Abstract

Titanium and its alloys are wildly used in industries. Shrouded plasma spray can be considered as a useful technology to produce low oxide containing titanium coatings. In this paper, the effect of shroud in plasma spraying on chemical composition and thickness of titanium coatings were investigated. Shrouded plasma-sprayed titanium coatings were deposited onto mild steel substrates. Air plasma-sprayed titanium coatings were also deposited for comparison under the same spraying parameters. Those titanium coatings were then studied in terms of microstructure, oxygen and nitrogen contents and coating’s thickness. The titanium coatings were assessed by scanning electron microscopy and quantitative chemical analysis. The results showed that the shroud played a key role in protecting the particles from oxidation in flight. The shrouded titanium coatings exhibited lower oxygen content and an enhanced microstructure. The reduction in air entrainment with the shroud resulted in better heating of the particles and increases in deposition efficiency and coating thickness.

1. Introduction

It is well known that titanium and its alloys are immune to environmental attack and are friendly to human. They are distinguished for the properties of high specific strength, light density, and excellent corrosion resistance especially to seawater and saltwater, and exceptional biocompatibility [1,2,3,4]. These properties give them more and more industrial applications like aerospace, power generation, food and chemical processing, and human implants, etc. [3,4,5]. However, titanium is usually more expensive than other metals because it is typically only found bonded to other elements and is hard to extract from its ore. In different circumstances, titanium and its alloys have a strong affinity to oxygen and other gases. This results in an inescapable request on the inert atmospheric conditions during the processing of titanium and its alloys.

The uncertain situation of material selection in an environmental corrosion is normally identified by the requirements for a strong resistance to corrosion, the necessity for quality mechanical properties, and the cost considerations. Plans taken to improve one property sometimes bring about the deterioration of other properties. A solution to make the most effective use of powerful corrosion resistance, robust mechanical properties and low cost is the application of advanced anti-corrosion coating technologies as the attack of corrosion normally occurs on the outer surface, and only localized surface areas require protection in most cases. Plasma spray technologies can integrate a thin layer of high-value materials onto cheap substrate materials, and a large number of coating materials are allowed to be plasma-sprayed to meet needs from many different industries [6,7]. Titanium and its alloys have had lot of applications in the anti-corrosion market and play an important role as key materials for corrosion resistance nowadays. Therefore, titanium coatings by plasma spraying could be a novel application for corrosion protection [8,9,10,11]. However, plasma spraying in ambient air is much more difficult for titanium coatings because titanium readily reacts with oxygen and nitrogen at high temperatures [3]. This will cause the coating properties get worse. Meanwhile, oxidation of these metals increases coating porosity and then dense coatings are not produced [12,13,14,15]. Therefore, a protective plasma spraying process by inert gas is necessary to prevent titanium coatings from too much oxidation.

Shrouded plasma spraying is such a process to potentially produce low oxide containing titanium coatings. In the plasma spraying with a shroud, the plasma gun is modified with a shroud attachment. The shroud attachment physically shields the plasma flame as it exits the plasma gun. Meanwhile, an inert gas from the end of the shroud attachment is introduced to envelops the plasma flame, which isolates the molten particles from encountering oxygen from the ambient air [16,17,18,19,20,21,22,23].

In this study, the effect of shroud in plasma spraying on chemical composition and thickness of titanium coatings were investigated. Shrouded plasma-sprayed titanium coatings were deposited onto mild steel substrates. Atmospheric plasma-sprayed titanium coatings were also fabricated for comparison by using the same plasma-spraying parameters. Those titanium coatings were then evaluated in terms of microstructure, oxygen and nitrogen content and coating’s thickness.

