The Impact Resistance of Highly Densified Metal Alloys Manufactured from Gas-Atomized Pre-Alloyed Powders

Abstract

1. Introduction

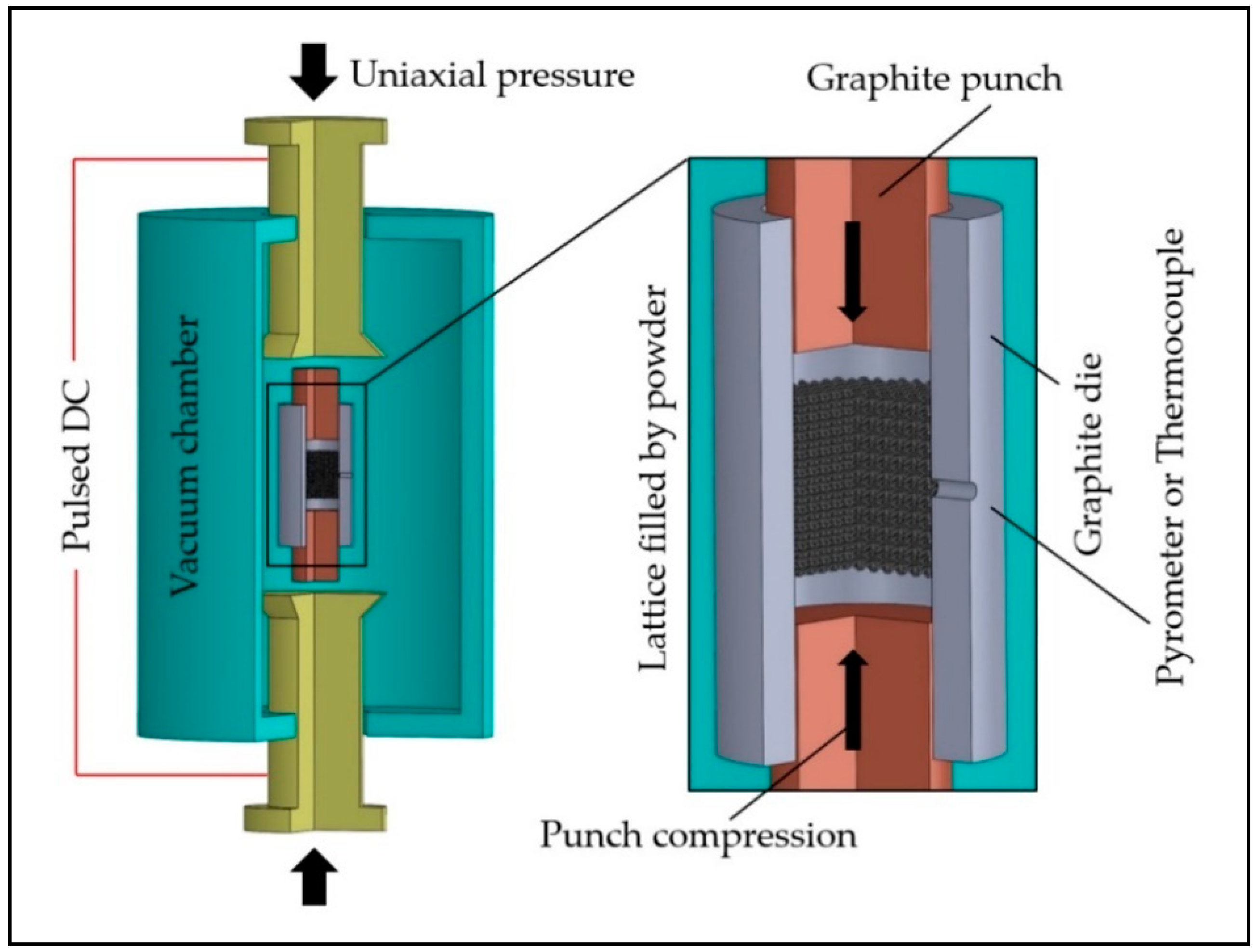

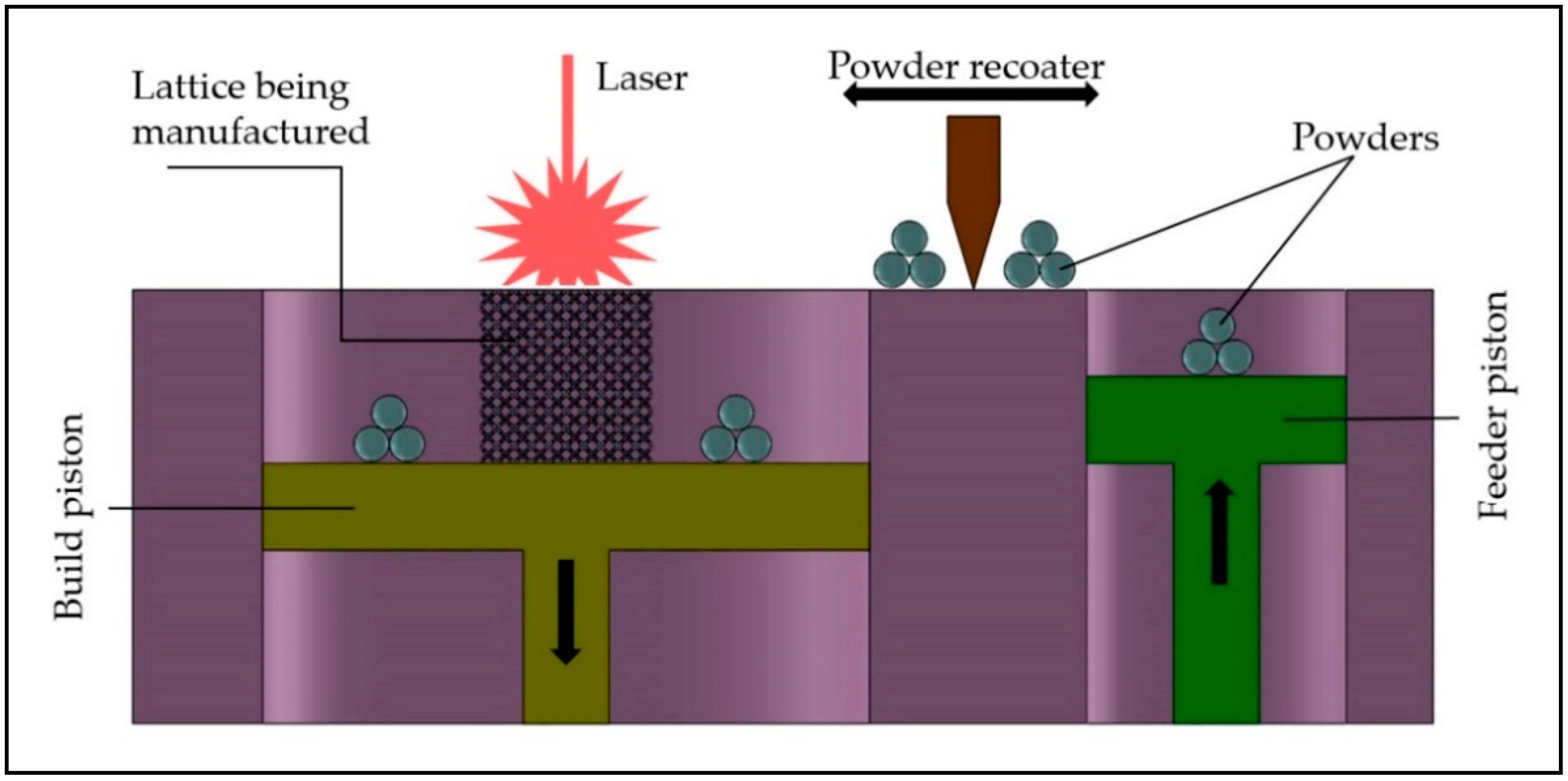

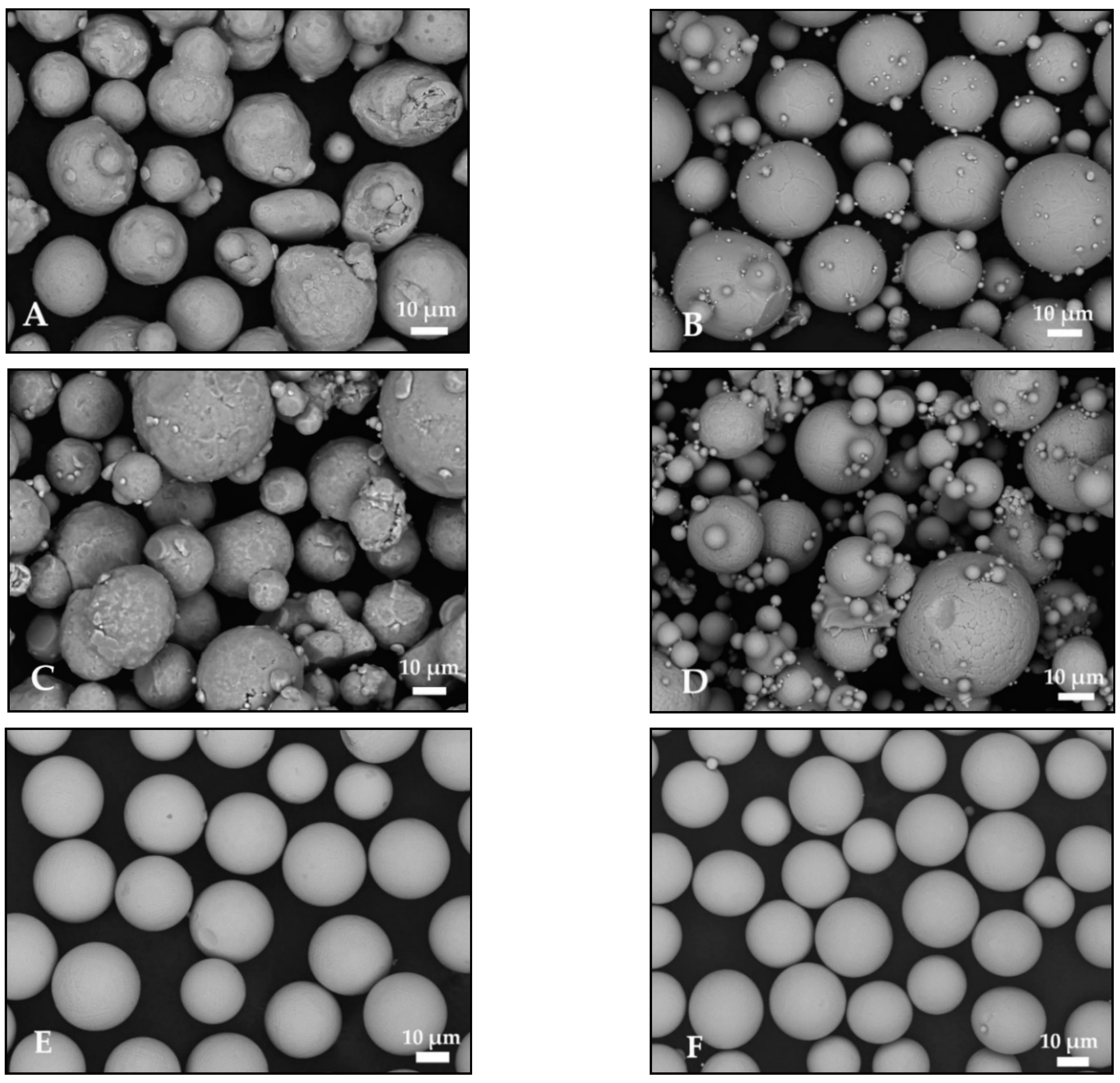

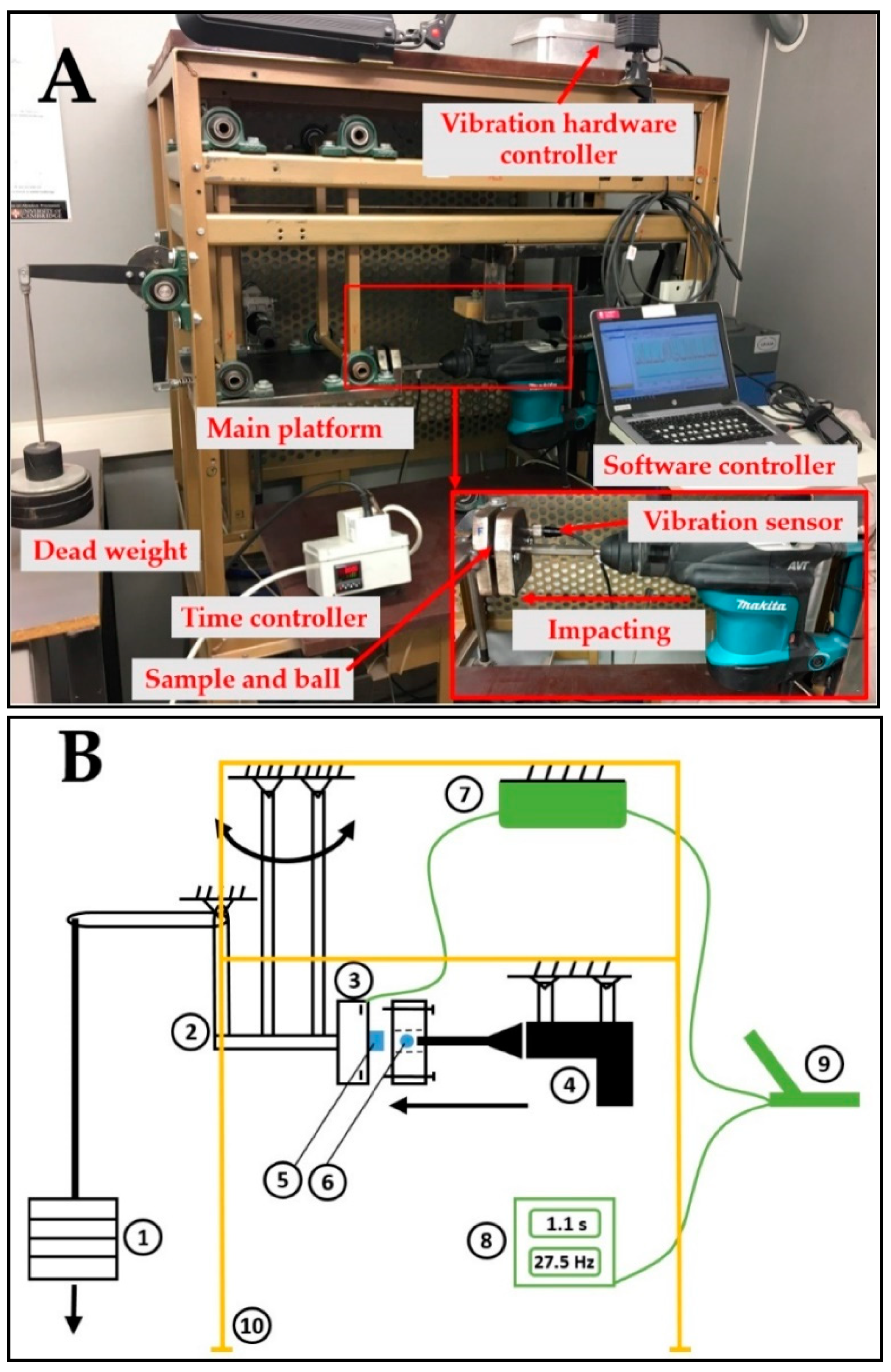

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saheb, N.; Iqbal, Z.; Khalil, A.; Hakeem, A.S.; Al-Aqeeli, N.; Laoui, T.; Al-Qutub, A.; Kirchner, R. Spark