Softening Behaviors of Severely Deformed Zn Alloy Studied by the Nanoindentation

Abstract

1. Introduction

2. Experimental Procedures

3. Results

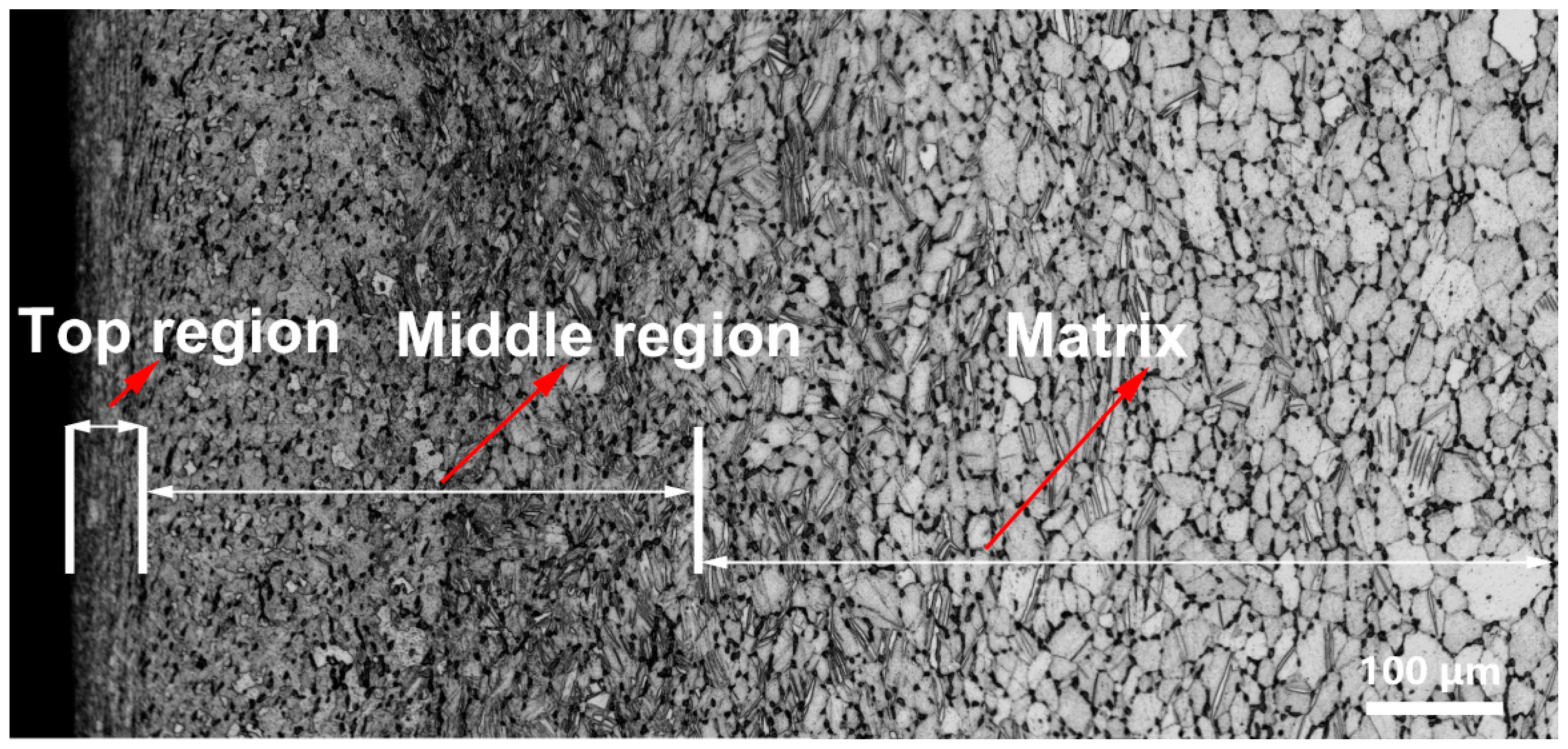

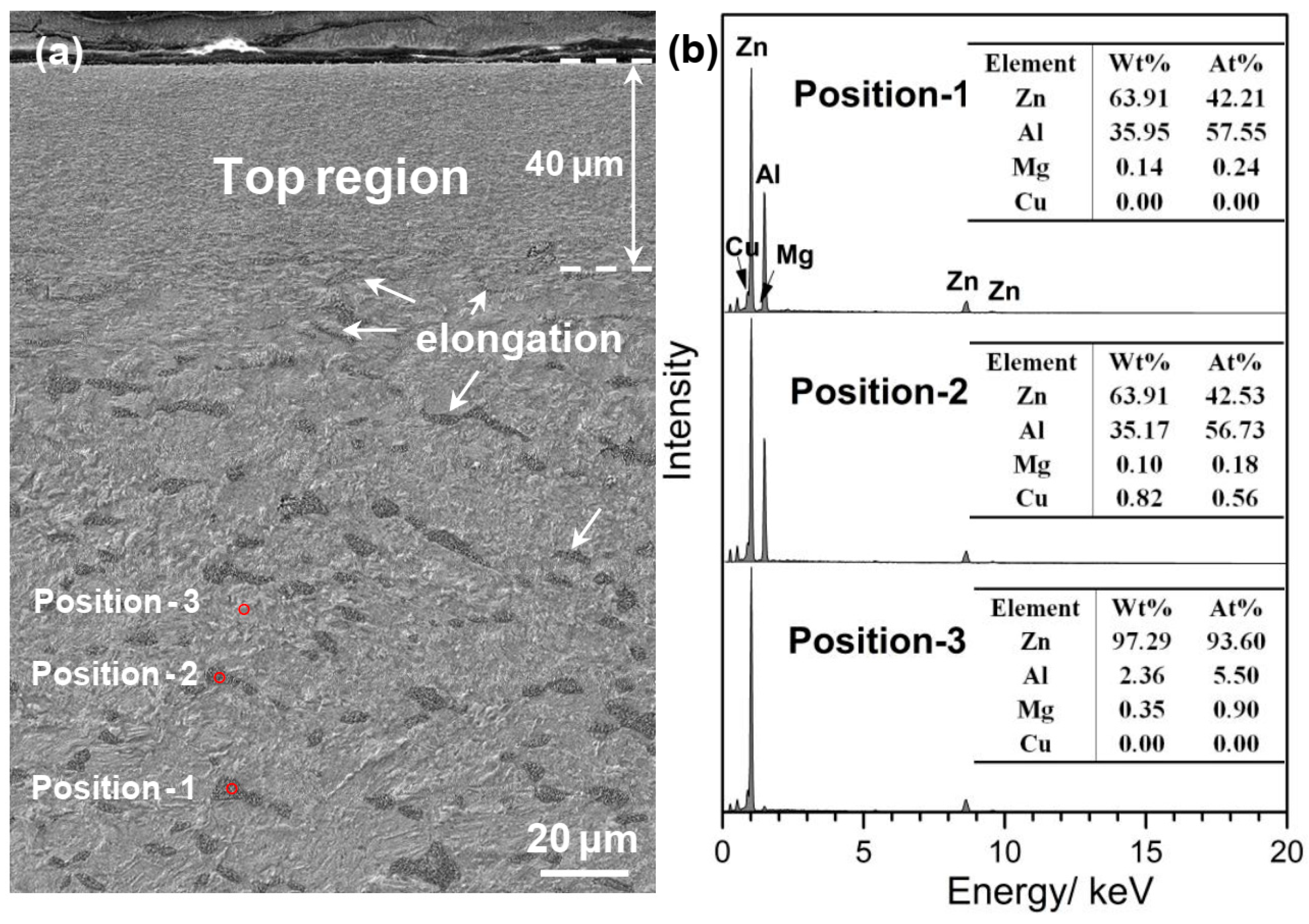

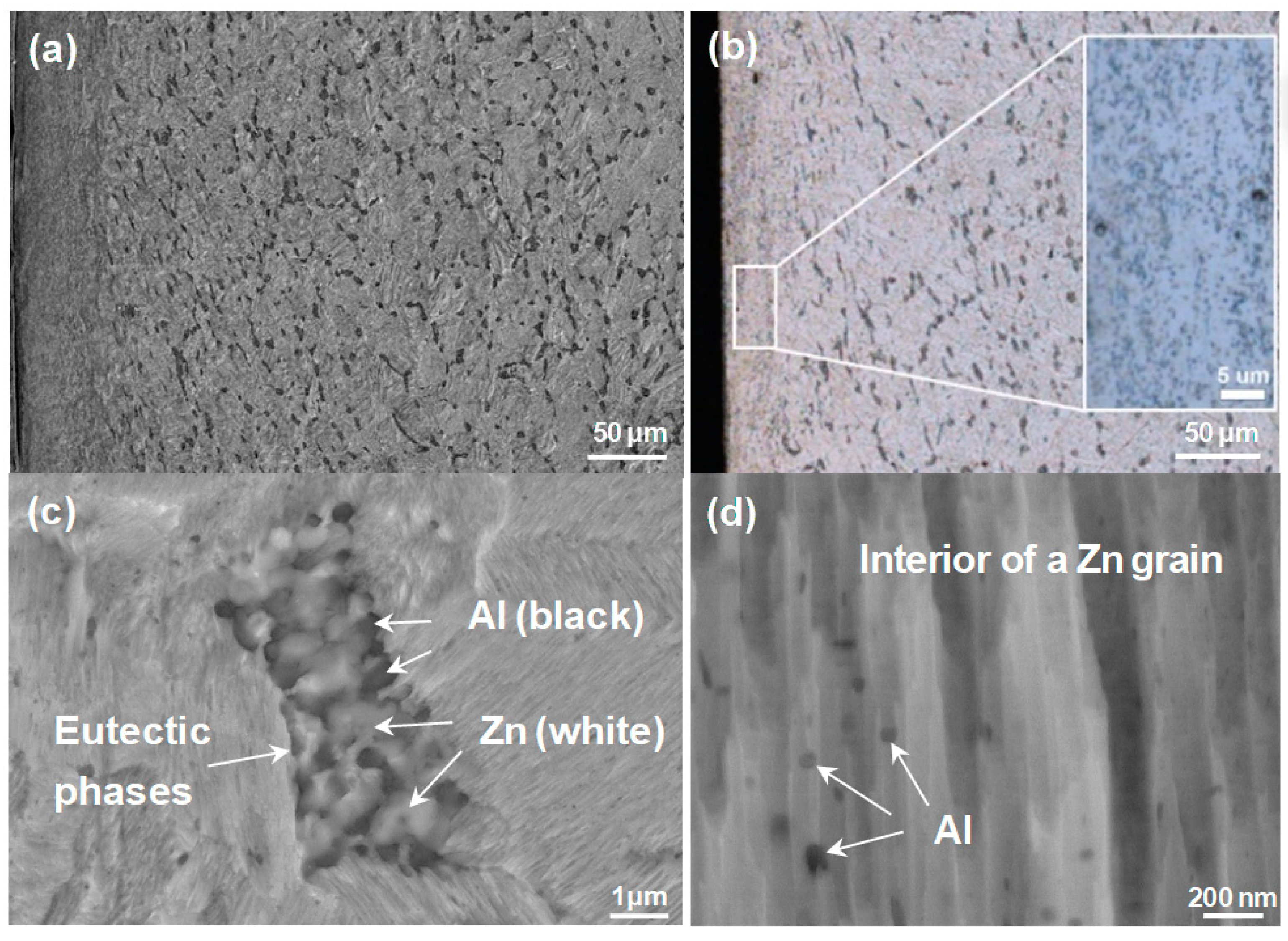

