Quo Vadis: AlCr-Based Coatings in Industrial Applications

Abstract

1. Introduction

2. Deposition Technologies and Coating Systems

2.1. Arc Deposition Methods

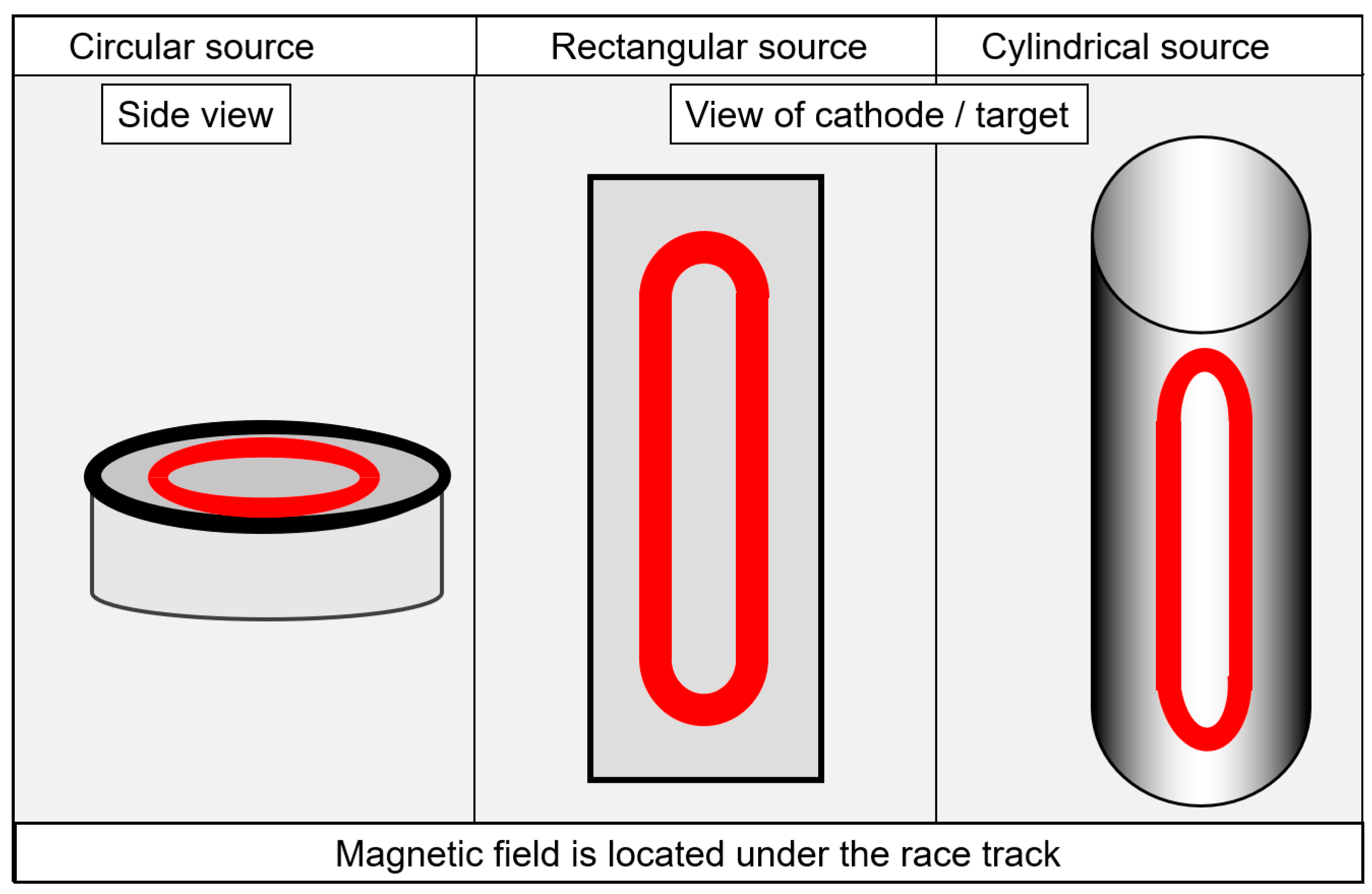

2.2. Sputtering Methods

2.2.1. DC and RF Sputtering

2.2.2. Standard Pulsed Sputtering and HiPIMS

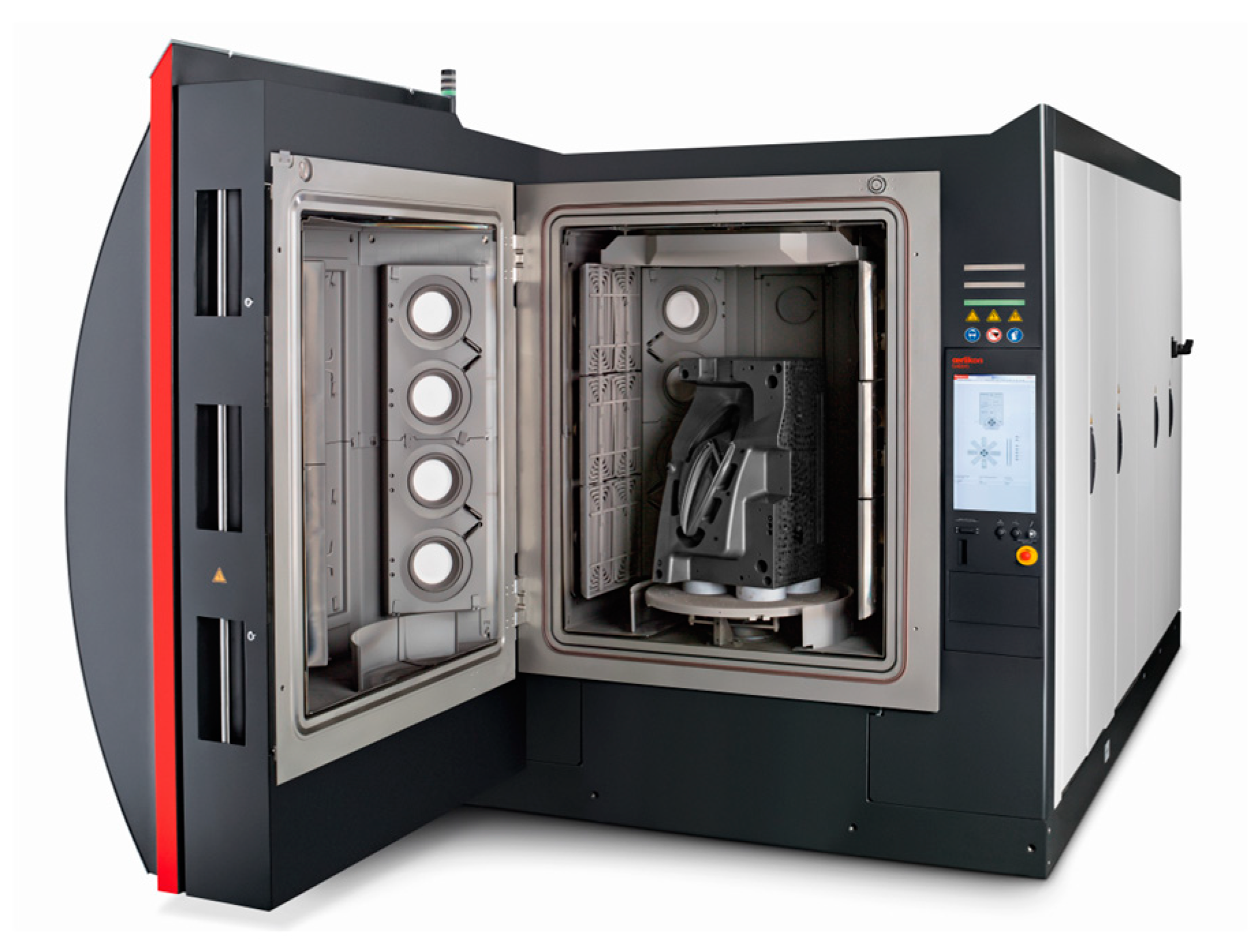

2.3. Industrial Coating Systems

3. Basic Properties of CrAlN and AlCrN Coatings

- If only the cathode composition is given and the stoichiometry in the coating is assumed to be equivalent to the cathode composition, the coating is described as (Al(100−x)Crx)N with 100 in at.%, e.g., (Al70Cr30)N.

- If the metallic elements (and metalloids) were measured, but only a general statement about the stoichiometry is made, the coatings are described as (Al(100−x)Cx)N with 100 in at.%, e.g., (Al70Cr30)N.

- If both metallic elements (and metalloids) and the N, O (and C) content were measured, all values are given as AlxCryNuOw, where x + y + u + w = 100 at.%, e.g., Al33Cr16N48O3.