Plasma Sintering of Metals and Metal Matrix Nanocomposites: A Review. J. Nanomater. 2012, 2012, 983470. [Google Scholar] [CrossRef]

- Chawake, N.; Pinto, L.D.; Srivastav, A.K.; Akkiraju, K.; Murty, B.S.; Kottada, R.S. On Joule heating during spark plasma sintering of metal powders. Scr. Mater. 2014, 93, 52–55. [Google Scholar] [CrossRef]

- Singh, N.; Hameed, P.; Ummethala, R.; Manivasagam, G.; Prashanth, K.G.; Eckert, J. Selective laser manufacturing of Ti-based alloys and composites: Impact of process parameters, application trends, and future prospects. Mater. Today Adv. 2020, 8, 100097. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Wang, Z.; Wang, L.; Liu, J.; Jiang, W. Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting. Appl. Surf. Sci. 2010, 256, 4350–4356. [Google Scholar] [CrossRef]

- Rahmani, R.; Brojan, M.; Antonov, M.; Prashanth, K.G. Perspectives of metal-diamond composites additive manufacturing using SLM-SPS and other techniques for increased wear-impact resistance. Int. J. Refract. Met. Hard Mater. 2020, 88, 105192. [Google Scholar] [CrossRef]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; Höges, S.; Wissenbach, K. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of pre-alloyed powders. Rapid Prototyp. J. 2010, 16, 450–459. [Google Scholar] [CrossRef]