2. Experimental Details

2.1. Materials

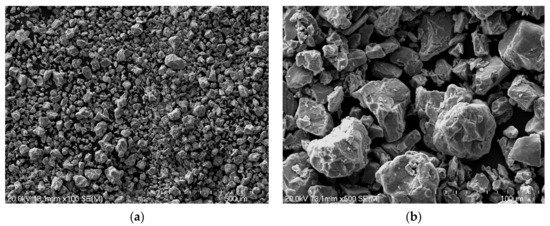

Pure titanium powder bought from Xi’an Lilin International Trade Co., Ltd. (Xi’an, China) was used in the experiment. The particle size of the titanium powder ranged from 20 to 75 µm. Figure 1 illustrates the surface morphology of the titanium particles. It is clear to see in the SEM images that the titanium powder has irregular shapes.

Figure 1.

SEM images of the surface morphology of the titanium particles. (a) The titanium powders with irregular shape; (b) magnified morphology.

The chemical composition of the titanium powder provided by the company is shown in Table 1. For pure titanium, the gas contents such as N, H, O, are critical parameters as they can exert significant influence on the mechanical properties of titanium.

Table 1.

Chemical composition of the pure titanium powder.

2.2. Methods and Material Characterization

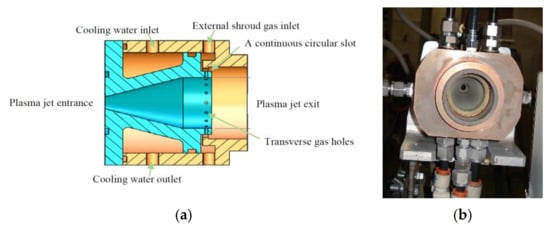

A SG-100 plasma gun from Praxair surface technologies, Indianapolis, IN, USA, together with a shroud attachment [24,25], was then used to plasma spray the pure titanium powder, as shown in Figure 2. The plasma gun with the shroud attachment was mounted on a 6-axis robot. A raster pattern was applied to plasma spray the samples. The plasma-spraying parameters are presented in Table 2. The substrates selected were mild steel plates with dimensions of 100 mm × 25 mm × 3 mm. The substrates were degreased, and sand was blasted before depositing titanium coatings onto them. The atmospheric plasma spraying was carried out after shrouded plasma spraying was completed by detaching the shroud from the plasma gun. The plasma-spraying with and without the shroud attachment used the same parameters as indicated in Table 2, except that there was a shroud inert gas flow in the shrouded plasma-spraying process.

Figure 2.

The shrouded plasma spraying of titanium coatings. (a) Schematic cross section of the shroud; (b) the experimental set-up of shrouded plasma spraying [24,25].

Table 2.

The spraying parameters for the titanium coatings with and without the shroud.

Freestanding specimens of titanium coating for chemical composition testing were obtained by physically removing from the substrates. The interior side of the titanium coatings were then polished to eliminate the elements from the mild steel substrate. Quantitative chemical analysis (oxygen, nitrogen and hydrogen) by using a LECO combustion method for the removed titanium coatings was conducted at Durkee testing laboratories Inc., Paramount, CA, USA.

Metallographic preparation for microstructural analysis was applied on the cross-sections of the titanium-coating specimens. The scanning electron microscopes with secondary electron imaging (SEM, Hitachi S4700, Tokyo, Japan and Zeiss EVO 18, Oberkochen, Germany) were used to observe microstructure and morphology, which were operated at 20 kV. The coating thickness was analysed by using an Olympus BX60 optical microscope (Olympus, Tokyo, Japan) equipped with a digital camera. The thickness values were averaged from 10 measurements per sample.

3. Results and Discussion

3.1. Coating Microstructure

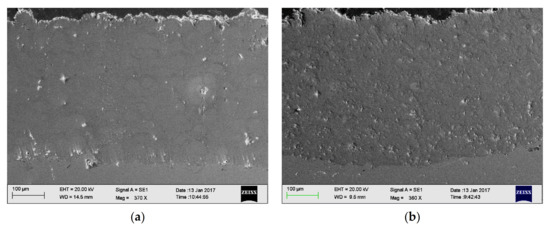

The SEM images of the polished cross sections of the titanium coatings at low magnification are shown in Figure 3. It indicates from those images that the plasma sprayed titanium coating with the shroud is much denser in the microstructure and has a low porosity, while the atmospheric plasma-sprayed titanium coating without the shroud holds a relatively high porosity.

