Active Biopolymer Coating Based on Sodium Caseinate: Physical Characterization and Antioxidant Activity

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Coating/Film-Making Procedure

2.3. Rheological Analysis

2.4. Kinetics of Water Desorption

2.5. Coating Application on Fennel and Thickness Estimation

2.6. Film Physiochemical Properties

2.7. Antioxidant Capacity of Bioactive Coating

3. Results

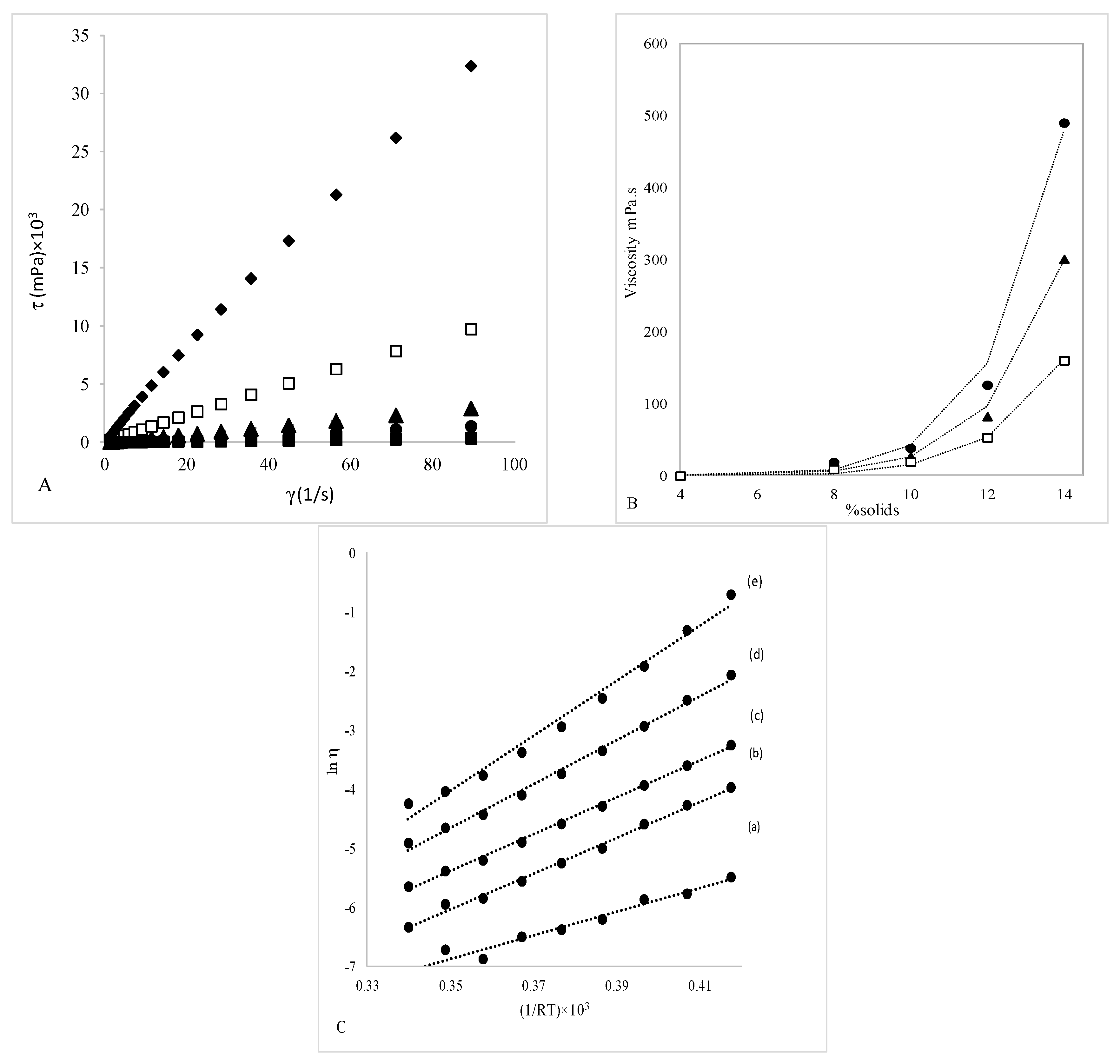

3.1. Rheological Analysis

3.2. Kinetics of Water Desorption

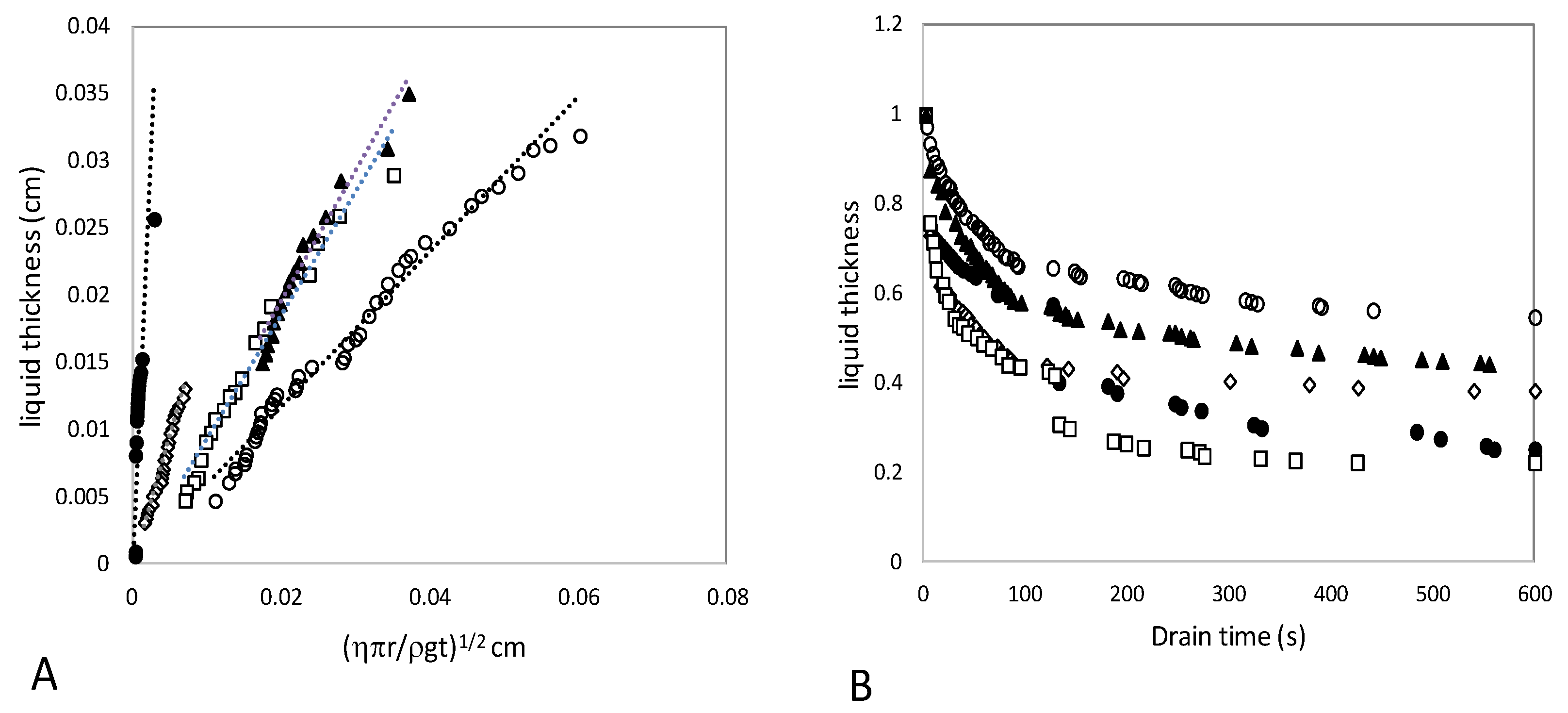

3.3. Amount of Coating Adhered on Fennel and Coating Thickness

3.4. Physiochemical Properties and WVP

