Effect of Current Density on the Performance of Ni–P–ZrO2–CeO2 Composite Coatings Prepared by Jet-Electrodeposition

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental

2.2. Instruments

3. Results and Discussion

3.1. Analysis of Micromorphology of the Composite Coating

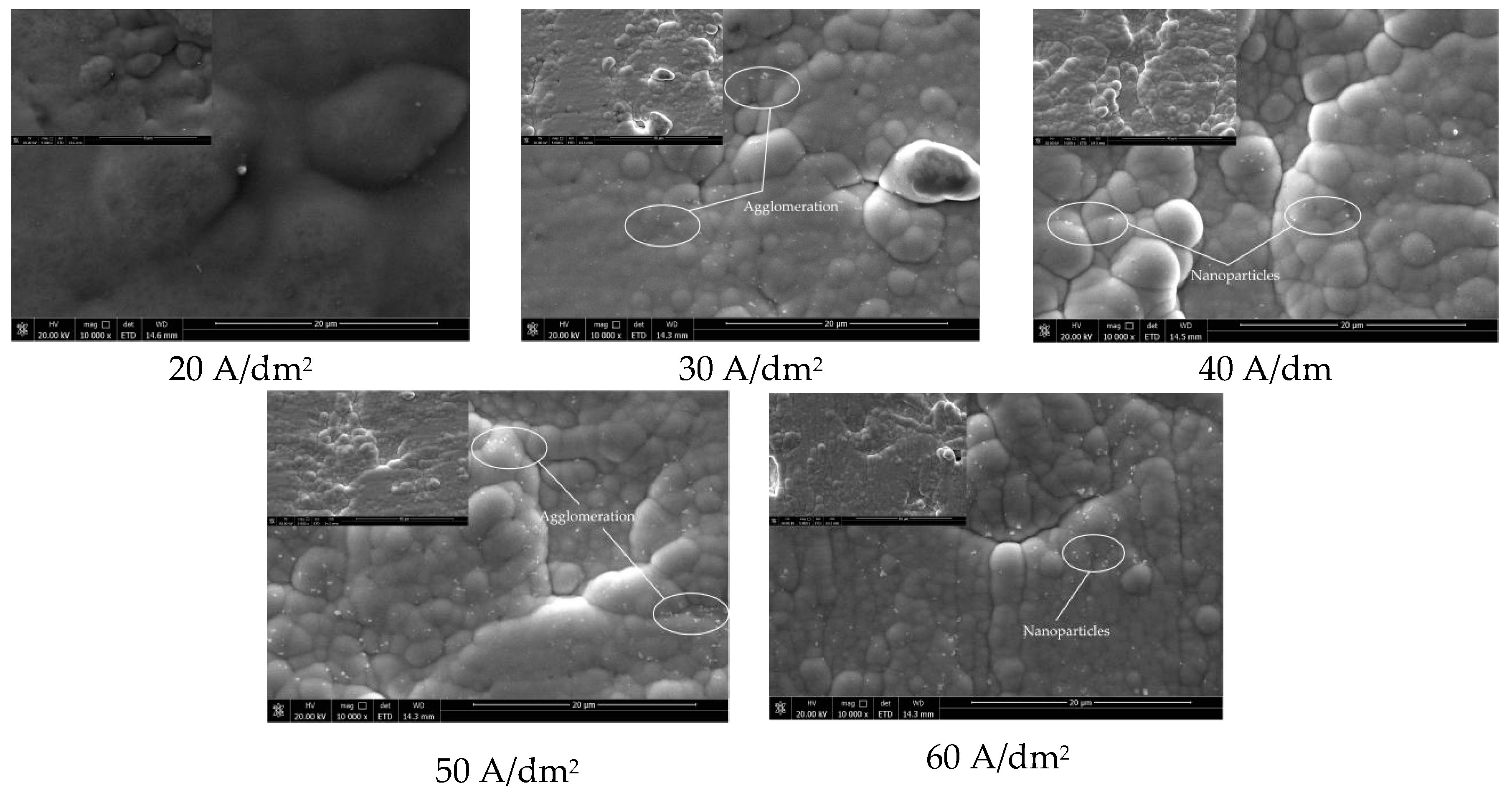

3.1.1. Analysis of Surface Micromorphology of the Composite Coating

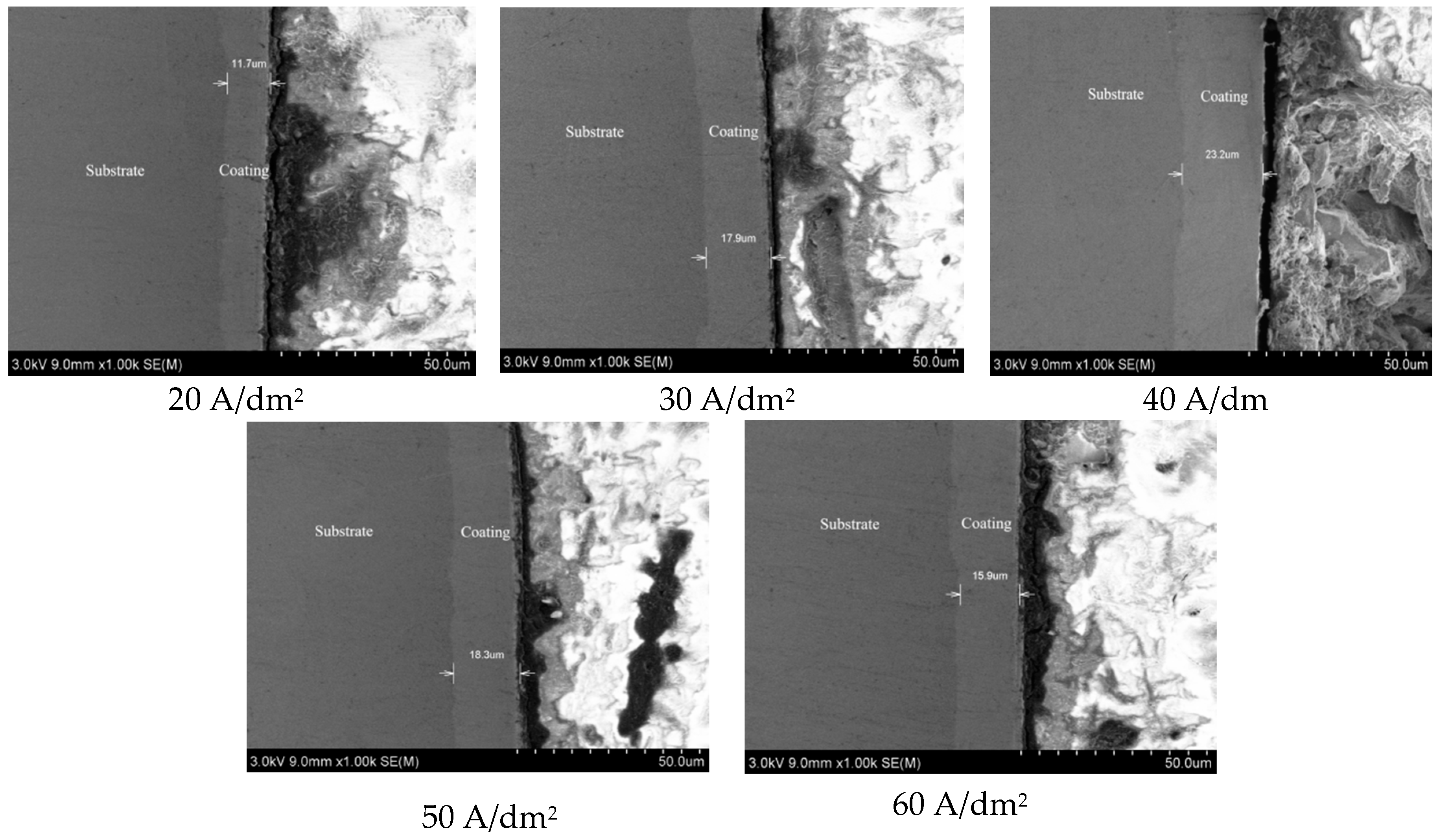

3.1.2. Analysis of Cross-Sectional Micromorphology of Composite Coating