Figure 3.

SEM images of the polished cross sections for (a) the shrouded plasma-sprayed Ti coating and (b) atmospheric plasma-sprayed Ti coating.

The information from the SEM pictures reveals that the application of shroud in plasma spraying has incurred an obvious reduction in the coating’s porosity. This could be explained by the shielding effect of the shroud in plasma spraying reducing the air entrainment. As we know, thermal dissociation of molecules of nitrogen and oxygen would remove energy from plasma if the ambient air were drawn into the plasma jet, and this endothermic reaction would also result in a sharp decline of temperature and velocity [26]. Therefore, the shielding effect of the shroud in the process of plasma spraying brought along a better heating of titanium particles, which was expected to have more powders in a molten state and to consequently reduce the porosity of the titanium coating plasma-sprayed with the shroud.

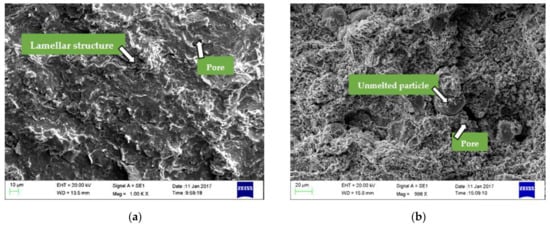

The SEM images of the fractured cross-section for the plasma-sprayed titanium coatings are presented in Figure 4. The titanium coating plasma sprayed with the shroud presents a lamellar structure, as noticed in Figure 3a. Those tiny splats are closely compacted within the coating and make a dense microstructure. There were no unmelted particles found in the shrouded plasma-sprayed titanium coatings. A small number of voids can be observed. The unshrouded titanium coating in Figure 3b shows a different microstructure. The loose microstructure is apparent, and the lamellar structure is not clearly apparent in the unshrouded titanium coating; whereas some un-melted titanium particles with a few of pores imply that the molten state of the titanium splats in-flight in the plasma jet was not well achieved.

Figure 4.

SEM photos of the fractured cross sections. (a) the shrouded plasma-sprayed Ti coating, (b) the unshrouded plasma-sprayed Ti coating.

As we know, the lamellar structure is a representative microstructure for plasma-sprayed coatings. In the plasma spraying process, the primary gas was ionized in the plasma gun, which resulted in a very high temperature and formed a plasma flame. The feedstock powders of titanium were then feed into the plasma flame which accelerated and heated the titanium particles into a fully or partially molten state. Subsequently the titanium particles struck onto the mild steel substrate, spread and quickly solidified, which took shape of the splats. This built up the titanium coatings and formed the lamellar structure [6,7]. The presence of the shroud attachment and the shrouded inert gas flow in the plasma spraying brought about the shielding effect and caused a better heating of titanium particle in the plasma jet. A higher temperature of the titanium particles in the plasma flame caused a better molten state of powder. Hence, the titanium splats could spread even more fully when hitting upon the mild steel substrate and then a dense lamellar structure came into being.

3.2. Oxygen/Nitrogen Content

The chemical composition of titanium powder was listed previously in Table 1. In addition, the ratio of powder surface area to volume is a key and dominant factor to the oxygen content of titanium powder. Usually, the powder surface area to volume ratio grows up dramatically as the particle diameter is diminished. Moreover, titanium powder just like many other metal powders displays a surface passive oxide film, that is, titanium dioxide [3,12,27]. A dense self-sealing titanium oxide layer can be constituted immediately after the titanium particles are exposed to an oxygen containing atmosphere. As a result, the oxygen content in the pure titanium powder would normally increase when the mean particle diameter decreases.

