Preparation and Characterization of Self-Dispersing Phthalocyanine Blue 15:4 Pigment for Dyeing of Wool Textiles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

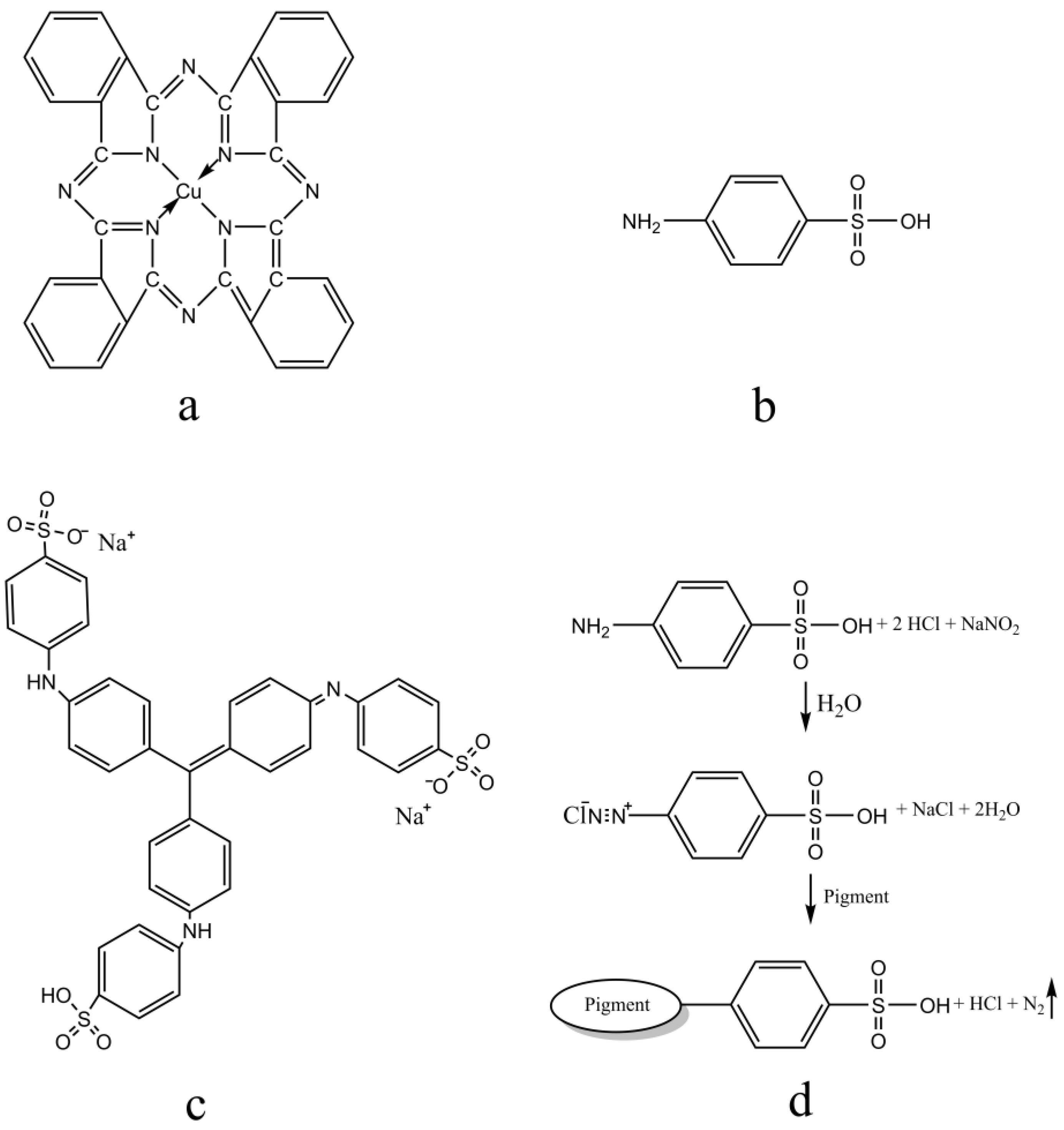

2.2. Preparation of Self-Dispersing Pigment

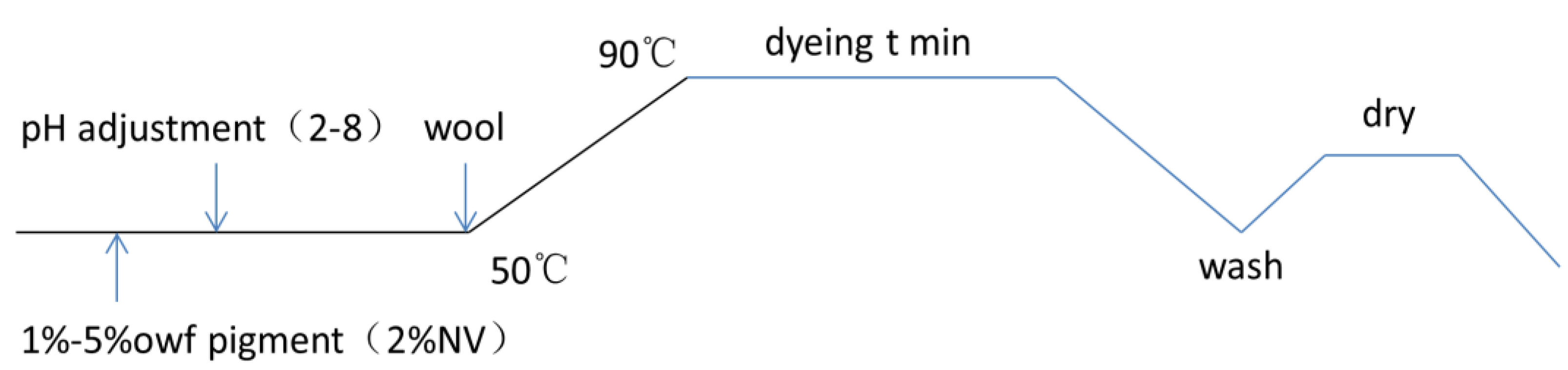

2.3. Dyeing Procedure

2.4. Testing and Measurements

2.4.1. Particle Size, PDI, and Zeta Potential

2.4.2. Absorption of Pigment and Pigment Uptake