3.2. Effect of Current Density on Coating Composition

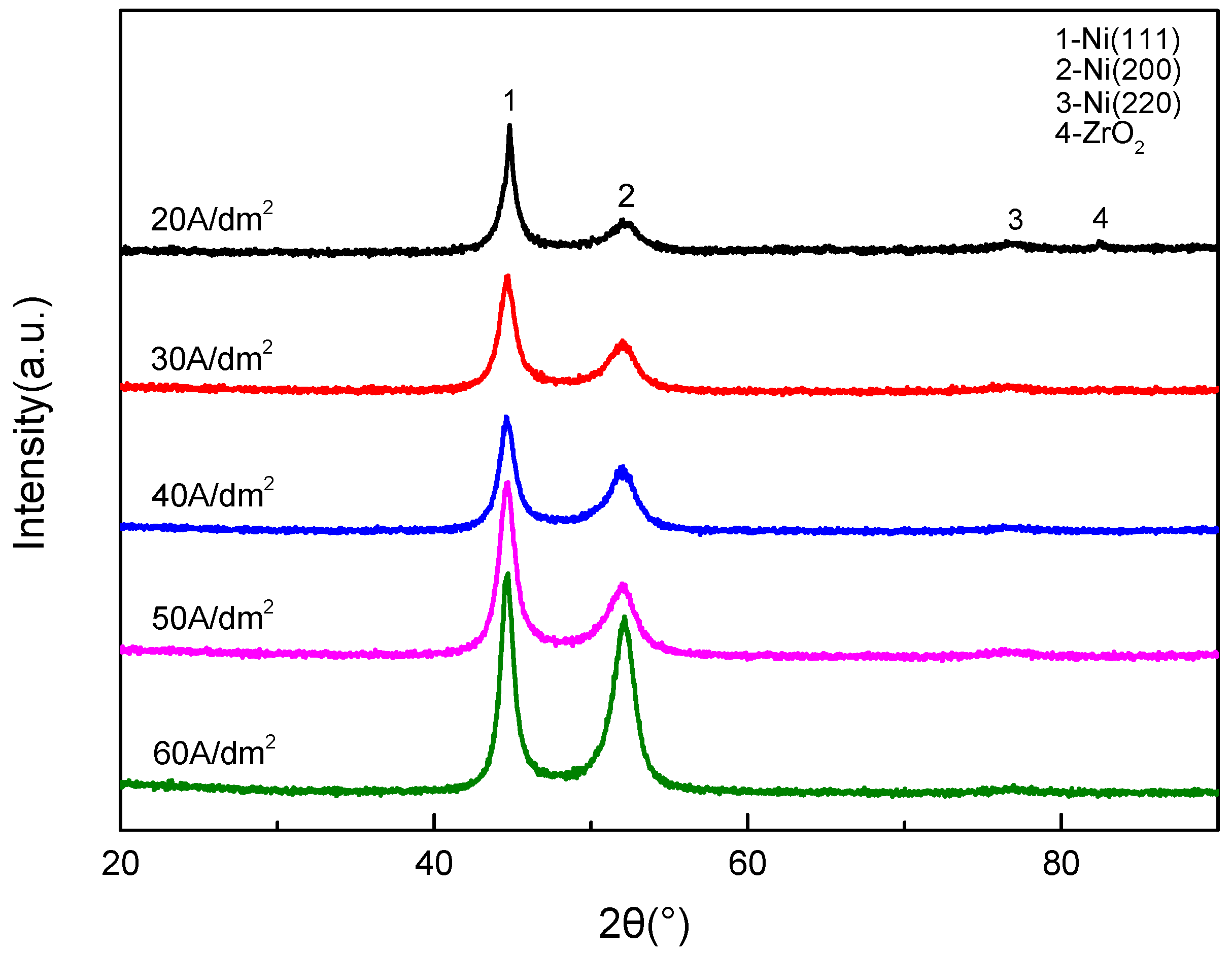

3.2.1. XRD Analysis of Composite Coating

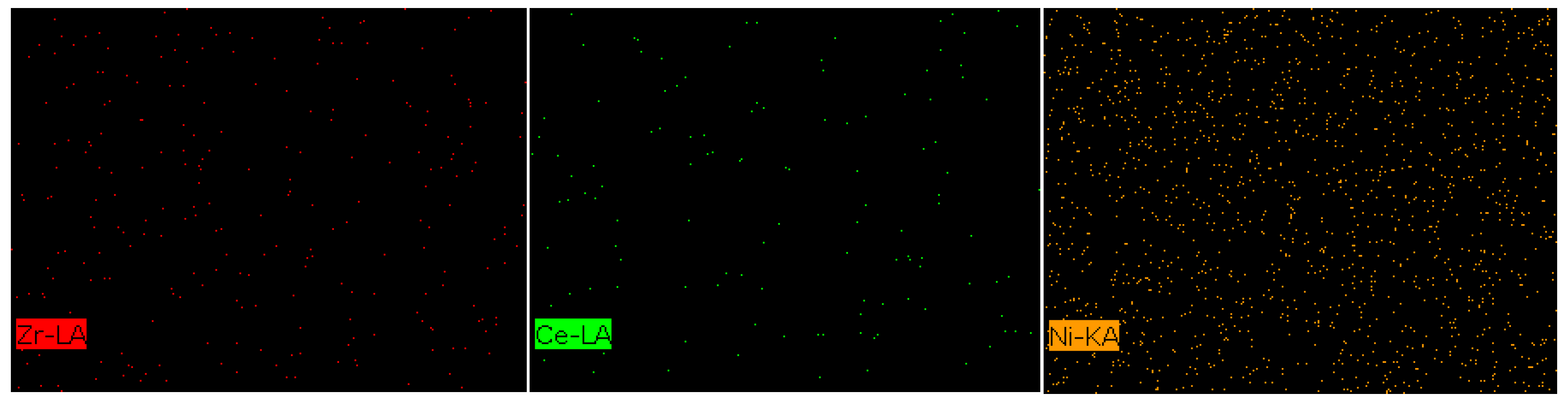

3.2.2. EDS and Mass Fraction Analysis of Composite Coatings

3.3. Effects of Current Density on Coating Hardness and Wear Resistance

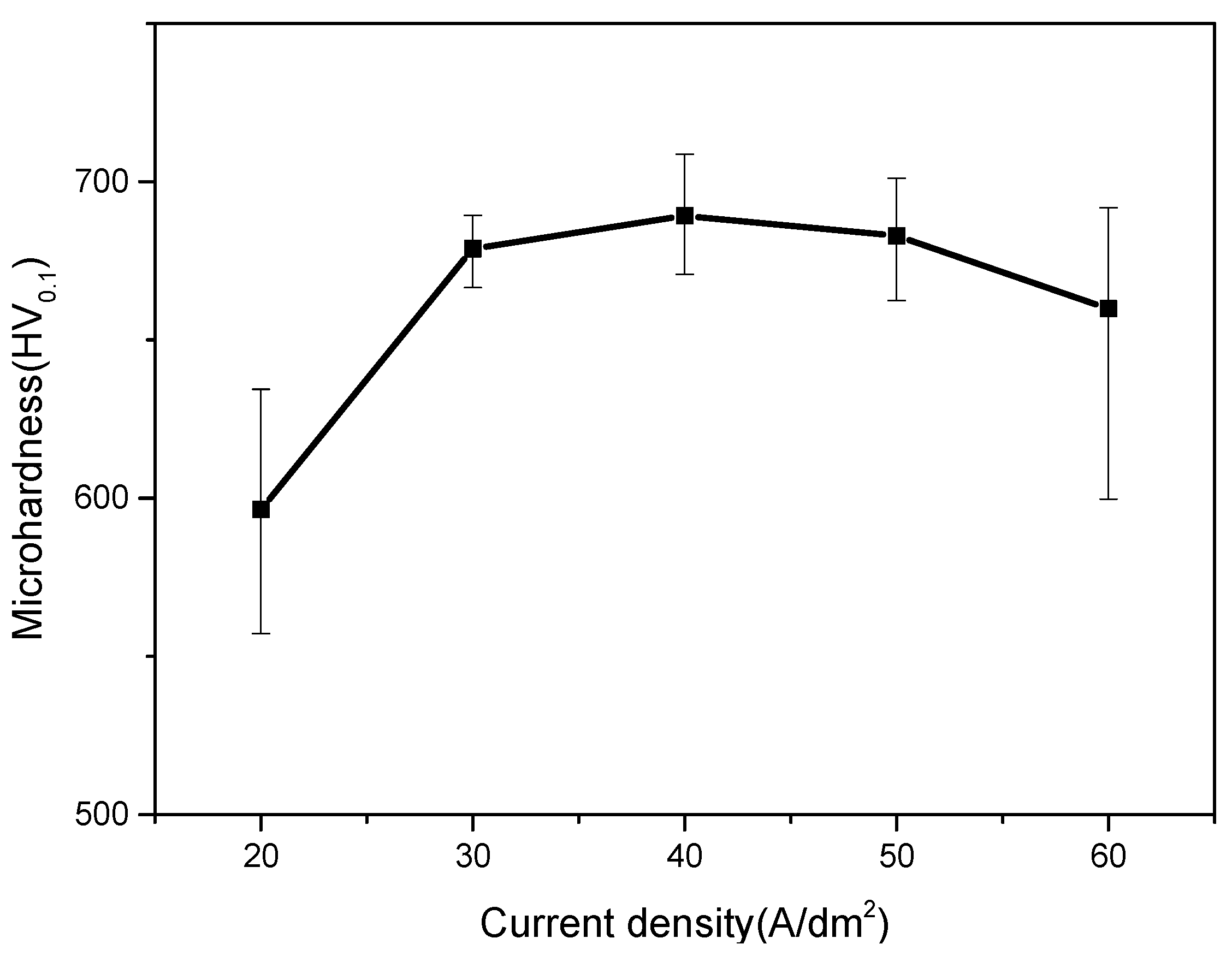

3.3.1. Analysis of Microhardness of Composite Coating

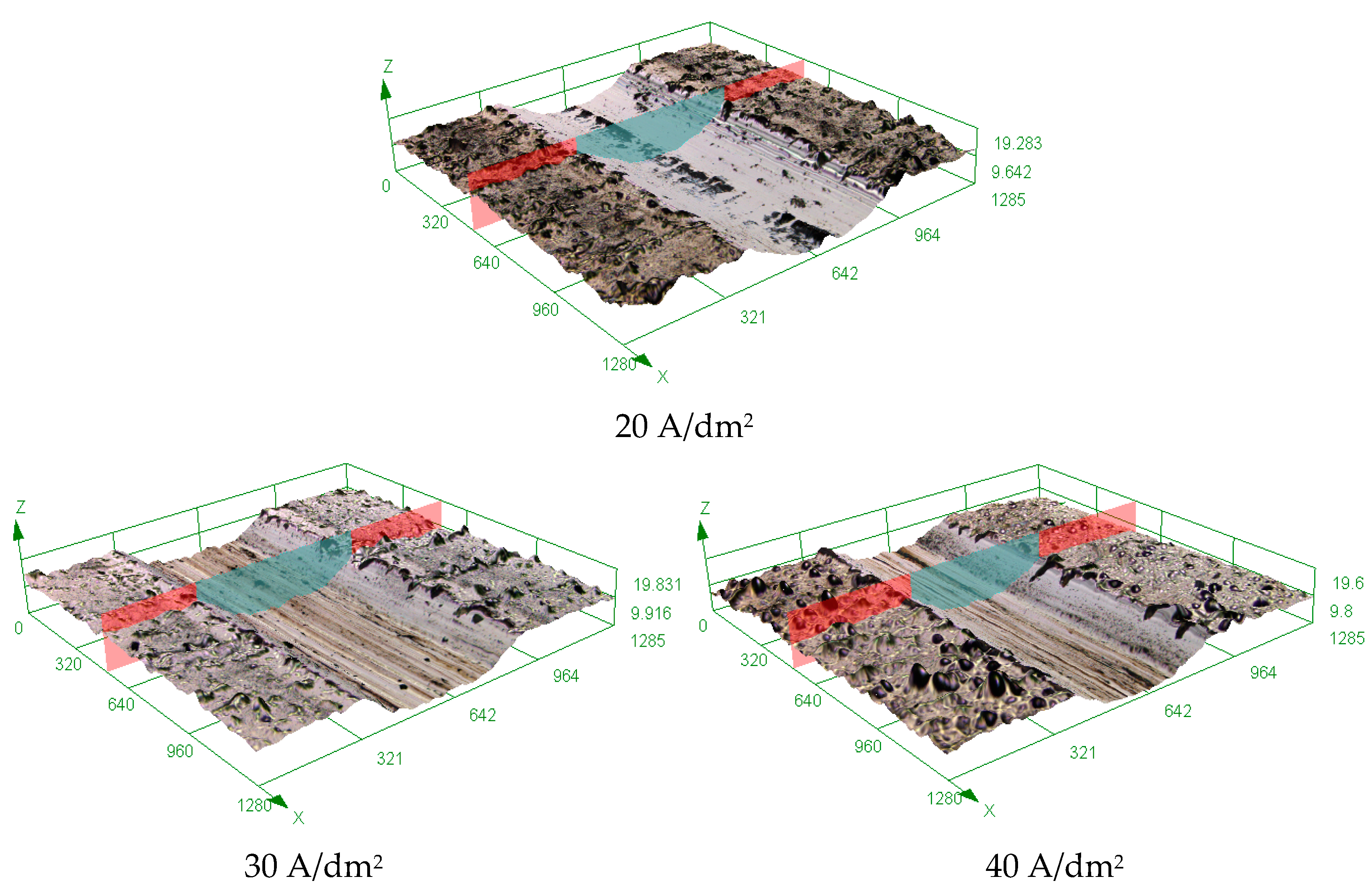