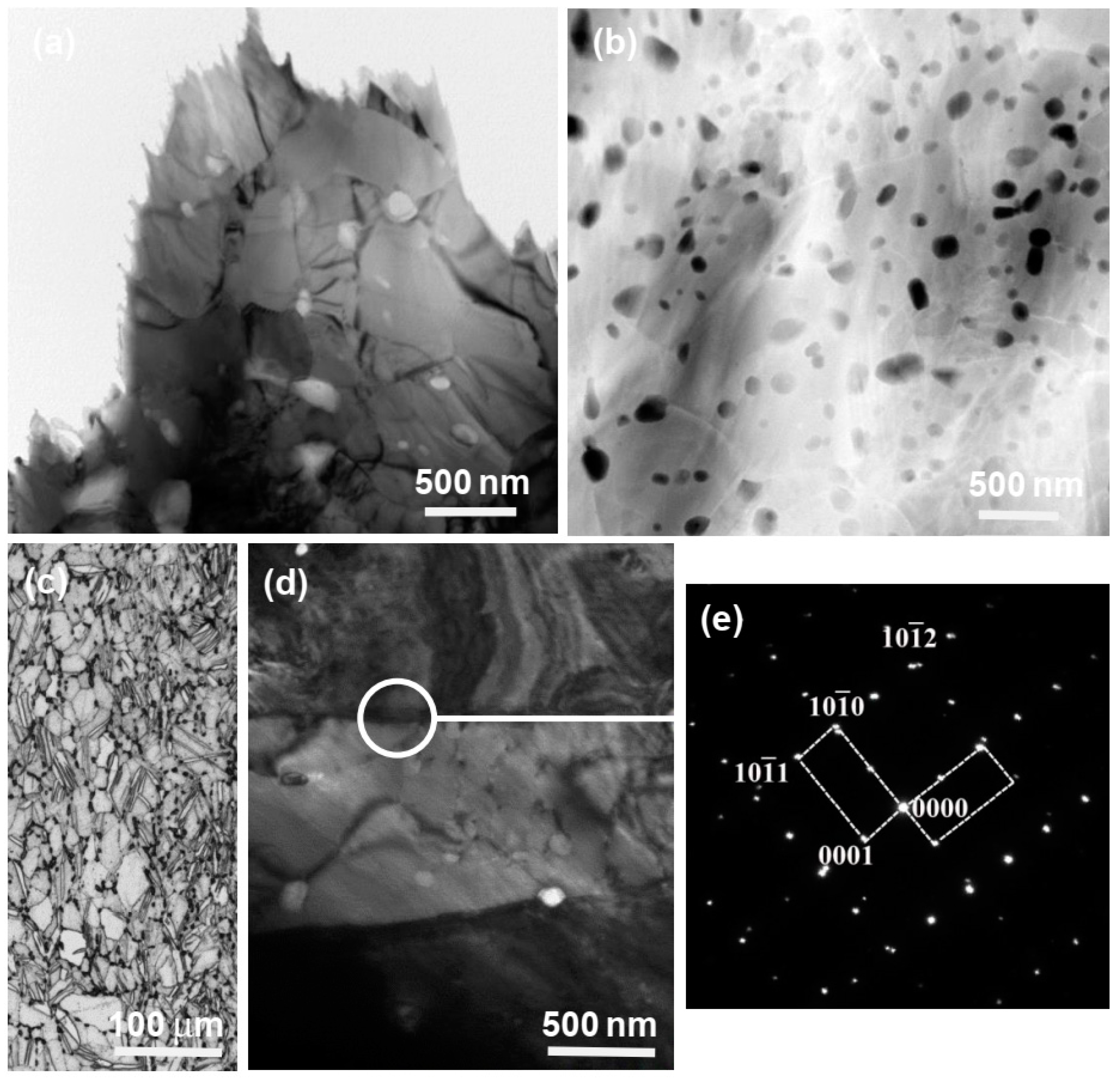

3.1. Microstructural Observation

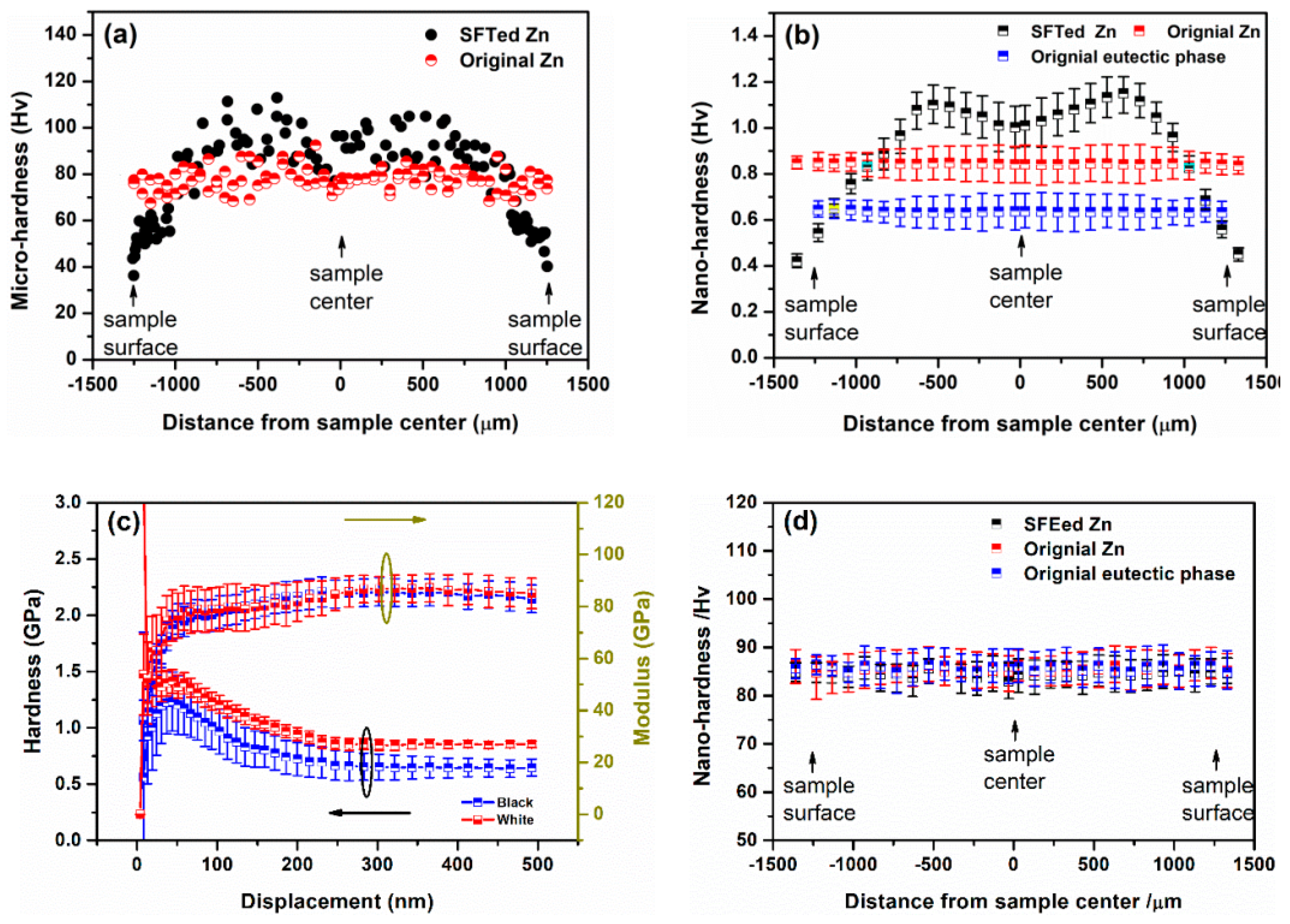

3.2. Hardness Evolution through SFT