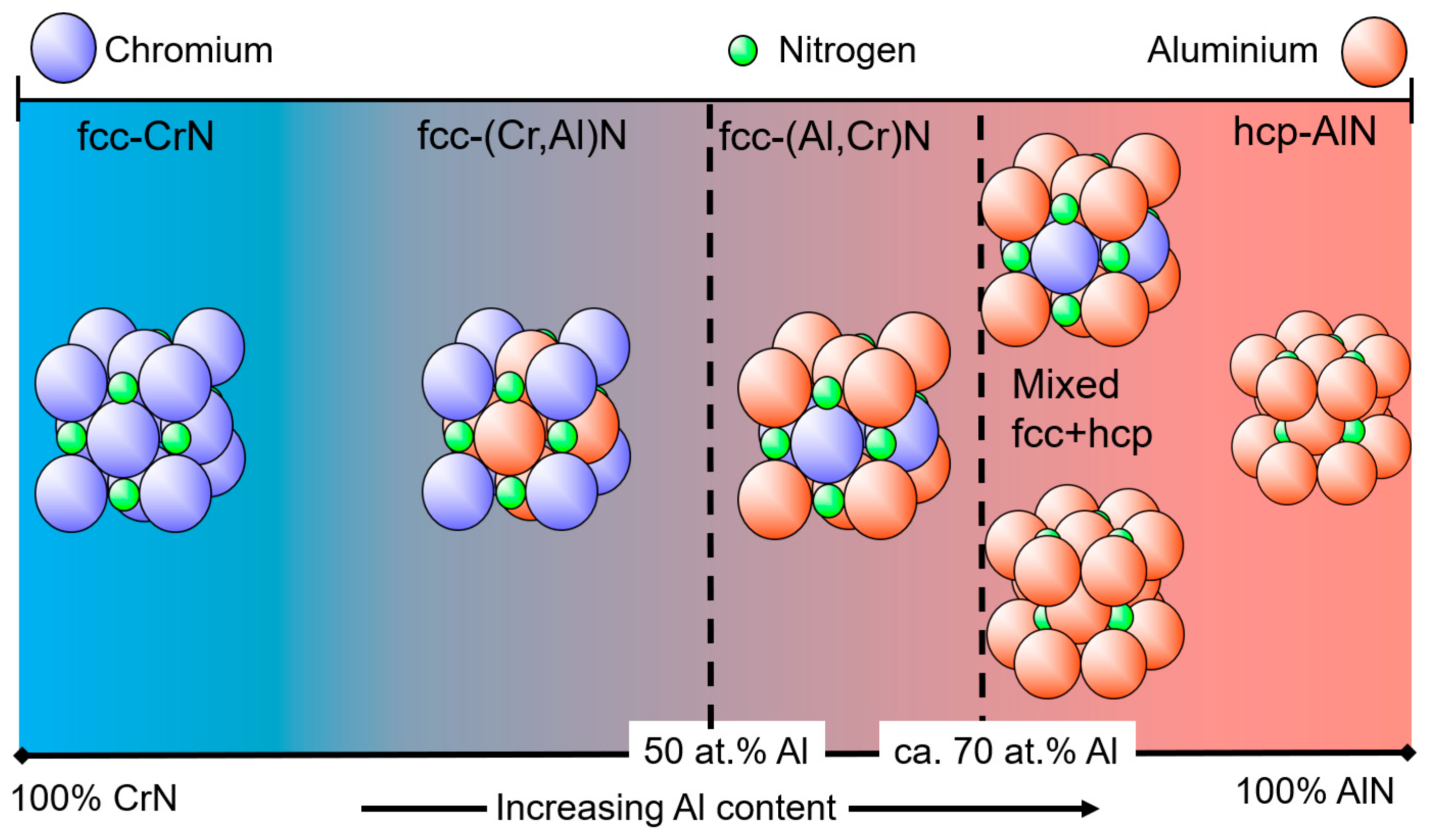

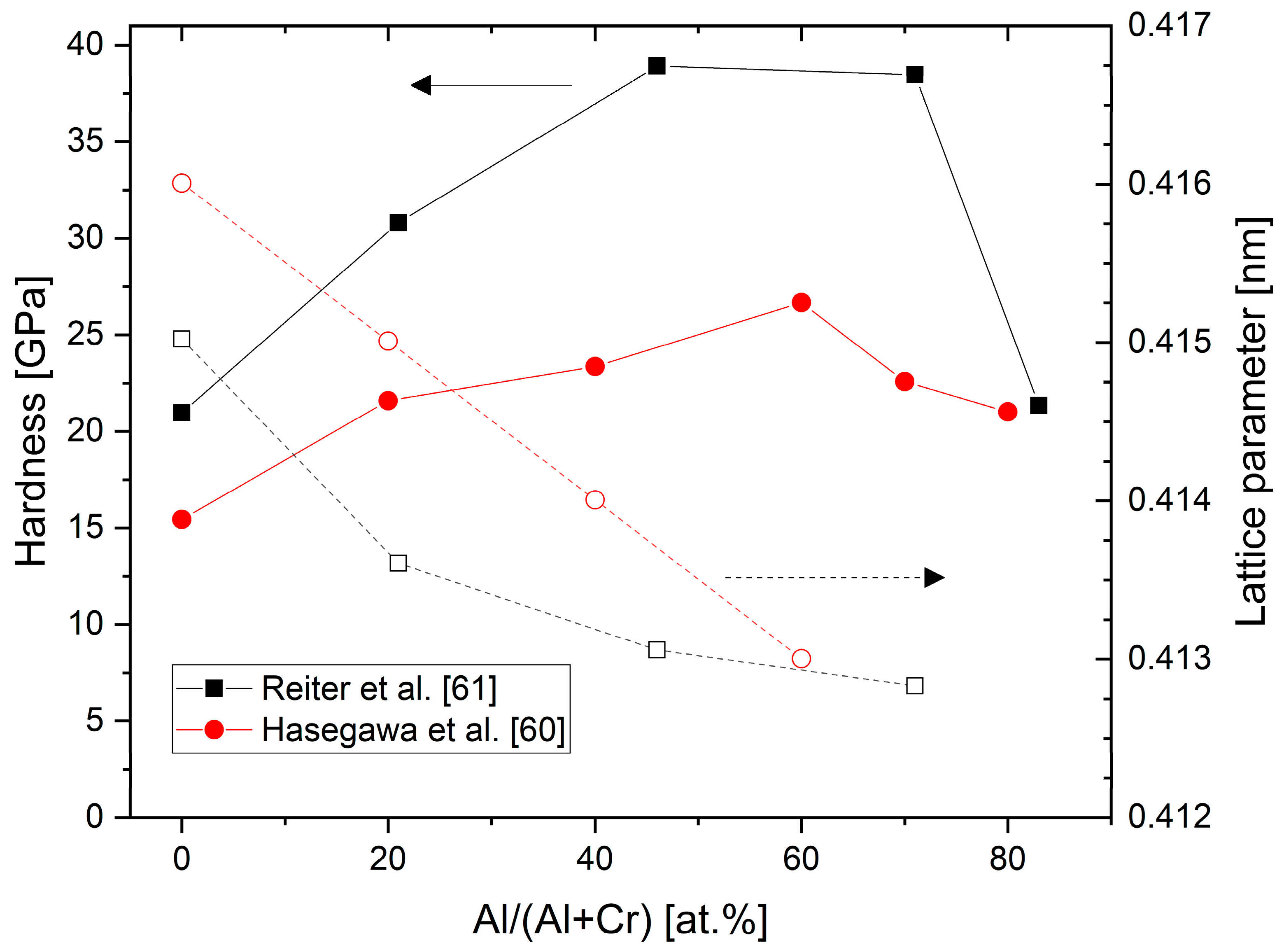

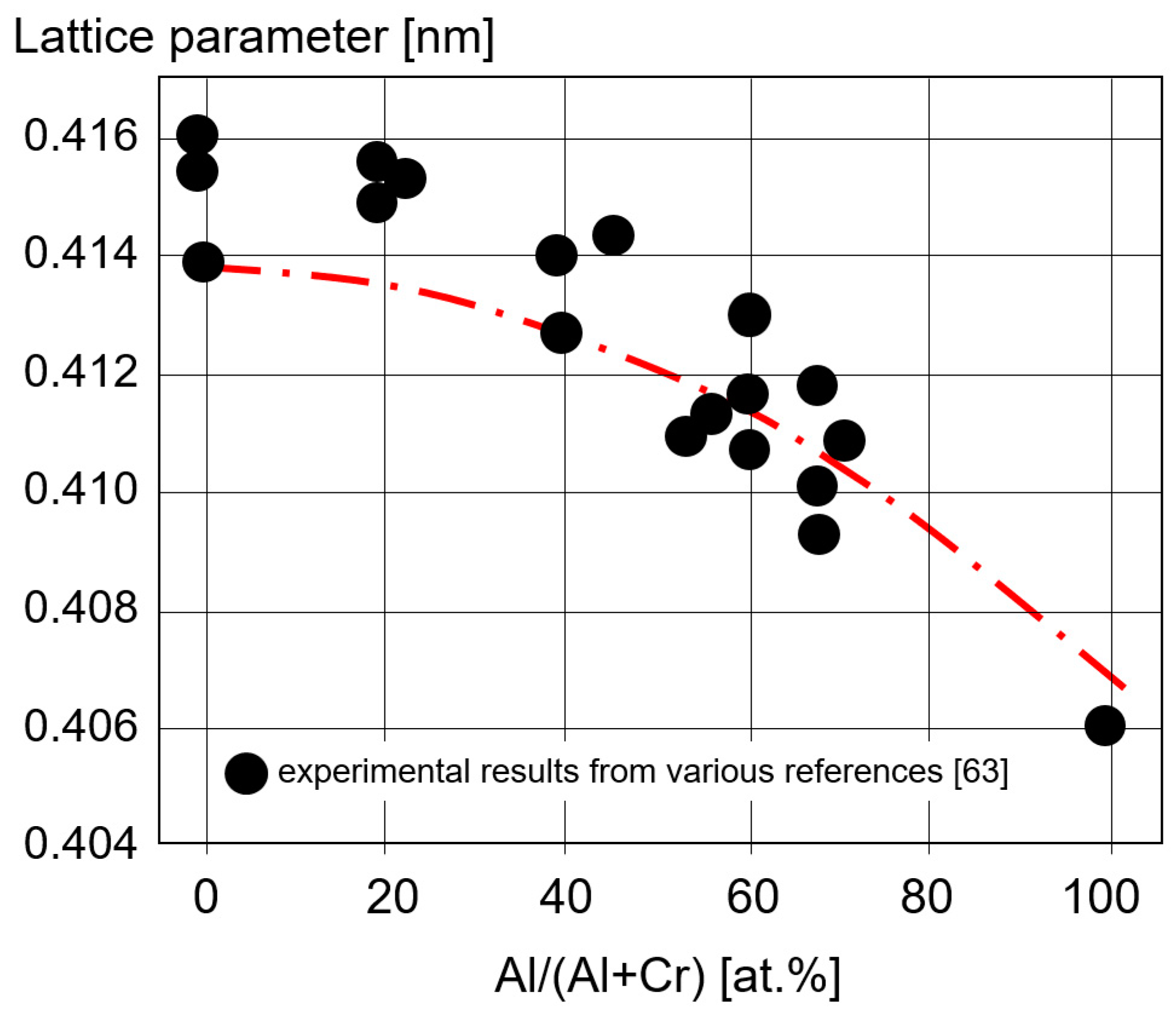

3.1. The Influence of Al Content on Lattice Parameters, Phases and Microhardness

3.2. Mechanical and Physical Properties

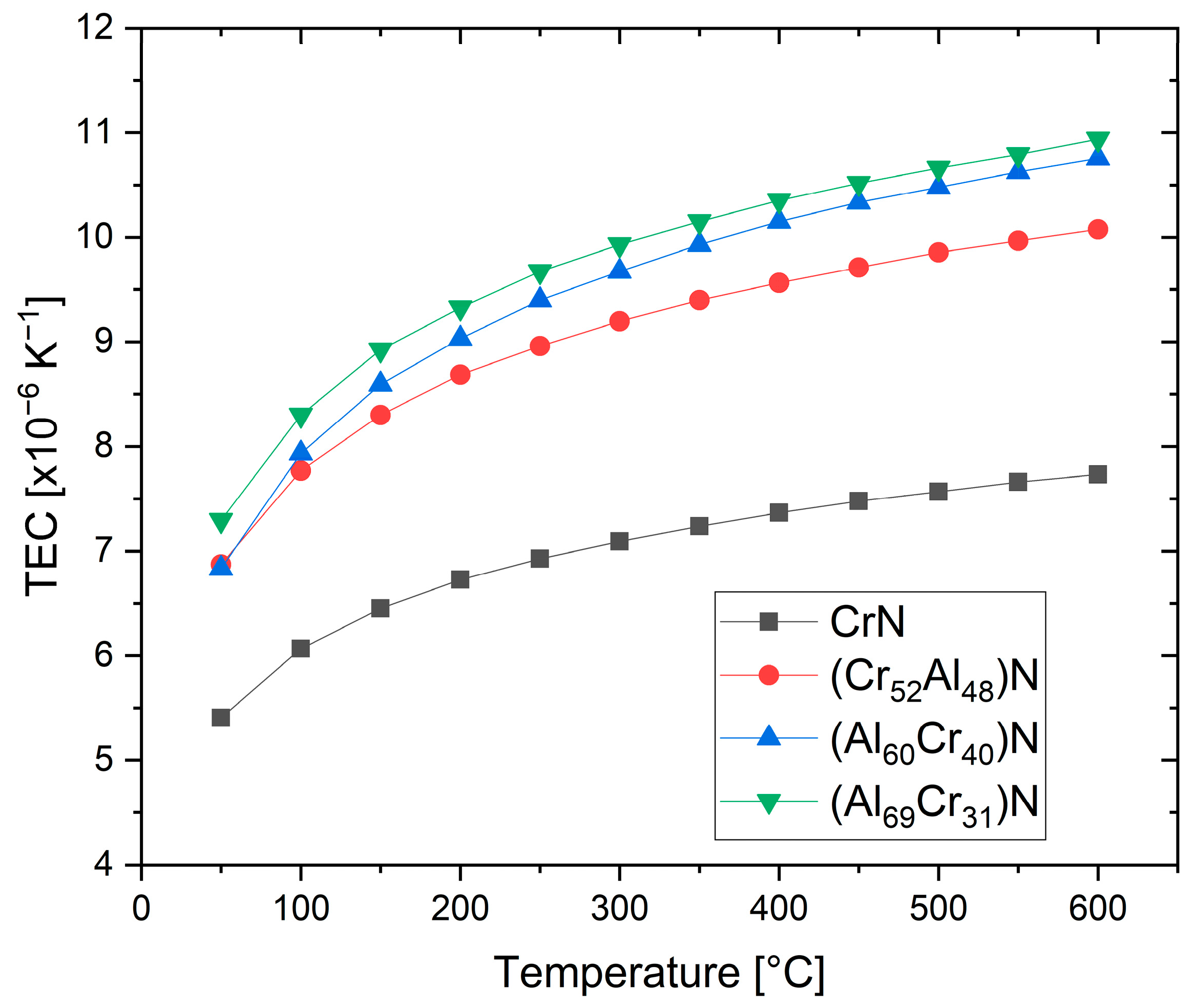

3.2.1. Thermal Expansion

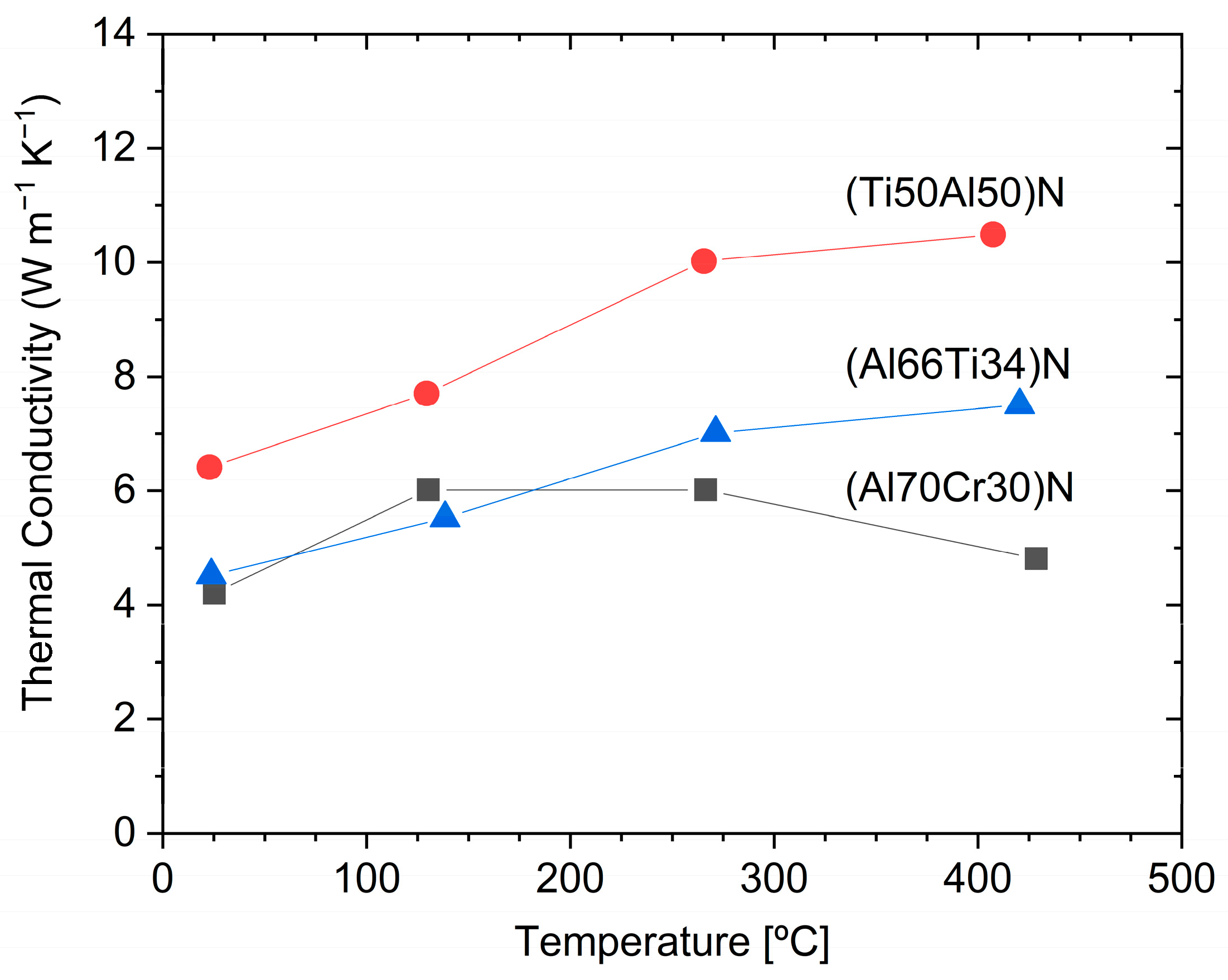

3.2.2. Thermal Conductivity

3.2.3. Electrical Resistivity

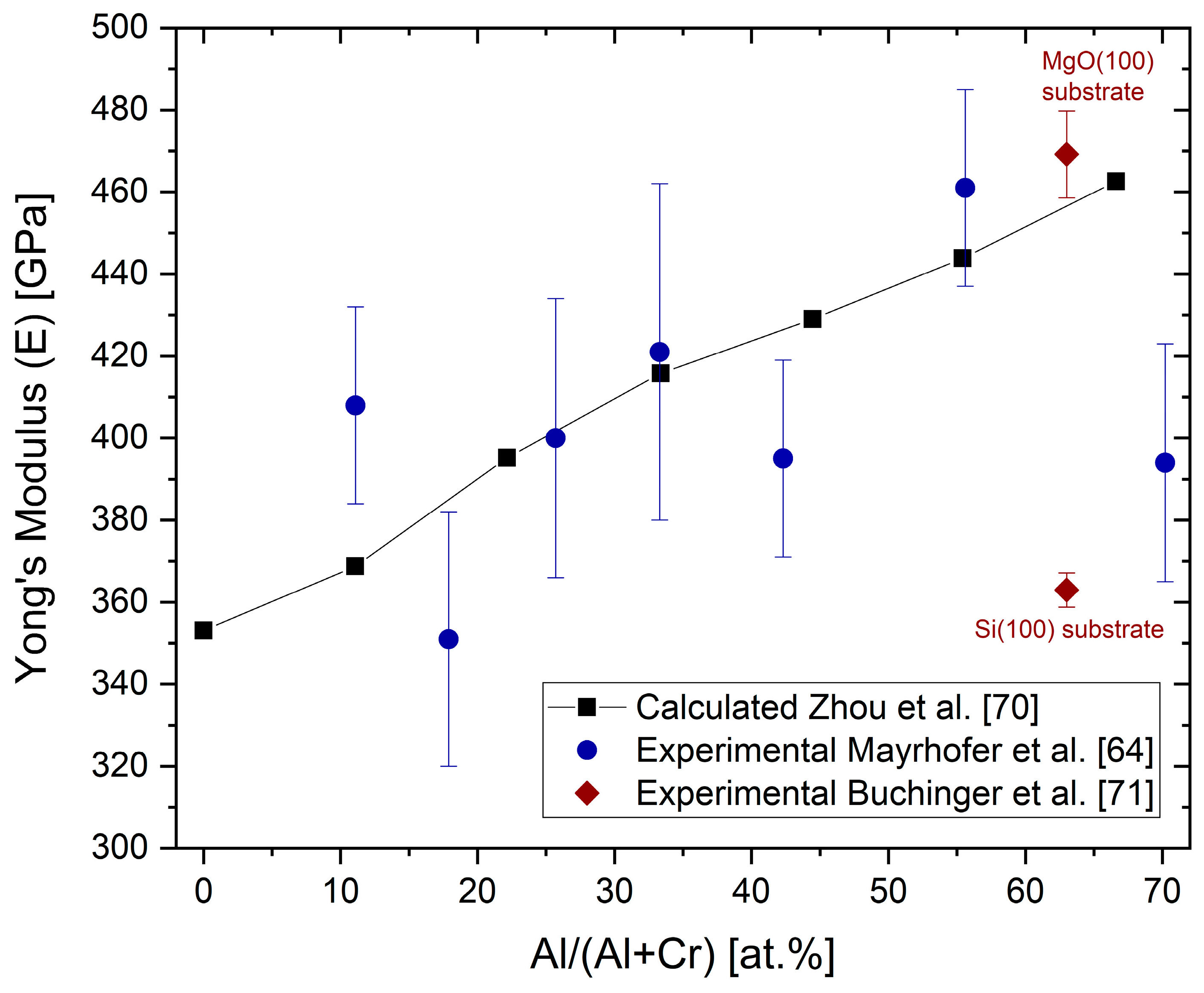

3.2.4. Poisson’s Ratio, Young’s Moduli, Fracture Toughness

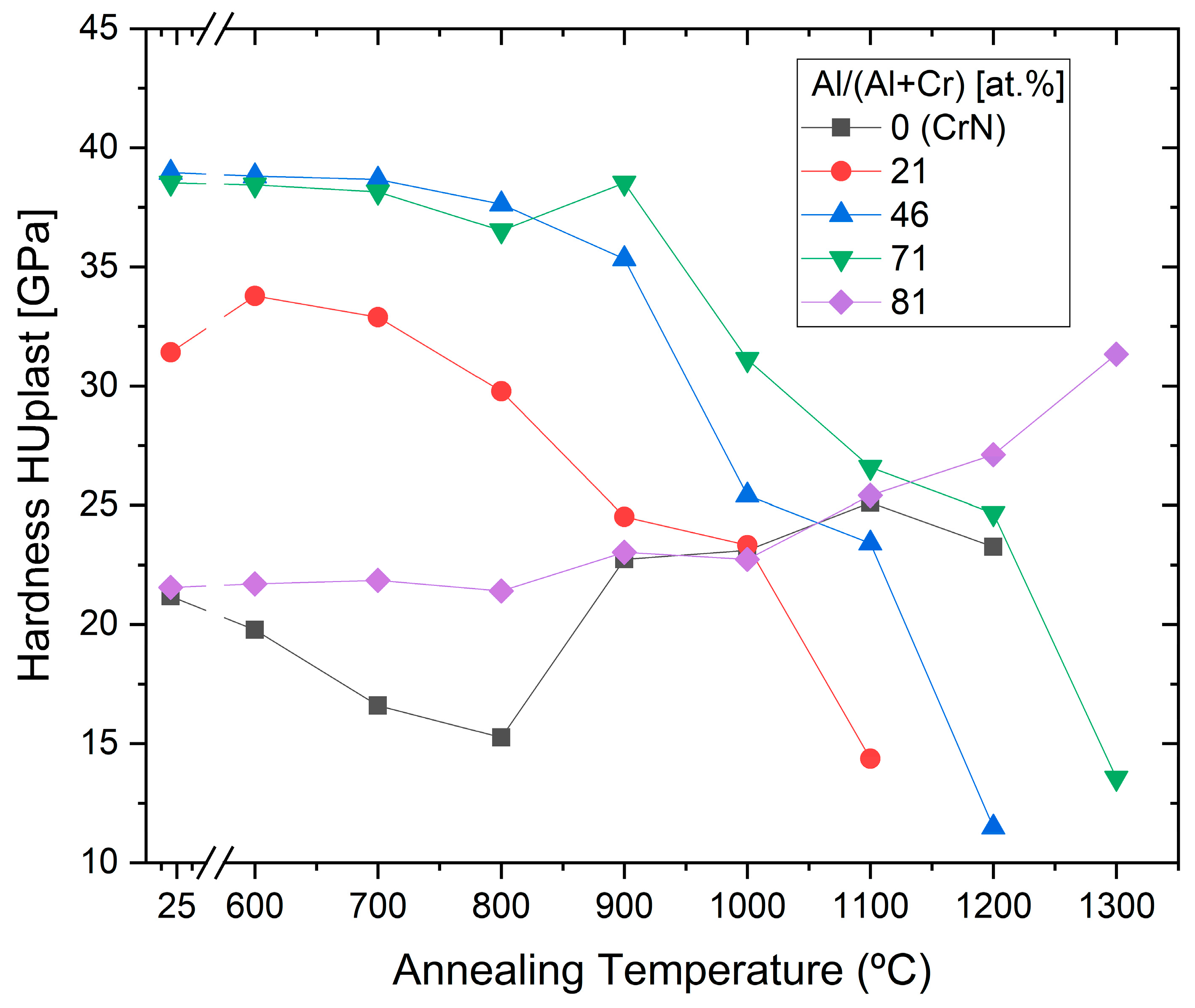

3.2.5. Thermal Phase Stability and Hardness after Annealing

- Transformation of fcc (Al,Cr)N to hcp (Al,Cr)N at the grain boundaries first [74],

- Segregation of Cr2N,

- Segregation of pure chromium.

