Surface Optimization of ZrC–SiC Inner Layer to Enhance Ablation Property of SiC/ZrC–SiC Multi-Layer Coating for C/C Composites

Abstract

1. Introduction

2. Materials and Methods

3. Results

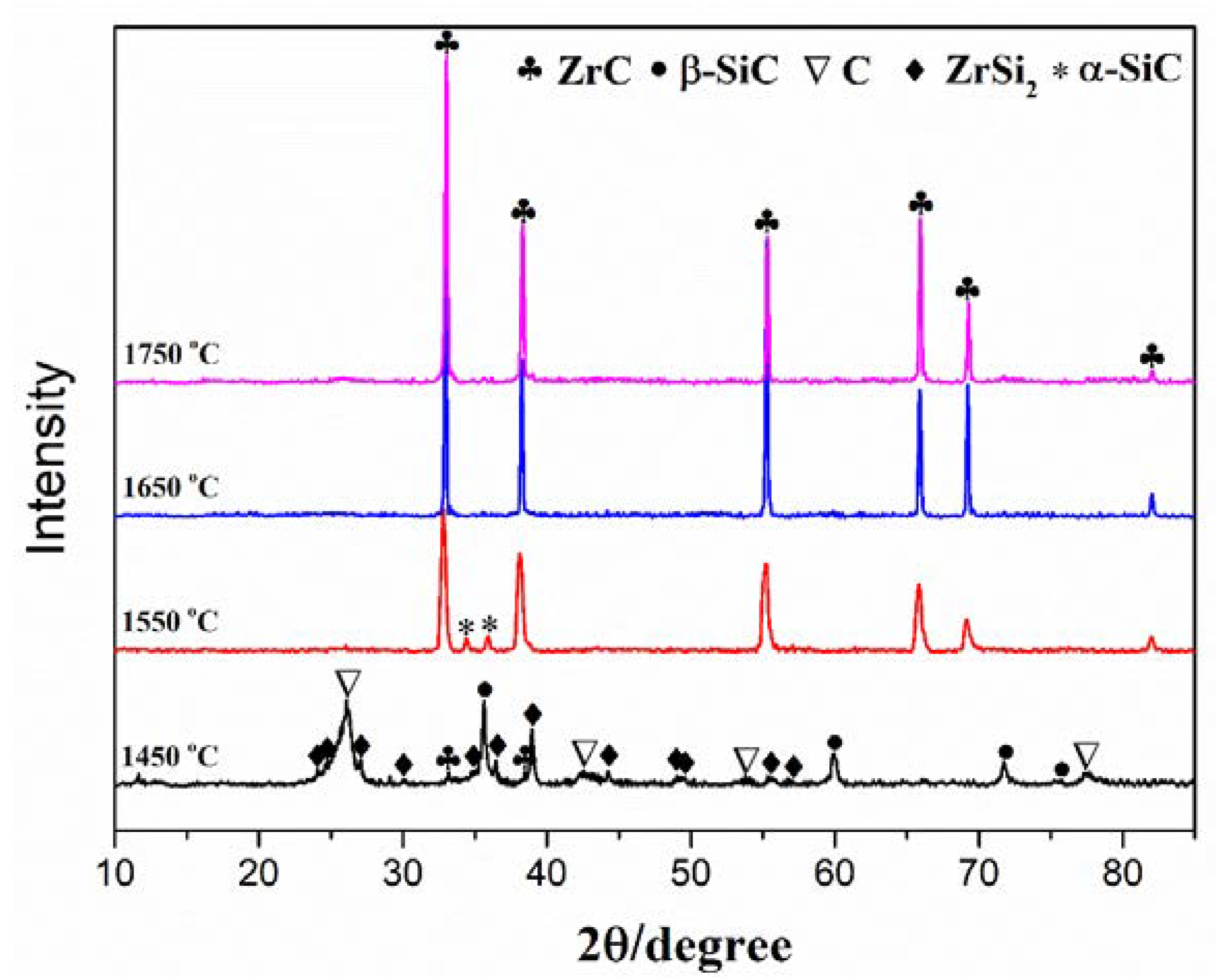

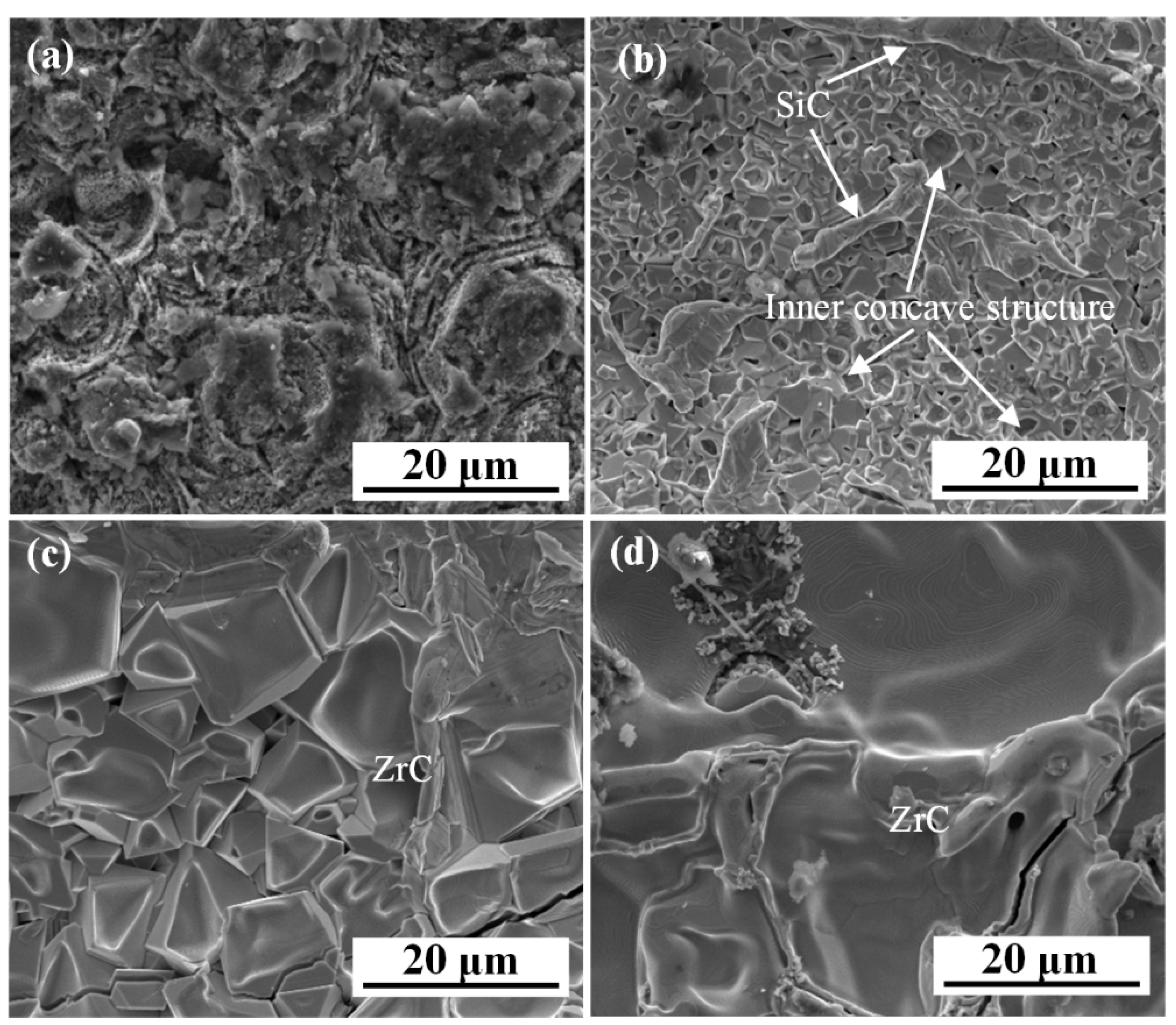

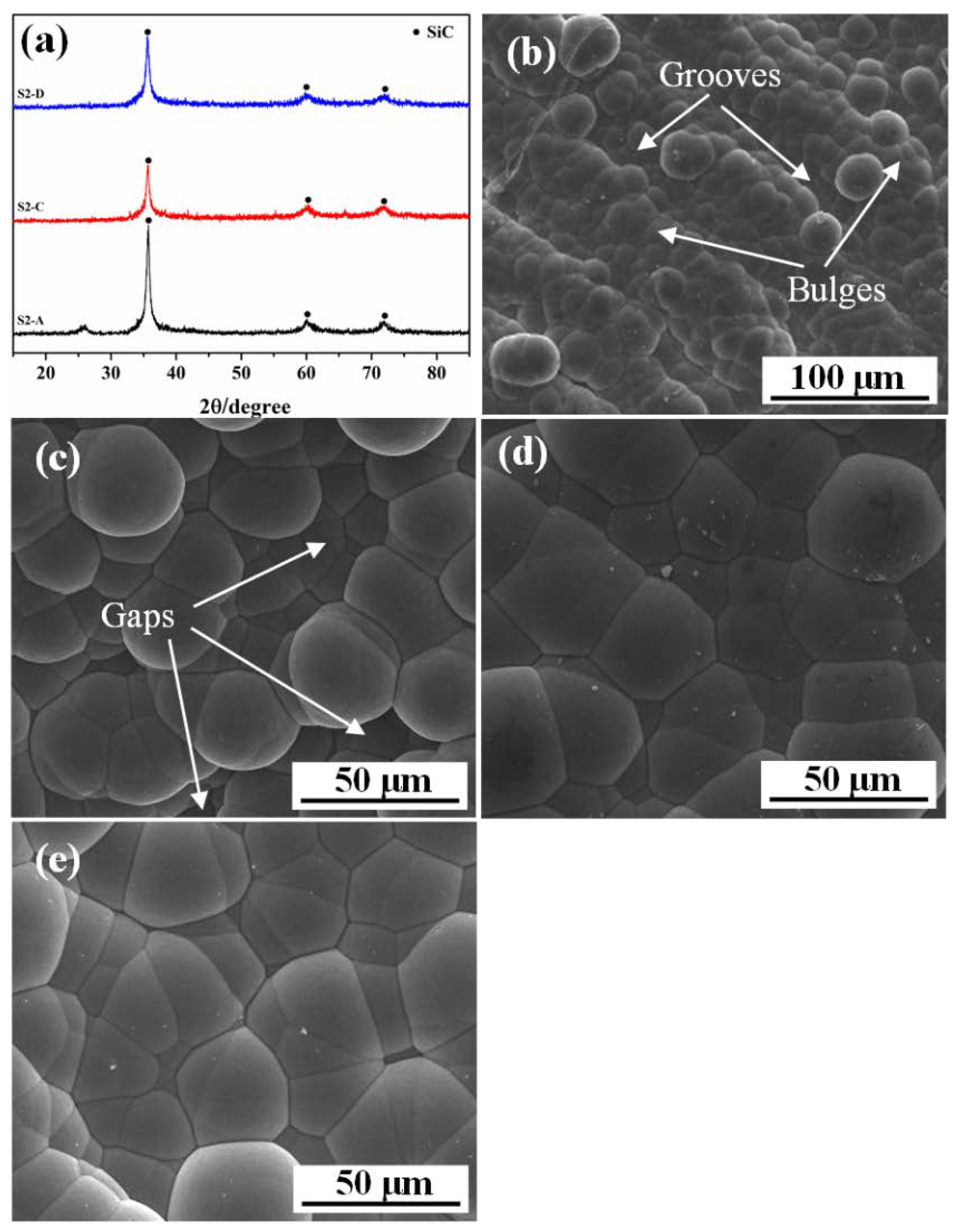

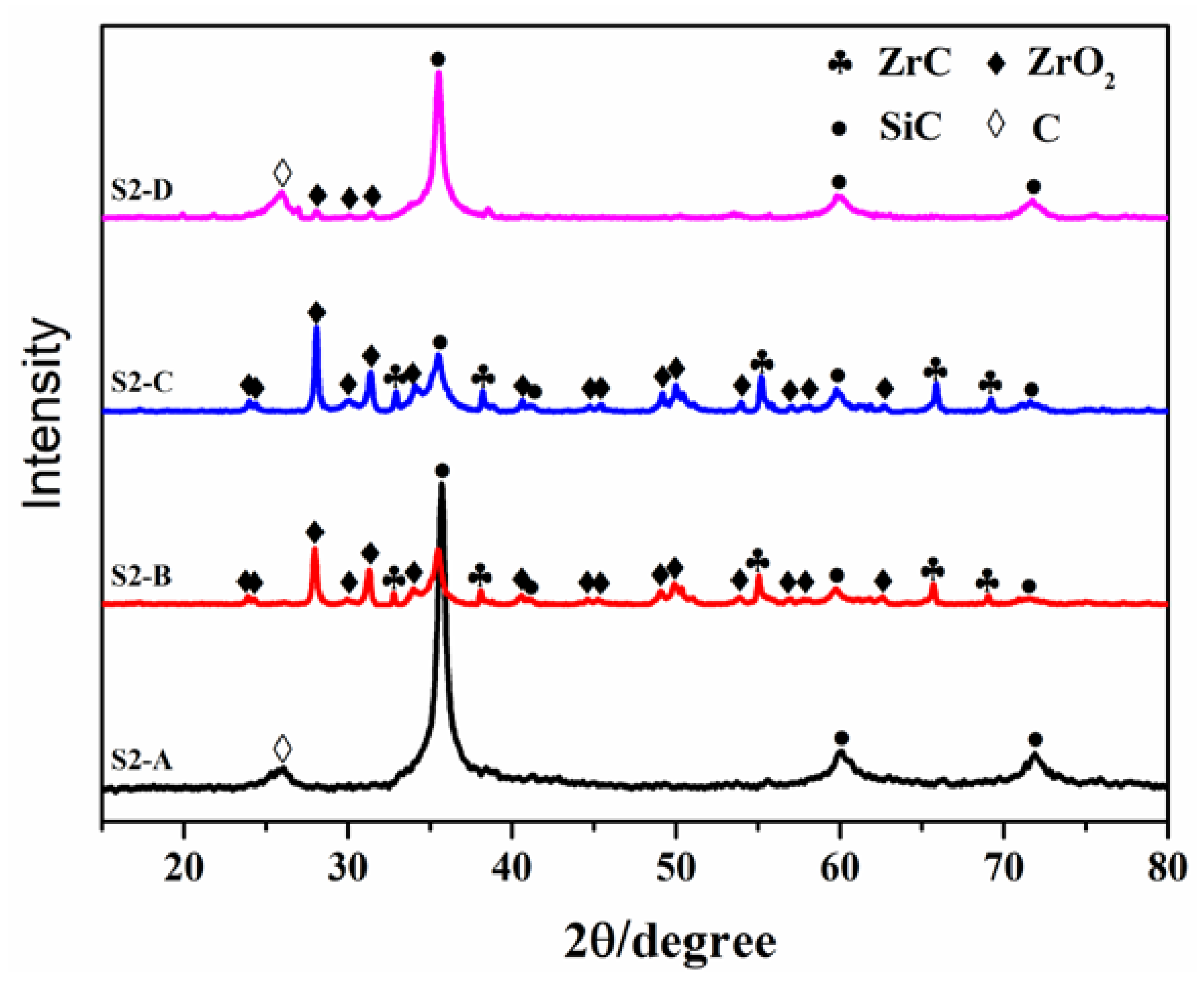

