Influences of Nitrogen Flow Rate on Microstructure, Mechanical and Tribological Properties of WCN Coatings Deposited by HiPIMS

Abstract

1. Introduction

2. Experiment Details

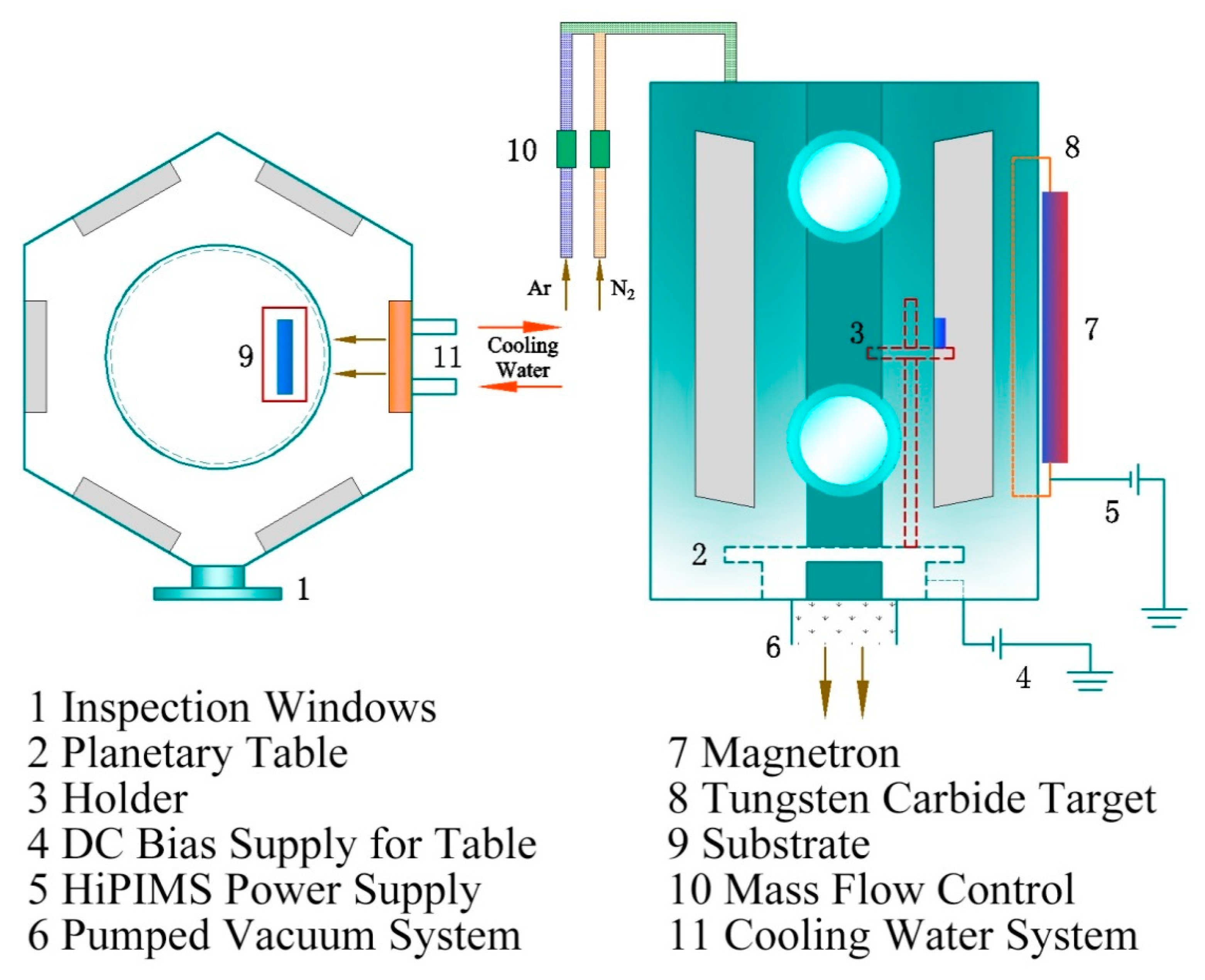

2.1. Coatings Preparation

2.2. Characterization

3. Results and Discussion

3.1. Plasma Discharge Characteristics

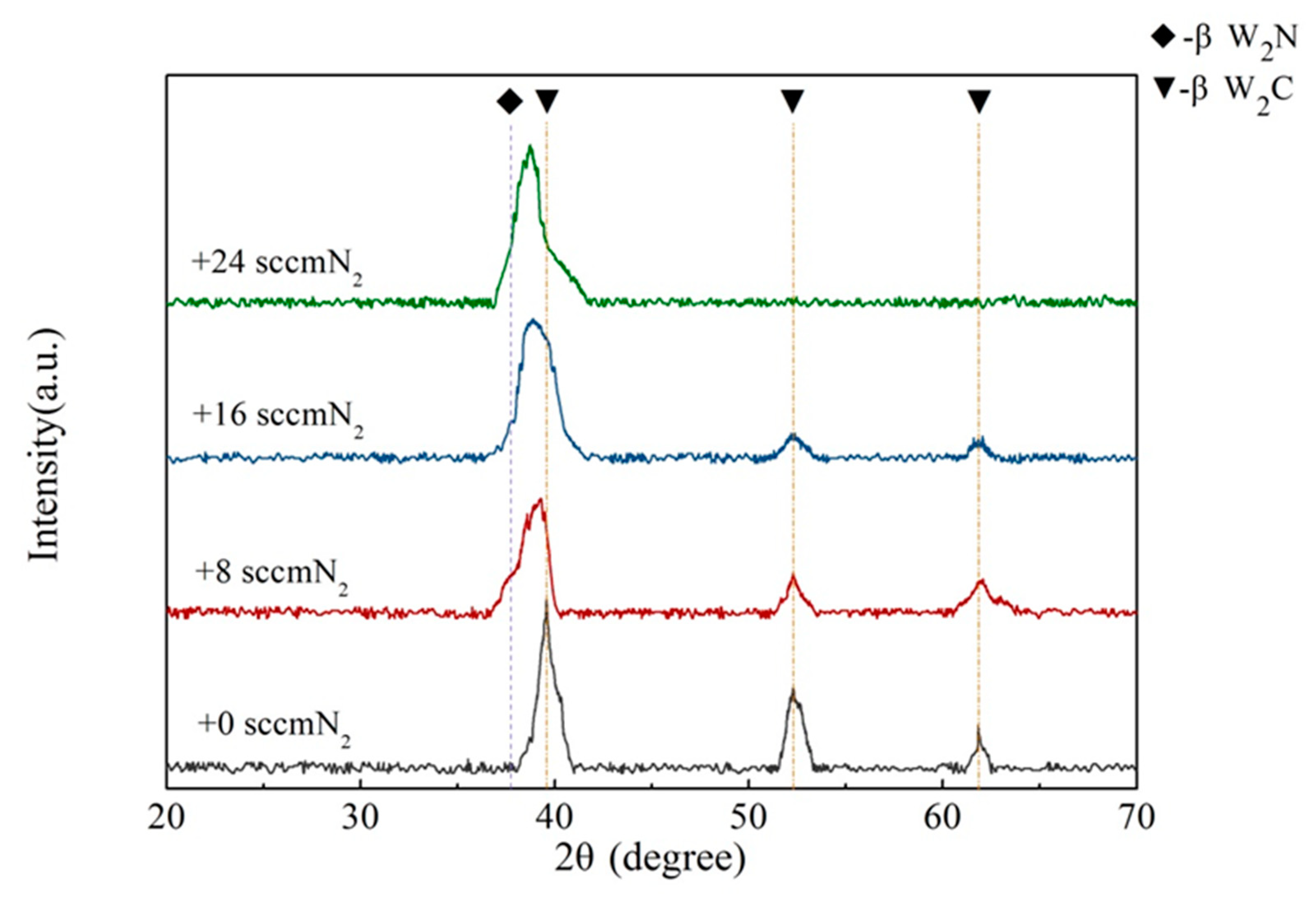

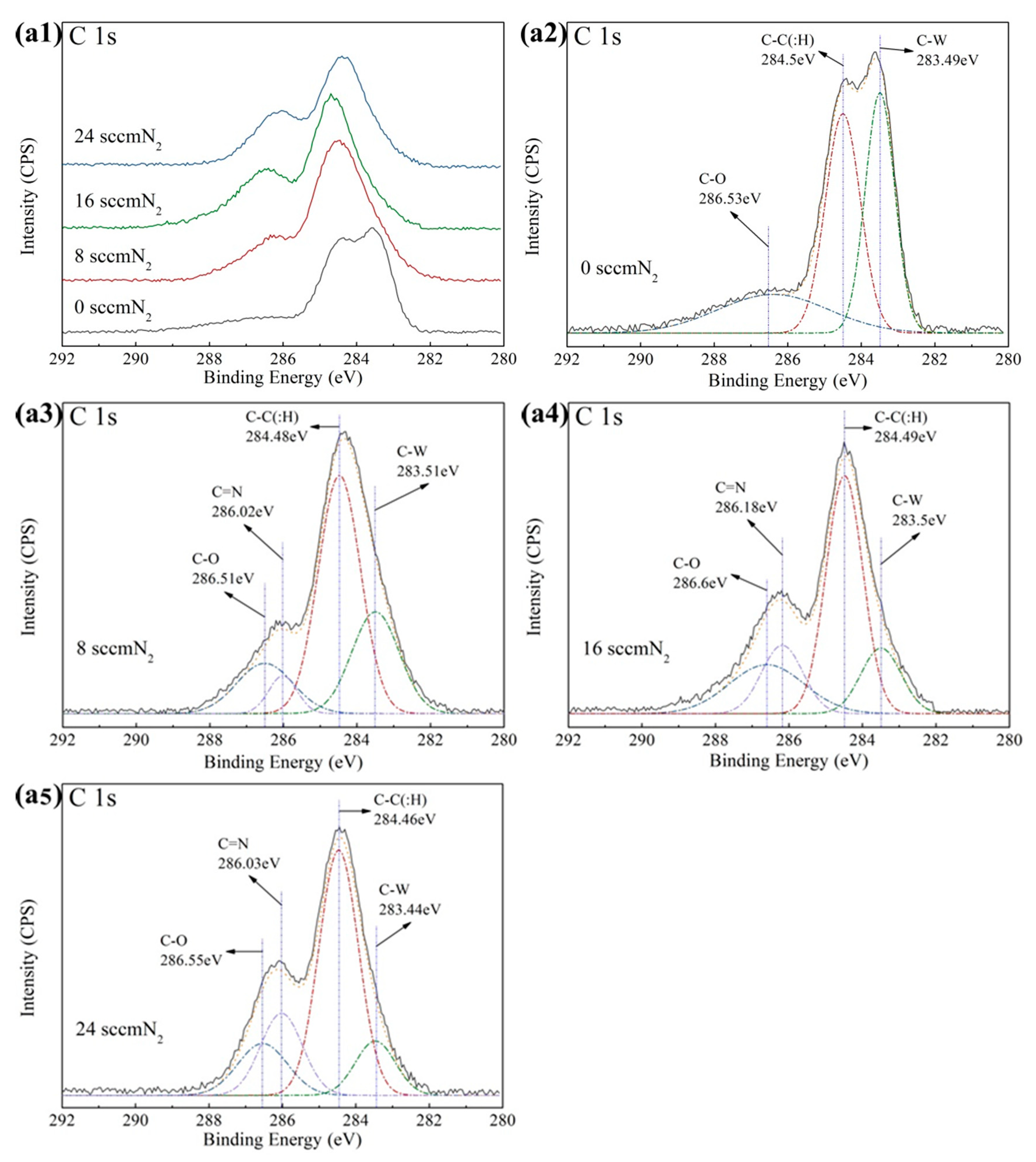

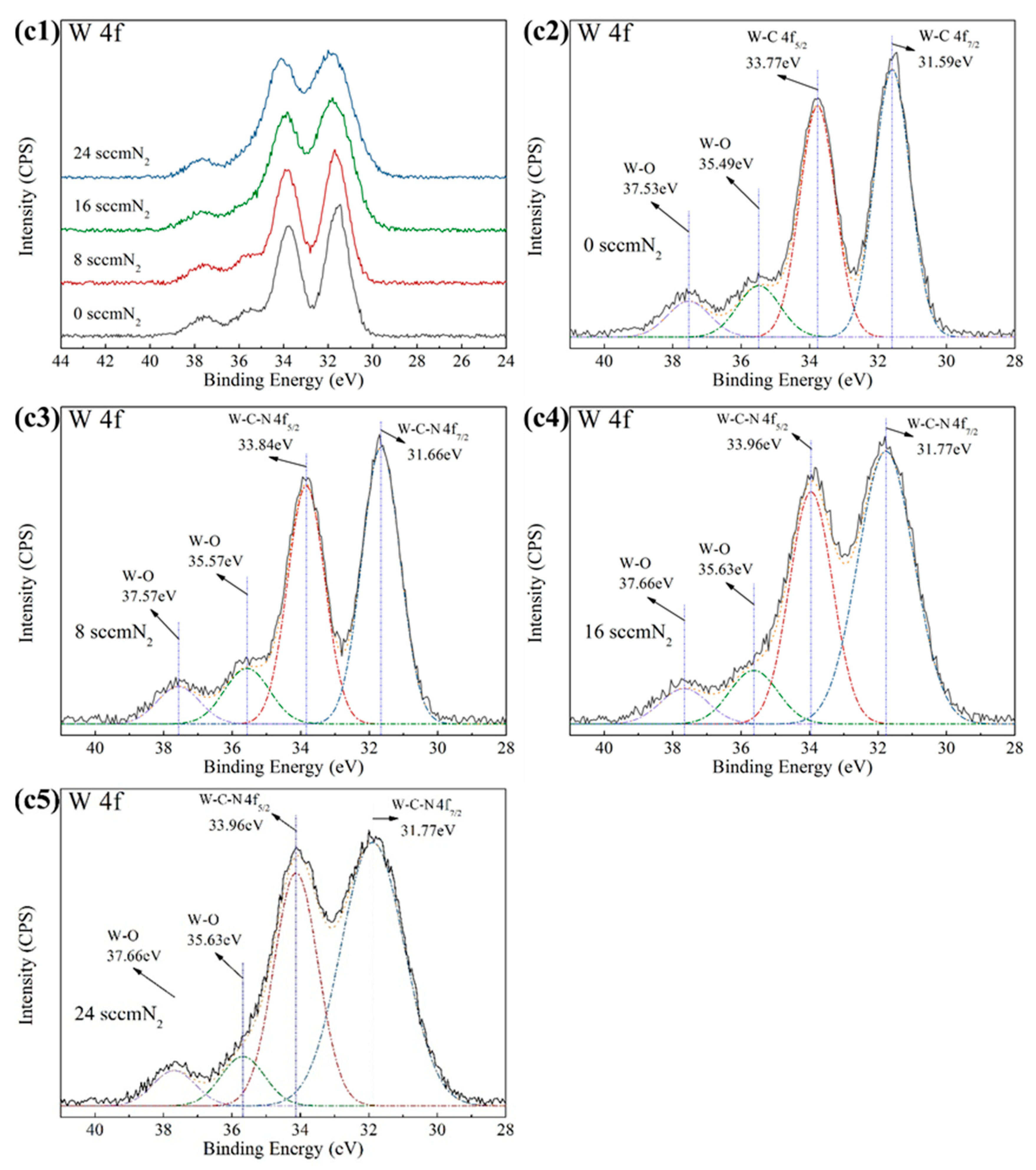

3.2. Microstructure and Morphology

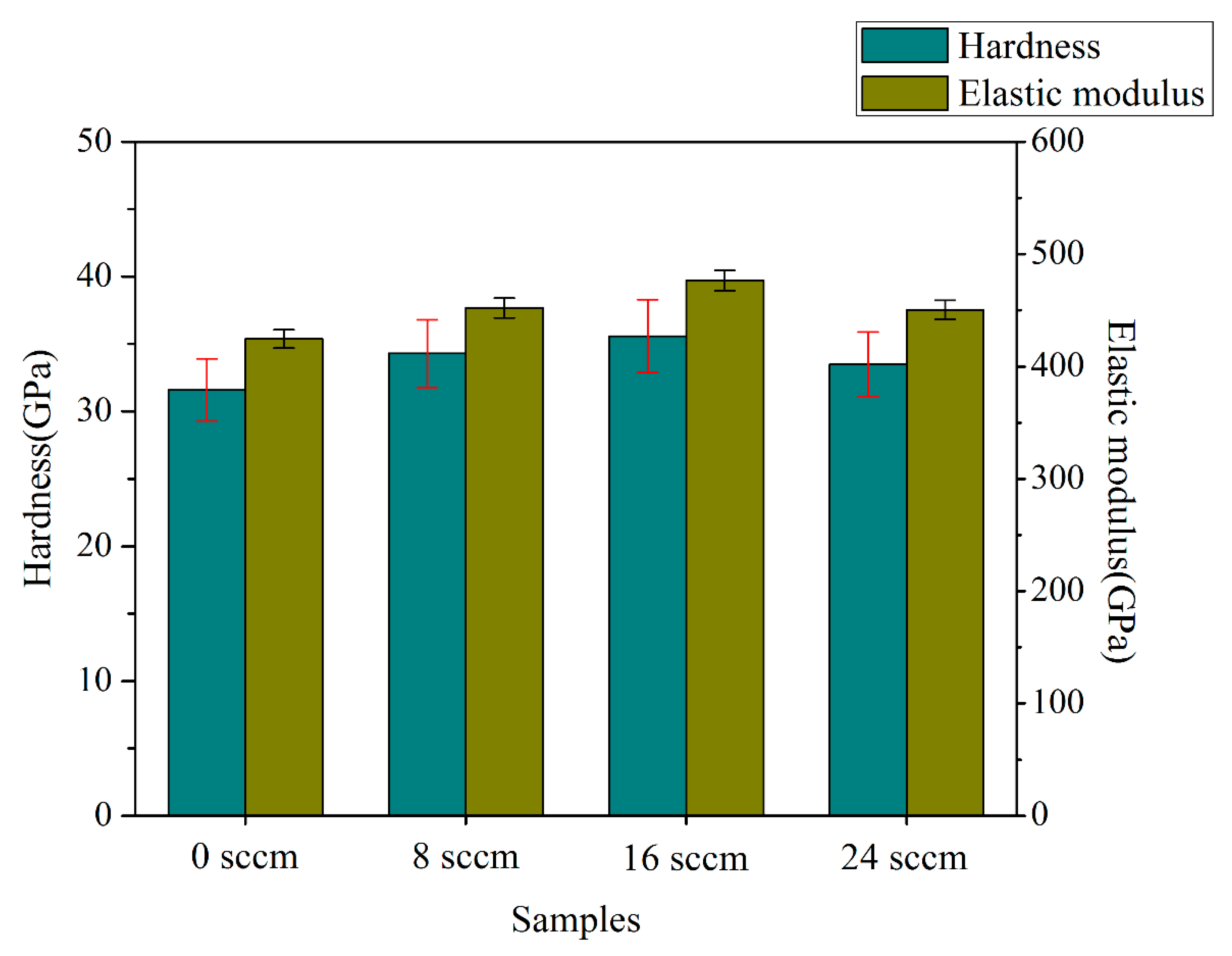

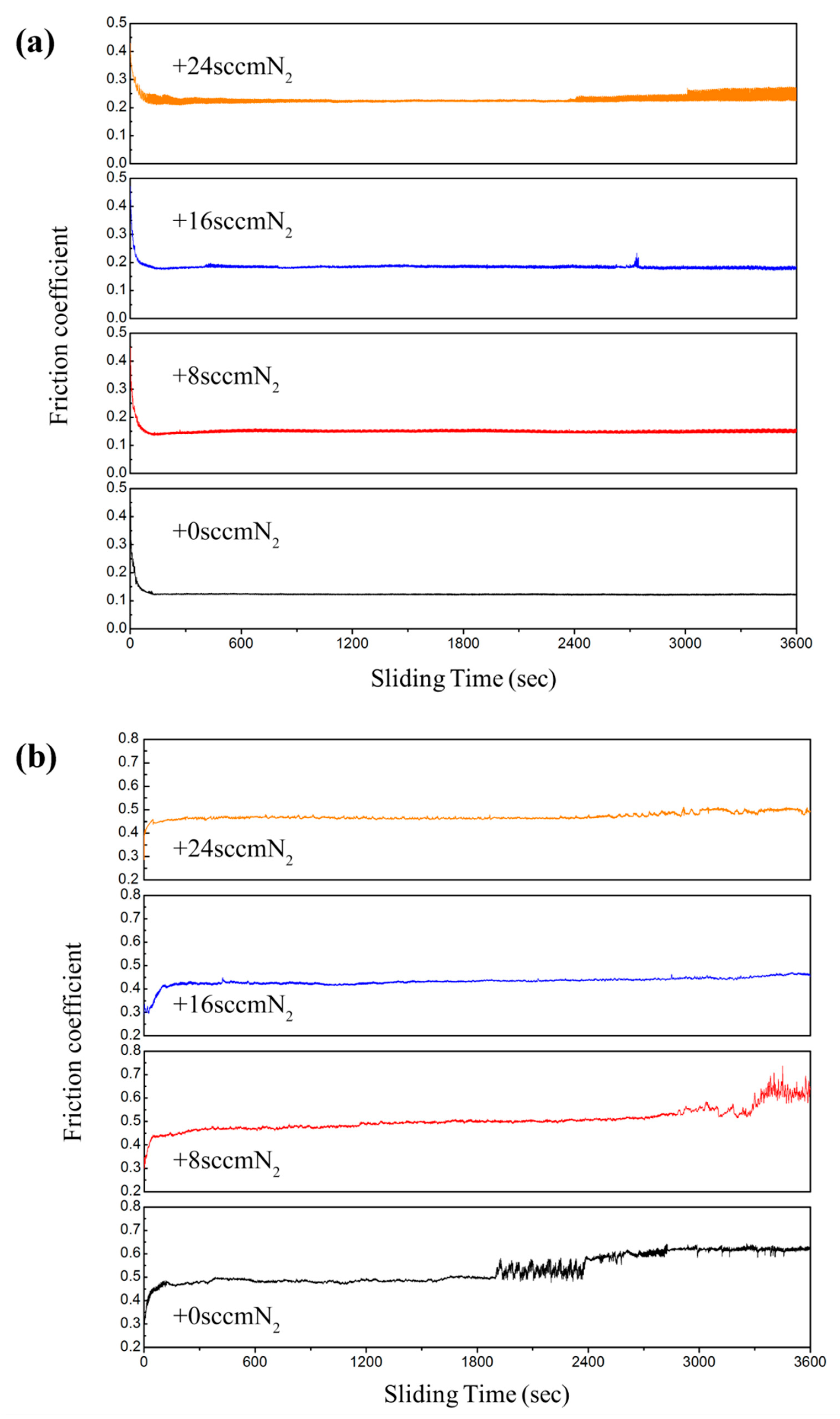

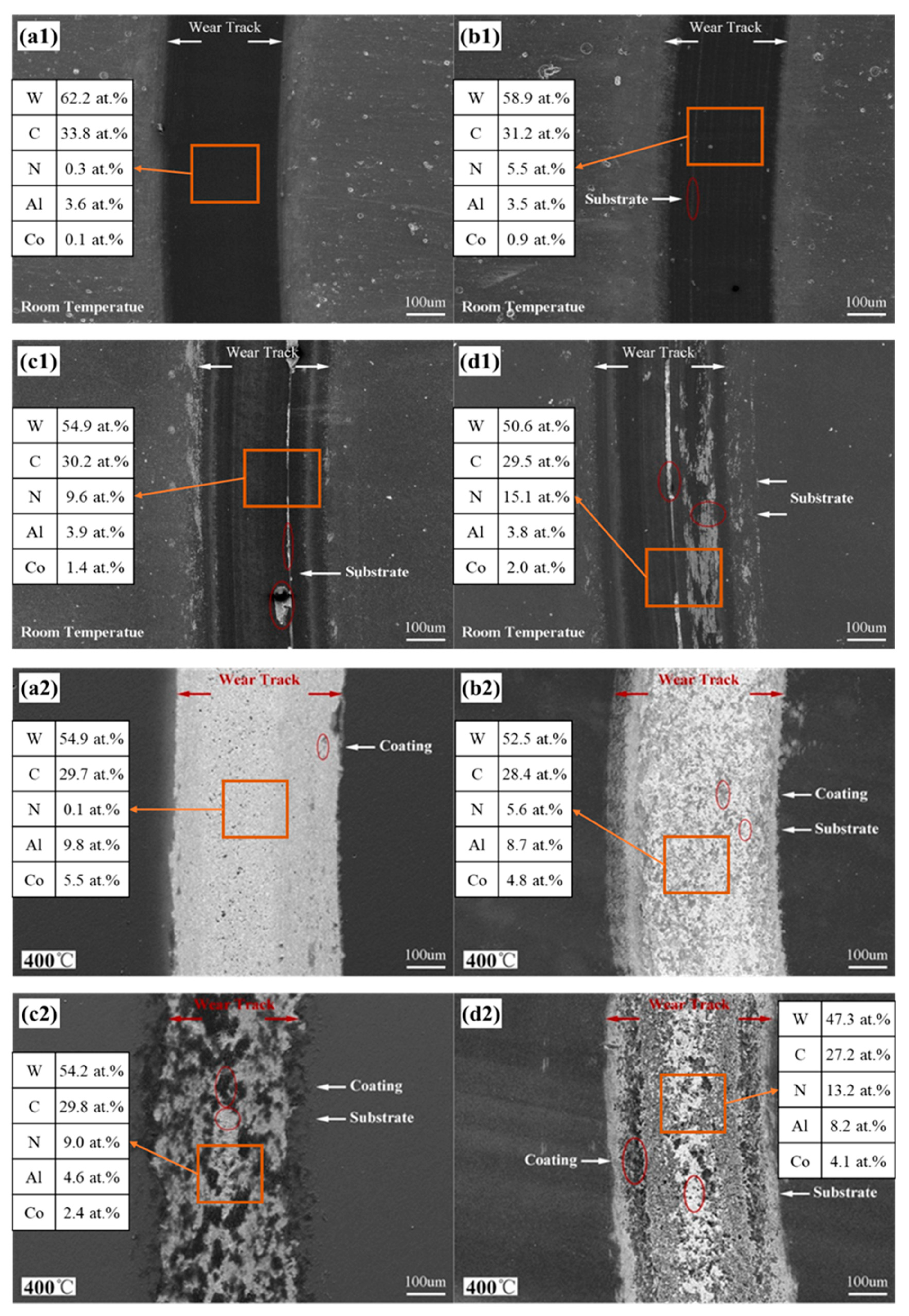

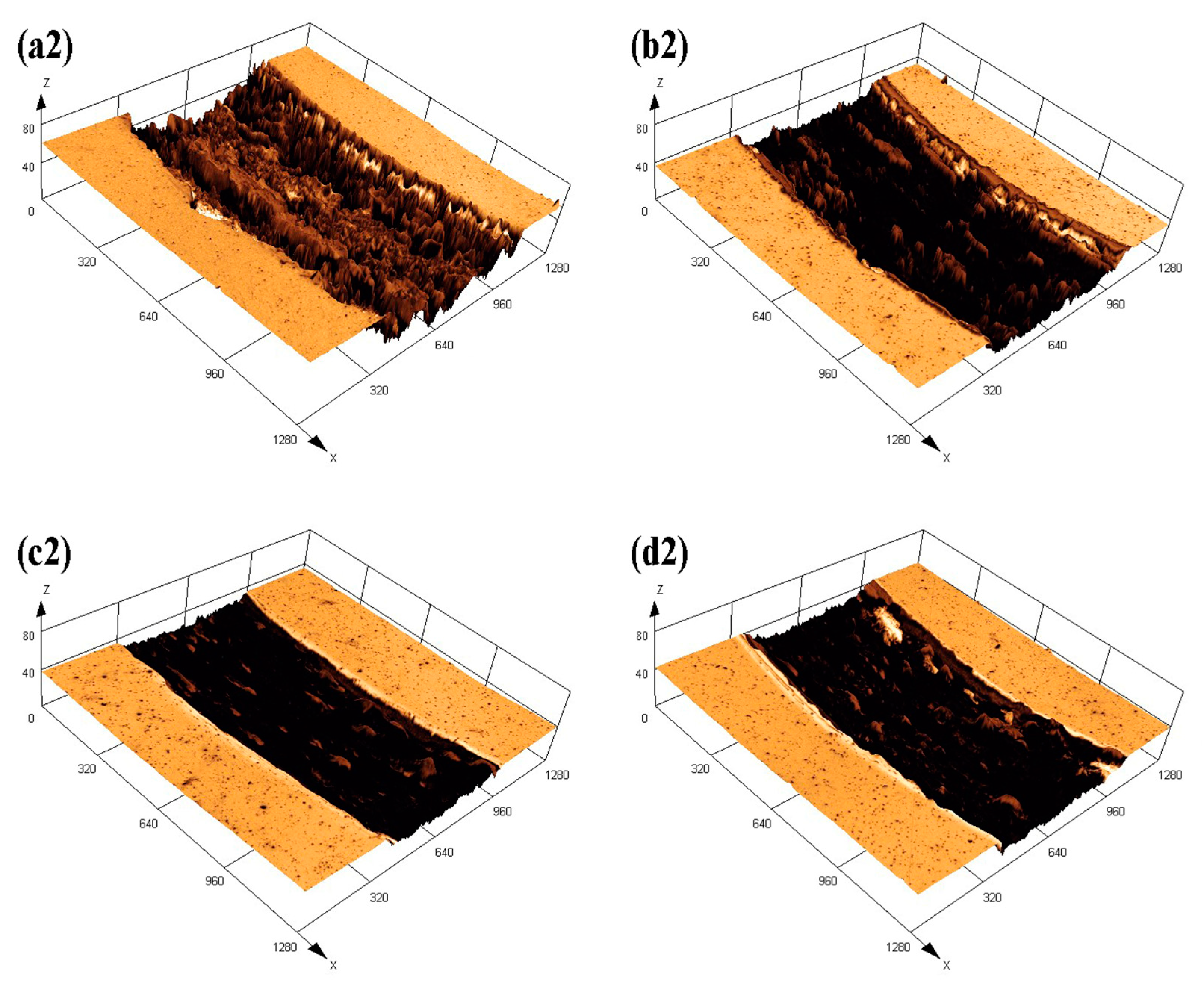