2.4.3. X-ray Photoelectron Spectroscopy (XPS) Measurements

2.4.4. Color Strength

2.4.5. Rubbing Fastness

2.4.6. Light Fastness

2.4.7. Dye Permeability

3. Results and Discussion

3.1. Particle Size, PDI, and Zeta Potential

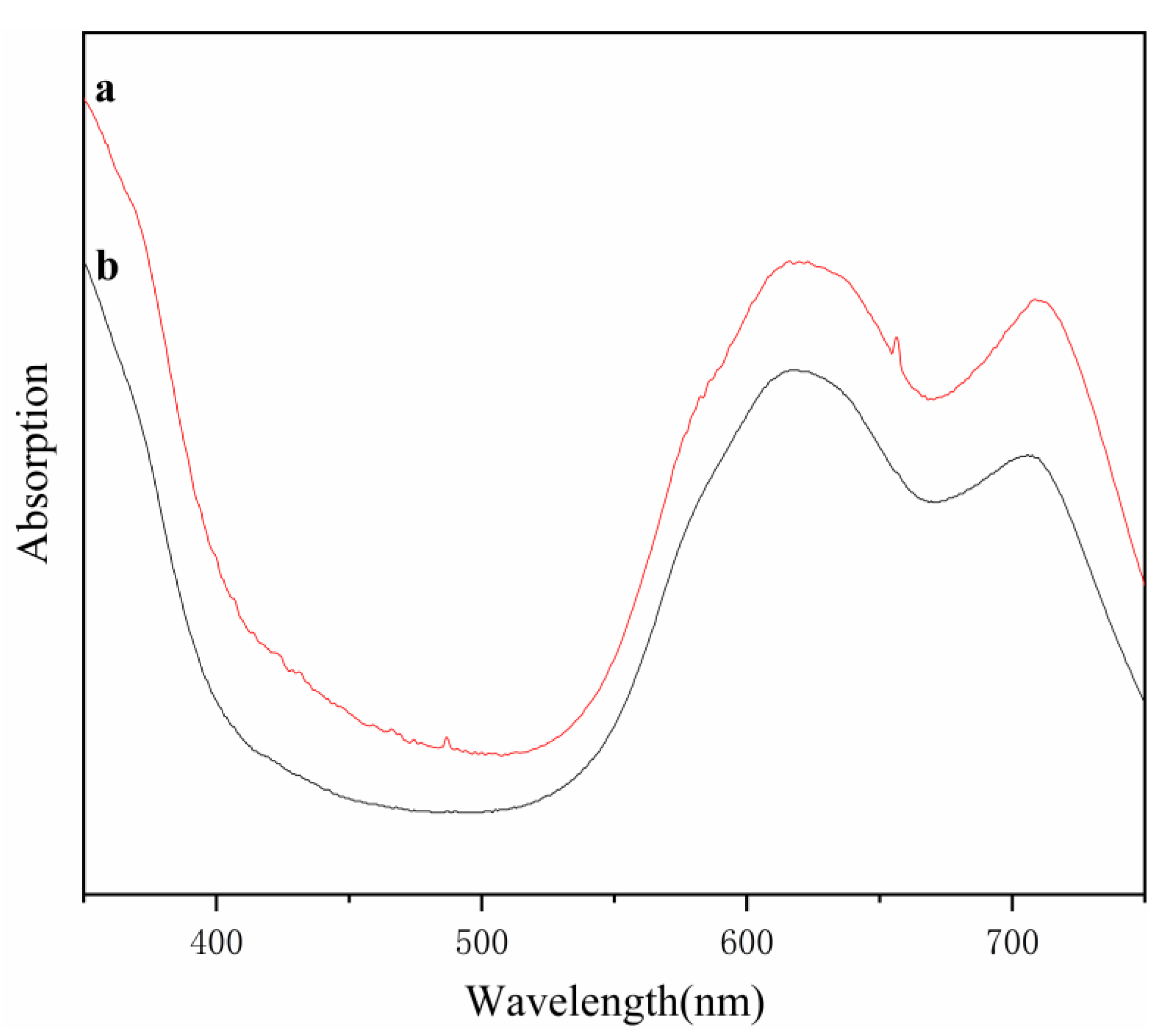

3.2. UV–Vis Absorption

3.3. XPS

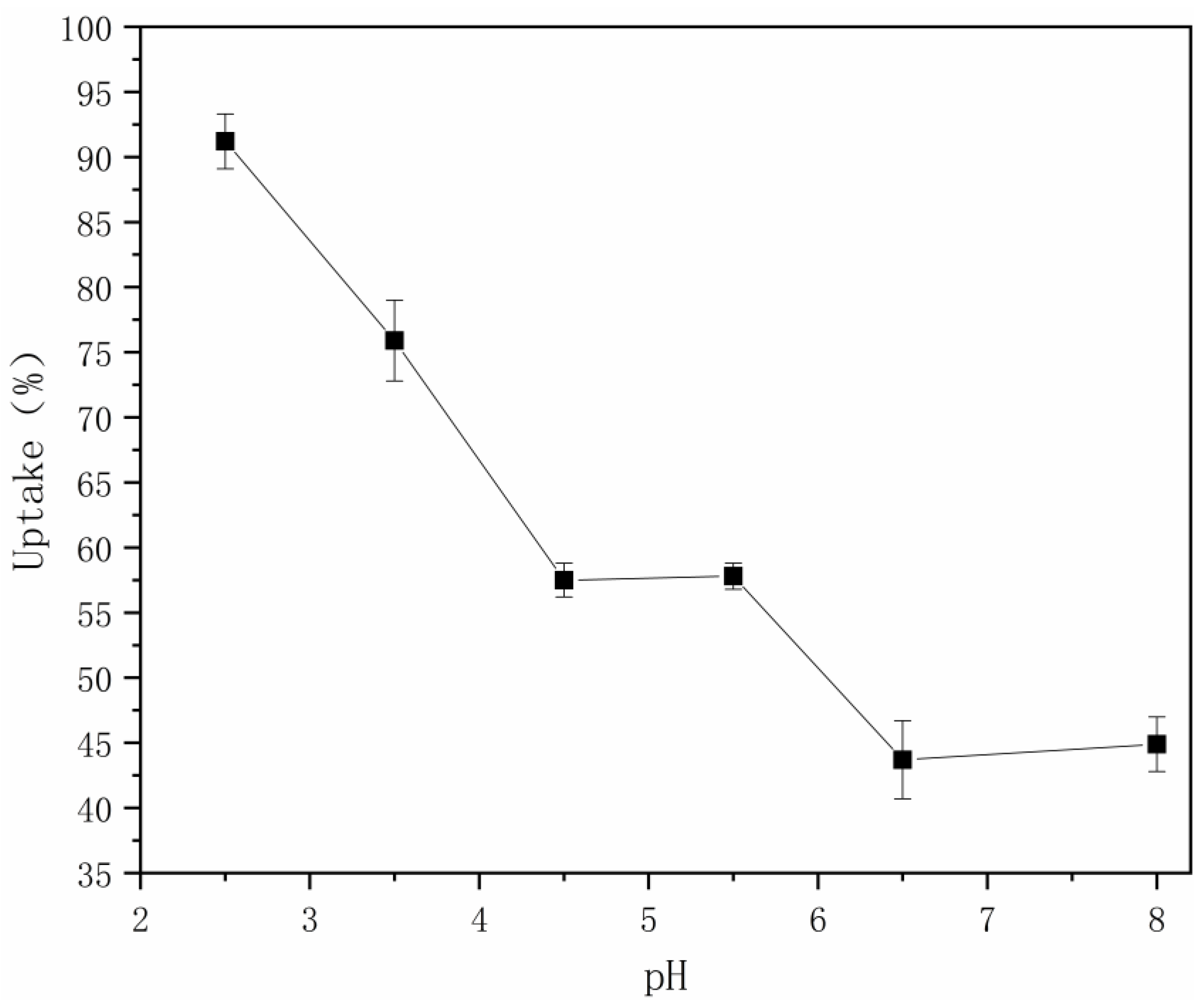

3.4. Effect of Dyebath pH on Uptake

3.5. Effect of Dyeing Time on Uptake

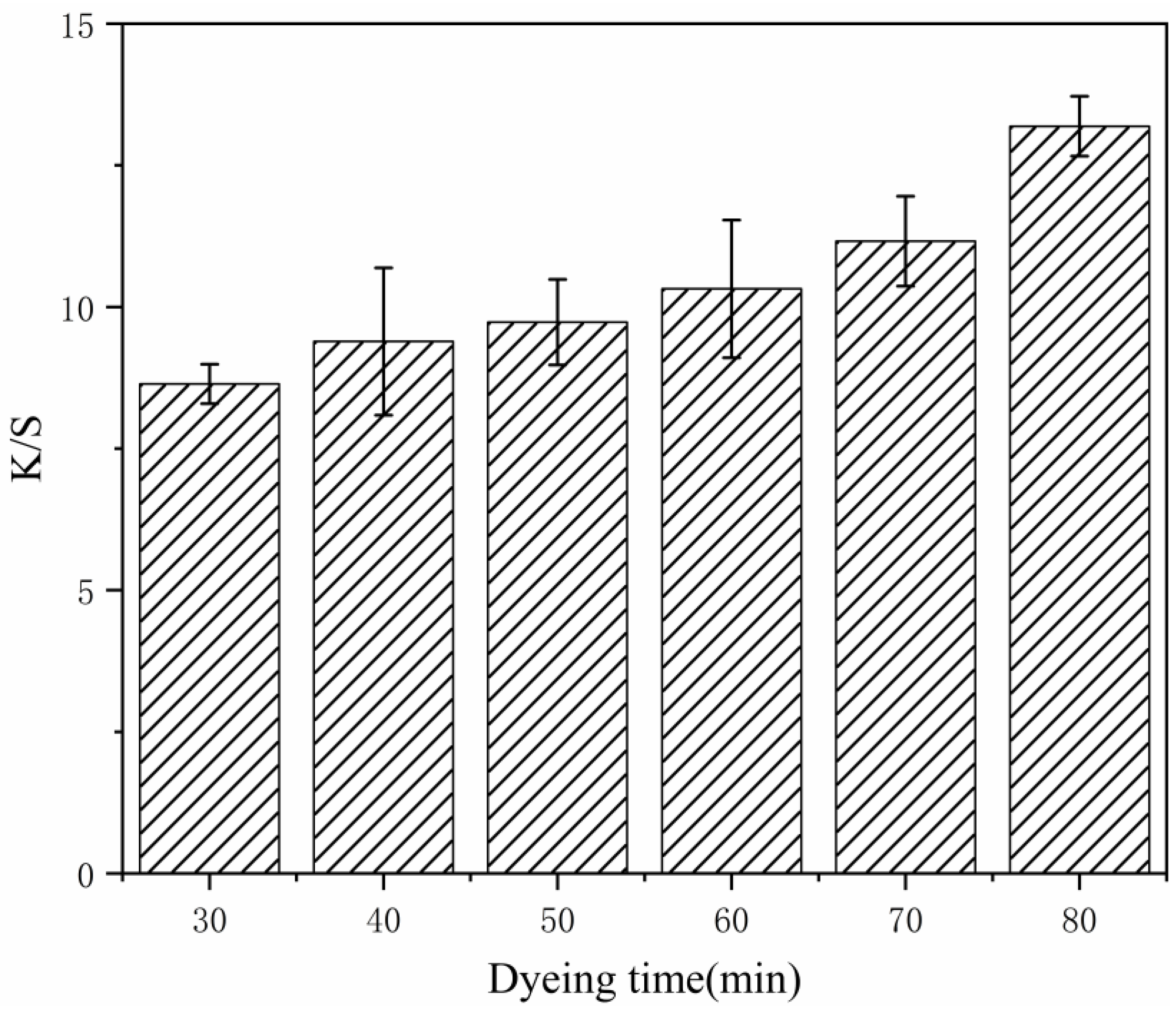

3.6. Effect of Dyeing Time on K/S Value

