Investigation of Properties of the Zr,Hf-(Zr,Hf)N-(Zr,Hf,Me,Al)N Coatings, Where Me Means Cr, Ti, or Mo

Abstract

1. Introduction

- Maximum hardness to resist abrasive wear;

- Maximum strength to resist adhesive-fatigue wear and brittle fracture, including resistance to cracking;

- Maximum heat resistance to maintain basic performance properties at high temperatures;

- Ability to provide optimal tribological parameters in the cutting zone, including at high temperatures;

- Ability to effectively perform barrier functions in relation to the diffusion of elements of the material being machined and oxygen.

2. Materials and Methods

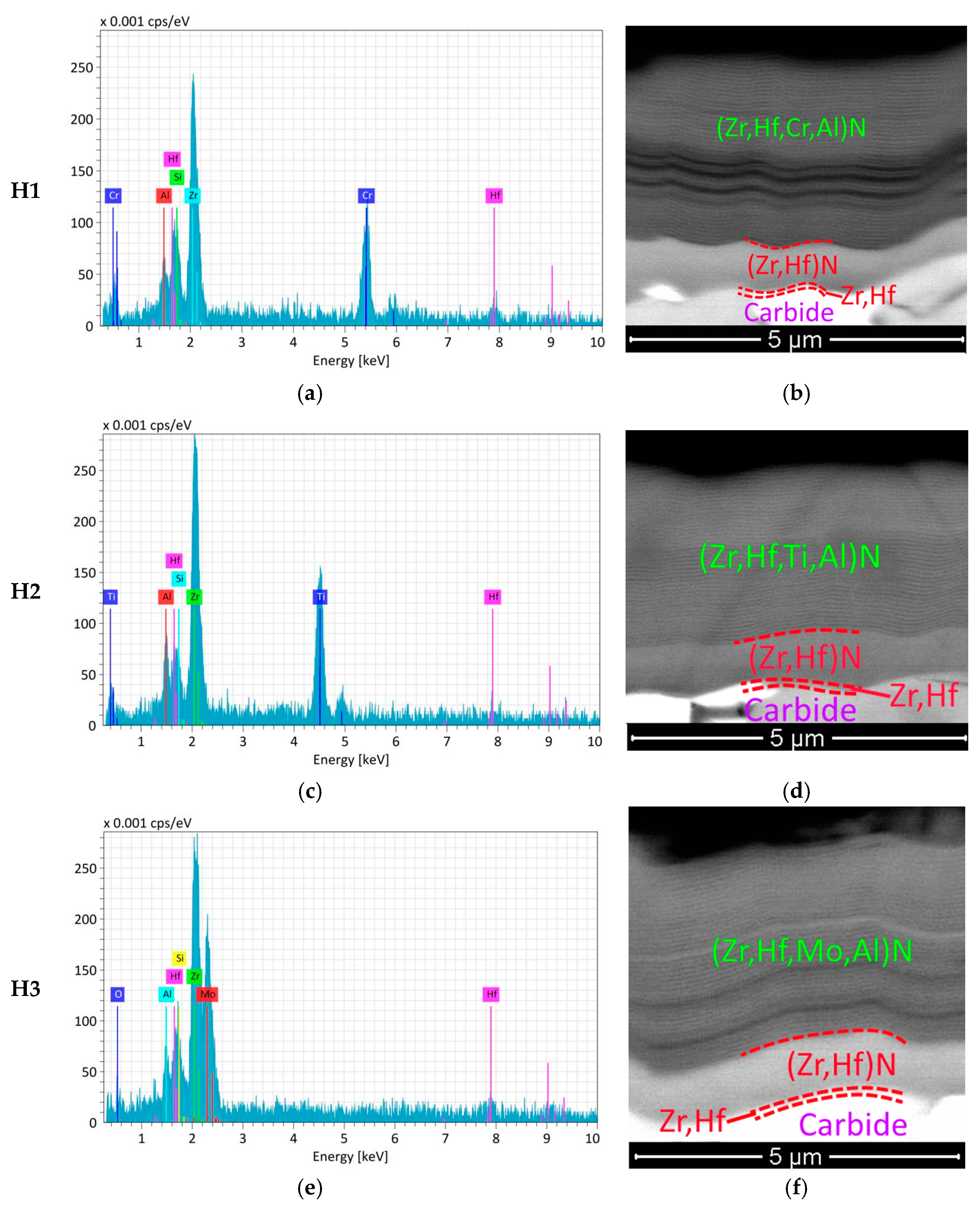

3. Results