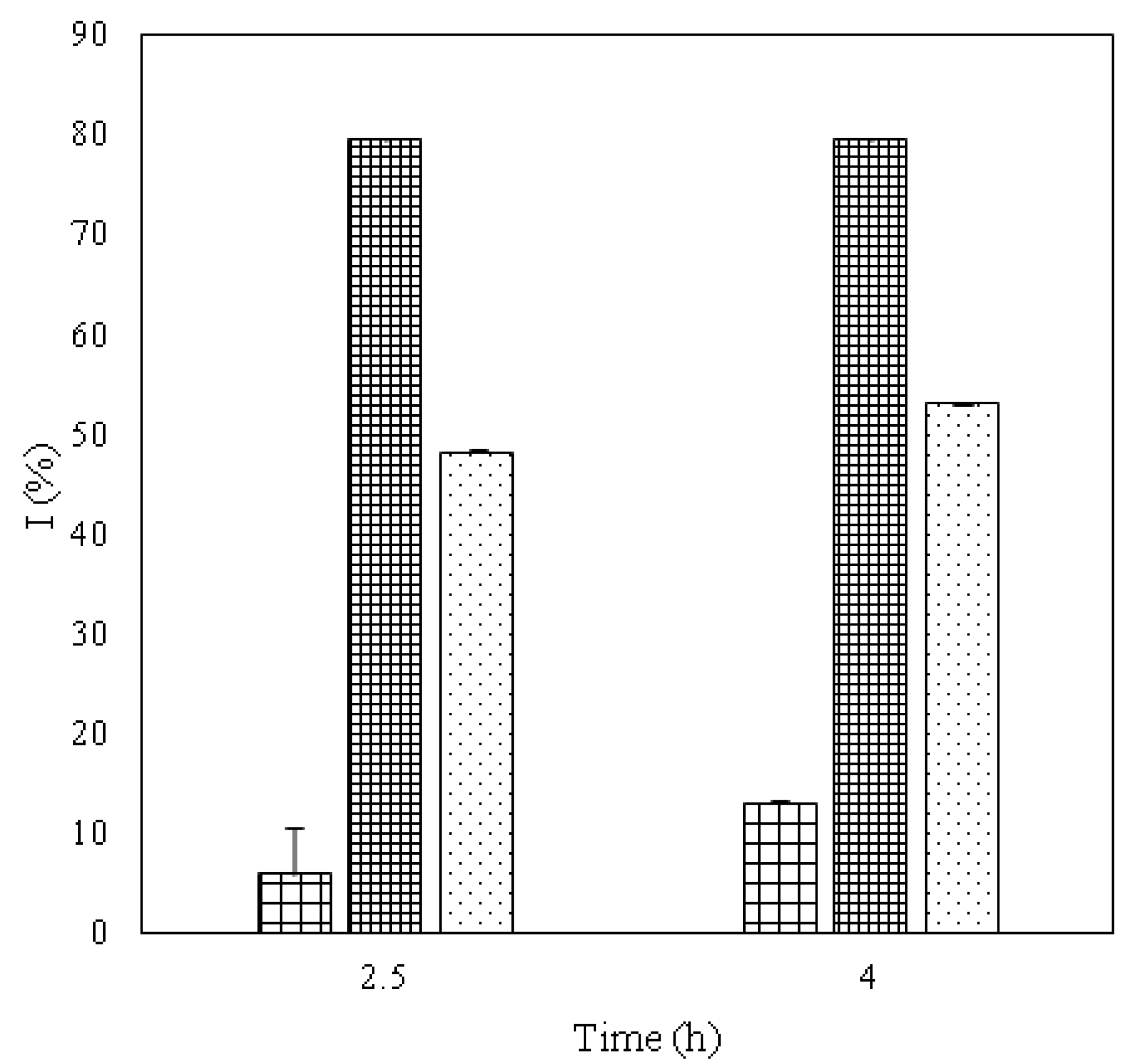

3.5. Antioxidant Activity

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yousuf, B.; Qadri, O.S.; Srivastava, A.K. Recent developments in shelf-life extension of fresh-cut fruits and vegetables by application of different edible coatings: A review. LWT 2018, 89, 198–209. [Google Scholar] [CrossRef]

