Effect of Preliminary Irradiation of 321 Steel Substrates with High-Intense Pulsed Ion Beams on Scratch Test Results of Subsequently Deposited AlN Coatings

Abstract

:1. Introduction

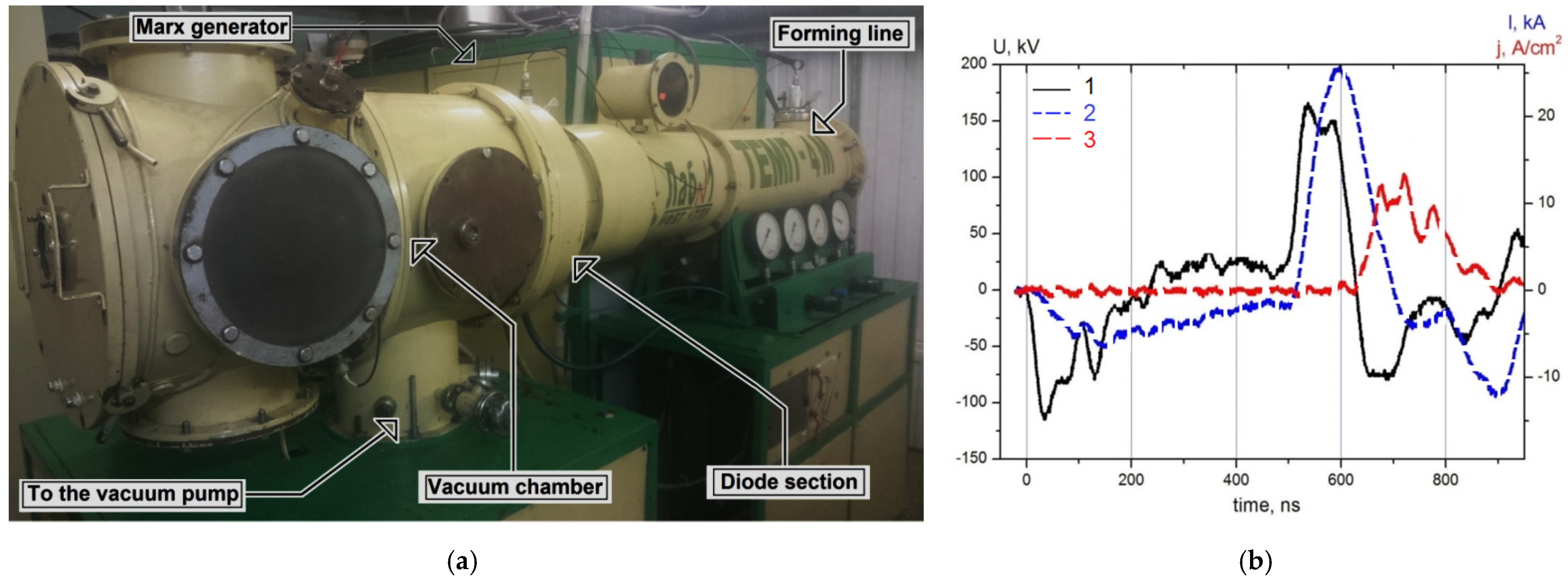

2. Materials and Methods

3. Results

3.1. Characteristics of the Trial AlN Coatings on the Silicon Substrates

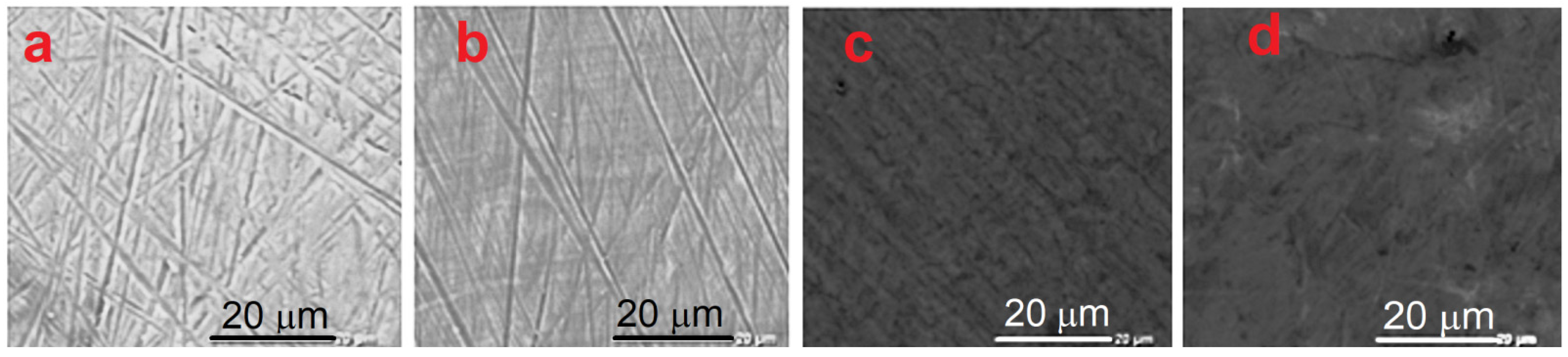

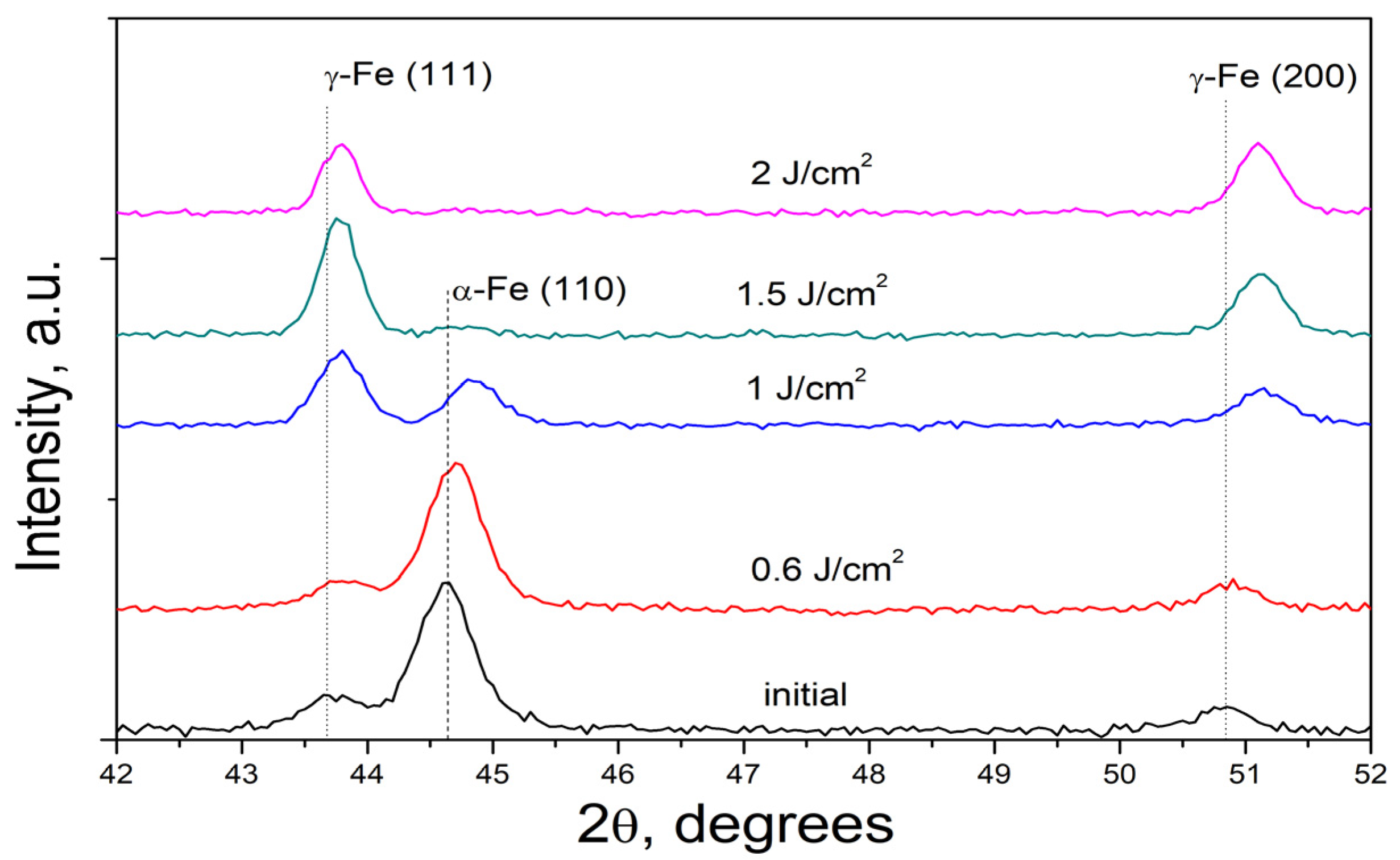

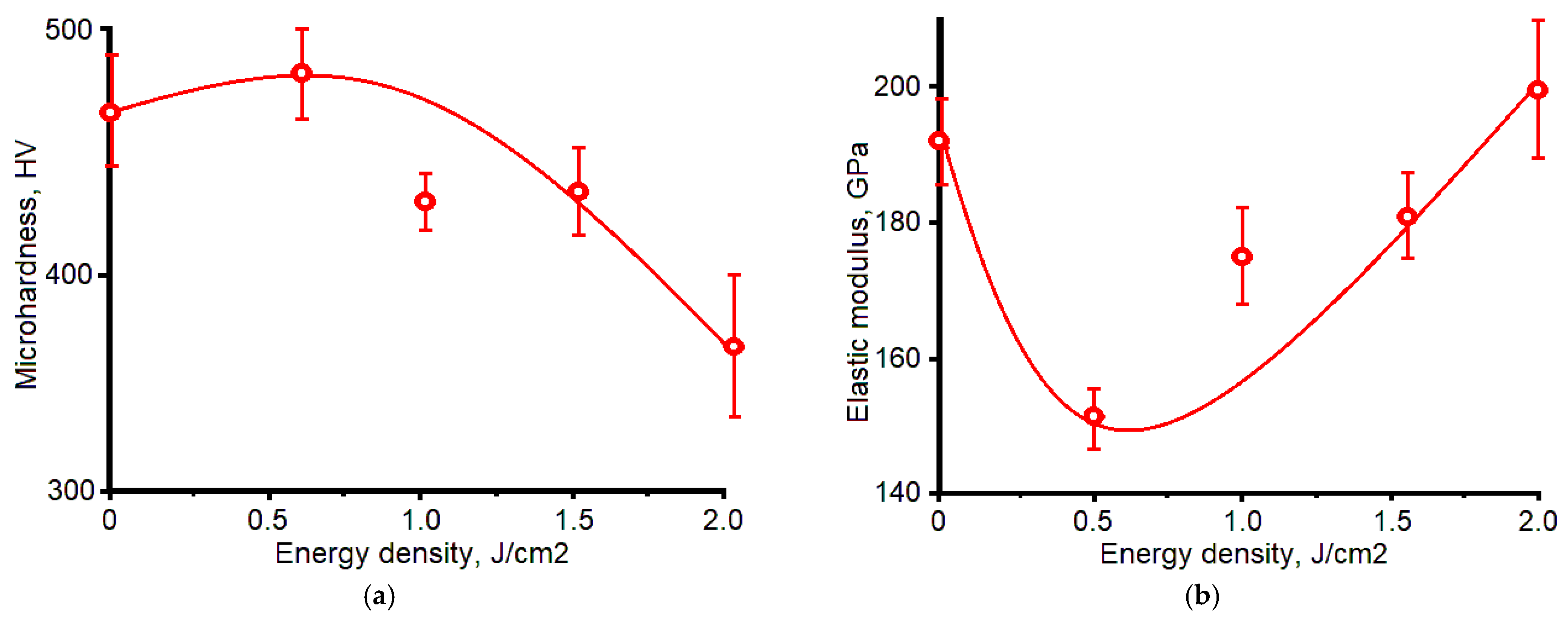

3.2. Properties of the Modified Layers on the 321 Steel Substrates

3.3. The Scratch Test Results of the AlN Coatings on the 321 Steel Substrates

4. Discussion

5. Conclusions

- HIPIB irradiation of the 321 steel surfaces caused partial melting of irregularities at the energy densities of 1.0 and 1.5 J/cm2 but full recrystallization of the surface layer at 2.0 J/cm2. As a result, roughness Ra of the modified surfaces increased by three times (from 20 up to 60 nm).