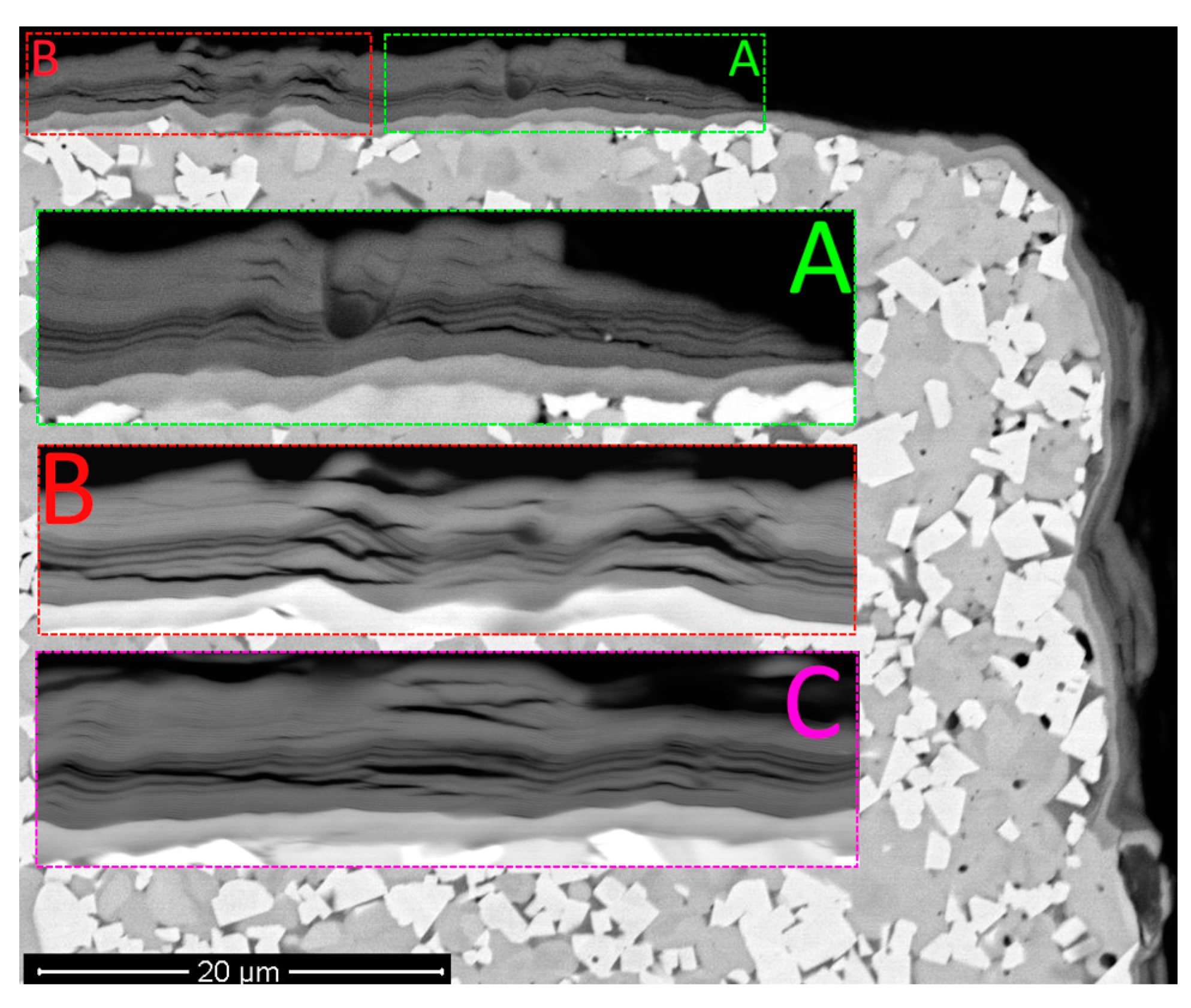

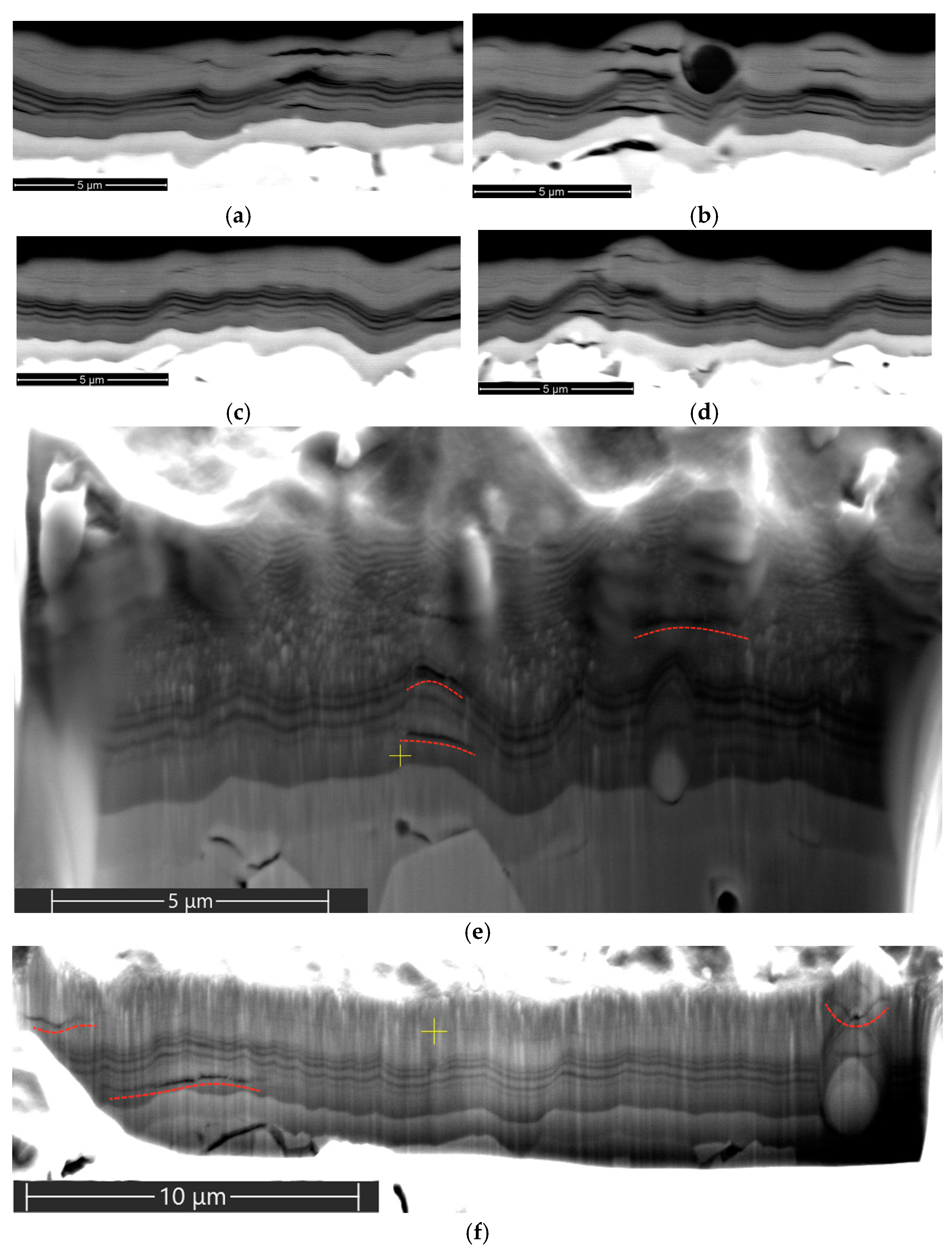

4. Discussion

5. Conclusions

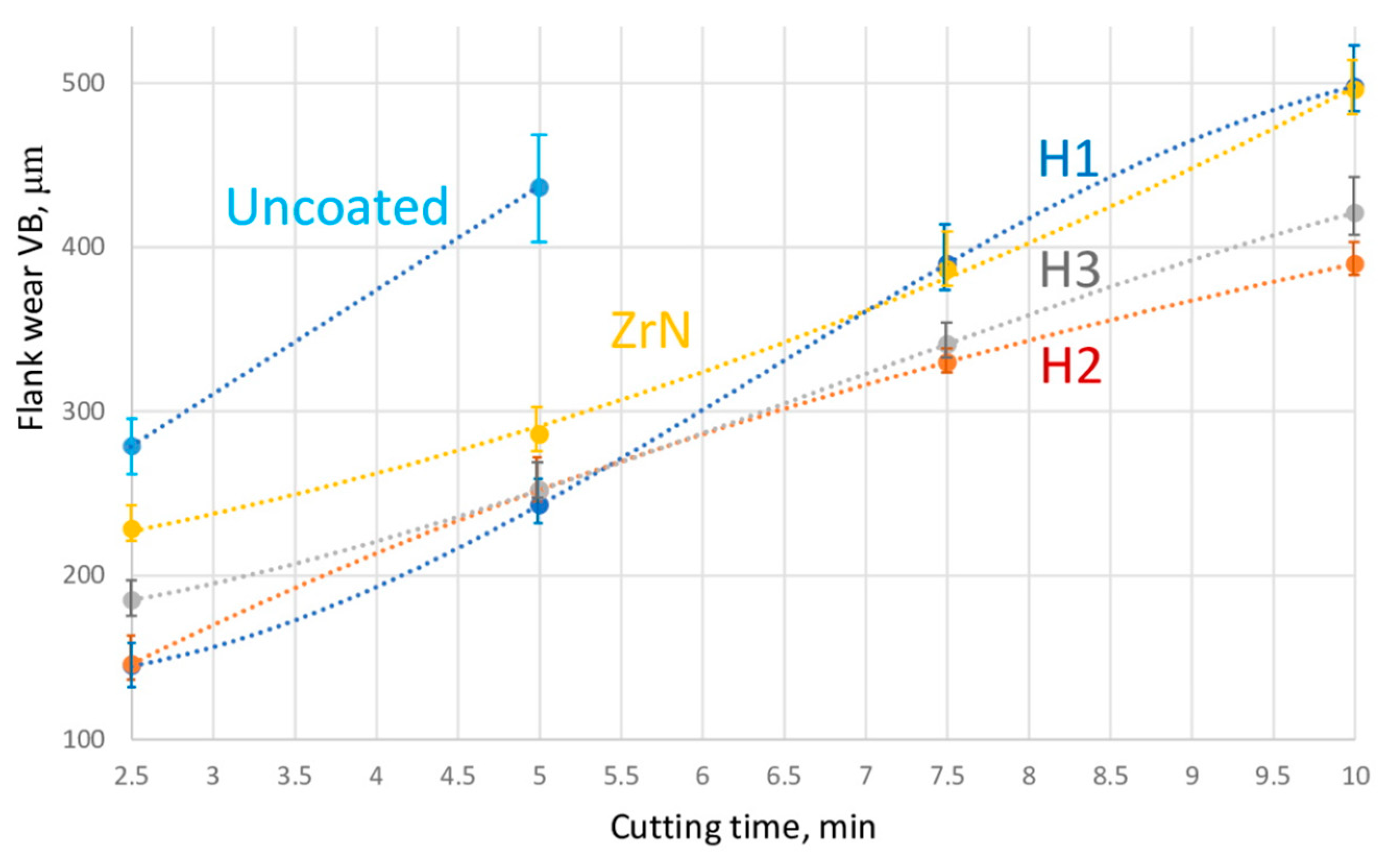

- The considered coatings have close values of hardness and critical fracture load LC2;

- After 5 min of cutting, the average flank wear VB detected for the uncoated tool was 1.8 times higher than that for the tools with Coatings H1, H2, and H3 and 1.5 times higher than for the ZrN-coated tool. For the tools with Coatings H1, H2, and H3, the rate of wear was in average 1.2 times lower after 5 min of cutting in comparison with that for the tool with the commercial ZrN coating. The ZrN-coated tool and the tool with Coating H1 demonstrated the tool life 1.5 times higher, and the tools with Coatings H2 and H3–2 times higher compared to that of the uncoated tool;

- A process of notchwear is typical for the rake faces of the tools with the coatings under study, with no formation of any noticeable wear crater. The patterns of rake wear were fairly close for all the tools with Coatings H1, H2, and H3. However, for the tool with Coating H3, the rate of wear was slightly higher (KB = 520 μm) than that for the tools with Coatings H1 and H2 (KB = 450 μm). In terms on notchwear, the more active wear was detected for the tools with Coatings H1 and H2, while less active wear was demonstrated by the tool with Coating H3;