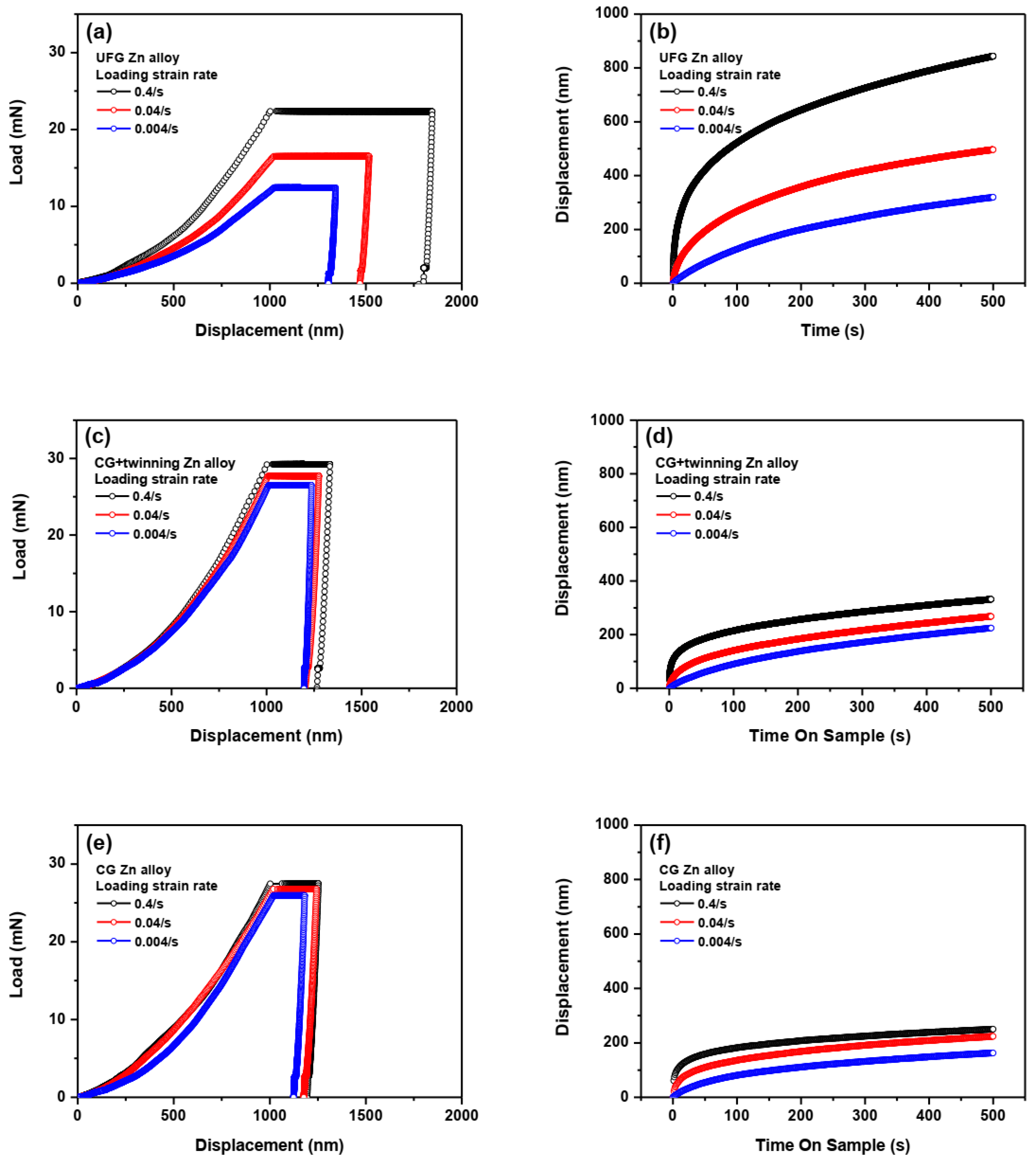

3.3. Nanoindentation Creep Behavior

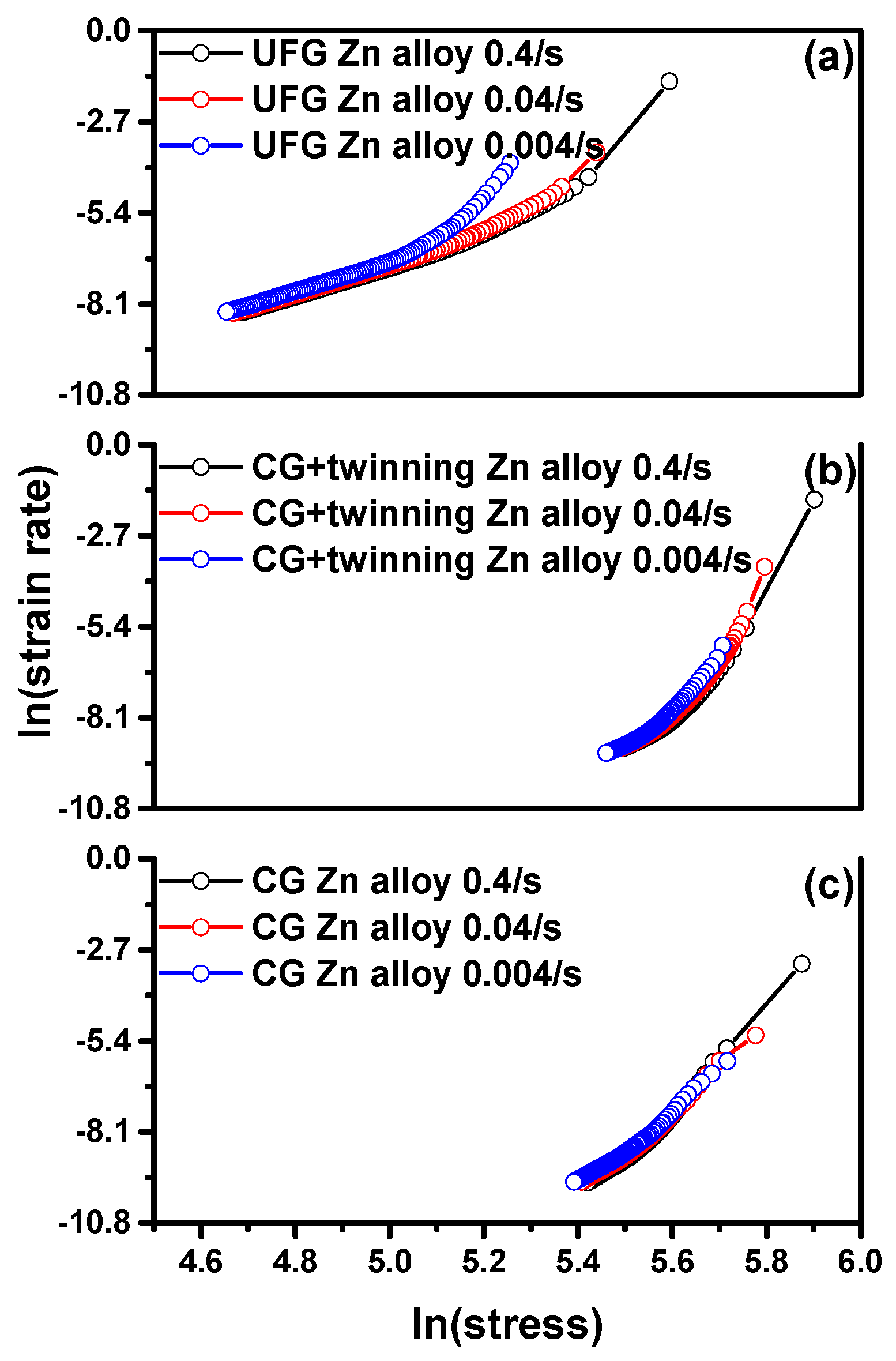

