1. Introduction

Nowadays, the most popular materials used for implants, such as dental and limb implants, hip joints, stents, or surgery tools, are metal alloys, such as stainless steel (316L), titanium alloys (Ti4Al6V), and cobalt–chromium alloys (CoCrMo) [

1]. The implant materials should be characterized not only by high biocompatibility but also by mechanical properties similar to the properties of human bone (Young’s modulus ~30 GPa), in addition to excellent corrosion resistance [

2]. Moreover, materials may contain toxic elements, such as V, Co, and Al, which can lead to many diseases [

3]. Commercially pure titanium (cp-Ti, grade 2) seems to be a good candidate material for use in medical applications. Ti has high biocompatibility and corrosion resistance in human body fluids. Furthermore, pure Ti exhibits a lower elastic modulus (~105 GPa) than Ti4Al6V (~125 GPa) [

4,

5].

Despite these advantages, titanium has poor tribological properties, such as a high coefficient of friction, low harnesses, and poor abrasive wear resistance, compared with Ti alloys [

6,

7]. One of the methods to improve the tribological and osteocompatibility properties of Ti is modification of the implant surface by coatings. The modification not only improves tribological properties but also create a bioactive area. Creation of adequate roughness on the surface of a titanium implant and supporting it with bioactive elements is an effective way to improve osseointegration between bone and implant [

8,

9,

10], leading to higher osteoblast adhesion and better integration of the tissue with the implant. In most cases, the bioactive coating materials used include hydroxyapatite (HAp) [

11], Al

2O

3 [

12], ZrO

2 [

13], or composites layers TiO

2/TiN [

14,

15]. In particular, as shown by Kure-Chu et al., a thin TiO

2/TiN nanolayer enhances wear resistance [

16], while ZrO

2 and Al

2O

3 are bioinert ceramics [

17]. Moreover, zirconium dioxide has highly stable dimensional and chemical properties, suitable hardness, and relatively low wear. Therefore, it is an attractive material for medicine. ZrO

2 occurs in three allotropic forms stable at different temperatures: cubic, monoclinic, and tetragonal [

18]. To stabilize the tetragonal phase at room temperature, additives, such as yttrium oxide (Y

2O

3), cerium oxide (CeO

2), or magnesium oxide (MgO), are used [

19]. In recent years, zirconium oxide stabilized with yttrium has been applied as dental implants and fillings, hips (total hip replacement), and femoral heads [

20,

21]. Many in vitro investigations have shown that YSZ coating causes better osseointegration. In vivo tests have shown that metal oxides are not cytotoxic, mutagenic, or carcinogenic [

22]. Moreover, zirconium dioxide can be antibacterial against

E. coli [

18,

23,

24].

Nowadays, scientists use different methods to produce coatings, depending on changing chemical or physical parameters [

25]. For example, micro-arc oxidation (MAO) is used for nonferrous materials. In this method, coatings are obtained through a chemical reaction initiated by an electric potential (higher than standard anodic oxidation) [

26]. Other methods are the sol–gel method based on colloidal solutions [

27], electrophoretic deposition involving colloidal solution, ceramic powder included in solution deposited on a substrate by an electric current [

28], or physical techniques, such as physical vapor deposition (PVD) and atmospheric plasma spray (APS) [

29]. One of the new promising methods of ceramic layer formation is plasma spray–physical vapor deposition (PS-PVD) [

10]. PS-PVD technology, based on the conventional low-pressure plasma spray (LPPS) method, enables controlling the thickness and structure of ceramic coatings deposited on different materials [

30]. One classic PVD technique is air plasma spray, where a powder is subjected to a high-temperature plasma flame, it is accelerated by plasma clouds, and then the melted powder is sprayed on a relatively cold substrate using a plasma jet, where crystallization occurs [

31].

The currently promising and alternative methods to APS are plasma spray–physical vapor deposition (PS-PVD) and very-low-pressure plasma spraying (LPPS) [

32]. These methods involve spraying and depositing melted or partly melted particles of powder on a metal substrate. The produced coatings have characteristically different microstructures. They are dense or columnar, depending on the process parameters used. Plasma spray–physical vapor deposition allows a wider spraying area compared with APS [

33,

34]. From a medical point of view, it is important for coatings to be characterized by the same phase composition, thickness, and surface roughness throughout the entire spray area. Therefore, in this paper, the PS-PVD technique was applied for Ti surface modification.

The main focus of this work, the YSZ coating, was deposited on a titanium substrate (cp-Ti, grade 2) using the PS-PVD method. The deposited coatings were extensively researched in terms of morphology, structure, corrosion resistance, and cell viability tests. The research material under study is expected to have potential medical applications, such as implants.