Oxidation and nitridation occur on titanium and its alloys during thermal exposure. Nitrogen and oxygen may enter the sub-surface region of a titanium component by diffusion at elevated temperatures, directly affecting mechanical properties by embrittlement. When an appreciable amount of oxygen is achieved, oxidation will take place on the titanium surface. The formation of a titanium oxide scale segregates the outer surface of titanium from the surrounding environment, thereby a barrier surface layer is generated that retard further the oxidation reaction and reduces titanium consumption. Thus, the content of nitrogen and oxygen in the titanium coatings becomes important.

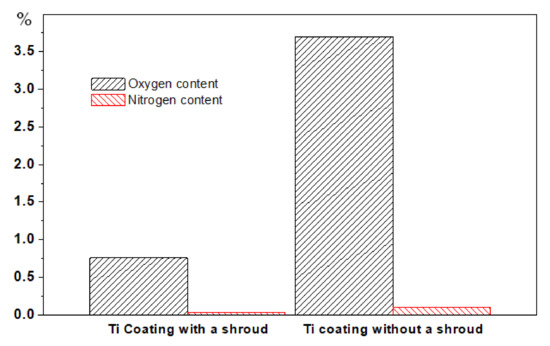

The quantitative chemical analysis by combustion method has been done for titanium coatings with/without the shroud. The nitrogen and oxygen contents in the plasma-sprayed titanium coatings are listed in Table 3.

Table 3.

The contents of nitrogen and oxygen in the plasma-sprayed titanium coatings.

It is evident that the nitrogen contents in both the titanium coatings plasma-sprayed with and without the shroud attachment are much less than the oxygen. When exposed to the surrounding air at high temperatures, titanium will re-join with the nitrogen and oxygen to form a TiN layer and the oxide of titanium in the initial phase of oxidation, and next TiN will oxidize at around 800 °C in a normal atmosphere [28]. There were such extremely high temperatures in the plasma flame that the in-flight titanium particle reactions would take place. If the powder feedstocks were sprayed in an open and static surrounding atmosphere without a shrouding system, a turbulent shear at the outer edge of the plasma flame would produce a few of sizeable vortices, which would then create some eddies of cold ambient air swept within the plasma flame [26,29,30,31,32]. Molecules of nitrogen and oxygen entrained into the plasma jet from the surrounding air were susceptible to thermal dissociation into highly reactive monotonic atoms when heated at the high temperatures by plasma. Consequently, oxidation was rather vigorous in atmospheric plasma spraying and took priority over nitridation of titanium during the particles’ flight in the plasma jet since the product of titanium nitride might oxidize at high temperatures in the plasma jet, and then transformed into titanium oxide. Likewise, both oxide and nitride of titanium might also be generated during the processes of splat formation and coating build-up because the temperatures at that moments still stayed at a high level.

The results also suggest that the contents of nitrogen and oxygen in the plasma-sprayed titanium coating with the shroud are obviously lower than those for the atmospheric plasma-sprayed titanium coating without the shroud attachment, as shown in Figure 5. The shrouding system is a shroud attachment with an inert gas-flow at the end, fastened onto an atmospheric plasma gun. The shroud itself shielded physically the plasma flame as it exited the torch, which prevented partially, or even fully, the cold air entrainment in the plasma jet and delayed the corresponding fall in temperature and velocity. Each molten/partially molten particle at high temperatures was prone to oxygen. The very low oxygen concentration in the shroud attachment, together with the short exposure time in the plasma flame mean that such oxidation was expected to be of a minimum amount. Meanwhile, an argon gas shroud at a flowrate of 300 slpm enveloped the plasma flame as it left the shroud attachment, significantly shielding the in-flight particles from reacting with the surrounding environment, diluting, and flushing away the entrained ambient air at room temperature from the surface. The high-volume flow of external shroud argon flow would be able to effectively cool down the surface temperature of the as-sprayed titanium coatings when the plasma gun with the shroud passed over the deposited materials. Thus, it might as well reduce oxygen and nitrogen reactions owing to the slower oxidation kinetics.

Figure 5.

The contents of nitrogen and oxygen in the plasma-sprayed titanium coatings with and without the shroud.