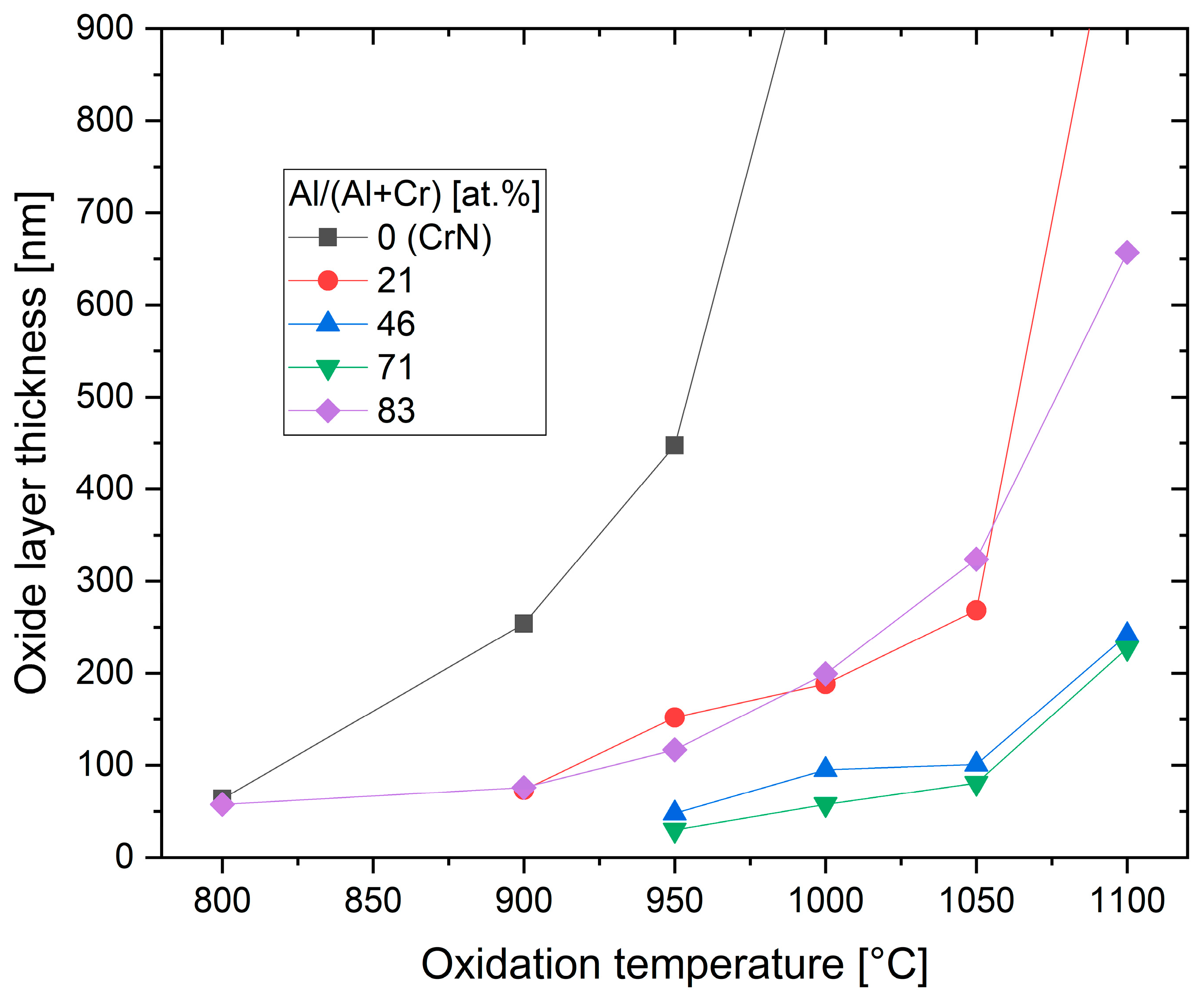

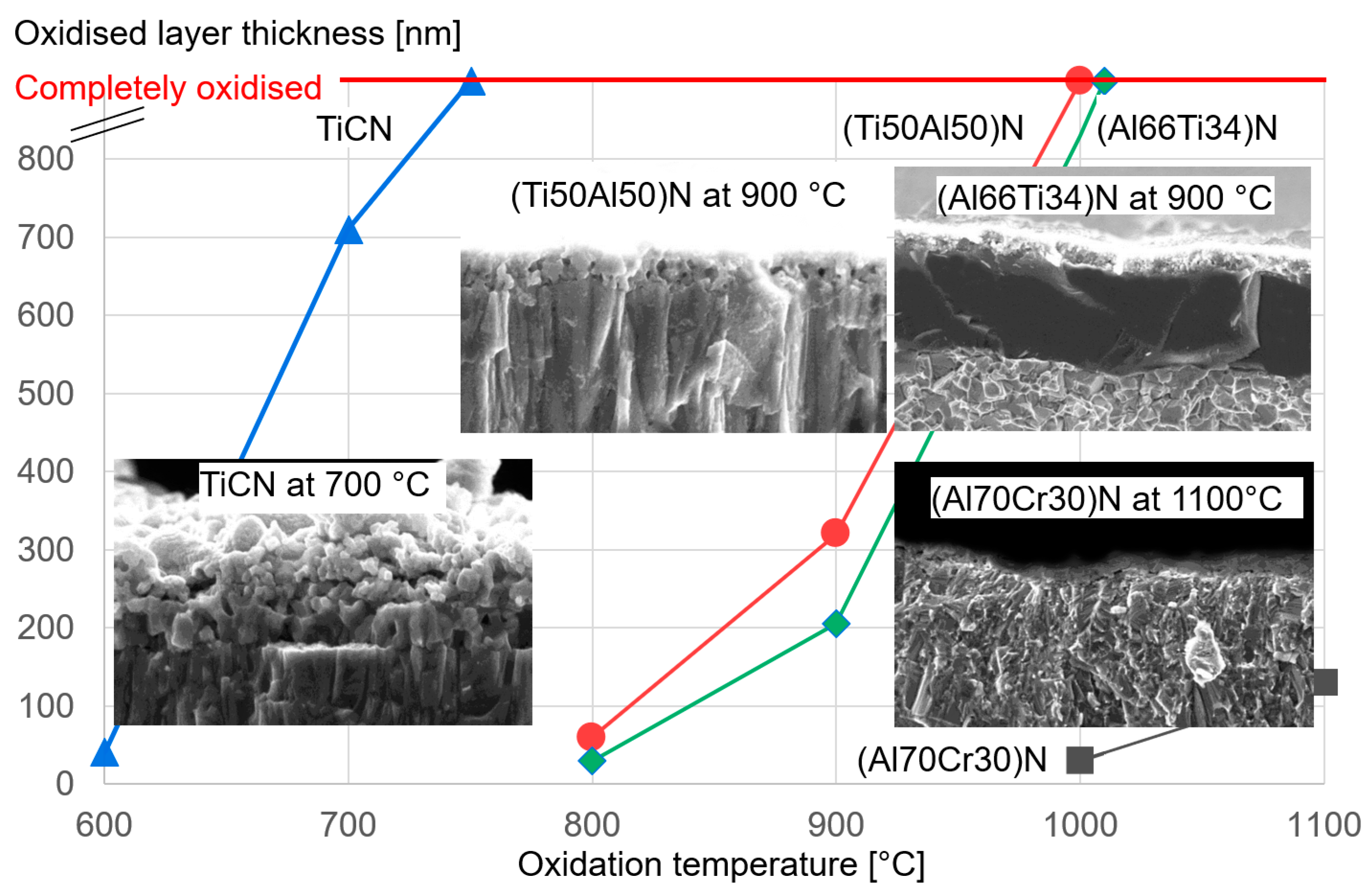

3.2.6. Oxidation Behaviour

3.3. Selected Tribological Properties

3.3.1. Dry Friction against Steel

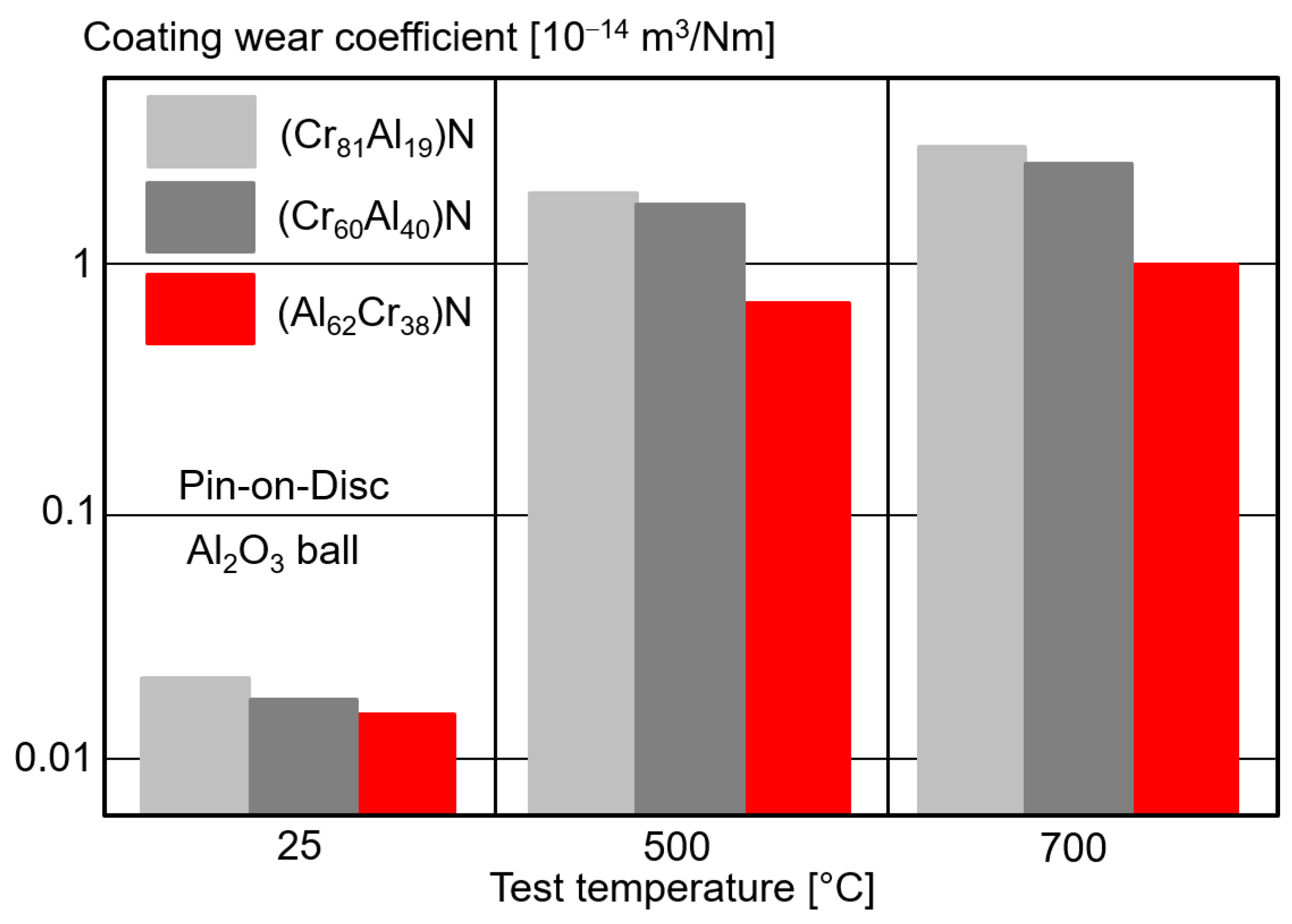

3.3.2. Dry Friction and Wear against Ceramics

3.4. Control of Coating Morphology, Stress and Texture

3.5. Features of (AlCr)N Coatings with Mixed fcc Plus hcp Structure

4. Alloying of AlCrN

4.1. Additional Metallic Elements

4.1.1. Coatings with the Addition of Ti, V, Zr

4.1.2. Coatings with the Addition of Refractory Metals

4.1.3. Coatings with the Addition of Non-Ferrous Metals

4.2. Coatings with the Addition of Rare Earth Elements

4.3. Coatings with the Addition of Carbon

4.4. Coatings with the Addition of Metalloids

4.4.1. Coatings with the Addition of B

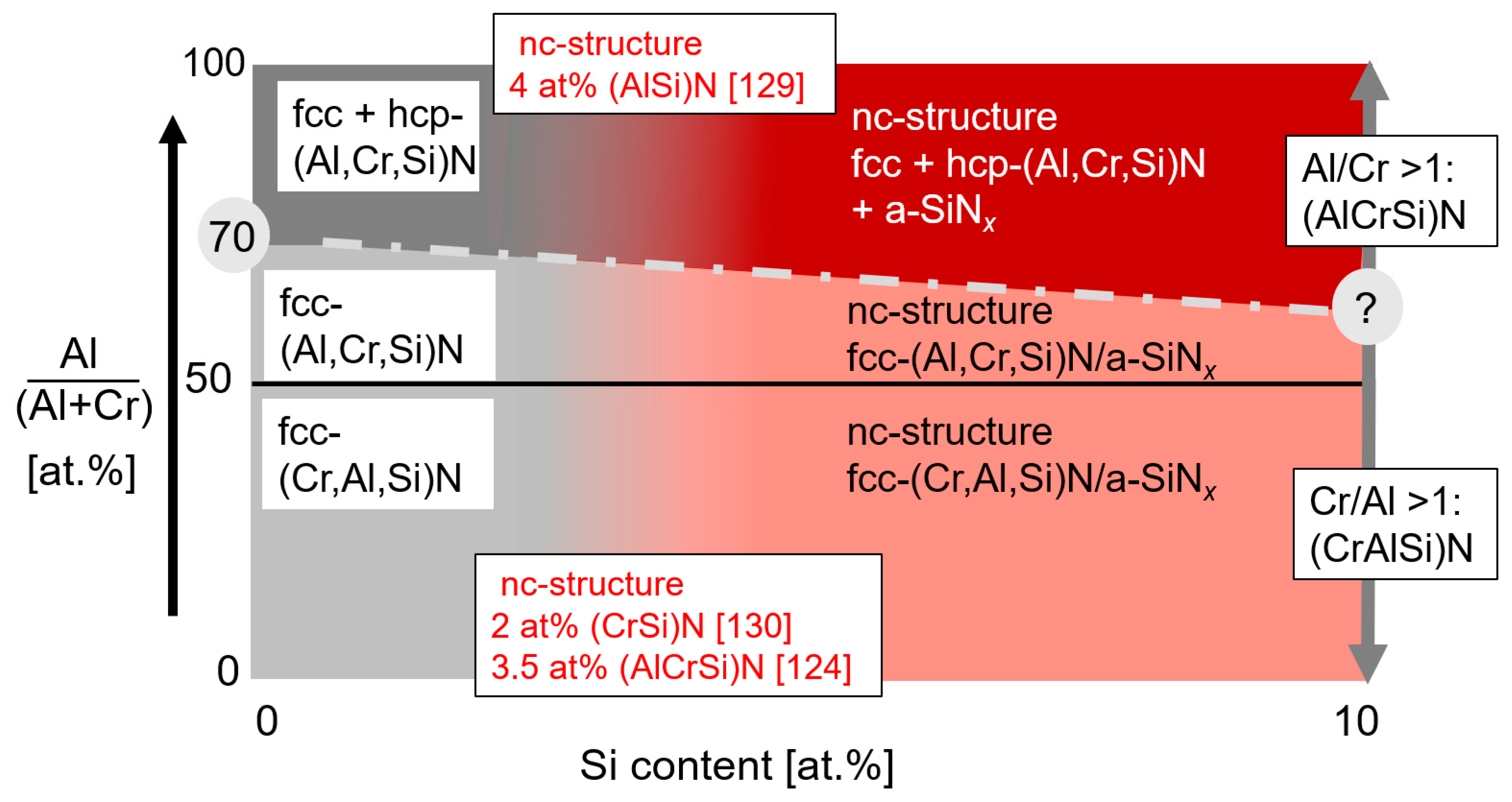

4.4.2. Coatings with the Addition of Si

4.5. Coatings with the Addition of Two or More Elements

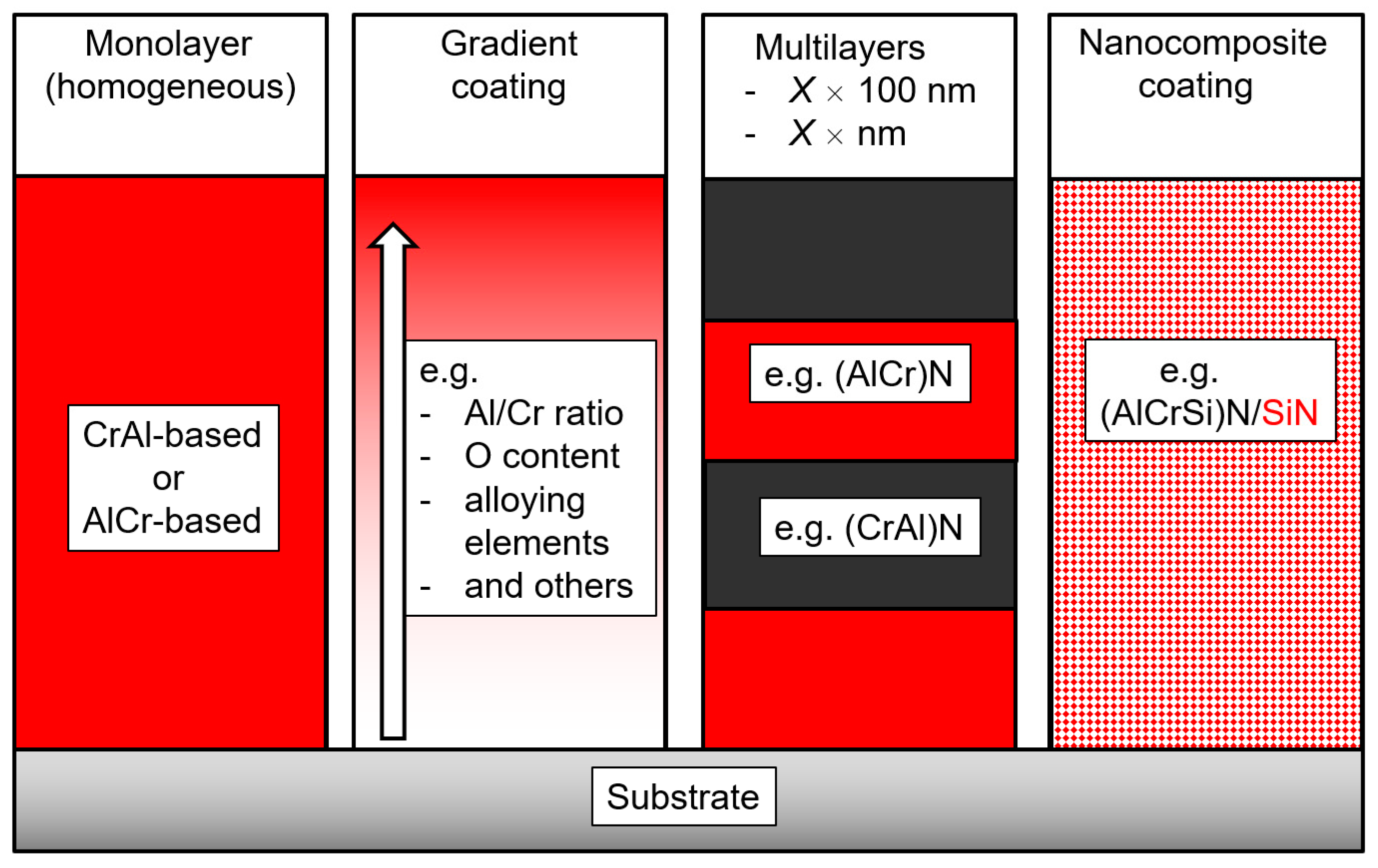

5. Complex Coating Architectures