3.1. Effect of the Fabrication Temperature on Microstructure and Phase Composition of the ZrC–SiC Inner Layer

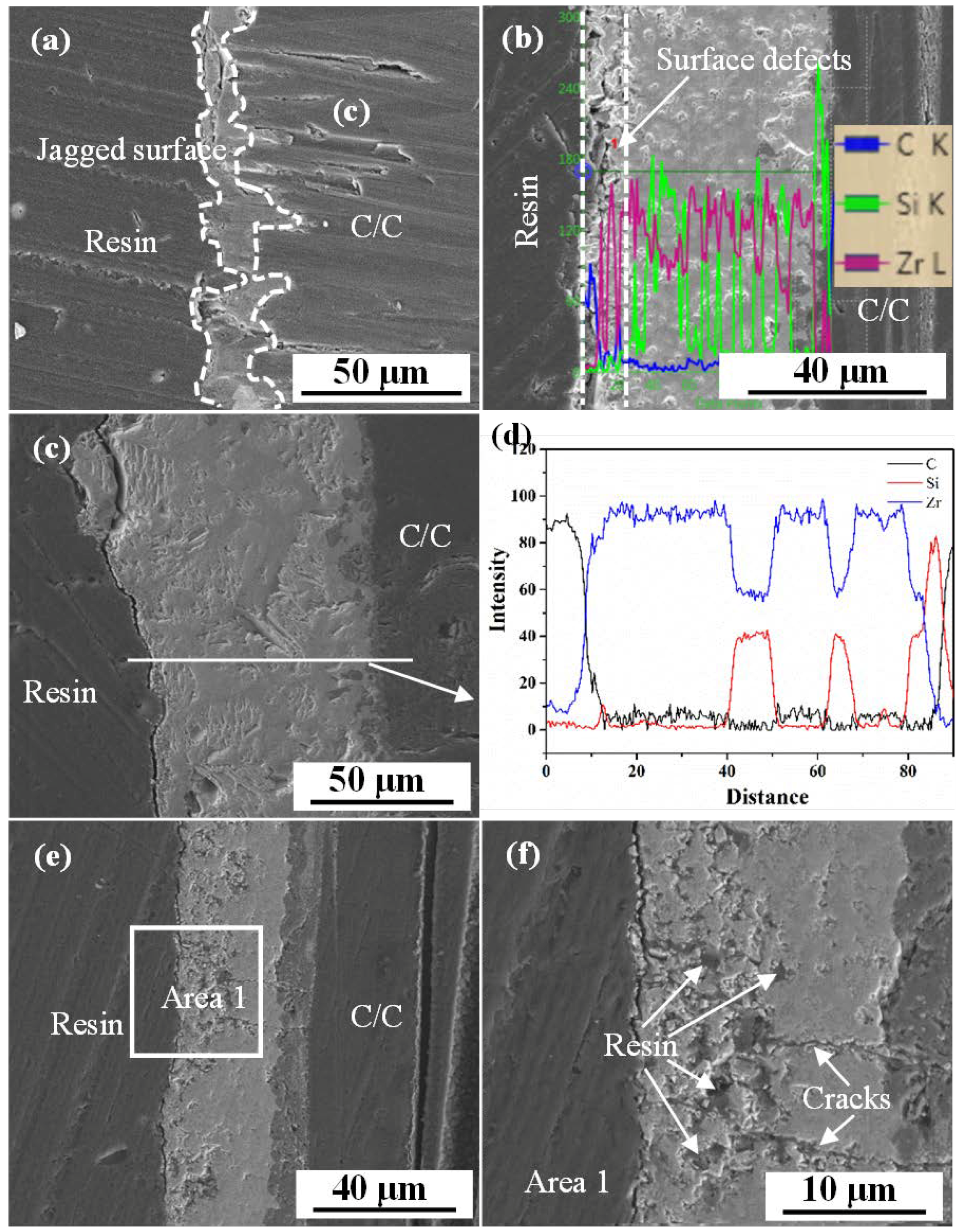

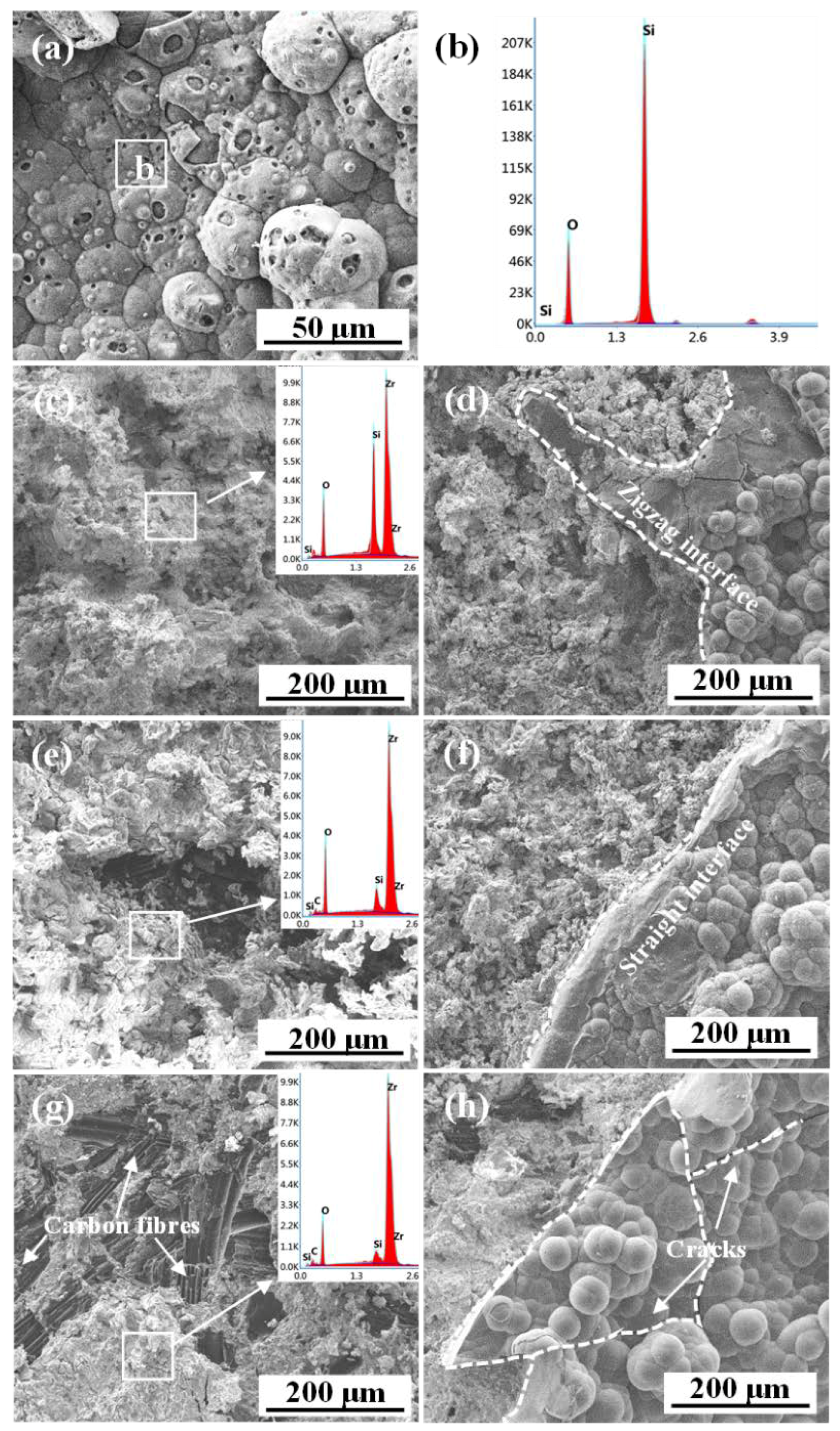

3.2. Effect of ZrC–SiC Inner Layer on Microstructure and Ablation Properties of Double-Layer ZrC–SiC/SiC Coating

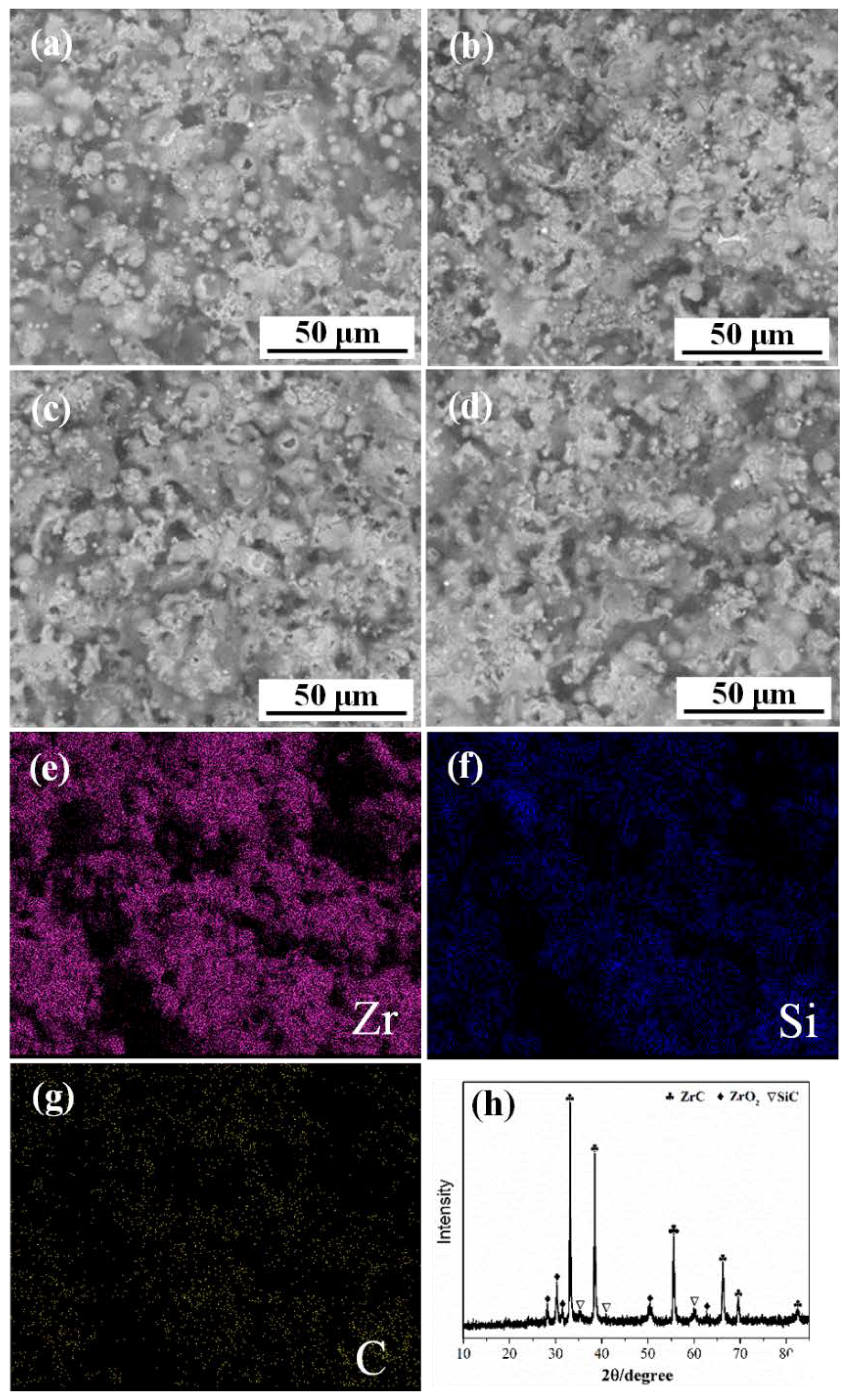

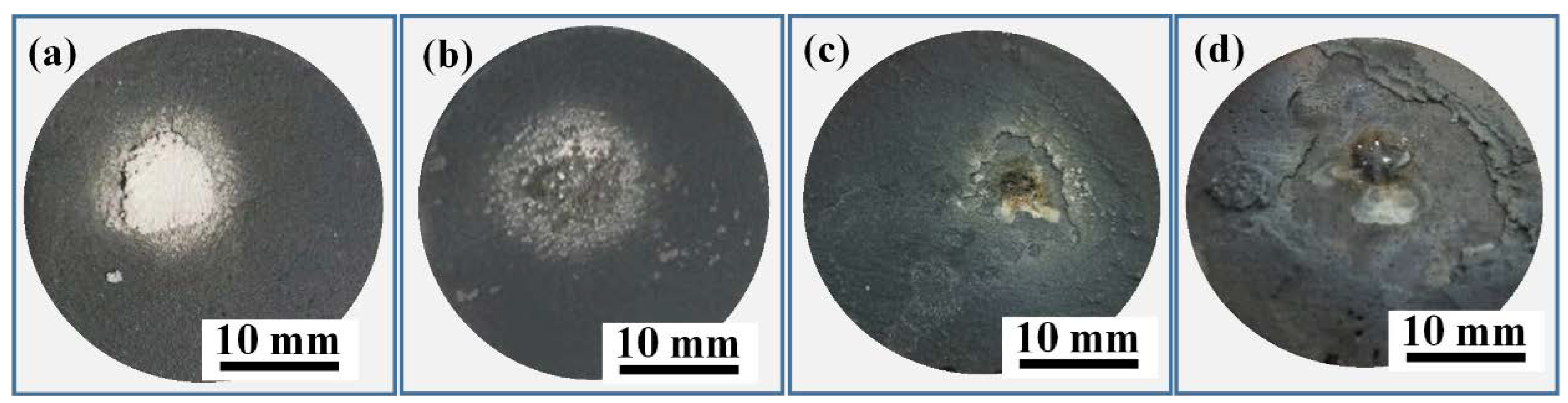