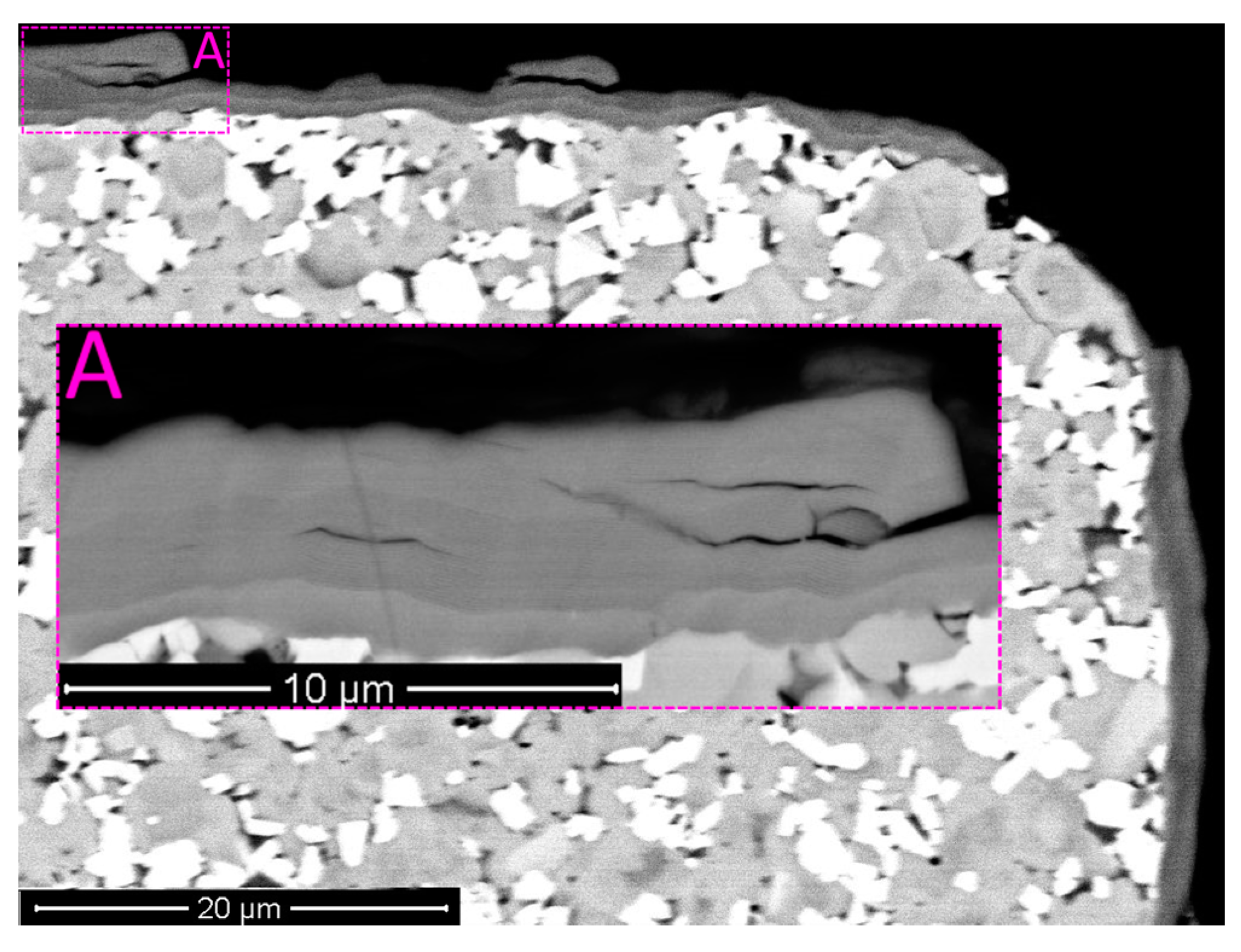

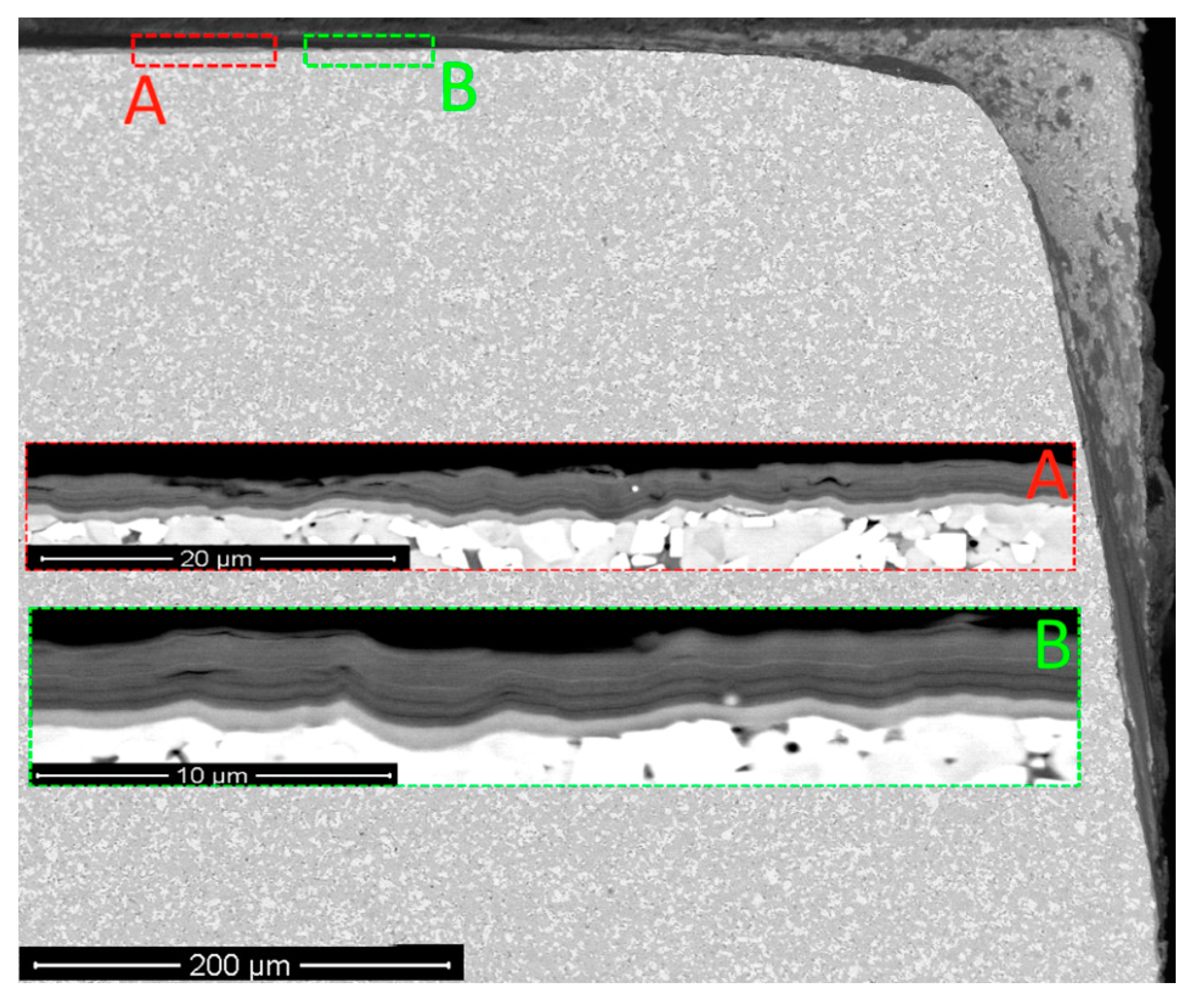

- Coating H1 undergoes active wear during the cutting process due to the formation of a large number of transverse cracks, cutting through the nanolayer structure of the coating. A formation of interlayer delaminations is more typical for Coating H2, whereas a combination of interlayer delaminations and longitudinal cracks is more typical for Coating H3. In general, Coatings H2 and H3 demonstrate less active cracking than Coating H1;

- Thus, the highest wear resistance is detected for the tool with Coating H2, and Coating H2 demonstrates the most favorable pattern of cracking, i.e., an insignificant amount of interlayer delaminations. In typical cutting operations of steel 1045, tools with H2 coating would likely give the best overall performance and tool life. Despite the additional cost to apply this coating, we anticipate that cutting speed and the added tool life would make this choice economic.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bouzakis, K.D.; Michailidis, N.; Skordaris, G.; Bouzakis, E.; Biermann, D.; M’Saoubi, R. Cutting with coated tools: Coating technologies, characterization methods and performance optimization. CIRP Ann. Manuf. Technol. 2012, 61, 703–723. [Google Scholar] [CrossRef]

- Tkadletz, M.; Schalk, N.; Daniel, R.; Keckes, J.; Czettl, C.; Mitterer, C. Advanced characterization methods for wear resistant hard coatings: A review on recent progress. Surf. Coat. Technol. 2016, 285, 31–46. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, D.; Fu, Y.; Du, H. Recent advances of superhard nanocomposite coatings: A review. Surf. Coat. Technol. 2003, 167, 113–119. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Kozochkin, M.P.; Sabirov, F.S.; Kutin, A.A. Diagnostic systems as basis for technological improvement. Procedia CIRP 2012, 1, 599–604. [Google Scholar] [CrossRef]

- Kuzin, V.; Grigoriev, S.N.; Volosova, M.A. The role of the thermal factor in the wear mechanism of ceramic tools: Part 1. Macrolevel. J. Frict. Wear 2014, 35, 505–510. [Google Scholar] [CrossRef]