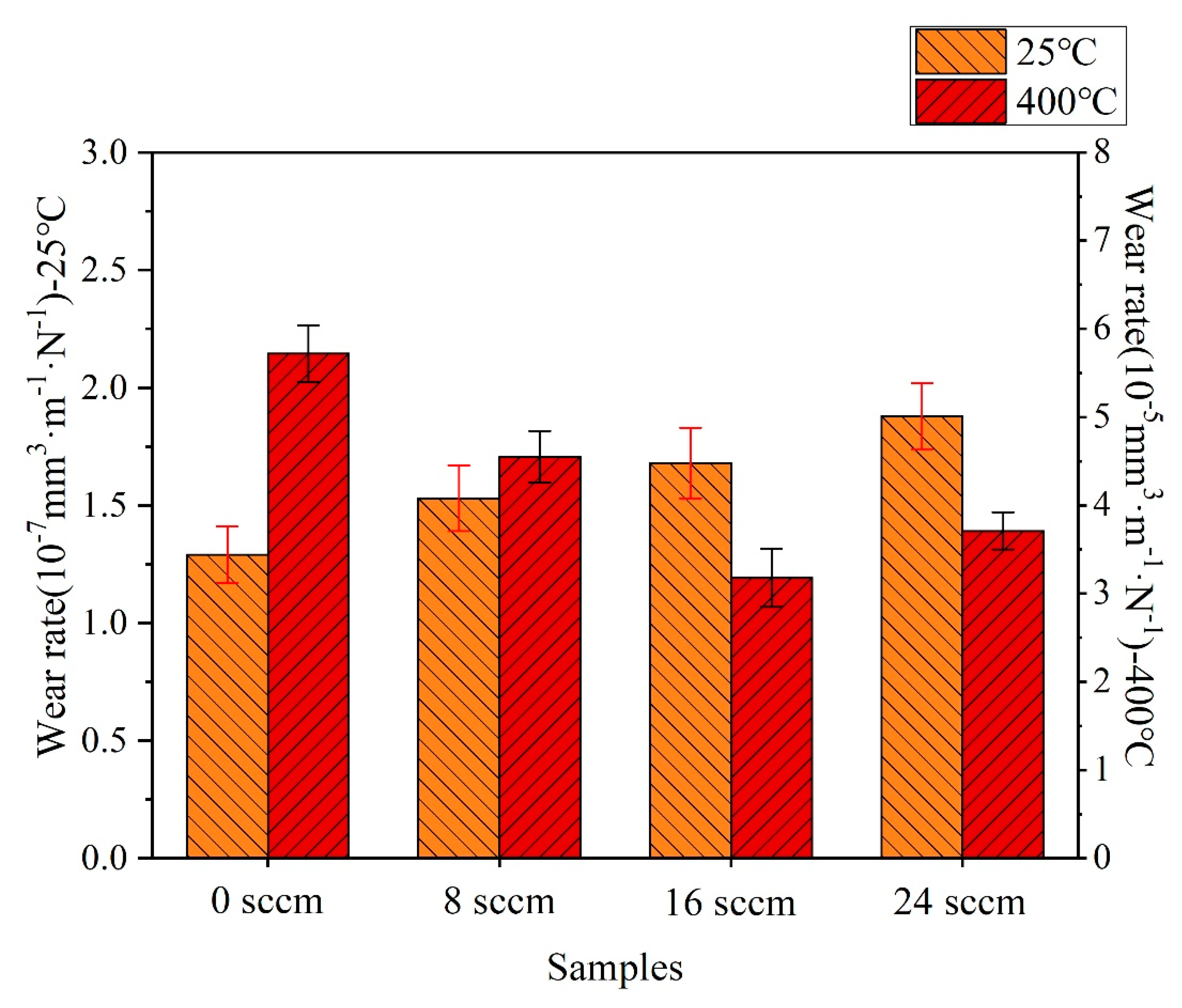

3.3. Mechanical and Tribological Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Benedetti, M.; Fontanari, V.; Torresani, E.; Girardi, C.; Giordanino, L. Investigation of lubricated rolling sliding behaviour of WC/C, WC/C-CrN, DLC based coatings and plasma nitriding of steel for possible use in worm gearing. Wear 2017, 378–379, 106–113. [Google Scholar] [CrossRef]

- Rivera-Tello, C.D.; Broitman, E.; Flores-Ruiz, F.J.; Jimenez, O.; Flores, M. Mechanical properties and tribological behavior at micro and macro-scale of WC/WCN/W hierarchical multilayer coatings. Tribol. Int. 2016, 101, 194–203. [Google Scholar] [CrossRef]