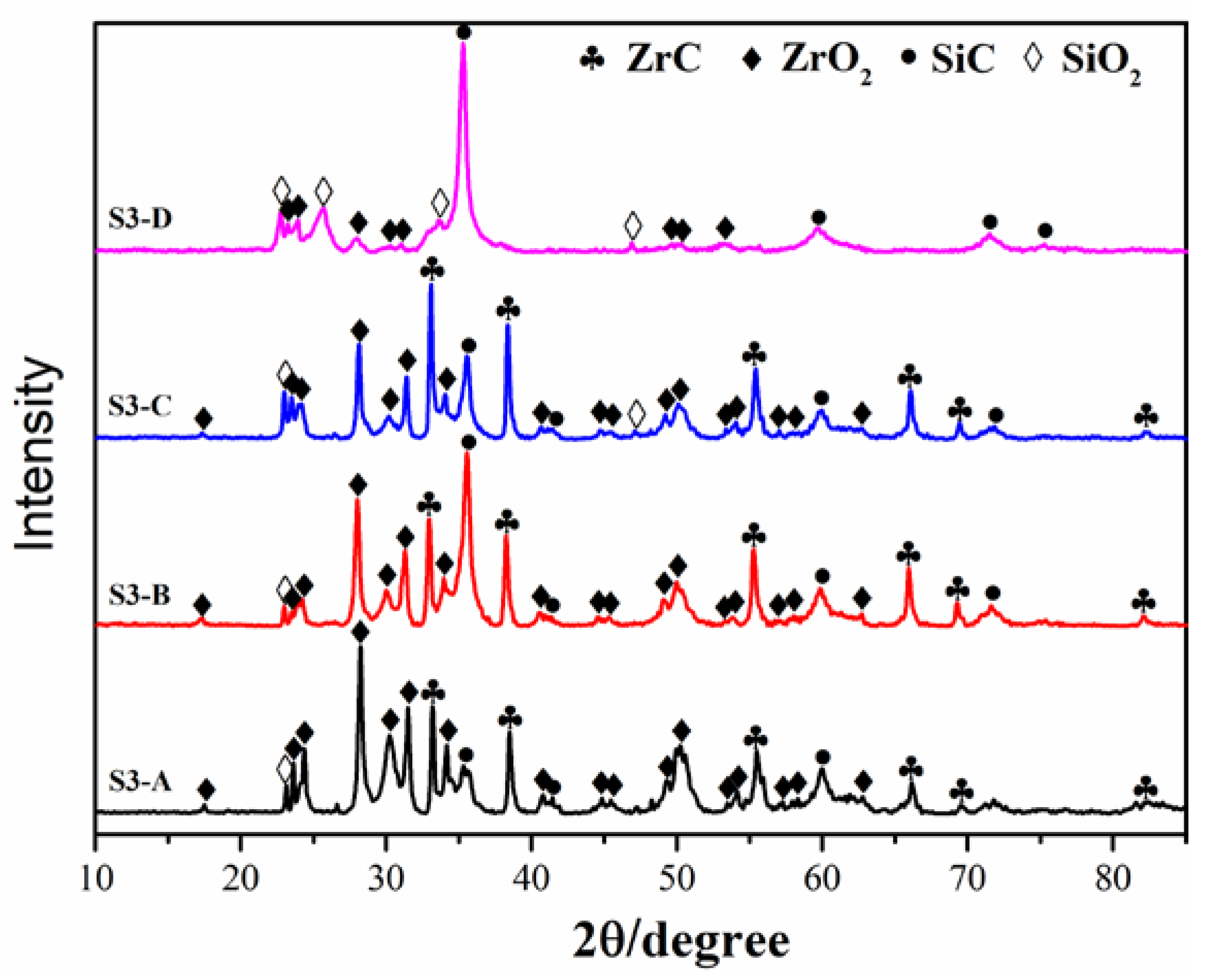

3.3. Effect of ZrC–SiC Inner Layer on Microstructure and Ablation Properties of ZrC–SiC/SiC/ZrC–SiC Tri-Layer Coating

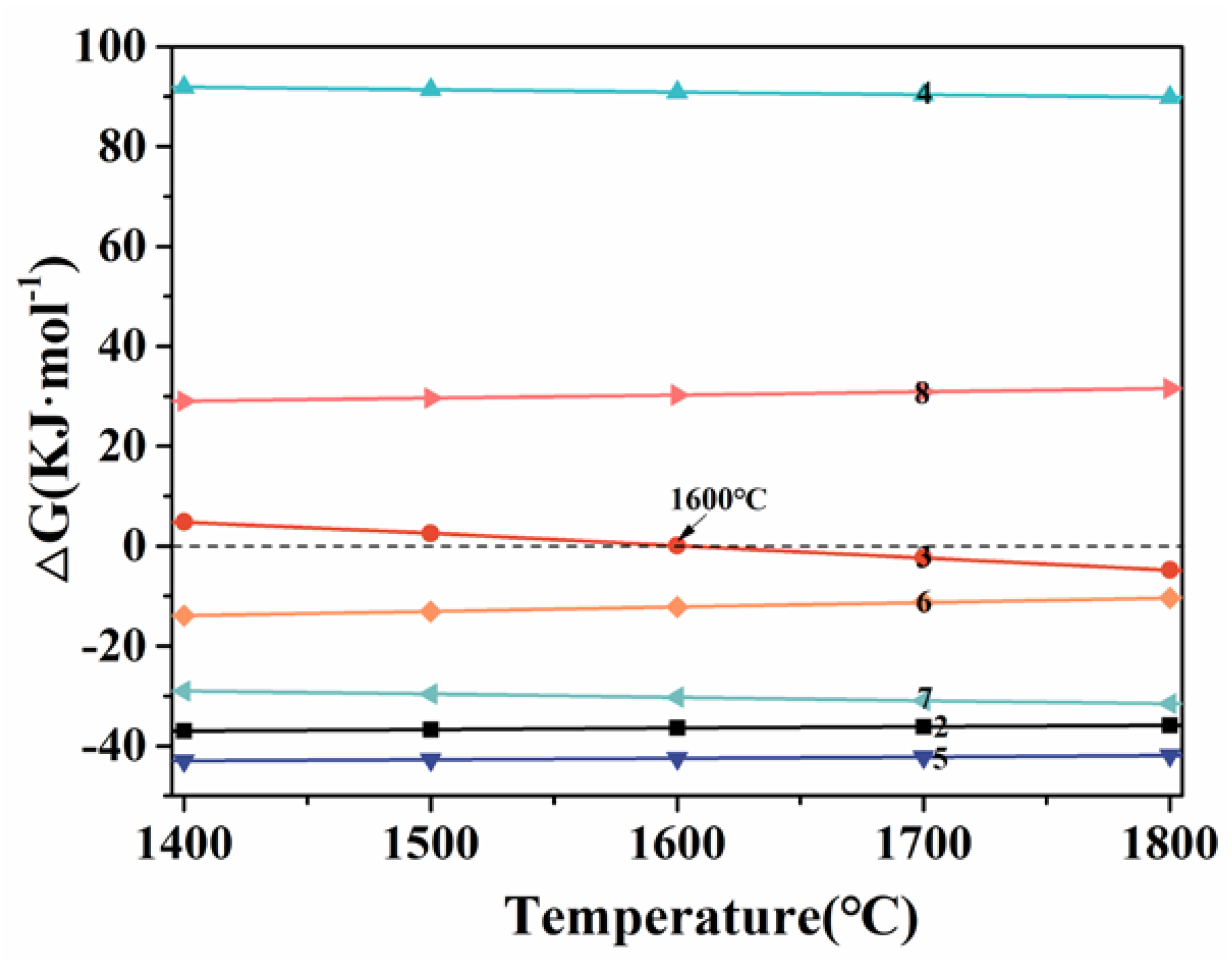

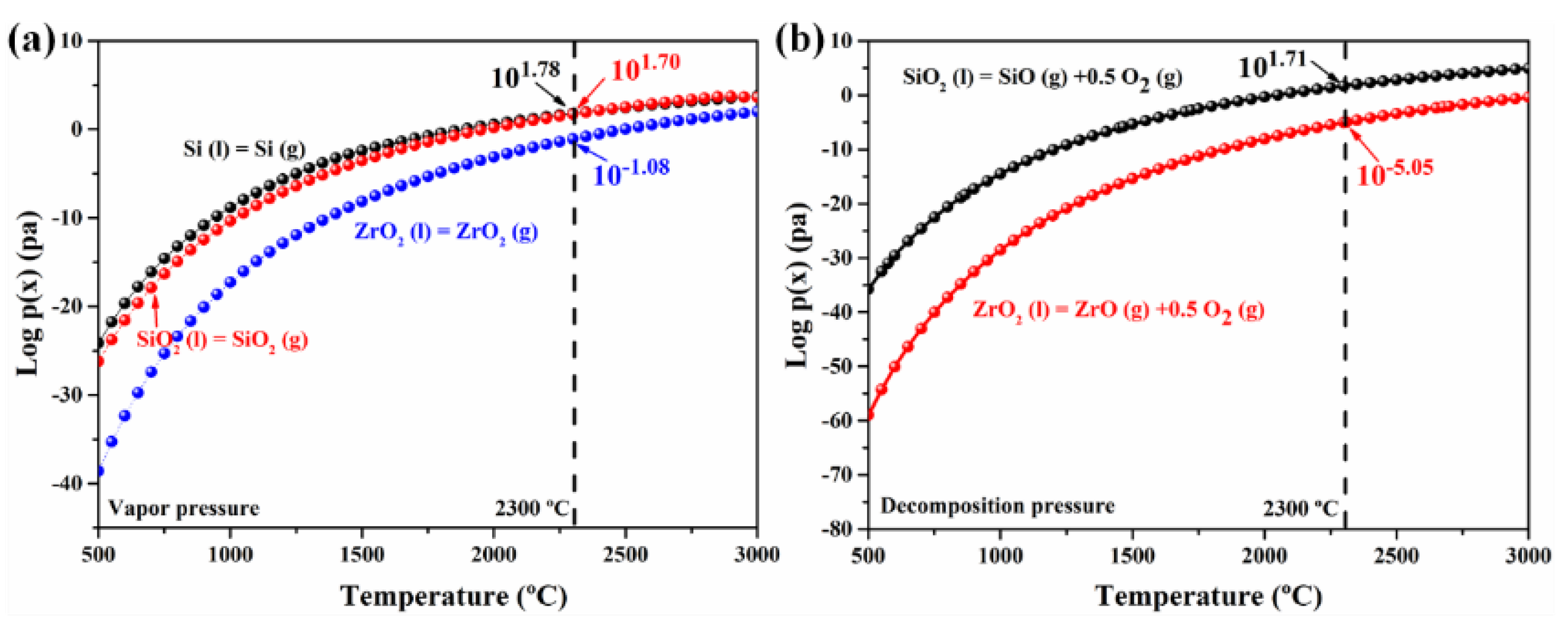

3.4. Ablation Mechanism

4. Conclusions

- (1)

- The S2-A and S3-A coatings exhibited the best ablation properties. The formation of a deep root-like pinning structure, with a strong bonding strength and good CTE match, contribute to the protection of C/C substrate;

- (2)

- With the elevated PC temperature, the growth of ZrC and SiC grains exhibited a more compact coating structure with a flat surface containing fewer defects, which could reduce interface bonding strength and deteriorate the thermal shock resistance of the multilayer coating;

- (3)

- At a higher PC temperature, the presence of high ZrC content, with a high CTE mismatch between the inner layer and outer, could cause the cracking even the failure of multilayer coating;

- (4)

- This work convinced us that the introduction of the porous ZrC–SiC inner layer had a positive effect in optimizing the ablation resistance of multilayer coatings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jin, X.; Fan, X.; Lu, C.; Wang, T. Advances in oxidation and ablation resistance of high and ultra-high temperature ceramics modified or coated carbon/carbon composites. J. Eur. Ceram. Soc. 2018, 38, 1–28. [Google Scholar] [CrossRef]