5.1. Multilayer and Nanomultilayer Coatings

- -

- CrAl- or AlCr-based structural multilayer

- -

- CrAl- or AlCr-based combined with a binary nitride coating

- -

- CrAl- or AlCr-based combined with a ternary nitride coating

- -

- CrAl- or AlCr-based combined with a quaternary nitride coating

- -

- CrAl- or AlCr-based combined with an oxynitride or oxide coating

5.2. Gradient Coatings

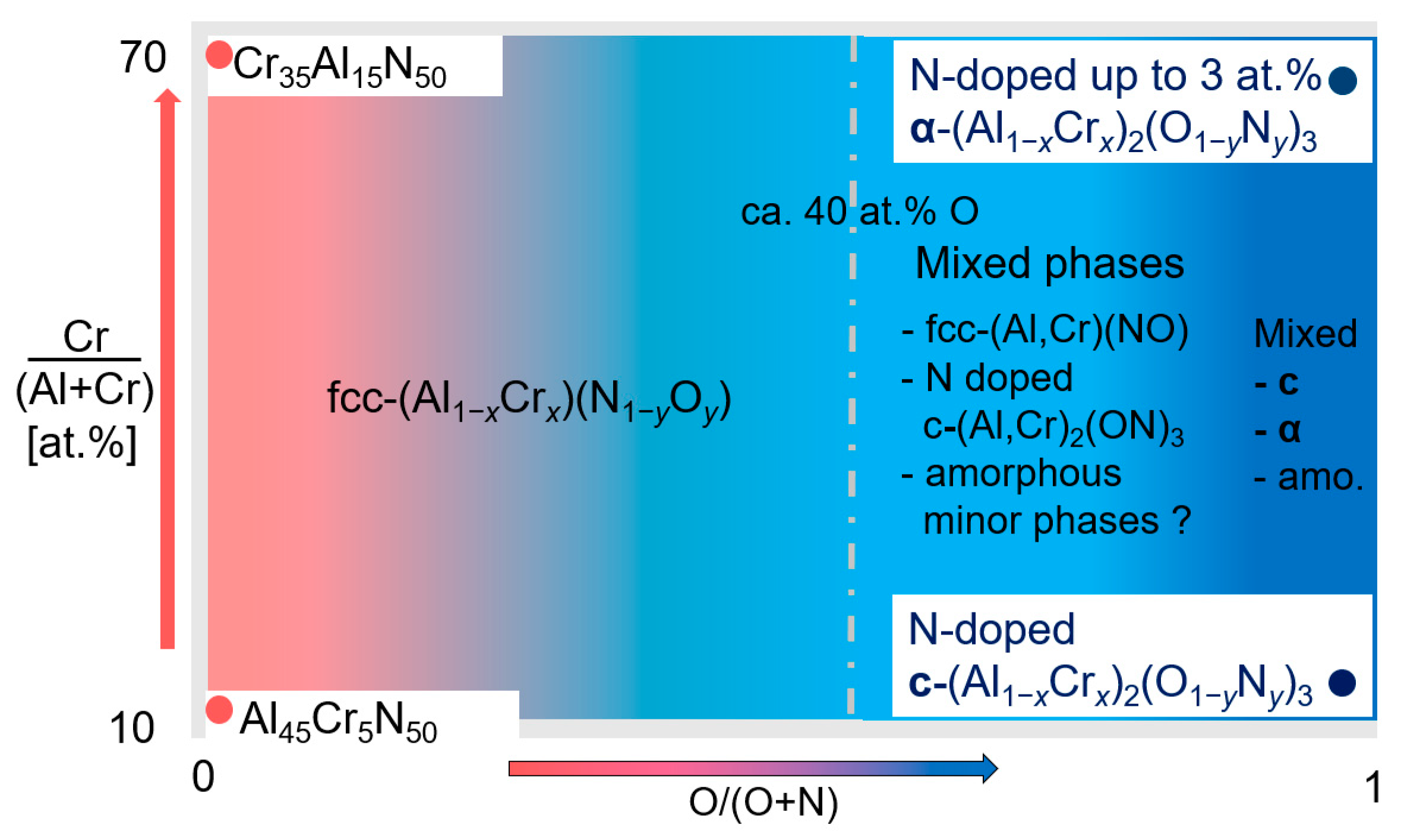

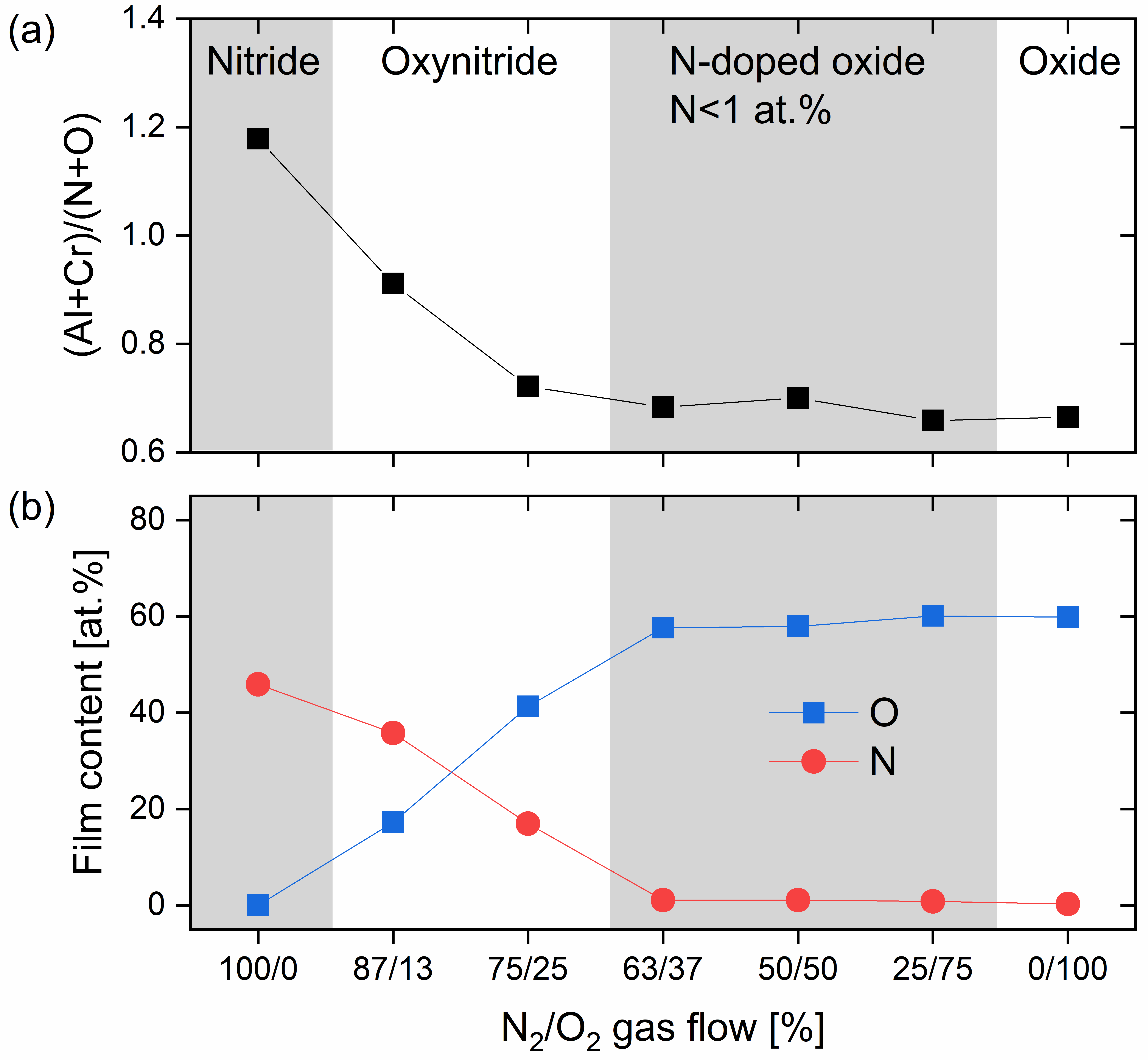

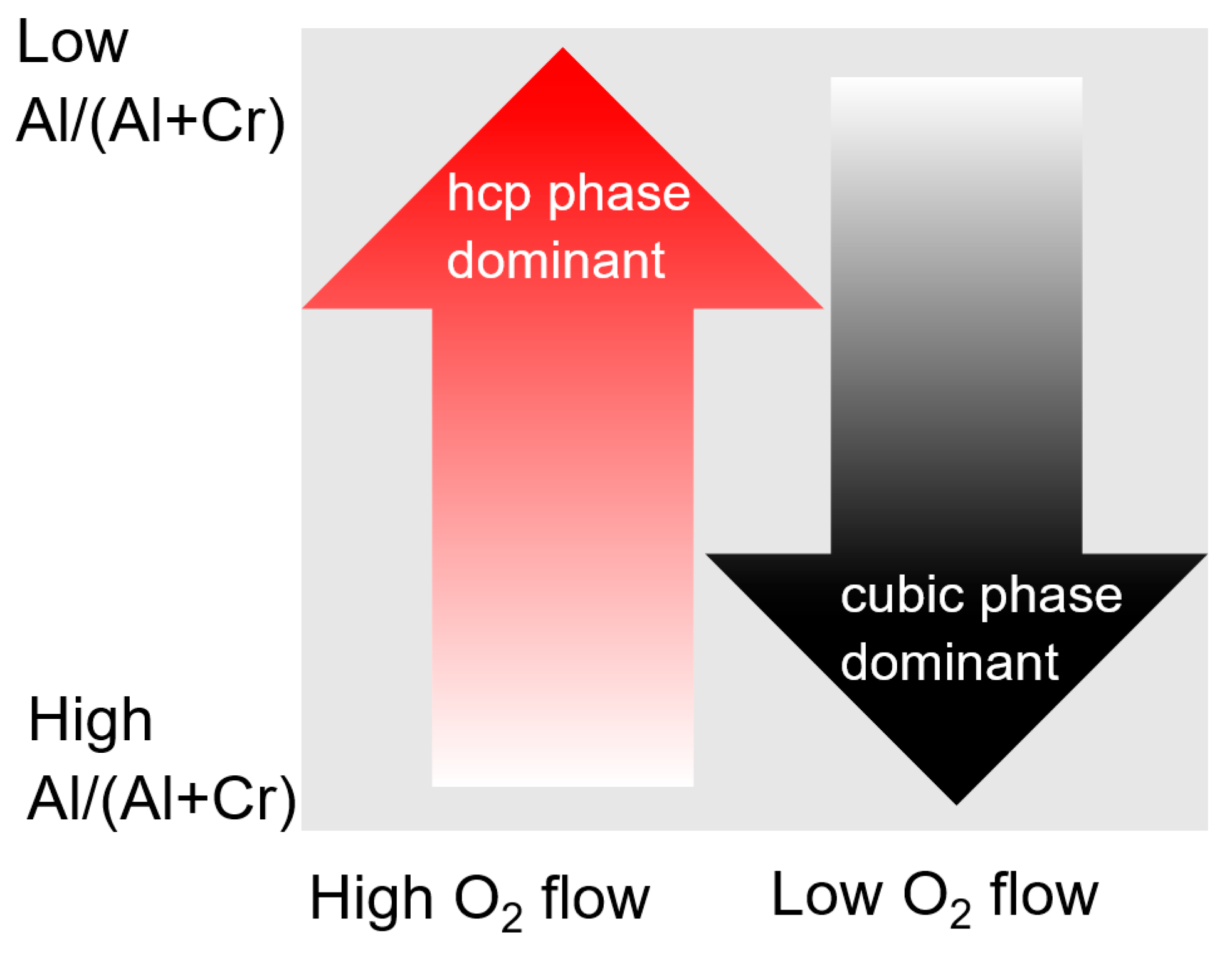

6. From (CrAl)N or (AlCr)N to Oxynitride and Oxide Coatings

6.1. Arc Evaporation: Oxynitride and Oxide Coatings

6.2. Sputtering: Oxynitride and Oxide Coatings

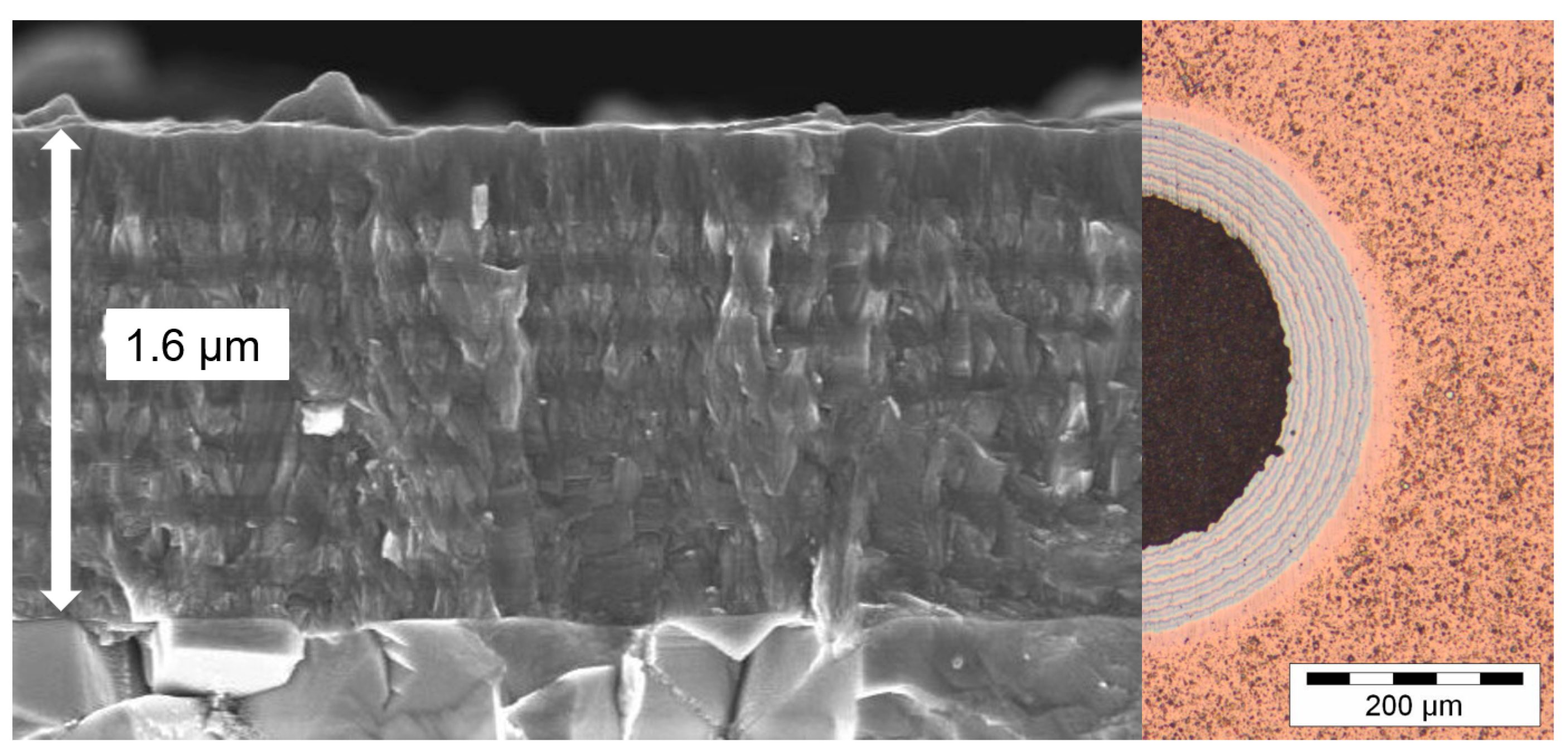

7. Selected Industrial Coating Types and Main Applications

7.1. Examples for Industrially Applied Coatings Types

7.2. Typical Application Fields of AlCr-Based Coatings

8. Summary and Outlook

- Besides arc, HiPIMS deposition methods will also be used more and more in addition to arc evaporation.