- Grigoriev, S.; Volosova, M.; Vereschaka, A.; Sitnikov, N.; Milovich, F.; Bublikov, J.; Fyodorov, S.; Seleznev, A. Properties of (Cr,Al,Si)N-(DLC-Si) composite coatings deposited on a cutting ceramic substrate. Ceram. Int. 2020, 46, 18241–18255. [Google Scholar] [CrossRef]

- Grigoriev, S.; Peretyagin, P.; Smirnov, A.; Solís, W.; Díaz, L.; Fernández, A.; Torrecillas, R. Effect of graphene addition on the mechanical and electrical properties of Al2O3-SiCw ceramics. J. Eur. Ceram. Soc. 2017, 37, 2473–2479. [Google Scholar] [CrossRef]

- Skordaris, G.; Bouzakis, K.; Charalampous, P.; Bouzakis, E.; Paraskevopoulou, R.; Lemmer, O.; Bolz, S. Brittleness and fatigue effect of mono- and multi-layer PVD films on the cutting performance of coated cemented carbide inserts. CIRP Ann. 2014, 63, 93–96. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Ehiasarian, A.; Deeming, A.; Schimpf, C. Novel TiAlCN/VCN nanoscale multilayer PVD coatings deposited by the combined high-power impulse magnetron sputtering/unbalanced magnetron sputtering (HIPIMS/UBM) technology. Vacuum 2008, 82, 1312–1317. [Google Scholar] [CrossRef]

- Araujo, J.A.; Araujo, G.M.; Souza, R.M.; Tschiptschin, A.P. Effect of periodicity on hardness and scratch resistance of CrN/NbNnanoscale multilayer coating deposited by cathodic arc technique. Wear 2015, 330–331, 469–477. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Aksenenko, A.; Sitnikov, N.; Oganyan, G.; Seleznev, A.; Shevchenko, S. Effect of adhesion and the wear-resistant layer thickness ratio on mechanical and performance properties of ZrN-(Zr,Al,Si)N coatings. Surf. Coat. Technol. 2018, 357, 218–234. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Andreev, N.; Sotova, C.; Kutina, N. Investigation of the influence of the thickness of nanolayers in wear-resistant layers of Ti-TiN-(Ti,Cr,Al)N coating on destruction in the cutting and wear of carbide cutting tools. Surf. Coat. Technol. 2020, 385, 125402. [Google Scholar] [CrossRef]

- Beresnev, V.M.; Torianyk, I.N.; Pogrebnjak, A.; Bondar, O.; Bilokur, M.; Sobol, O.; Kolesnikov, D.A.; Lytovchenko, S.; Turbin, P. Structure and physical and mechanical properties of nanocomposite (Zr-Ti-Cr-Nb)N and (Ti-Zr-Al-Nb-Y)N coatings, obtained by vacuum-arc evaporation method. In Nanocomposites, Nanophotonics, Nanobiotechnology, and Applications; Fesenko, O., Yatsenko, L., Eds.; Springer: Cham, Switzerland, 2014; pp. 75–84. [Google Scholar]

- Liang, S.C.; Chang, Z.C.; Tsai, D.C.; Lin, Y.C.; Sung, H.S.; Deng, M.J.; Shieu, F.S. Effects of substrate temperature on the structure and mechanical properties of (TiVCrZrHf)N coatings. Appl. Surf. Sci. 2011, 257, 7709–7713. [Google Scholar] [CrossRef]

- Lai, C.-H.; Lin, S.-J.; Yeh, J.-W.; Chang, S.-Y. Preparation and characterization of AlCrTaTiZr multi-element nitride coatings. Surf. Coat. Technol. 2006, 201, 3275–3280. [Google Scholar] [CrossRef]

- Chang, K.-S.; Chen, K.-T.; Hsu, C.-Y.; Hong, P.-D. Growth (AlCrNbSiTiV)N thin films on the interrupted turning and properties using DCMS and HIPIMS system. Appl. Surf. Sci. 2018, 440, 1–7. [Google Scholar] [CrossRef]

- Koshy, R.A.; Graham, M.E.; Marks, L.D. Temperature activated self-lubrication in CrN/Mo2N nanolayer coatings. Surf. Coat. Technol. 2010, 204, 1359–1365. [Google Scholar] [CrossRef]

- Glatz, S.A.; Moraes, V.; Koller, C.M.; Riedl, H.; Bolvardi, H.; Kolozsvári, S.; Mayrhofer, P.H. Effect of Mo on the thermal stability, oxidation resistance, and tribo-mechanical properties of arc evaporated Ti-Al-N coatings. J. Vac. Sci. Technol. A 2017, 35, 061515. [Google Scholar] [CrossRef]

- Ju, H.; Yu, D.; Xu, J.; Yu, L.; Zuo, B.; Geng, Y.; Huang, T.; Shao, L.; Ren, L.; Du, C.; et al. Crystal structure and tribological properties of ZrAlMoN composite films deposited by magnetron sputtering. Mater. Chem. Phys. 2019, 230, 347–354. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Sobol, O.V.; Beresnev, V.M.; Serdyuk, I.V.; Pogrebnyak, A.D.; Kolesnikov, D.A.; Nemchenko, U.S. Tribological characteristics of (TiZrHfVNbTa)N coatings applied using the vacuum arc deposition method. J. Frict. Wear 2014, 35, 359–364. [Google Scholar] [CrossRef]

- Franz, R.; Lechthaler, M.; Polzer, C.; Mitterer, C. Oxidation behaviour and tribological properties of arc-evaporated ZrAlN hard coatings. Surf. Coat. Technol. 2012, 206, 2337–2345. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Tabakov, V.; Sitnikov, N.; Andreev, N.; Sviridova, T.; Bublikov, J. Investigation of multicomponent nanolayer coatings based on nitrides of Cr, Mo, Zr, Nb, and Al. Surf. Coat. Technol. 2020, 401, 126258. [Google Scholar] [CrossRef]

- Atar, E.; Cimenoglu, H.; Kayali, E.S. An investigation of fretting wear behaviour of a ternary (Zr,Hf)N coating. In Proceedings of the 2005 World Tribology Congress III, Washington, DC, USA, 12–16 September 2005; Volume 2, pp. 395–396. [Google Scholar] [CrossRef]

- Atar, E.; Kayali, E.; Çimenoğlu, H. Reciprocating wear behaviour of (Zr, Hf)N coatings. Wear 2004, 257, 633–639. [Google Scholar] [CrossRef]

- Atar, E.; Çimenoğlu, H.; Kayalı, E.; Kayali, E. Hardness characterisation of thin Zr(Hf,N) coatings. Surf. Coat. Technol. 2003, 162, 167–173. [Google Scholar] [CrossRef]