- With an increase in the energy density, the α-Fe phase content in the surface layers reduced with the corresponding increase in the γ-Fe amount, which was the only one found at 2.0 J/cm2. The γ-Fe lattice parameter decreased with an increase in the energy density up to 1.0 J/cm2 but slightly enhanced (up to 0.3587 nm) at 1.5 and 2.0 J/cm2. Microstrains rose much faster in the α-Fe phase than in the γ-Fe one.

- After HIPIB irradiation, the microhardness of the surface layers increased slightly at the minimum studied energy density of 0.6 J/cm2 and then decreased by 25% compared to the initial values, at the maximum level of 2.0 J/cm2. The elastic modulus values showed directly opposite dependences due to the reduced work-hardening effect.

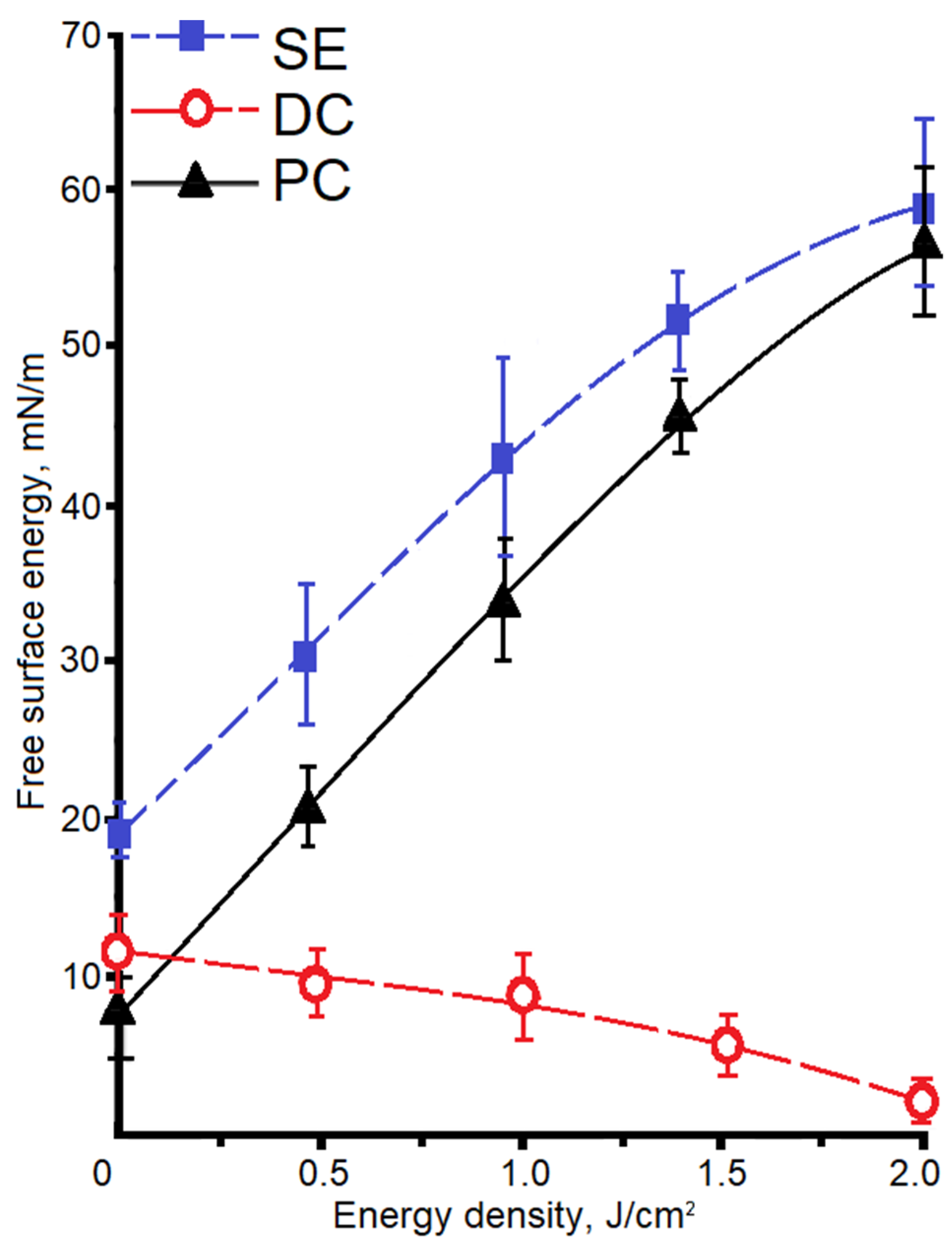

- The FSE values and their polar components monotonically increased over the entire studied range of the energy densities, which resulted in the chemical activity of the surfaces. However, suppression of the dispersed component was observed that decreased both residual stresses at the coating/substrate interfaces and Van der Waals forces.

