Influence of the Bottom Color Modification and Material Color Modification Process on the Performance of Modified Poplar

Abstract

1. Introduction

2. Experiment

2.1. Materials

2.2. Preparation of Sample

2.3. Testing and Characterization

3. Results and Discussion

3.1. Analysis of Factors Affecting Coloring Process Performance

3.2. The Influence of Different Surface Pretreatments on the Coloring Effect

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, X.X. Effect of different color paste on properties of fluorine resin/aluminum infrared low emissivity coating. Coatings 2020, 10, 70. [Google Scholar] [CrossRef]

- Yan, X.X.; Chang, Y.J.; Qian, X.Y. Effect of concentration of thermochromic ink on performance of waterborne finish films for the surface of cunninghamia lanceolata. Polymers 2020, 12, 552. [Google Scholar] [CrossRef]

- Cakicier, N.; Korkut, S.; Korkut, D.S. Varnish nayer hardness, scratch resistance, and golssiness of various wood species as affected by heat treatment. Bioresources 2011, 6, 1648–1658. [Google Scholar]

- Yan, X.X.; Han, Y.; Yin, T.Y. Synthesis of urea-formaldehyde microcapsule containing fluororesin and its effect on performances of waterborne coatings on wood surface. Polymers 2021, 13, 1674. [Google Scholar] [CrossRef]

- Yan, X.X.; Zhao, W.T.; Qian, X.Y. Effect of water-based emulsion core microcapsules on aging resistance and self-repairing properties of water-based coatings on Linden. Appl. Sci. 2021, 11, 4662. [Google Scholar] [CrossRef]

- Yan, X.X.; Peng, W.W. Effect of microcapsules of a waterborne core material on the properties of a waterborne primer coating on a wooden surface. Coatings 2021, 11, 657. [Google Scholar]

- Salca, E.A.; Krystofiak, T.; Lis, B.; Mazela, B.; Proszyk, S. Some coating properties of Black Alder Wood as a function of varnish type and application method. Bioresources 2016, 11, 7580–7594. [Google Scholar] [CrossRef]

- Paula, M.H.; Mesquita, R.R.S.; Costa, M.D.; Goncalez, J.C.; Ananias, R.A.; Janin, G. Effect of applying finishing products and sanding on the surface of marupa wood. Maderas. Ciencia y Tecnología 2020, 22, 45–54. [Google Scholar] [CrossRef]

- Meijer, M.; Thurich, K.; Militz, H. Comparative study on penetration characteristics of modern wood coatings. Wood Sci. Technol. 1998, 32, 347–365. [Google Scholar] [CrossRef]

- Moura, L.F.; Brito, J.O.; Nolasco, A.M.; Uliana, L.R.; De Muniz, G.I.B. Evaluation of coating performance and color stability on thermally rectified eucalyptus grandis and pinus caribaea war. Wood Res. 2013, 5, 231–242. [Google Scholar]

- Hernandez, R.E.; Cool, J. Evaluation of three surfacing methods on paper birch wood in relation to water- and solvent-borne coating performance. Wood Fiber Sci. 2008, 40, 459–469. [Google Scholar]

- Pelit, H.; Budakci, M.; Sonmez, A.; Burdurlu, E. Surface roughness and brightness of scots pine (Pinus sylvestris) applied with water-based varnish after densification and heat treatment. J. Wood Sci. 2015, 61, 586–594. [Google Scholar] [CrossRef]

- Aksoy, A.; Deveci, M.; Baysal, E.; Toker, H. Colour and gloss changes of socts pine after heat modification. Wood Res. 2011, 56, 329–336. [Google Scholar]

- Yan, X.X.; Wang, L.; Qian, X.Y. Effect of coating process on performance of reversible thermochromic waterborne coatings for Chinese Fir. Coatings 2020, 10, 223. [Google Scholar] [CrossRef]