- Rahmani, R.; Antonov, M.; Kollo, L.; Holovenko, Y.; Prashanth, K.G. Mechanical Behavior of Ti6Al4V Scaffolds Filled with CaSiO3 for Implant Applications. Appl. Sci. 2019, 9, 3844. [Google Scholar] [CrossRef]

- Rahmani, R.; Rosenberg, M.; Ivask, A.; Kollo, L. Comparison of mechanical and antibacterial properties of TiO2/Ag ceramics and Ti6Al4V-TiO2/Ag composite materials using combining SLM-SPS techniques. Metals 2019, 9, 874. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Smurov, I. Parametric analysis of the selective laser melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef]

- Tiberto, D.; Klotz, U.E.; Held, F.; Wolf, G. Additive manufacturing of copper alloys: Influence of process parameters and alloying elements. Mater. Sci. Technol. 2018, 35, 969–977. [Google Scholar] [CrossRef]

- Hedberg, Y.S.; Qian, B.; Shen, Z.; Virtanen, S.; Wallinder, I.O. In vitro biocompatibility of CoCrMo dental alloys fabricated by selective laser melting. Dent. Mater. 2014, 30, 525–534. [Google Scholar] [CrossRef]

- Available online: https://scheftner.dental/starbond-cos-powder-en.html (accessed on 10 January 2021).

- Available online: https://www.hoganas.com/en/powder-technologies/surface-coating/rockit-abrasive-wear (accessed on 10 January 2021).

- Trosch, T.; Strößner, J.; Völkl, R.; Glatzel, U. Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting. Mater. Lett. 2016, 164, 428–431. [Google Scholar] [CrossRef]

- Rahmani, R.; Antonov, M.; Kamboj, N. Modelling of impact-abrasive wear of ceramic, metallic, and composite materials. Proc. Est. Acad. Sci. 2019, 68, 191–197. [Google Scholar] [CrossRef]

- Rahmani, R.; Antonov, M.; Kollo, L. Wear Resistance of (Diamond-Ni)-Ti6Al4V Gradient Materials Prepared by Combined Selective Laser Melting and Spark Plasma Sintering Techniques. Adv. Tribol. 2019, 2019, 5415897. [Google Scholar] [CrossRef]

- Rahmani, R.; Antonov, M. Axial and torsional buckling analysis of single- and multi-walled carbon nanotubes: Finite element comparison between armchair and zigzag types. SN Appl. Sci. 2019, 9, 1134. [Google Scholar] [CrossRef]

- Available online: https://www.slm-solutions.com/en/products/accessories-consumables/slmr-metal-powder (accessed on 10 January 2021).

- Available online: https://www.tls-technik.de/en/products.html (accessed on 10 January 2021).

- Available online: https://en.c-semt.com/metal-powder (accessed on 10 January 2021).

- Available online: http://www.fct-systeme.de/en/ (accessed on 10 January 2021).

- Rahmani, R.; Brojan, M.; Antonov, M. Lightweight 3D printed Ti6Al4V-AlSi10Mg hybrid composite for impact resistance and armor piercing shielding. J. Mater. Res. Technol. 2020, 9, 13842–13854. [Google Scholar] [CrossRef]

- Antonov, M.; Veinthal, R.; Yung, D.L.; Katusin, D.; Hussainova, I. Mapping of impact abrasive wear performance of WC-Co cemented carbides. Wear 2015, 332–333, 971–978. [Google Scholar] [CrossRef]

- Rahmani, R.; Antonov, M.; Kollo, L. Selective Laser Melting of Diamond-Containing or Postnitrided Materials Intended for Impact-Abrasive Conditions: Experimental and Analytical Study. Adv. Mater. Sci. Eng. 2019, 2019, 4210762. [Google Scholar] [CrossRef]

- Kamboj, N.; Kazantseva, J.; Rahmani, R.; Rodríguez, M.A.; Hussainova, I. Selective laser sintered bio-inspired silicon-wollastonite scaffolds for bone tissue engineering. Mater. Sci. Eng. C 2020, 116, 111223. [Google Scholar] [CrossRef] [PubMed]

- Kamboj, N.; Rodríguez, M.A.; Rahmani, R.; Prashanth, K.G.; Hussainova, I. Bioceramic scaffolds by additive manufacturing for controlled delivery of the antibiotic vancomycin. Proc. Est. Acad. Sci. USA 2019, 68, 185–190. [Google Scholar] [CrossRef]