3.7. Effect of Pigment Amount on K/S Value

3.8. Comparison of Distribution on Dyed Fabric

3.9. Comparison of Fastness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Burkinshaw, S.M.; Kumar, N. The mordant dyeing of wool using tannic acid and FeSO4, Part 1: Initial findings. Dyes Pigment. 2009, 80, 53–60. [Google Scholar] [CrossRef]

- Fakin, D.; Ojstrsek, A.; Benkovic, S.C. The impact of corona modified fibres’ chemical changes on wool dyeing. J. Mater. Process. Technol. 2009, 209, 584–589. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Hou, W.F.; Tan, Y.P. Structure and dyeing properties of some anthraquinone violet acid dyes. Dyes Pigment. 1997, 34, 25–35. [Google Scholar] [CrossRef]

- Wang, H.Y.; Wang, G.W.; Zheng, C.L.; Zhou, T.J.; Sun, J. Synthesis of acid dyes containing polyetheramine moieties and their low-temperature dyeing properties on wool fiber. J. Appl. Polym. Sci. 2018, 135, 9. [Google Scholar] [CrossRef]

- Cai, Z.S.; Qiu, Y.P. Dyeing properties of wool fabrics treated with atmospheric pressure plasmas. J. Appl. Polym. Sci. 2008, 109, 1257–1261. [Google Scholar] [CrossRef]

- Abdelrahman, M.S.; Nassar, S.H.; Mashaly, H.; Mahmoud, S.; Maamoun, D.; El-Sakhawy, M.; Khattab, T.A.; Kamel, S. Studies of Polylactic Acid and Metal Oxide Nanoparticles-Based Composites for Multifunctional Textile Prints. Coatings 2020, 10, 58. [Google Scholar] [CrossRef]