- Volpe, S.; Cavella, S.; Torrieri, E. Biopolymer coatings as alternative to modified atmosphere packaging for shelf life extension of minimally processed apples. Coatings 2019, 9, 569. [Google Scholar] [CrossRef]

- Colak, B.Y.; Gouanve, F.; Degraeve, P.; Espuche, E.; Prochazka, F. Study of the influences of film processing conditions and glycerol amount on the water sorption and gas barrier properties of novel sodium caseinate films. J. Membr. Sci. 2015, 478, 1–11. [Google Scholar] [CrossRef]

- Hernandez-Izquierdo, V.M.; Krochta, J.M. Thermoplastic processing of proteins for film formation—A review. J. Food Sci. 2008, 73, R30–R39. [Google Scholar] [CrossRef] [PubMed]

- Certel, M.; Uslu, M.K.; Ozdemir, F. Effects of sodium caseinate- and milk protein concentrate-based edible coatings on the postharvest quality of Bing cherries. J. Sci. Food Agric. 2004, 84, 1229–1234. [Google Scholar] [CrossRef]

- Iahtisham-Ul-Haq; Butt, M.S.; Suleria, H.A.R.; Ahmed, W. Physicochemical behavior of zinc-fortified, sodium caseinate-based, edible-coated apricots during storage in controlled atmosphere: Zinc-fortified edible coating of apricots. J. Food Process. Preserv. 2015, 39, 2431–2441. [Google Scholar] [CrossRef]

- Park, H.; Bunn, J.; Vergano, P.; Testin, R. Gas permeation and thickness of the sucrose polyester Semperfresh coatings on apples. J. Food Proc. Preserv. 1994, 8, 349–358. [Google Scholar] [CrossRef]

- Cisneros-Zevallos, L.; Krochta, J.M. Dependence of coating thickness on viscosity of coating solution applied to fruits and vegetables by dipping method. J. Food Sci. 2003, 68, 503–510. [Google Scholar] [CrossRef]

- Carocho, M.; Barreiro, M.F.; Morales, P.; Ferreira, I.C.F.R. Adding molecules to food, pros and cons: A review on synthetic and natural food additives. Compr. Rev. Food Sci. Food Saf. 2014, 13, 377–399. [Google Scholar] [CrossRef]

- Bonilla, J.; Sobral, P.J.A. Antioxidant and physicochemical properties of blended films based on gelatin-sodium caseinate activated with natural extracts. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Strlič, M.; Radovič, T.; Kolar, J.; Pihlar, B. Anti- and prooxidative properties of gallic acid in fenton-type systems. J. Agric. Food Chem. 2002, 50, 6313–6317. [Google Scholar] [CrossRef] [PubMed]

- Kivilompolo, M.; Obůrka, V.; Hyötyläinen, T. Comparison of GC–MS and LC–MS methods for the analysis of antioxidant phenolic acids in herbs. Anal. Bioanal. Chem. 2007, 388, 881–887. [Google Scholar] [CrossRef] [PubMed]

- Shan, B.; Cai, Y.Z.; Sun, M.; Corke, H. Antioxidant capacity of 26 spice extracts and characterization of their phenolic constituents. J. Agric. Food Chem. 2005, 53, 7749–7759. [Google Scholar] [CrossRef] [PubMed]