- Alloying to adapt coating properties makes use of at least one element from the metals, metalloids or rare earth elements.

- The main alloying element presently in use is silicon.

- The variety in alloying will continue to increase to optimise coatings for dedicated applications.

- The addition of oxygen offers a possibility for tuning properties, e.g., tribological and optical.

- Multilayer architectures, including nano multilayers, are increasingly being applied in combination with binary, ternary and quaternary hard coatings.

- Besides AlTi-based coatings, CrAl- and AlCr-based coatings are the predominant coating type applied to tools.

- More and more general engineering parts will be coated in addition to tools, also with thicker coatings.

- Sustainability aspects (sustainable surface engineering) will be taken into account, for example, selecting a specific alloying element, minimising the environmental impact in the production of the coating, the use of the coating, and recycling.

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Aksenov, I.I.; Andreev, A.A. Vacuum arc coating technologies at NSC KIPT. Probl. At. Sci. Technol. Ser. Plasma Phys. 1999, 3, 242–246. [Google Scholar]

- Vogel, J. Harte Schichten, Goldene Zeiten (Hard Coatings, Golden Times); Informationsmappe; Oerlikon-Bührle Holding AG: Zurich, Switzerland, 1982; Volume 5004. [Google Scholar]

- Sue, J.A.; Perry, A.J.; Vetter, J. Young’s modulus and stress of CrN deposited by cathodic vacuum arc evaporation. Surf. Coat. Technol. 1994, 68, 126–130. [Google Scholar] [CrossRef]

- Vetter, J. Vacuum arc coatings for tools: Potential and application. Surf. Coat. Technol. 1995, 76, 719–724. [Google Scholar] [CrossRef]

- Vetter, J. 60 years of DLC coatings: Historical highlights and technical review of cathodic arc processes to synthesize various DLC types, and their evolution for industrial applications. Surf. Coat. Technol. 2014, 257, 213–240. [Google Scholar] [CrossRef]

- Vetter, J.; Burgmer, W.; Dederichs, H.G.; Perry, A.J. The architecture and performance of multilayer and compositionally gradient coatings made by cathodic arc evaporation. Surf. Coat. Technol. 1993, 61, 209–214. [Google Scholar] [CrossRef]

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti,Al)N: A review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Vetter, J. (Alx:Tiy)N coatings deposited by cathodic vacuum arc evaporation. J. Adv. Mater. 1999, 31, 41–47. [Google Scholar]

- Andersson, J.M.; Vetter, J.; Müller, J.; Sjölén, J. Structural effects of energy input during growth of Ti1−xAlxN (0.55 ≤ x ≤ 0.66) coatings by cathodic arc evaporation. Surf. Coat. Technol. 2014, 240, 211–220. [Google Scholar] [CrossRef]

- Tanaka, Y.; Ichimiya, N.; Onishi, Y.; Yamada, Y. Structure and properties of Al-Ti-Si-N coatings prepared by the cathodic arc ion plating method for high speed cutting applications. Surf. Coat. Technol. 2001, 146, 215–221. [Google Scholar] [CrossRef]

- Donohue, L.A.; Smith, I.J.; Münz, W.-D.; Petrov, I.; Greene, J.E. Microstructure and oxidation resistance of Ti1−x−y−zAlxCryYzN layers grown by combined steered arc/unbalanced magnetron- sputter deposition. Surf. Coat. Technol. 1997, 94, 226–231. [Google Scholar] [CrossRef]

- Vetter, J.; Krug, T.; von der Heide, V. AlTiCrNO coatings for dry cutting deposited by reactive cathodic vacuum arc evaporation. Surf. Coat. Technol. 2003, 174, 615–619. [Google Scholar] [CrossRef]

- Vetter, J.; Ishikawa, T.; Shima, N. Nanocomposite AlTiNCO coatings deposited by reactive cathodic arc evaporation. Plasma Process. Polym. 2007, 4, S668–S672. [Google Scholar] [CrossRef]

- Knotek, O.; Atzor, M.; Barimani, C.; Jungblut, F. Development of low temperature ternary coatings for high wear resistance. Surf. Coat. Technol. 1990, 42, 21–28. [Google Scholar] [CrossRef]

- Hoffmann, S.; Jehn, H.A. Oxidation behaviour of CrNx and (Cr,Al)N hard coatings. Werkst. Korros. 1990, 47, 756–760. [Google Scholar] [CrossRef]

- Schulze, D.; Wilberg, R.; Fleischer, W.; Lunow, T. Multicomponent Hard Thin Films Deposited by Hollow Cathode Arc Evaporator (HCA). In Proceedings of the International Conference on Metallurgical Coatings and Thin Films, San Diego, CA, USA, 2–6 April 1990. [Google Scholar]

- Knotek, O.; Löffler, F.; Scholl, H.J. Properties of arc-evaporated CrN and (Cr,Al)N. Surf. Coat. Technol. 1991, 45, 53–58. [Google Scholar] [CrossRef]

- Knotek, O.; Löffler, F.; Scholl, H.J.; Barimani, C. The multisource arc process for depositing ternary Cr- and Ti-based Coatings. Surf. Coat. Technol. 1994, 68, 309–313. [Google Scholar] [CrossRef]

- Vetter, J.; Lugscheider, E.; Guerreiro, S.S. (Cr:Al)N coatings deposited by the cathodic vacuum are evaporation. Surf. Coat. Technol. 1998, 98, 1233–1239. [Google Scholar] [CrossRef]

- Ishikawa, T.; Fuji, F. Improvement of the Cutting Performance of TiSiN Coated Cemented Carbide-Tools. In Proceedings of the 34th International Conference and Metallurgical Coatings and Thin Films ICMCTF, San Diego, CA, USA, 23–27 April 2007; p. B6-1-8. [Google Scholar]

- Li, W.; Liu, P.; Meng, J.; Zhang, K.; Ma, F.; Liu, X.; Chen, X.; He, D. Microstructure and mechanical prop erty of TiSiN nanocomposite film with inserted CrAlN nanomultilayers. Surf. Coat. Technol. 2016, 286, 313–318. [Google Scholar] [CrossRef]

- Schulz, H.; Bergmann, E. Hard Layer, Work Piece Coated with Such a Layer and Process for Coating with the Layer. EP 513,662. 11 November 1992. [Google Scholar]

- Ramm, J.; Ante, M.; Bachmann, T.; Widrig, B.; Brändle, H.; Döbeli, M. Pulse enhanced electron emission (P3eTM) arc evaporation and the synthesis of wear resistant Al-Cr-O coatings in corundum structure. Surf. Coat. Technol. 2007, 202, 876–883. [Google Scholar] [CrossRef]

- Boxman, R.L.; Philip, J.M.; David, M.S. Handbook of Vacuum Arc Science and Technology: Fundamentals and Applications, 1st ed.; Noyes Publications: Park Ridge, NJ, USA, 1995. [Google Scholar]

- Anders, A. Cathodic Arcs: From Fractal Spots to Energetic Condensation; Springer: New York, NY, USA, 2008. [Google Scholar]

- Anders, A. A review comparing cathodic arcs and high power impulse magnetron sputtering (HiPIMS). Surf. Coat. Technol. 2014, 257, 308–325. [Google Scholar] [CrossRef]

- Vetter, J. PVD processes for depositing wear- and friction- reducing and decorative coatings. In Handbook of Thermoprocessing Technologies; Beneke, F., Nacke, B., Pfeifer, H., Eds.; Vulkan-Verlag Eifel: Essen, Germany, 2015; pp. 661–692. [Google Scholar]

- Vetter, J. Surface treatments for automotive applications. In Coating Technology for Vehicle Applications; Cha, S.C., Erdemir, A., Eds.; Springer: Cham, Switzerland, 2015; pp. 91–132. [Google Scholar]

- Vetter, J.; Kubota, K.; Isaka, M.; Mueller, J.; Krienke, T.; Rudigier, H. Characterization of advanced coating architectures deposited by an arc-HiPIMS hybrid process. Surf. Coat. Technol. 2018, 350, 154–160. [Google Scholar] [CrossRef]

- Vetter, J.; Berger, M.; Derflinger, V.; Krassnitzer, S. Plasma-Assisted Coating Processes. Available online: https://www.oerlikon.com/balzers/com/en/portfolio/surface-technologies/plasma-assisted-coating-processes-new-pvd-and-cvd-book/ (accessed on 12 February 2020).

- Lundin, D.; Minea, T.; Gudmundsson, T. High Power Impulse Magnetron Sputtering: Fundamentals, Technologies, Challenges and Applications; Elsevier Science: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Ide, Y.; Inada, K.; Nakamura, T. Formation of Al-Cr-N films by an activated reactive evaporation (ARE) method. High Temp. Mater. Process. 2000, 19, 265–274. [Google Scholar] [CrossRef]

- Schulze, D.; Wilberg, R. Multicomponent hard thin films deposited by hollow cathode arc evaporator (HCA). In Proceedings of the 4th joint International Symposium on Trends and New Applications in Thin Films TATF ‘94 and the 11th Conference om High Vacuum, Interfaces and Thin Films HVITF ‘94; DGM-Informationsges: Chemnitz, Germany, 1994. [Google Scholar]

- Holzherr, M.; Falz, M.; Schmidt, T. Influence of hollow cathode plasma on AlCrN-thin film deposition with vacuum arc evaporation sources. Surf. Coat. Technol. 2008, 203, 505–509. [Google Scholar] [CrossRef]

- Park, I.W.; Kang, D.S.; Moore, J.J.; Kwon, S.C.; Rha, J.J.; Kim, K.H. Microstructures, mechanical properties, and tribological behaviors of Cr-Al-N, Cr-Si-N, and Cr-Al-Si-N coatings by a hybrid coating system. Surf. Coat. Technol. 2007, 201, 5223–5227. [Google Scholar] [CrossRef]

- Anders, A. Ion charge state distributions of vacuum arc plasmas: The origin of species. Phys. Rev. E 1997, 55, 969–981. [Google Scholar] [CrossRef]

- Vetter, J.; Müller, J.; Erkens, G. Domino platform: PVD coaters for arc evaporation and high current pulsed magnetron sputtering. IOP Conf. Ser. Mater. Sci. Eng. 2012, 39, 012004. [Google Scholar] [CrossRef]

- Vetter, J. Entwicklung und Erprobung von Beschichtungen für Stanz-, Zieh- und Prägewerkzeuge für die Schmiermittelarme und Schmiermittelfreie Fertigung; Final Report of Joint Project 13N6271; Metaplas Ionon GmbH: Bergisch Gladbach, Germany, 1996. [Google Scholar]

- Kawate, M.; Kimura, A.; Suzuki, T. Microhardness and lattice parameter of Cr1−xAlxN films. J. Vac. Sci. Technol. A 2002, 20, 569–571. [Google Scholar] [CrossRef]

- Kawate, M.; Hashimoto, A.K.; Suzuki, T. Oxidation resistance of Cr1−xAlxN and Ti1−xAlxN films. Surf. Coat. Technol. 2003, 165, 163–167. [Google Scholar] [CrossRef]

- Bagcivan, N.; Bobzin, K.; Theiß, S. (Cr1−xAlx)N: A comparison of direct current, middle frequency pulsed and high power pulsed magnetron sputtering for injection, molding components. Thin Solid Film. 2013, 528, 180–186. [Google Scholar] [CrossRef]

- Wuhrer, R.; Yeung, W.Y. A comparative study of magnetron co-sputtered nanocrystalline titanium aluminium and chromium aluminium nitride coatings. Scr. Mater. 2004, 50, 1461–1466. [Google Scholar] [CrossRef]

- Tritremmel, C. Comparison of Magnetron Sputtering and Arc Evaporation by Al-Cr-N Hard Coating. Diploma Thesis, Montanuniversität Leoben, Leoben, Austria, 2007. [Google Scholar]

- Bobzin, K.; Lugscheider, E.; Nickel, R.; Bagcivan, N.; Kramer, A. Wear behavior of Cr1−xAlxN PVD-coatings in dry running conditions. Wear 2007, 263, 1274–1280. [Google Scholar] [CrossRef]

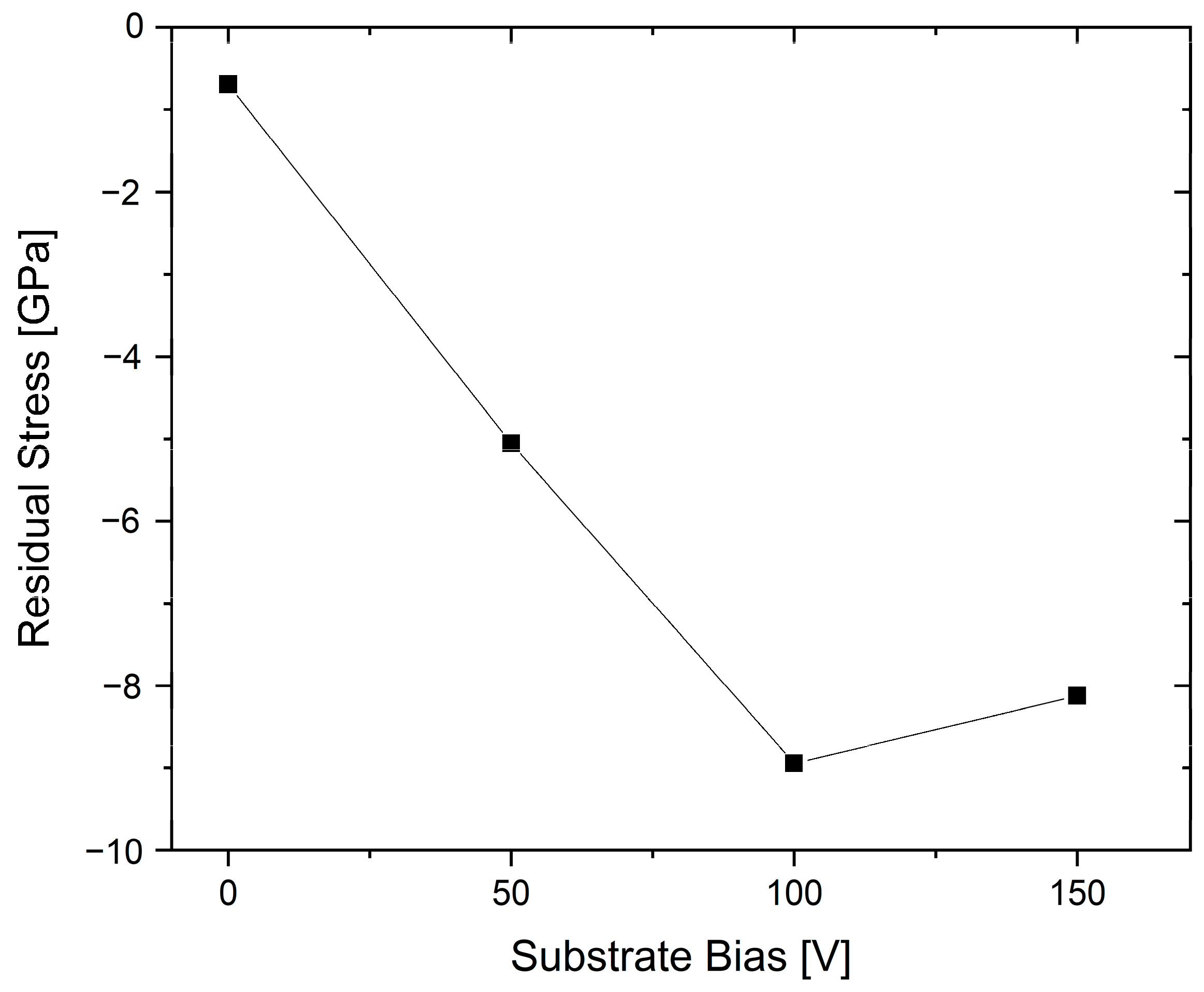

- Wang, Y.X.; Zhang, S.; Lee, J.W.; Lew, W.S.; Li, B. Influence of bias voltage on the hardness and toughness of CrAlN coatings via magnetron sputtering. Surf. Coat. Technol. 2012, 206, 5103–5107. [Google Scholar] [CrossRef]

- Drnovšek, A.; Rebelo de Figueiredo, M.; Vo, H.; Xia, A.; Vachhani, S.J.; Kolozsvár, S.; Hosemann, P.; Franz, R. Correlating high temperature mechanical and tribological properties of CrAlN and CrAlSiN hard coatings. Surf. Coat. Technol. 2019, 372, 361–368. [Google Scholar] [CrossRef]