- Assefi Pour, R.; He, J. Surface Functionalization of Wool via Microbial-Transglutaminase as Bio-Mordant to Improve Dyeability with Madder in the Presence of Alum. Coatings 2020, 10, 78. [Google Scholar] [CrossRef]

- Shams-Nateri, A. Reusing wastewater of madder natural dye for wool dyeing. J. Clean. Prod. 2011, 19, 775–781. [Google Scholar] [CrossRef]

- Ozturk, E.; Karaboyaci, M.; Yetis, U.; Yigit, N.O.; Kitis, M. Evaluation of Integrated Pollution Prevention Control in a textile fiber production and dyeing mill. J. Clean. Prod. 2015, 88, 116–124. [Google Scholar] [CrossRef]

- Tigini, V.; Prigione, V.; Giansanti, P.; Mangiavillano, A.; Pannocchia, A.; Varese, G.C. Fungal Biosorption, an Innovative Treatment for the Decolourisation and Detoxification of Textile Effluents. Water 2010, 2, 550–565. [Google Scholar] [CrossRef]

- Zhou, L.; Zhou, H.J. Evaluation of textile industry wastewater treatment and reuse in China. Desalin. Water Treat. 2019, 144, 330–338. [Google Scholar] [CrossRef]

- Bisschops, I.; Spanjers, H. Literature review on textile wastewater characterisation. Environ. Technol. 2003, 24, 1399–1411. [Google Scholar] [CrossRef]

- Liang, W.; Hu, H.Y.; Song, Y.D.; Wang, H.; Guo, Y.F. Effects of thiamine on treatment performance of textile wastewater. Desalination 2009, 242, 110–114. [Google Scholar] [CrossRef]

- Wang, C.; Fang, K.; Ji, W. Superfine pigment dyeing of silk fabric by exhaust process. Fibers Polym. 2007, 8, 225–229. [Google Scholar] [CrossRef]

- Hao, L.Y.; Cai, Y.Q.; Wang, R. Preparation of Ultrafine Pigment Dispersion and Investigation of its Adsorption Performance on Cationized Flax Substrate. Adsorpt. Sci. Technol. 2011, 29, 875–885. [Google Scholar] [CrossRef]

- Ma, W.; Du, S.; Yan, S.; Yu, X.; Zhang, Z.; Zhang, S. Salt-Free Dyeing of Modified Cotton through Graft Polymerization with Highly Enhanced Dye Fixation and Good Strength Properties. Polymers 2020, 12, 462. [Google Scholar] [CrossRef]

- Wang, M.; Wang, X.; Guo, C.; Zhao, T.; Li, W. A Feasible Method Applied to One-Bath Process of Wool/Acrylic Blended Fabrics with Novel Heterocyclic Reactive Dyes and Application Properties of Dyed Textiles. Polymers 2020, 12, 285. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.Z.; Wei, X.F.; Huang, P.Q.; Liu, Q.L. Preparation of the Plastic Water-Based Gravure Primary Ink with High Pigment. Adv. Mater. Res. 2011, 380, 15–19. [Google Scholar] [CrossRef]

- Vega Gutierrez, S.M.; He, Y.; Cao, Y.; Stone, D.; Walsh, Z.; Malhotra, R.; Chen, H.-L.; Chang, C.-H.; Robinson, S.C. Feasibility and Surface Evaluation of the Pigment from Scytalidium cuboideum for Inkjet Printing on Textiles. Coatings 2019, 9, 266. [Google Scholar] [CrossRef]

- Rocha, S.; Freitas, L., Jr.; Costa, C. Smart, Photocatalytic and Self-Cleaning Asphalt Mixtures: A Literature Review. Coatings 2019, 9, 696. [Google Scholar] [CrossRef]

- Chiloeches, A.; Echeverría, C.; Fernández-García, M.; Muñoz-Bonilla, A. Influence of Polymer Composition and Substrate on the Performance of Bioinspired Coatings with Antibacterial Activity. Coatings 2019, 9, 733. [Google Scholar] [CrossRef]