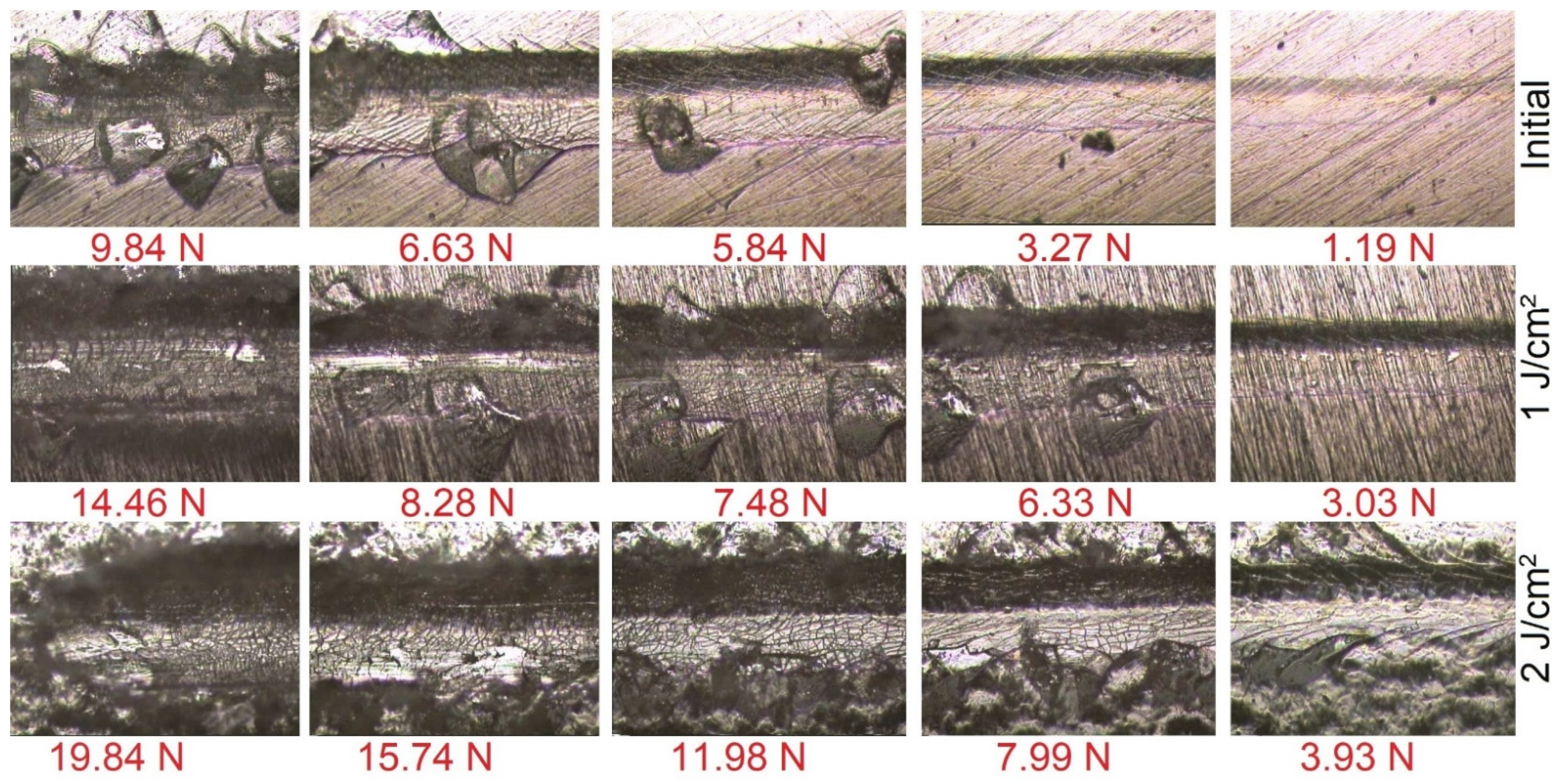

- During the scratch tests, the fracture threshold was 3 N for the AlN coating on the initial 321 steel substrate. HIPIB irradiation caused a shift at the beginning of the coating fracture up to 5 and 6 N at the energy densities of 2.0 and 1.0 J/cm2, respectively. The lower fracture threshold value in the case of 2.0 J/cm2 could be associated with the decrease in the substrate hardness and, as a consequence, its greater strains under the load.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rieu, J. Ceramic formation on metallic surfaces (ceramization) for medical applications. Clin. Mater. 1993, 12, 227–235. [Google Scholar] [CrossRef]

- Wolfe, D.; Singh, J. Functionally gradient ceramic/metallic coatings for gas turbine components by high-energy beams for high-temperature applications. J. Mater. Sci. 1998, 33, 3677–3692. [Google Scholar] [CrossRef]

- Agüero, A. Progress in the development of coatings for protection of new generation steam plant components. Energy Mater. 2008, 3, 35–44. [Google Scholar] [CrossRef]

- Mehran, Q.M.; Fazal, M.A.; Bushroa, A.R.; Rubaiee, S. A critical review on physical vapor deposition coatings applied on different engine components. Crit. Rev. Solid State Mater. Sci. 2018, 43, 158–175. [Google Scholar] [CrossRef]

- Aouadi, S.M.; Gu, J.; Berman, D. Self-healing ceramic coatings that operate in extreme environments: A review. J. Vac. Sci. Technol. A Vac. Surf. Film. 2020, 38, 050802. [Google Scholar] [CrossRef]

- Selvaraj, S.K.; Srinivasan, K.; Deshmukh, J.; Agrawal, D.; Mungilwar, S.; Jagtap, R.; Hu, Y.-C. Performance comparison of advanced ceramic cladding approaches via solid-state and traditional welding processes: A review. Materials 2020, 13, 5805. [Google Scholar] [CrossRef]

- Akahoshi, E.; Matsunaga, M.; Kimura, K.; Nakamura, K.; Balden, M.; Hishinuma, Y.; Chikada, T. Corrosion tests of multi-layer ceramic coatings in liquid lithium-lead. Fusion Eng. Design 2020, 160, 111874. [Google Scholar] [CrossRef]

- Wang, H.; Xiao, J.; Wang, H.; Chen, Y.; Yin, X.; Guo, N. Corrosion behavior and surface treatment of cladding materials used in high-temperature lead-bismuth eutectic alloy: A review. Coatings 2021, 11, 364. [Google Scholar] [CrossRef]

- Attarzadeh, N.; Molaei, M.; Babaei, K.; Fattah-alhosseini, A. New promising ceramic coatings for corrosion and wear protection of steels: A review. Surf. Interfaces 2021, 23, 100997. [Google Scholar] [CrossRef]

- Khatkhatay, F.; Jiao, L.; Jian, J.; Zhang, W.; Jiao, Z.; Gan, J.; Zhang, H.; Zhang, X.; Wang, H. Superior corrosion resistance properties of TiN-based coatings on Zircaloy tubes in supercritical water. J. Nucl. Mater. 2014, 451, 346–351. [Google Scholar] [CrossRef]

- Iwamoto, N.; Makino, Y.; Umesaki, N.; Endo, S.; Kobayashi, H. Effect of pretreatments of metals on bond adhesion. In Proceedings of the International Thermal Spraying Conference, Essen, Germany, 2–6 May 1983; DVS-Berichte: Duesseldorf, Germany, 1983; pp. 18–20. [Google Scholar]

- Aries, L.; Jalama, L.; Laaouini, A.; Roy, J. Preparation and characterisation of electrolytically deposited ceramic coating on stainless steel. Surf. Eng. 1998, 14, 235–239. [Google Scholar] [CrossRef]

- Chen, B.F.; Hwang, J.; Yu, G.P.; Huang, J.H. In situ observation of the cracking behavior of TiN coating on 304 stainless steel subjected to tensile strain. Thin Solid Film. 1999, 352, 173–178. [Google Scholar] [CrossRef]