- Kim, G.S.; Lee, S.Y. Microstructure and mechanical properties of AlCrN films deposited by CFUBMS. Surf. Coat. Technol. 2006, 201, 4361–4366. [Google Scholar] [CrossRef]

- Weirather, T.; Czettl, C.; Polcik, P.; Kathrein, M.; Mitterer, C. Industrial-scale sputter deposition of Cr1−xAlx coatings with 0.21 ≤ x ≤ 0.74 from segmented targets. Surf. Coat. Technol. 2013, 232, 303–310. [Google Scholar] [CrossRef]

- Sugishima, A.; Kajioka, H.; Makino, Y. Phase transition of pseudobinary Cr-Al-N films deposited by magnetron sputtering method. Surf. Coat. Technol. 1997, 97, 590–594. [Google Scholar] [CrossRef]

- Makino, Y.; Nogi, K. Synthesis of pseudobinary Cr-Al-N films with B1 structure by rf-assisted magnetron sputtering method. Surf. Coat. Technol. 1998, 98, 1008–1012. [Google Scholar] [CrossRef]

- Banakh, O.; Schmid, P.E.; Sanjinés, R.; Lévy, F. High-temperature oxidation resistance of Cr1−xAlxN thin films deposited by reactive magnetron sputtering. Surf. Coat. Technol. 2003, 163, 57–61. [Google Scholar] [CrossRef]

- Shah, H.N.; Jayaganthan, R. Influence of Al contents on the microstructure, mechanical, and wear properties of magnetron sputtered CrAlN coatings. J. Mater. Eng. Perform. 2012, 21, 2002–2009. [Google Scholar] [CrossRef]

- Anders, A. Tutorial: Reactive high power impulse magnetron sputtering (R-HiPIMS). J. Appl. Phys. 2017, 121, 171101. [Google Scholar] [CrossRef]

- Hsiao, Y.-C.; Lee, J.-W.; Yang, Y.-C.; Lou, B.-S. Effects of duty cycle and pulse frequency on the fabrication of AlCrN thin films deposited by high power impulse magnetron sputtering. Thin Solid Film. 2013, 549, 281–291. [Google Scholar] [CrossRef]

- Avila, P.R.T.; da Silva, E.P.; Rodrigues, A.M.; Aristizabal, K.; Pineda, F.; Coelho, R.S.; Garcia, G.L.; Soldera, F.; Walczak, M.; Pinto, H.C. On manufacturing multilayer-like nanostructures using misorientation gradients in PVD films. Sci. Rep. 2019, 9, 15898. [Google Scholar] [CrossRef]

- Tang, J.F.; Lin, C.Y.; Yang, F.C.; Chang, C.L. Influence of nitrogen content and bias voltage on residual stress and the tribological and mechanical properties of CrAlN films. Coatings 2020, 10, 546. [Google Scholar] [CrossRef]

- Zheng, J.; Zhou, H.; Gui, B.; Luo, Q.; Li, H.; Wang, Q. Influence of power pulse parameters on the microstructure and properties of the AlCrN coatings by a modulated pulsed power magnetron sputtering. Coatings 2017, 7, 216. [Google Scholar] [CrossRef]

- Chen, W.; Hu, T.; Hong, Y.; Zhang, D.; Meng, X. Comparison of microstructures, mechanical and tribological properties of arc-deposited AlCrN, AlCrBN and CrBN coatings on Ti-6Al-4V alloy. Surf. Coat. Technol. 2020, 404, 126429. [Google Scholar] [CrossRef]

- Lin, J.; Mishra, B.; Moore, J.J.; Sproul, W.D. Microstructure, mechanical and tribological properties of Cr1−xAlxN films deposited by pulsed-closed field unbalanced magnetron sputtering (P-CFUBMS). Surf. Coat. Technol. 2006, 201, 4329–4334. [Google Scholar] [CrossRef]

- Hasegawa, H.; Masahiro Kawate, M.; Suzuki, T. Effects of Al contents on microstructures of Cr1−xAlxN and (Zr1−xAlx)N films synthesized by cathodic arc method. Surf. Coat. Technol. 2005, 200, 2409–2413. [Google Scholar] [CrossRef]

- Reiter, A.E.; Derflinger, V.H.; Hanselmann, B.; Bachmann, T.; Sartory, B. Investigation of the properties of Al1−xCrx coatings prepared by cathodic arc evaporation. Surf. Coat. Technol. 2005, 200, 2114–2122. [Google Scholar] [CrossRef]

- Willmann, H.; Mayrhofer, P.H.; Persson, P.O.A.; Reiter, A.E.; Hultman, L.; Mitterer, C. Thermal stability of Al-Cr-N hard coatings. Scr. Mater. 2006, 54, 1847–1851. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Willmann, H.; Reiter, A.E. Structure and phase evolution of Cr-Al-N coatings during annealing. Surf. Coat. Technol. 2008, 202, 4935–4938. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Music, D.; Reeswinkel, T.; Fuß, H.-G.; Schneider, J.M. Structure, elastic properties and phase stability of Cr1–xAlxN. Acta Mater. 2008, 56, 2469–2475. [Google Scholar] [CrossRef]

- Bartosik, M.; Holec, D.; Apel, D.; Klaus, M.; Genzel, C.; Keckes, J.; Arndt, M.; Polcik, P.; Koller, C.M.; Mayrhofer, P.H. Thermal expansion of Ti-Al-N and Cr-Al-N coatings. Scripta Mater. 2017, 127, 182–185. [Google Scholar] [CrossRef]

- Sabitzer, C.; Paulitsch, J.; Kolozsvári, S.; Rachbauer, R.; Mayrhofer, P.H. Influence of bias potential and layer arrangement on structure and mechanical properties of arc evaporated Al-Cr-N coatings. Vacuum 2014, 106, 49–52. [Google Scholar] [CrossRef]

- Kalss, W.; Reiter, A.; Derflinger, V.; Gey, C.; Endrino, J.L. Modern coatings in high performance cutting applications. Int. J. Refract. Met. Hard Mater. 2006, 24, 399–404. [Google Scholar] [CrossRef]

- Martan, J.; Benes, P. Thermal properties of cutting tool coatings at high temperatures. Thermochim. Acta 2012, 539, 51–55. [Google Scholar] [CrossRef]

- Böttger, P.H.M.; Gusarov, A.V.; Shklover, V.; Patscheider, J.; Sobiech, M. Anisotropic layered media with microinclusions: Thermal properties of arc-evaporation multilayer metal nitrides. Int. J. Therm. Sci. 2014, 77, 75–83. [Google Scholar] [CrossRef]

- Zhou, L.; Holec, D.; Mayrhofer, P.H. First-principles study of elastic properties of cubic Cr1−xAlxN alloys. J. Appl. Phys. 2013, 113, 043511. [Google Scholar] [CrossRef]

- Buchinger, J.; Wagner, A.; Chen, Z.; Zhang, Z.L.; Holec, D.; Mayrhofer, P.H.; Bartosik, M. Fracture toughness trends of modulus-matched TiN/(Cr,Al)N thin film superlattices. Acta Mater. 2021, 202, 376–386. [Google Scholar] [CrossRef]

- Soldán, J.; Neidhardt, J.; Sartory, B.; Kaindl, R.; Čerstvý, R.; Mayrhofer, P.H.; Tessadri, R.; Polcik, P.; Lechthaler, M.; Mitterer, C. Structure-property relations of arc-evaporated Al-Cr-Si-N coatings. Surf. Coat. Technol. 2008, 202, 3555–3562. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Myslinski, P.; Dobruchowska, E.; Murzynski, D.; Kuznetsova, T.A. Effect of silicon concentration on the properties of Al-Cr-Si-N coatings deposited using cathodic arc evaporation. Materials 2020, 13, 4717. [Google Scholar] [CrossRef] [PubMed]

- Willman, H.; Mayrhofer, P.H.; Hultman, L.; Mitterer, C. Hardness evolution of Al-Cr-N coatings under thermal load. Mater. Res. 2008, 23, 2880–2885. [Google Scholar] [CrossRef]

- Meindlhumer, M.; Klima, S.; Jäger, N.; Stark, A.; Hruby, H.; Mitterer, C.; Kecks, J.; Daniel, R. Stress-controlled decomposition routes in cubic AlCrN films assessed by in-situ high-temperature high-energy grazing incidence transmission X-ray diffraction. Sci. Rep. 2019, 9, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Mishra, B.; Moore, J.J.; Sproul, W.D. Study of the oxidation behavior of CrN and CrAlN thin films inir using DSC and TGA analyses. Surf. Coat. Technol. 2008, 202, 3272–3283. [Google Scholar] [CrossRef]

- Chim, Y.C.; Ding, Z.Z.; Zeng, X.T.; Zhang, S. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateralrotating cathode arc. Thin Solid Film. 2009, 517, 4845–4849. [Google Scholar] [CrossRef]

- Feng, Y.-P.; Zhang, L.; Ke, R.-X.; Wan, Q.-L.; Wang, Z.; Lu, Z.-H. Thermal stability and oxidation behavior of AlTiN, AlCrN and AlCrSiWN coatings. Int. J. Refract. Met. Hard Mater. 2014, 43, 241–249. [Google Scholar] [CrossRef]

- Khamseh, S.; Nose, M.; Kawabata, T.; Matsuda, K.; Ikeno, S. Oxidation resistance of CrAlN films with different microstructures prepared by pulsed DC balanced magnetron sputtering system. Mater. Trans. 2010, 51, 271–276. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. High temperature properties of CrAlN, CrAlSiN and AlCrSiN coatings—Structure and oxidation. Mater. Chem. Phys. 2011, 129, 195–201. [Google Scholar] [CrossRef]

- Endrino, J.; Fox-Rabinovich, G.; Reiter, A.; Veldhuis, S.; Galindo, R.E.; Albella, J.; Marco, J. Oxidation tuning in AlCrN coatings. Surf. Coat. Technol. 2007, 201, 4505–4511. [Google Scholar] [CrossRef]

- Souza, P.S.; Santos, A.J.; Cotrim, M.A.P.; Abrão, A.M.; Câmara, M.A. Analysis of the surface energy interactions in the tribological behavior of AlCrN and TiAlN coatings. Tribol. Int. 2020, 146, 106206. [Google Scholar] [CrossRef]

- Reiter, A.E.; Mitterer, C.; de Figueiredo, M.R.; Franz, R. Abrasive and adhesive wear behavior of arc-evaporated Al1−xCrxN hard coatings. Tribol. Lett. 2010, 37, 605–611. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H. Tribological oxidation behaviour of PVD hard coatings. Tribol. Int. 2009, 42, 1758–1764. [Google Scholar] [CrossRef]

- Anders. A structure zone diagram including plasma-based deposition and ion etching. Thin Solid Film. 2010, 518, 4087–4090. [Google Scholar] [CrossRef]

- Abadias, G.; Chason, E.; Keckes, J.; Sebastiani, M.; Thompson, G.B.; Barthel, E.; Doll, G.L.; Murray, C.E.; Stoessel, C.H.; Martinu, L. Review Article: Stress in thin films and coatings: Current status, challenges and prospects. J. Vac. Sci. Technol. A 2018, 36, 020801. [Google Scholar] [CrossRef]

- Lomello, F.; Sanchette, F.; Schuster, F.; Tabarant, M.; Billard, A. Influence of bias voltage on properties of AlCrN coatings prepared by cathodic arc deposition. Surf. Coat. Technol. 2013, 224, 77–81. [Google Scholar] [CrossRef]

- Kohlscheen, J.; Shibata, T. Phase and residual stress evaluation of dual-phase Al70Cr30N and Al80Cr20N PVD films. Crystals 2019, 9, 362. [Google Scholar] [CrossRef]

- Tritremmel, C.; Daniel, R.; Lechthaler, M.; Rudigier, H.; Polcik, P.; Mitterer, C. Microstructure and mechanical properties of nanocrystalline Al-Cr-B-N thin films. Surf. Coat. Technol. 2012, 213, 1–7. [Google Scholar] [CrossRef]

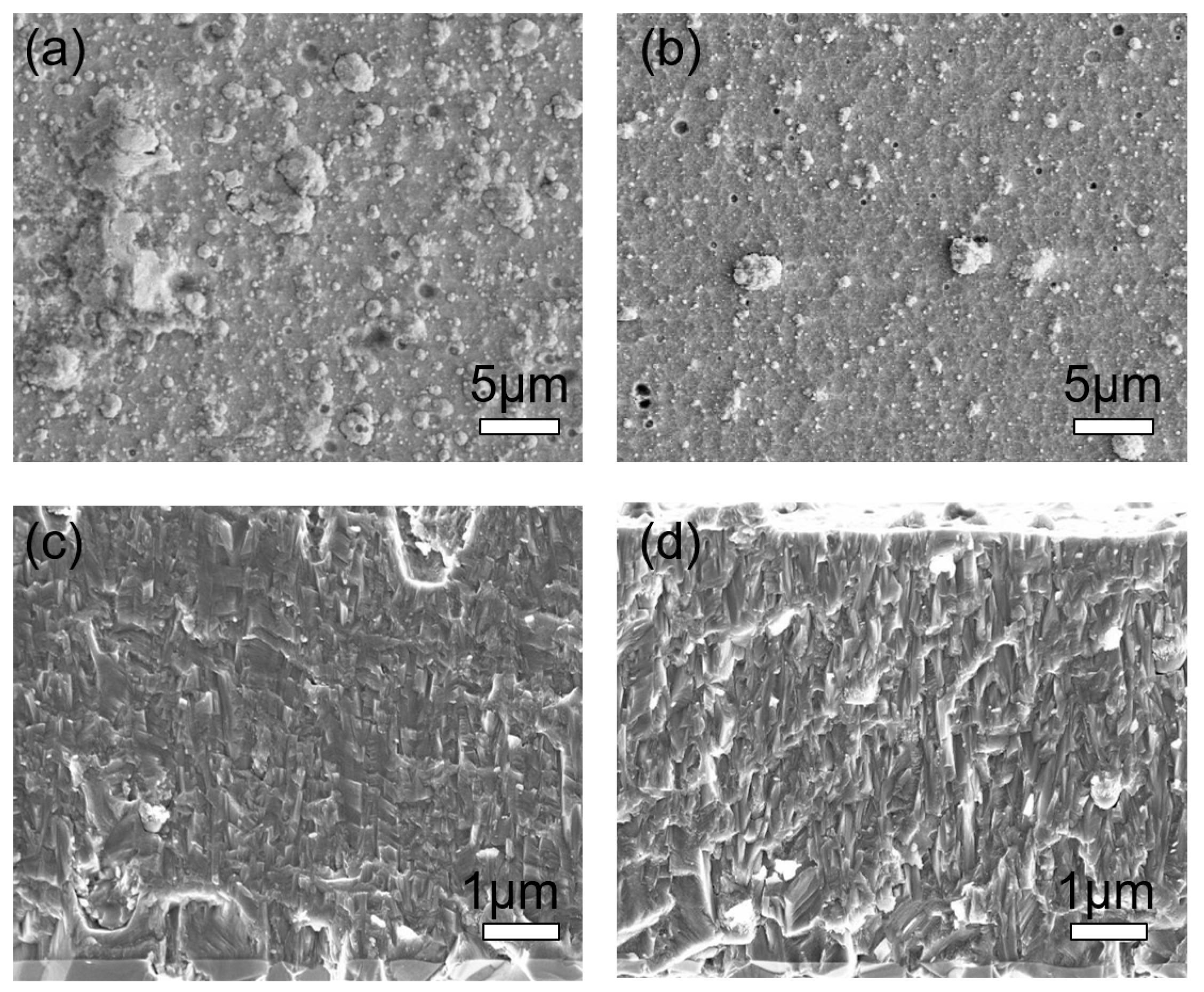

- Gilewicz, A.; Jedrzejewski, R.; Myslinski, P.; Warcholinski, B. Structure, morphology and mechanical properties of AlCrN coatings deposited by cathodic arc evaporation. J. Mater. Eng. Perform. 2019, 28, 1522–1531. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Myslinski, P.; Dobruchowska, E.; Murzynski, D. Structure and Properties of AlCrN Coatings Deposited Using Cathodic Arc Evaporation. Coatings 2020, 10, 793. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S.; Chen, Z.; Li, J.; Li, M. Influence of deposition parameters on hard Cr-Al-N coatings deposited by multi-arc ion plating. Appl. Surf. Sci. 2012, 258, 3629–3636. [Google Scholar] [CrossRef]

- Vetter, J.; Ishikawa, T. Developments of Plasma Enhanced Evaporator for High Al Coating (Al70Cr30)NO; Unpublished Report; Metaplas Ionon GmbH: Bergisch Gladbach, Germany, 2003. [Google Scholar]

- Gilewicz, A.; Jedrzejewski, R.; Myslinski, P.; Warcholinski, B. Influence of Substrate Bias Voltage on Structure, Morphology and Mechanical Properties of AlCrN Coatings Synthesized Using Cathodic Arc Evaporation. Tribol. Ind. 2019, 41, 484–497. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Brugnara, R.H. Aluminum-rich HPPMS (Cr1−xAlx)N coatings deposited with different target compositions and at various pulse lengths. Vacuum 2015, 122, 201–207. [Google Scholar] [CrossRef]

- Jeager, N.; Klima, S.; Hruby, H.; Julin, J.; Burghammer, M.; Keckes, J.F.; Mitterer, C.; Daniel, R. Evolution of structure and residual stress of a fcc/hex-AlCrN multi-layered system upon thermal loading revealed by cross-sectional Xray nano-diffraction. Acta Mater. 2019, 162, 55–66. [Google Scholar] [CrossRef]