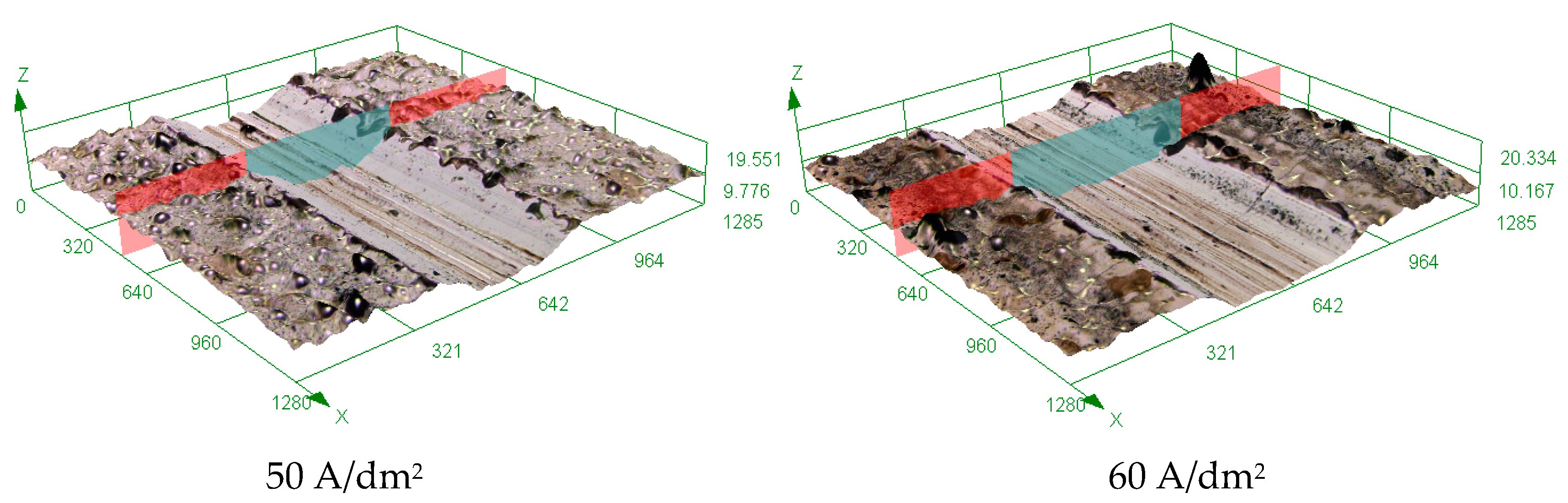

3.3.2. Wear Resistance Analysis of Composite Coating

3.4. Effect of Current Density on Corrosion Resistance of Composite Coating

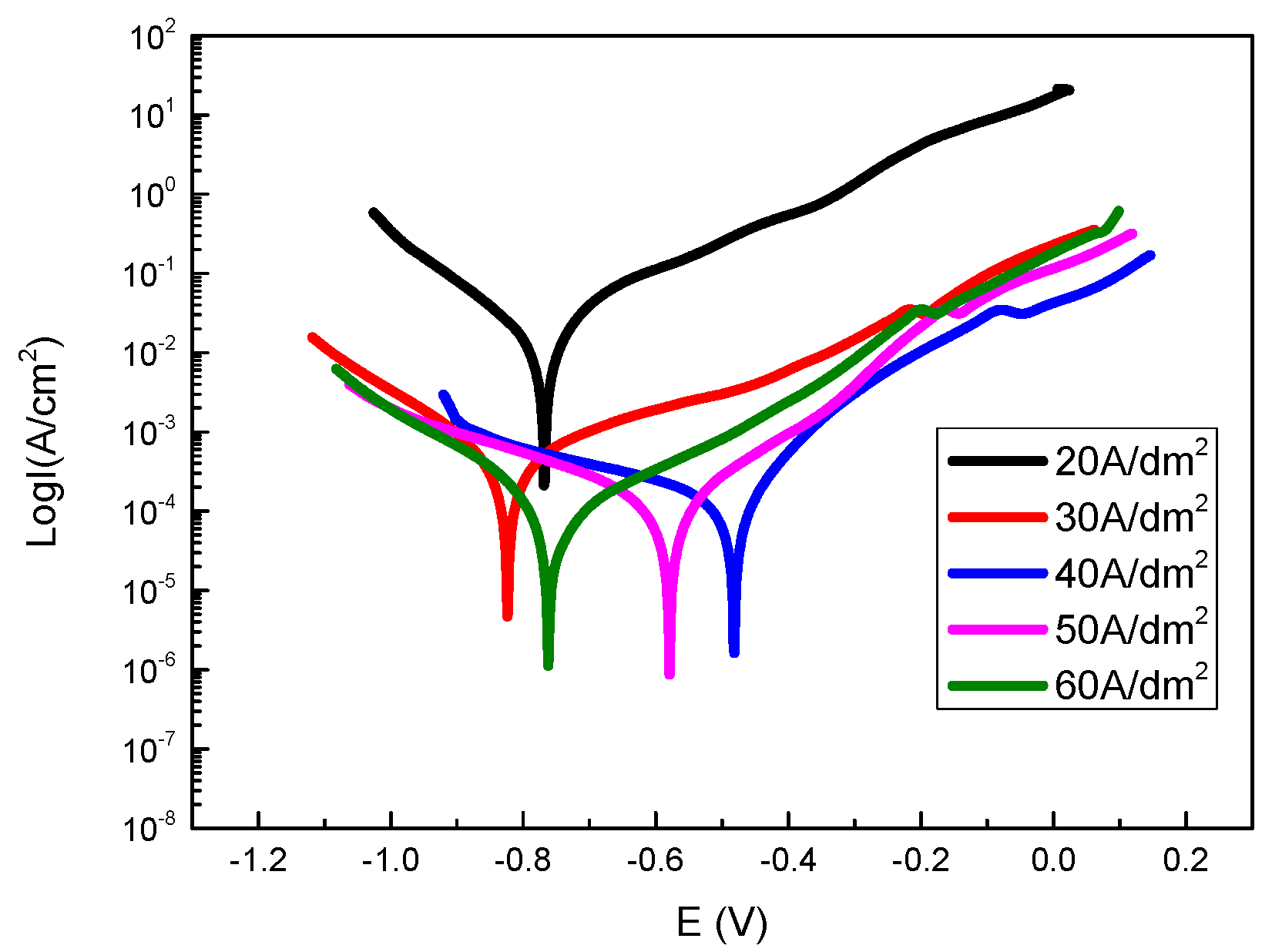

3.4.1. Corrosion-Resistance Polarization Curve of Composite Coating

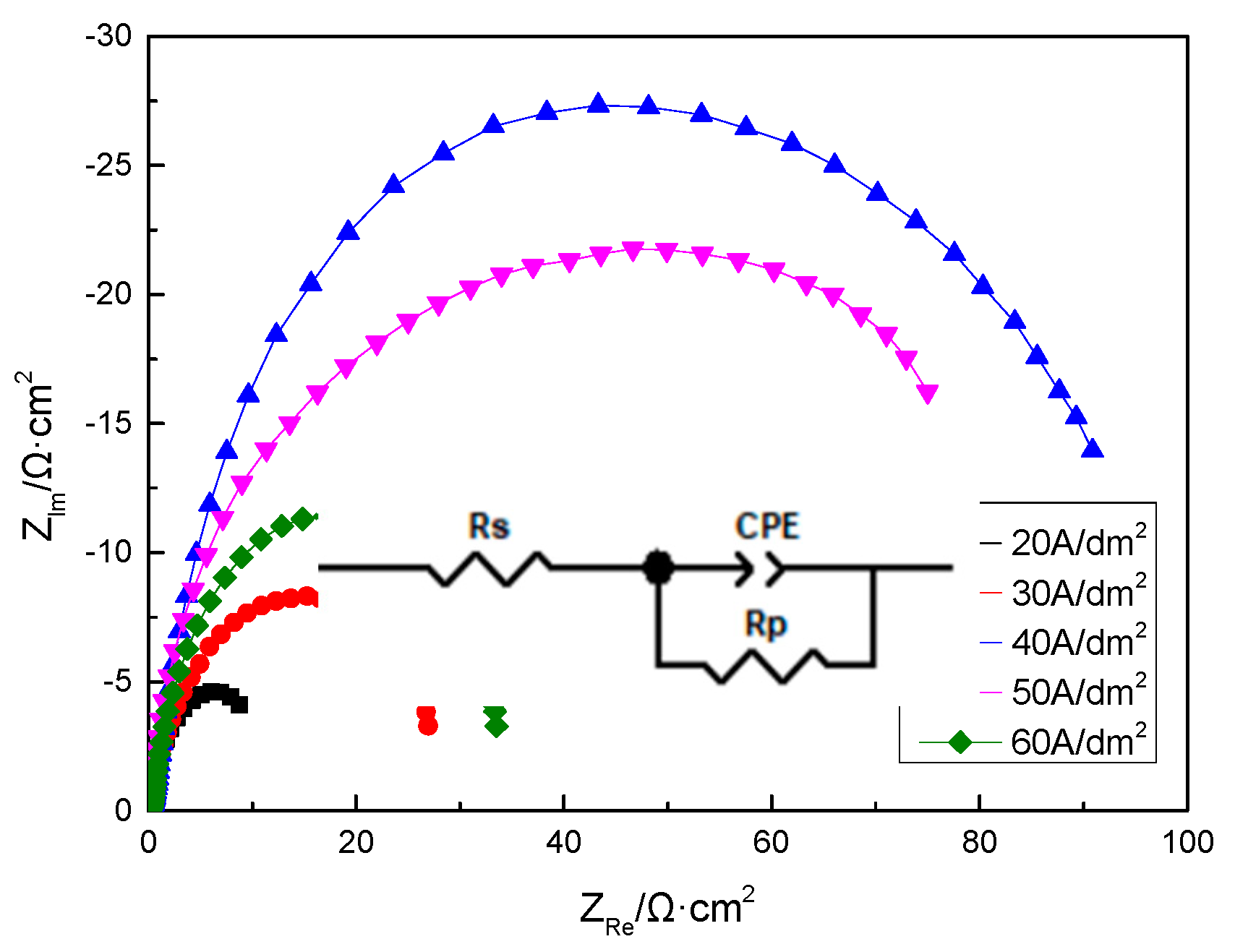

3.4.2. Corrosion-Resistance Impedance Curve of Composite Coating

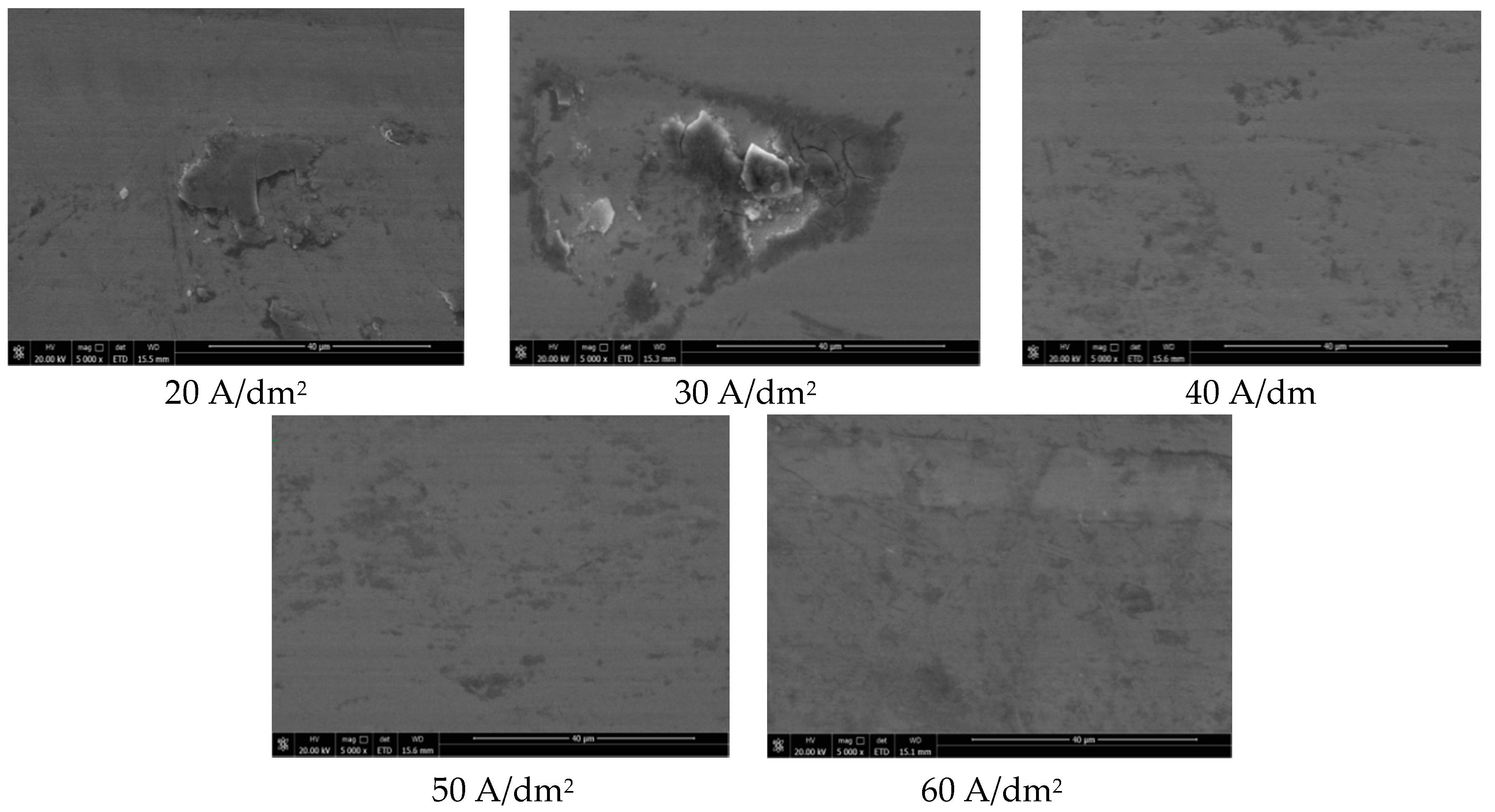

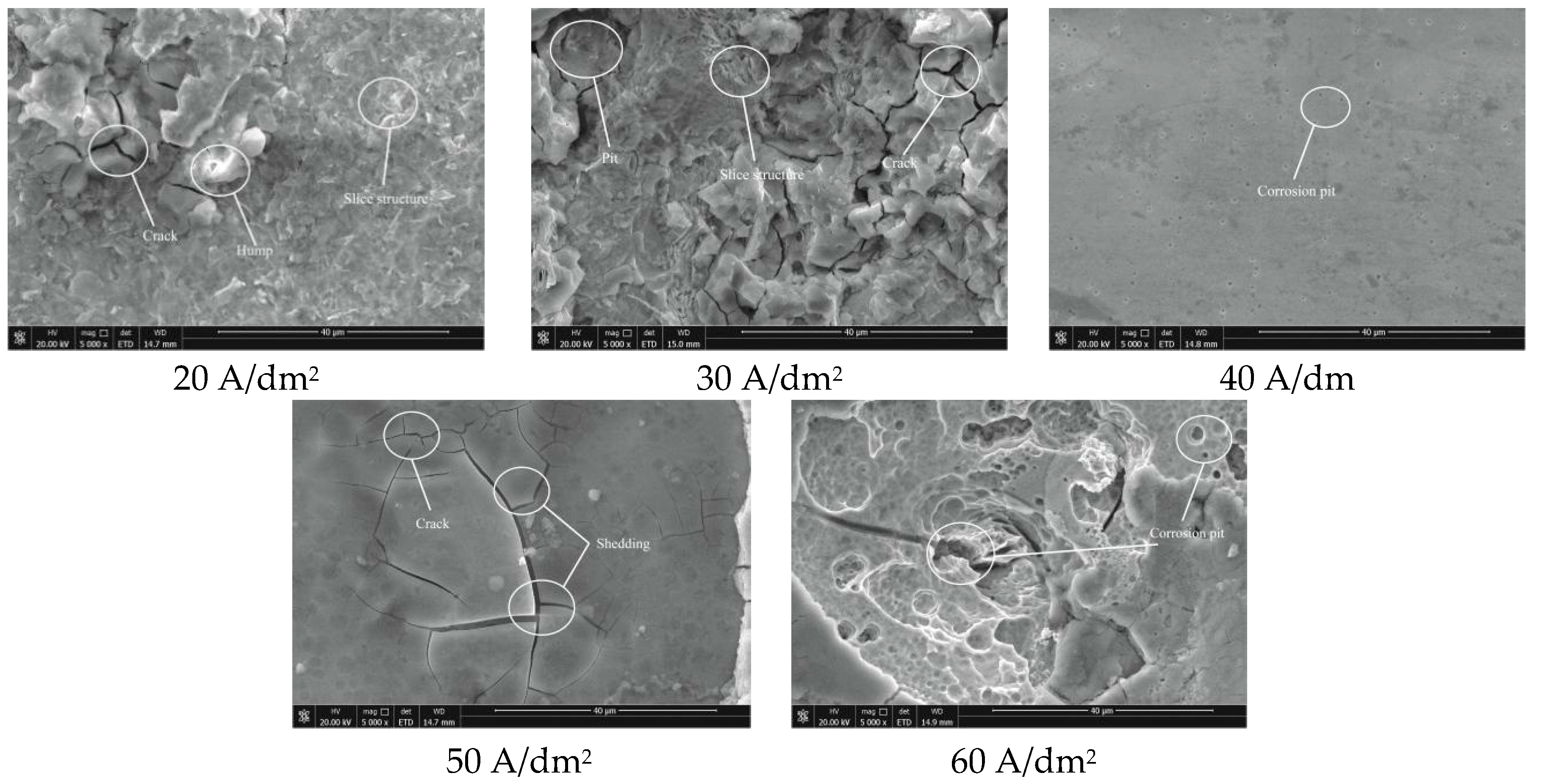