- Pu, J.B.; He, D.Q.; Wang, L.P. Effects of WC phase contents on the microstructure, mechanical properties and tribological behaviors of WC/a-C superlattice coatings. Appl. Surf. Sci. 2015, 357, 2039–2047. [Google Scholar] [CrossRef]

- Pouraliakbar, H.; Khalaj, G.; Gomidželović, L.; Khalaj, M.J.; Nazerfakhari, M. Duplex ceramic coating produced by low temperature thermo-reactive deposition and diffusion on the cold work tool steel substrate: Thermodynamics, kinetics and modeling. Ceram. Int. 2015, 41, 9350–9360. [Google Scholar] [CrossRef]

- Khalaj, G.; Khalaj, M.J. Application of ANFIS for modeling of layer thickness of chromium carbonitride coating. Neural Comput. Appl. 2014, 24, 685–694. [Google Scholar] [CrossRef]

- Pourasad, J.; Ehsani, N.; Khalifesoltani, S.A. Preparation and characterization of SiO2 thin film and SiC nanofibers to improve of graphite oxidation resistance. J. Eur. Ceram. Soc. 2016, 36, 3947–3956. [Google Scholar] [CrossRef]

- Ehrburger, P.; Lahaye, J.; Bourgeois, C. Characterization of carbon-carbon composites—II: Oxidation behaviour. Carbon 1981, 19, 7–10. [Google Scholar] [CrossRef]

- Banerji, A.; Bhowmick, S.; Alpas, A.T. High temperature tribological behavior of W containing diamond-like carbon (DLC) coating against titanium alloys. Surf. Coat. Technol. 2014, 241, 93–104. [Google Scholar] [CrossRef]