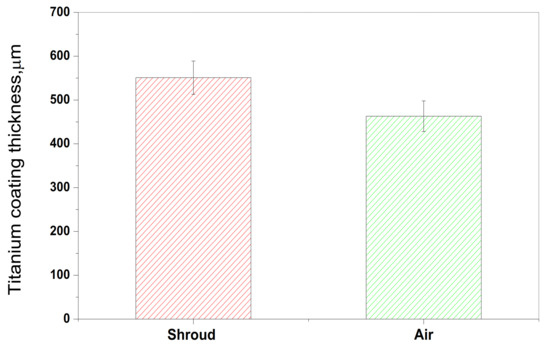

3.3. Coating’s Thickness

Titanium coatings were deposited onto the mild steel substrates with or without the shroud attachment by using the same spraying parameters. Coating thicknesses were measured by using the optical microscope and averaged from 10 measurements per sample. The thickness of titanium coating without a shroud is 463 ± 35 μm, and that for the shrouded titanium coatings is increased to 551 ± 38 μm, as shown in Figure 6.

Figure 6.

The thicknesses of plasma-sprayed Ti coatings with/without the shroud. The error bars represent the standard deviation.

When the powder feedstock was sprayed under the same spraying parameters, the coating thickness could act as an indicator for spray deposition efficiency. The thicker the plasma-sprayed coating, the higher the deposition efficiency obtained. This result reveals that the deposition efficiency with a shroud was higher than that plasma-sprayed in air. The difference in thickness between the titanium coatings with and without the shroud attachment was 88 μm, and that in percentage for the titanium coatings sprayed in air was 19% thinner when it was compared to the shrouded counterparts. For the shrouded plasma-spraying process, less surrounding air would be entrapped into the plasma jet because of the shielding effect of the shroud. In principle, the scaling down in air entrainment with the shroud system would give rise to a better heating of the titanium particles. It has been explained previously that less heat energy would be taken away from the plasma since less thermal dissociation of entrapped air would take place. Thus, titanium particles in flight could stay at higher temperatures, and more particles would be melted, which consequently would increase the deposition efficiency when particles impact on the substrate. On the other hand, air entrainment and friction with the surrounding air would also remove kinetic energy from the plasma when spraying without the shroud attachment, leading to a sharp drop in velocity [32]. Therefore, higher velocity of particles in flight could be obtained due to less air entrainment when it was sprayed with the shroud. Higher velocity of particles in flight would help increase the deposition efficiency as well. Furthermore, there was a shrouding argon gas with a flow rate of 300 slpm at the exit of the shroud attachment. Its aim was to envelop the plasma flame by an inert gas between the shroud and the substrate. The additional shroud gas was preheated by the plasma flame and shielded the molten titanium particles from reacting with the ambient air, diminishing the amount of air entrainment and postponing the relevant decrease in temperature and velocity. This also helped increase deposition efficiency, and then built up thicker titanium coatings.

4. Conclusions

This work investigated the effect of shroud in plasma spraying on chemical composition and thickness of titanium coatings. Shrouded plasma-sprayed titanium coatings were deposited onto the mild steel substrates. Atmospheric plasma-sprayed titanium coatings were also fabricated for comparison by using the same plasma-spraying parameters. Those titanium coatings were then assessed in terms of microstructure, oxygen and nitrogen contents and coating thickness. The key conclusions from the work were as follows:

- The nitrogen content was much less than oxygen in both plasma-sprayed titanium coatings with and without the shroud. The nitrogen and oxygen contents in the air plasma-sprayed titanium coatings were obviously higher than those in the shrouded plasma-sprayed titanium coatings.

- The thickness of titanium coating without a shroud was 463 ± 35 μm, and that for the shrouded titanium coatings was increased to 551 ± 38 μm. The deposition efficiency with the shroud was higher than that plasma-sprayed in air, while the shielding effect of the shroud contributed to a better heating condition for the in-flight titanium particles in plasma spraying and led to a higher deposition efficiency.