- Holovenko, Y.; Kollo, L.; Saarna, M.; Rahmani, R.; Soloviova, T.; Antonov, M.; Prashanth, K.G.; Cygan, S.; Veinthal, R. Effect of lattice surface treatment on performance of hardmetal-titanium interpenetrating phase composites. Int. J. Refract. Met. Hard Mater. 2020, 86, 105087. [Google Scholar] [CrossRef]

- Baronins, J.; Antonov, M.; Bereznev, S.; Raadik, T.; Hussainova, I. Raman Spectroscopy for Reliability Assessment of Multilayered AlCrN Coating in Tribo-Corrosive Conditions. Coatings 2018, 8, 229. [Google Scholar] [CrossRef]

- Leicht, A.; Yu, C.H.; Luzin, V.; Klement, U.; Hryha, E. Effect of scan rotation on the microstructure development and mechanical properties of 316L parts produced by laser powder bed fusion. Mater. Charact. 2020, 163, 110309. [Google Scholar] [CrossRef]

- Garlea, E.; Choo, H.; Sluss, C.C.; Koehler, M.R.; Bridges, R.L.; Xiao, X.; Ren, Y.; Jared, B.H. Variation of elastic mechanical properties with texture, porosity, and defect characteristics in laser powder bed fusion 316L stainless steel. Mater. Sci. Eng. A 2019, 763, 138032. [Google Scholar] [CrossRef]

- Marnier, G.; Keller, C.; Noudem, J.; Hug, E. Functional properties of a spark plasma sintered ultrafine-grained 316L steel. Mater. Design 2014, 63, 633–640. [Google Scholar] [CrossRef]

- Keller, C.; Tabalaiev, K.; Marnier, G.; Noudem, J.; Sauvage, X.; Hug, E. Influence of spark plasma sintering conditions on the sintering and functional properties of an ultra-fine grained 316L stainless steel obtained from ball-milled powder. Mater. Sci. Eng. A 2016, 665, 125–134. [Google Scholar] [CrossRef]

| Metal Alloys | Suppliers | Density | Powder Size | Composition | Sintering Temperature |

|---|---|---|---|---|---|

| 316L | SLM Solutions AG (Lübeck, Germany) | 7.95 g/cm3 | 10–45 µm | Fe-balance, Cr, Ni, Mo | 1000 °C |

| Ti6Al4V | SLM Solutions AG | 4.43 g/cm3 | 20–63 µm | Ti-balance, Al, V | 950 °C |

| AlSi10Mg | TLS Technik GmbH (Bitterfeld-Wolfen, Germany) | 2.59 g/cm3 | 20–63 µm | Al-balance, Si, Mg | 480 °C |

| CuNi2SiCr | TLS Technik GmbH | 8.84 g/cm3 | 10–63 µm | Cu-balance, Ni, Si, Cr | 820 °C |

| CoCr28Mo6 | Sino-Euro Ltd (Shaanxi, China) | 4.96 g/cm3 | 15–45 µm | Co-balance, Cr, Mo | 1000 °C |

| Inconel718 | Sino-Euro Ltd | 4.77 g/cm3 | 15–45 µm | Ni-balance, Cr, Mo, Nb | 1000 °C |