- Goncalez, J.C.; Felix, T.L.F.; Gouveia, F.N.; Camargos, J.A.A.; Ribeiro, P.G. Effect of ultraviolet radiation on the color of freijo wood (Cordia goeldiana Huber) after application of finishing products. Ciência Florest. 2010, 20, 657–664. [Google Scholar]

- Imirzi, H.O.; Ulker, O.; Burdurlu, E. Effect of densification temperature and some surfacing techniques on the surface roughness of densified scots pine (Pinus sylvestris L.). Bioresources 2014, 9, 191–209. [Google Scholar] [CrossRef]

- Demirci, Z.; Sonmez, A.; Budakci, M. Effect of thermal ageing on the gloss and the adhesion strength of the wood varnish layers. Bioresources 2013, 8, 1852–1867. [Google Scholar] [CrossRef]

- Nejad, M.; Shafaghi, R.; Ali, H.; Cooper, P. Coating performance on oil-heat treated wood for flooring. Bioresources 2013, 8, 1881–1892. [Google Scholar] [CrossRef]

- Baysal, E.; Tomak, E.D.; Ozbey, M.; Altin, E. Surface properties of impregnated and varnished scots pine wood after accelerated weathering. Color Technol. 2014, 130, 140–146. [Google Scholar] [CrossRef]

- Gong, M.; Lamason, C.; Li, L. Interactive effect of surface densification and post-heat-treatment on aspen wood. J. Mater. Process. Technol. 2010, 210, 293–296. [Google Scholar] [CrossRef]

- Korkut, D.S.; Korkut, S.; Bekar, I.; Budakci, M.; Dilik, T.; Cakicier, N. The effects of heat treatment on the physical properties and surface roughness of Turkish Hazel (Corylus colurna L.) wood. Int. J. Mol. Sci. 2008, 9, 1772–1783. [Google Scholar] [CrossRef] [PubMed]

- Mendes, T.J.; Gonalez, J.C.; Teles, R.F.; Lima, C.M. Effect of artificial weathering on wood laminates color treated with two finishing products. Cerne 2016, 22, 101–109. [Google Scholar] [CrossRef][Green Version]

- Liu, Q.Q.; Gao, D.; Xu, W. Effect of sanding processes on the surface properties of modified poplar coated by primer compared with mahogany. Coatings 2020, 10, 856. [Google Scholar] [CrossRef]

- Yan, X.X.; Zhao, W.T.; Qian, X.Y. Effect of urea-formaldehyde (UF) with waterborne emulsion microcapsules on properties of waterborne acrylic coatings based on coating process for American Lime. Appl. Sci. 2020, 10, 6341. [Google Scholar] [CrossRef]

- Wang, L.; Yan, X.X. Mechanical and optical properties of thermochromic reversible waterborne primer film on Tilia europaea with 1,2-benzo-6-diethylaminofluorane based microcapsules. Polymers 2020, 12, 2062. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.X.; Qian, X.Y.; Lu, R.; Miyakoshi, T. Comparison and optimization of reactive dyes and coating performance on Fraxinus mandshurica veneer. Polymers 2018, 10, 1302. [Google Scholar] [CrossRef]

- Yan, X.X.; Tao, Y.; Qian, X.Y. Preparation and optimization of waterborne acrylic core microcapsules for waterborne wood coatings and comparison with epoxy resin core. Polymers 2020, 12, 2366. [Google Scholar] [CrossRef] [PubMed]

| Species | Enterprise | Origin | The Main Component |

|---|---|---|---|

| Didebao | Mingshida Co., Ltd. | Taian, China | water, oil, resin, pigment, thinner, auxiliary materials |

| Modified poplar | Jiayue Wood Industry Co., Ltd. | Dezhou, China | – |

| Mahogany | Jiayue Wood Industry Co., Ltd. | Dezhou, China | – |

| Red paint water | Bixiang Wood Co., Ltd. | Ganzhou, China | 4.35% disperse, 26.09% N-dimethylformamide, 34.8% cyclohexanone, 30.41% butyl acetate, 4.35% Q22-1 nitro varnish |