- Forsén, R.; Johansson, M.P.; Odén, M.; Ghafoor, N. Effects of Ti alloying of AlCrN coatings on thermal stability and oxidation resistance. Thin Solid Film. 2013, 534, 394–402. [Google Scholar] [CrossRef]

- Hasegawa, H.; Yamamoto, T.; Suzuki, T.; Yamamoto, K. The effects of deposition temperature and post-annealing on the crystal structure and mechanical property of TiCrAlN films with high Al contents. Surf. Coat. Technol. 2006, 200, 2864–2869. [Google Scholar] [CrossRef]

- Yamamoto, K.; Sato, T.; Takahara, K.; Hanaguri, K. Properties of (Ti,Cr,Al)N coatings with high Al content deposited by new plasma enhanced arc-cathode. Surf. Coat. Technol. 2003, 174, 620–626. [Google Scholar] [CrossRef]

- Xu, Y.X.; Hu, C.; Chen, L.; Pei, F.; Du, Y. Effect of V-addition on the thermal stability and oxidation resistance of CrAlN coatings. Ceram. Int. 2018, 44, 7013–7019. [Google Scholar] [CrossRef]

- Franz, R.; Neidhardt, J.; Sartory, B.; Tessadri, R.; Mitterer, C. Micro- and bonding structure of arc-evaporated AlCrVN hard coatings. Thin Solid Film. 2008, 516, 6151–6157. [Google Scholar] [CrossRef]

- Bobzin, K.; Bagcivan, N.; Ewering, M.; Brugnara, R.H.; Theiß, S. DC-MSIP/HPPMS (Cr,Al,V)N and (Cr,Al,W)N thin films for high-temperature friction reduction. Surf. Coat. Technol. 2011, 205, 2887–2892. [Google Scholar] [CrossRef]

- Iram, S.; Cai, F.; Wang, J.; Zhang, J.; Liang, J.; Ahmad, F.; Zhang, S. Effect of addition of Mo or V on the structure and cutting performance of AlCrN-based coatings. Coatings 2020, 10, 298. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Contreras, A.; Domínguez-Meister, S.; García-Luis, A.; Brizuela, M. Tribological behaviour at high temperature of hard CrAlN coatings doped with Y or Zr. Thin Solid Film. 2014, 550, 413–420. [Google Scholar] [CrossRef]

- Klimashin, F.F.; Mayrhofer, P.H. Ab initio-guided development of super-hard Mo-Al-Cr-N coatings. Scr. Mater. 2017, 140, 27–30. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C. Arc PVD (Cr,Al,Mo)N and (Cr,Al,Cu)N coatings for mobility applications. Surf. Coat. Technol. 2020, 384, 125046. [Google Scholar] [CrossRef]

- Tillmann, W.; Dias, N.F.L.; Stangier, D. Effect of Hf on the microstructure, mechanical properties, and oxidation behavior of sputtered CrAlN films. Vacuum 2018, 154, 208–213. [Google Scholar] [CrossRef]

- Hu, C.; Xu, Y.X.; Chen, L.; Pei, F.; Zhang, L.J.; Du, Y. Structural, mechanical and thermal properties of CrAlNbN coatings. Surf. Coat. Technol. 2018, 349, 894–900. [Google Scholar] [CrossRef]

- Rovere, F.; Mayrhofer, P.H.; Reinholdt, A.; Mayer, J.; Schneider, J.M. The effect of yttrium incorporation on the oxidation resistance of Cr-Al-N coatings. Surf. Coat. Technol. 2008, 202, 5870–5875. [Google Scholar] [CrossRef]

- Rovere, F.; Music, D.; Schneider, J.M.; Mayrhofer, P.H. Experimental and computational study on the effect of yttrium on the phase stability of sputtered Cr-Al-Y-N hard coatings. Acta Mater. 2010, 58, 2708–2715. [Google Scholar] [CrossRef]

- Qi, Z.B.; Wu, Z.T.; Wang, Z.C. Improved hardness and oxidation resistance for CrAlN hard coatings with Y addition by magnetron co-sputtering. Surf. Coat. Technol. 2014, 259, 146–151. [Google Scholar] [CrossRef]

- Rojas, T.C.; Domínguez-Meister, S.; Brizuela, M.; Sanchez-Lopez, J.C. Influence of Al and Y content on the oxidation resistance of CrAlYN protective coatings for high temperature applications: New insights about the Y role. J. Alloys Compd. 2019, 773, 1172–1181. [Google Scholar] [CrossRef]

- Du, H.; Wang, L.; Young, M.; Zhao, H.; Xiong, J.; Wan, W. Structure and properties of lanthanum doped AlCrN coatings. Surf. Coat. Technol. 2018, 337, 439–446. [Google Scholar] [CrossRef]

- Shtansky, D.V.; Kiryukhantsev-Korneev, P.V.; Sheveyko, A.N.; Mavrin, B.N.; Rojas, C.; Fernandez, A.; Levashov, E.A. Comparative investigation of TiAlC(N), TiCrAlC(N), and CrAlC(N) coatings deposited by sputtering of МАХ-phase Ti2−хCrхAlC targets. Surf. Coat. Technol. 2009, 203, 3595–3609. [Google Scholar] [CrossRef]

- Tillmann, W.; Stangier, D.; Roese, P.; Shamout, K.; Berges, U.; Westphal, C.; Debus, J. Structural and mechanical properties of carbon incorporation in DC/HiPIMS CrAlN coatings. Surf. Coat. Technol. 2019, 374, 774–783. [Google Scholar] [CrossRef]

- Stueber, M.; Albers, U.; Leiste, H.; Ulrich, S.; Holleck, H.; Barna, P.B.; Kovacs, A.; Hovsepian, P.; Gee, I. Multifunctional nanolaminated PVD coatings in the system Ti-Al-N-C by combination of metastable fcc phases and nanocomposite microstructures. Surf. Coat. Technol. 2006, 200, 6162–6171. [Google Scholar] [CrossRef]

- Lee, D.B.; Nguyen, T.D.; Kim, S.K. Air-oxidation of nano-multilayered CrAlSiN thin films between 800 and 1000 °C. Surf. Coat. Technol. 2009, 203, 1199–1204. [Google Scholar] [CrossRef]

- Chen, H.W.; Chan, Y.C.; Lee, J.W.; Duh, J.G. Oxidation behavior of Si-doped nanocomposite CrAlSiN coatings. Surf. Coat. Technol. 2010, 205, 1189–1194. [Google Scholar] [CrossRef]

- Tritremmel, C.; Daniel, R.; Mayerhofer, P.H.; Lechthaler, M.; Polcik, P.; Mitterer, C. Oxidation behavior of arc evaporated Al-Cr-Si-N thin films. J. Vac. Sci. Technol. A 2012, 30, 061501. [Google Scholar] [CrossRef]

- Wu, W.; Chen, W.; Yang, S.; Lin, Y.; Zhang, S.; Cho, T.-Y.; Lee, G.H.; Kwon, S.-C. Design of AlCrSiN multilayers and nanocomposite coating for HSS cutting tools. Appl. Surf. Sci. 2015, 351, 803–810. [Google Scholar] [CrossRef]

- Cai, F.; Gao, Y.; Zhang, S.; Zhang, L.; Wang, Q. Gradient architecture of Si containing layer and improved cutting performance of AlCrSiN coated tools. Wear 2019, 424, 193–202. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhang, S.; Lee, J.W.; Lew, W.S.; Sun, D.; Li, B. Toward hard yet tough CrAlSiN coatings via compositional grading. Surf. Coat. Technol. 2013, 231, 346–352. [Google Scholar] [CrossRef]

- Sun, S.Q.; Ye, Y.W.; Wang, Y.X.; Liu, M.Q.; Liu, X.; Li, J.L.; Wang, L.P. Structure and tribological performances of CrAlSiN coatings with different Si percentages in seawater. Tribol. Int. 2017, 115, 591–599. [Google Scholar] [CrossRef]

- Haršáni, M.; Ghafoor, N.; Calamba, K.; Zacková, P.; Sahul, M.; Vopát, T.; Satrapinskyy, L.; Čaplovičová, M. Čaplovič Adhesive-deformation relationships and mechanical properties of nc-AlCrN/a-SiNx hard coatings deposited at different bias voltages. Thin Solid Film. 2018, 650, 11–19. [Google Scholar] [CrossRef]

- Gao, Y.; Cai, F.; Zhang, L.; Zhang, S. Structure optimization and cutting performance of gradient multilayer AlCrSiN films with ion source etching pretreatment. J. Mater. Eng. Perform. 2020, 29, 997–1006. [Google Scholar] [CrossRef]

- Jäger, N.; Meindlhumer, M.; Spor, S.; Hruby, H.; Julin, J.; Stark, A.; Nahif, F.; Keckes, J.; Mitterer, C.; Daniel, R. Microstructural evolution and thermal stability of AlCr(Si)N hard coatings revealed by in-situ high-temperature high-energy grazing incidence transmission X-ray diffraction. Acta Mater. 2020, 186, 545–554. [Google Scholar] [CrossRef]

- Kolaklieva, L.; Kakanakov, R.; Stefanov, P.; Kovacheva, D.; Atanasova, G.; Russev, S.; Chitanov, V.; Cholakova, T.; Bahchedjiev, C. Mechanical and structural properties of nanocomposite CrAlSiN-AlSiN coating with periodically modulated composition. Coatings 2020, 10, 41. [Google Scholar] [CrossRef]

- Wang, Q.M.; Kim, K.H. Microstructural control of Cr-Si-N films by a hybrid arc ion plating and magnetron sputtering process. Acta Mater. 2009, 57, 4974–4987. [Google Scholar] [CrossRef]

- Pélisson, A.; Hug, H.J.; Patscheider, J. Morphology, microstructure evolution and optical properties of Al-Si-N nanocomposite coating. Surf. Coat. Technol. 2014, 257, 114–120. [Google Scholar] [CrossRef]

- Schmitt, T.; Steyer, P.; Fontaine, J.; Mary, N.; Esnouf, C.; O’Sullivan, M.; Sanchette, F. Cathodic arc deposited (Cr,Six)N coatings: From solid solution to nanocomposite structure. Surf. Coat. Technol. 2012, 213, 117–125. [Google Scholar] [CrossRef]

- Rafaja, D.; Dopita, M.; Růžička, M.; Klemm, V.; Heger, D.; Schreiber, G.; Šíma, M. Microstructure development in Cr-Al-Si-N nanocomposites deposited by cathodic arc evaporation. Surf. Coat. Technol. 2006, 201, 2835–2843. [Google Scholar] [CrossRef]

- Geng, D.; Li, H.; Zhang, Q.; Zhang, X.; Wang, C.; Wu, Z.; Wang, Q. Effect of incorporating oxygen on microstructure and mechanical properties of AlCrSiON coatings deposited by arc ion plating. Surf. Coat. Technol. 2017, 310, 223–230. [Google Scholar] [CrossRef]

- Chen, Y.; Du, H.; Chen, M.; Yang, J.; Xiong, J.; Zhao, H. Structure and wear behavior of AlCrSiN-based coatings. Appl. Surf. Sci. 2016, 370, 176–183. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Pierson, J.F.; Kuptsov, K.A.; Shtansky, D.V. Hard Cr-Al-Si-B-(N) coatings deposited by reactive and non-reactive magnetron sputtering of CrAlSiB target. Appl. Surf. Sci. 2014, 314, 104–111. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Y.; Feng, Y.-P.; Chen, S.; Wan, Q.-L.; Zhu, J.-F. Electrochemical characterization of AlTiN, AlCrN and AlCrSiWN coatings. Int. J. Refract. Met. Hard Met. 2015, 53, 68–73. [Google Scholar] [CrossRef]

- Tillmann, W.; Fehr, A.; Stangier, D. Powder metallurgic fabricated plug targets for the synthesis of AlCrSiWN multicomponent coating systems. Int. J. Refract. Met. Hard Mater. 2019, 85, 105081. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhang, S.; Leeb, J.-W.; Lew, W.S.; Li, B. Toughening effect of Ni on nc-CrAlN/a-SiNx hard nanocomposite. Appl. Surf. Sci. 2013, 265, 418–423. [Google Scholar] [CrossRef]

- Najafi, H.; Karimi, A.; Alexander, D.; Dessarzin, P.; Morstein, M. Effects of Si and Y in structural development of (Al,Cr,Si/Y)OxN1−x thin films N deposited by magnetron sputtering. Thin Solid Film. 2013, 549, 224–231. [Google Scholar] [CrossRef]

- Chen, M.; Chen, W.; Cai, F.; Zhang, S.; Wang, Q. Structural evolution and electrochemical behaviors of multilayer Al-Cr-Si-N coatings. Surf. Coat. Technol. 2016, 296, 33–39. [Google Scholar] [CrossRef]

- Bakalova, T.; Petkov, N.; Bahchedzhiev, H.; Kejzlar, P.; Louda, P.; Ďurák, M. improving the tribological and mechanical properties of an aluminium alloy by deposition of AlSiN and AlCrSiN coatings. Manuf. Technol. 2017, 17, 824–830. [Google Scholar] [CrossRef]

- Tang, J.-F.; Huang, C.-H.; Lin, C.-Y.; Yang, F.-C.; Chang, C.-L. Effects of substrate rotation speed on structure and adhesion properties of CrN/CrAlSiN multilayer coatings prepared using high-power impulse magnetron sputtering. Coatings 2020, 10, 742. [Google Scholar] [CrossRef]

- Tao, H.; Tsai, M.T.; Chen, H.-W.; Huang, J.C.; Duh, J.-G. Improving high-temperature tribological characteristics on nanocomposite CrAlSiN coating by Mo doping. Surf. Coat. Technol. 2018, 349, 752–756. [Google Scholar] [CrossRef]

- Liu, Z.R.; Peng, B.; Xu, Y.X.; Zhang, Q.; Wang, Q.; Chen, L. Influence of Ni-addition on mechanical, tribological properties and oxidation resistance of AlCrSiN coatings. Ceram. Int. 2019, 45, 3735–3742. [Google Scholar] [CrossRef]

- Liu, Z.R.; Xu, Y.X.; Peng, B.; Wei, W.; Chen, L.; Wang, Q. Structure and property optimization of Ni-containing AlCrSiN coatings by nano-multilayer construction. J. Alloys Compd. 2019, 808, 151630. [Google Scholar] [CrossRef]

- Yamamoto, K.; Kujime, S.; Takahara, K. Structural and mechanical property of Si incorporated (Ti,Cr,Al)N coatings deposited by arc ion plating process. Surf. Coat. Technol. 2005, 200, 1383–1390. [Google Scholar] [CrossRef]

- Chen, W.; Hu, T.; Wang, C.; Xiao, H.; Meng, X. The effect of microstructure on corrosion behavior of a novel AlCrTiSiN ceramic coating. Ceram. Int. 2020, 46, 12584–12592. [Google Scholar] [CrossRef]

- Dai, W.; Kwon, S.-H.; Wang, Q.; Liu, J. Influence of frequency and C2H2 flow on growth properties of diamond-like carbon coatings with AlCrSi co-doping deposited using a reactive high power impulse magnetron sputtering. Thin Solid Film. 2018, 647, 26–32. [Google Scholar] [CrossRef]

- Vetter. J. Layer System for the Formation of a Surface Layer on a Surface of a Substrate and Also Arc Vaporization Source for the Manufacture of a Layer System. U.S. Patent 8,119,261 B2, 21 February 2012.

