Thermal Analysis and Optimization of Nano Coated Radiator Tubes Using Computational Fluid Dynamics and Taguchi Method

Abstract

1. Introduction

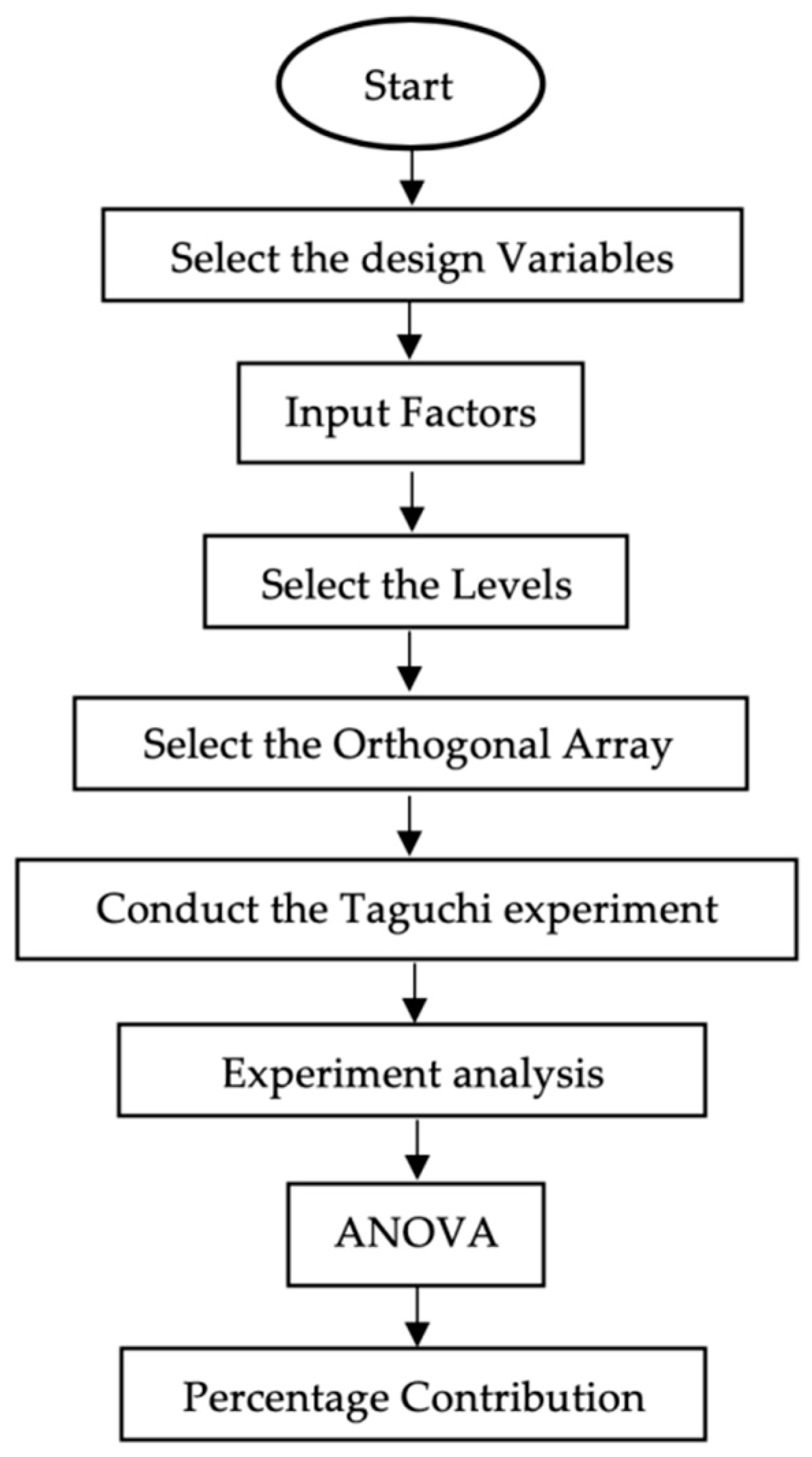

2. Taguchi Method

3. Analysis of Variance (ANOVA)

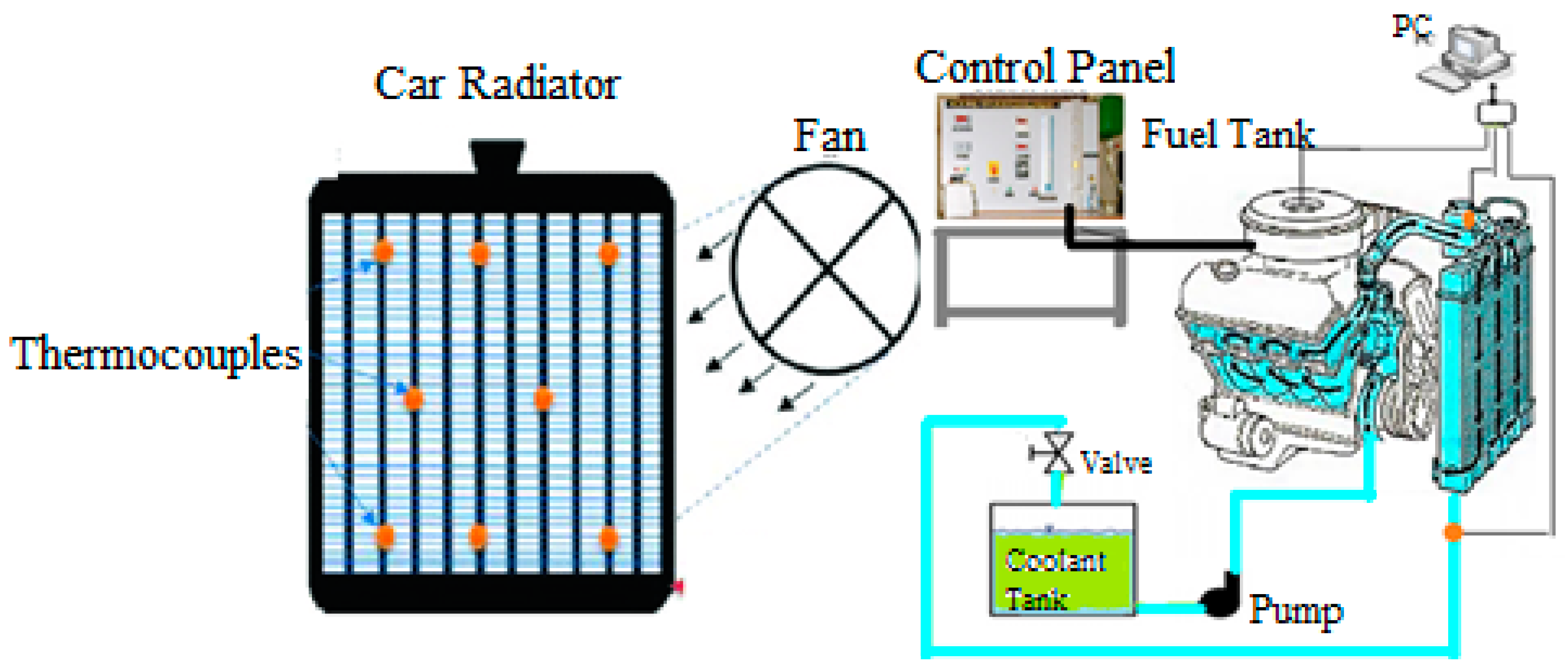

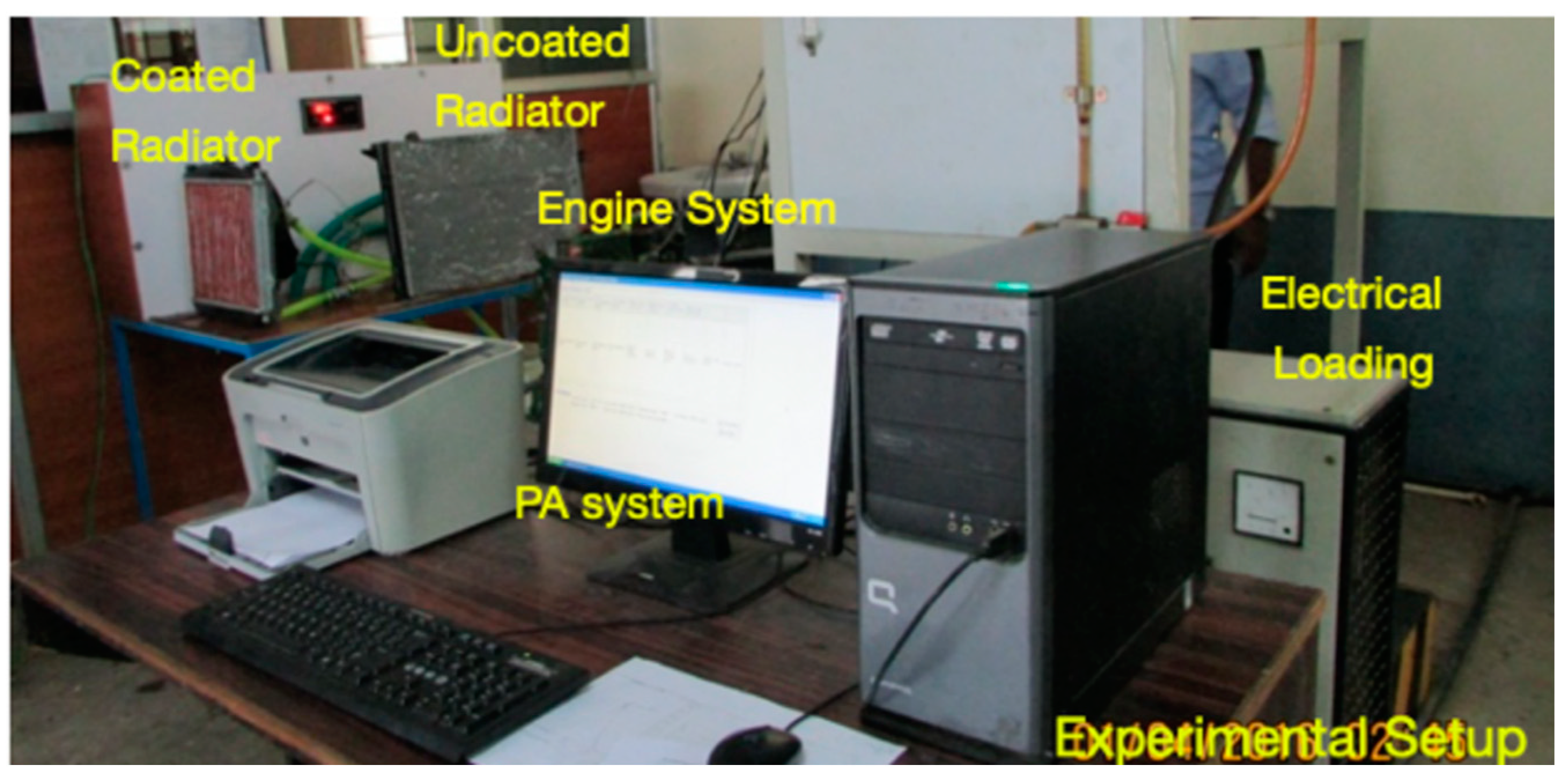

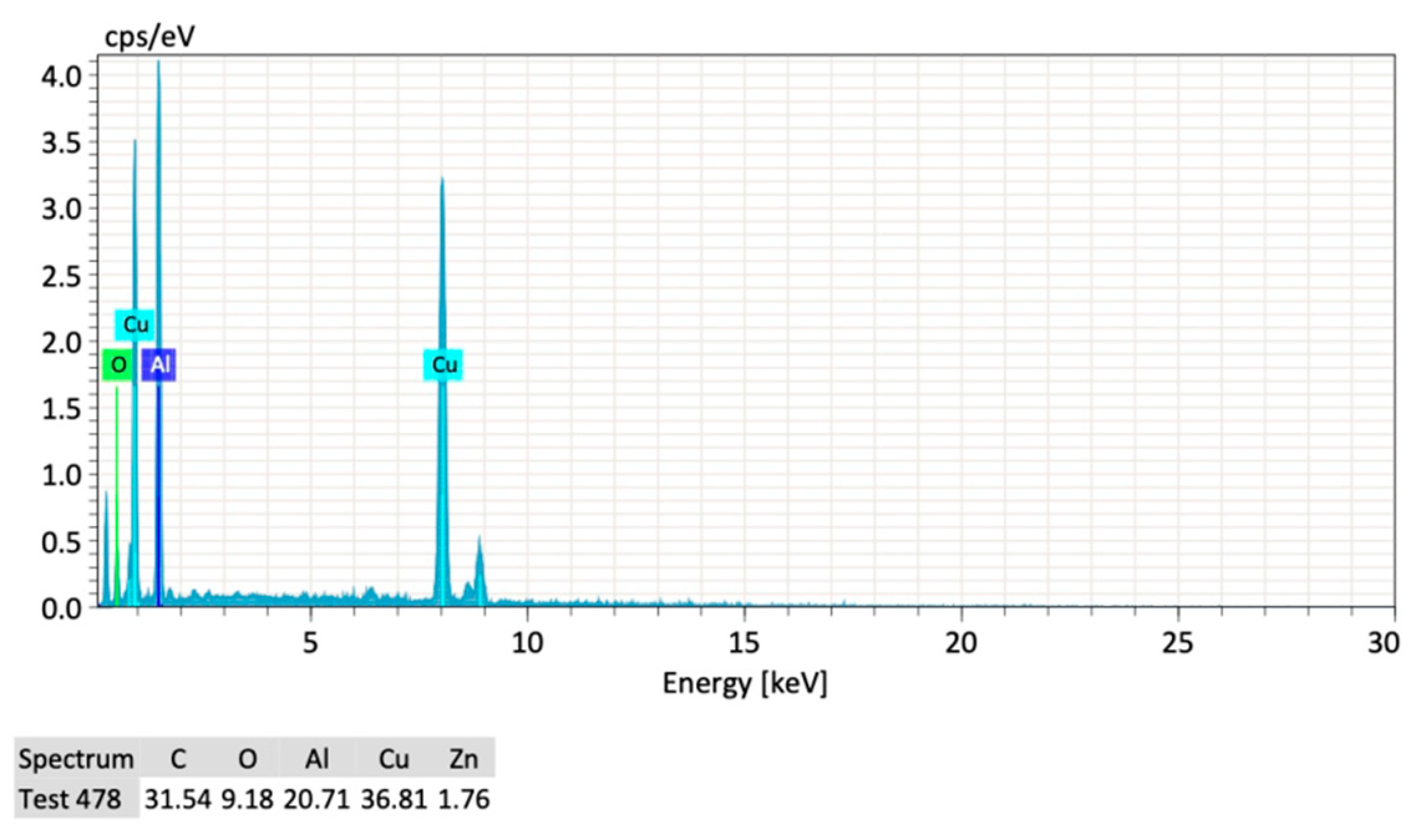

4. Result Conversion to S/N Ratios

5. Experimental Setup

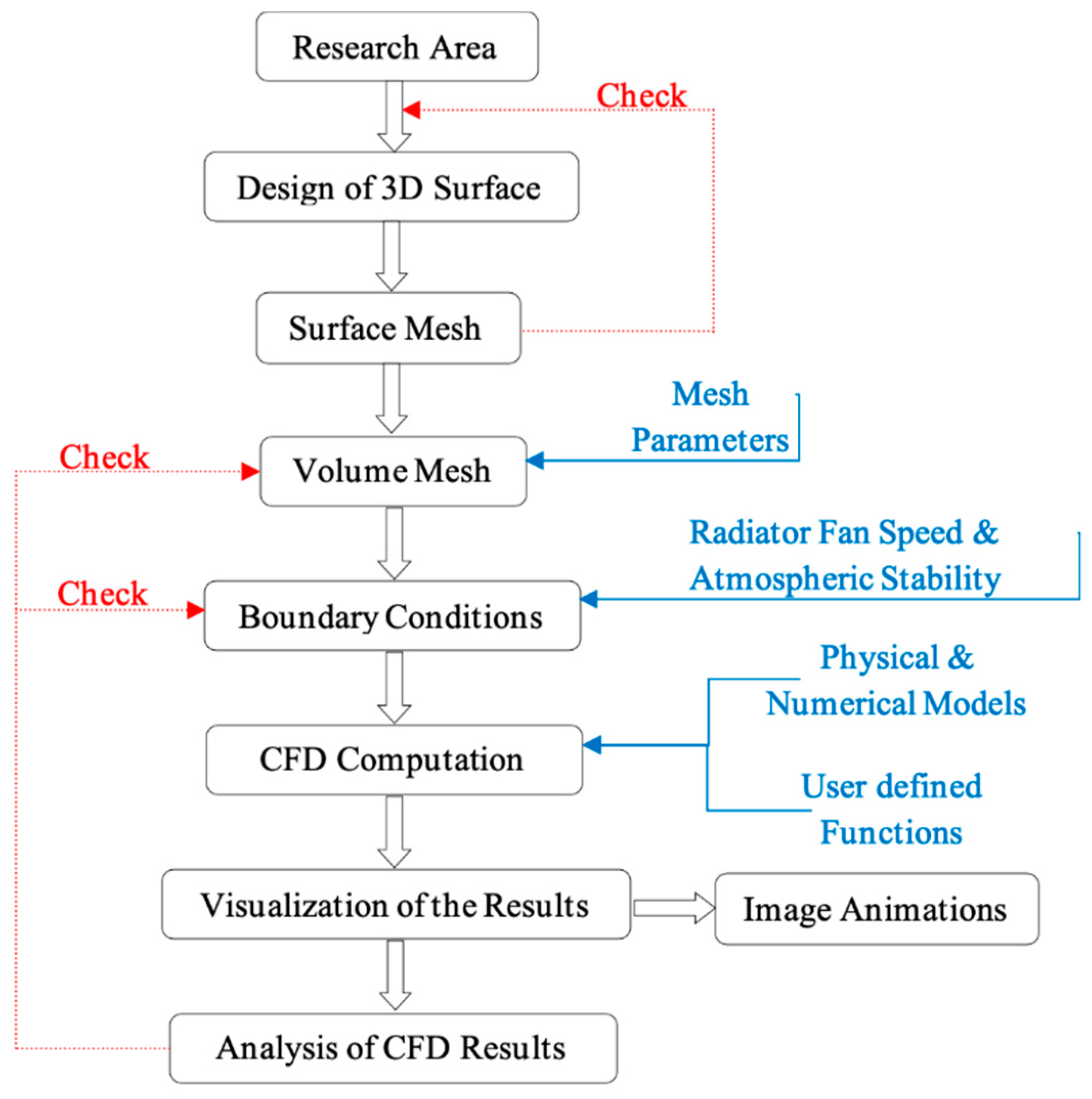

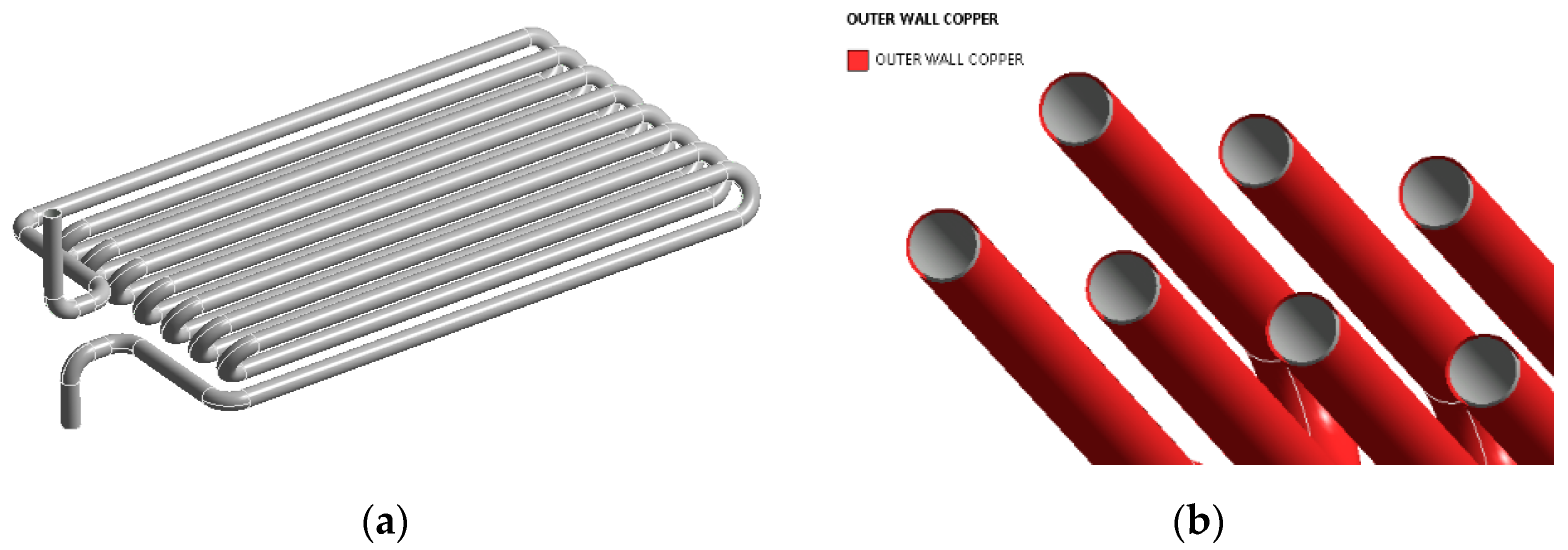

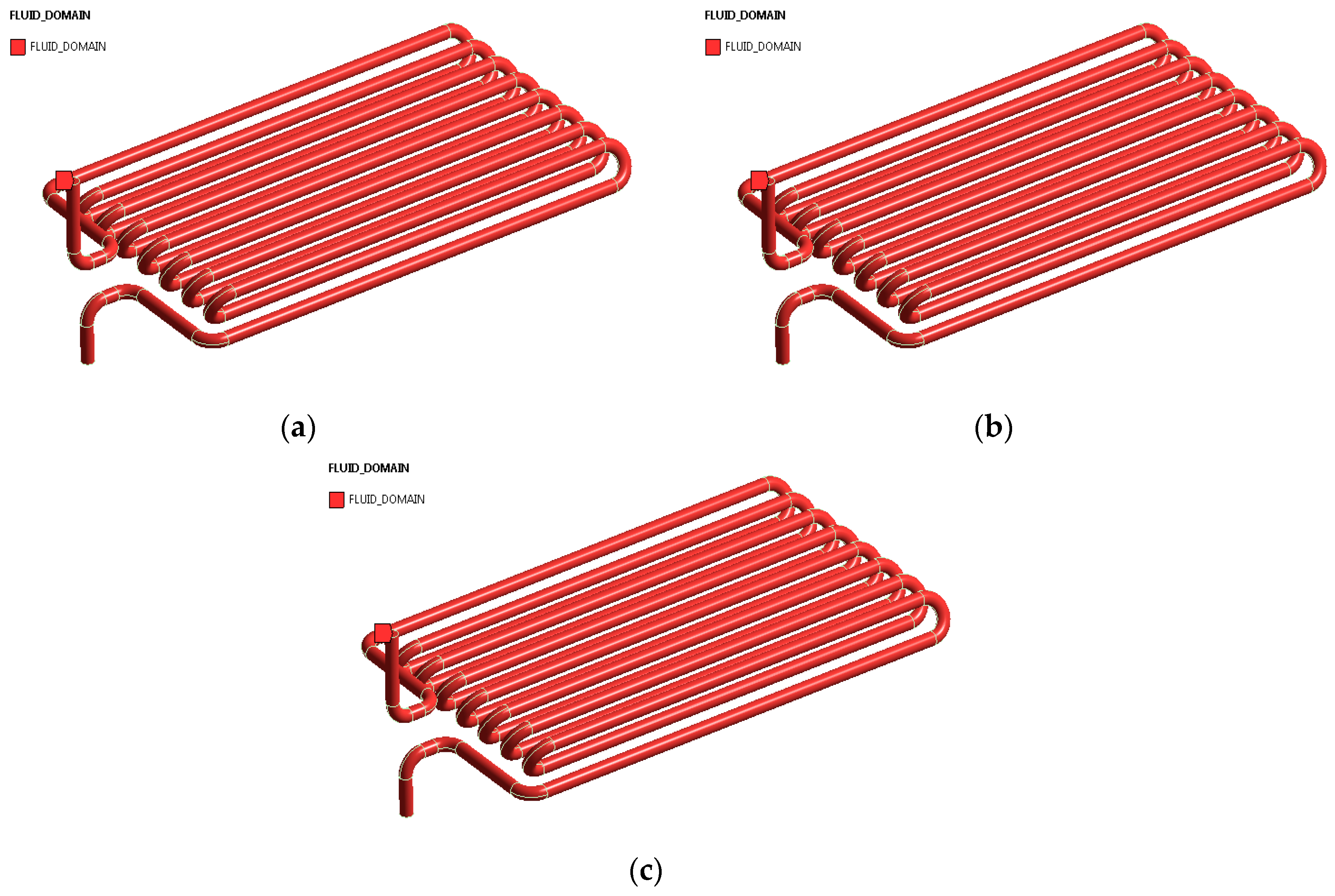

6. CFD Model Analysis

7. Geometry

8. Mesh

9. Physical Models

- Two Layer All and Wall Treatment

- Realizable K-Epsilon

- Two Layer Reynolds-Mean

10. Boundary Conditions

| Coolant Inlet | Mass Flow Rate |

| Coolant Outlet | Pressure Outlet |

| Air Inlet | Velocity Inlet |

| Air Outlet | Velocity Outlet |

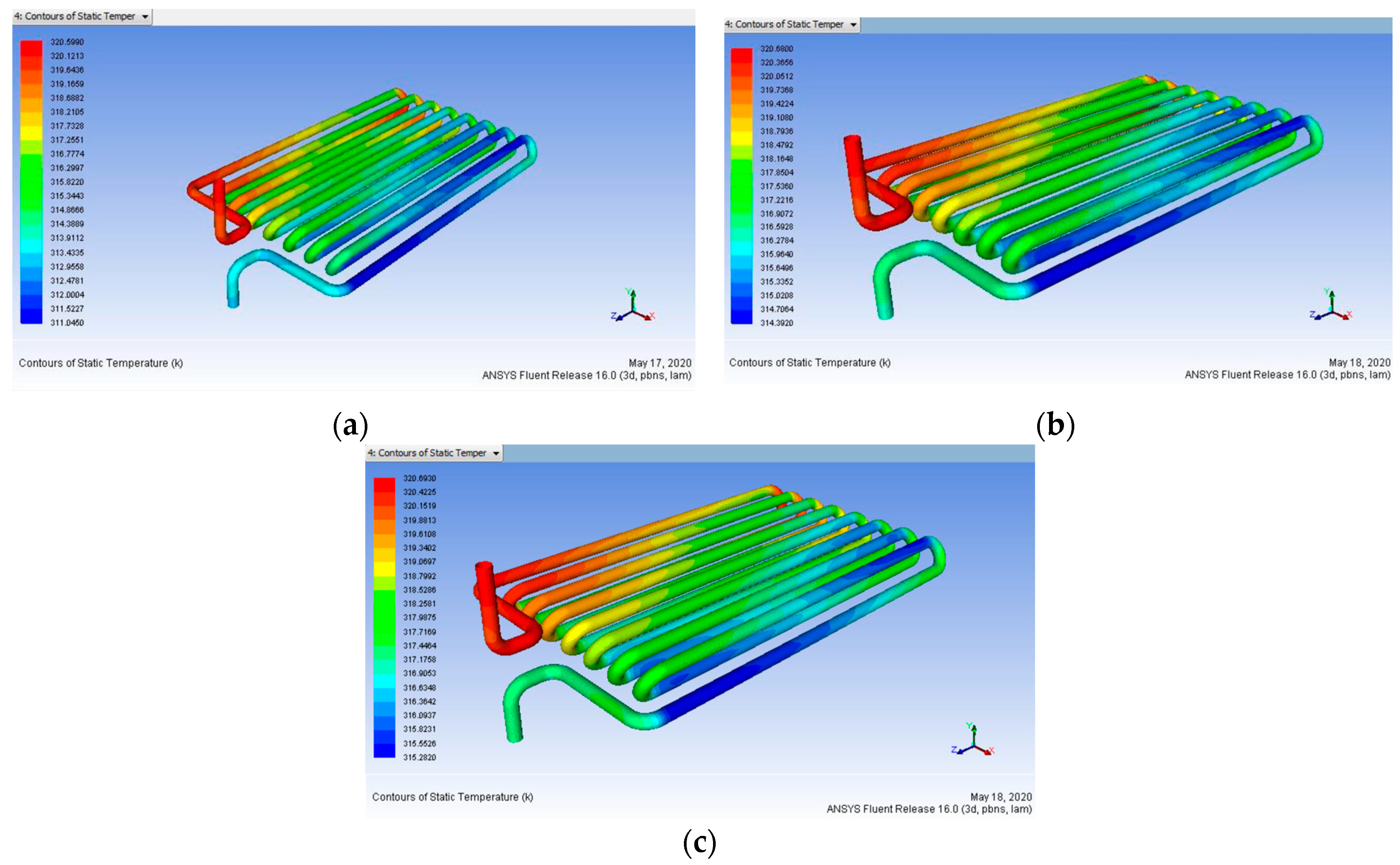

11. Thermal Simulation

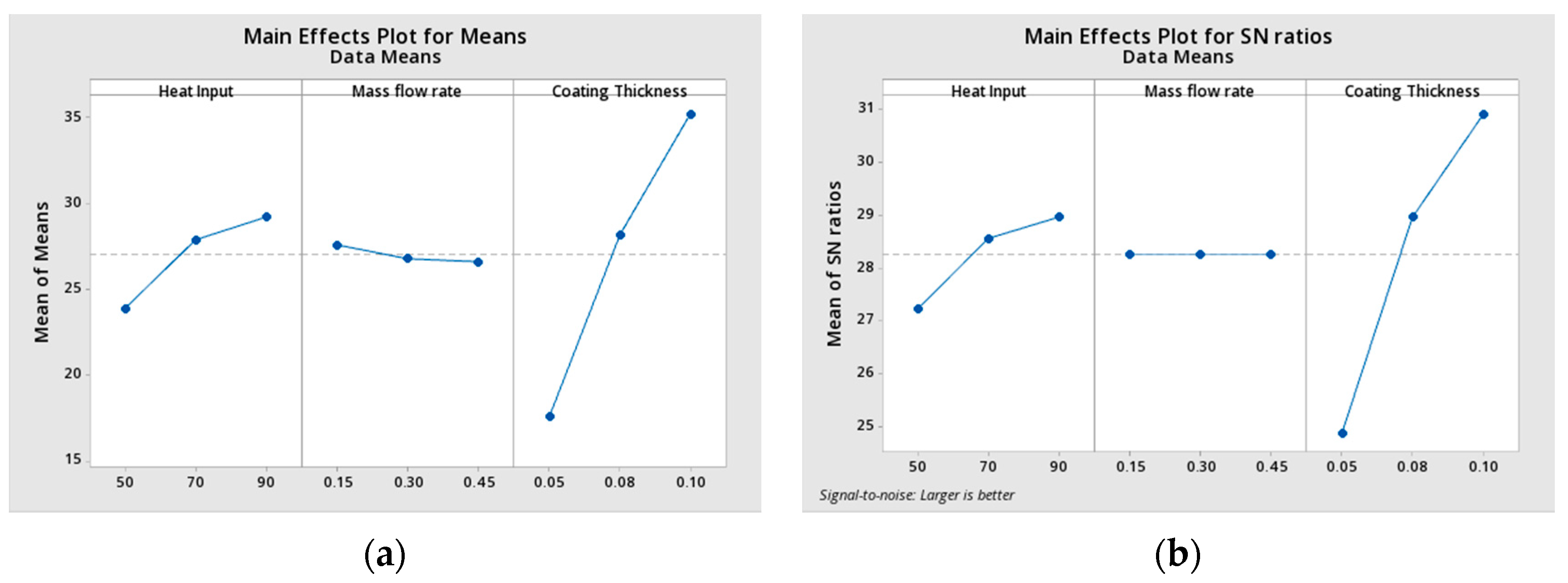