- Shen, Y.-Q.; Zhang, Z.-Q.; Liao, B.; Wu, X.-Y.; Zhang, X.; Hua, Q.-S.; Bao, M.-Y. Tribocorrosion performance of Nitrogen-doped diamond like carbon coating by high power impulse magnetron sputtering technique. Acta Phys. Sin. Chin. Ed. 2020, 69, 108101. [Google Scholar]

- Bootkul, D.; Supsermpol, B.; Saenphinit, N.; Aramwit, C.; Intarasiri, S. Nitrogen doping for adhesion improvement of DLC film deposited on Si substrate by Filtered Cathodic Vacuum Arc (FCVA) technique. Appl. Surf. Sci. 2014, 310, 284–292. [Google Scholar] [CrossRef]

- Corona-Gomez, J.; Shiri, S.; Mohammadtaheri, M.; Yang, Q. Adhesion enhancement of DLC on CoCrMo alloy by diamond and nitrogen incorporation for wear resistant applications. Surf. Coat. Technol. 2017, 332, 120–127. [Google Scholar] [CrossRef]

- Ju, H.; Wang, R.; Ding, N.; Yu, L.; Xu, J.; Ahmed, F.; Zuo, B.; Geng, Y. Improvement on the oxidation resistance and tribological properties of molybdenum disulfide film by doping nitrogen. Mater. Des. 2019, 186, 108300. [Google Scholar] [CrossRef]

- Wang, L.; Li, L.; Li, G.; Ma, Q. Improved Adhesion of TiAlSiN Nanocomposite Coatings on Cemented Carbide Substrate by Pre-Implantation. Coatings 2019, 9, 209. [Google Scholar] [CrossRef]