- The shrouded plasma-sprayed titanium coating held a dense microstructure with a porosity at relatively low level; while the atmospheric plasma-sprayed titanium coating presented a loose microstructure with a relatively high porosity. The presence of the shroud attachment and the inert gas-flow after the shroud brought down the titanium coating’s porosity.

Author Contributions

H.Z. and C.P. conceived and designed the experiment, and H.Z. performed the experiments; H.Z. analyzed the data and wrote the paper; H.Z. and C.P. provided materials/analysis tools. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available in a publicly accessible repository.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Liu, X.; Chu, P.K.; Ding, C. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater. Sci. Eng. R Rep. 2004, 47, 49–121. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys; Wiley-VCH GmbH & Co. KGaA: Weinheim, Germany, 2003; pp. 6–18. [Google Scholar]

- Antunes, R.; de Oliveiraa, M.; Salvador, C. Materials selection of optimized titanium alloys for aircraft applications. Mater. Res. 2018, 21, e20170979. [Google Scholar] [CrossRef]

- Zhou, H.; Gabbitas, B.; Mathews, S.; Zhang, D. Titanium and Titanium Alloy Coatings for Corrosion Protection. In Proceedings of the 12th World Conference on Titanium, Beijing, China, 19–24 June 2011; Volume 3, pp. 1287–1291. [Google Scholar]

- Fauchais, P.; Vardelle, M.; Goutier, S. Latest researches advances of plasma spraying: From splat to coating formation. J. Therm. Spray Technol. 2016, 25, 1534–1553. [Google Scholar] [CrossRef]

- Fauchais, P.; Montavon, G.; Bertrand, G. From powders to thermally sprayed coatings. J. Therm. Spray Technol. 2010, 19, 56–80. [Google Scholar] [CrossRef]

- Kawakita, J.; Kuroda, S.; Fukushima, T.; Katanoda, H.; Matsuo, K.; Fukanuma, H. Dense titanium coatings by modified HVOF spraying. Surf. Coat Technol. 2006, 201, 1250–1255. [Google Scholar] [CrossRef]

- Steffens, H.D.; Erturk, E.; Busse, K.H. A comparison of low-pressure arc and low-pressure plasma sprayed titanium coatings. J. Vac. Sci. Technol. 1985, A3, 2459–2463. [Google Scholar] [CrossRef]

- Ann Gan, J.; Berndt, C.C. Thermal Spray Forming of Titanium and its Alloys. In Titanium Powder Metallurgy: Science, Technology and Applications; Qian, M., Froes, F.H., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 425–446. [Google Scholar] [CrossRef]

- Lugscheider, E.; Lu, P.; Haeuser, B.; Jaeger, D. Optimized vacuum plasma-sprayed titanium coatings. Surf. Coat. Technol. 1987, 32, 215–226. [Google Scholar] [CrossRef]

- Kitashima, T.; Kawamura, T. Prediction of oxidation behavior of near-α titanium alloys. Scr. Mater. 2016, 124, 56–58. [Google Scholar] [CrossRef]

- Bagot, P.; Radecka, A.; Magyar, A.P.; Dye, D.; Rugg, D. The effect of oxidation on the subsurface microstructure of a Ti-6Al-4V alloy. Scr. Mater. 2018, 148, 24–28. [Google Scholar] [CrossRef]

- Gan, J.A.; Berndt, C.C. Review on the oxidation of metallic thermal sprayed coatings: A case study with reference to rare-earth permanent magnetic coatings. J. Therm. Spray Technol. 2013, 22, 1069–1091. [Google Scholar] [CrossRef]

- Planche, M.P.; Liao, H.; Coddet, C. Oxidation control in atmospheric plasma spraying coating. Surf. Coat Technol. 2007, 202, 69–76. [Google Scholar] [CrossRef]