12. Optimization of Temperature

13. Data Analysis

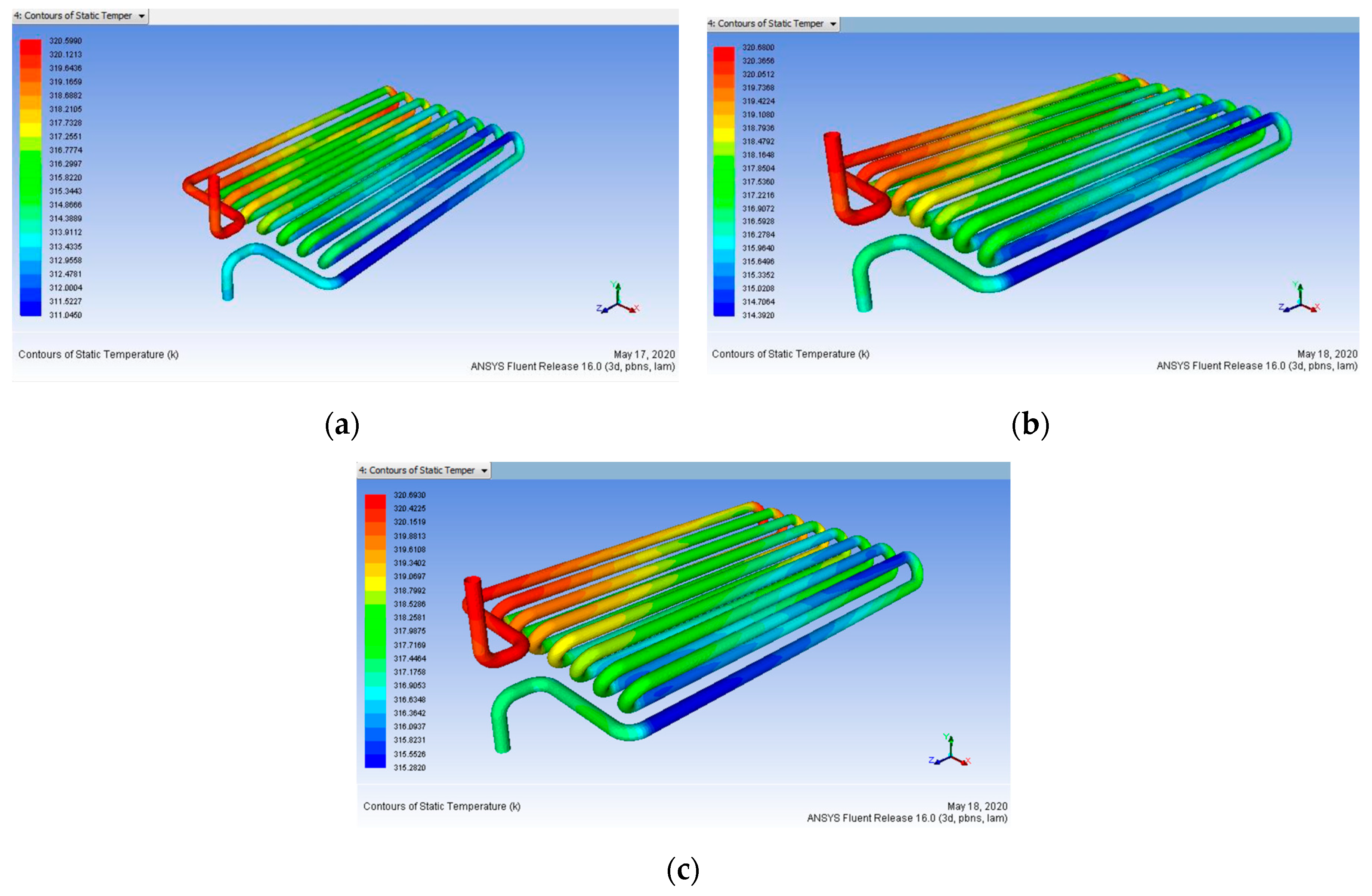

14. Results & Discussion

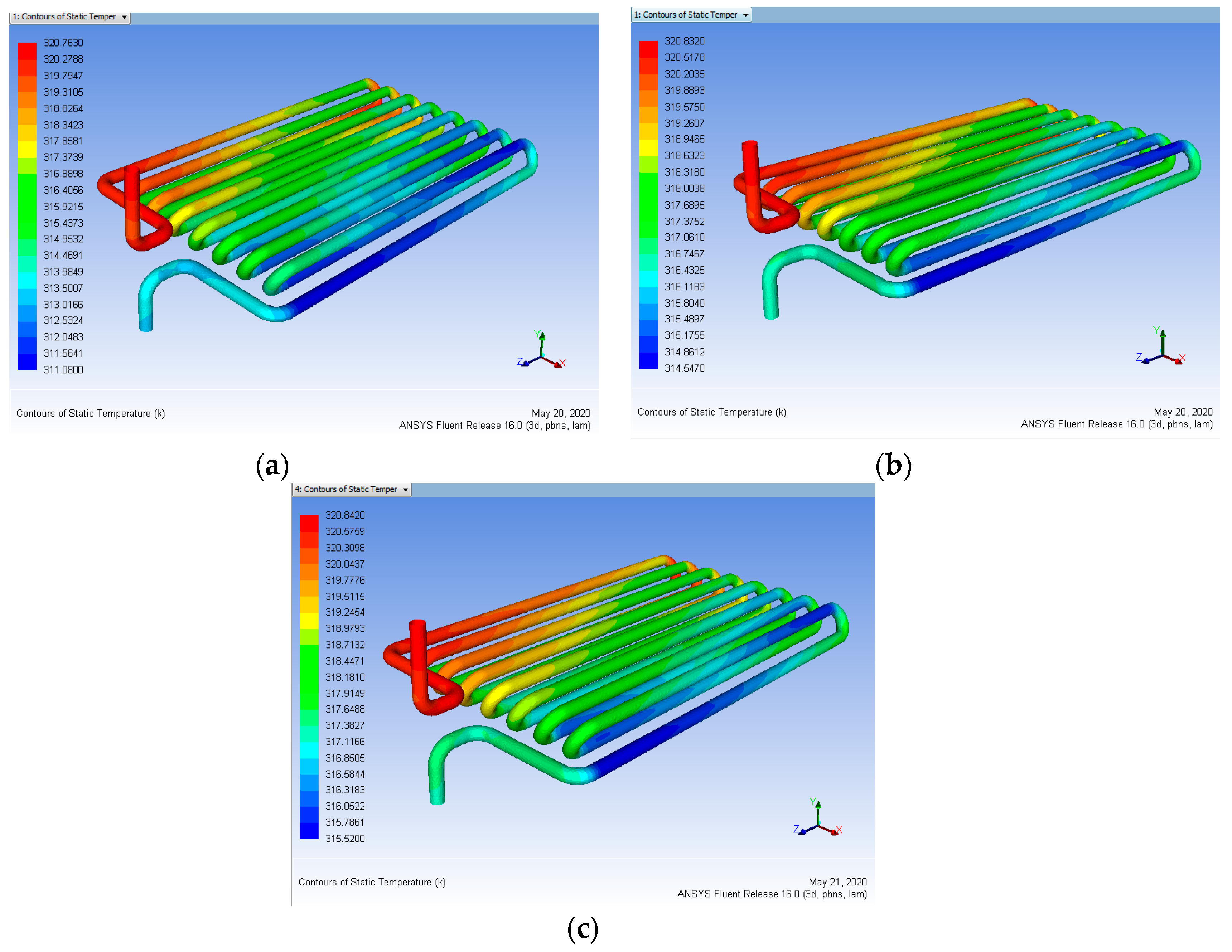

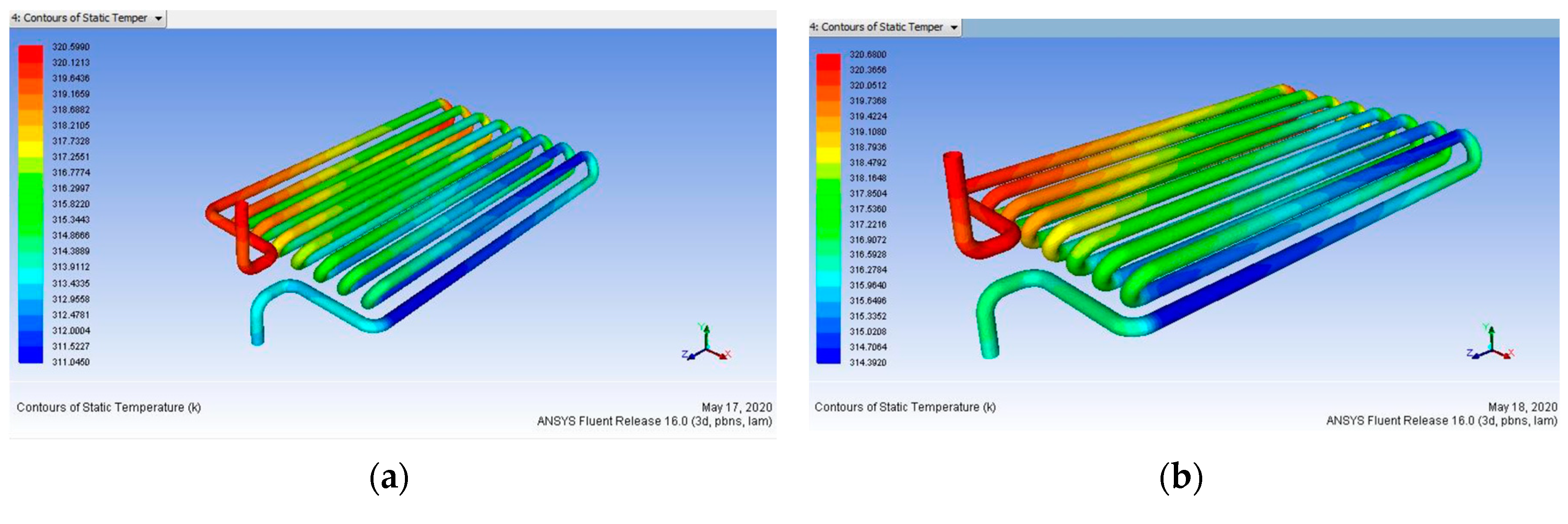

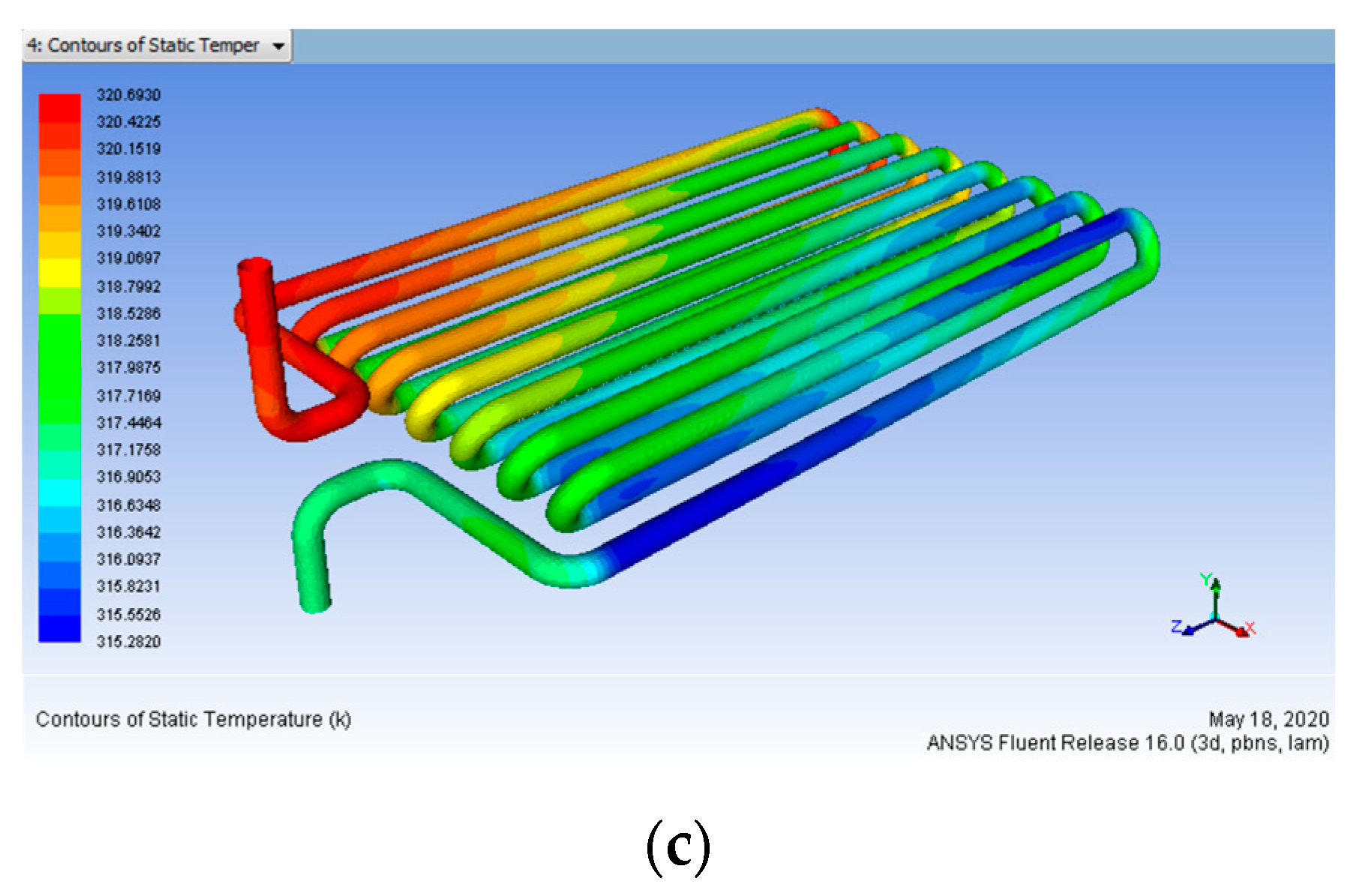

14.1. Case 1: (Heat Input = 323 K)

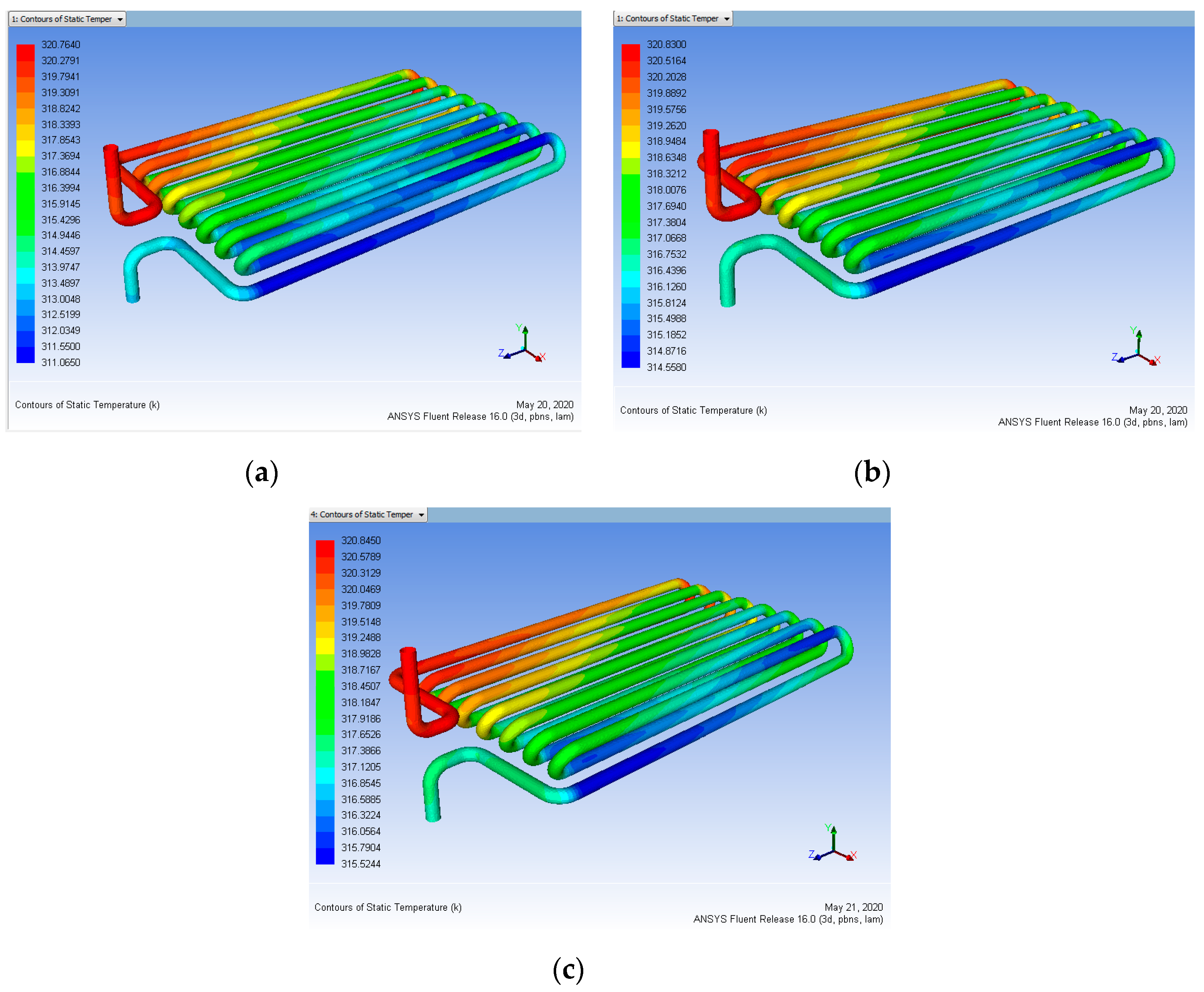

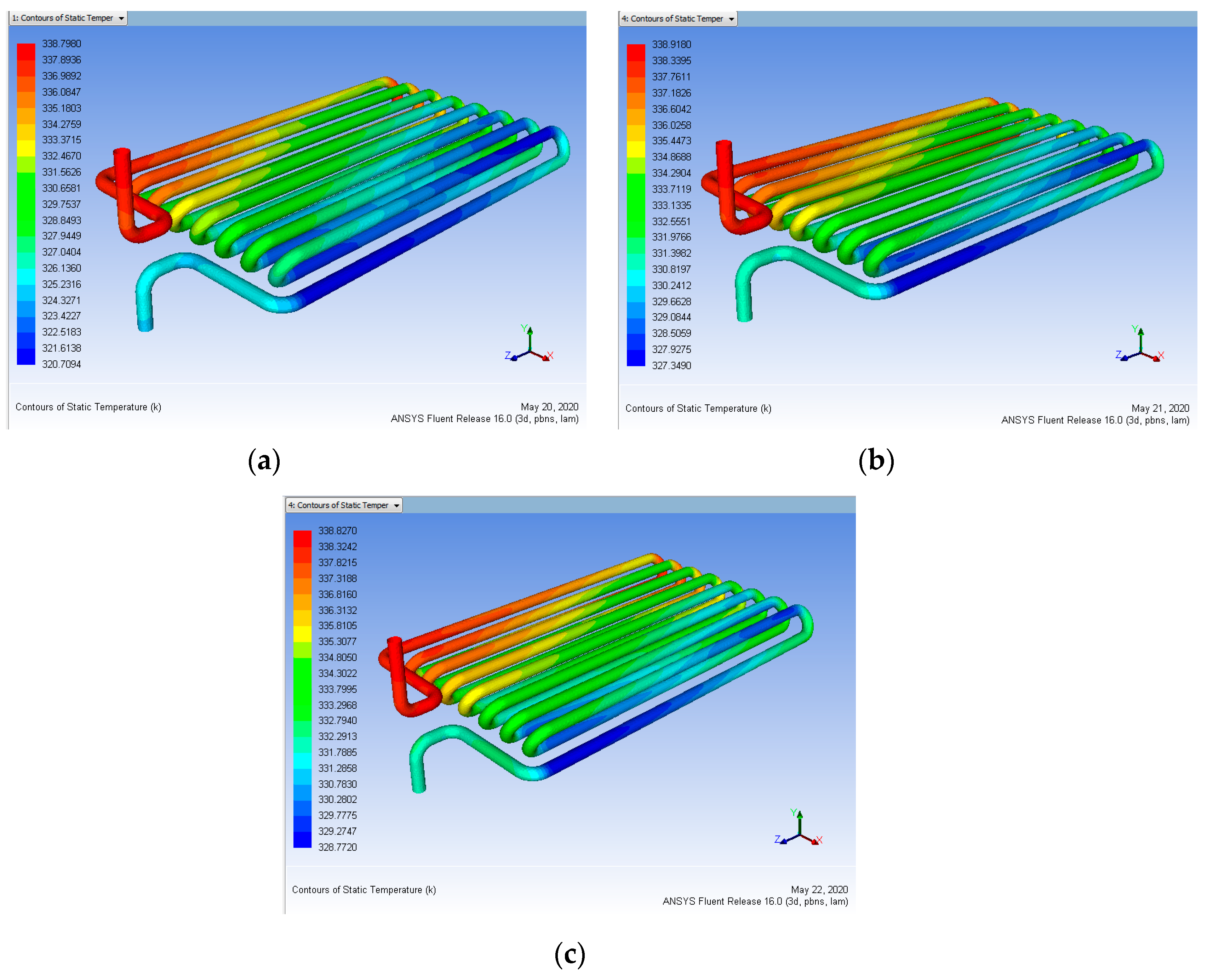

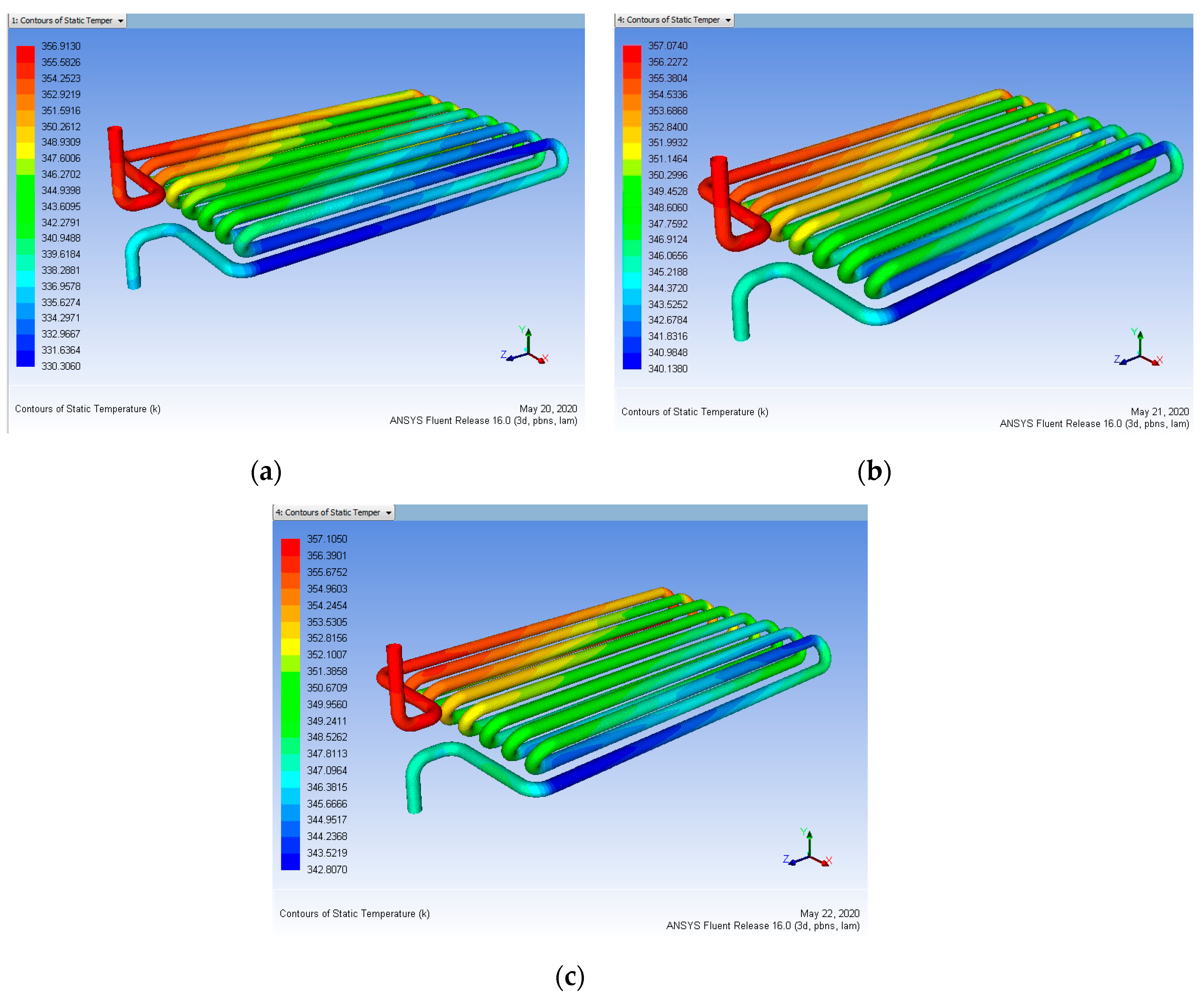

14.2. Case 2: (Heat Input = 343 K)

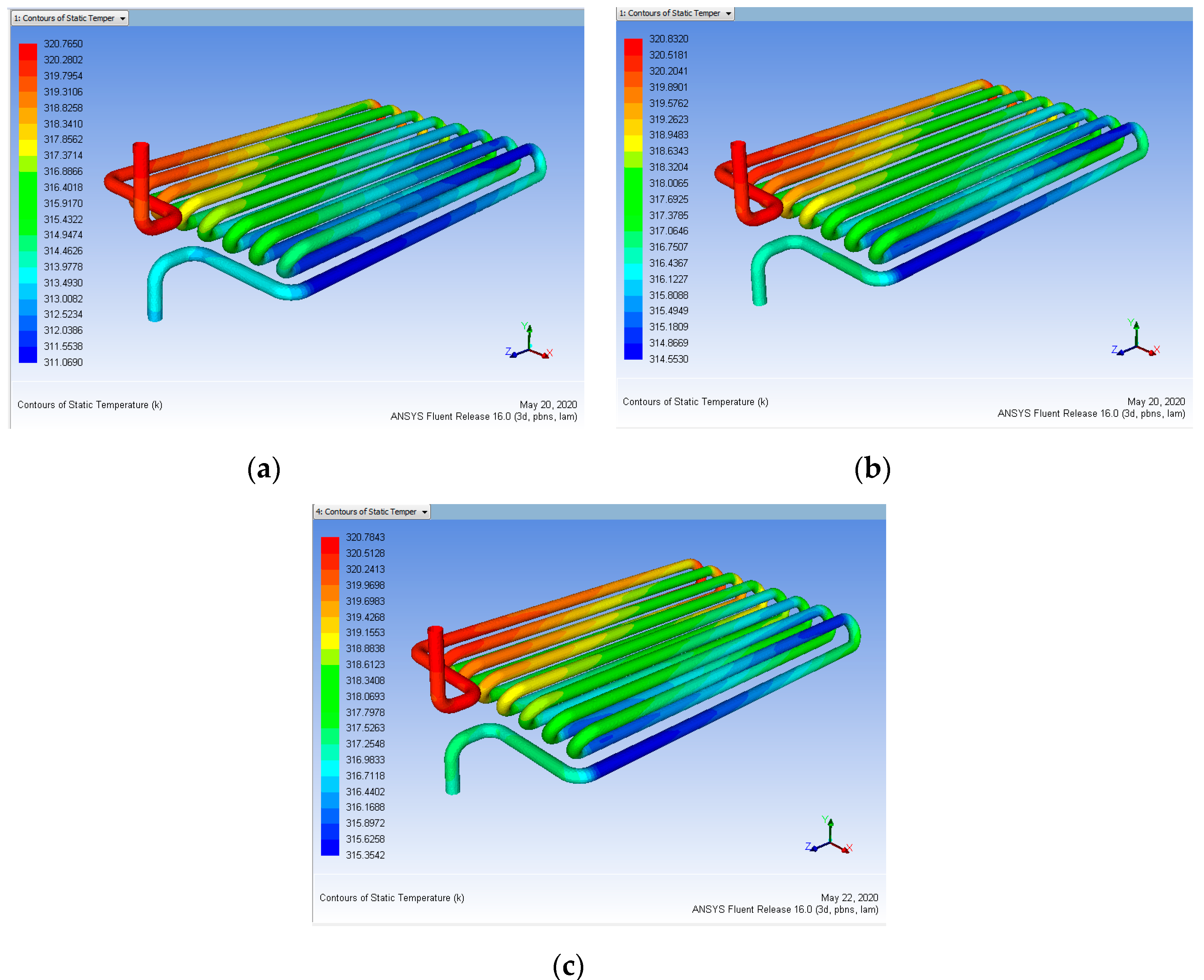

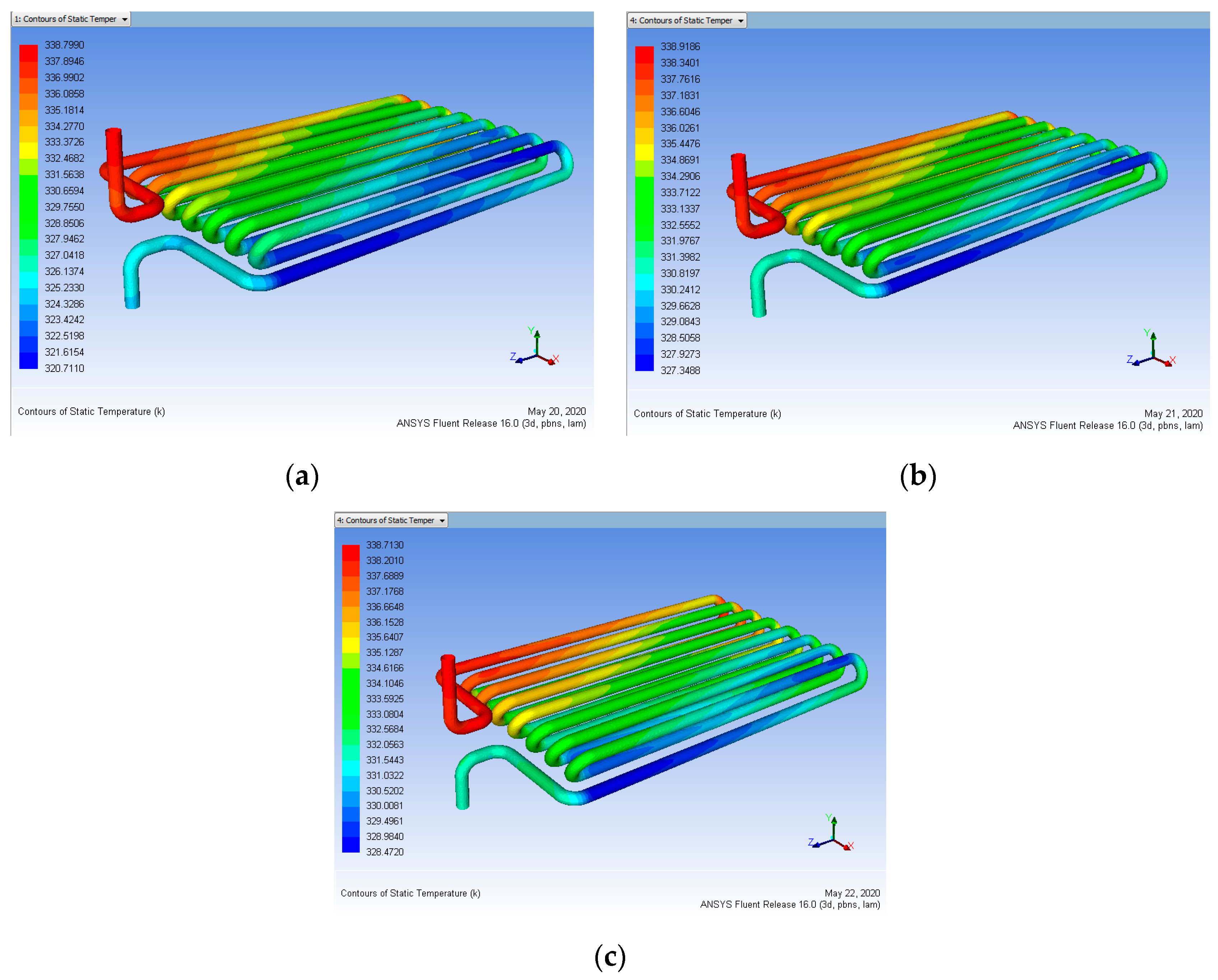

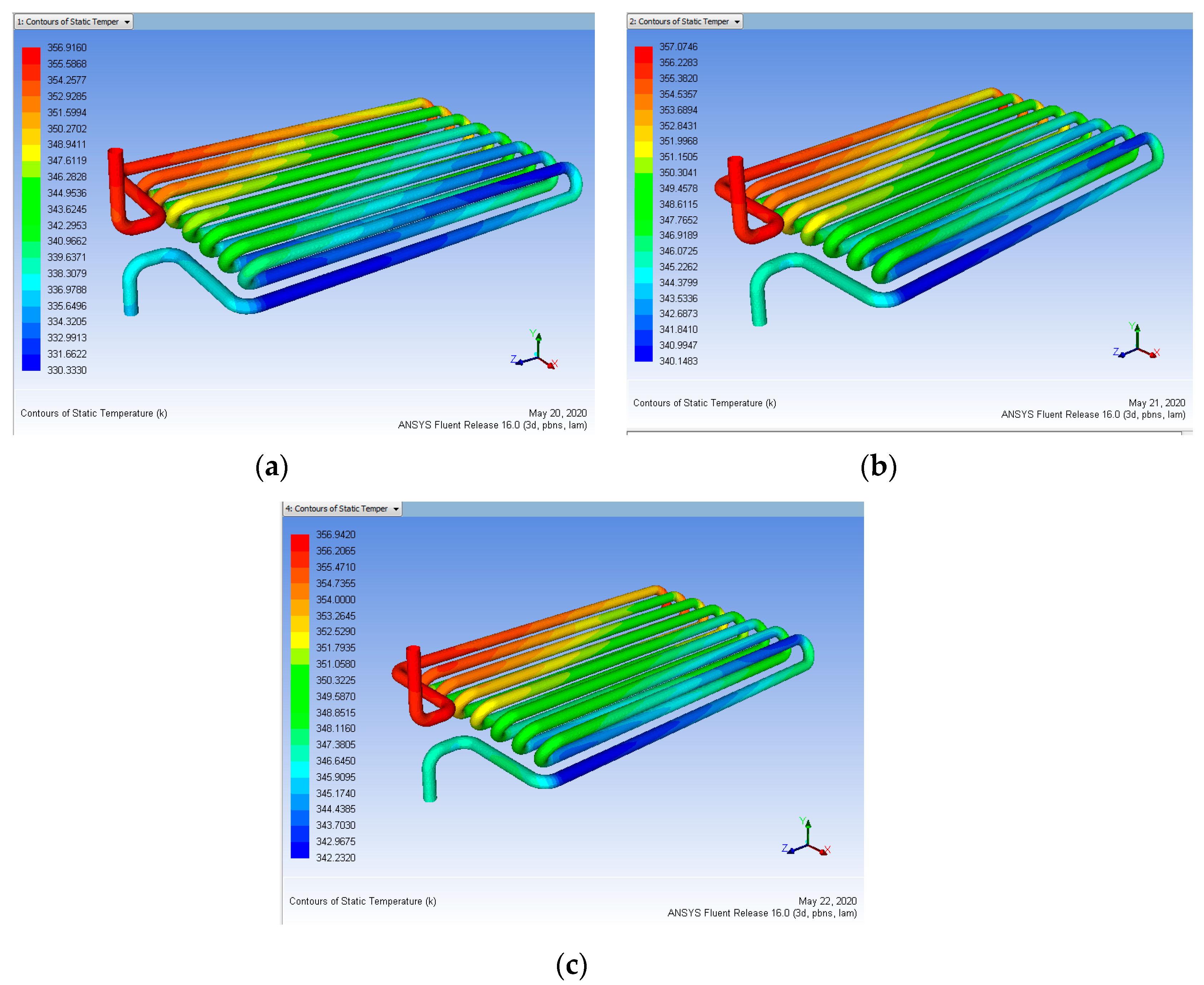

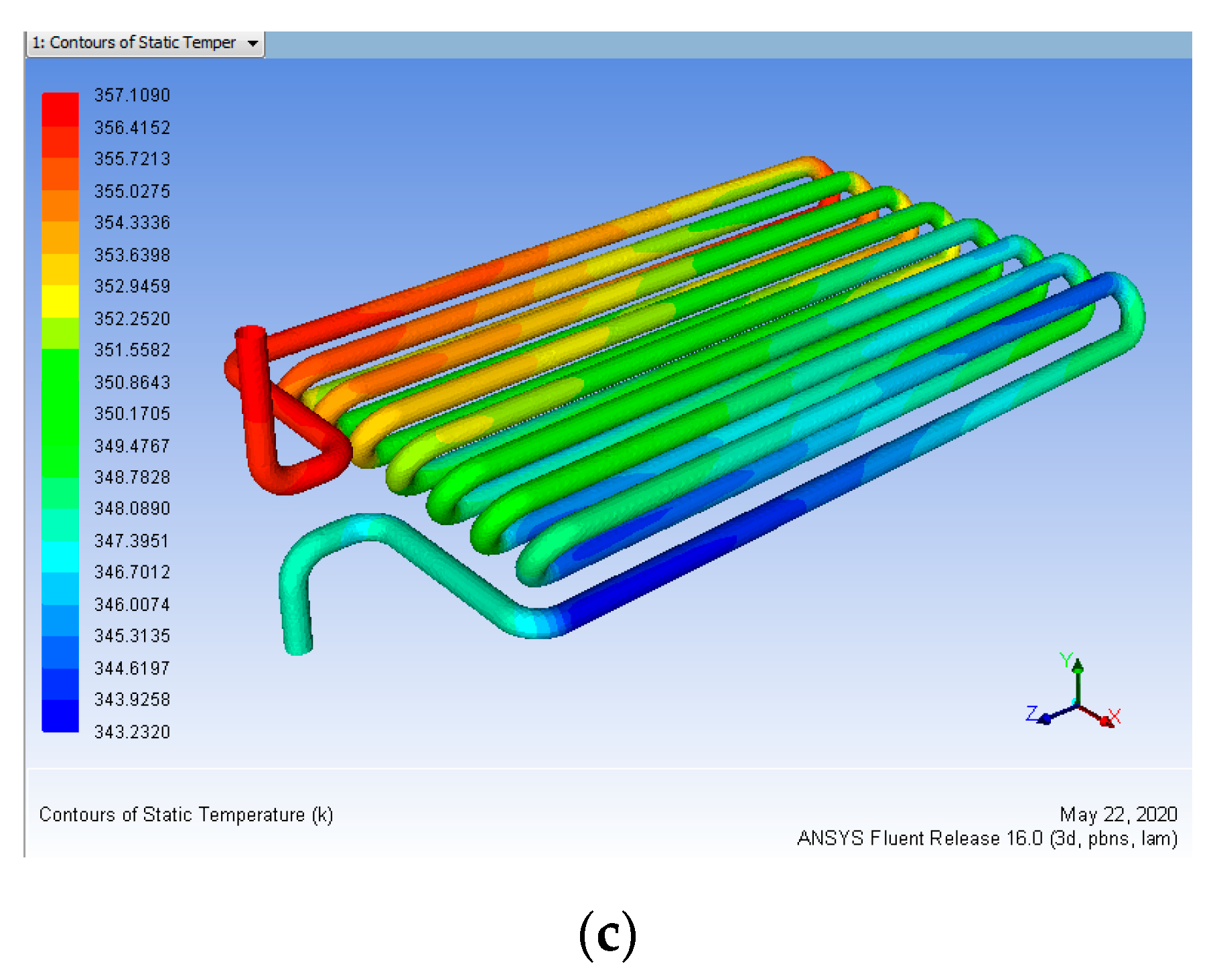

14.3. Case 3: (Heat Input = 363 K)

15. Prediction of Optimum Results

16. Conclusions

- The A1 B3 C2 of Taguchi analysis is found to be the optimum operating parameter level for temperature.

- 100 µm nano-coated pipes have higher heat transfer coefficients at all rates.

- For maximum temperature as heat input, 0.15 litre/min mass flow rate of coolant fluid conducted more heat.