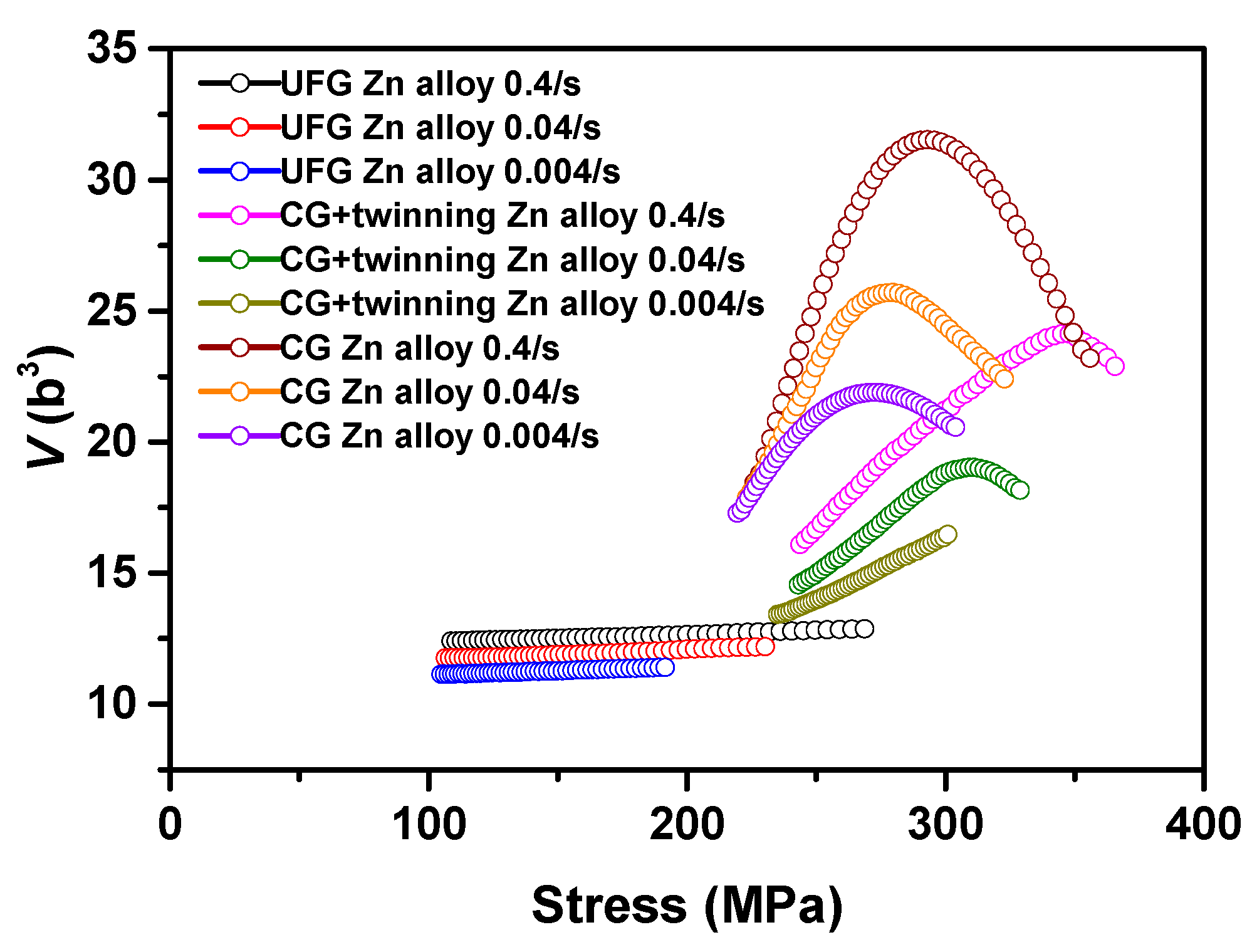

4. Discussion

5. Conclusions

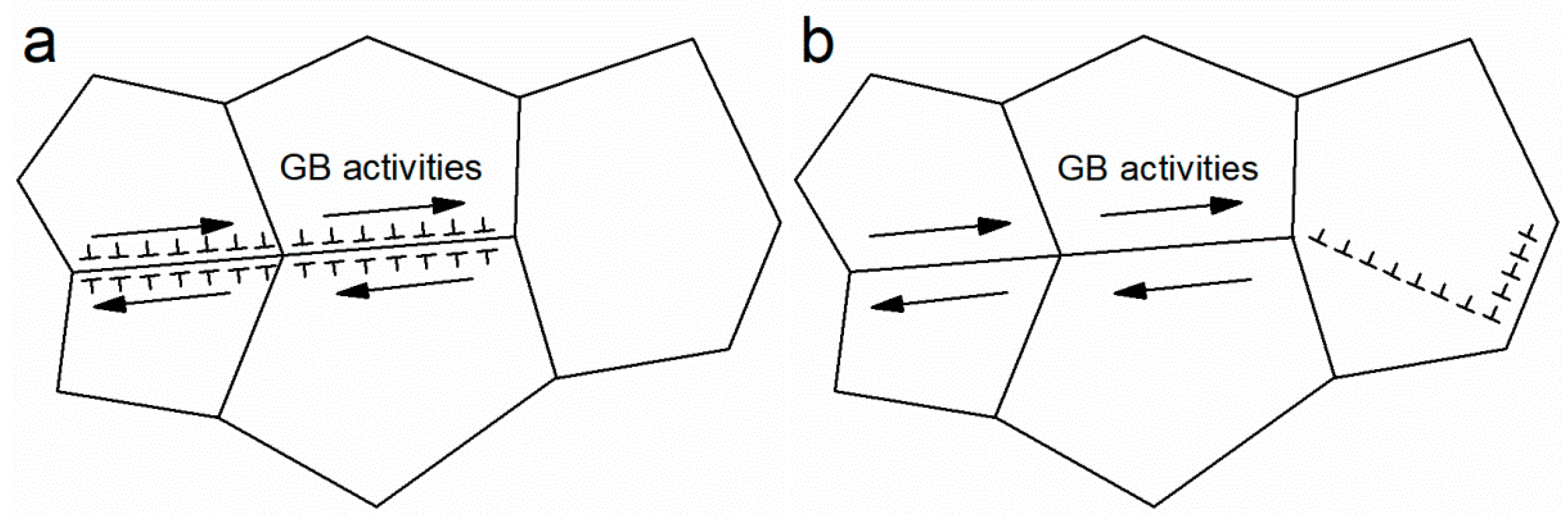

- For UFG Zn alloy, the almost constant values of V in the UFG Zn implies that its superplasticity is ruled by the dislocations moving along the GB not crossing the grain interior;

