Sintering Modeling of Thermal Barrier Coatings at Elevated Temperatures: A Review of Recent Advances

Abstract

:1. Introduction

2. Constituents of TBC System

3. Numerical Modelling Principles and Methodology

3.1. Variational Principle

3.2. Constitutive Sintering Models

4. Three Dimension Periodic APS TBC Sintering Model

4.1. Geometry of the Sintering Model

4.2. Modelling Principle

4.3. Model Prediction

4.4. Summary of the Model

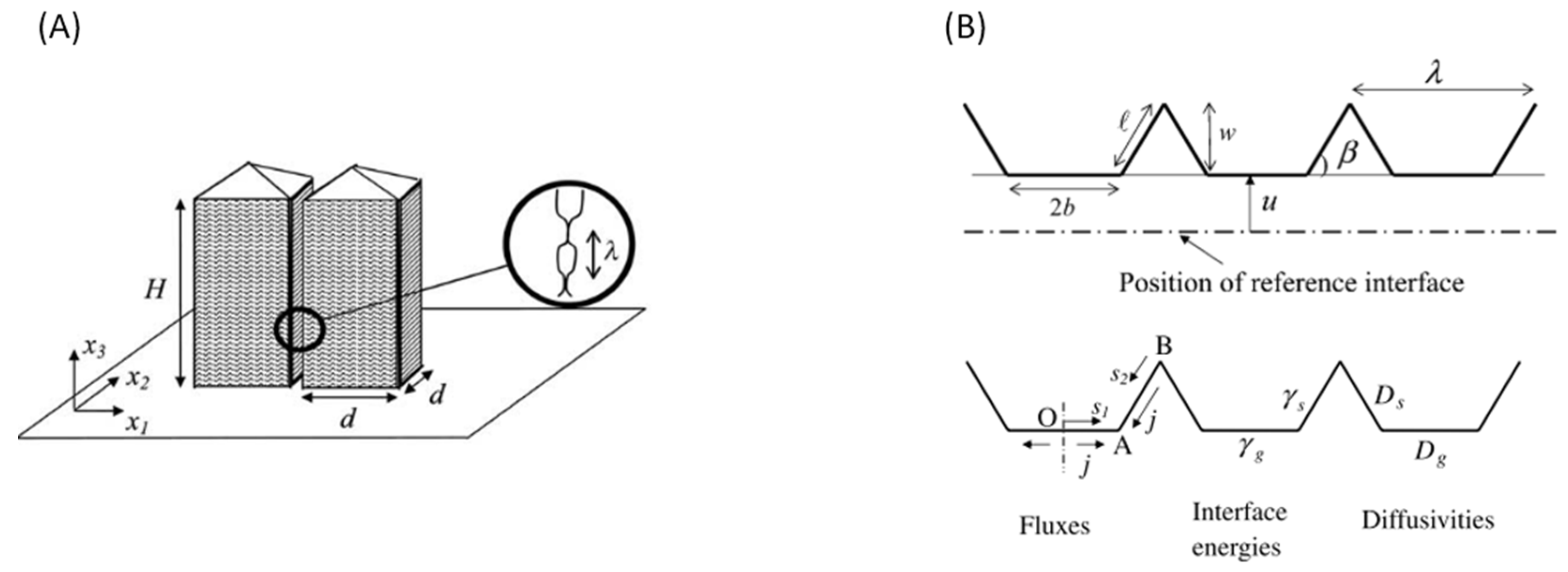

5. Brick Model of Sintering

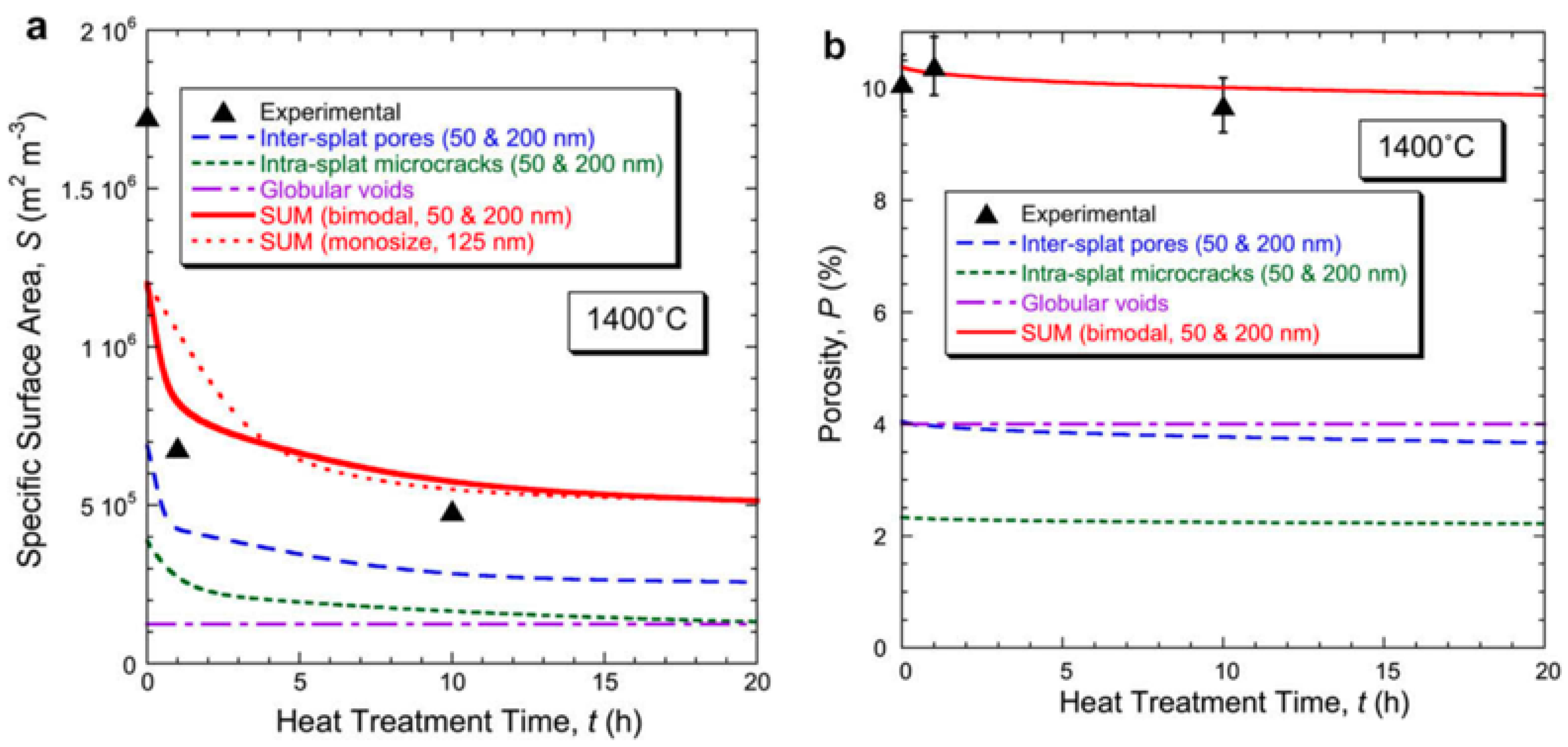

5.1. Geometry of the Model

5.2. Modelling Principle

5.3. Model Predictions

5.4. Summary of the Model

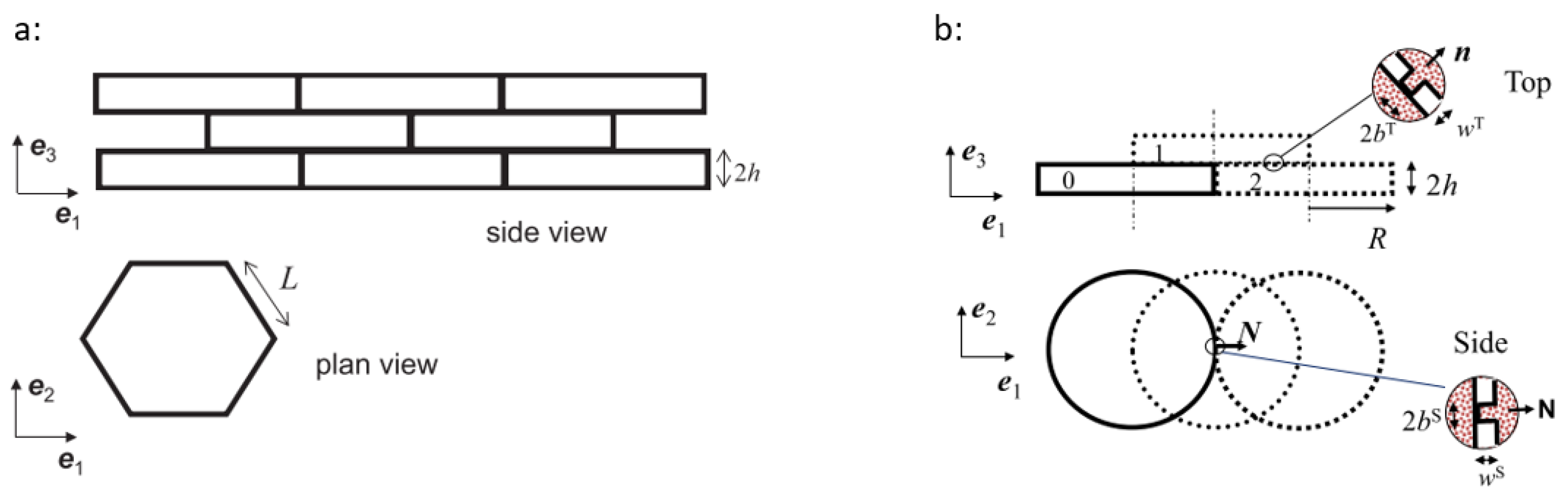

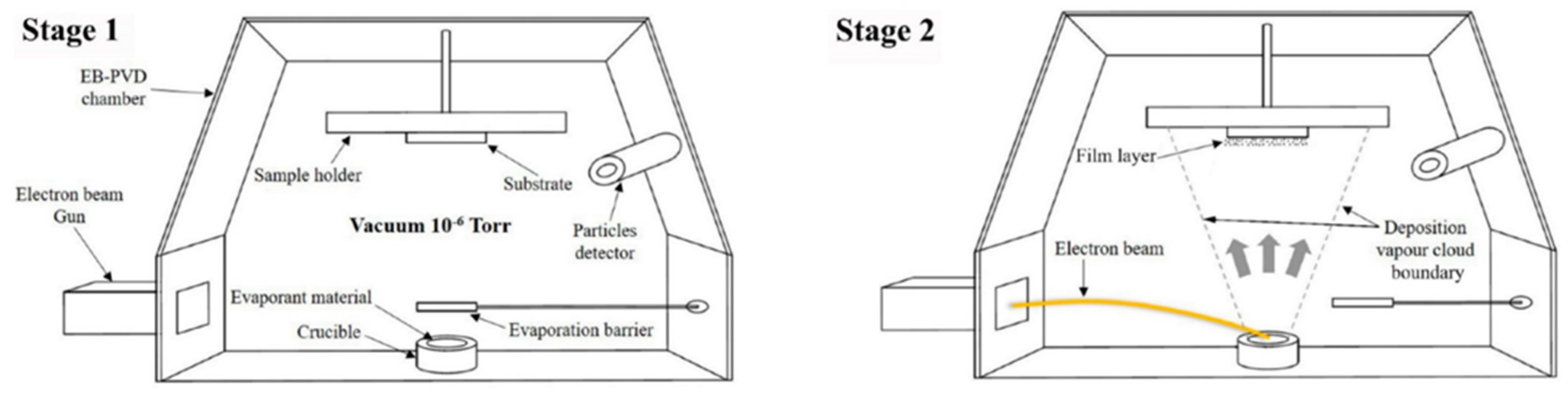

6. An EB-PVD TBC Sintering Model

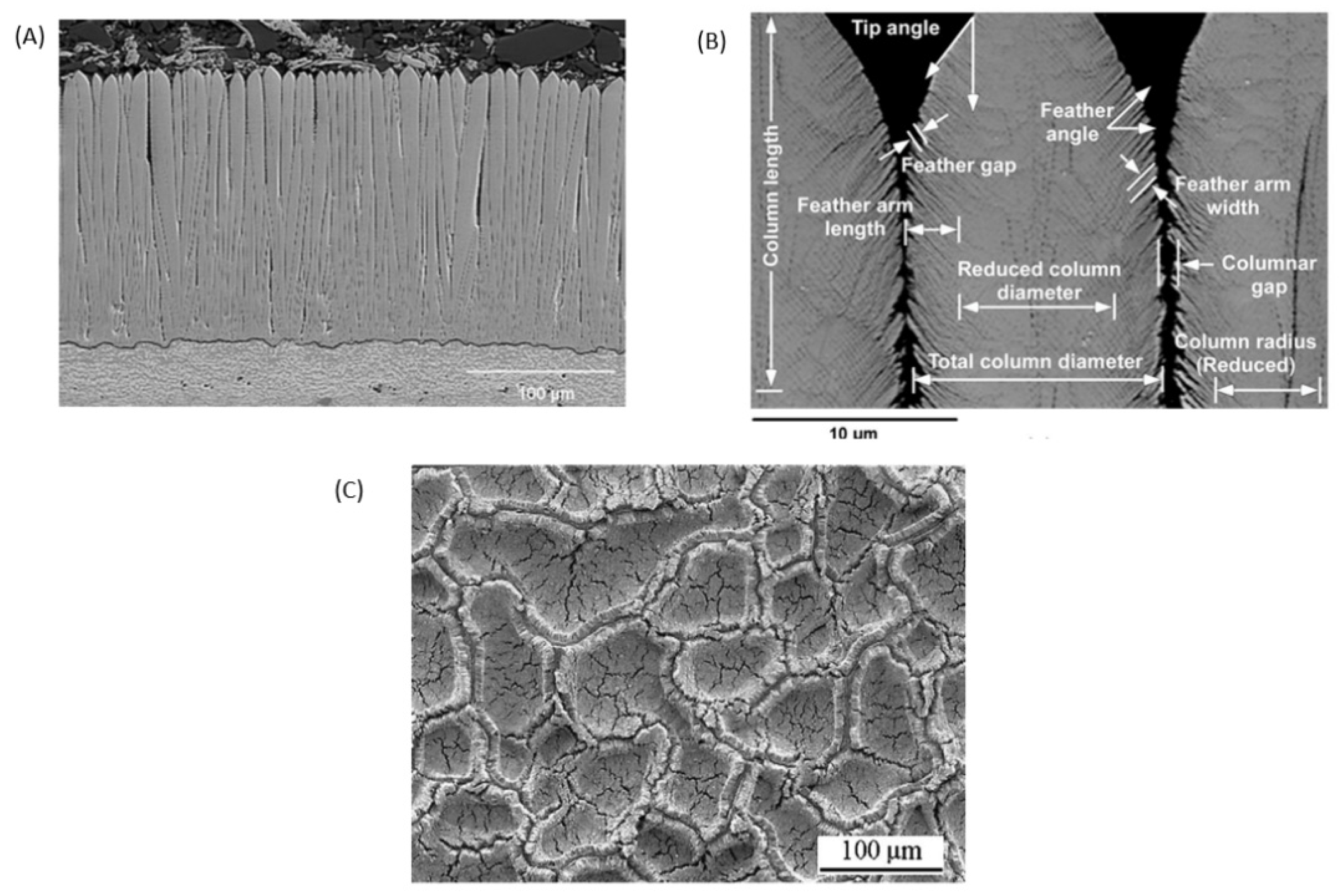

6.1. EB-PVD Process and Coating Microstructure