- Optimal solutions using the Taguchi method provide better results for nano-coated pipes operations and the number of experiments required to find its efficiency metrics.

- Findings from experiments show that heat input, mass flow rate, and coating thickness play a significant role in the nano-coated pipe operations.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Klabunde, K.J. Introduction to Nanotechnology; Wiley: Hoboken, NJ, USA, 2003; pp. 1–13. [Google Scholar]

- Bernecki, T. Surface science. In Handbook of Thermal Spray Technology; Davis, R., Ed.; ASM International: Geauga County, OH, USA, 2004; pp. 14–35. [Google Scholar]

- Park, K.S.; Won, J.P.; Heo, H.S. Thermal flow analysis of vehicle engine cooling system. KSME Int. J. 2002, 16, 975–985. [Google Scholar] [CrossRef]

- Lee, S.H.; Hur, N.; Kang, S. An efficient method to predict the heat transfer performance of a louver fin radiator in an automotive power system. J. Mech. Sci. Technol. 2014, 28, 145–155. [Google Scholar] [CrossRef]

- Anand, K.D. Investigation on suitability of Aluminium to Copper in a Radiator. Manuf. Sci. Technol. 2015, 3, 16–23. [Google Scholar]

- Bae, K.E.; Chae, K.W. Oxidation behaviour of amorphous boron carbide-silicon carbide nano multi-layer thin films. Surf. Coat. Technol. 2015, 276, 55–58. [Google Scholar] [CrossRef]

- Wang, B.; Peng, X. Experimental investigation on liquid forced-convection heat transfer through microchannels. Int. J. Heat Mass Transf. 1994, 37, 73–82. [Google Scholar] [CrossRef]

- Rajput, K.A.; Kulkarni, A.V. A Review on Effect of Perforation and Carbon Nanotubes coating on Heat transfer augmentation. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 9412–9415. [Google Scholar]

- Sujith, K.C.S.; Suresh, S.; Rajiv, K. Heat transfer enhancement by Nanostructured carbon Nanotube Coating. Int. J. Sci. Res. 2012, 3, 1–5. [Google Scholar]