| Yellow paint water | Bixiang Wood Co., Ltd. | Ganzhou, China | 4.48% dispersible yellow RGFL, 29.85% N-dimethylformamide, 41.79% cyclohexanone, 23.88% butyl acetate ester |

| Grace | Nippon Co., Ltd. | Singapore | 53.59% refined linseed oil, 10% extender pigment calcium carbonate, 15% color pigment C.IPigment Red 101 77491, 20% turpentine solvent, 0.5% dispersant, 0.3% organic drier, 0.1% antioxidant, 0.5% cobalt salt, 0.01% manganese salt |

| Sample (#) | Specific Instructions |

|---|---|

| 1 | modified poplar—don’t brush primer—no sanding—1/3 bottom modification color—1/3 material modification color |

| 2 | modified poplar—brush primer—no sanding—1/3 bottom modification color—1/3 material modification color |

| 3 | modified poplar—brush primer—180# sanding—1/3 bottom modification color—1/3 material modification color |

| 4 | modified poplar—brush primer—240# sanding—1/3 bottom modification color—1/3 material modification color |

| 5 | modified poplar—brush primer—320# sanding—1/3 bottom modification color—1/3 material modification color |

| 6 | modified poplar—brush primer—400# sanding—1/3 bottom modification color—1/3 material modification color |

| 7 | mahogany—brush primer—320# sanding—1/3 bottom modification color—1/3 material modification color |