- For the CG+twinning/CG Zn alloy, the highly frequent dislocation–TB and dislocation–dislocation interactions intergranular are responsible for subsequent inverse Cottrell–Stokes at lower stress, respectively.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hu, J.J.; Han, S.; Sun, G.X.; Sun, S.C.; Jiang, Z.H.; Wang, G.Y.; Lian, J.S. Effect of strain rate on tensile properties of electric brush-plated nanocrystalline copper. Mater. Sci. Eng. A 2014, 618, 621–628. [Google Scholar] [CrossRef]

- Hu, J.J.; Sun, G.X.; Zhang, X.P.; Wang, G.Y.; Jiang, Z.H.; Han, S.; Zhang, J.Y.; Lian, J.S. Effects of loading strain rate and stacking fault energy on nanoindentation creep behaviors of nanocrystalline Cu, Ni-20 wt.%Fe and Ni. J. Alloy. Compd. 2015, 647, 670–680. [Google Scholar] [CrossRef]

- Hu, J.J.; Sun, W.M.; Jiang, Z.H.; Zhang, W.; Lu, J.W.; Huo, W.T.; Zhang, Y.S.; Zhang, P.X. Indentation size effect on hardness in the body-centered cubic coarse-grained and nanocrystalline tantalum. Mater. Sci. Eng. A 2017, 686, 19–25. [Google Scholar] [CrossRef]

- Hu, J.J.; Zhang, W.; Bi, G.L.; Lu, J.W.; Huo, W.T.; Zhang, Y.S. Nanoindentation creep behavior of coarse-grained and ultrafine-grained pure magnesium and AZ31 alloy. Mater. Sci. Eng. A 2017, 698, 348–355. [Google Scholar] [CrossRef]

- Hu, J.J.; Zhang, W.; Peng, G.J.; Zhang, T.H.; Zhang, Y.S. Nanoindentation deformation of refine-grained AZ31 magnesium alloy: Indentation size effect, pop-in effect and creep behavior. Mater. Sci. Eng. A 2018, 725, 522–529. [Google Scholar] [CrossRef]

- Zhang, W.; Huo, W.T.; Lu, J.W.; Hu, J.J.; Wei, Q.; Zhang, Y.S. Gradient shear banding in a magnesium alloy induced by sliding friction treatment. Vacuum 2017, 143, 95–97. [Google Scholar] [CrossRef]

- Ma, Y.; Huang, X.W.; Hang, W.; Liu, M.; Song, Y.X.; Yuan, L.; Zhang, T.H. Nanoindentation size effect on stochastic behavior of incipient plasticity in a LiTaO3 single crystal. Eng. Fract. Mech. 2020, 226, 106877. [Google Scholar] [CrossRef]

- Cho, T.-S.; Lee, H.-J.; Ahn, B.; Kawasaki, M.; Langdon, T.G. Microstructural evolution and mechanical properties in a Zn–Al eutectoid alloy processed by high-pressure torsion. Acta Mater. 2014, 72, 67–79. [Google Scholar] [CrossRef]

- Mazilkin, A.; Straumal, B.; Rabkin, E.; Baretzky, B.; Enders, S.; Protasova, S.; Kogtenkova, O.; Valiev, R. Softening of nanostructured Al–Zn and Al–Mg alloys after severe plastic deformation. Acta Mater. 2006, 54, 3933–3939. [Google Scholar] [CrossRef]

- Choi, I.-C.; Kim, Y.-J.; Ahn, B.; Kawasaki, M.; Langdon, T.G.; Jang, J.-I. Evolution of plasticity, strain-rate sensitivity and the underlying deformation mechanism in Zn–22% Al during high-pressure torsion. Scr. Mater. 2014, 75, 102–105. [Google Scholar] [CrossRef]

- Feldner, P.; Merle, B.; Göken, M. Superplastic deformation behavior of Zn-22% Al alloy investigated by nanoindentation at elevated temperatures. Mater. Des. 2018, 153, 71–79. [Google Scholar] [CrossRef]

- Sun, Z.; Van Petegem, S.; Cervellino, A.; Durst, K.; Blum, W.; Van Swygenhoven, H. Dynamic recovery in nanocrystalline Ni. Acta Mater. 2015, 91, 91–100. [Google Scholar] [CrossRef]

- Sun, W.M.; Jiang, Y.; Sun, G.X.; Hu, J.J.; Zhou, T.Y.; Jiang, Z.H.; Lian, J.S. Nanoindentation creep behavior and its relation to activation volume and strain rate sensitivity of nanocrystalline Cu. Mater. Sci. Eng. A 2019, 751, 35–41. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Wei, Q.M.; Niu, H.Z.; Li, Y.S.; Chen, C.; Yu, Z.T.; Bai, X.F.; Zhang, P.X. Formation of nanocrystalline structure in tantalum by sliding-friction treatment. Int. J. Refract. Met. H. 2014, 45, 71–75. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Zhang, P.X.; Niu, H.Z.; Chen, C.; Wang, G.; Xiao, D.H.; Chen, X.H.; Yu, Z.T.; Yuan, S.B.; Bai, X.F. Surface nanocrystallization of Cu and Ta by sliding friction. Mater. Sci. Eng. A 2014, 607, 351–355. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, J.W.; Huo, W.T.; Zhang, Y.S.; Wei, Q.M. Microstructural evolution of AZ31 magnesium alloy subjected to sliding-friction treatment. Philos. Mag. 2018, 98, 1576–1593. [Google Scholar] [CrossRef]