- Fang, C.; Huang, B.; Yang, X.; He, K.; Chen, L.; Shi, A.; Zhang, Z.; Huang, Q. Effects of LaB6 on the microstructures and ablation properties of 3D C/C-SiC-ZrB2-LaB6 composites. J. Eur. Ceram. Soc. 2020, 40, 2781–2790. [Google Scholar] [CrossRef]

- Mao, Z.; Yang, L. Addition of Si3N4 strengthens SiC coatings via heat treatment with nitrogen gas onto carbon/carbon composites. Coatings 2020, 10, 787. [Google Scholar] [CrossRef]

- Hu, C.; Tang, S.; Pang, S.; Cheng, H. Long-term oxidation behaviors of C/SiC composites with a SiC/UHTC/SiC three-layer coating in a wide temperature range. Corros. Sci. 2019, 147, 1–8. [Google Scholar] [CrossRef]

- Li, J.; Yang, X.; Su, Z.; Xue, L.; Zhong, P.; Li, S.; Huang, Q.; Liu, H. Effect of ZrC-SiC content on microstructure and ablation properties of C/C composites. T. Nonferr. Metal. Soc. 2016, 26, 2653–2664. [Google Scholar] [CrossRef]

- Kovaleva, M.; Goncharov, I.; Novikov, V.; Yapryntsev, M.; Vagina, O.; Pavlenko, I.; Sirota, V.; Tyurin, Y.; Kolisnichenko, O. Effect of heat treatment on the microstructure and phase composition of ZrB2-MoSi2 coating. Coatings 2019, 9, 779. [Google Scholar] [CrossRef]

- Chen, X.; Feng, Q.; Kan, Y.; Ni, D.; Zhou, H.; Gao, L.; Zhang, X.; Ding, Y.; Dong, S. Effects of preform pore structure on infiltration kinetics and microstructure evolution of RMI-derived Cf/ZrC-ZrB2-SiC composite. J. Eur. Ceram. Soc. 2020, 40, 2683–2690. [Google Scholar] [CrossRef]

- Feng, T.; Tong, M.; Yao, S.; Wen, S. A New assistant method for characterizing ablation resistance of ZrC-SiC dispersive biphasic coating on C/C composites. Coatings 2019, 9, 735. [Google Scholar] [CrossRef]

- Qing, X.; Sun, W.; Tian, T.; Xiong, X.; Zhang, H.; Chen, Z.; Zeng, Y. Structural characteristics and ablative behavior of C/C-ZrC-SiC composites reinforced with “Z-pins like” Zr-Si-B-C multiphase ceramic rods. Ceram. Int. 2020, 46, 18895–18902. [Google Scholar] [CrossRef]

- Sanchez, L.; Mello, H.; Neto, R.; Davim, J. Hot turning of a difficult-to-machine steel (sae xev-f) aided by infrared radiation. Int. J. Adv. Manuf. Tech. 2014, 73, 887–898. [Google Scholar] [CrossRef]

- Polvorosa, R.; Suárez, A.; Lacalle, L.; Cerrillo, I.; Wretland, A.; Veiga, F. Tool wear on nickel alloys with different coolant pressures: Comparison of alloy 718 and waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; López de Lacalle, L.; Polvorosa, R. Enhanced performance of nanostructured coatings for drilling by droplet elimination. Mater. Manuf. Process. 2014, 31, 593–602. [Google Scholar] [CrossRef]

- Qiang, X.; Li, H.; Zhang, Y.; Wang, Z.; Ba, Z.; Zhang, X. Mechanical and oxidation protective properties of SiC nanowires-toughened SiC coating prepared in-situ by a CVD process on C/C composites. Surf. Coat. Tech. 2016, 307, 91–98. [Google Scholar] [CrossRef]

- Zhuang, L.; Fu, Q.; Yu, X. Improved thermal shock resistance of SiCnw/PyC core-shell structure-toughened CVD-SiC coating. J. Eur. Ceram. Soc. 2018, 38, 2808–2814. [Google Scholar] [CrossRef]

- Fu, Q.; Zhuang, L.; Li, H.; Feng, L.; Jing, J.; Tan, B. Effect of carbon nanotubes on the toughness, bonding strength and thermal shock resistance of SiC coating for C/C-ZrC-SiC composites. J. Alloys Compd. 2015, 645, 206–212. [Google Scholar] [CrossRef]

- Chu, Y.; Li, H.; Fu, Q.; Qi, L.; Li, L. Bamboo-shaped SiC nanowire-toughened SiC coating for oxidation protection of C/C composites. Corros. Sci. 2013, 70, 11–16. [Google Scholar] [CrossRef]

- Madhura, B.; Vetrivendan, E.; Jagadeeswara, R.C.; Udayakumar, A.; Ningshen, S. Surface optimization of CVD grown silicon carbide interlayer on graphite for plasma sprayed yttria topcoat. Surf. Coat. Tech. 2020, 383, 125250. [Google Scholar]

- Zhang, J.; Fu, Q.; Qu, J.; Yuan, R.; Li, H. Blasting treatment and chemical vapor deposition of SiC nanowires to enhance the thermal shock resistance of SiC coating for carbon/carbon composites in combustion environment. J. Alloys Compd. 2016, 666, 77–83. [Google Scholar] [CrossRef]

- Zhang, J.; Fu, Q.; Qu, J. Enhanced bonding strength and thermal cycling performance of MoSi2-CrSi2-SiC-Si coating for carbon/carbon composites by surface modification via blasting treatment. Ceram. Int. 2016, 42, 14021–14027. [Google Scholar] [CrossRef]

- Zhang, Y.; Fei, T.; Zeng, W.; Yang, B.; Li, H.; Li, K. Microstructure and oxidation behavior of C/C-ZrB2-SiC composites coated with SiC coating at high temperature. Corros. Sci. 2015, 100, 421–427. [Google Scholar] [CrossRef]

- Wang, P.; Tong, M.; Wang, H.; Li, H.; Jia, Y.; Li, B.; Zhang, Y.; Zhao, Z. Gradient HfB2-SiC multilayer oxidation resistant coating for C/C composites. Ceram. Int. 2018, 44, 20968–20973. [Google Scholar] [CrossRef]

- Vetrivendan, E.; Madhura, B.; Rao, C.J.; Ningshen, S. Pack cemented silicon carbide interlayer for plasma sprayed yttria over graphite. Mater. Manuf. Process. 2019, 34, 681–688. [Google Scholar] [CrossRef]

- Shi, A.; Yang, X.; Fang, C.; Chen, L.; Weng, Y.; Liu, H.; Huang, Q. Effect of CNTs addition on microstructure, ablation property and mechanism of ZrC-SiC coating for C/C-ZrC-SiC composites. Vacuum 2020, 172, 109099. [Google Scholar] [CrossRef]