- Saleemi, S.; Naveed, T.; Riaz, T.; Memon, H.; Awan, J.A.; Siyal, M.I.; Xu, F.; Bae, J. Surface Functionalization of Cotton and PC Fabrics Using SiO2 and ZnO Nanoparticles for Durable Flame Retardant Properties. Coatings 2020, 10, 124. [Google Scholar] [CrossRef]

- Rossi, S.; Russo, F.; Bouchakour Rahmani, L. Study of the Durability and Aesthetical Properties of Powder Coatings Admixed with Pearlescent Pigments. Coatings 2020, 10, 229. [Google Scholar] [CrossRef]

- Kasaw, E.; Haile, A.; Getnet, M. Conductive Coatings of Cotton Fabric Consisting of Carbonized Charcoal for E-Textile. Coatings 2020, 10, 579. [Google Scholar] [CrossRef]

- Gorgieva, S.; Virant, N.; Ojstrsek, A. Complementary Assessment of Commercial Photoluminescent Pigments Printed on Cotton Fabric. Polymers 2019, 11, 1216. [Google Scholar] [CrossRef]

- Hakeim, O.A.; Abdelghaffar, F.; Haroun, A.A. UV-curable hyperbranched polyester acrylate encapsulation of phthalocyanine pigments for high performance synthetic fabrics printing. Dyes Pigment. 2020, 177. [Google Scholar] [CrossRef]

- Gao, D.; Feng, J.; Ma, J.; Lu, B.; Lin, J.; Zhang, J. Synthesis of cationic binder through surfactant-free emulsion polymerization for textile pigment applications. Prog. Org. Coat. 2014, 77, 1834–1840. [Google Scholar] [CrossRef]

- El-Shishtawy, R.M.; Nassar, S.H. Cationic pretreatment of cotton fabric for anionic dye and pigment printing with better fastness properties. Color. Technol. 2002, 118, 115–120. [Google Scholar] [CrossRef]

- Hakeim, O.A.; Abdou, L.A.W.; El-Gammal, M.S.; El-Naggar, A.M. An approach for vat color printing on cotton and polyester fabrics with electron beam irradiation curable formulations. Carbohydr. Polym. 2012, 87, 1467–1475. [Google Scholar] [CrossRef]

- Fang, K.; Jiang, X.; Wang, C.; Wu, M.; Yan, Y. Properties of the nanoscale hydrophilic cationic pigment based on quaternary surfactant. J. Dispers. Sci. Technol. 2008, 29, 52–57. [Google Scholar] [CrossRef]

- Cao, L.; Fei, X.; Zhao, H.; Huang, C. Preparation of phthalocyanine blue/rutile TiO2 composite pigment with a ball milling method and study on its NIR reflectivity. Dyes Pigment. 2020, 173. [Google Scholar] [CrossRef]

- Zhang, B.L.; Zhang, Z.Z.; Fei, X.N.; Gu, Y.C.; Yu, L. Preparation and properties of CI Pigment Red 170 modified with silica fume. Pigment. Resin. Technol. 2016, 45, 141–148. [Google Scholar] [CrossRef]

- Hao, L.; Wang, R.; Liu, J.; Liu, R. Ultrasound-assisted adsorption of anionic nanoscale pigment on cationised cotton fabrics. Carbohydr. Polym. 2012, 90, 1420–1427. [Google Scholar] [CrossRef]

- Li, Y.; Ren, J.; Chen, S.; Fan, F.; Shen, Q.; Wang, C. Cationic Superfine Pigment Dyeing for Wool Using Exhaust Process by pH Adjustment. Fibers Polym. 2015, 16, 67–72. [Google Scholar] [CrossRef]

- Wang, K.; Wang, C.; Wang, C. Acrylic yarns dyeing properties of cationic ultra-fine pigment modified by TDBAC. Colloids Surf. A 2013, 431, 114–119. [Google Scholar] [CrossRef]