- De Vasconcelos, M.D.C.B.M.; Bennett, R.N.; Rosa, E.A.S.; Cardoso, J.V.F. Primary and secondary metabolite composition of kernels from three cultivars of portuguese chestnut (castanea sativa mill.) at different stages of industrial transformation. J. Agric. Food Chem. 2007, 55, 3508–3516. [Google Scholar] [CrossRef]

- Kahraman, T.; Issa, G.; Bingol, E.B.; Kahraman, B.B.; Dumen, E. Effect of rosemary essential oil and modified-atmosphere packaging (MAP) on meat quality and survival of pathogens in poultry fillets. Braz. J. Microbiol. 2015, 46, 591–599. [Google Scholar] [CrossRef]

- Pereira, P.S.; Maia, A.J.; Tintino, S.R.; Oliveira-Tintino, C.D.D.M.; Raulino, I.S.D.S.; Vega, M.C.; Rolón, M.; Coronel, C.; Barros, L.M.; Duarte, A.E.; et al. Trypanocide, antileishmania and cytotoxic activities of the essential oil from Rosmarinus officinalis L in vitro. Ind. Crops Prod. 2017, 109, 724–729. [Google Scholar] [CrossRef]

- Qiu, X.; Jacobsen, C.; Sørensen, A.-D.M. The effect of rosemary (Rosmarinus officinalis L.) extract on the oxidative stability of lipids in cow and soy milk enriched with fish oil. Food Chem. 2018, 263, 119–126. [Google Scholar] [CrossRef]

- Wang, B.; Ma, L.; Yin, L.; Chen, J.; Zhang, Y.; Dong, L.; Zhang, X.; Fu, X. Regional variation in the chemical composition and antioxidant activity of Rosmarinus officinalis L. from China and the Mediterranean region. Pak. J. Pharm. Sci. 2018, 31, 221–229. [Google Scholar]

- Moreno, S.; Scheyer, T.; Romano, C.S.; Vojnov, A.A. Antioxidant and antimicrobial activities of rosemary extracts linked to their polyphenol composition. Free Radic. Res. 2006, 40, 223–231. [Google Scholar] [CrossRef]

- Volpe, S.; Cavella, S.; Masi, P.; Torrieri, E. Effect of solid concentration on structure and properties of chitosan-caseinate blend films. Food Packag. Shelf Life 2017, 13, 76–84. [Google Scholar] [CrossRef]

- Barreto, P.L.M.; Roeder, J.; Crespo, J.S.; Maciel, G.R.; Terenzi, H.; Pires, A.T.N.; Soldi, V. Effect of concentration, temperature and plasticizer content on rheological properties of sodium caseinate and sodium caseinate/sorbitol solutions and glass transition of their films. Food Chem. 2003, 82, 425–431. [Google Scholar] [CrossRef]

- ASTM. Standard Test Methods for Water-Vapor Transmission Of Materials E96-93; ASTM: West Conshohocken, PA, USA, 1993; Volume 04.06, pp. 701–708. [Google Scholar]

- Gülçin, İ.; Huyut, Z.; Elmastaş, M.; Aboul-Enein, H.Y. Radical scavenging and antioxidant activity of tannic acid. Arab. J. Chem. 2010, 3, 43–53. [Google Scholar] [CrossRef]

- Hromis, N.; Lazic, V.; Markov, S.; Vastag, Z.; Popovic, S.; Suput, D.; Dzinic, N. Improvement of antioxidant and antimicrobial activity of chitosan film with caraway and oregano essential oils. Acta Per. Tech. 2014, 33–43. [Google Scholar] [CrossRef]

- Hermansson, A.-M. Functional properties of proteins for foods-flow properties. J. Texture Stud. 1975, 5, 425–439. [Google Scholar] [CrossRef]

- Khwaldia, K.; Banon, S.; Perez, C.; Desobry, S. Properties of sodium caseinate film-forming dispersions and films. J. Dairy Sci. 2004, 87, 2011–2016. [Google Scholar] [CrossRef]

