Physical, Optical, and Visual Performance of Coated Cross-Laminated Timber during Natural and Artificial Weathering

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation and Coating Systems

2.2. Natural and Artificial Weathering

2.3. Surface Appearance Analysis

2.4. Color and Gloss Measurements

2.5. Moisture Content during Exposure

2.6. Statistical Analysis

3. Results and Discussion

3.1. Natural Weathering

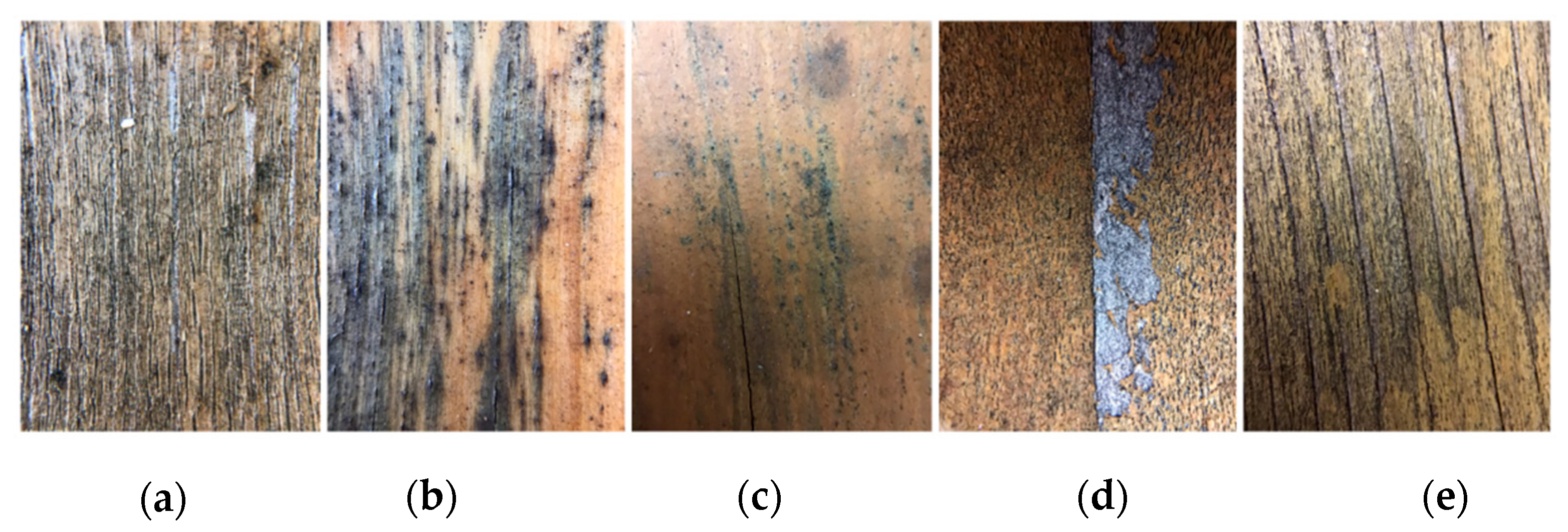

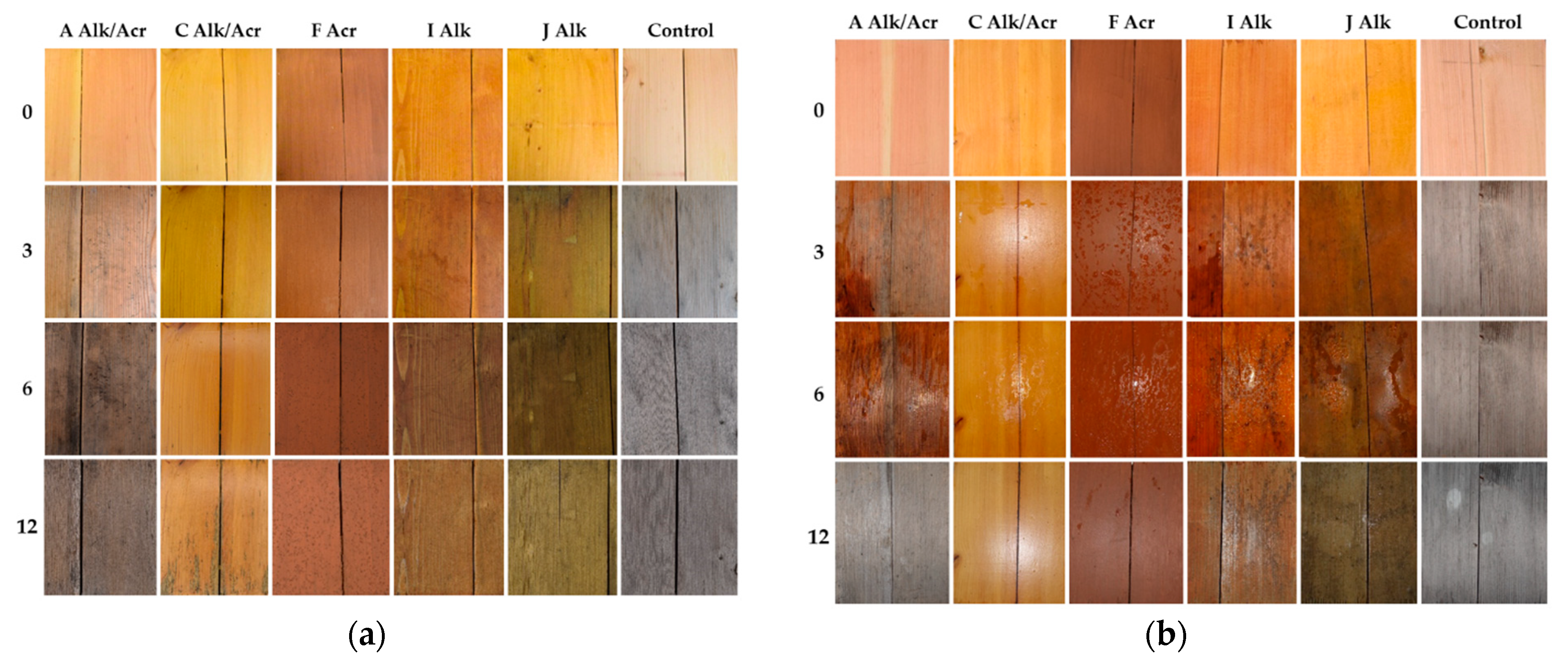