- Fang, C.; Yang, X.; He, K.; Chen, L.; Zeng, G.; Shi, A.; Huang, Q.; Huang, B. Microstructure and ablation properties of La2O3 modified C/C-SiC composites prepared via precursor infiltration pyrolysis. J. Eur. Ceram. Soc. 2019, 39, 762–772. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, H.; Ren, J.; Li, T.; Fei, T.; Wang, C. Effect of the surface microstructure of SiC inner coating on the bonding strength and ablation resistance of ZrB2-SiC coating for C/C composites. Ceram. Int. 2016, 42, 18657–18665. [Google Scholar] [CrossRef]

- Liu, B.; Shi, A.; Yang, G.; Su, Q.; Chen, G.; Zhang, L.; Yang, B. Recovery of tungsten carbides for preparing ultrafine WC-Co composite powder using core-shell structured precursor synthesized by CVD. Int. J. Refract. Met. Hard Mater. 2017, 67, 74–81. [Google Scholar] [CrossRef]

- Valle, R.; Lévêque, D.; Parlier, M. Optimizing substrate and intermediate layers geometry to reduce internal thermal stresses and prevent surface crack formation in 2-D multilayered ceramic coatings. J. Eur. Ceram. Soc. 2008, 28, 711–716. [Google Scholar] [CrossRef]

- Tong, Y.; Bai, S.; Chen, K. C/C-ZrC composite prepared by chemical vapor infiltration combined with alloyed reactive melt infiltration. Ceram. Int. 2012, 38, 5723–5730. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, F.; You, Y.; Guo, M.; Zhong, Y.; Wang, P.; Lin, J.; Zhu, Z.; Zhu, L. Growth process and mechanism of SiC layer deposited by CVD method at normal atmosphere. J. Eur. Ceram. Soc. 2019, 39, 4495–4500. [Google Scholar] [CrossRef]

- Xu, Y.; Cheng, L.; Zhang, L.; Zhou, W. Morphology and growth mechanism of silicon carbide chemical vapor deposited at low temperatures and normal atmosphere. J. Mater. Sci. 1999, 34, 551–555. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, F.; Guo, M.; Zhong, Y.; Wang, P.; Lin, J.; Zhu, Z. Preparation of SiC layer with sub-micro grain structure in TRISO particles by spouted bed CVD. J. Eur. Ceram. Soc. 2019, 39, 2839–2845. [Google Scholar] [CrossRef]

- Sciti, D.; Guicciardi, S.; Nygren, M. Spark plasma sintering and mechanical behaviour of ZrC-based composites. Scripta. Mater. 2008, 59, 638–641. [Google Scholar] [CrossRef]

- Liu, T.; Niu, Y.; Li, C.; Pan, X.; Shi, M.; Zheng, X.; Ding, C. Ablation resistance of ZrC-MoSi2/ZrC-SiC double-layered coating in a plasma flame. Corros. Sci. 2018, 145, 239–248. [Google Scholar] [CrossRef]

- Liu, T.; Niu, Y.; Li, C.; Pan, X.; Shi, M.; Zheng, X.; Ding, C. Laser ablation behaviors of vacuum plasma sprayed ZrC-based coatings. J. Am. Ceram. Soc. 2019, 102, 4247–4258. [Google Scholar] [CrossRef]

- Xu, J.; Sun, W.; Xu, Y.; Xiong, X.; Deng, N.; Zhang, H.; Yin, J. Microstructures and ablation resistance of WSi2/ZrSi2/ZrxHf1−xC/SiC coating based on a pattern strengthening one-step method. J. Eur. Ceram. Soc. 2021, 41, 38–53. [Google Scholar] [CrossRef]

- Zou, J.; Rubio, V.; Binner, J. Thermoablative resistance of ZrB2-SiC-WC ceramics at 2400 °C. Acta Mater. 2017, 133, 293–302. [Google Scholar] [CrossRef]

- Sun, J.; Fu, Q.; Guo, L.; Wang, L. Silicide Coating Fabricated by HAPC/SAPS Combination to Protect Niobium Alloy from Oxidation. ACS Appl. Mater. Inter. 2016, 8, 15838–15847. [Google Scholar] [CrossRef]

| Parameters | PS |

|---|---|

| Plasma gas, Ar (L/min) | 30~75 |

| Plasma gas, H2 (L/min) | 6~15 |

| Powder, kW | 35~55 |

| Spray distance, mm | 80~120 |

| Sample | Temperature (°C) | Porosity (%) | Density (g/cm3) |

|---|---|---|---|

| S1-A | 1450 | 2.2 | 1.77 |

| S1-B | 1550 | 2.0 | 2.00 |

| S1-C | 1650 | 1.6 | 2.03 |

| S1-D | 1750 | 2.2 | 1.91 |

| Sample | Mass Ablation Rate (mg/s) | Linear Ablation Rate (μm/s) |

|---|---|---|

| 0–60 s | 0–60 s | |

| S2-A | 0.13 ± 0.07 | −0.12 ± 0.01 |

| S2-B | 0.30 ± 0.05 | 12.35 ± 0.06 |

| S2-C | 0.33 ± 0.12 | 15.43 ± 0.09 |

| S2-D | 0.90 ± 0.16 | 24.69 ± 0.15 |

| Sample | Mass Ablation Rate (mg/s) | Linear Ablation Rate (μm/s) |

|---|---|---|

| 60 s | 60 s | |

| S3-A | 0.03 ± 0.02 | 0.02 ± 0.05 |

| S3-B | 0.18 ± 0.07 | 2.00 ± 0.02 |

| S3-C | 0.82 ± 0.04 | 3.07 ± 0.06 |

| S3-D | 1.92 ± 0.15 | 3.20 ± 0.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, A.; Yang, X.; Fang, C.; Weng, Y.; Luo, X.; Zhang, Z.; Huang, Q. Surface Optimization of ZrC–SiC Inner Layer to Enhance Ablation Property of SiC/ZrC–SiC Multi-Layer Coating for C/C Composites. Coatings 2021, 11, 378. https://doi.org/10.3390/coatings11040378

Shi A, Yang X, Fang C, Weng Y, Luo X, Zhang Z, Huang Q. Surface Optimization of ZrC–SiC Inner Layer to Enhance Ablation Property of SiC/ZrC–SiC Multi-Layer Coating for C/C Composites. Coatings. 2021; 11(4):378. https://doi.org/10.3390/coatings11040378

Chicago/Turabian StyleShi, Anhong, Xin Yang, Cunqian Fang, Yuanqi Weng, Xiao Luo, Ze Zhang, and Qizhong Huang. 2021. "Surface Optimization of ZrC–SiC Inner Layer to Enhance Ablation Property of SiC/ZrC–SiC Multi-Layer Coating for C/C Composites" Coatings 11, no. 4: 378. https://doi.org/10.3390/coatings11040378

APA StyleShi, A., Yang, X., Fang, C., Weng, Y., Luo, X., Zhang, Z., & Huang, Q. (2021). Surface Optimization of ZrC–SiC Inner Layer to Enhance Ablation Property of SiC/ZrC–SiC Multi-Layer Coating for C/C Composites. Coatings, 11(4), 378. https://doi.org/10.3390/coatings11040378