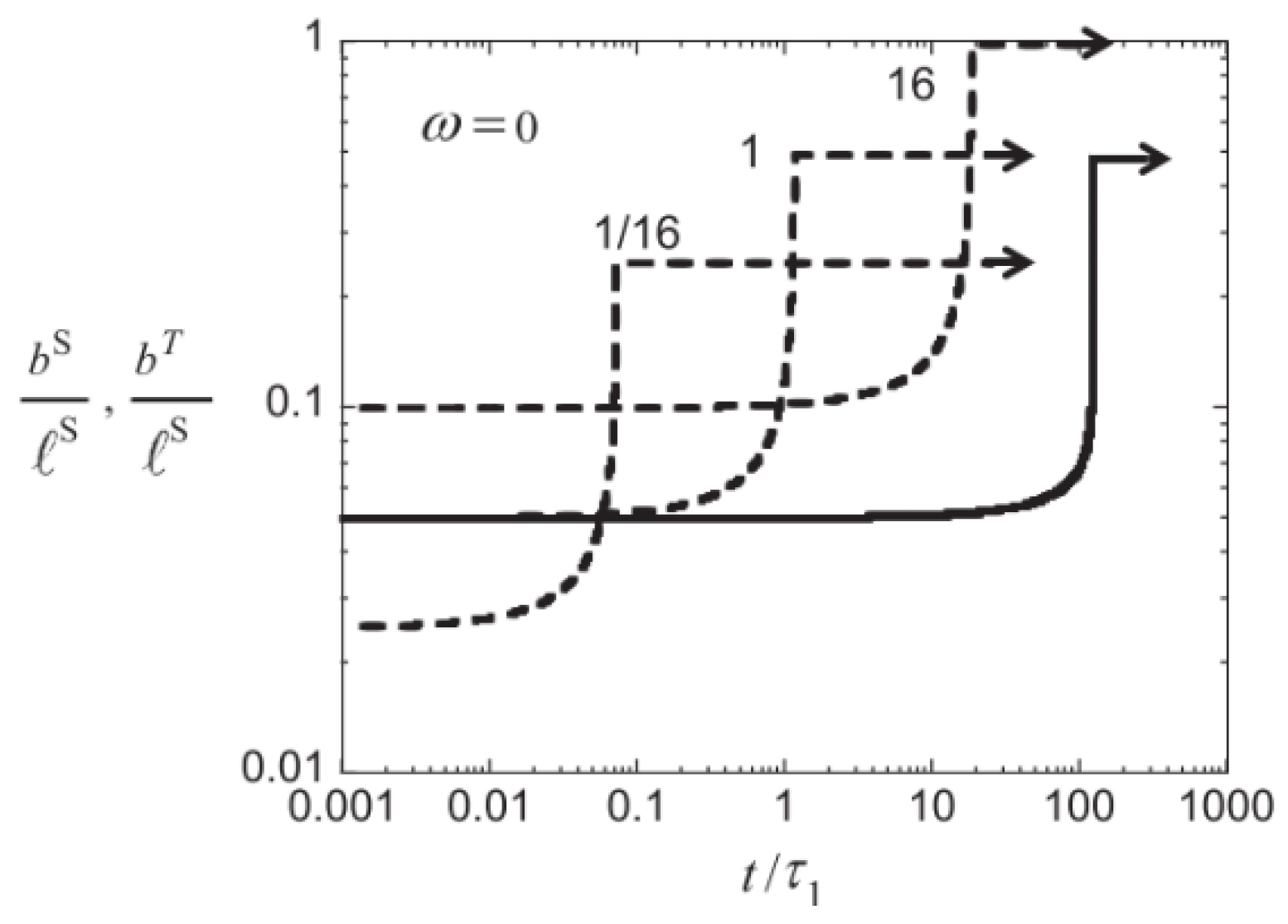

6.2. Modelling Principle

6.3. Model Predictions

6.4. Model Summary

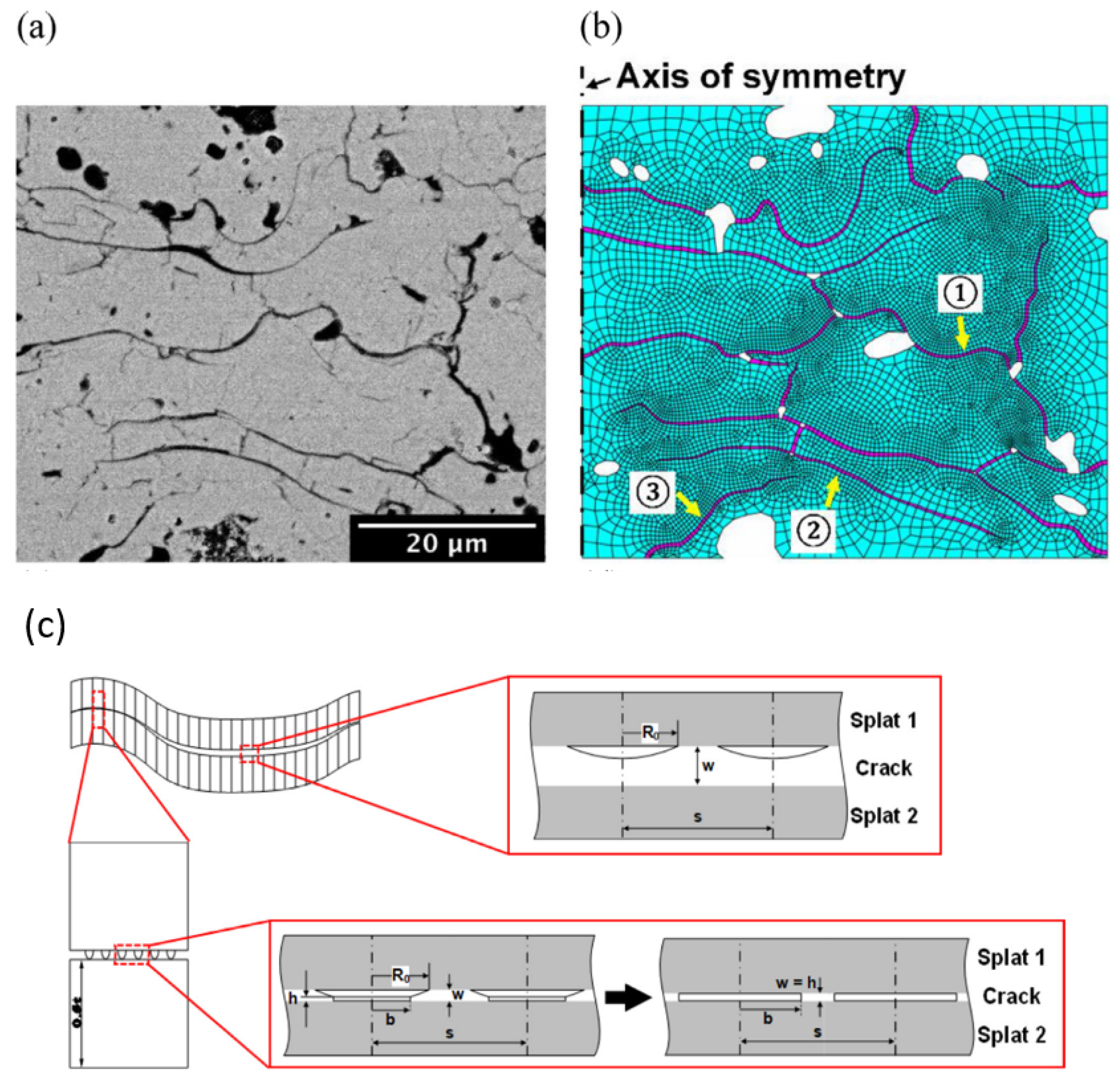

7. FEM Implementations and Future Developments

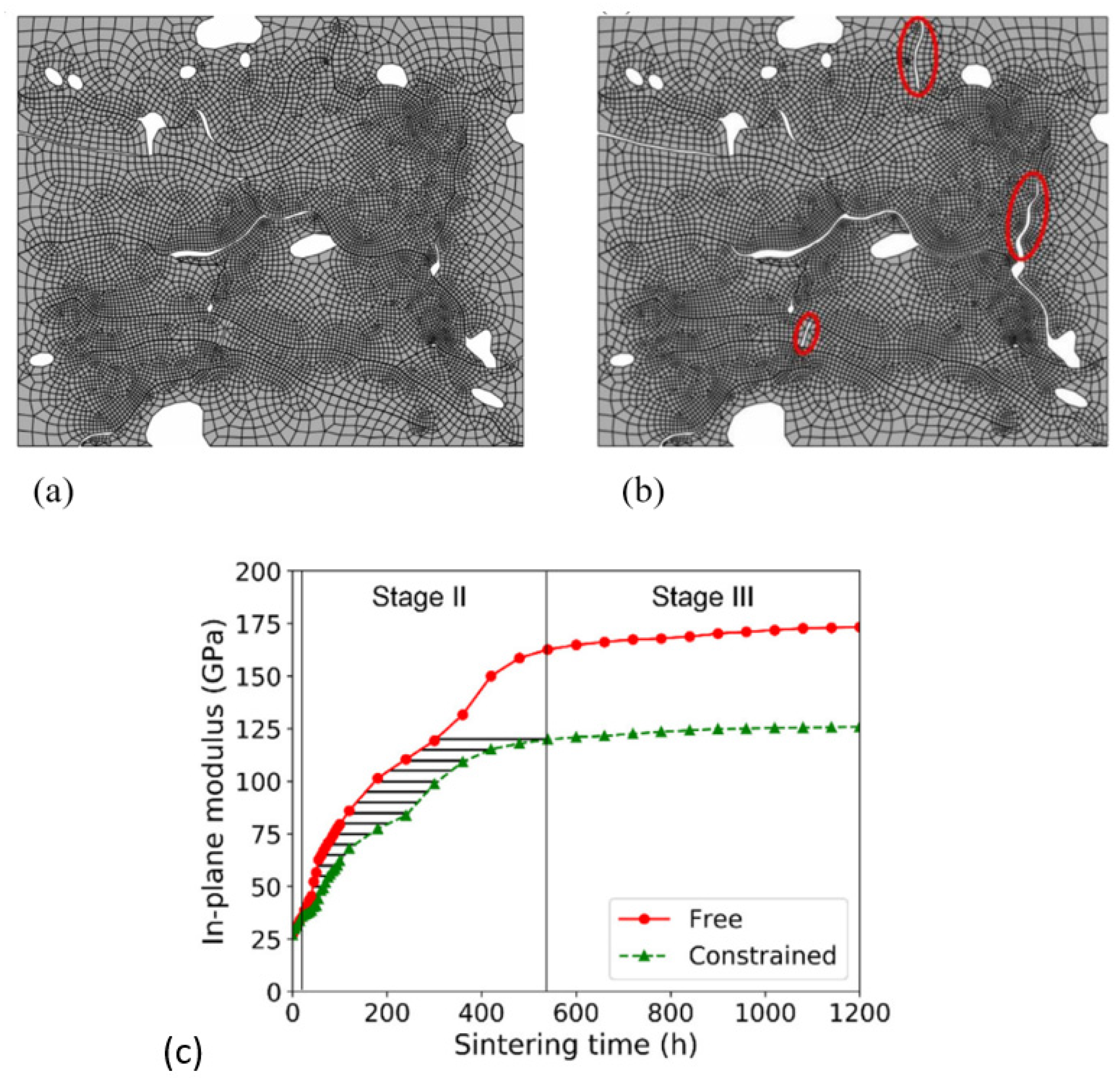

7.1. The Image-Based FE Model

7.2. Geometry of the Model and Sintering Principle

7.3. Model Predictions

7.4. Summary of the Model

8. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Clarke, D.R.; Levi, C.G. Materials design for the next generation thermal barrier coatings. Annu. Rev. Mater. Res. 2003, 33, 383–417. [Google Scholar] [CrossRef]

- Gleeson, B. Thermal barrier coatings for aeroengine applications. J. Propuls. Power 2006, 22, 375–383. [Google Scholar] [CrossRef]

- Sahith, M.S.; Giridhara, G.; Kumar, R.S. Development and analysis of thermal barrier coatings on gas turbine blades—A Review. Mater. Today Proc. 2018, 5, 2746–2751. [Google Scholar] [CrossRef]

- Cocks, A.; Fleck, N.; Lampenscherf, S. A brick model for asperity sintering and creep of APS TBCs. J. Mech. Phys. Solids 2014, 63, 412–431. [Google Scholar] [CrossRef]

- Levi, C.G. Emerging materials and processes for thermal barrier systems. Curr. Opin. Solid State Mater. Sci. 2004, 8, 77–91. [Google Scholar] [CrossRef]