3.4.3. Surface Morphology of Composite Coating after Corrosion

4. Conclusions

- The morphology of Ni–P–ZrO2–CeO2 composite coatings exhibited a typical cellular structure. With the increase in the current density, the surface flatness and surface quality of the composite coating increased first and then decreased. At a current density of 40 A/dm2, the cell structure of the composite coating was uniform, the particle distribution was uniform, and the surface quality was the best.

- The composite coating was composed of a mixture of crystalline and amorphous phases. The grain size of the Ni (111) crystal plane tended to first decrease, and then increase with increasing current density. At a current density of 40 A/dm2, the grain size reached a minimum of 6.2 nm. At this time, the effect of grain refinement was the most evident. When the current density was 40 A/dm2, the contents of Zr and Ce in the composite coating were the maximum: 3.79% and 10.36%, respectively.

- The microhardness of Ni–P–ZrO2–CeO2 composite coating tended to first increase and then decrease with increasing current density. At a current density of 40 A/dm2, the hardness of the composite coatings reached a maximum of 688.9 HV0.1, which was approximately 12.5% higher than those prepared at a current density of 20 A/dm2. At this time, the composite coating exhibited a dense structure and the highest hardness value.

- With the increase in the current density, the wear resistance of the Ni–P–ZrO2–CeO2 composite coatings tended to increase first and then decrease. At a current density of 40 A/dm2, a large number of nanoparticles evenly distributed in the composite coating played the role of a “sliding ball.” To a certain extent, it made up for the pits and scratches left after the coating surface was damaged by abrasion and a “protective film” structure was formed on the surface, thereby improving the wear resistance.