- Ohmura, T.; Matsuoka, S. Evaluation of mechanical properties of ceramic coatings on a metal substrate. Surf. Coat. Technol. 2003, 169–170, 728–731. [Google Scholar] [CrossRef]

- Pugal Mani, S.; Srinivasan, A.; Rajendran, N. Effect of nitrides on the corrosion behaviour of 316L SS bipolar plates for Proton Exchange Membrane Fuel Cell (PEMFC). Int. J. Hydrog. Energy 2015, 40, 3359–3369. [Google Scholar] [CrossRef]

- Lee, S.H.; Woo, S.P.; Kakati, N.; Lee, Y.N.; Yoon, Y.S. Corrosion and electrical properties of carbon/ceramic multilayer coated on stainless steel bipolar plates. Surf. Coat. Technol. 2016, 303, 162–169. [Google Scholar] [CrossRef]

- Omrani, M.; Habibi, M.; Saeed, M.; Birjandi, M. Enhanced electrical conductivity of two layers AlN-TiN coating on SS316L as bipolar plate using plasma focus device. Int. J. Hydrog. Energy 2016, 41, 5028–5036. [Google Scholar] [CrossRef]

- Cubillos, G.I.; Bethencourt, M.; Alfonso, J.E.; Rodríguez-Castellón, E.; Romero, E. Porosity reduction in new thin films of ceramic coatings on stainless steel by annealing at reduced pressure. Metall. Mater. Trans. A 2018, 49, 5858–5870. [Google Scholar] [CrossRef]

- Yi, P.; Zhu, L.; Dong, C.; Xiao, K. Corrosion and interfacial contact resistance of 316L stainless steel coated with magnetron sputtered ZrN and TiN in the simulated cathodic environment of a proton-exchange membrane fuel cell. Surf. Coat. Technol. 2019, 363, 198–202. [Google Scholar] [CrossRef]

- Huang, J.-H.; Kuo, K.-L.; Yu, G.-P. Oxidation behavior and corrosion resistance of vacuum annealed ZrN-coated stainless steel. Surf. Coat. Technol. 2019, 358, 308–319. [Google Scholar] [CrossRef]

- Sharma, G.S.; Sugavaneswaran, M.; Vijayalakshmi, U.; Prakash, R. Influence of γ-alumina coating on surface properties of direct metal laser sintered 316L stainless steel. Ceram. Int. 2019, 45, 13456–13463. [Google Scholar] [CrossRef]

- Andrei, V.A.; Radulescu, C.; Malinovschi, V.; Marin, A.; Coaca, E.; Mihalache, M.; Mihailescu, C.N.; Dulama, I.D.; Teodorescu, S.; Bucurica, I.A. Aluminum oxide ceramic coatings on 316L austenitic steel obtained by plasma electrolysis oxidation using a pulsed unipolar power supply. Coatings 2020, 10, 318. [Google Scholar] [CrossRef] [Green Version]

- Zaborowska, A.; Kurpaska, Ł.; Wyszkowska, E.; Clozel, M.; Vanazzi, M.; Di Fonzo, F.; Turek, M.; Jóźwik, I.; Kosińska, A.; Jagielski, J. Influence of ion irradiation on the nanomechanical properties of thin alumina coatings deposited on 316L SS by PLD. Surf. Coat. Technol. 2020, 386, 125491. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H. High temperature erosion behavior of plasma sprayed Al2O3 coating on AISI-304 stainless steel. World J. Eng. 2021. [Google Scholar] [CrossRef]

- Leng, Y.; Ming, P.; Yang, D.; Zhang, C. Stainless steel bipolar plates for proton exchange membrane fuel cells: Materials, flow channel design and forming processes. J. Power Sources 2020, 451, 227783. [Google Scholar] [CrossRef]

- Buckley, D.H. The role of material properties in adhesion. In Proceedings of the Fall Meeting of the Materials Research Society, Boston, MA, USA, 26–30 November 1984; pp. 1–26. [Google Scholar]

- Finnis, M.W. Metal-ceramic cohesion and the image interaction. Acta Metall. Mater. 1992, 40, S25–S37. [Google Scholar] [CrossRef]

- Howe, J.M. Bonding, structure, and properties of metal/ceramic interfaces. Part 1. Chemical bonding, chemical reaction, and interfacial structure. Int. Mater. Rev. 1993, 38, 233–256. [Google Scholar] [CrossRef]

- Howe, J.M. Bonding, structure, and properties of metal/ceramic interfaces. Part 2. Interface fracture behaviour and property measurement. Int. Mater. Rev. 1993, 38, 257–271. [Google Scholar] [CrossRef]

- Finnis, M.W. The theory of metal-ceramic interfaces. J. Phys. Condens. Matter 1996, 8, 5811–5836. [Google Scholar] [CrossRef]

- Li, J.-G. Energetics of metal/ceramic interfaces, metal-semiconductor Schottky contacts, and their relationship. Mater. Chem. Phys. 1997, 47, 126–145. [Google Scholar] [CrossRef]

- Liu, L.M.; Wang, S.Q.; Ye, H.Q. Atomic and electronic structures of the lattice mismatched metal-ceramic interface. J. Phys. Condens. Matter 2004, 16, 5781–5790. [Google Scholar] [CrossRef]

- Gerberich, W.W.; Cordill, M.J. Physics of adhesion. Rep. Prog. Phys. 2006, 69, 2157–2203. [Google Scholar] [CrossRef]

- Siddiq, A.; Schmauder, S.; Ruehle, M. Niobium/alumina bicrystal interface fracture: A theoretical interlink between local adhesion capacity and macroscopic fracture energies. Eng. Fract. Mech. 2008, 75, 2320–2332. [Google Scholar] [CrossRef]

- Poklad, A.; Klemm, V.; Schreiber, G.; Wustefeld, C.; Rafaja, D. Microstructure investigation of the PVD thin films of TRIP steels. Solid State Phenom. 2010, 160, 273–279. [Google Scholar] [CrossRef] [Green Version]

- Siddiq, A.; Schmauder, S. Multiscale simulation of metal/ceramic interface fracture. In Proceedings of the IUTAM Symposium on Multi-Functional Material Structures and Systems, Bangalore, India, 10–12 December 2008; Dattaguru, B., Gopalakrishnan, S., Aatre, V., Eds.; Springer: Dordrecht, Germany, 2010; Volume 19, pp. 343–355. [Google Scholar] [CrossRef]