- Wang, L.; Jin, J.; Zhu, C.; Li, G.; Kuang, X.; Huang, K. Effects of HiPIMS pulse-length on plasma discharge and on the properties of WC-DLC coatings. Appl. Surf. Sci. 2019, 487, 526–538. [Google Scholar] [CrossRef]

- Syed, B.; Hsu, T.W.; Chaar, A.B.B.; Polcik, P.; Kolozsvari, S.; Håkansson, G.; Rosen, J.; Johnson, L.J.S.; Zhirkov, I.; Andersson, J.M.; et al. Effect of varying N2 pressure on DC arc plasma properties and microstructure of TiAlN coatings. Plasma Sources Sci. Technol. 2020, 29, 095015. [Google Scholar] [CrossRef]

- Safi, I. Recent aspects concerning DC reactive magnetron sputtering of thin films: A review. Surf. Coat. Technol. 2000, 127, 203–218. [Google Scholar] [CrossRef]

- Fekete, M.; Bernátová, K.; Klein, P.; Hnilica, J.; Vašina, P. Evolution of discharge parameters and sputtered species ionization in reactive HiPIMS with oxygen, nitrogen and acetylene. Plasma Sources Sci. Technol. 2019, 28, 025011. [Google Scholar] [CrossRef]

- Lin, J.; Sproul, W.D.; Wei, R.; Chistyakov, R. Diamond like carbon films deposited by HiPIMS using oscillatory voltage pulses. Surf. Coat. Technol. 2014, 258, 1212–1222. [Google Scholar] [CrossRef]

- Peng, Y.L.; Guo, C.Q.; Lin, S.S.; Shi, Q.; Wei, C.B.; Su, Y.F.; Wu, Y.Q.; Tang, P.; Zhu, X.G.; Dai, M.J. Effects of working pressure on structure and properties of Al-containing amorphous carbon films prepared by high-power impulse magnetron sputtering. J. Alloys Compd. 2019, 816, 152587. [Google Scholar] [CrossRef]

- Zuo, X.; Zhang, D.; Chen, R.; Ke, P.; Odén, M.; Wang, A. Spectroscopic investigation on the near-substrate plasma characteristics of chromium HiPIMS in low density discharge mode. Plasma Sources Sci. Technol. 2020, 29, 0150013. [Google Scholar] [CrossRef]

- Yarin, A.L.; Rovagnati, B.; Mashayek, F.; Matsoukas, T. A reaction model for plasma coating of nanoparticles by amorphous carbon layers. J. Appl. Phys. 2006, 99, 064310. [Google Scholar] [CrossRef]

- Guillaumot, A.; Lapostolle, F.; Dublanche-Tixier, C.; Oliveira, J.C.; Billard, A.; Langlade, C. Reactive deposition of Al-N coatings in Ar/N2 atmospheres using pulsed-DC or high power impulse magnetron sputtering discharges. Vacuum 2010, 85, 120–125. [Google Scholar] [CrossRef]

- Lu, C.-Y.; Diyatmika, W.; Lou, B.-S.; Lee, J.-W. Superimposition of high power impulse and middle frequency magnetron sputtering for fabrication of CrTiBN multicomponent hard coatings. Surf. Coat. Technol. 2018, 350, 962–970. [Google Scholar] [CrossRef]

- Zhao, H.; Ni, Z.; Ye, F. Effect of carbon content on structure and properties of WCN coatings prepared by RF magnetron sputtering. Surf. Coat. Technol. 2016, 287, 129–137. [Google Scholar] [CrossRef]

- Su, Y.D.; Hu, C.Q.; Wen, M.; Wang, C.; Liu, D.S.; Zheng, W.T. Effects of bias voltage and annealing on the structure and mechanical properties of WC0.75N0.25 thin films. J. Alloys Compd. 2009, 486, 357–364. [Google Scholar] [CrossRef]

- Ospina, R.; Escobar-Rincón, D.; Arango, P.J.; Restrepo-Parra, E.; Jurado, J.F. Structural and chemical composition analysis of WCN produced by pulsed vacuum arc discharge. Surf. Coat. Technol. 2013, 232, 96–100. [Google Scholar] [CrossRef]

- Olaya, J.; Rodil, S.; Muhl, S.; Sánchez, E. Comparative study of chromium nitride coatings deposited by unbalanced and balanced magnetron sputtering. Thin Solid Film. 2005, 474, 119–126. [Google Scholar] [CrossRef]

- Kaoumi, D.; Motta, A.T.; Birtcher, R.C. A thermal spike model of grain growth under irradiation. J. Appl. Phys. 2008, 104, 073525. [Google Scholar] [CrossRef]

- Luo, H.; Gao, F.; Billard, A. Tunable microstructures and morphology of zirconium films via an assist of magnetic field in HiPIMS for improved mechanical properties. Surf. Coat. Technol. 2019, 374, 822–832. [Google Scholar] [CrossRef]

- Pradhan, A.A.; Shah, S.I.; Unruh, K.M. Reactive sputter deposition of alumina thin films using a hollow cathode sputtering source. Rev. Sci. Instrum. 2002, 73, 3841–3845. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Dominguez-Meister, S.; Rojas, T.C.; Colasuonno, M.; Bazzan, M.; Patelli, A. Tribological properties of TiC/a-C:H nanocomposite coatings prepared via HiPIMS. Appl. Surf. Sci. 2018, 440, 458–466. [Google Scholar] [CrossRef]

- Wang, W.; Pelenovich, V.O.; Yousaf, M.I.; Yan, S.; Bin, H.; Wang, Z.; Tolstogouzov, A.B.; Kumar, P.; Yang, B.; Fu, D.J. Microstructure, mechanical and tribological properties of WC/a-C:H coatings deposited by cathodic arc ion-plating. Vacuum 2016, 132, 31–39. [Google Scholar] [CrossRef]

- Hinnen, C.; Imbert, D.; Siffre, J.M.; Marcus, P. An in situ XPS study of sputter-deposited aluminium thin films on graphite. Appl. Surf. Sci. 1994, 78, 219–231. [Google Scholar] [CrossRef]

- Qureshi, A.; Shah, S.; Pelagade, S.; Singh, N.L.; Mukherjee, S.; Tripathi, A.; Despande, U.P.; Shripathi, T. Surface modification of polycarbonate by plasma treatment. J. Phys. Conf. Ser. 2010, 208, 012108. [Google Scholar] [CrossRef]