- Qi, H.; Yang, X. Life prediction of thermal barrier coatings. In Thermal Barrier Coatings; Elsevier: Amsterdam, The Netherlands, 2011; pp. 294–316. [Google Scholar]

- Chen, K.; Seo, D.; Canteenwalla, P. The effect of high-temperature water vapour on degradation and failure of hot section components of gas turbine engines. Coatings 2021, 11, 1061. [Google Scholar] [CrossRef]

- Essa, S.K.; Chen, K.; Liu, R.; Wu, X.; Yao, M.X. Failure mechanisms of APS-YSZ-CoNiCrAlY thermal barrier coating under isothermal oxidation and solid particle erosion. J. Therm. Spray Technol. 2021, 30, 424–441. [Google Scholar] [CrossRef]

- Liu, Y.; Ravichandran, R.; Chen, K.; Patnaik, P. Application of machine learning to solid particle erosion of APS-TBC and EB-PVD TBC at elevated temperatures. Coatings 2021, 11, 845. [Google Scholar] [CrossRef]

- Ghai, R.S.; Chen, K.; Baddour, N. Modelling thermal conductivity of porous thermal barrier coatings. Coatings 2019, 9, 101. [Google Scholar] [CrossRef] [Green Version]

- Moteb, A.; Chen, K. Modelling and evaluating thermal conductivity of porous thermal barrier coatings at elevated temperatures. Ceram. Int. 2020, 46, 21939–21957. [Google Scholar] [CrossRef]

- Martena, M.; Botto, D.; Fino, P.; Sabbadini, S.; Gola, M.; Badini, C. Modelling of TBC system failure: Stress distribution as a function of TGO thickness and thermal expansion mismatch. Eng. Fail. Anal. 2006, 13, 409–426. [Google Scholar] [CrossRef]

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal Barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Cheng, B.; Zhang, Y.-M.; Yang, N.; Zhang, M.; Chen, L.; Yang, G.-J.; Li, C.-X.; Li, C.-J. Sintering-induced delamination of thermal barrier coatings by gradient thermal cyclic test. J. Am. Ceram. Soc. 2017, 100, 1820–1830. [Google Scholar] [CrossRef]

- Bakan, E.; Vassen, R. Ceramic top coats of plasma-sprayed thermal barrier coatings: Materials, processes, and properties. J. Therm. Spray Technol. 2017, 26, 992–1010. [Google Scholar] [CrossRef]

- Li, G.; Xie, H.; Yang, G.; Liu, G.; Li, C.; Li, C.-J. A comprehensive sintering mechanism for TBCs-Part I: An overall evolution with two-stage kinetics. J. Am. Ceram. Soc. 2017, 100, 2176–2189. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, K.; Baddour, N.; Patnaik, P.C. Life prediction of atmospheric plasma-sprayed thermal barrier coatings using temperature-dependent model parameters. J. Therm. Spray Technol. 2017, 26, 902–912. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, K.; Baddour, N.; Patnaik, P. Failure and life evaluation of EB-PVD thermal barrier coatings using temperature-process-dependent model parameters. Corros. Sci. 2019, 156, 1–9. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, K.; Baddour, N. Stress models for electron beam-physical vapor deposition thermal barrier coatings using temperature-process-dependent model parameters. J. Eur. Ceram. Soc. 2021, 41, 5658–5674. [Google Scholar] [CrossRef]

- Zhang, X.; Cocks, A.C.; Okajima, Y.; Takeno, K.; Torigoe, T. An image-based model for the sintering of air plasma sprayed thermal barrier coatings. Acta Mater. 2021, 206, 116649. [Google Scholar] [CrossRef]

- Cipitria, A.; Golosnoy, I.; Clyne, T. A sintering model for plasma-sprayed zirconia TBCs. Part I: Free-standing coatings. Acta Mater. 2009, 57, 980–992. [Google Scholar] [CrossRef]

- Lv, B.; Fan, X.; Xie, H.; Wang, T. Effect of neck formation on the sintering of air-plasma-sprayed thermal barrier coating system. J. Eur. Ceram. Soc. 2017, 37, 811–821. [Google Scholar] [CrossRef]

- Zhu, D.; Miller, R.A. Sintering and creep behavior of plasma-sprayed zirconia- and hafnia-based thermal barrier coatings. Surf. Coatings Technol. 1998, 108–109, 114–120. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.-J. Basis of Sintering Science. In Sintering: Densification, Grain Growth and Microstructure; Elsevier Butterworth-Heinemann: Oxford, UK, 2011; pp. 1–27. [Google Scholar]

- Sadowski, T.; Golewski, P. Loadings in Thermal Barrier Coatings of Jet Engine Turbine Blades; Springer Science and Business Media LLC: Singapore; Springer Singapore Pte. Limited: Singapore, 2016; Volume 39. [Google Scholar]

- Nicholls, J. Advances in coating design for high-performance gas turbines. MRS Bull. 2003, 28, 659–670. [Google Scholar] [CrossRef]

- Xu, H.; Wu, J. New materials, technologies and processes in thermal barrier coatings. In Thermal Barrier Coatings; Elsevier: Amsterdam, The Netherlands, 2011; pp. 317–328. [Google Scholar]

- Fergus, J.W. Zirconia and pyrochlore oxides for thermal barrier coatings in gas turbine engines. Met. Mater. Trans. E 2014, 1, 118–131. [Google Scholar] [CrossRef] [Green Version]

- Vaßen, R.; Jarligo, M.O.; Steinke, T.; Mack, D.E.; Stöver, D. Overview on advanced thermal barrier coatings. Surf. Coat. Technol. 2010, 205, 938–942. [Google Scholar] [CrossRef]