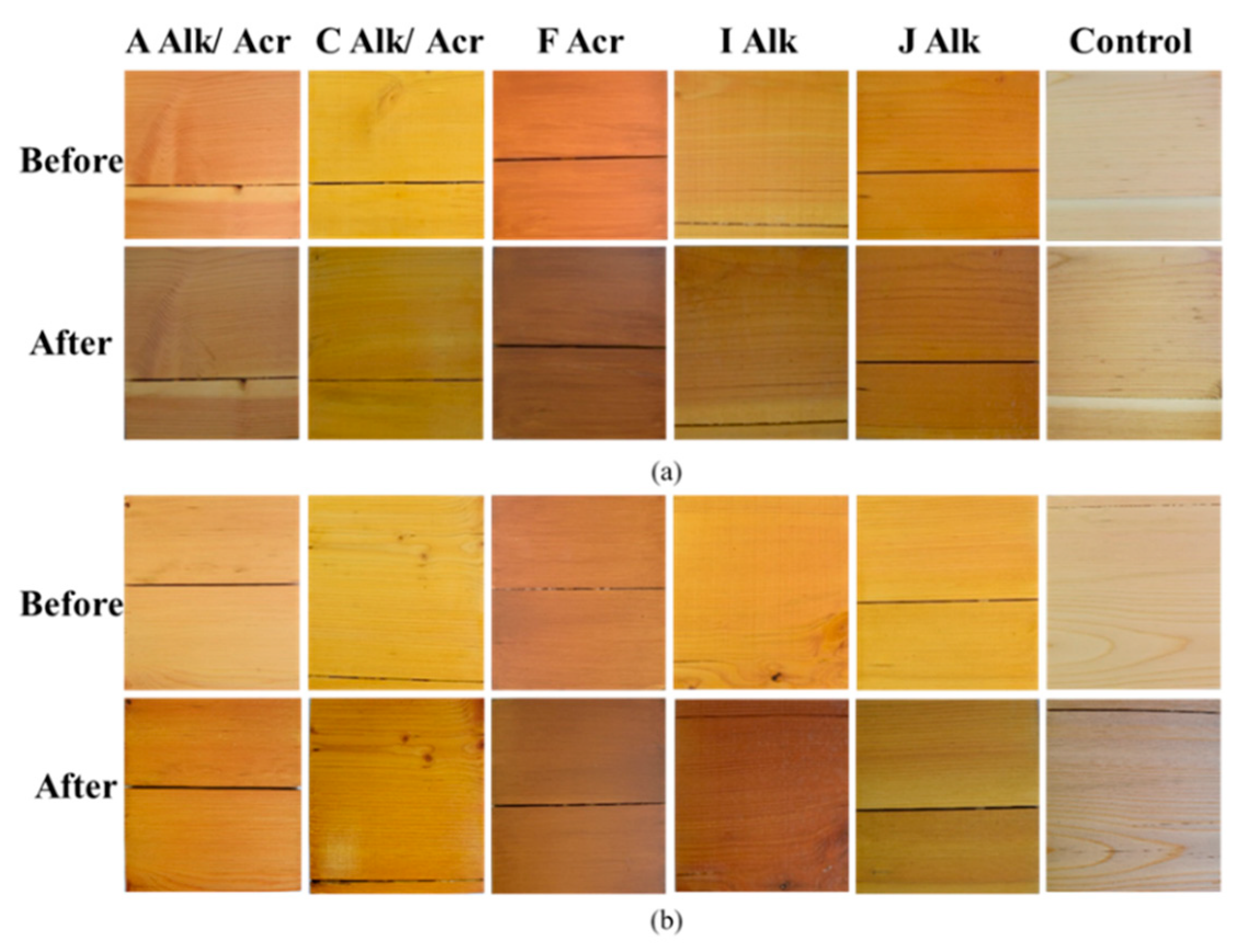

3.1.1. Visual Assessments

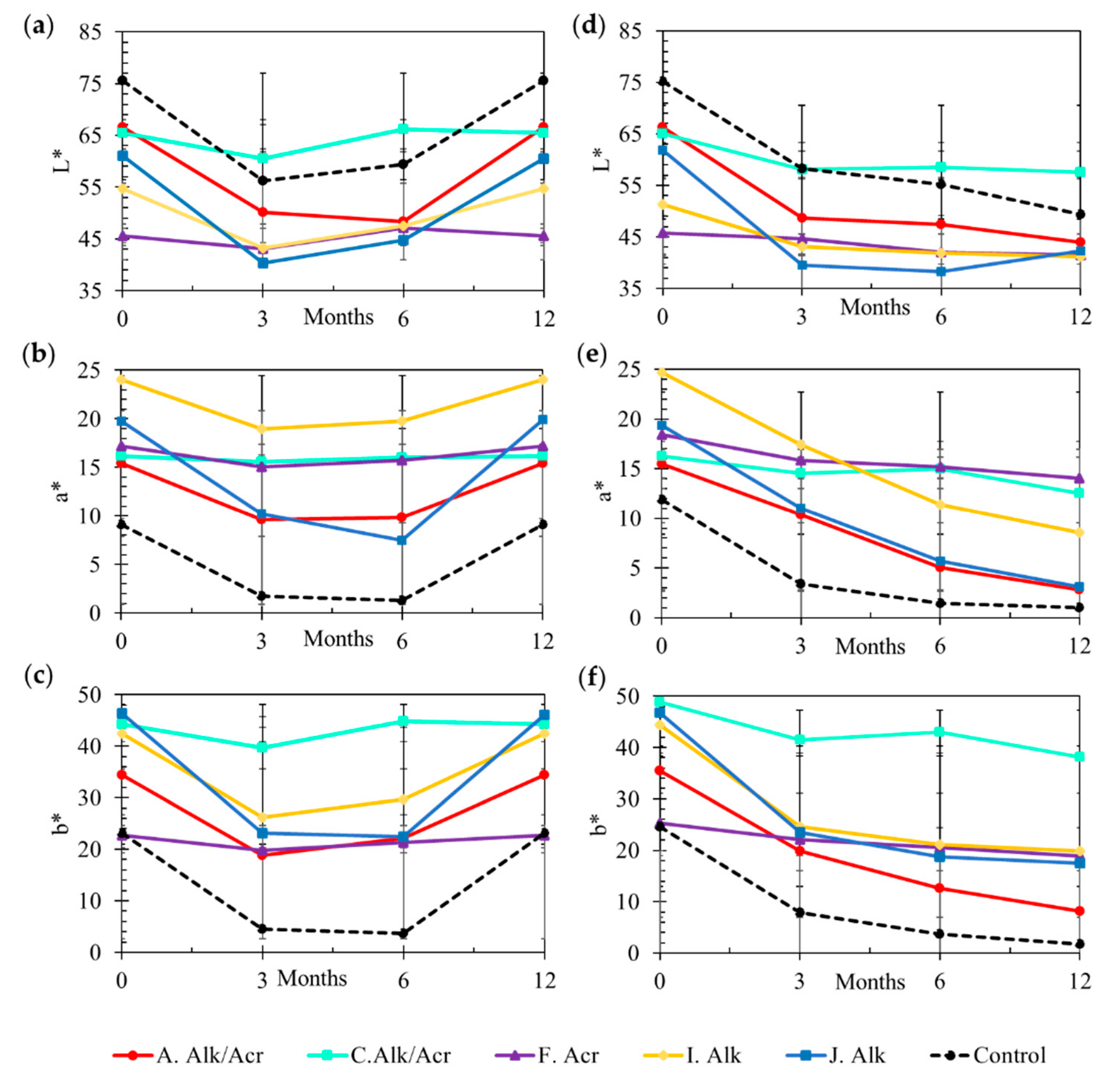

3.1.2. Color and Gloss Change

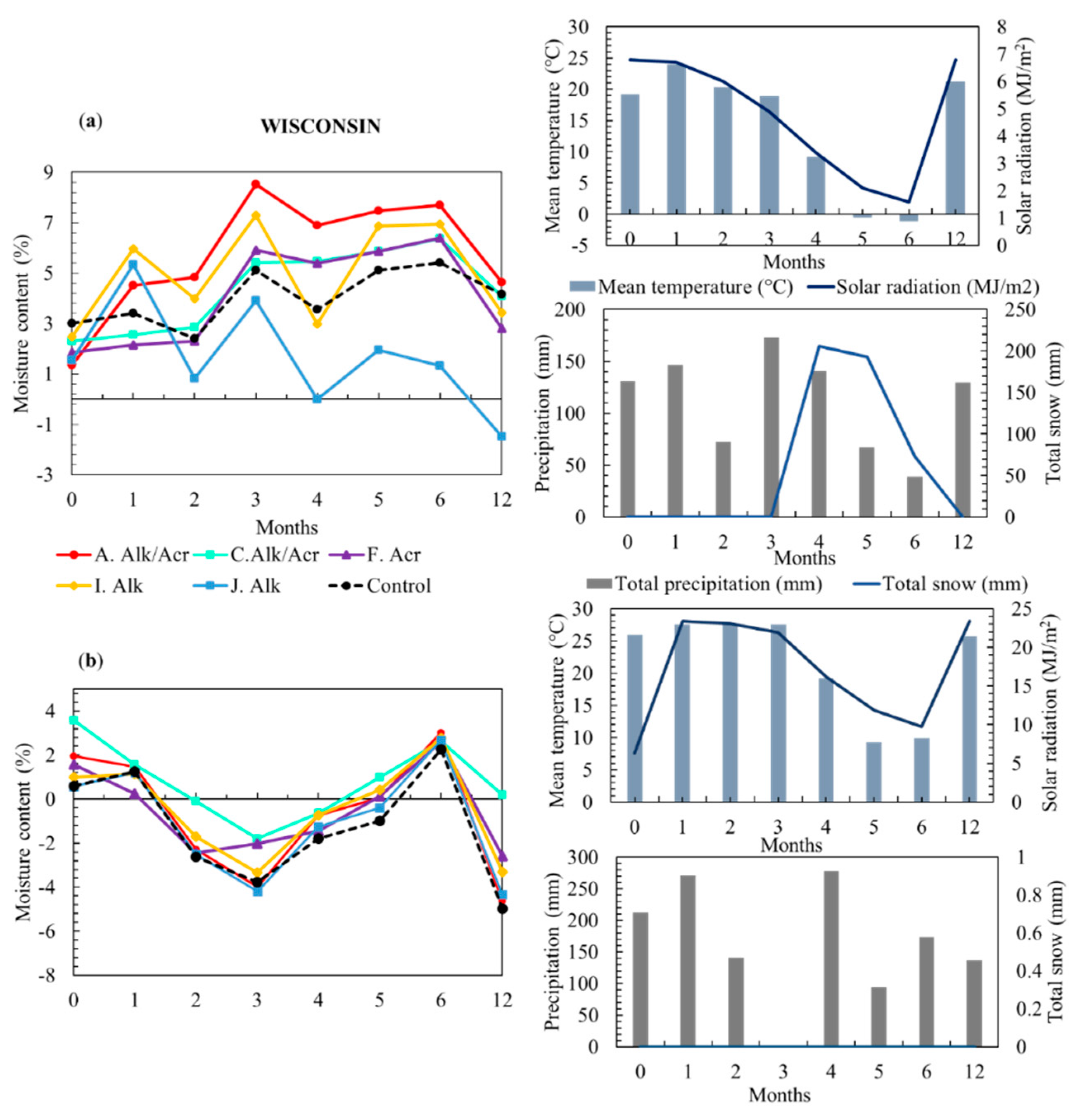

3.1.3. Moisture Content during Exposure

3.2. Artificial Weathering

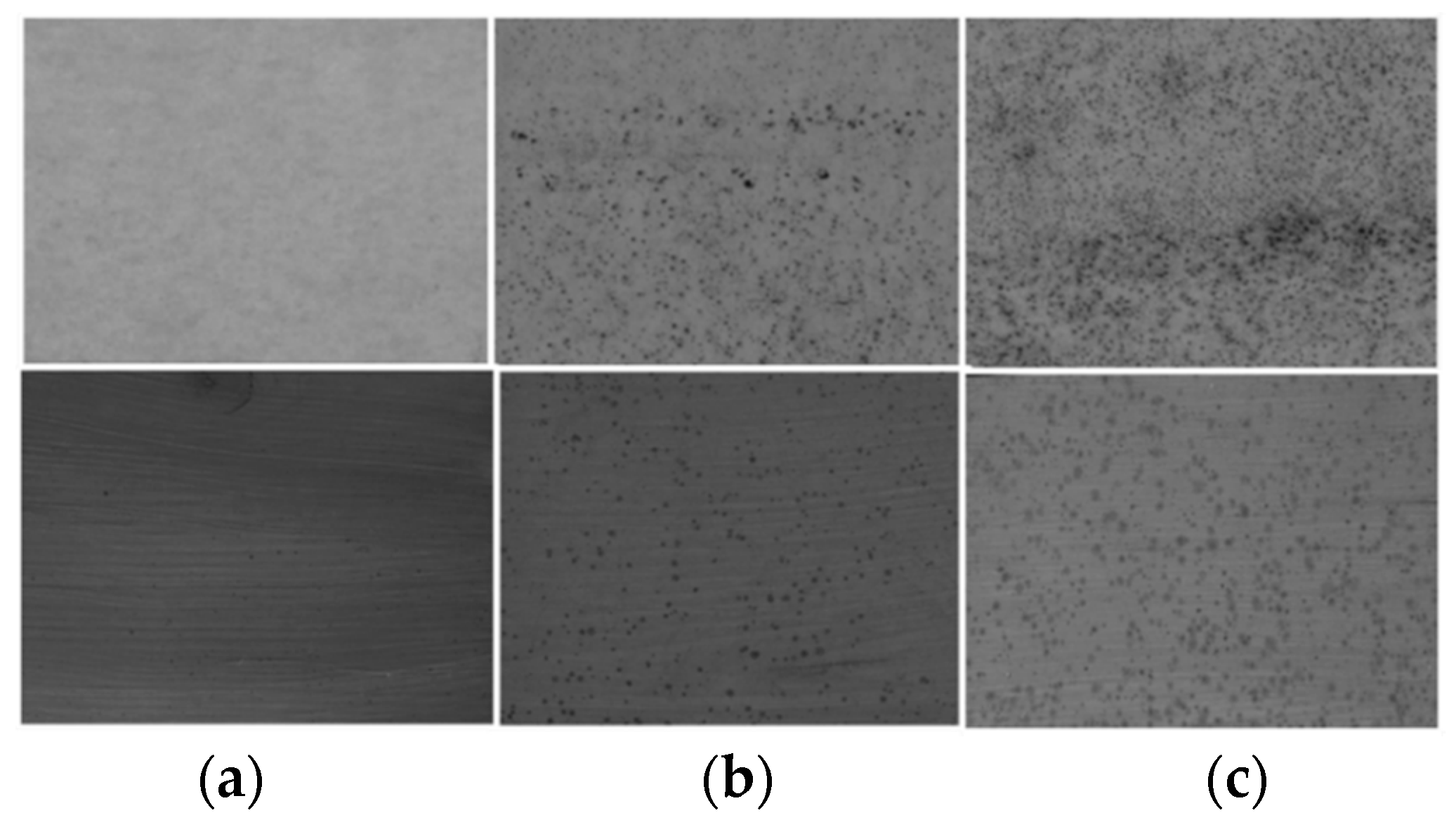

3.2.1. Visual Analysis

3.2.2. Color and Gloss Changes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mallo, M.F.L.; Espinoza, O. Outlook for cross-laminated timber in the United States. BioResources 2014, 9, 7427–7443. [Google Scholar]

