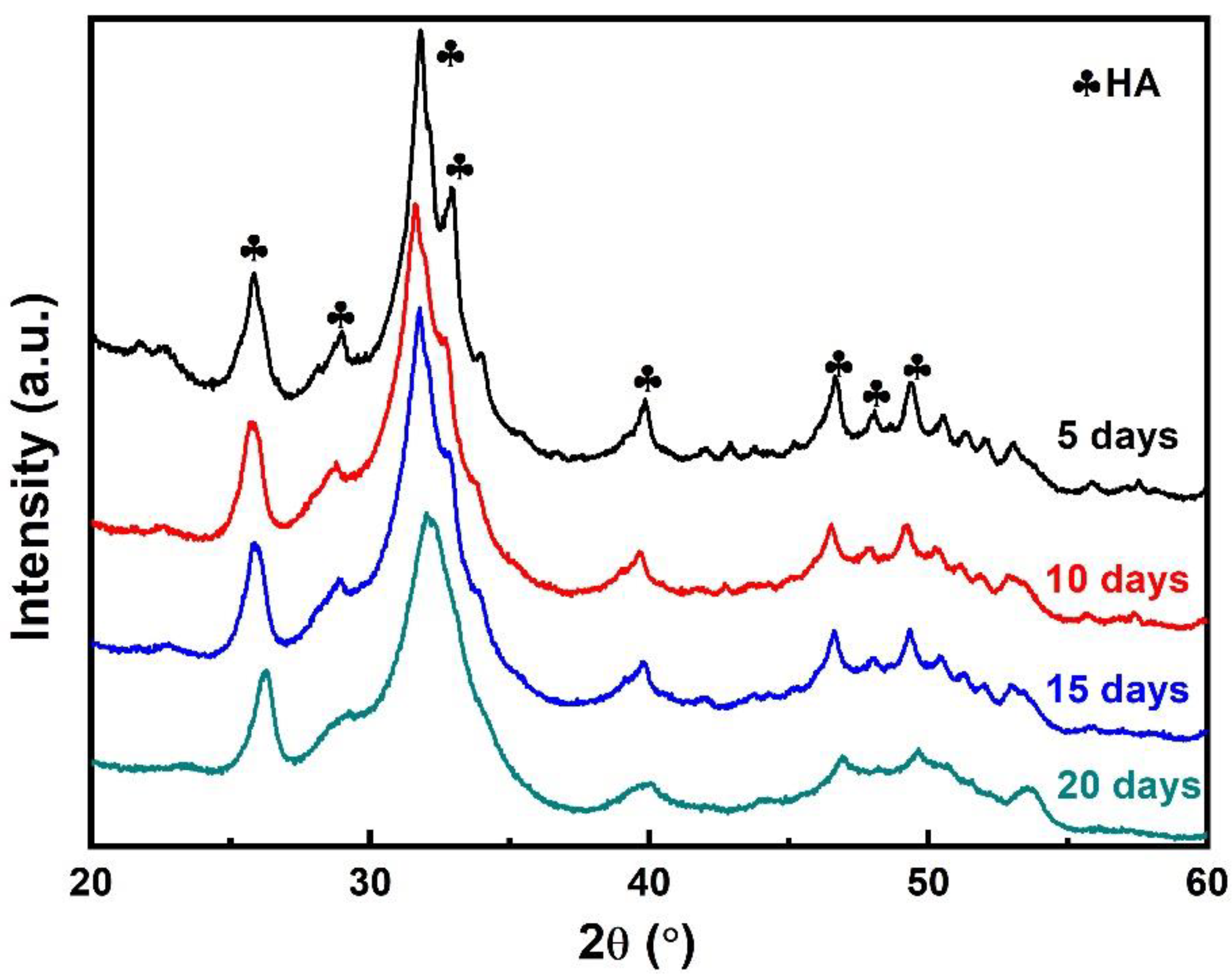

It can be seen from XRD in

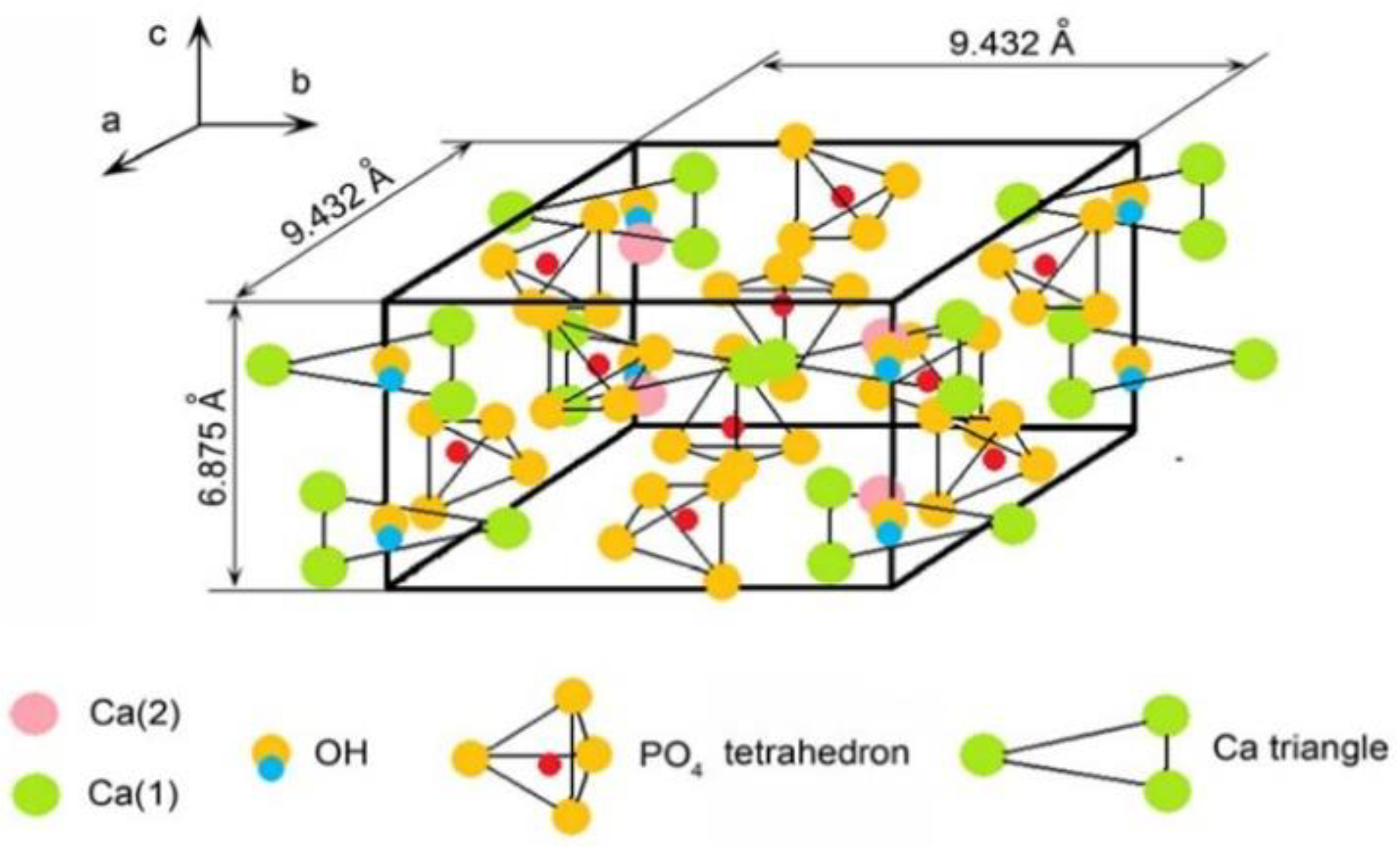

Figure 11 that under different immersion times, the product on the surface of the coating is mainly HA. On one hand, the initial dissolution of the amorphous phase and the decomposition phase promotes the induction of HA. In the initial stage, the surface of the implant forms certain osseointegration with bone tissue, which has good biological characteristics. On the other hand, there is no obvious compound of C in the XRD pattern; hence, it is speculated that the C element may be due to the formation of CO

32− containing calcium-deficient hydroxyapatite (hydroxy-carbonate-apatite, HCA). HCA is similar to the human body’s natural bone composition, so it is also called “hydroxyapatite-like”. The main reason for its formation is that the CO

32− ions in the simulated body fluid replace the hydroxyl or phosphate in the HA crystal lattice, forming the A-type, B-type or AB-type substituted hydroxyapatite carbonate [

69].