- Kyaw, S.; Jones, A.; Hyde, T. Predicting failure within TBC system: Finite element simulation of stress within TBC system as affected by sintering of APS TBC, geometry of substrate and creep of TGO. Eng. Fail. Anal. 2013, 27, 150–164. [Google Scholar] [CrossRef]

- Rösler, J.; Baker, M.; Volgmann, M. Stress state and failure mechanisms of thermal barrier coatings: Role of creep in thermally grown oxide. Acta Mater. 2001, 49, 3659–3670. [Google Scholar] [CrossRef]

- Vaßen, R.; Kerkhoff, G.; Stöver, D. Development of a micromechanical life prediction model for plasma sprayed thermal barrier coatings. Mater. Sci. Eng. A 2001, 303, 100–109. [Google Scholar] [CrossRef]

- Cocks, A.C.; Gill, S.P.; Pan, J. Modeling microstructure evolution in engineering materials. Adv. Appl. Mech. 1998, 36, 81–162. [Google Scholar] [CrossRef]

- Ch’Ng, H.; Pan, J. Sintering of particles of different sizes. Acta Mater. 2007, 55, 813–824. [Google Scholar] [CrossRef]

- Cocks, A.; Fleck, N. Constrained sintering of an air-plasma-sprayed thermal barrier coating. Acta Mater. 2010, 58, 4233–4244. [Google Scholar] [CrossRef]

- Budiansky, B.; O’Connell, R.J. Elastic moduli of a cracked solid. Int. J. Solids Struct. 1976, 12, 81–97. [Google Scholar] [CrossRef]

- Gasik, M.; Zhang, B. A constitutive model and FE simulation for the sintering process of powder compacts. Comput. Mater. Sci. 2000, 18, 93–101. [Google Scholar] [CrossRef]

- Xu, J.; Khor, K. Plasma spraying for thermal barrier coatings: Processes and applications. Therm. Barrier Coat. 2011, 99–114. [Google Scholar] [CrossRef]

- Cipitria, A.; Golosnoy, I.; Clyne, T. Sintering kinetics of plasma-sprayed zirconia TBCs. J. Therm. Spray Technol. 2007, 16, 809–815. [Google Scholar] [CrossRef] [Green Version]

- Cipitria, A.; Golosnoy, I.; Clyne, T. A sintering model for plasma-sprayed zirconia thermal barrier coatings. Part II: Coatings bonded to a rigid substrate. Acta Mater. 2009, 57, 993–1003. [Google Scholar] [CrossRef] [Green Version]

- Fauchais, P.; Vardelle, M.; Vardelle, A. Reliability of plasma-sprayed coatings: Monitoring the plasma spray process and improving the quality of coatings. J. Phys. D Appl. Phys. 2013, 46, 224016. [Google Scholar] [CrossRef]

- Takagi, K.; Kudo, D.; Kawasaki, A.; Harada, Y. Microstructural dependency of thermal expansion and sintering shrinkage in plasma-sprayed zirconia coatings. Surf. Coat. Technol. 2011, 205, 4411–4417. [Google Scholar] [CrossRef]

- Li, G.; Yang, G. Understanding of degradation-resistant behavior of nanostructured thermal barrier coatings with bimodal structure. J. Mater. Sci. Technol. 2019, 35, 231–238. [Google Scholar] [CrossRef]

- Eriksson, R.; Brodin, H.; Johansson, S.; Östergren, L.; Li, X.-H. Fractographic and microstructural study of isothermally and cyclically heat treated thermal barrier coatings. Surf. Coat. Technol. 2014, 243, 82–90. [Google Scholar] [CrossRef]

- Li, G.; Xie, H.; Yang, G.; Liu, G.; Li, C.; Li, C.-J. A comprehensive sintering mechanism for TBCs-Part II: Multiscale multipoint interconnection-enhanced initial kinetics. J. Am. Ceram. Soc. 2017, 100, 4240–4251. [Google Scholar] [CrossRef]

- Vasile, B.S.; Birca, A.C.; Surdu, V.A.; Neacsu, I.-A.; Nicoară, A.I. Ceramic composite materials obtained by electron-beam physical vapor deposition used as thermal barriers in the aerospace industry. Nanomaterials 2020, 10, 370. [Google Scholar] [CrossRef] [Green Version]

- Kabir, M.R.; Sirigiri, A.K.; Naraparaju, R.; Schulz, U. Flow kinetics of molten silicates through thermal barrier coating: A numerical study. Coatings 2019, 9, 332. [Google Scholar] [CrossRef] [Green Version]

- Ali, N.; Teixeira, J.A.; Addali, A.; Saeed, M.; Al-Zubi, F.; Sedaghat, A.; Bahzad, H. Deposition of stainless steel thin films: An electron beam physical vapour deposition approach. Materials 2019, 12, 571. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Von Niessen, K.; Gindrat, M. Plasma spray-PVD: A new thermal spray process to deposit out of the vapor phase. J. Therm. Spray Technol. 2011, 20, 736–743. [Google Scholar] [CrossRef] [Green Version]

- Lughi, V.; Tolpygo, V.K.; Clarke, D.R. Microstructural aspects of the sintering of thermal barrier coatings. Mater. Sci. Eng. A 2004, 368, 212–221. [Google Scholar] [CrossRef]

- Schulz, U.; Saruhan, B.; Fritscher, K.; Leyens, C. Review on advanced EB-PVD ceramic topcoats for TBC applications. Int. J. Appl. Ceram. Technol. 2005, 1, 302–315. [Google Scholar] [CrossRef]

- Hutchinson, R.; Fleck, N.; Cocks, A. A sintering model for thermal barrier coatings. Acta Mater. 2006, 54, 1297–1306. [Google Scholar] [CrossRef]