2. Materials and Methods

Plasma spray–physical vapor deposition (PS-PVD)—Commercially pure titanium rods (Ø 9 mm) were used as a substrate. The chemical composition of cp-Ti is shown in

Table 1. The substrate was cleaned and de-greased by isopropanol alcohol and distilled water before deposition. For the coating, commercially available yttria-stabilized zirconia powder (7.5Y2O

3-ZrO

2, Metco 6700, Oerlikon, Pfäffikon, Switzerland) was used. Plasma spray–physical vapor deposition (PS-PVD) was used for the production of coatings. The experiment was performed using a 03CP-type plasma gun and a 60CD powder feeder. Constant process parameters were applied, such as plasma gases (He = 60/Ar = 35 normal liters per minute (NLPM)), power current 2400 A, sample rotation 20 rpm, and chamber pressure 150 Pa, based on previous research [

35]. Two different deposition times of 50 and 200 s were used for each sample (

Table 2).

Next, rods with YSZ coatings were cut into slices of 5 mm thickness The deposition process obtained two representative samples, Ti_10_100 and Ti_10_400, which were subjected to extensive material testing.

Characterization of ceramic coatings—Quantitative and qualitative X-ray analysis was carried out using a Philips X’Pert PW 3040/60 diffractometer (PANalytical, Almelo, The Netherlands), with used CuKα radiation (λ = 1.54178 Ǻ), voltage 40 kV, and current 30 mA. The measurement was carried out at a range of angles from 10° 2θ to 140° 2θ, with step scanning at 0.04 steps. The ICCD Card PDF 4 database was used to analyze the resulting diffractograms. Structural analyses of the obtained coatings were performed using Rietveld’s method.

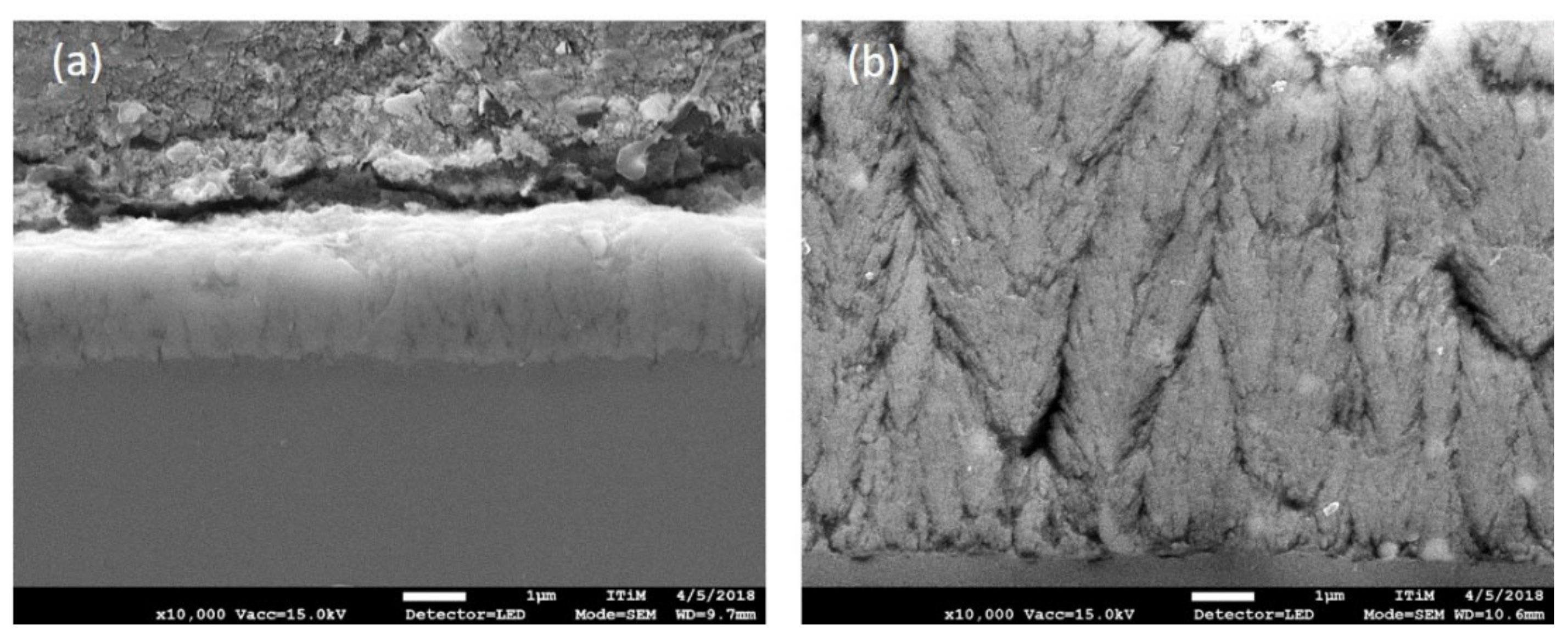

To observe the cross sections, columnar structures, and surfaces of the obtained coatings, a JEOL JMS-7100F TTL LV high-resolution scanning microscope (JEOL, Tokyo, Japan) with an accelerating voltage of 15 kV was used. The cross-sectional and top views of samples were characterized. An EDS detector was used to determine the maps of element distribution. HR-SEM EDS analysis was carried out to observe the cross sections of the obtained coatings. To determine the linear dispersion of energy and the map of energy dispersion, a JEOL 6480 JSM 6480 scanning microscope (JEOL, Tokyo, Japan) with an accelerating voltage of 20 kV was used, with standard EDS equipment for linear chemical analysis of the cross sections of the samples.