- Atar, E.; Kayali, E.S.; Cimenoglu, H. Sliding wear behaviour of ZrN and (Zr, 12 wt% Hf)N coatings. Tribol. Int. 2006, 39, 297–302. [Google Scholar] [CrossRef]

- Wu, Z.; Qi, Z.; Zhang, D.; Wang, Z. Microstructure, mechanical properties and oxidation resistance of (Zr, Hf)Nx coatings by magnetron co-sputtering. Surf. Coat. Technol. 2015, 276, 219–227. [Google Scholar] [CrossRef]

- Prathumsit, J.; Gitgeatpong, G.; Phae-Ngam, W.; Chananonnawathorn, C.; Lertvanithphol, T.; Horprathum, M. The effect of thickness on the properties of Zr-Hf-N thin films prepared by reactive co-magnetron sputtering. In Proceedings of the Second Materials Research Society of Thailand International Conference, Pattaya, Thailand, 10–12 July 2019; Maensiri, S., Meevasana, W., Pecharapa, W., Eds.; AIP Publishing: College Park, MD, USA, 2020. [Google Scholar] [CrossRef]

- Atar, E.; Sarioglu, C.; Cimenoglu, H.; Kayali, E. Residual stresses in (Zr,Hf)N films (up to 11.9 at.% Hf) measured by X-ray diffraction using experimentally calculated XECs. Surf. Coat. Technol. 2005, 191, 188–194. [Google Scholar] [CrossRef]

- Fernandez, D.A.R.; Brito, B.S.S.; Santos, I.A.D.; Soares, V.F.D.; Terto, A.R.; de Oliveira, G.B.; Hubler, R.; Batista, W.W.; Ten-tardini, E.K. Effect of hafnium contaminant present in zirconium targets on sputter deposited ZrN thin films. NIMB 2020, 462, 90–94. [Google Scholar] [CrossRef]

- Atar, E.; Kayali, E.S.; Cimenoglu, H. The effect of oxidation on the structure and hardness of (Zr, Hf)N coatings. Defect Diffus. Forum 2010, 297–301, 1395–1399. [Google Scholar] [CrossRef]

- Sarioglu, C. The effect of anisotropy on residual stress values and modification of Serruys approach to residual stress calculations for coatings such as TiN, ZrN and HfN. Surf. Coat. Technol. 2006, 201, 707–717. [Google Scholar] [CrossRef]

- Serruys, W.; Houtte, P.; Aernoudt, E.; Peters, J. Why are x-ray measurements of residual stresses different from mechanical residual stress measurements? CIRP Ann. Manuf. Technol. 1988, 37, 527–530. [Google Scholar] [CrossRef]

- Feng, C.; Zhu, S.; Li, M.; Xin, L.; Wang, F. Effects of incorporation of Si or Hf on the microstructure and mechanical properties of Ti–Al–N films prepared by arc ion plating (AIP). Surf. Coat. Technol. 2008, 202, 3257–3262. [Google Scholar] [CrossRef]

- Xu, Y.X.; Chen, L.; Pei, F.; Du, Y.; Liu, Y.; Yue, J.L. Influence of Hf on the structure, thermal stability and oxidation resistance of Ti-Al-N coatings. Thin Solid Film. 2014, 565, 25–31. [Google Scholar] [CrossRef]

- Guo, F.; Holec, D.; Wang, J.; Li, S.; Du, Y. Impact of V, Hf and Si on oxidation processes in Ti–Al–N: Insights from ab initio molecular dynamics. Surf. Coat. Technol. 2020, 381, 125125. [Google Scholar] [CrossRef]

- Rachbauer, R.; Blutmager, A.; Holec, D.; Mayrhofer, P. Effect of Hf on structure and age hardening of Ti–Al-N thin films. Surf. Coat. Technol. 2012, 206, 2667–2672. [Google Scholar] [CrossRef]

- Lugscheider, E.; Bobzin, K.; Piñero, C.; Klocke, F.; Massmann, T. Development of a superlattice (Ti,Hf,Cr)N coating for cold metal forming applications. Surf. Coat. Technol. 2004, 177–178, 616–622. [Google Scholar] [CrossRef]

- Bobzin, K.; Bagcivan, N.; Immich, P.; Warnke, C.; Klocke, F.; Zeppenfeld, C.; Mattfeld, P. Advancement of a nanolaminated TiHfN/CrN PVD tool coating by a nano-structured CrN top layer in interaction with a biodegradable lubricant for green metal forming. Surf. Coat. Technol. 2009, 203, 3184–3188. [Google Scholar] [CrossRef]

- Liu, Z.; Li, H.; Li, J.; Huang, J.; Kong, J.; Wu, Q.; Xiong, D. Microstructure, mechanical and tribological properties of Hf-Mo-Si-N films with different Si contents. Surf. Coat. Technol. 2020, 401, 126268. [Google Scholar] [CrossRef]

- Liu, Z.; Li, H.; Li, J.; Huang, J.; Kong, J.; Xiong, X. Tribological properties improvement of Mo-alloyed HfN films with a high H/E ratio at elevated temperature. J. Tribol. 2021, 143, 011704. [Google Scholar] [CrossRef]

- Nyemchenko, U.S.; Beresnev, V.M.; Gorban, V.F.; Novikov, V.J.; Yaremenko, O.V. Comparing the tribological properties of the coatings (Ti-Hf-Zr-V-Nb-Ta)N and (Ti-Hf-Zr-V-Nb-Ta)N + DLC. J. Nano Electron. Phys. 2015, 7, 03041. [Google Scholar]

- Komarov, F.F.; Pogrebnyak, A.D.; Konstantinov, S.V. Physics of nanostructures at radiation resistance of high-entropy nanostructured (Ti,Hf,Zr,V,Nb)N coatings. Tech. Phys. 2015, 60, 1519–1524. [Google Scholar] [CrossRef][Green Version]

- Pogrebnyak, A.D.; Beresnev, V.M.; Kolesnikov, D.A.; Kaverin, M.V.; Shypylenko, A.P.; Oyoshi, K.; Takeda, Y.; Krause-Rehberg, R.; Ponomarev, A.G. The effect of segregation and thermodiffusion on the formation of interfaces in nanostructured (Ti-Hf-Zr-V-Nb)N multielement coatings. Tech. Phys. Lett. 2013, 39, 280–283. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Borisyuk, V.N.; Bagdasaryan, A.A.; Maksakova, O.V.; Smirnova, E.V. The multifractal investigation of surface microgeometry of (Ti-Hf-Zr-V-Nb)N nitride coatings. J. Nano Electron. Phys. 2014, 6, 04018. [Google Scholar]