- Cao, G.; Lu, X.; Xu, W.; Wang, X. Electrochemical Pigment Coloring of Wool Fabrics. Fibers Polym. 2018, 19, 65–70. [Google Scholar] [CrossRef]

- Li, M.; Zhang, L.; Qiu, M.; Zhang, Y.; Fu, S. Dyeing property of fluorescent pigment latex on cationic knitted cotton fabrics. Text. Res. J. 2019, 89, 422–433. [Google Scholar] [CrossRef]

- Ma, T.; Cao, Y.; Chen, H. Synthesis and characterization of cationic carbon black pigment with quaternary ammonium groups and its dyeing properties for wool fabrics. Colloids Surf. A 2018, 549, 43–49. [Google Scholar] [CrossRef]

- Eshkalak, S.K.; Khatibzadeh, M.; Kowsari, E.; Chinnappan, A.; Ramakrishna, S. A novel surface modification of copper (II) phthalocyanine with ionic liquids as electronic ink. Dyes Pigment. 2018, 154, 296–302. [Google Scholar] [CrossRef]

- Eshkalak, S.K.; Khatibzadeh, M.; Kowsari, E.; Chinnappan, A.; Ramakrishna, S. Application of ionic liquids as charge control agents of pigments and preparation of microcapsules as electronic inks through electrospraying. Opt. Mater. 2018, 84, 73–81. [Google Scholar] [CrossRef]

- Leelajariyakul, S.; Noguchi, H.; Kiatkamjornwong, S. Surface-modified and micro-encapsulated pigmented inks for ink jet printing on textile fabrics. Prog. Org. Coat. 2008, 62, 145–161. [Google Scholar] [CrossRef]

- Li, D.; Sun, G. Coloration of textiles with self-dispersible carbon black nanoparticles. Dyes Pigment. 2007, 72, 144–149. [Google Scholar] [CrossRef]

- Nagose, S.; Rose, E.; Joshi, A. Study on wetting and dispersion of the Pigment Yellow 110. Prog. Org. Coat. 2019, 133, 55–60. [Google Scholar] [CrossRef]

- Yu, Y.; Gambale, R.J.; Amici, R.M. Process for Preparing Surface-Modified Pigments and Applications for Ink Jet Ink. Patent WO2000052102A1, 8 September 2000. [Google Scholar]

- Shakhnovich, A.I. Modified Pigments. U.S. Patent 8,771,411B2, 8 July 2014. [Google Scholar]

| Particle Size (nm) | PDI | Zeta Potential (mV) |

|---|---|---|

| 134.5 | 0.216 | −45.4 |

| Sample | C (%) | N (%) | O (%) | S (%) |

|---|---|---|---|---|

| UP | 80.09 | 16.63 | 3.07 | 0.21 |

| MP | 75.61 | 12.45 | 10.19 | 1.74 |

| Sample | Light Fastness | Dry Rubbing Fastness | Wet Rubbing Fastness |

|---|---|---|---|

| MP | 5 | 3 | 3 |

| Dye | 3 | 3 | 3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nie, L.; Chang, G.; Li, R. Preparation and Characterization of Self-Dispersing Phthalocyanine Blue 15:4 Pigment for Dyeing of Wool Textiles. Coatings 2020, 10, 741. https://doi.org/10.3390/coatings10080741

Nie L, Chang G, Li R. Preparation and Characterization of Self-Dispersing Phthalocyanine Blue 15:4 Pigment for Dyeing of Wool Textiles. Coatings. 2020; 10(8):741. https://doi.org/10.3390/coatings10080741

Chicago/Turabian StyleNie, Lun, Guangtao Chang, and Ruoxin Li. 2020. "Preparation and Characterization of Self-Dispersing Phthalocyanine Blue 15:4 Pigment for Dyeing of Wool Textiles" Coatings 10, no. 8: 741. https://doi.org/10.3390/coatings10080741

APA StyleNie, L., Chang, G., & Li, R. (2020). Preparation and Characterization of Self-Dispersing Phthalocyanine Blue 15:4 Pigment for Dyeing of Wool Textiles. Coatings, 10(8), 741. https://doi.org/10.3390/coatings10080741