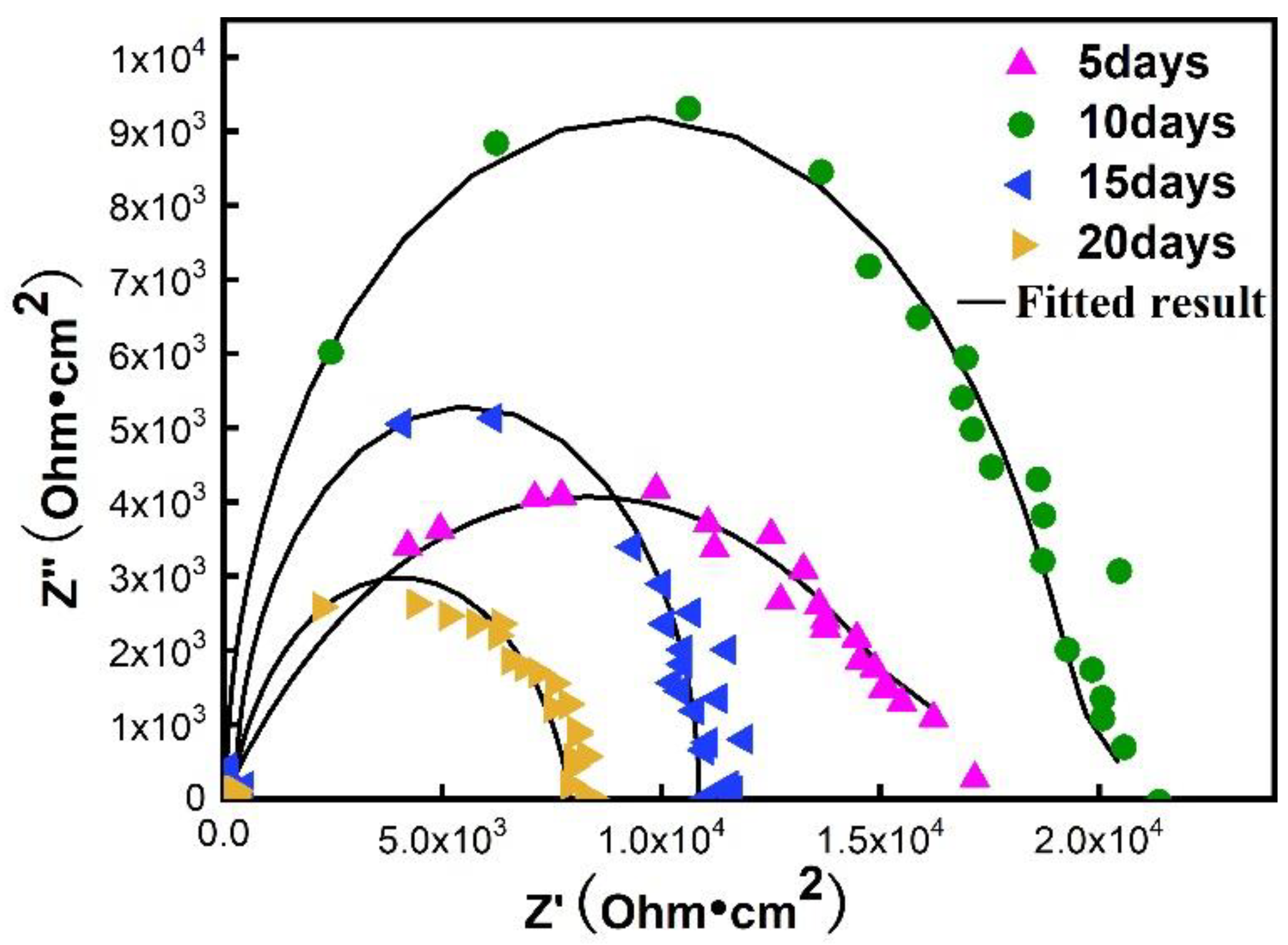

Figure 12 shows the Nyquist diagrams of the immersed samples; it can be found that the radius of the capacitive reactance loop and the impedance value at the low-frequency end of the MAO/APS, immersed for the tenth day, are at their maximum, and that the charge transfer resistance