- Yamamoto, K.; Kujime, S.; Fox-Rabinovich, G. Effect of alloying element (Si,Y) on properties of AIP deposited (Ti,Cr,Al)N coating. Surf. Coat. Technol. 2008, 203, 579–583. [Google Scholar] [CrossRef]

- Shen, W.-J.; Tsai, M.-H.; Yeh, J.-W. Machining Performance of Sputter-Deposited (Al0.34Cr0.22Nb0.11Si0.11Ti0.22)50N50 High-Entropy Nitride Coatings. Coatings 2015, 5, 312–325. [Google Scholar] [CrossRef]

- Chen, W.; Yan, A.; Meng, X.; Wu, D.; Yao, D.; Zhang, D. Microstructural change and phase transformation in each individual layer of a nano-multilayered AlCrTiSiN high-entropy alloy nitride coating upon annealing. Appl. Surf. Sci. 2018, 462, 1017–1028. [Google Scholar] [CrossRef]

- Qiu, Y.; Zhang, S.; Lee, J.-W.; Li, B.; Wang, Y.; Zhao, D. Self-lubricating CrAlN/VN multilayer coatings at room temperature. Appl. Surf. Sci. 2013, 279, 189–196. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, J.-W.; Duh, J.-G. Mechanical strengthening in self-lubricating CrAlN/VN multilayer coatings for improved high-temperature tribological characteristics. Surf. Coat. Technol. 2016, 303, 12–17. [Google Scholar] [CrossRef]

- Hosokawa, A.; Saito, R.; Ueda, T. Milling characteristics of VN/AlCrN-multilayer PVD coated tools with lubricity and heat resistance. CIRP Ann. Manuf. Technol. 2020, 69, 49–52. [Google Scholar] [CrossRef]

- Liew, W.Y.H.; Jie, J.L.L.; Yan, L.Y.; Dayou, J.; Sipaut, C.S.; Madlan, M.F.B. Frictional and wear behaviour of AlCrN, TiN, TiAlN single-layer coatings, and TiAlN/AlCrN, AlN/TiN nano-multilayer coatings in dry sliding. Procedia Eng. 2013, 68, 512–517. [Google Scholar] [CrossRef]

- Kumar, T.S.; Prabu, S.B.; Manivasagam, G. Metallurgical characteristics of TiAlN/AlCrN coating synthesized by the PVD Process on a cutting insert. J. Mater. Eng. Perform. 2014, 23, 2877–2884. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Weng, S.-Y.; Chen, C.-H.; Fu, F.-X. High temperature oxidation and cutting performance of AlCrN, TiVN and multilayered AlCrN/TiVN hard coatings. Surf. Coat. Technol. 2017, 332, 494–503. [Google Scholar] [CrossRef]

- Xiao, B.J.; Li, H.X.; Mei, H.J. A study of oxidation behavior of AlTiN-and AlCrN-based multilayer coatings. Surf. Coat. Technol. 2018, 333, 229–237. [Google Scholar] [CrossRef]

- Chen, W.; Lin, Y.; Zheng, J.; Zhang, S.; Liu, S.; Kwon, S. Preparation and characterization of CrAlN/TiAlSiN nano-multilayers by cathodic vacuum arc. Surf. Coat. Technol. 2015, 265, 205–211. [Google Scholar] [CrossRef]

- He, L.; Chen, L.; Xu, Y. Interfacial structure, mechanical properties and thermal stability of CrAlSiN/CrAlN multilayer coatings. Mater. Charact. 2017, 125, 1–6. [Google Scholar] [CrossRef]

- Seidl, W.M.; Bartosik, M.; Kolozsváric, S.; Bolvardid, H.; Mayrhofer, P.H. Mechanical properties and oxidation resistance of Al-Cr-N/Ti-Al-Ta-N multilayer coatings. Surf. Coat. Technol. 2018, 347, 427–433. [Google Scholar] [CrossRef]

- Ahmad, F.; Zhang, L.; Zheng, J.; Sidra, I.; Zhang, S. Characterization of AlCrN and AlCrON coatings deposited on plasma nitrided AISI H13 steels using ion-source-enhanced arc ion plating. Coatings 2020, 10, 306. [Google Scholar] [CrossRef]

- Raab, R.; Koller, C.M.; Kolozsvári, S.; Ramm, J.; Mayrhofer, P.H. Interfaces in arc evaporated Al-Cr-N/Al-Cr-O multi layers and their impact on hardness. Surf. Coat. Technol. 2017, 324, 236–242. [Google Scholar] [CrossRef]

- Wang, X.; Luo, T.; Li, Q.; Cheng, X.; Li, K. High performance aperiodic metal-dielectric multilayer stacks for solar energy thermal conversion. Sol. Energy Mater. Sol. Cells 2019, 191, 372–380. [Google Scholar] [CrossRef]

- Vetter, J. Oxynitrides and Oxides Deposited by Cathodic Vacuum Arc. In Metallic Oxynitride Thin Films by Reactive Sputtering and Related Deposition Methods: Process, Properties and Applications; Vaz, F., Martin, N., Fenker, M., Eds.; Bentham Science Publisher: Bussum, The Netherlands, 2013; pp. 265–284. [Google Scholar]

- Khatibi, A.; Sjölen, J.; Greczynski, G.; Jensen, J.; Eklund, P.; Hultman, L. Structural and mechanical properties of Cr-Al-O-N thin films grown by cathodic arc deposition. Acta Mater. 2012, 60, 6494–6507. [Google Scholar] [CrossRef]

- Khatibi, A.; Genvad, A.; Goethelid, E.; Jensen, J.; Eklund, P.; Hultman, L. Structural and mechanical properties of corundum and cubic (AlxCr1–x)2+yO3–y coatings grown by reactive cathodic arc evaporation in as-deposited and annealed states. Acta Mater. 2013, 61, 4811–4822. [Google Scholar] [CrossRef]

- Pilkington, A.; Dowey, S.J.; Toton, J.T.; Doyle, E.D. Machining with AlCr-oxinitride PVD coated cutting tools. Tribol. Int. 2013, 65, 303–313. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C.; Naderi, M. Hybrid dcMS/HPPMS PVD nitride and oxynitride hard coatings for adhesion and abrasion reduction in plastics processing. Surf. Coat. Technol. 2016, 308, 349–359. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C.; Liang, T. High-rate deposition of thick (Cr,Al)ON coatings by high speed physical vapor deposition. Surf. Coat. Technol. 2017, 322, 152–162. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, X.; Li, Q.; Min, J.; Cheng, X. Spectral properties of AlCrNO-based multi-layer solar selective absorbing coating during the initial stage of thermal aging upon exposure to air. Sol. Energy Mater. Sol. Cells 2018, 188, 81–92. [Google Scholar] [CrossRef]

- Najafi, H.; Karimi, A.; Dessarzin, P.; Morstein, M. Correlation between anionic substitution and structural properties in AlCr(OxN1–x) coatings deposited by lateral rotating cathode arc PVD. Thin Solid Film. 2011, 520, 1597–1602. [Google Scholar] [CrossRef]

- Stueber, M.; Diechle, D.; Leiste, H.; Ulrich, S. Synthesis of Al-Cr-O-N thin films in corundum and f.c.c. structure by reactive r.f. magnetron sputtering. Thin Solid Film. 2011, 519, 4025–4031. [Google Scholar] [CrossRef]

- Koller, C.M.; Stueber, M.; Mayrhofer, P.-H. Progress in the synthesis of Al- and Cr-based sesquioxide coatings for protective applications. J. Vac. Sci. Technol. A 2019, 37, 060802. [Google Scholar] [CrossRef]

- Brögelmann, T.; Bobzin, K.; Kruppe, N.C.; Carlet, M. (Cr,Al)ON Deposited by Hybrid dcMS/HPPMS. A study on incorporation of Oxygen. Surf. Coat. Technol. 2019, 369, 238–243. [Google Scholar] [CrossRef]

- Zhou, H.; Zheng, J.; Gui, B.; Geng, D.; Wang, Q. AlTiCrN coatings deposited by hybrid HIPIMS/D C magnetronco-sputtering. Vacuum 2017, 136, 129–136. [Google Scholar] [CrossRef]

- Veprek, S.; Veprek-Heijman, M.J.G. Industrial applications of superhard nanocomposite coatings. Surf. Coat.Technol. 2008, 202, 5063–5073. [Google Scholar] [CrossRef]

- Cheng, Y.T.; Qiu, W.Q.; Zhou, K.S.; Jiao, D.L.; Liu, Z.W.; Zhong, X.C.; Zhang, H. The influence of Cr content on the phase structure of the Al-rich Al-Cr-O films deposited by magnetron sputtering at low temperature. Ceram. Int. 2019, 45, 8175–8180. [Google Scholar] [CrossRef]

- Najafi, H.; Karimi, A.; Dessarzin, P.; Morstein, M. Formation of cubic structured (Al1−xCrx)2+δO3 and its dynamic transition to corundum phase during cathodic arc evaporation. Surf. Coat. Technol. 2013, 214, 46–52. [Google Scholar] [CrossRef]

- Almandoz, E.; Fuentes, G.G.; Fernández, J.; de Bujanda, J.M.; Rodríguez, R.J.; Pérez-Trujillo, F.J.; Alcalá, G.; Lousa, A.; Qin, Y. Chemical and mechanical stability of air annealed cathodic arc evaporated CrAlON coatings. Surf. Coat. Technol. 2018, 351, 153–161. [Google Scholar] [CrossRef]

- Gao, Y.; Cai, F.; Fang, W.; Chen, Y.; Zhang, S.; Wang, Q. Effect of oxygen content on wear and cutting performance of AlCrON coatings. J. Mater. Eng. Perform. 2019, 28, 828–837. [Google Scholar] [CrossRef]

- Stüber, M.; Albers, U.; Leiste, H.; Seemann, K.; Ziebert, C.; Ulrich, S. Magnetron sputtering of hard Cr-Al-N-O thin films. Surf. Coat. Technol. 2008, 203, 661–665. [Google Scholar] [CrossRef]

- Diechle, D.; Stueber, M.; Leiste, H.; Ulrich, S. Combinatorial approach to the growth of α-(Al1−x,Crx)2+δ(O1−y,Ny)3 solid solution strengthened thin films by reactive r.f. magnetron sputtering. Surf. Coat. Technol. 2011, 206, 1545–1551. [Google Scholar] [CrossRef]

- Gerth, J.; Larsson, M.; Wiklund, U.; Riddar, F.; Hogmark, S. On the wear of PVD-coated HSS hobs in dry gear cutting. Wear 2009, 266, 444–452. [Google Scholar] [CrossRef]

- Cselle, T.; Morstein, M.; Luemkemann, A. QuadCoatings4® new generation of PVD coatings for cutting tools. Werkzeug Tech. 2012, 130, 2–3. [Google Scholar]

- Wang, B. An Investigation of the Adhesion Behavior of Aluminium on Various PVD Coatings Applied to H13 Tool Steel to Minimize Lubrication during High Pressure Die Casting. Ph.D. Thesis, Colorado School of Mines, Golden, CO, USA, 2016. [Google Scholar]

- Uestuenyagiz, E.; Nielsen, C.V.; Tiedje, N.S.; Bay, N. Combined numerical and experimental determination of the convective heat transfer coefficient between an AlCrN-coated Vanadis 4E tool and Rhenus oil. Measurement 2018, 127, 565–570. [Google Scholar] [CrossRef]

- Kim, D.; Swan, S.R.; He, B.; Khominich, V.; Bell, E.; Lee, S.-W.; Kim, T.-G. A study on the machinability of advanced arc PVD AlCrN-coated tungsten carbide tools in drilling of CFRP/titanium alloy stacks. Carbon Lett. 2020. [Google Scholar] [CrossRef]

| Deposition Method | Source Composition (Targets/Cathodes) | Pure fcc Phases by X-Ray at Al [at.%] Coating or Source | Fcc + hcp Phases by X-Ray at Al [at.%] Coating or Source | Range of Transition Almax [at.%] | Reference |

|---|---|---|---|---|---|

| RF sputtering | Al and Cr targets | Coating 57 at RT 56 at 300 °C | Coating 75 at RT 67 at 300 °C | Coating 57 < Almax < 67 | [49] |

| RF/DC sputtering | Al and Cr targets | Coating 63 at 300 °C | - | 63 < Almax | [51] |

| Pulsed CFUBM sputtering | Al and Cr targets | Coating 60.9 at 175 °C | Coating 64 at 175 °C | Coating 60.9 < Almax < 64 | [59] |

| Arc | Alloyed cathodes | Cathodes 60 at 600 °C | Cathodes 70 at 600 °C | Cathodes 60 < Almax < 70 | [60] |

| Arc | Alloyed cathodes | Coating 70 at 500 °C TEM traces hcp | - | Coating 70 < Almax | [62] |

| Arc | Alloyed cathodes | Coating 71 at 450 °C | Coating 75 at 450 °C | Coating 71 < Almax < 83 | [61] |

| Arc | Alloyed cathodes | Coating 71 at 450 °C | Coating 75 at 450 °C | Coating 71 < Almax < 75 | [63] |

| DC sputtering | Segmented target | Coating 70 at 400 °C | - | Coating 70 < Almax | [64] |

| DC sputtering | Alloyed targets | Targets 1 70 at 500 °C | - | Targets 70 < Almax | [65] |

| Arc | Alloyed cathodes | Coating 70 at 500 °C | Coating 82 at 500 °C | Coating 70 < Almax < 82 | [66] |

| Alloying Element | Coating Composition | Cathodes/Targets | Deposition Method | Results | Reference |

|---|---|---|---|---|---|

| Ti | e.g., Al30.5Cr14 Ti5.5N50 | Al66Ti29Cr5, Al67Cr33, Al34Cr33, Al67Ti33 | Arc/ different AlCrTi composition in one batch | Age hardening | [97] |

| (Al66Cr24Ti10)N | Al70Cr20Ti10 | Arc | Age hardening | [98] | |

| e.g., (Al69Cr20Ti11)N | Al65Cr21Ti14, Al71Cr19Ti10, Al74Cr18Ti8 | Arc | Oxidation onset 1000 °C | [99] | |

| V | Al25Cr22V3N50 | Al55Cr45, Al55Cr40V5 | Arc | Higher hardness, reduced oxidation onset | [100] |

| e.g., Al34Cr10.5V5.5N50 | Al70Cr30–xVx; x = 0, 10, 15, 20, 25, and 30 | Arc | Metastable solubility limit decreases at low bias | [101] | |

| Cr29.5Al10.5V10N50 | Al80Cr20 Cr80Al insert targets, and Cr, V | DC sputter Plus HiPIMS | Lower friction (Magnéli phases) | [102] | |

| (AlCrV)N | Al70Cr30, Cr70V30 | Arc | Cutting test hardness, structure | [103] | |

| Zr | Cr38.8Al4.5V2N54.8 | Al90Cr10, Al80Cr20, and Cr, Al, Zr | DC sputter | Lower friction and wear | [104] |

| Mo | e.g., Cr20Al18.5 Mo7N54.5 | Al60Cr40, Al70Cr30, Al55Mo45, with inserts Mo,Cr,Al60Cr40, Al85Cr15 | DC sputter | H/E optimisation | [105] |

| e.g., (Al50Cr37 Mo13)N | Cr35Al65, and Cr, Mo | Arc | Triboactive, element Mo | [106] | |

| (AlCrMo)N | Al70Cr30, Cr70Mo30 | Arc | Cutting test hardness, structure | [103] | |

| Hf | e.g., Al37Cr11Hf2N50 | AlCr20 (Cr in Al) inserted, and Hf | DC sputter | Higher oxidation resistance | [107] |

| Nb | e.g., Al27.5Cr17.5Nb5N50 | Al55Cr45, Al60Cr35Nb5, Al60Cr30Nb10 | Arc | Higher hardness, lower oxidation resistance | [108] |

| W | e.g., (Al64Cr31W5)N | Al70Cr30, Al70Cr25W5 | Arc | Improved oxidation resistance at 1100 °C | [81] |

| Cu | e.g., (Al47Cr34Cu19)N | Cr35Al65, and Cr, Cu | DC sputter | Triboactive, hardness decrease | [106] |

| Y | e.g., Al26.5Cr22.5Y1N50 | Al/Cr = 1.5 with 0, 2, 4, 8 at.% Y | DC sputter | Structure, improved oxidation resistance | [109,110] |

| e.g., Al23.8Cr23.1Y0.7N50O2.4 | Al50Cr50, Y | DC sputter | Improved oxidation | [111] | |

| e.g., Cr25.8Al15.3Y3.4N55.5 | Al90Cr10, Al80Cr20, and Y | DC sputter | Structure, improved oxidation | [112] | |

| La | e.g., Al28.1Cr12.5La1.4N58 | Al70Cr30, and La | DC sputter | Wear, friction, structure | [113] |

| C | e.g., Cr44.4Al12C27.6N16 | Cr2AlC | DC sputter | Wear, friction, structure | [114] |

| e.g., Cr24Al24N48C4 | AlCr20, AlCr24, Cr inserts in Al, and Cr | DC sputter HiPIMS | Structure, hardness | [115] | |

| B | e.g., Al26.7Cr21.7B2.3N49.3 | Al60Cr40, Al70Cr30, B alloyed Al/Cr =1.8, with 10, 20, 30 at.% | Arc | Structure, phases, hardness, nano composite | [89] |

| e.g., Al30.4Cr16.3B2.1N48.1O3.1 | Al55Cr35B10, Al70Cr30 | Arc | Structure, wear, tribology | [58] | |

| e.g., (Al64.5Cr32.9B2.6)N | Al70Cr30, Al70Cr25B5, | DC sputter | Oxidation, structure | [81] | |

| Si | See Section 4.4 paragraph Cr-Al-Si N and Al-Cr-Si-N | ||||

| Feature | Monolayer Arc (e.g., BALINIT® ALCRONA PRO) | Multilayer (e.g., BALINIT® HELICA) | Monolayer Sputtering (e.g., BALIQ® ALCRONOS) |

|---|---|---|---|

| Source type | Magnetic steered arc | Magnetic steered arc | Magnetron optimised for S3p (HiPIMS) |

| Cathode type/form | Powder metallurgical/circular | Powder metallurgical and vacuum melting/circular | Powder metallurgical/circular |

| Coating temp. [°C] | 400–500 °C | 400–500 °C | 400–500 °C |

| Chemical composition | Al > Cr content at.%

|

| Al > Cr content at.%

|

| Alloying types |

| - |

|

| Coating hardness/Indentation E-modul range [GPa] | 29–37 390–420 | 32–39 380–410 | 31–38 370–430 |

| Thickness [um] | 0.5–6 | 1–4 | 0.5–5 |

| Speciality | Universal use | High hardness | Low defect density, smooth |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vetter, J.; Eriksson, A.O.; Reiter, A.; Derflinger, V.; Kalss, W. Quo Vadis: AlCr-Based Coatings in Industrial Applications. Coatings 2021, 11, 344. https://doi.org/10.3390/coatings11030344

Vetter J, Eriksson AO, Reiter A, Derflinger V, Kalss W. Quo Vadis: AlCr-Based Coatings in Industrial Applications. Coatings. 2021; 11(3):344. https://doi.org/10.3390/coatings11030344

Chicago/Turabian StyleVetter, Joerg, Anders O. Eriksson, Andreas Reiter, Volker Derflinger, and Wolfgang Kalss. 2021. "Quo Vadis: AlCr-Based Coatings in Industrial Applications" Coatings 11, no. 3: 344. https://doi.org/10.3390/coatings11030344

APA StyleVetter, J., Eriksson, A. O., Reiter, A., Derflinger, V., & Kalss, W. (2021). Quo Vadis: AlCr-Based Coatings in Industrial Applications. Coatings, 11(3), 344. https://doi.org/10.3390/coatings11030344