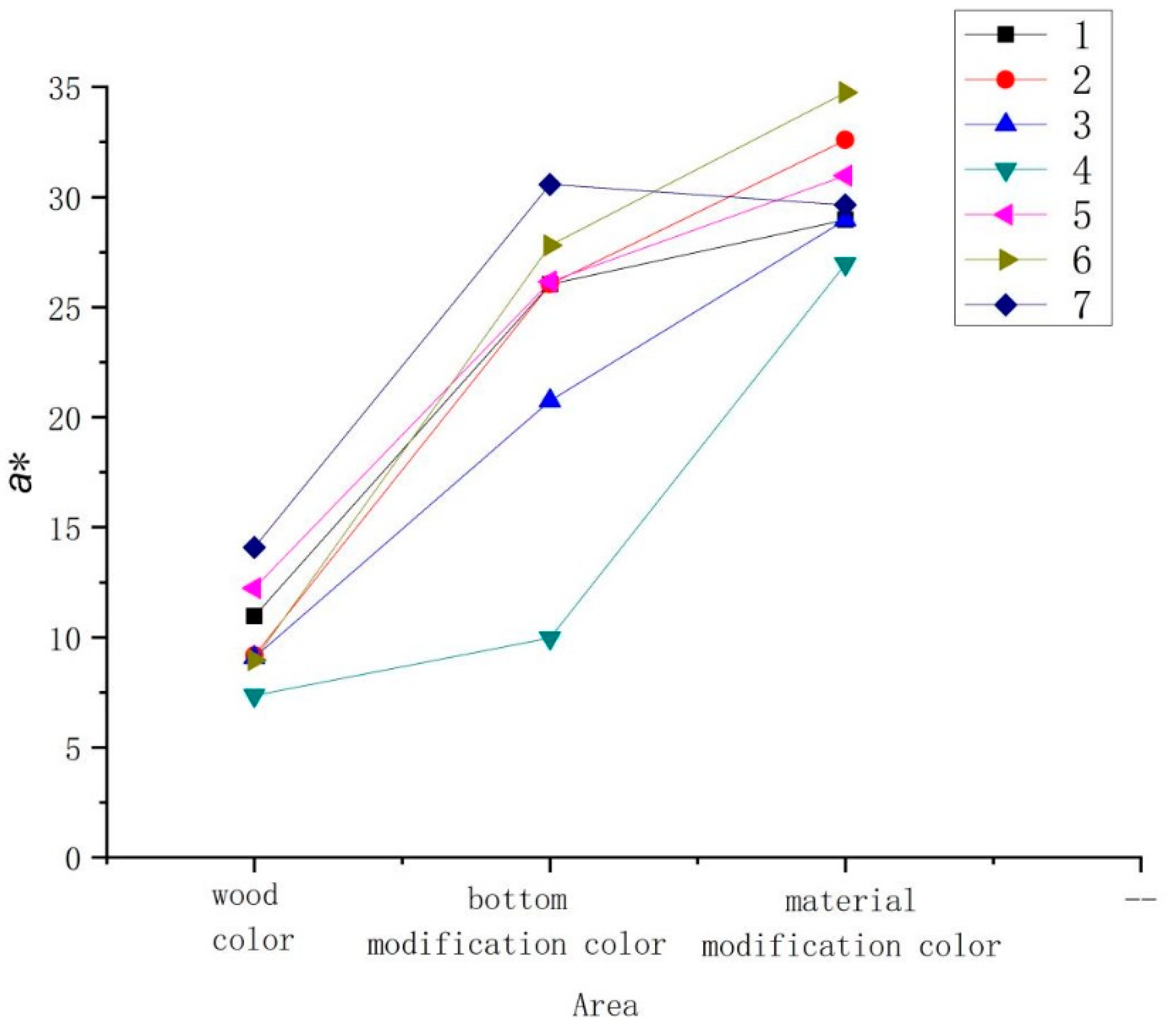

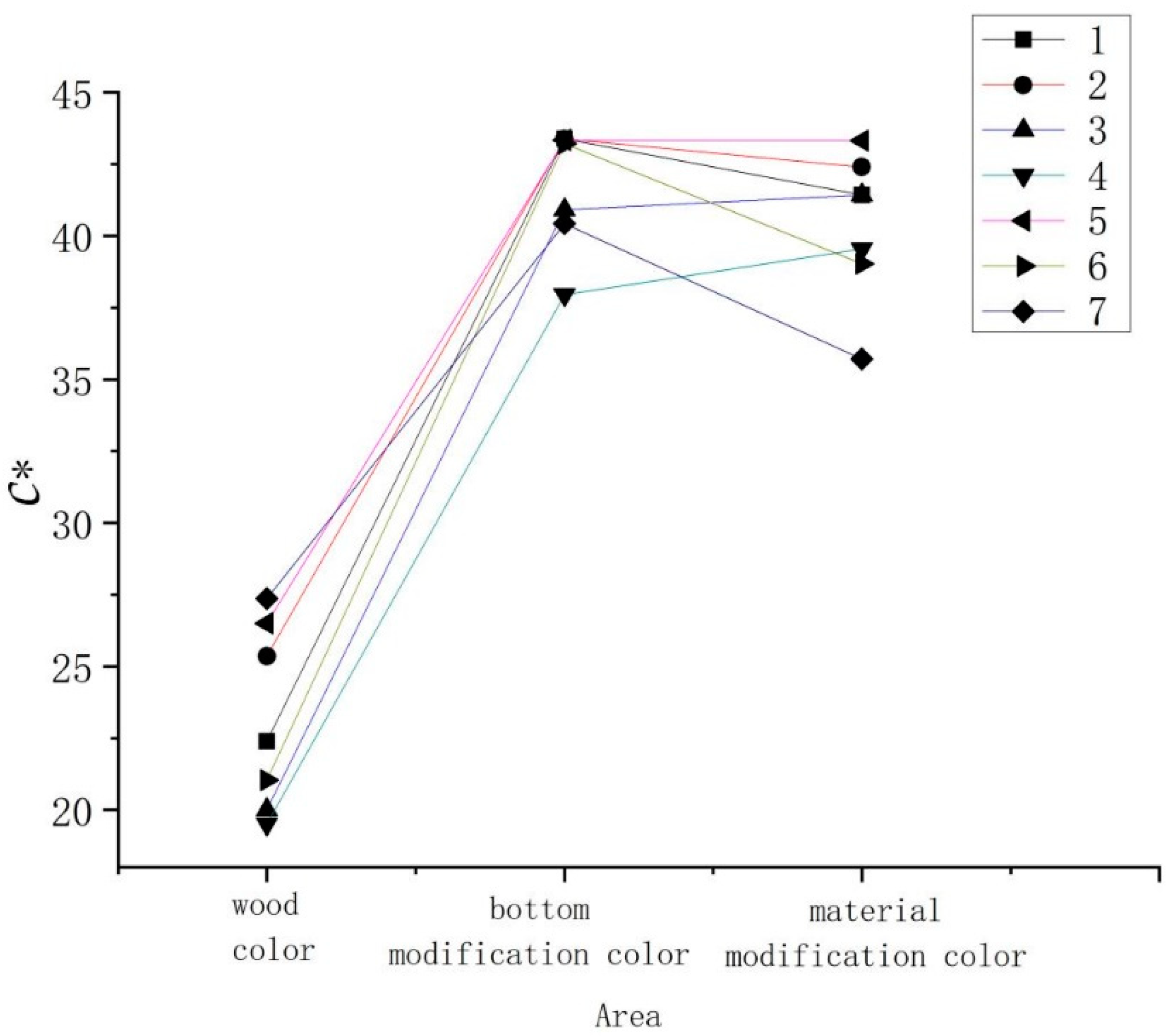

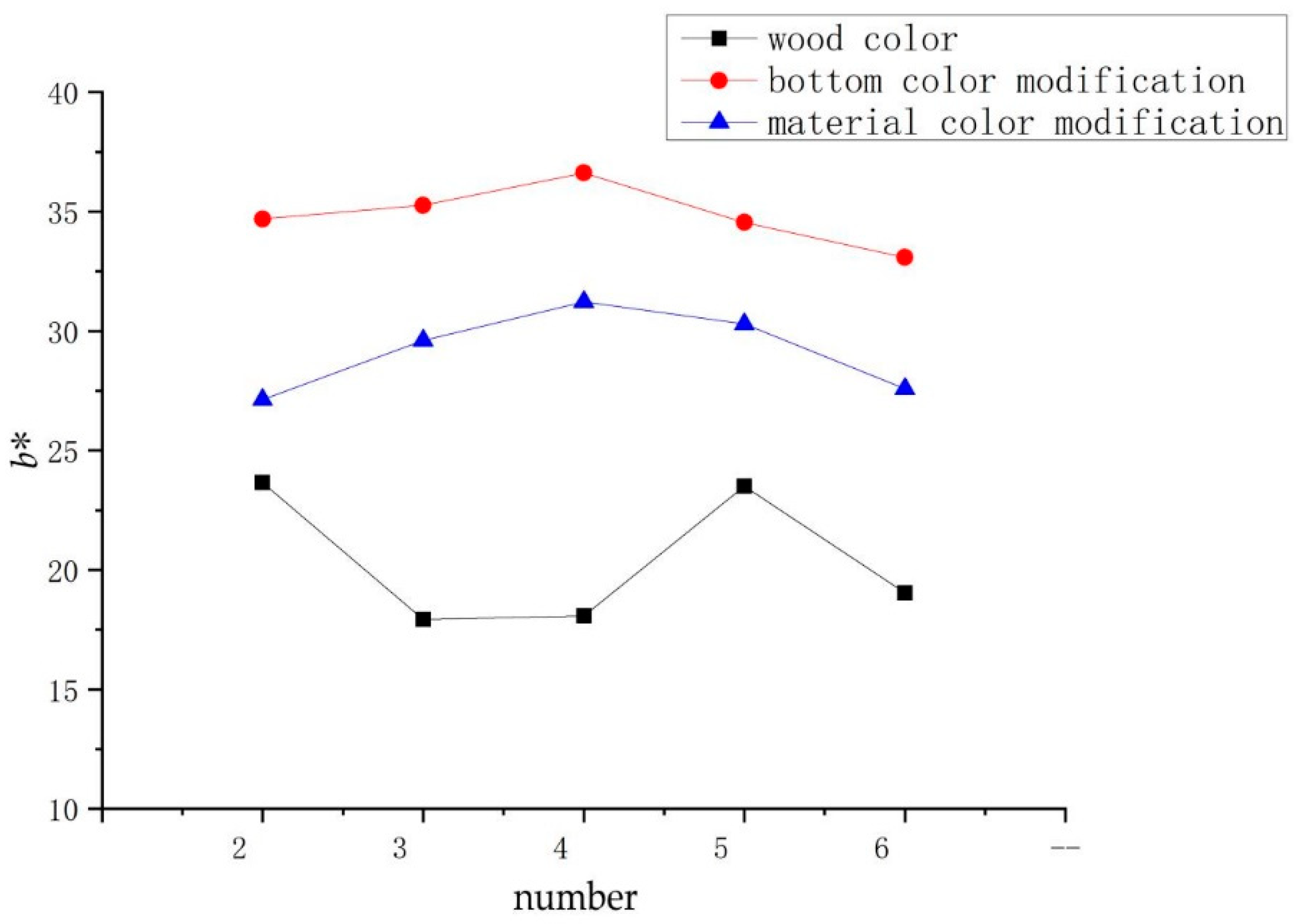

| Sample (#) | Area | L* | a* | b* | ΔE* |

|---|---|---|---|---|---|

| 1 | wood color | 72.01 ± 1.9 | 10.95 ± 0.25 | 19.52 ± 0.46 | – |

| bottom modification color | 43.22 ± 1.05 | 26.04 ± 0.6 | 34.69 ± 1.35 | 35.87 | |

| material modification color | 31.69 ± 0.74 | 28.97 ± 0.71 | 29.61 ± 0.7 | 12.93 | |

| 2 | wood color | 62.42 ± 1.56 | 9.17 ± 0.22 | 23.65 ± 0.59 | – |