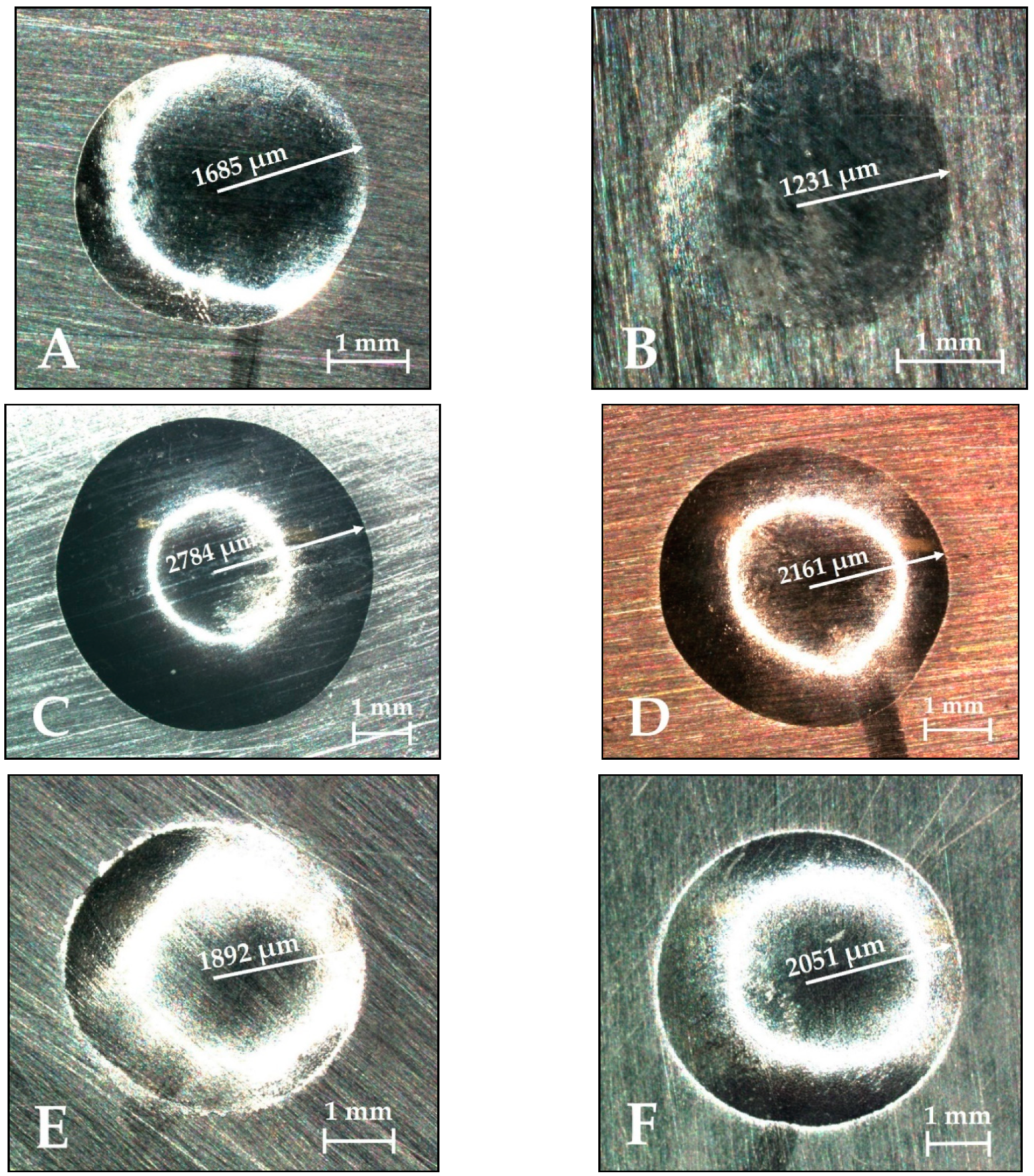

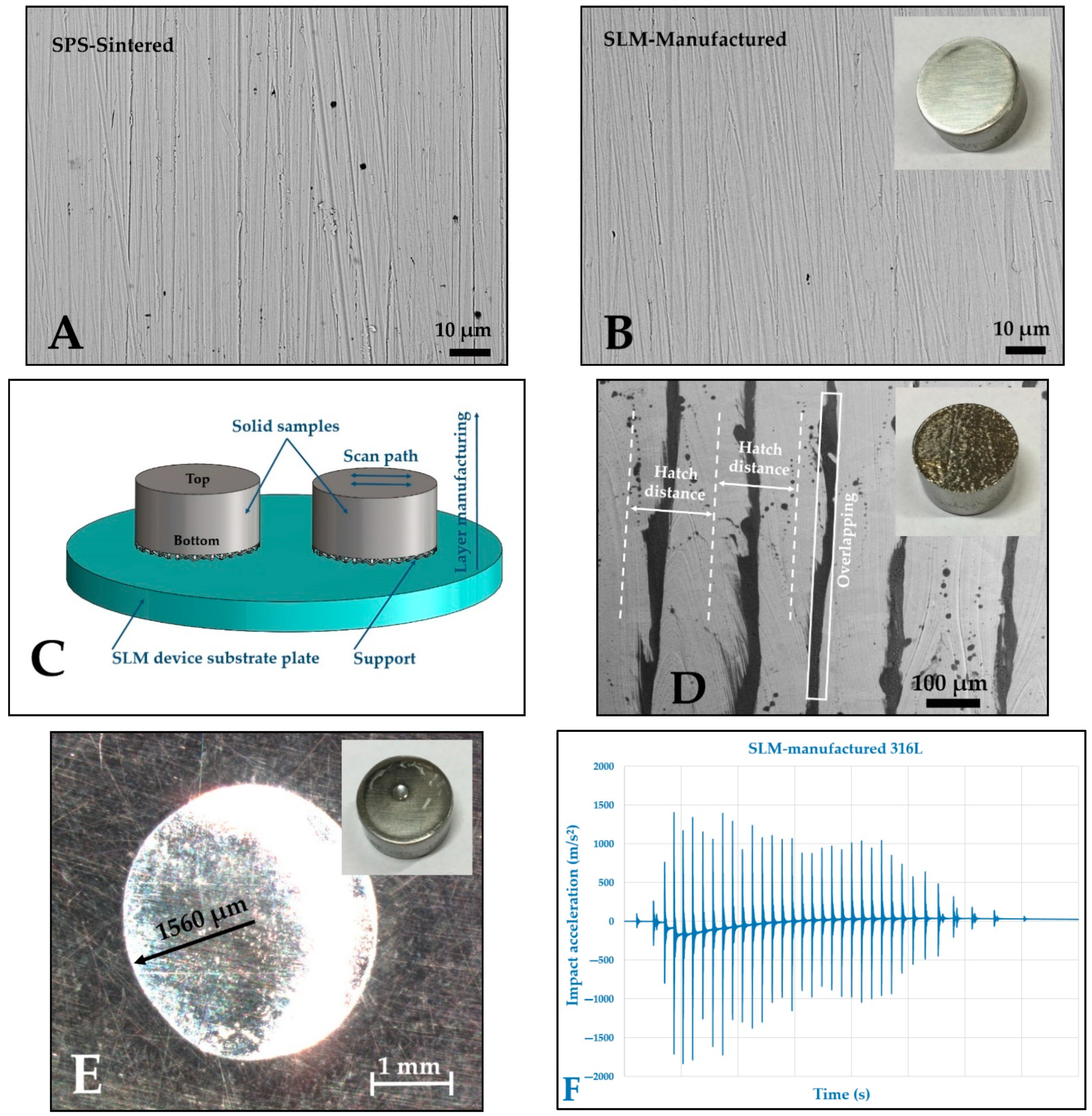

| Metal Alloys | Vickers Hardness | Densification | Diameter of Indent | Volume of Indent | Average Max Acceleration |

|---|---|---|---|---|---|

| 316L | ≈200–240 HV | 97.0% | 3370 µm | 3.2 mm3 | 740 m/s2 |

| Ti6Al4V | ≈330–380 HV | 91.5% | 2462 µm | 1.1 mm3 | 880 m/s2 |

| AlSi10Mg | ≈70–95 HV | 90.0% | 5568 µm | 28.8 mm3 | 1190 m/s2 |

| CuNi2SiCr | ≈135–170 HV | 98.5% | 4322 µm | 11.1 mm3 | 820 m/s2 |

| CoCr28Mo6 | ≈260–300 HV | 94.5% | 3784 µm | 7.4 mm3 | 810 m/s2 |

| Inconel718 | ≈175–210 HV | 95.5% | 4102 µm | 7.7 mm3 | 750 m/s2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahmani, R.; Antonov, M.; Prashanth, K.G. The Impact Resistance of Highly Densified Metal Alloys Manufactured from Gas-Atomized Pre-Alloyed Powders. Coatings 2021, 11, 216. https://doi.org/10.3390/coatings11020216

Rahmani R, Antonov M, Prashanth KG. The Impact Resistance of Highly Densified Metal Alloys Manufactured from Gas-Atomized Pre-Alloyed Powders. Coatings. 2021; 11(2):216. https://doi.org/10.3390/coatings11020216

Chicago/Turabian StyleRahmani, Ramin, Maksim Antonov, and Konda Gokuldoss Prashanth. 2021. "The Impact Resistance of Highly Densified Metal Alloys Manufactured from Gas-Atomized Pre-Alloyed Powders" Coatings 11, no. 2: 216. https://doi.org/10.3390/coatings11020216

APA StyleRahmani, R., Antonov, M., & Prashanth, K. G. (2021). The Impact Resistance of Highly Densified Metal Alloys Manufactured from Gas-Atomized Pre-Alloyed Powders. Coatings, 11(2), 216. https://doi.org/10.3390/coatings11020216