- Zumbrunnen, P.; Fovargue, J. Mid-rise CLT buildings, the UK’s experience and potential for Australia and New Zealand. In Proceedings of the 12th World Conference on Timber Engineering, Auckland, New Zealand, 15–19 July 2012; pp. 91–98. [Google Scholar]

- Pei, S.; Rammer, D.; Popovski, M.; Williamson, T.; Line, P.; van de Lindt, J.W. An Overview of CLT Research and Implementation in North America. In Proceedings of the 16th World Conference on Timber Engineering (WCTE), Vienna, Austria, 15–22 August 2016. [Google Scholar]

- Morris, P. Optimizing the Design of Mass Timber in Exterior Applications. 2015. Available online: www.durable-wood.com (accessed on 12 December 2020).

- Williams, R.S. Finishing of Wood. In Wood Handbook: Wood as an Engineering Material; Ross, R.J., Ed.; General Technical Report FPL: Madison, WI, USA, 1999; pp. 15–37. [Google Scholar]

- Cappellazzi, J.; Konkler, M.J.; Sinha, A.; Morrell, J.J. Potential for decay in mass timber elements: A review of the risks and identifying possible solutions. Wood Mat. Sci. Eng. 2020, 15, 351–360. [Google Scholar] [CrossRef]

- Joshi, A.A.; Pagni, P.J. Fire induced thermal fields in window glass. II- Experiments. Fire Saf. J. 1994, 22, 45–65. [Google Scholar] [CrossRef]

- Clausen, C.A. Biodeterioration of Wood. In Wood Handbook: Wood as an Engineering Material; Ross, R.J., Ed.; General Technical Report FPL: Madison, WI, USA, 2010; pp. 1–16. [Google Scholar]

- Kataoka, Y.; Kiguchi, M.; Williams, R.S.; Evans, P.D. Violet light causes photodegradation of wood beyond the zone affected by ultraviolet region. Holzforschung 2007, 61, 23–27. [Google Scholar] [CrossRef]

- Shupe, T.; Lebow, S.; Ring, D. Wood Decay, Degradation & Stain. In Causes and Control of Wood Decay, Degradation & Stain; Louisiana Cooperative Extension Service: Baton Rouge, LA, USA; Louisiana State University Agricultural Center: Baton Rouge, LA, USA, 2008; p. 26. [Google Scholar]

- Isaksson, T.; Thelandersson, S. Experimental investigation on the effect of detail design on wood moisture content in outdoor above ground applications. Build. Environ. 2013, 59, 239–249. [Google Scholar] [CrossRef]

- Koch, P. Finishing. In Utilization of the Southern Pines; U.S. Southern Forest Experiment Station, USDA: Washington, DC, USA, 1972; pp. 1327–1366. [Google Scholar]

- Scheffer, T.C. A climate index for estimating potential for decay in wood structures above ground. For. Prod. J. 1971, 21, 25–31. [Google Scholar]

- APA—The Engineered Wood Association. Cross Laminated Timber Standards; American National Standards Institute: Tacoma, WA, USA, 2018. [Google Scholar]

- Lepage, R.; Higgins, J.; Finch, G. Moisture uptake test for CLT floor panels in a tall wood building in Vancouver. In Proceedings of the 15th Canadian Conference on Building Science and Technology, British Columbia Building Envelope Council, Vancouver, BC, Canada, 6–8 November 2017; p. 17. [Google Scholar]

- Crespell, P.; Gagnon, S. Cross Laminated Timber: A Primer, FPInnovations, Special Publication (52). Vancouver, British Columbia. 2010. Available online: https://fpinnovations.ca/media/factsheets/Documents/cross-laminated-timber-the-boook.pdf (accessed on 25 November 2020).

- de Meijer, M.; Thurich, K.; Militz, H. Quantitative measurements of capillary coating penetration in relation to wood and coating properties. Holz Roh Werkst 2001, 59, 35–45. [Google Scholar] [CrossRef]

- Bonura, T.; Bussjeager, S.; Christensen, L.; Daisey, G.; Daniels, T.; Hirsch, M.; Jourdain, C.J.; Mall, D.D.; Springate, B.; Wagner, L.E.; et al. Finishes checklist: A guide to achieving optimum coating performance on exterior wood surfaces. Coat. Technol. 2004, 1, 36–49. [Google Scholar]

- Pánek, M.; Oberhofnerová, E.; Zeidler, A.; Šedivka, P. Efficacy of hydrophobic coatings in protecting oak wood surfaces during accelerated weathering. Coatings 2018, 7, 172. [Google Scholar] [CrossRef]

- Bobadilha, G.S.; Stokes, C.E.; Verly Lopes, D.J. Artificial neural networks modelling based on visual analysis of coated cross laminated timber (CLT) to predict color change during outdoor exposure. Holzforschung 2020. published online ahead of print 2020. [Google Scholar] [CrossRef]

- Bobadilha, G.S.; Stokes, C.E.; Kirker, G.; Ahmed, S.A.; Ohno, K.M.; Lopes, D.J.V. Effect of exterior wood coatings on the durability of cross-laminated timber against mold and decay fungi. BioRes 2020, 15, 8420–8433. [Google Scholar]

- ASTM D1006 / D1006M-13. Standard Practice for Conducting Exterior Exposure Tests of Paints on Wood; American Society for Testing Material: West Conshohoken, PA, USA, 2013. [Google Scholar]

- National Oceanic and Atmospheric Administration—NOAA. Global Summary of the Month Station Details. Mississippi State University Station, 2020. Available online: https://www.ncdc.noaa.gov/cdo-web/datasets/GSOM/stations/GHCND:USC00228374/detail (accessed on 29 September 2020).