Rct, during the corrosion reaction, is the largest. At this moment, the sample shows good corrosion resistance. The reason may be that when the sample is immersed for the tenth day, the deposition of Ca–P compound on the surface is preferentially formed at the defect, which has a good inhibitory effect on the further penetration of the corrosive medium into the coating. It can also be seen from the fitted data that the resistance

Rcp, representing the corrosion product, exhibits a maximum value at this time. When immersed for 20 days, the

Rct was the smallest, which indicates that the deposition rate of Ca–P compound on the surface was significantly lower than the degradation rate of the coating. It can be seen from

Figure 10 that the coating was dissolved after 15 days of immersion. Meanwhile, a certain amount of active Ca and P elements could be produced in the SBF solution during the degradation process. Hence, the biological activity of the composite coating presents a gradient change during the SBF solution immersion process, which is different from the immersion process of the MAO coating. To sum up, good corrosion resistance and biocompatibility can be received from the MAO/APS composite bio-coating.

According to the degradation model of AZ31 magnesium alloy in SBF, proposed by Gu et al. [

70] and Khalajabadi et al. [

71] to describe the degradation behavior of Mg/HA/MgO nanostructured materials prepared by powder metallurgy in SBF, combined with MAO/APS sample immersion process phenomena and analysis test results, the degradation model, and the equivalent circuit, are proposed. These are considered in accordance with the MAO/APS composite coating in SBF, which are mainly divided into the following three stages, and

Table 8 lists the fitted result of EIS:

During the initial immersion process of the composite membrane, a dissolution process mainly occurs. The Ca and P ions produced by the dissolution accumulate on the surface in a short time. These free Ca and P ions are easily absorbed by the damaged bone tissue to promote its growth. Therefore, part of the amorphous structure and decomposition phase existing in the HA coating is conducive, to a certain extent, to the recovery and growth of damaged bones. The equivalent circuit is shown in

Figure 13a, which mainly includes three pairs of Constant Phase Element (CPE), where Rs, Rh, and Rm represent solution resistance, HA coating resistance, and MAO coating resistance, respectively.

- 2.

Middle period of immersion

On the one hand, due to the inconsistency of the decomposition phase (HCA), amorphous structure and crystalline HA degradation rate at the initial stage of immersion, the microcracks generated at the interface between each other expand during the middle stage of immersion, as shown in

Figure 13b. On the other hand, the large amount of calcium and phosphorus ions produced by the rapid degradation of the amorphous structure and the decomposition phase produce supersaturation in the local area of the composite coating, especially at the surface defects of the composite coating. These ions react with the ions in the SBF. Ca–P compounds are formed at the coating defects and deposited on the surface. The possible reactions are represented in Equations (5) and (6). It should be noted here that HA may be crystalline hydroxyphosphorus. Greystone may also be hydroxyapatite-like, but both have good biological activity. On the other hand, as shown in

Figure 13, new HA formation occurs, at this time, on the surface of the membrane, as well as the continuous expansion of cracks, and the continuous penetration of simulated body fluids into the membrane. This phenomenon is conducive to the recovery of the implant in the bone injury tissue during the formation of osseointegration. Due to the formation of the new phase of HA, the corrosion product resistance

Rcp appears in the equivalent circuit.

- 3.

Late time of immersion

With the progression of the immersion test, the existence of cracks and micropores causes the surface HA coating to further fail and gradually fall off. The corrosive medium further penetrates the interior and contacts the substrate. Due to the existence of the MAO coating, the service cycle of the implant during bone healing is prolonged. During the continuous immersion process, the MAO coating will gradually degrade, participate in the normal metabolism of bone growth, and be excreted from the body.