- Josell, D.; Bonevich, J.; Nguyen, T.; Johnson, R. Heat transfer through nanoscale multilayered thermal barrier coatings at elevated temperatures. Surf. Coat. Technol. 2015, 275, 75–83. [Google Scholar] [CrossRef]

- Dario, B. Nanostructure coatings remove heat four times faster. N. Atlas Artic. 2018, 7, 15384. [Google Scholar]

- Babu, K.A.; Sherjin, P. Experimental investigations of the performance of a thermoacoustic refrigerator based on the Taguchi method. J. Mech. Sci. Technol. 2018, 32, 929–935. [Google Scholar] [CrossRef]

- Dar, A.A.; Anuradha, N. Use of orthogonal arrays and design of experiment via Taguchi L9 method in probability of default. Accounting 2018, 4, 113–122. [Google Scholar] [CrossRef]

- Chan, Y.H.; Dang, K.V.; Yusup, S.; Lim, M.T.; Zain, A.M.; Uemura, Y. Studies on catalytic pyrolysis of empty fruit bunch (EFB) using Taguchi’s L9 Orthogonal Array. J. Energy Inst. 2014, 87, 227–234. [Google Scholar] [CrossRef]

- Pavani, P.N.L.; Rao, R.P.; Srikiran, S. Performance evaluation and optimization of nano boric acid powder weight percentage mixed with vegetable oil using the Taguchi approach. J. Mech. Sci. Technol. 2015, 29, 4877–4883. [Google Scholar] [CrossRef]

- Amir, F. Performance characteristics of a concentric annular heat pipe—Part II—Vapour flow analysis. ASME J. Heat Transf. 1989, 111, 847–851. [Google Scholar]

- Thomas, V.H. Orthogonal array experiment in systems engineering and architecting. Syst. Eng. 2011, 14, 208–222. [Google Scholar]

- Athreya, S.; Venkatesh, Y.D. Application of Taguchi method for optimization of process parameters in improving the surface roughness of lathe facing operation. Int. Ref. J. Eng. Sci. 2012, 1, 13–19. [Google Scholar]

- Amir, F. Heat Pipe Science and Technology; Taylor & Francis: Washington, DC, USA, 1995. [Google Scholar]

- Chandourene, S.; Gruss, A. Theoretical and experimental study of high temperature heat pipe heat exchanger application to 1300kW respirator. In Proceedings of the Sixth International Heat Pipe Conference, Grenoble, France, 25–29 May 1987. [Google Scholar]

- Kaminaga, F.; Hashimoto, H.; Feroz, C.; Goto, K.; Masumura, K. Heat transfer characteristics of evaporation and condensation in a two-phase closed thermosyphon. In Proceedings of the 10th International Heat Pipe Conference, Stuttgart, Germany, 21–25 September 1997; pp. 1–6. [Google Scholar]

- Mariya, I.; Yvan, A. Christian schaeffer, jean-bernard dezord, and juergen schulz-harder, heat pipe integrated in Direct Bonded Copper (DBC) technology for cooling of power electronics packaging. IEEE Trans. Power Electron. 2006, 21, 1541–1547. [Google Scholar]

- Lee, K.-H.; Yi, J.-W.; Park, J.-S.; Park, G.-J. An optimization algorithm using orthogonal arrays in discrete design space for structures. Finite Elem. Anal. Des. 2003, 40, 121–135. [Google Scholar] [CrossRef]

- Merton, R.C. On the pricing of corporate debt: The risk structure of interest rates. J. Financ. 1974, 29, 449. [Google Scholar] [CrossRef]