- Miculescu, M.; Bane, M.; Miculescu, F.; Ciocan, L.T.; Preda, O.; Antoniac, I. A study on metal-ceramic interface on metal base dental alloys. Key Eng. Mater. 2014, 638, 14–19. [Google Scholar] [CrossRef]

- Feldbauer, G.; Wolloch, M.; Bedolla, P.O.; Mohn, P.; Redinger, J.; Vernes, A. Adhesion and material transfer between contacting Al and TiN surfaces from first principles. Phys. Rev. B Condens. Matter Mater. Phys. 2015, 91, 165413. [Google Scholar] [CrossRef] [Green Version]

- Mu, Y.; Zhang, X.; Hutchinson, J.W.; Meng, W.J. Measuring critical stress for shear failure of interfacial regions in coating/interlayer/substrate systems through a micro-pillar testing protocol. J. Mater. Res. 2017, 32, 1421–1431. [Google Scholar] [CrossRef] [Green Version]

- Lin, Z.; Peng, X.; Fu, T.; Zhao, Y.; Feng, C.; Huang, C.; Wang, Z. Atomic structures and electronic properties of interfaces between aluminum and carbides/nitrides: A first-principles study. Phys. E Low-Dimens. Syst. Nanostruct. 2017, 89, 15–20. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, B.; Mu, Y.; Shao, S.; Wick, C.D.; Ramachandran, B.R.; Meng, W.J. Mechanical failure of metal/ceramic interfacial regions under shear loading. Acta Mater. 2017, 138, 224–236. [Google Scholar] [CrossRef]

- Iwasaki, T. Efficient optimum design of metal with strong adhesion to ceramics with a combination of orthogonal array and response-surface method. J. Soc. Mater. Sci. 2018, 67, 803–810. [Google Scholar] [CrossRef]

- Zhang, X.; Mu, Y.; Dodaran, M.; Shao, S.; Moldovan, D.; Meng, W.J. Mechanical failure of CrN/Cu/CrN interfacial regions under tensile loading. Acta Mater. 2018, 160, 1–13. [Google Scholar] [CrossRef]

- Liu, X.; Dong, H.; Lv, X.; Hu, N.; Wen, L.; Yang, Z. First-principle study of interfacial properties between γ-TiAl and TiC, VN. Mol. Simul. 2019, 45, 50–57. [Google Scholar] [CrossRef]

- Mohammad Miraz, A.S.; Sun, S.; Shao, S.; Meng, W.J.; Ramachandran, B.R.; Wick, C.D. Computational study of metal/ceramic interfacial adhesion and barriers to shear displacement. Comput. Mater. Sci. 2019, 168, 104–115. [Google Scholar] [CrossRef]

- Mei, Z.-G.; Bhattacharya, S.; Yacout, A.M. Adhesion of ZrN and Al2O3 coatings on U metal from first-principles. Appl. Surf. Sci. 2019, 473, 121–126. [Google Scholar] [CrossRef]

- Guan, X.; Wang, Y.; Xue, Q. Effects of constituent layers and interfaces on the mechanical and tribological properties of metal (Cr, Zr)/ceramic (CrN, ZrN) multilayer systems. Appl. Surf. Sci. 2020, 502, 144305. [Google Scholar] [CrossRef]

- Li, R.; Chen, Q.; Zhang, Z.; Ouyang, L.; Zhang, Y.; Nie, B.; Ding, Y. Revealing the atomic-scale structure and the fracture mechanism of the α-Al2O3/γ-Fe ceramic-metal interface. J. Alloy. Compd. 2021, 885, 161163. [Google Scholar] [CrossRef]

- Miraz, A.S.M.; Meng, W.J.; Ramachandran, B.R.; Wick, C.D. Computational observation of the strengthening of Cu/TiN metal/ceramic interfaces by sub-nanometer interlayers and dopants. Appl. Surf. Sci. 2021, 554, 149562. [Google Scholar] [CrossRef]

- Imbriglio, S.I.; Chromik, R.R. Factors affecting adhesion in metal/ceramic interfaces created by cold spray. J. Therm. Spray Technol. 2021. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, F.; Cao, L.; Du, Y.; Li, B.; Li, J.; Xu, Y. Investigation of indentation response, scratch resistance, and wear behavior of tungsten carbide coatings fabricated by two-step interstitial carburization on tungsten. Ceram. Int. 2021. [Google Scholar] [CrossRef]

- Lyubimov, V.V.; Voevodin, A.A.; Spassky, S.E.; Yerokhin, A.L. Stress analysis and failure possibility assessment of multilayer physically vapour deposited coatings. Thin Solid Film. 1992, 207, 117–125. [Google Scholar] [CrossRef]

- Skalka, P.; Slámečka, K.; Pokluda, J.; Čelko, L. Finite element simulation of stresses in a plasma-sprayed thermal barrier coating with a crack at the TGO/bond-coat interface. Surf. Coat. Technol. 2018, 337, 321–334. [Google Scholar] [CrossRef]

- Muraoka, S.; Tateno, M. Dependence of bonding strength and variations in residual stress on interface wedge angles and bonding temperature conditions. MRS Adv. 2020, 5, 1765–1774. [Google Scholar] [CrossRef]

- Mehboob, G.; Liu, M.-J.; Xu, T.; Hussain, S.; Mehboob, G.; Tahir, A. A review on failure mechanism of thermal barrier coatings and strategies to extend their lifetime. Ceram. Int. 2020, 46, 8497–8521. [Google Scholar] [CrossRef]

- Tabor, D. Future directions of research in adhesion and friction. In Proceedings of the Tribology International Conference, Cleveland, OH, USA, 18–21 April 1983; NASA: Washington, DC, USA, 1984; Volume 2, pp. 119–142. [Google Scholar]

- Takadoum, J.; Houmid Bennani, H. Influence of substrate roughness and coating thickness on adhesion, friction and wear of TiN films. Surf. Coat. Technol. 1997, 96, 272–282. [Google Scholar] [CrossRef]

- Giouse, J.-B.; White, K.; Tromas, C. Nanoindentation characterization of the surface mechanical properties of a 17-4PH stainless steel substrate treated with grit blasting and coated with a Cr3C2-NiCr coating. Surf. Coat. Technol. 2019, 368, 119–125. [Google Scholar] [CrossRef]