- Carr, A. Rheology of Sodium Caseinate Solutions. Master’s Thesis, Massey University, Palmerston North, New Zaeland, 1994. [Google Scholar]

- Guglielmi, M.; Colombo, P.; Peron, F.; Mancinelli Degli Esposti, L. Dependence of thickness on the withdrawal speed for SiO2 and TiO2 coatings obtained by the dipping method. J. Mater Sci. 1992, 27, 5052–5056. [Google Scholar] [CrossRef]

- Schou, M.; Longares, A.; Montesinos-Herrero, C.; Monahan, F.J.; O’Riordan, D.; O’Sullivan, M. Properties of edible sodium caseinate films and their application as food wrapping. LWT-Food Sci. Technol. 2005, 38, 605–610. [Google Scholar] [CrossRef]

- Longares, A.; Monahan, F.J.; O’Riordan, E.D.; O’Sullivan, M. Physical properties of edible films made from mixtures of sodium caseinate and WPI. Int. Dairy J. 2005, 15, 1255–1260. [Google Scholar] [CrossRef]

- Moghaddas Kia, E.; Ghasempour, Z.; Alizadeh, M. Fabrication of an eco-friendly antioxidant biocomposite: Zedo gum/sodium caseinate film by incorporating microalgae (Spirulina platensis): ARTICLE. J. Appl. Polym. Sci. 2018, 135, 46024. [Google Scholar] [CrossRef]

- Brzoska, N.; Müller, M.; Nasui, L.; Schmid, M. Effects of film constituents on packaging-relevant properties of sodium caseinate-based emulsion films. Prog. Org. Coat. 2018, 114, 250–258. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Rhim, J.-W.; Azizi-Lalabadi, M.; Hemmati-Dinarvand, M.; Ehsani, A. Preparation and characterization of functional sodium caseinate/guar gum/TiO2/cumin essential oil composite film. Int. J. Biol. Macromol. 2020, 145, 835–844. [Google Scholar] [CrossRef] [PubMed]

- Khan, R.A.; Khan, M.R.; Khan, A. Comparative antioxidant scavenging and lipid peroxidation activity of rutin and gallic acid. Bangladesh J. Pharmacol. 2015, 10, 637. [Google Scholar] [CrossRef]

- Yildirim-Elikoglu, S.; Erdem, Y.K.A. Interactions between milk proteins and polyphenols: Binding mechanisms, related changes and the future trends in dairy industry. Food Rev. Int. 2017, 34, 665–697. [Google Scholar] [CrossRef]

- Helal, A.; Tagliazucchi, D.; Conte, A.; Desobry, S. Antioxidant properties of polyphenols incorporated in casein/sodium caseinate films. Int. Dairy J. 2012, 25, 10–15. [Google Scholar] [CrossRef]

), sodium caseinate/gallic acid 50 μg/mL (

), sodium caseinate/gallic acid 50 μg/mL ( ), and sodium caseinate/rosemary essential oil 1.5% (

), and sodium caseinate/rosemary essential oil 1.5% ( ) (w/v ), after 2.5 and 4 h of contact with DPPH radicals at room temperature.

) (w/v ), after 2.5 and 4 h of contact with DPPH radicals at room temperature.

), sodium caseinate/gallic acid 50 μg/mL (

), sodium caseinate/gallic acid 50 μg/mL ( ), and sodium caseinate/rosemary essential oil 1.5% (

), and sodium caseinate/rosemary essential oil 1.5% ( ) (w/v ), after 2.5 and 4 h of contact with DPPH radicals at room temperature.