| bottom modification color | 43.22 ± 1.08 | 26.04 ± 0.65 | 34.69 ± 0.86 | 27.85 | |

| material modification color | 31.92 ± 0.79 | 32.59 ± 0.81 | 27.12 ± 0.67 | 15.09 | |

| 3 | wood color | 71.30 ± 1.77 | 9.09 ± 0.22 | 17.93 ± 0.44 | – |

| bottom modification color | 40.45 ± 1.01 | 20.74 ± 0.518 | 35.26 ± 0.88 | 37.26 | |

| material modification color | 31.69 ± 0.79 | 28.97 ± 0.72 | 29.61 ± 0.74 | 13.28 | |

| 4 | wood color | 63.90 ± 1.59 | 7.35 ± 0.18 | 18.07 ± 0.45 | – |

| bottom modification color | 41.87 ± 1.04 | 9.97 ± 0.24 | 36.62 ± 0.91 | 28.92 | |

| material modification color | 30.09 ± 0.75 | 26.96 ± 0.67 | 28.92 ± 0.72 | 22.06 | |

| 5 | wood color | 63.73 ± 1.59 | 12.23 ± 0.3 | 23.51 ± 0.58 | – |

| bottom modification color | 38.57 ± 0.96 | 26.16 ± 0.65 | 34.55 ± 0.86 | 30.80 | |

| material modification color | 33.30 ± 0.83 | 30.97 ± 0.77 | 30.29 ± 0.77 | 8.31 | |

| 6 | wood color | 56.96 ± 1.42 | 8.97 ± 0.22 | 19.03 ± 0.47 | – |

| bottom modification color | 35.27 ± 0.88 | 27.80 ± 0.69 | 33.08 ± 0.82 | 31.98 | |