- Nemchenko, U.S.; Beresnev, V.M.; Klimenko, S.A.; Podchernyaeva, I.A.; Turbin, P.V.; Andreev, A. Wear resistance of the multicomponent coatings of the (Ti-Zr-Hf-V-Nb-Ta)N system at elevated temperature. J. Superhard Mater. 2015, 37, 322–326. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Vereschaka, A.; Fyodorov, S.V.; Sitnikov, N.; Batako, A.D. Comparative analysis of cutting properties and nature of wear of carbide cutting tools with multi-layered nano-structured and gradient coatings produced by using of various deposition methods. Int. J. Adv. Manuf. Technol. 2016, 90, 3421–3435. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Metel, A.S.; Fedorov, S.V. Modification of the structure and properties of high-speed steel by combined vac-uum-plasma treatment. Met. Sci. Heat Treat. 2012, 54, 8–12. [Google Scholar] [CrossRef]

- Vereschaka, A.S.; Grigoriev, S.N.; Tabakov, V.P.; Sotova, E.S.; Vereschaka, A.A.; Kulikov, M.Y. Improving the efficiency of the cutting tool made of ceramic when machining hardened steel by applying nano-dispersed multi-layered coatings. Key Eng. Mater. 2013, 581, 68–73. [Google Scholar] [CrossRef]

- Vereschaka, A.S.; Vereschaka, A.A.; Sladkov, D.; Aksenenko, A.; Sitnikov, N. Control of structure and properties of nanostructured multilayer composite coatings applied to cutting tools as a way to improve efficiency of technological cutting operations. J. Nano Res. 2015, 37, 51–57. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Vereschaka, A.S.; Grigoriev, S.N.; Kirillov, A.K.; Khaustova, O.U. Development and research of environ-mentally friendly dry technological machining system with compensation of physical function of cutting fluids. Procedia CIRP 2013, 7, 311–316. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Andreev, N.; Bublikov, J. Investigation of wear mechanisms for the rake face of a cutting tool with a multilayer composite nanostructured Cr–CrN-(Ti,Cr,Al,Si)N coating in high-speed steel turning. Wear 2019, 438–439, 203069. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Oganyan, G.; Andreev, N.; Milovich, F. Investigation of wear dynamics for cutting tools with multilayer composite nanostructured coatings in turning constructional steel. Wear 2018, 420, 17–37. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Popov, A.; Batako, A. Nano-scale multilayered composite coatings for cutting tools operating under heavy cutting conditions. Procedia CIRP 2014, 14, 239–244. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Andreev, N.; Milovich, F. Investigation of wear and diffusion processes on rake faces of carbide inserts with Ti-TiN-(Ti,Al,Si)N composite nanostructured coating. Wear 2018, 416, 72–80. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Tabakov, V.; Migranov, M.; Sitnikov, N.; Milovich, F.; Andreev, N. Influence of the nanostructure of Ti-TiN-(Ti,Al,Cr)N multilayer composite coating on tribological properties and cutting tool life. Tribol. Int. 2020, 150, 106388. [Google Scholar] [CrossRef]

- Vereschaka, A.; Aksenenko, A.; Sitnikov, N.; Migranov, M.; Shevchenko, S.; Sotova, C.; Batako, A.; Andreev, N. Effect of ad-hesion and tribological properties of modified composite nano-structured multi-layer nitride coatings on WC-Co tools life. Tribol. Int. 2018, 128, 313–327. [Google Scholar] [CrossRef]

- Vereshchaka, A.S.; Vereshchaka, A.A.; Kirillov, A.K. Ecologically friendly dry machining by cutting tool from layered com-position ceramic with nano-scale multilayered coatings. Key Eng. Mater. 2012, 496, 67–74. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Melnik, Y.A.; Metel, A.; Panin, V.V. Broad beam source of fast atoms produced as a result of charge exchange collisions of ions accelerated between two plasmas. Instrum. Exp. Tech. 2009, 52, 602–608. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.; Prudnikov, V.V. Glow discharge with electrostatic confinement of electrons in a chamber bombarded by fast electrons. Plasma Phys. Rep. 2011, 37, 628–637. [Google Scholar] [CrossRef]

- Sobol, O.V.; Andreev, A.A.; Grigoriev, S.N.; Gorban, V.F.; Volosova, M.A.; Aleshin, S.V.; Stolbovoi, V.A. Effect of high-voltage pulses on the structure and properties of titanium nitride vacuum-arc coatings. Met. Sci. Heat Treat. 2012, 54, 195–203. [Google Scholar] [CrossRef]

- Metel, A.; Bolbukov, V.; Volosova, M.; Grigoriev, S.; Melnik, Y. Source of metal atoms and fast gas molecules for coating deposition on complex shaped dielectric products. Surf. Coat. Technol. 2013, 225, 34–39. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- ASTM International. C1624-05(2015) Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Migranov, M.; Andreev, N.; Bublikov, J.; Sitnikov, N.; Oganyan, G. Investigation of the tribological properties of Ti-TiN-(Ti,Al,Nb,Zr)N composite coating and its efficiency in increasing wear resistance of metal cutting tools. Tribol. Int. 2021, 164, 107236. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Andreev, N.; Bublikov, J.; Kutina, N. Investigation of the properties of the Cr,Mo-(Cr,Mo,Zr,Nb)N-(Cr,Mo,Zr,Nb,Al)N multilayer composite multicomponent coating with nanostructured wear-resistant layer. Wear 2021, 468–469, 203597. [Google Scholar] [CrossRef]

- Vereschaka, A.; Volosova, M.; Chigarev, A.; Sitnikov, N.; Ashmarin, A.; Sotova, C.; Bublikov, J.; Lytkin, D. Influence of the thickness of a nanolayer composite coating on values of residual stress and the nature of coating wear. Coatings 2020, 10, 63. [Google Scholar] [CrossRef]

- George, M.; Coupeau, C.; Colin, J.; Grilhé, J. Mechanical behaviour of metallic thin films on polymeric substrates and the effect of ion beam assistance on crack propagation. Acta Mater. 2005, 53, 411–417. [Google Scholar] [CrossRef]

- Marx, V.M.; Toth, F.; Wiesinger, A.; Berger, J.; Kirchlechner, C.; Cordill, M.J.; Fischer, F.D.; Rammerstorfer, F.G.; Dehm, G. The influence of a brittle Cr interlayer on the deformation behavior of thin Cu films on flexible substrates: Experiment and mode. Acta Mater. 2015, 89, 278–289. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Sitnikov, N.N.; Batako, A. Delamination and longitudinal cracking in multi-layered com-posite nano-structured coatings and their influence on cutting tool life. Wear 2017, 390, 209–219. [Google Scholar] [CrossRef]