) (w/v ), after 2.5 and 4 h of contact with DPPH radicals at room temperature.

| Code Sample | SC | Gly | GA | REO | E | η0 |

|---|---|---|---|---|---|---|

| g/100 mL | g/100 mL | g/100 mL | mL/100 mL | kJ·mol−1 | Pa·s | |

| SC + GA | 4 | 0.4 | 0.005 | – | n.a. | n.a. |

| SC + REO | 4 | 0.4 | – | 1.5 | n.a. | n.a. |

| SC 4% | 4 | 0.4 | – | – | 20.06 | 13.9 |

| SC 8% | 8 | 0.8 | – | – | 30.23 | 16.6 |

| SC 10% | 10 | 1.0 | – | – | 31.11 | 16.3 |

| SC 12% | 12 | 1.2 | – | – | 37.21 | 17.7 |

| SC 14% | 14 | 1.4 | – | – | 46.45 | 20.3 |

| Sample | ρ (mg·cm−2) | x (µm) | L* | a* | b* | ∆E | m (%) | WVP × 10−11 g·m–1·s−1·Pa−1 | WVTR g·m–2·day–1 |

|---|---|---|---|---|---|---|---|---|---|

| SC 4% | 3.88 | 35 ± 5a | 96.1 ± 0.2c | 0.10 ± 0.06c | 2.2 ± 0.5a | 1.0 ± 0.3a | 10.4 | 6.0 ± 0.3b | 346 ± 17b |

| SC 8% | 7.76 | 54 ± 9b | 95.3 ± 0.6b | 0.02 ± 0.13b | 2.2 ± 0.5a | 1.74 ± 0.6a | 12.06 | 5 ± 2ab | 216 ± 35a |

| SC 10% | 9.7 | 76 ± 17c | 95.2 ± 0.8b | −0.04 ± 0.12b | 2.4 ± 0.5a | 1.9 ± 0.9a | 11.70 | 5.0 ± 0.8ab | 207 ± 35a |

| SC 12% | 11.64 | 83 ± 9c | 96.5 ± 0.3c | −0.10 ± 0.09b | 4.7 ± 0.4b | 2.9 ± 0.4b | 12.75 | 4.0 ± 0.6a | 190 ± 26a |

| SC 14% | 13.58 | 101 ± 14d | 92.8 ± 0.8a | −1.82 ± 0.28a | 16.3 ± 2.3 c | 15.1 ± 2.5c | 14.1 | 8.00 ± 0.09c | 204 ± 3a |

| Sample | ρ (g·cm−3) | K | havg (μm) | ρf (g·cm−3) | Havg (μm) |

|---|---|---|---|---|---|

| SC 4% | 0.98 | 13 | 18 | 1.14 | 0.61 |

| SC 8% | 0.96 | 1.91 | 33 | 1.33 | 1.90 |

| SC 10% | 0.94 | 0.92 | 36 | 1.35 | 2.52 |

| SC 12% | 0.93 | 0.97 | 74 | 1.37 | 6.06 |

| SC 14% | 0.92 | 0.58 | 78 | 1.40 | 7.20 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valentino, M.; Volpe, S.; Di Giuseppe, F.A.; Cavella, S.; Torrieri, E. Active Biopolymer Coating Based on Sodium Caseinate: Physical Characterization and Antioxidant Activity. Coatings 2020, 10, 706. https://doi.org/10.3390/coatings10080706

Valentino M, Volpe S, Di Giuseppe FA, Cavella S, Torrieri E. Active Biopolymer Coating Based on Sodium Caseinate: Physical Characterization and Antioxidant Activity. Coatings. 2020; 10(8):706. https://doi.org/10.3390/coatings10080706

Chicago/Turabian StyleValentino, Marika, Stefania Volpe, Fabio Angelo Di Giuseppe, Silvana Cavella, and Elena Torrieri. 2020. "Active Biopolymer Coating Based on Sodium Caseinate: Physical Characterization and Antioxidant Activity" Coatings 10, no. 8: 706. https://doi.org/10.3390/coatings10080706

APA StyleValentino, M., Volpe, S., Di Giuseppe, F. A., Cavella, S., & Torrieri, E. (2020). Active Biopolymer Coating Based on Sodium Caseinate: Physical Characterization and Antioxidant Activity. Coatings, 10(8), 706. https://doi.org/10.3390/coatings10080706