| material modification color | 29.54 ± 0.72 | 34.75 ± 0.85 | 17.76 ± 0.43 | 17.77 | |

| 7 | wood color | 50.39 ± 1.25 | 14.09 ± 0.34 | 23.46 ± 0.57 | – |

| bottom modification color | 30.31 ± 0.75 | 30.58 ± 0.76 | 26.44 ± 0.66 | 26.15 | |

| material modification color | 31.49 ± 0.78 | 29.64 ± 0.74 | 19.91 ± 0.48 | 6.70 |

| Sample (#) | Area | L* | a* | b* | ΔL* | Δa* | Δb* | ΔE* |

|---|---|---|---|---|---|---|---|---|

| 1 | wood | 72.01 | 10.95 | 19.52 | – | – | – | – |

| bottom | 43.22 | 26.04 | 34.69 | −28.79 | 15.09 | 15.17 | 35.87 | |

| material | 31.69 | 28.97 | 29.61 | −11.53 | 2.93 | −5.08 | 12.93 | |

| 2 | wood | 62.42 | 9.17 | 23.65 | – | – | – | – |

| bottom | 43.22 | 26.04 | 34.69 | −19.2 | 16.87 | 11.04 | 27.85 | |

| material | 31.92 | 32.59 | 27.12 | −11.3 | 6.55 | −7.57 | 15.09 | |

| 3 | wood | 71.3 | 9.09 | 17.93 | – | – | – | – |

| bottom | 40.45 | 20.74 | 35.26 | −30.85 | 11.66 | 17.33 | 37.26 | |

| material | 31.69 | 28.97 | 29.61 | −8.75 | 8.22 | −5.66 | 13.28 | |

| 4 | wood | 63.9 | 7.35 | 18.07 | – | – | – | – |

| bottom | 41.87 | 9.97 | 36.62 | −22.03 | 2.62 | 18.55 | 28.92 | |

| material | 30.09 | 26.96 | 31.22 | −11.78 | 16.99 | −7.7 | 22.06 | |

| 5 | wood | 63.73 | 12.23 | 23.51 | – | – | – | – |

| bottom | 38.57 | 26.16 | 34.55 | −25.16 | 13.93 | 11.04 | 30.8 | |

| material | 33.3 | 30.97 | 30.29 | −5.27 | 4.81 | −4.26 | 8.31 | |

| 6 | wood | 56.96 | 8.97 | 19.03 | – | – | – | – |

| bottom | 35.27 | 27.8 | 33.08 | −21.69 | 18.84 | 14.06 | 31.98 | |

| material | 29.54 | 34.75 | 27.58 | −5.73 | 6.94 | −15.32 | 17.77 | |

| 7 | wood | 50.39 | 14.09 | 23.46 | – | – | – | – |

| bottom | 30.31 | 30.58 | 26.44 | −20.08 | 16.49 | 2.98 | 26.15 | |

| material | 31.49 | 29.64 | 19.91 | 1.18 | −0.95 | −6.53 | 6.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Gao, D.; Xu, W. Influence of the Bottom Color Modification and Material Color Modification Process on the Performance of Modified Poplar. Coatings 2021, 11, 660. https://doi.org/10.3390/coatings11060660

Liu Q, Gao D, Xu W. Influence of the Bottom Color Modification and Material Color Modification Process on the Performance of Modified Poplar. Coatings. 2021; 11(6):660. https://doi.org/10.3390/coatings11060660

Chicago/Turabian StyleLiu, Qingqing, Di Gao, and Wei Xu. 2021. "Influence of the Bottom Color Modification and Material Color Modification Process on the Performance of Modified Poplar" Coatings 11, no. 6: 660. https://doi.org/10.3390/coatings11060660

APA StyleLiu, Q., Gao, D., & Xu, W. (2021). Influence of the Bottom Color Modification and Material Color Modification Process on the Performance of Modified Poplar. Coatings, 11(6), 660. https://doi.org/10.3390/coatings11060660