- Sonan, R.; Harmand, S.; Pelle, J.; Léger, D.; Fakès, M. Transient thermal and hydrodynamic model of flat heat pipe for the cooling of electronics components. Int. J. Heat Mass Transf. 2008, 51, 6006–6017. [Google Scholar] [CrossRef]

- Hull, J.C.; Basu, S. Options, Futures and Other Derivatives; Pearson Education India: Chennai, India, 2016. [Google Scholar]

- Ranjit, K.R. Design of Experiments Using the Taguchi Approach; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Oliet, C.; Oliva, A.; Castro, J.; Perez-Segarra, C.-D. Parametric studies on automotive radiators. Appl. Therm. Eng. 2007, 27, 2033–2043. [Google Scholar] [CrossRef]

- Upendra, K. CFD analysis of automobile radiator—A review. In Proceedings of the International Journal of Engineering Research and Applications, International Conference on Emerging Trends in Mechanical and Electrical Engineering, Thai Nguyen, Vietnam, 13–14 March 2014. [Google Scholar]

| Control Parameters | Level_One | Level_Two | Level_Three |

|---|---|---|---|

| Heat input (K) | 323 | 343 | 363 |

| Mass flow rate (L/min) | 0.15 | 0.30 | 0.45 |

| Coating thickness (µm) | 50 | 80 | 100 |

| Condition | Level_One | Level_Two | Level_Three |

|---|---|---|---|

| One | One | One | One |

| Two | One | Two | Two |

| Three | One | Three | Three |

| Four | Two | One | Two |

| Five | Two | Two | Three |

| Six | Two | Three | One |

| Seven | Three | One | Three |

| Eight | Three | Two | One |

| Nine | Three | Three | Two |

| Engine Specification | Radiator Specification | ||

|---|---|---|---|

| Type | Water Cooled Sohc Engine | Radiator’s Type | Compact Heat Exchanger-Circular Tube with Continuous Fin |

| Fuel Used | Petrol | Radiator’s Volume | P × L × T = 500 × 30 × 550 mm3 |

| Max. Power (bhp@rpm) | 37bhp @5000 rpm | Tube Diameter | 10 mm |

| Engine Displacement | 796 CC | Tube Length | 330 mm |

| Max. Torque | 59 nm @2500 rpm | Number of Row | 2 |

| No. of Cylinders | 4 | Number of tubes per Row | 8 |

| No. of valves | 2 valves/cylinder | Pit Length | 11 mm |

| Valve Train | Sohc | Material | Coper coated Aluminium tubes |

| Fuel train | Mpfi | Fin Material | Aluminium |

| Pressure Ratio | 8.8:1 | Fin thickness | 0.1 mm |

| Material | Thermal Conductivity (W m−1 K−1) | Density (kg/m3) | Specific Heat (J kg−1 K−1) | Viscosity (kg m−1 s−1) |

|---|---|---|---|---|

| Aluminium | 190 | 2719 | 871 | - |

| Copper | 401 | 3210 | 385 | - |

| Water | 0.6 | 998.2 | 4182 | 0.001003 |

| Element | At. No. | Mass [%] | Mass Norm [%] | Atom [%] | Abs. Error [%] (1 Sigma) | Rel. Error [%] (1 Sigma) |

|---|---|---|---|---|---|---|

| Cu | 29 | 41.27 | 36.81 | 12.67 | 1.07 | 2.59 |

| C | 6 | 35.36 | 31.54 | 57.42 | 6.51 | 18.40 |

| Al | 13 | 23.22 | 20.71 | 16.78 | 1.22 | 5.25 |

| O | 8 | 10.29 | 9.18 | 12.55 | 2.16 | 21.02 |

| Zn | 30 | 1.97 | 1.76 | 0.59 | 0.10 | 5.04 |

| 112.11 | 100.00 | 100.00 | ||||

| No. of Test | Heat Input (K) | Mass Flow Rate (L/min) | Coating Thickness (µm) | Rate of Heat Transfer (kW) | SNRA | Effectiveness | SNRA | Overall Heat Transfer Coefficient (W m−2 K−1) | SNRA |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 323 | 0.15 | 50 | 3.14 | 9.94 | 15.60 | 23.86 | 270.45 | 48.64 |

| 2 | 323 | 0.30 | 80 | 5.02 | 14.01 | 24.96 | 27.94 | 459.29 | 53.24 |

| 3 | 323 | 0.45 | 100 | 6.27 | 15.95 | 31.19 | 29.88 | 598.52 | 55.54 |

| 4 | 343 | 0.15 | 80 | 11.70 | 21.36 | 29.11 | 29.28 | 1284.52 | 62.17 |

| 5 | 343 | 0.30 | 100 | 14.63 | 23.30 | 36.39 | 31.21 | 1687.8 | 64.54 |

| 6 | 343 | 0.45 | 50 | 7.32 | 17.29 | 18.20 | 25.20 | 746.82 | 57.46 |

| 7 | 363 | 0.15 | 100 | 22.99 | 27.23 | 38.13 | 31.62 | 2816.56 | 68.99 |

| 8 | 363 | 0.30 | 50 | 11.50 | 21.21 | 19.06 | 25.60 | 1238.11 | 61.85 |

| 9 | 363 | 0.45 | 80 | 18.39 | 25.29 | 30.50 | 29.68 | 2135.89 | 66.59 |

| Coating Thickness | Mass Flow Rate | Heat Input (K) | Heat Output (Without Coating) (K) | Heat Output (With Coating) (K) |

|---|---|---|---|---|

| 50 | 0.15 | 323 | 314.5623 | 311.6682 |

| 80 | 323 | 311.2169 | ||

| 100 | 323 | 310.4896 | ||

| 50 | 0.30 | 323 | 315.9843 | 312.1283 |

| 80 | 323 | 311.8257 | ||

| 100 | 323 | 311.2673 | ||

| 50 | 0.45 | 323 | 317.2348 | 312.2314 |

| 80 | 323 | 311.9846 | ||

| 100 | 323 | 311.4213 |

| Level | Heat Input | Mass Flow Rate | Coating Thickness |

|---|---|---|---|

| 1 | 13.30 | 19.51 | 16.15 |

| 2 | 20.65 | 19.51 | 20.22 |

| 3 | 24.58 | 19.51 | 22.16 |

| Delta | 11.28 | 0.00 | 6.01 |

| Rank | 1 | 3 | 2 |

| Level | Heat Input | Mass Flow Rate | Coating Thickness |

|---|---|---|---|

| 1 | 4.810 | 12.610 | 7.320 |

| 2 | 11.217 | 10.383 | 11.703 |

| 3 | 17.627 | 10.660 | 14.630 |

| Delta | 12.817 | 2.227 | 7.310 |

| Rank | 1 | 3 | 2 |

| Coating Thickness | Mass Flow Rate | Heat Input (K) | Heat Output (Without Coating) (K) | Heat Output (With Coating) (K) |

|---|---|---|---|---|

| 50 | 0.15 | 343 | 328.2653 | 324.1464 |

| 80 | 343 | 323.6230 | ||

| 100 | 343 | 321.7859 | ||

| 50 | 0.30 | 343 | 330.8934 | 325.1792 |

| 80 | 343 | 324.6932 | ||

| 100 | 343 | 323.9572 | ||

| 50 | 0.45 | 343 | 332.3284 | 325.8741 |

| 80 | 343 | 324.7642 | ||

| 100 | 343 | 323.1260 |

| Level | Heat Input | Mass Flow Rate | Coating Thickness |

|---|---|---|---|

| 1 | 27.23 | 28.26 | 24.89 |

| 2 | 28.57 | 28.26 | 28.97 |

| 3 | 28.97 | 28.26 | 30.91 |

| Delta | 1.74 | 0.00 | 6.02 |

| Rank | 1 | 3 | 2 |

| Level | Heat Input | Mass Flow Rate | Coating Thickness |

|---|---|---|---|

| 1 | 23.92 | 27.61 | 17.62 |

| 2 | 27.90 | 26.80 | 28.19 |

| 3 | 29.23 | 26.63 | 35.24 |

| Delta | 5.31 | 0.98 | 17.62 |

| Rank | 1 | 3 | 2 |

| Coating Thickness | Mass Flow Rate | Heat Input (K) | Heat Output (Without Coating) (K) | Heat Output (With Coating) (K) |

|---|---|---|---|---|

| 50 | 0.15 | 363 | 341.1494 | 339.1287 |

| 80 | 363 | 336.8967 | ||

| 100 | 363 | 333.9843 | ||

| 50 | 0.30 | 363 | 344.8634 | 340.1275 |

| 80 | 363 | 337.1278 | ||

| 100 | 363 | 334.9483 | ||

| 50 | 0.45 | 363 | 347.9631 | 341.4793 |

| 80 | 363 | 338.4752 | ||

| 100 | 363 | 336.6382 |

| Level | Heat Input | Mass Flow Rate | Coating Thickness |

|---|---|---|---|

| 1 | 52.48 | 59.94 | 55.99 |

| 2 | 61.40 | 59.88 | 60.67 |

| 3 | 65.81 | 59.87 | 63.03 |

| Delta | 13.34 | 0.07 | 7.04 |

| Rank | 1 | 3 | 2 |

| Level | Heat Input | Mass Flow Rate | Coating Thickness |

|---|---|---|---|

| 1 | 442.80 | 1457.20 | 751.8 |

| 2 | 1239.7 | 1128.4 | 1239.2 |

| 3 | 2063.5 | 1160.4 | 1701.00 |

| Delta | 1620.80 | 328.80 | 949.20 |

| Rank | 1 | 3 | 2 |

| Heat Input | Mass Flow Rate | Coating Thickness | PSNRA | PMEANS |

|---|---|---|---|---|

| 323 | 0.15 | 50 | 48.6098 | 154.40 |

| 323 | 0.30 | 80 | 53.2362 | 367.06 |

| 323 | 0.45 | 100 | 55.5790 | 806.80 |

| 343 | 0.15 | 80 | 62.2123 | 1492.80 |

| 343 | 0.30 | 100 | 64.5145 | 1571.75 |

| 343 | 0.45 | 50 | 57.4588 | 654.59 |

| 363 | 0.15 | 100 | 68.9889 | 2724.33 |

| 363 | 0.30 | 50 | 61.8926 | 1446.39 |

| 363 | 0.45 | 80 | 66.5596 | 2019.84 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pungaiah, S.S.; Kailasanathan, C.K. Thermal Analysis and Optimization of Nano Coated Radiator Tubes Using Computational Fluid Dynamics and Taguchi Method. Coatings 2020, 10, 804. https://doi.org/10.3390/coatings10090804

Pungaiah SS, Kailasanathan CK. Thermal Analysis and Optimization of Nano Coated Radiator Tubes Using Computational Fluid Dynamics and Taguchi Method. Coatings. 2020; 10(9):804. https://doi.org/10.3390/coatings10090804

Chicago/Turabian StylePungaiah, Sudalai Suresh, and Chidambara Kuttalam Kailasanathan. 2020. "Thermal Analysis and Optimization of Nano Coated Radiator Tubes Using Computational Fluid Dynamics and Taguchi Method" Coatings 10, no. 9: 804. https://doi.org/10.3390/coatings10090804

APA StylePungaiah, S. S., & Kailasanathan, C. K. (2020). Thermal Analysis and Optimization of Nano Coated Radiator Tubes Using Computational Fluid Dynamics and Taguchi Method. Coatings, 10(9), 804. https://doi.org/10.3390/coatings10090804