- Parchovianský, M.; Parchovianská, I.; Švančárek, P.; Motz, G.; Galusek, D. PDC glass/ceramic coatings applied to differently pretreated AISI441 stainless steel substrates. Materials 2020, 13, 629. [Google Scholar] [CrossRef] [Green Version]

- Inan, Ö.; Acar, A.; Halkaci, S. Effects of sandblasting and electrical discharge machining on porcelain adherence to cast and machined commercially pure titanium. J. Biomed. Mater. Res. Part B Appl. Biomater. 2006, 78, 393–400. [Google Scholar] [CrossRef]

- Troia, M.G., Jr.; Henriques, G.E.P.; Mesquita, M.F.; Fragoso, W.S. The effect of surface modifications on titanium to enable titanium-porcelain bonding. Dent. Mater. 2008, 24, 28–33. [Google Scholar] [CrossRef]

- Mittal, K.L.; Lei, W.-S. (Eds.) Laser Technology: Applications in Adhesion and Related Areas; Scrivener Publishing: Beverly, MA, USA, 2018. [Google Scholar] [CrossRef]

- Kromer, R.; Danlos, Y.; Aubignat, E.; Verdy, C.; Costil, S. Coating deposition and adhesion enhancements by laser surface texturing—metallic particles on different classes of substrates in cold spraying process. Mater. Manuf. Process. 2017, 32, 1642–1652. [Google Scholar] [CrossRef]

- Jang, K.-B.; Mhin, S.; Lim, S.-C.; Song, Y.-S.; Lee, K.-H.; Park, S.-K.; Moon, K.-I.; Lee, S.H.; Hyun, S.-K. Room temperature bonding on interface between metal and ceramic. J. Electron. Mater. 2019, 48, 72–78. [Google Scholar] [CrossRef]

- Legg, K.O. Surface engineering with ion-assisted coatings. Nucl. Instrum. Methods Phys. Res. B 1987, 24–25, 565–567. [Google Scholar] [CrossRef]

- Baglin, J.E.E. Thin film bonding using ion beam techniques—A review. IBM J. Res. Dev. 1994, 38, 413–422. [Google Scholar] [CrossRef]

- Escobar Galindo, R.; van Veen, A.; Schut, H.; Janssen, G.C.A.M.; Hoy, R.; de Hosson, J.T.M. Adhesion behaviour of CrNx coatings on pre-treated metal substrates studied in situ by PBA and ESEM after annealing. Surf. Coat. Technol. 2005, 199, 57–65. [Google Scholar] [CrossRef] [Green Version]

- Remnev, G.E.; Isakov, I.F.; Opekounov, M.S.; Matvienko, V.M.; Ryzhkov, V.A.; Struts, V.K.; Grushin, I.I.; Zakoutayev, A.N.; Potyomkin, A.V.; Tarbokov, V.A.; et al. High intensity pulsed ion beam sources and their industrial applications. Surf. Coat. Technol. 1999, 114, 206–212. [Google Scholar] [CrossRef]

- Remnev, G.E.; Tarbokov, V.A. Increasing the durability of carbide tools by pretreatment with a powerful ion beam and deposition of titanium nitride coating. Phys. Mesomech. 2004, 7, 329–332. (In Russian) [Google Scholar]

- Liu, X.; Mei, X.; Qiang, J.; Remnev, G.E.; Wang, Y. Effects on structure and properties of Zr55Al10Cu30Ni5 metallic glass irradiated by high intensity pulsed ion beam. Appl. Surf. Sci. 2014, 313, 911–917. [Google Scholar] [CrossRef]

- Ma, X.; Zhang, G.; Wang, G.; Zhu, G.; Zhou, W.; Wang, J.; Sun, B. Surface morphology, microstructure and properties of as-cast AZ31 magnesium alloy irradiated by high intensity pulsed ion beams. Appl. Surf. Sci. 2014, 311, 567–573. [Google Scholar] [CrossRef]

- Li, P.; Zou, Y.; Zhang, Z.P. Influence of high-intensity pulsed ion beam irradiation energy on magnesium alloy surface modification. Vacuum 2015, 117, 8–11. [Google Scholar] [CrossRef]

- Lei, M.K.; Zhu, X.P.; Li, Y.P.; Guo, D.M. Significance of surface integrity on high-performance manufacturing by surface modification. Int. J. Adv. Manuf. Technol. 2016, 82, 1831–1842. [Google Scholar] [CrossRef]

- Mei, X.; Zhang, X.; Liu, X.; Wang, Y. Effect on structure and mechanical property of tungsten irradiated by high intensity pulsed ion beam. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2017, 406, 697–702. [Google Scholar] [CrossRef]

- Han, X.G.; Lv, J.F.; Chen, Y.Z.; Shan, Y.C.; Xu, J.J. Influence of irradiation intensity on corrosion properties of microarc oxidation film on AZ31 magnesium alloy with HIPIB. Anti-Corrosion Methods Mater. 2019, 66, 418–424. [Google Scholar] [CrossRef]

- Nazipov, R.A.; Batalov, R.I.; Bayazitov, R.M.; Novikov, H.A.; Shustov, V.A.; Dulov, E.N. High-intensity pulsed ion beam treatment of amorphous iron-based metal alloy. J. Phys Conf. Ser. 2020, 1588, 012039. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, L.; Guan, T.; Zhang, X.; Remnev, G.E.; Pavlov, S.K.; Wang, Y.; Mei, X. Effect on mechanics properties and microstructure of molybdenum by high intensity pulsed ion beam irradiation. Surf. Coat. Technol. 2020, 384, 125333. [Google Scholar] [CrossRef]

- Slobodyan, M.S.; Pavlov, S.K.; Remnev, G.E. Corrosion and high-temperature steam oxidation of E110 alloy and its laser welds after ion irradiation. Corros. Sci. 2019, 152, 60–74. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, J.; Shen, J.; Liang, G.; Zhang, S.; Xu, M.; Yu, X.; Yan, S.; Remnev, G.E.; Le, X. Dynamic mechanism of crater formation induced by inclusion during intense pulsed ion beam irradiation. Vacuum 2020, 179, 109541. [Google Scholar] [CrossRef]

- Zhidkov, M.V.; Gazizova, M.Y.; Ligachev, A.E.; Pavlov, S.K.; Remnev, G.E. Structure and corrosion properties of stainless steel after high-power ion beam processing. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1014, 012061. [Google Scholar] [CrossRef]