- Czyzniewski, A. Deposition and some properties of nanocrystalline WC and nanocomposite WC/a-C:H coatings. Thin Solid Film. 2003, 433, 180–185. [Google Scholar] [CrossRef]

- Jiang, P.C.; Chen, J.S.; Lin, Y.K. Structural and electrical characteristics of W–N thin films prepared by reactive rf sputtering. J. Vac. Sci. Technol. 2003, 21, 616–622. [Google Scholar] [CrossRef]

- Shen, Y.G.; Mai, Y.W.; Mckenzie, D.R.; Zhang, Q.C.; McFall, W.D.; McBride, W.E. Composition, residual stress, and structural properties of thin tungsten nitride films deposited by reactive magnetron sputtering. J. Appl. Phys. 2000, 88, 1380–1388. [Google Scholar] [CrossRef]

- Moulder, J.F.; Stickle, W.F.; Sobol, P.E.; Bomben, K.D. Handbook of X-Ray Photoelectron Spectroscopy: A Reference Book of Standard Spectra for Identification and Interpretation of XPS Data; Moulder, J.F., Chastain, J., Eds.; Physical Electronics: Chanhassen, MN, USA, 1993. [Google Scholar]

- Wang, C.; Tao, Q.; Li, Y.; Ma, S.; Dong, S.; Cui, T.; Wang, X.; Zhu, P. Excellent mechanical properties of metastable c-WN fabricated at high pressure and high temperature. Int. J. Refract. Met. Hard Mater. 2017, 66, 63–67. [Google Scholar] [CrossRef]

- Tang, J.-F.; Lin, C.-Y.; Yang, F.-C.; Tsai, Y.-J.; Chang, C.-L. Effects of nitrogen-argon flow ratio on the microstructural and mechanical properties of AlCrN coatings prepared using high power impulse magnetron sputtering. Surf. Coat. Technol. 2020, 386, 125484. [Google Scholar] [CrossRef]

- Snyders, R.; Gouttebaron, R.; Dauchot, J.P.; Hecq, M. Mass spectrometry diagnostic of dc magnetron reactive sputtering. J. Anal. At. Spectrom. 2003, 18, 618–623. [Google Scholar] [CrossRef]

- Yu, L.; Zhao, H.; Xu, J. Mechanical, tribological and corrosion performance of WBN composite films deposited by reactive magnetron sputtering. Appl. Surf. Sci. 2014, 315, 380–386. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Samples (0 Sccm/8 Sccm/16 Sccm/24 Sccm) | |

| Target-Substrate Distance (cm) | 10 |

| Temperature (°C) | 150 |

| Deposition Pressure (Pa) | 0.8 |

| N2 Pressure (Pa) | 0.0/0.04/0.08/0.12 |

| Total Deposition Time (min) | 30 |

| Substrate Bias Voltage (V) | −80 |

| Pulse Width (μs) | 100 |

| Repetition frequency (Hz) | 200 |

| Pulse Negative Voltage (V) | −800 |

| Peak Discharge Current (A) | 61.5/70.9/77.6/61.6 |

| Species | Position (nm) | Intensity (Relative, a.u.) | |||

|---|---|---|---|---|---|

| Samples (Different N2 Flow Rates) | |||||

| +0 Sccm | +8 Sccm | +16 Sccm | +24 Sccm | ||

| W0 | 265.6 | 524.4 | 703.8 | 675.1 | 515.0 |

| 601.3 | 963.7 | 921.3 | 832.3 | 783.3 | |

| 909.5 | 1463.9 | 1385.5 | 1298.0 | 1182.1 | |

| C0 | 247.8 | 627.9 | 592.3 | 549.9 | 514.1 |

| 255.1 | 460.8 | 626.8 | 598.1 | 318.4 | |

| 400.8 | 664.1 | 915.7 | 859.5 | 462.6 | |

| 657.0 | 2647.9 | 2682.3 | 2807.5 | 1942.8 | |

| N0 | 575.2 | 127.0 | 553.5 | 682.6 | 655.9 |

| 744.2 | 281.5 | 722.5 | 906.2 | 860.6 | |

| 862.9 | 244.2 | 780.2 | 957.8 | 930.2 | |

| Samples | Deposition Rate (nm/min) | Grain Size (nm) | Roughness (Ra/nm) | Chemical Compositions | ||

|---|---|---|---|---|---|---|

| W | C | N | ||||

| Sample1 (0 sccm) | 88.0 | 8.9 | 11.6 | 67.8 ± 0.5 | 32.2 ± 0.3 | - |

| Sample2 (8 sccm) | 96.4 | 7.7 | 9.5 | 62.9 ± 0.7 | 32.0 ± 0.2 | 5.1 ± 0.2 |

| Sample3 (16 sccm) | 110.7 | 6.8 | 8.2 | 57.4 ± 0.8 | 30.2 ± 0.4 | 12.4 ± 0.4 |

| Sample4 (24 sccm) | 90.0 | 6.4 | 5.7 | 51.6 ± 0.6 | 29.2 ± 0.4 | 19.2 ± 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, W.; Yang, Y.; Huang, S.; Fan, S.; Hu, M.; Wang, Y.; Xu, W.; Wang, L. Influences of Nitrogen Flow Rate on Microstructure, Mechanical and Tribological Properties of WCN Coatings Deposited by HiPIMS. Coatings 2021, 11, 481. https://doi.org/10.3390/coatings11040481

He W, Yang Y, Huang S, Fan S, Hu M, Wang Y, Xu W, Wang L. Influences of Nitrogen Flow Rate on Microstructure, Mechanical and Tribological Properties of WCN Coatings Deposited by HiPIMS. Coatings. 2021; 11(4):481. https://doi.org/10.3390/coatings11040481

Chicago/Turabian StyleHe, Weifeng, Yuhui Yang, Shuqi Huang, Shuyu Fan, Min Hu, Yongchao Wang, Wei Xu, and Lei Wang. 2021. "Influences of Nitrogen Flow Rate on Microstructure, Mechanical and Tribological Properties of WCN Coatings Deposited by HiPIMS" Coatings 11, no. 4: 481. https://doi.org/10.3390/coatings11040481

APA StyleHe, W., Yang, Y., Huang, S., Fan, S., Hu, M., Wang, Y., Xu, W., & Wang, L. (2021). Influences of Nitrogen Flow Rate on Microstructure, Mechanical and Tribological Properties of WCN Coatings Deposited by HiPIMS. Coatings, 11(4), 481. https://doi.org/10.3390/coatings11040481