A JEOL JSM 6480 (JEOL, Tokyo, Japan) scanning electron microscope (SEM) with an accelerating voltage of 20 kV was used to observe images of surfaces and the morphology of obtained coatings after corrosion resistance measurements. EDS analysis was completed of the top view of the obtained coatings in 15 different areas.

Electrochemical measurements were carried out using a Metrohm/Eco Chemie Autloab PGSTAT30 Potentiostat/Galvanostat Electrochemical System (Metrohm Middle East FZC, Sharjah, UAE). A three-electrode electrochemical cell was used where the material under study was the working electrode (WE), the Pt mesh was used as a counter electrode (CE), and the saturated calomel electrode (SCE) with a Luggin capillary was the reference electrode (RE). The in vitro corrosion resistance of the tested materials was investigated in Ringer’s solution (

Table 3) deaerated with argon (Ar, 99.999%) at 37 °C. The open circuit potential (EOC) and potentiodynamics polarization methods were applied. The EOC was registered until a stable potential value was found. Anodic polarization curves were registered potentiodynamically at a sweep rate of v = 4 mV s

−1 in the potential range from EOC −150 mV to 9 V vs. SCE.

The roughness profile of the obtained coatings was determined by a Mitutoyo SURFTEST SJ-500 profilometer (Mitutoyo, Tokyo, Japan) to determinate changes in roughness. The following parameters of the raw profile were analyzed: arithmetic mean deviation (RA), maximum peak height (RP), maximum height (RZ), and maximum valley depth (RV). Five measurements were made for each sample, with a working distance of 2 cm for each sample.

Topography measurements and roughness cross-sections of the obtained coatings were characterized with a Hysitron TI 950 nano-indenter (Hysitron, Eden Prairie, MN, USA) on 40 µm × 40 µm areas. The experiments were carried out with a Bregovic tip at a load of 500 µN.

Surface observations of the obtained coatings were made by an Olympus LEXT OLS-4000 confocal scanning microscope (Olympus Corp., Tokyo, Japan) with a wavelength of 405 nm. Observations were made at a magnification of ×20. Three-dimensional pictures were prepared using the free software Gwyddion 2.51.

A viability assay was carried out using human fibroblasts. Fibroblasts were seeded on investigated surfaces at a density of 50 × 103/cm2 for 24 h before viability examination and cultured under strictly controlled conditions: 5% CO2 and temperature 37 °C. For staining, the cell cultures were incubated for 10 min (RT) with the fluorescent dyes fluorescein diacetate (FDA) and ethidium bromide (EB) at concentrations provided by the producers. After washing with phosphate-buffered saline (PBS), the samples were mounted in glass chambers and then visualized with a Leica DMI6000B fluorescence microscope equipped with a DFC360FX CCD camera (Leica, Wetzlar, Germany).

4. Conclusions

The conducted research results indicate that PS-PVD allows one to obtain compact, homogeneous, characteristic, columnar yttrium-stabilized zirconium oxide coatings on a metallic cp-Ti substrate suitable for medical applications. Using variable parameters of the PS-PVD process significantly affects the structure and properties of the deposited coatings. The above experiment shows that by only changing the deposition time, different surface properties were obtained, such as surface development (topography, roughness) and thickness. At the same time, it was shown that spraying the coating does not cause significant structural changes and does not introduce contaminants into the material. The above research allow us to state that the deposited coatings do not show microcracks and delamination and do not crumble. However, unmelted particles were present during PS-PVD inside and on the surface, and the amount of unmelted particles depends on the process parameters used. In addition, it was proven that the deposited coatings slightly changed the hardness value of the material, although they significantly reduced the Young’s modulus. It has been found that Ti_10_100 is a good material for use in an environment of aggressive body fluids. In contrast, Ti_10_400 has poor bone cell viability and less adhesion. The cells are mostly round. The Ti_10_100 samples has good adhesion and distribution, and the cell viability is comparable to the control sample. Importantly, it was indicated that the Ti_10_100 coating could be used as potential bone implants. Further work should focus on the development of optimal thickness and roughness and the continuous reduction of Young’s modulus to improve osseointegration and bioactivity and reduce the risk of bone stiffness.