- National Oceanic and Atmospheric Administration—NOAA. Global Summary of the Month Station Details. Madison Dane CO Regional Airport Station, 2020. Available online: https://www.ncdc.noaa.gov/cdo-web/datasets/GSOM/stations/GHCND:USW00014837/detail (accessed on 29 September 2020).

- ASTM D772. Standard Test Method for Evaluating Degree Flaking (Scaling) of Exterior Paints; American Society for Testing Material: West Conshohoken, PA, USA, 2018. [Google Scholar]

- ASTM D3274-09. Standard Test Method for Evaluating Degree of Surface Disfigurement of Paint Films by Fungal or Algal Growth, or Soil and Dirt Accumulation; American Society for Transforming Material: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM D714. Standard Test Method for Evaluating Degree of Blistering of Paints; American Society for Testing Material: West Conshohoken, PA, USA, 2015. [Google Scholar]

- ASTM D4214. Standard Test Method for Evaluating Degree of Chalking of Exterior Paint Films; American Society for Testing Material: West Conshohoken, PA, USA, 2015. [Google Scholar]

- ASTM D660-93. Standard Test Method for Evaluating Degree of Checking of Exterior Paints; American Society for Testing and Material: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM D661-93. Standard Test Method for Evaluating Degree of Cracking of Exterior Paints; American Society for Testing Material: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM D662-93. Standard Test Method for Evaluating Degree of Erosion of Exterior Paints; American Society for Testing Material: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ISO 11664-4. Colorimetry—Part 4: CIE 1976 L*a*b* Colour Space; International Organization for Standardization: Geneva, Switzerland, 2008. [Google Scholar]

- ISO 2813. Paints and Varnishes–Determination of Gloss Value at 20 Degrees, 60 Degrees and 85 Degrees; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- SAS Institute Inc. SAS/ACCESS® 9.4 Interface to ADABAS: Reference; SAS Institute Inc: Cary, NC, USA, 2013. [Google Scholar]

- Stirling, R.; Uzunovic, A.; Morris, P.I. Control of black stain fungi with biocides in semitransparent wood coatings. For. Prod. J. 2011, 61, 359–364. [Google Scholar] [CrossRef]

- Schultz, T.P.; Militz, H.; Freeman, M.H.; Goodell, B.; Nicholas, D.D. Development of Commercial Wood Preservatives; American Chemical Society Symposium Series 982; Oxford University Press: Washington, DC, USA, 2008; 655p. [Google Scholar]

- Roux, M.I.; Wozniak, E.; Miller, E.R.; Boxall, J.; Botcher, P.; Kropf, F.; Sell, J. Natural weathering of various surface coatings on five species at four European sites. Holz Roh Werkst 1988, 46, 165–170. [Google Scholar] [CrossRef]

- ANSI/APA—American National Standard. Standard for Performance-Rated Cross-Laminated Timber; Form No. PRG 320-2019; APA: Tacoma, WA, USA, 2020. [Google Scholar]

- Han, Y.; Park, Y.; Yang, S.-Y.; Chung, H.; Chang, Y.-S.; Yeo, H. Dimensional changes of cross-laminated specimens produced under different conditions due to humidity variation. BioRes 2019, 14, 4035–4046. [Google Scholar]

- Feist, W.C.; Hon, D.N.S. Chemistry of weathering and protection. In The Chemistry of Solid Wood; Rowell, R.M., Ed.; Advances in Chemistry Series 20; American Chemical Society: Washington, DC, USA, 1984; pp. 401–454. [Google Scholar]

- Wood, K.A.; Cypcar, C.; Hedhli, L. Predicting the exterior durability of new fluoropolymer coatings. J. Fluor. Chem. 2000, 104, 63–71. [Google Scholar] [CrossRef]

- Wang, J.Y.; Stirling, R.; Morris, P.I.; Taylor, A.; Lloyd, J.; Kirker, G.; Lebow, S.; Mankowski, M.; Barnes, H.M.; Morrel, J.J. Durability of mass timber structures: A review of the biological risks. Wood Fiber. Sci. 2018, 50, 110–127. [Google Scholar] [CrossRef]

- Grigsby, W.; Steward, D. Applying the protective role of condensed tannins to acrylic-based surface coatings exposed to accelerated weathering. J. Pol. Environ. 2018, 26, 895–905. [Google Scholar] [CrossRef]

- Feist, W.C. Weathering performance of painted wood pretreated with water-repellent preservatives. For. Prod. J. 1990, 40, 21–26. [Google Scholar]

- Berdahl, P.; Akbari, H.; Levinson, R.; Miller, W.A. Weathering of roofing materials–an overview. Constr. Build. Mater. 2008, 22, 423–433. [Google Scholar] [CrossRef]