- Zhang, W.; Du, Y.; Huo, W.T.; Hu, J.J.; Lu, J.W.; Zhao, X.; Zhang, L.C.; Zhang, Y.S. Microstructure and mechanical properties of Zamak 3 alloy subjected to sliding-friction treatment. Metall. Mater. Trans. A 2019, accepted. [Google Scholar] [CrossRef]

- Lucas, B.N.; Oliver, W.C. Indentation Power-Law Creep of High-Purity Indium. Metall. Mater. Trans. A 1999, 30, 601–610. [Google Scholar] [CrossRef]

- Peng, G.J.; Xu, F.L.; Chen, J.F.; Hu, Y.H.; Wang, H.D.; Zhang, T.H. A cost-effective voice coil motor-based portable micro-indentation device for in situ testing. Measurement 2020, 165, 108105. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Conrad, H.; Narayan, J. Mechanisms for grain size hardening and softening in Zn. Acta Mater. 2002, 50, 5067–5078. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Langdon, T.G. Developing superplasticity in a magnesium AZ31 alloy by ECAP. J. Mater. Sci. 2008, 43, 7366–7371. [Google Scholar] [CrossRef]

- Xun, Y.; Mohamed, F.A. Slip-accommodated superplastic flow in Zn-22 wt%Al. Philos. Mag. 2010, 83, 2247–2266. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Langdon, T.G. Principles of grain refinement and superplastic flow in magnesium alloys processed by ECAP. Mater. Sci. Eng. A 2009, 501, 105–114. [Google Scholar] [CrossRef]

- Park, K.-T.; Lee, H.-J.; Lee, C.S.; Nam, W.J.; Shin, D.H. Enhancement of high strain rate superplastic elongation of a modified 5154 Al by subsequent rolling after equal channel angular pressing. Scr. Mater. 2004, 51, 479–483. [Google Scholar] [CrossRef]

- Conrad, H. Thermally activated deformation of metals. J. Miner. Met. Mater. Soc. 1964, 16, 582–588. [Google Scholar] [CrossRef]

- Cahn, J.; Nabarro, F. Thermal activation under shear. Philos. Mag. A 2001, 81, 1409–1426. [Google Scholar] [CrossRef]

- Wei, Q.; Cheng, S.; Ramesh, K.T.; Ma, E. Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: Fcc versus bcc metals. Mater. Sci. Eng. A 2004, 381, 71–79. [Google Scholar] [CrossRef]

- Kobrinsky, M.J.; Thompson, C.V. Activation volume for inelastic deformation in polycrystalline Ag thin films. Acta Mater. 2000, 48, 625–633. [Google Scholar] [CrossRef]

- Duhamel, C.; Brechet, Y.; Champion, Y. Activation volume and deviation from Cottrell–Stokes law at small grain size. Int. J. Plast. 2010, 26, 747–757. [Google Scholar] [CrossRef]

- Li, H.; Duan, Q.Q.; Li, X.W.; Zhang, Z.F. Compressive and fatigue damage behavior of commercially pure zinc. Mater. Sci. Eng. A 2007, 466, 38–46. [Google Scholar] [CrossRef]

- Phani, P.S.; Oliver, W.C. A direct comparison of high temperature nanoindentation creep and uniaxial creep measurements for commercial purity aluminum. Acta Mater. 2016, 111, 31–38. [Google Scholar] [CrossRef]

| Materials | n (0.004/s) | n (0.04/s) | n (0.4/s) |

|---|---|---|---|

| UFG Zn alloy | 3.71 | 3.93 | 4.03 |

| CG+twinning Zn alloy | 5.08 | 6.66 | 7.15 |

| CG Zn alloy | 8.66 | 10.97 | 12.88 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Sun, S.; Zhang, W.; Peng, G.; Han, S.; Sun, X.; Zhang, Y.; Zhang, T. Softening Behaviors of Severely Deformed Zn Alloy Studied by the Nanoindentation. Coatings 2020, 10, 803. https://doi.org/10.3390/coatings10090803

Hu J, Sun S, Zhang W, Peng G, Han S, Sun X, Zhang Y, Zhang T. Softening Behaviors of Severely Deformed Zn Alloy Studied by the Nanoindentation. Coatings. 2020; 10(9):803. https://doi.org/10.3390/coatings10090803

Chicago/Turabian StyleHu, Jiangjiang, Shuo Sun, Wei Zhang, Guangjian Peng, Shuang Han, Xu Sun, Yusheng Zhang, and Taihua Zhang. 2020. "Softening Behaviors of Severely Deformed Zn Alloy Studied by the Nanoindentation" Coatings 10, no. 9: 803. https://doi.org/10.3390/coatings10090803

APA StyleHu, J., Sun, S., Zhang, W., Peng, G., Han, S., Sun, X., Zhang, Y., & Zhang, T. (2020). Softening Behaviors of Severely Deformed Zn Alloy Studied by the Nanoindentation. Coatings, 10(9), 803. https://doi.org/10.3390/coatings10090803