- Kazantsev, E.I. Industrial Furnaces. Reference Manual for Calculations and Design; Mir Publishers: Moscow, Russia, 1975. [Google Scholar]

- Tumanov, A.T. Refractory Materials in Mechanical Engineering; Mashinostroyeniye: Moscow, Russia, 1967. [Google Scholar]

- Hume-Rothery, W. The liquid state of the elements. J. Phys. Chem. 1940, 44, 824–825. [Google Scholar] [CrossRef]

- Mann, J.B.; Meek, T.L.; Allen, L.C. Configuration energies of the main group elements. J. Am. Chem. Soc. 2000, 122, 2780–2783. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Chen, S.K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, Y. Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 2012, 132, 233–238. [Google Scholar] [CrossRef]

- Takeuchi, A.; Amiya, K.; Wada, T.; Yubuta, K.; Zhang, W.; Makino, A. Alloy designs of high-entropy crystalline and bulk glassy alloys by evaluating mixing enthalpy and delta parameter for quinary to decimal equi-atomic alloys. Mater. Trans. 2014, 55, 165–170. [Google Scholar] [CrossRef]

- Wieser, M.; Holden, N.; Coplen, T.B.; Bohlke, J.K.; Berglund, M.; Brand, W.A.; De Bièvre, P.; Gröning, M.; Loss, R.D.; Meija, J.; et al. Atomic weights of the elements 2011 (IUPAC Technical Report). Pure Appl. Chem. 2013, 85, 1047–1078. [Google Scholar] [CrossRef]

- Chang, Y.A.; Chen, S.; Zhang, F.; Yan, X.; Xie, F.; Schmid-Fetzer, R.; Oates, W.A. Phase diagram calculation: Past, present and future. Prog. Mater. Sci. 2004, 49, 313–345. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, C.; Chen, S.; Zhu, J.; Cao, W.; Kattner, U. An understanding of high entropy alloys from phase diagram calculations. Calphad 2013, 45, 1–10. [Google Scholar] [CrossRef]

- Samal, S.; Tyc, O.; Cizek, J.; Klecka, J.; Lukáč, F.; Molnárová, O.; de Prado, E.; Weiss, Z.; Kopeček, J.; Heller, L.; et al. Fabrication of thermal plasma sprayed NiTi coatings possessing functional properties. Coatings 2021, 11, 610. [Google Scholar] [CrossRef]

- Samal, S.; Cibulková, J.; Čtvrtlík, R.; Tomáštík, J.; Václavek, L.; Kopeček, J.; Šittner, P. Tribological behavior of NiTi alloy produced by spark plasma sintering method. Coatings 2021, 11, 1246. [Google Scholar] [CrossRef]

- Vereschaka, A.; Milovich, F.; Migranov, M.; Andreev, N.; Alexandrov, I.; Muranov, A.; Mikhailov, M.; Tatarkanov, A. Investigation of the tribological and operational properties of (Mex,Moy,Al1-(x + y))N (Me–Ti, Zr or Cr) coatings. Tribol. Int. 2022, 165, 107305. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Andreev, N.; Bublikov, J.; Sitnikov, N.; Sotova, C.; Kutina, N. Investigation of wear mechanisms of multilayer nanostructured wear-resistant coatings during turning of steel. Part 2: Diffusion, oxidation processes and cracking in Ti-TiN-(Ti,Cr,Mo,Al)N coating. Wear 2021, 486–487, 204096. [Google Scholar] [CrossRef]

| Specimen | Zr | Hf | Al | Cr | Ti | Mo | Hardness, GPa | LC2, N |

| H1 | 42.3 | 18.1 | 10.1 | 29.5 | – | – | 27.20 ± 0.40 | 32 |

| H2 | 43.0 | 19.7 | 11.3 | – | 26.0 | – | 28.70 ± 0.80 | 34 |

| H3 | 41.9 | 19.2 | 9.4 | – | – | 29.5 | 26.30 ± 0.70 | 35 |

| ZrN | 100 | – | – | – | – | – | 25.10 ± 1.10 | 35 |

| Metal/Nitride | 100 °C | 200 °C | 400 °C | 600 °C | 700 °C |

|---|---|---|---|---|---|

| Ti | 8.1 | 8.5 | 9.2 | 10.0 | 10.4 |

| TiN | 7.1 | 7.1 | – * | 6.75 | 6.7 |

| Cr | 6.6 | 7.3 | 8.4 | 9.2 | 9.4 |

| CrN | – | 7.5 | - | – | – |

| Mo | 5.2 | 5.3 | 5.4 | 5.7 | 5.9 |

| Mo2N | – | 6.4 | – | – | – |

| Zr | 5.7 | 6.3 | 7.1 | 7.8 | 8.6 |

| ZrN | 8.0 | 8.1 | 8.2 | 8.4 | 8.6 |

| Hf ** | 5.9 | 6.4 | 6.9 | – | – |

| Metal | Atomic Radius, pm | Electronegativity (Pauling Scale) |

|---|---|---|

| Zr | 160 | 1.33 |

| Hf | 167 | 1.3 |

| Ti | 147 | 1.54 |

| Al | 143 | 1.61 |

| Cr | 130 | 1.66 |

| Mo | 139 | 2.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vereschaka, A.; Sitnikov, N.; Volosova, M.; Seleznev, A.; Sotova, C.; Bublikov, J. Investigation of Properties of the Zr,Hf-(Zr,Hf)N-(Zr,Hf,Me,Al)N Coatings, Where Me Means Cr, Ti, or Mo. Coatings 2021, 11, 1471. https://doi.org/10.3390/coatings11121471

Vereschaka A, Sitnikov N, Volosova M, Seleznev A, Sotova C, Bublikov J. Investigation of Properties of the Zr,Hf-(Zr,Hf)N-(Zr,Hf,Me,Al)N Coatings, Where Me Means Cr, Ti, or Mo. Coatings. 2021; 11(12):1471. https://doi.org/10.3390/coatings11121471

Chicago/Turabian StyleVereschaka, Alexey, Nikolay Sitnikov, Marina Volosova, Anton Seleznev, Catherine Sotova, and Jury Bublikov. 2021. "Investigation of Properties of the Zr,Hf-(Zr,Hf)N-(Zr,Hf,Me,Al)N Coatings, Where Me Means Cr, Ti, or Mo" Coatings 11, no. 12: 1471. https://doi.org/10.3390/coatings11121471

APA StyleVereschaka, A., Sitnikov, N., Volosova, M., Seleznev, A., Sotova, C., & Bublikov, J. (2021). Investigation of Properties of the Zr,Hf-(Zr,Hf)N-(Zr,Hf,Me,Al)N Coatings, Where Me Means Cr, Ti, or Mo. Coatings, 11(12), 1471. https://doi.org/10.3390/coatings11121471