- Grüneberger, F.; Künniger, T.; Zimmermann, T.; Arnold, M. Nanofibrillated Cellulose in Wood Coatings: Mechanical Properties of Free Composite Films. J. Mater. Sci. 2014, 49, 6437–6448. [Google Scholar] [CrossRef]

| Treatment | Coating or Surface Description | Resin Type | No. of Coats | No. of Reps |

|---|---|---|---|---|

| A (Alk/Acr, W1) | Transparent penetrating wood finish | Alkyd/Acrylic | 2 | 6 |

| C (Alk/Acr, W) | Transparent, UV resistant | Alkyd/Acrylic | 3 | 6 |

| F (Acr, W) | Semi-transparent, water and UV resistant | Acrylic | 2 | 6 |

| I (Alk, S2) | Transparent, mildew and water resistant | Alkyd | 2 | 6 |

| J (Alk, S) | Semitransparent and water repellent | Alkyd | 1 | 6 |

| Control | Uncoated sample | None | None | 6 |

| Mississippi * | ||||

|---|---|---|---|---|

| 2019/2020 | Weather Conditions | |||

| Months | Mean Temperature (°C) | Total Precipitation (mm) | Mean Radiation (kW-h/m2) | Total Snow (mm) |

| Jun (0) | 26 | 211.6 | 6.3 | - |

| Jul (1) | 27.5 | 271.3 | 6.5 | - |

| Aug (2) | 27.5 | 140.5 | 6.4 | - |

| Sept (3) | 27.5 | 1 | 6.1 | - |

| Oct (4) | 19.2 | 278.4 | 4.5 | - |

| Nov (5) | 9.3 | 93.7 | 3.3 | - |

| Dec (6) | 9.9 | 172.5 | 2.7 | - |

| Jan (7) | 9.4 | 261.1 | 2.9 | - |

| Feb (8) | 9.3 | 373.4 | 3.7 | - |

| Mar (9) | 16.8 | 180.8 | 4.9 | - |

| Apr (10) | 16.1 | 287.3 | 6.1 | - |

| May (11) | 20.5 | 46.2 | 6.5 | |

| Jun (12) | 25.7 | 137.2 | 6.5 | - |

| Wisconsin | ||||

| Jun (0) | 19.2 | 131.1 | 6.8 | - |

| Jul (1) | 24 | 146.6 | 6.7 | - |

| Aug (2) | 20.3 | 72.4 | 6 | - |

| Sept (3) | 18.9 | 172.7 | 4.9 | - |

| Oct (4) | 9.2 | 140.7 | 3.4 | 205.7 |

| Nov (5) | −0.5 | 66.8 | 2.1 | 193.0 |

| Dec (6) | −1.1 | 38.6 | 1.6 | 73.7 |

| Jan (7) | −3.2 | 1.7 | 1.9 | 464.82 |

| Feb (8) | −4.9 | 0.9 | 2.9 | 337.8 |

| Mar (9) | 3.6 | 88.1 | 4.1 | 71.2 |

| Apr (10) | 7.2 | 52.1 | 5.2 | 5.1 |

| May (11) | 13.5 | 137.7 | 6.2 | - |

| Jun (12) | 21.2 | 129.5 | 6.8 | - |

| Coatings | Mississippi 1 | Wisconsin | ||||

|---|---|---|---|---|---|---|

| Mildew Growth | ||||||

| 3 | 6 | 12 | 3 | 6 | 12 | |

| A. Alk/Acr | 4 (1.0) | 3 (1.4) | 7 (0.8) | 7 (1.1) | 5 (0.7) | 5 (1.0) |

| C. AlkAcr | 9 (0.5) | 7 (1.1) | 7 (1.1) | 10 (0.5) | 10 (0.9) | 8 (0.8) |

| F. Acr | 7 (1.1) | 5 (0.8) | 5 (0.0) | 10 (0.4) | 8 (0.5) | 9 (0.5) |

| I. Alk | 7 (1.3) | 4 (0.9) | 9 (0.5) | 7 (0.8) | 6 (1.3) | 5 (0.9) |

| J. Alk | 1 (0.6) | 1 (0.0) | 5 (1.6) | 6 (0.5) | 3 (0.4) | 4 (0.4) |

| Control | 5 (1.2) | 5 (1.1) | 9 (0.7) | 7 (0.5) | 7 (0.0) | 9 (0.5) |

| Checking | ||||||

| 3 | 6 | 12 | 3 | 6 | 12 | |

| A. Alk/Acr | 6 (0.9) | 4 (2.3) | 0 (1.1) | 6 (1.4) | 4 (0.9) | 0 (0.0) |

| C. Alk/Acr | 10 (0.0) | 8 (1.8) | 8 (2.2) | 10 (0.0) | 8 (1.1) | 8 (1.7) |

| F. Acr | 10 (0.9) | 10 (0.9) | 8 (1.9) | 8 (0.9) | 8 (0.0) | 8 (0.0) |

| I. Alk | 8 (1.1) | 6 (1.1) | 2 (3.6) | 10 (0.0) | 8 (0.0) | 4 (1.1) |

| J. Alk | 6 (1.7) | 2 (1.1) | 2 (1.7) | 6 (1.7) | 8 (1.1) | 2 (0.0) |

| Flaking | ||||||

| 3 | 6 | 12 | 3 | 6 | 12 | |

| A. Alk/Acr | 8 (1.4) | 6 (1.1) | 2 (1.1) | 10 (0.0) | 6 (1.7) | 0 (0.0) |

| C. Alk/Acr | 10 (0.0) | 10 (0.0) | 8 (2.2) | 10 (0.0) | 10 (0.0) | 4 (1.1) |