- RussianGost. Russian State Standard GOST 58175-2014 Stainless Steels and Corrosion Resisting, Heat-resisting and Creep Resisting Alloys. Grades; RussianGost: Moscow, Russia, 2014. (In Russian) [Google Scholar]

- Davis, J.R. ASM Specialty Handbook—Stainless Steels; ASM International: Materials Park, OH, USA, 1994. [Google Scholar]

- Panda, P.; Ramaseshan, R.; Ravi, N.; Mangamma, G.; Jose, F.; Dash, S.; Suzuki, K.; Suematsu, H. Reduction of residual stress in AlN thin films synthesized by magnetron sputtering technique. Mater. Chem. Phys. 2017, 200, 78–84. [Google Scholar] [CrossRef] [Green Version]

- Stoney, G.G. The tension of metallic films deposited by electrolysis. Proc. R. Soc. Lond. A 1909, 82, 172–175. [Google Scholar]

- Hopcroft, M.A.; Nix, W.D.; Kenny, T.W. What is the Young’s Modulus of Silicon? J. Microelectromech. Syst. 2010, 19, 229–238. [Google Scholar] [CrossRef] [Green Version]

- Klug, H.P.; Alexander, L.E. X-ray Diffraction Procedures; John Wiley & Sons Inc.: Hoboken, NJ, USA, 1974. [Google Scholar]

- Attar, F.; Ericsson, T. Adhesion evaluation of metallic and ceramic coatings during straining of a steel substrate: Flaking and crack behavior. Scand. J. Metall. 1994, 23, 94–102. [Google Scholar]

- Hadef, Z.; Doghmane, A.; Kamli, K. Acoustical investigation of adhesion in liquid metal–ceramic interfaces. Metallofiz. Noveishie Tekhnologii 2018, 40, 955–965. [Google Scholar] [CrossRef]

- Paredes, V.I.O.; Gómez, M.P.; Dócimo, L.; Nieva, N.; Pumarega, M.I.L. Analysis of acoustic emission waveform signals produced in test on ceramo-metallics interfaces. Rev. Mater. 2018, 23, e12122. [Google Scholar] [CrossRef] [Green Version]

- Kamli, K.; Hadef, Z.; Gacem, A.; Houaidji, N. Prediction of adhesion energy terms in metal/ceramic systems by using acoustic parameters. Metallofiz. Noveishie Tekhnologii 2020, 42, 717–730. [Google Scholar] [CrossRef]

- Slobodyan, M. High-energy surface processing of zirconium alloys for fuel claddings of water-cooled nuclear reactors. Nucl. Eng. Des. 2021, 382, 111364. [Google Scholar] [CrossRef]

- Martin, P.M. Handbook Deposition Technologies for Film Coatings; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Gentleman, M.M.; Gentleman, E. The role of surface free energy in osteoblast-biomaterial interactions. Int. Mater. Rev. 2014, 59, 417–429. [Google Scholar] [CrossRef]

- Ichimura, H.; Ishii, Y. Effects of indenter radius on the critical load in scratch testing. Surf. Coat. Technol. 2003, 165, 1–7. [Google Scholar] [CrossRef]

| Modes | Deposition Temperature, °C | Coating Thickness, μm | Substrate Bending Radius, m | Average Stresses in Coating, GPa (‘+’ Is Tensile, ‘−’ Is Compressive) | Lattice Parameters | Microstrains, % | |

|---|---|---|---|---|---|---|---|

| a, nm | c, nm | ||||||

| 1 | 120 | 5.7 | 9.0 | +0.1 | 0.31140 ± 0.00050 | 0.49820 ± 0.00080 | 0.184 ± 0.015 |

| 2 | 280 | 4.6 | −20.0 | −0.1 | 0.31170 ± 0.00050 | 0.50160 ± 0.00070 | 0.920 ± 0.180 |

| 3 | 500 | 4.2 | −1.6 | −0.8 | 0.31237 ± 0.00009 | 0.49980 ± 0.00015 | 0.372 ± 0.017 |

| HIPIB Energy Density, J/cm2 | Lattice Parameter a, nm | α-Fe/γ-Fe Ratio | Microstrains, % | ||

|---|---|---|---|---|---|

| α-Fe | γ-Fe | α-Fe | γ-Fe | ||

| initial | 0.2873 | 0.3593 | 40/60 | 0.41 | 0.00 |

| 0.6 | 0.2869 | 0.3590 | 41/59 | 0.42 | 0.05 |

| 1.0 | 0.2858 | 0.3585 | 27/73 | 1.00 | 0.10 |

| 1.5 | – | 0.3587 | 2/98 | – | 0.17 |

| 2.0 | – | 0.3587 | 3/97 | – | 0.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tarbokov, V.; Pavlov, S.; Smolyanskiy, E.; Uglov, V.; Slobodyan, M.; Remnev, G. Effect of Preliminary Irradiation of 321 Steel Substrates with High-Intense Pulsed Ion Beams on Scratch Test Results of Subsequently Deposited AlN Coatings. Coatings 2021, 11, 1169. https://doi.org/10.3390/coatings11101169

Tarbokov V, Pavlov S, Smolyanskiy E, Uglov V, Slobodyan M, Remnev G. Effect of Preliminary Irradiation of 321 Steel Substrates with High-Intense Pulsed Ion Beams on Scratch Test Results of Subsequently Deposited AlN Coatings. Coatings. 2021; 11(10):1169. https://doi.org/10.3390/coatings11101169

Chicago/Turabian StyleTarbokov, Vladislav, Sergey Pavlov, Egor Smolyanskiy, Vladimir Uglov, Mikhail Slobodyan, and Gennady Remnev. 2021. "Effect of Preliminary Irradiation of 321 Steel Substrates with High-Intense Pulsed Ion Beams on Scratch Test Results of Subsequently Deposited AlN Coatings" Coatings 11, no. 10: 1169. https://doi.org/10.3390/coatings11101169

APA StyleTarbokov, V., Pavlov, S., Smolyanskiy, E., Uglov, V., Slobodyan, M., & Remnev, G. (2021). Effect of Preliminary Irradiation of 321 Steel Substrates with High-Intense Pulsed Ion Beams on Scratch Test Results of Subsequently Deposited AlN Coatings. Coatings, 11(10), 1169. https://doi.org/10.3390/coatings11101169