- Liu, T.; Zheng, L.; Zhang, H. Effect of solid shield on coating properties in atmospheric plasma spray process. J. Therm. Spray Technol. 2016, 25, 1502–1515. [Google Scholar] [CrossRef]

- Morks, M.F.; Berndt, C.C. Corrosion and oxidation properties of NiCr coatings sprayed in presence of gas shroud system. Appl. Surf. Sci. 2010, 256, 4322–4327. [Google Scholar] [CrossRef]

- Kim, S.; Choi, S.; Kim, G.; Hong, S.H. Effects of shroud gas injection on material properties of tungsten layers coated by plasma spraying. Thin Solid Film 2010, 518, 6369–6372. [Google Scholar] [CrossRef]

- Matthews, S. Shrouded plasma spray of Ni–20Cr coatings utilizing internal shroud film cooling. Surf. Coat. Technol. 2014, 249, 56–74. [Google Scholar] [CrossRef]

- Thomson, I.; Pershin, V.; Mostaghimi, J.; Chandra, S. Experimental testing of a curvilinear gas shroud nozzle for improved plasma spraying. Plasma Chem. Plasma Process. 2001, 21, 65–82. [Google Scholar] [CrossRef]

- Jankovic, M.; Mostaghimi, J.; Pershin, V. Design of a new nozzle for direct current plasma guns with improved spraying parameters. J. Thermal Spray Technol. 2000, 9, 114–120. [Google Scholar] [CrossRef]

- Li, J.; Li, C.-X.; Yang, G.-J.; Li, C.-J. Effect of vapor deposition in shrouded plasma spraying on morphology and wettability of the metallic Ni20Cr coating surface. J. Alloys Compd. 2018, 735, 430–440. [Google Scholar] [CrossRef]

- Vetrivendan, E.; Jayaraj, J.; Ningshen, S.; Mallika, C.; Kamachi Mudali, U. Argon shrouded plasma spraying of tantalum over titanium for corrosion protection in fluorinated nitric acid media. J. Therm. Spray Technol. 2018, 27, 512–523. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, Z.; Luo, L. Microstructural characterization of shrouded plasma sprayed titanium coatings. J. Manuf. Mater. Process. 2019, 3, 4. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, Z.; Luo, L. Microstructure and phase composition of titanium coatings plasma sprayed with a shroud. MATEC Web Conf. 2018, 142, 03006. [Google Scholar] [CrossRef]

- Pfender, E.; Fincke, J.; Spores, R. Entrainment of cold gas into thermal plasma jets. Plasma Chem. Plasma Process. 1991, 11, 529–543. [Google Scholar] [CrossRef]

- Luthra, K. Stability of protective oxide films on Ti-base alloys. Oxid. Met. 1991, 36, 475–490. [Google Scholar] [CrossRef]

- Boyer, R.; Welsch, G.; Collings, E. Materials Properties Handbook: Titanium Alloys; ASM International: Metals Park, OH, USA, 1994. [Google Scholar]

- Fauchais, P. Understanding plasma spraying. J. Phys. D Appl. Phys. 2004, 37, 86–108. [Google Scholar] [CrossRef]

- Cheng, K.; Chen, X.; Pan, W. Comparison of laminar and turbulent thermal plasma jet characteristics—A modeling study. Plasma Chem. Plasma Process. 2006, 26, 211–235. [Google Scholar] [CrossRef][Green Version]

- Pfender, E. Fundamental studies associated with the plasma spray process. Surf. Coat. Technol. 1988, 34, 1–14. [Google Scholar] [CrossRef]

- Choi, S.S.; Hwang, T.H.; Kim, D.U.; Seo, J.H.; Kim, K.S.; Hong, S.H. Effects of Anode Nozzle Geometry on Ambient Air Entrainment into Thermal Plasma Jets Generated by a Non-transferred Plasma Torch. In Proceedings of the 30th International Conference on Plasma Science, 2003. ICOPS 2003. IEEE Conference Record—Abstracts, Jeju, Korea, 5 June 2003; p. 388. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).