| F. Acr | 10 (0.0) | 10 (0.0) | 10 (0.0) | 10 (0.0) | 10 (0.0) | 10 (0.0) |

| I. Alk | 10 (1.8) | 8 (0.9) | 6 (1.7) | 8 (0.0) | 6 (1.1) | 4 (1.1) |

| J. Alk | 6 (1.1) | 4 (0.9) | 4 (2.3) | 8 (1.1) | 8 (1.1) | 4 (0.0) |

| Erosion | ||||||

| 3 | 6 | 12 | 3 | 6 | 12 | |

| A. Alk/Acr | 10 (0.0) | 8 (1.1) | 4 (1.1) | 6 (1.7) | 4 (0.0) | 0 (0.0) |

| C. Alk/Acr | 10 (0.0) | 10 (0.0) | 10 (0.0) | 10 (0.0) | 10 (0.0) | 8 (0.9) |

| F. Acr | 10 (0.0) | 10 (0.0) | 10 (0.0) | 10 (0.0) | 10 (0.0) | 10 (1.1) |

| I. Alk | 10 (0.9) | 10 (0.9) | 6 (2.0) | 8 (0.0) | 8 (1.1) | 8 (0.9) |

| J. Alk | 8 (1.4) | 8 (1.1) | 6 (1.7) | 6 (2.3) | 6 (0.0) | 8 (0.0) |

| 360 h | 1800 h | |||||||

|---|---|---|---|---|---|---|---|---|

| Coating | CIE Lab Coordinates | |||||||

| ΔL* | Δa* | Δb* | ΔE* | ΔL* | Δa* | Δb* | ΔE* | |

| A. Alk/Acr | −2.6 | −0.9 | 0.2 | 2.9 | −12.9 | 3.2 | −1.3 | 13.4 |

| (1.3) | (0.5) | (0.7) | (1.1) | (1.4) | (0.7) | (0.8) | (1.5) | |

| C. Alk/Acr | −1.2 | 0.0 | −1.1 | 1.8 | −7.6 | 3.0 | −3.4 | 8.9 |

| (0.2) | (0.6) | (0.7) | (0.7) | (1.1) | (0.4) | (0.2) | (1.0) | |

| F. Acr | 1.5 | −0.2 | −0.3 | 1.7 | −1.7 | −1.3 | −1.6 | 2.9 |

| (2.2) | (0.2) | (0.3) | (2.1) | (0.4) | (1.3) | (0.3) | (0.8) | |

| I. Alk | −1.6 | 0.3 | −3.5 | 4.2 | −11 | −0.6 | −12.6 | 16.9 |

| (1.7) | (1.3) | (2.7) | (2.9) | (2.2) | (1.0) | (3.9) | (4.2) | |

| J. Alk | −4.8 | −0.4 | −2.4 | 5.5 | −12 | 0.7 | −6.7 | 13.9 |

| (0.5) | (1.0) | (0.4) | (0.4) | (0.6) | (1.7) | (1.9) | (0.4) | |

| Control | −10.4 | 2.0 | 7.3 | 12.6 | −11.3 | −0.8 | −5.5 | 13 |

| (0.8) | (1.0) | (1.8) | (1.8) | (0.2) | (0.6) | (1.9) | (0.9) | |

| Treatment | ΔG360 | ΔG1800 |

|---|---|---|

| A. Alk/Acr | −0.5 | −0.7 |

| (0.4) | (0.1) | |

| C. Alk/Acr | 0.2 | 4.2 |

| (0.4) | (0.9) | |

| F. Acr | −0.3 | −0.2 |

| (0.2) | (0.4) | |

| I. Alk | −0.9 | −0.9 |

| (0.7) | (0.8) | |

| J. Alk | −0.9 | −1.2 |

| (0.7) | (0.2) | |

| Control | −0.8 | 1.0 |

| (0.3) | (0.5) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bobadilha, G.d.S.; Stokes, C.E.; Ohno, K.M.; Kirker, G.; Lopes, D.J.V.; Nejad, M. Physical, Optical, and Visual Performance of Coated Cross-Laminated Timber during Natural and Artificial Weathering. Coatings 2021, 11, 252. https://doi.org/10.3390/coatings11020252

Bobadilha GdS, Stokes CE, Ohno KM, Kirker G, Lopes DJV, Nejad M. Physical, Optical, and Visual Performance of Coated Cross-Laminated Timber during Natural and Artificial Weathering. Coatings. 2021; 11(2):252. https://doi.org/10.3390/coatings11020252

Chicago/Turabian StyleBobadilha, Gabrielly dos Santos, C. Elizabeth Stokes, Katie M. Ohno, Grant Kirker, Dercilio Junior Verly Lopes, and Mojgan Nejad. 2021. "Physical, Optical, and Visual Performance of Coated Cross-Laminated Timber during Natural and Artificial Weathering" Coatings 11, no. 2: 252. https://doi.org/10.3390/coatings11020252

APA StyleBobadilha, G. d. S., Stokes, C. E., Ohno, K. M., Kirker, G., Lopes, D. J. V., & Nejad, M. (2021). Physical, Optical, and Visual Performance of Coated Cross-Laminated Timber during Natural and Artificial Weathering. Coatings, 11(2), 252. https://doi.org/10.3390/coatings11020252