- Yang, J.; Wang, L.; Tan, X.; Zhi, Q.; Yang, R.; Zhang, G.; Liu, Z.; Ge, X.; Liang, E. Effect of sintering temperature on the thermal expansion behavior of ZrMgMo3O12p/2024Al composite. Ceram. Int. 2018, 44, 10744–10752. [Google Scholar] [CrossRef]

- Altun, Ö.; Böke, Y.E. Effect of the microstructure of EB-PVD thermal barrier coatings on the thermal conductivity and the methods to reduce the thermal conductivity. Arch. Mater. Sci. Eng. 2009, 40, 47–52. [Google Scholar]

- Kumar, S.; Cocks, A.C.F. Computational modelling of constrained sintering in EB-PVD thermal barrier coatings. Model. Simul. Mater. Sci. Eng. 2013, 21, 65008. [Google Scholar] [CrossRef]

- Freborg, A.; Ferguson, B.; Brindley, W.; Petrus, G. Modeling oxidation induced stresses in thermal barrier coatings. Mater. Sci. Eng. A 1998, 245, 182–190. [Google Scholar] [CrossRef]

- Xie, W.; Jordan, E.; Gell, M. Stress and cracking behavior of plasma sprayed thermal barrier coatings using an advanced constitutive model. Mater. Sci. Eng. A 2006, 419, 50–58. [Google Scholar] [CrossRef]

- Białas, M. Finite element analysis of stress distribution in thermal barrier coatings. Surf. Coatings Technol. 2008, 202, 6002–6010. [Google Scholar] [CrossRef]

- Cheng, J.; Jordan, E.; Barber, B.; Gell, M. Thermal/residual stress in an electron beam physical vapor deposited thermal barrier coating system. Acta Mater. 1998, 46, 5839–5850. [Google Scholar] [CrossRef]

- Ranjbar-Far, M.; Absi, J.; Mariaux, G.; Dubois, F. Simulation of the effect of material properties and interface roughness on the stress distribution in thermal barrier coatings using finite element method. Mater. Des. 2010, 31, 772–781. [Google Scholar] [CrossRef]

- Abdelgawad, A.; Al-Athel, K. Effect of TGO thickness, pores, and creep on the developed residual stresses in thermal barrier coatings under cyclic loading using SEM image-based finite element model. Ceram. Int. 2021, 47, 20064–20076. [Google Scholar] [CrossRef]

- Lv, B.; Xie, H.; Xu, R.; Fan, X.; Zhang, W.; Wang, T. Effects of sintering and mixed oxide growth on the interface cracking of air-plasma-sprayed thermal barrier coating system at high temperature. Appl. Surf. Sci. 2016, 360, 461–469. [Google Scholar] [CrossRef]

- Lv, B.; Mücke, R.; Zhou, D.; Fan, X.; Wang, T.J.; Guillon, O.; Vaßen, R. A constitutive model for the sintering of suspension plasma-sprayed thermal barrier coating with vertical cracks. J. Am. Ceram. Soc. 2019, 102, 6202–6212. [Google Scholar] [CrossRef]

- Lv, B.; Fan, X.; Li, D.; Wang, T. Towards enhanced sintering resistance: Air-plasma-sprayed thermal barrier coating system with porosity gradient. J. Eur. Ceram. Soc. 2018, 38, 1946–1956. [Google Scholar] [CrossRef]

- Kumar, S.; Cocks, A. Sintering and mud cracking in EB-PVD thermal barrier coatings. J. Mech. Phys. Solids 2012, 60, 723–749. [Google Scholar] [CrossRef]

- Zhang, X.; Cocks, A.C.; Okajima, Y.; Takeno, K.; Torigoe, T. Constrained sintering and cracking of air plasma sprayed thermal barrier coatings: Experimental observation and modeling. J. Am. Ceram. Soc. 2021, 104, 4759–4772. [Google Scholar] [CrossRef]

- Fleck, N.; Cocks, A. A multi-scale constitutive model for the sintering of an air-plasma-sprayed thermal barrier coating, and its response under hot isostatic pressing. J. Mech. Phys. Solids 2009, 57, 689–705. [Google Scholar] [CrossRef]

- Burnett, T.L.; Kelley, R.; Winiarski, B.; Contreras, L.; Daly, M.; Gholinia, A.; Burke, M.G.; Withers, P. Large volume serial section tomography by Xe Plasma FIB dual beam microscopy. Ultramicroscopy 2016, 161, 119–129. [Google Scholar] [CrossRef] [PubMed]

- Lv, B.; Jin, X.; Cao, J.; Xu, B.; Wang, Y.; Fang, D. Advances in numerical modeling of environmental barrier coating systems for gas turbines. J. Eur. Ceram. Soc. 2020, 40, 3363–3379. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Wang, X.; Chen, K.; Lee, K.N. Sintering Modeling of Thermal Barrier Coatings at Elevated Temperatures: A Review of Recent Advances. Coatings 2021, 11, 1214. https://doi.org/10.3390/coatings11101214

Yan J, Wang X, Chen K, Lee KN. Sintering Modeling of Thermal Barrier Coatings at Elevated Temperatures: A Review of Recent Advances. Coatings. 2021; 11(10):1214. https://doi.org/10.3390/coatings11101214

Chicago/Turabian StyleYan, Jinrong, Xin Wang, Kuiying Chen, and Kang N. Lee. 2021. "Sintering Modeling of Thermal Barrier Coatings at Elevated Temperatures: A Review of Recent Advances" Coatings 11, no. 10: 1214. https://doi.org/10.3390/coatings11101214

APA StyleYan, J., Wang, X., Chen, K., & Lee, K. N. (2021). Sintering Modeling of Thermal Barrier Coatings at Elevated Temperatures: A Review of Recent Advances. Coatings, 11(10), 1214. https://doi.org/10.3390/coatings11101214