- With the increase in the current density, the corrosion resistance tended to first increase and then decrease. At a current density of 40 A/dm2, the corrosion current reached a minimum of 8.2501 × 10−5 A·cm−2, and the corrosion potential reached a maximum of −0.45957 V. At this time, the capacitive arc radius was the largest, and the charge transfer resistance was the highest, indicating that the surface charge conduction resistance was the highest, and the coating exhibited the best corrosion resistance.

Author Contributions

Funding

Conflicts of Interest

References

- Lin, L.B.; Dai, P.Q.; Lin, L.F.; Liao, Y.X. Corrosion characteristics of nanocrystalline Co-Ni-Fe deposits in 3.5% NaCl solution. Rare Metal Mater. Eng. 2012, 41, 851–856. (In Chinese) [Google Scholar]

- Ding, W.Y.; He, X.C.; Xing, B.Y.; Zeng, K. Corrosion behavior and failure form of AA5052 aluminum alloy self-piercing riveted joint in periodic immersion environment. Hot Working Technol. 2018, 47, 1–4. (In Chinese) [Google Scholar]

- Karimzadeha, A.; Aliofkhazraei, M.; Walsh, F.C. A review of electrodeposited Ni-Co alloy and composite coating: Microstructure, properties and applications. Surf. Coat. Technol. 2019, 372, 463–499. [Google Scholar] [CrossRef]

- Tam, J.; Lau, J.C.F.; Erb, U. Thermally robust non-wetting Ni-PTFE electrodeposited nanocomposite. Nanomaterials 2018, 9, 2. [Google Scholar] [CrossRef] [PubMed]

- Ding, X.L.; Hu, Z.F.; Jin, G.; Lyu, B.; Wang, X.H. Microstructure and properties of electro-brush plating Ni-graphene composite coating. J. Mater. Eng. 2018, 46, 110–117. (In Chinese) [Google Scholar]

- Tahmasebpour, M.B.; Babaluo, A.A.; Aghjeh, M.K.R. Synthesis of zirconia nanopowders from various zirconium salts via polyacrylamide gel method. J. Eur. Ceram. Soc. 2008, 28, 773–778. [Google Scholar] [CrossRef]

- Xue, Y.J.; Liu, H.B.; Lan, M.M.; Ku, X.C.; Li, J.X. High temperature oxidation resistance of Ni-CeO2 nanocomposite coatings by pulse electrodeposition under ultrasound condition. Trans. Nonferrous Met. Soc. 2010, 20, 1599–1604. (In Chinese) [Google Scholar]

- Schmidt, T.; Mennig, M.; Schmidt, H. New method for the preparation and stabilization of nanoparticulate t-ZrO2 by a combined sol-gel and sovlvothermal process. J. Am. Ceram. Soc. 2007, 90, 1401–1405. [Google Scholar] [CrossRef]

- Sheng, M.Q.; Weng, W.P.; Wang, Y.; Wu, Q.; Hou, S. Co-W/CeO2 composite coatings for highly active electrocatalysis of hydrogen evolution reaction. J. Alloys Compd. 2018, 743, 682–690. [Google Scholar] [CrossRef]

- Li, B.S.; Zhang, W.W.; Li, D.D. Synthesis and properties of a novel Ni-Co and Ni-Co/ZrO2 composite coating by DC electrodeposition. J. Alloys Compd. 2020, 821, 153258. [Google Scholar] [CrossRef]

- Laszczyńska, A.; Winiarski, J.; Szczygieł, B.; Szczygieł, I. Electrodeposition and characterization of Ni-Mo-ZrO2 composite coatings. Appl. Surf. Sci. 2016, 369, 224–231. [Google Scholar] [CrossRef]

- Li, J.S.; Xue, Y.J.; Lan, M.M.; Liu, Y.; Yu, Y.J. Effects of ultrasound on microstructures and properties of Ni-CeO2 nanocomposite electroforming deposits. Chin. J. Nonferr. Metal. 2009, 19, 517–522. [Google Scholar]

- Li, B.S.; Li, D.D.; Mei, T.Y.; Zhang, W. Fabrication and optimization of Ni-W/ZrO2-CeO2 composite coating for enhanced hardness and corrosion resistance. Results Phys. 2019, 13, 102375. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, P.; Wang, G.; Wang, A.; Chen, X.; Wei, S.; Xie, J. Effect of graphene oxide concentration in electrolyte on corrosion behavior of electrodeposited Zn–electrochemical reduction graphene composite coatings. Coatings 2019, 9, 758. [Google Scholar] [CrossRef]

- Fu, X.; Ma, W.; Duan, S.; Wang, Q.; Lin, J. Electrochemical corrosion behavior of Ni-Fe-Co-P alloy coating containing nano-CeO2 particles in NaCl solution. Materials 2019, 12, 2614. [Google Scholar] [CrossRef]

- Wang, Y.; Ju, Y.; Wei, S.; Lu, W.; Yan, B.; Gao, W. Mechanical properties and microstructure of Au-Ni-TiO2 nano-composite coatings. Mater. Charact. 2015, 102, 189–194. [Google Scholar] [CrossRef]

- Guglielmi, N. Kinetics of the deposition of inert particles from electrolytic baths. J. Electrochem. Soc. 1972, 119, 1009–1012. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, G.L.; Liu, J.D.; Li, L. Electroplating n-ZrO2/Ni composite coatings on AZ91D magnesium alloy and corrosion resistance. Funct. Mater. 2012, 43, 650–652, 656. (In Chinese) [Google Scholar]

- Zhang, H.; Zhang, X.; Zhao, X.; Tang, Y.; Zuo, Y. Preparation of Ti-Zr-based conversion coating on 5052 aluminum alloy, and its corrosion resistance and antifouling performance. Coatings 2018, 8, 397. [Google Scholar] [CrossRef]

- Zheng, Z.; Li, N.; Li, D.Y.; Meng, F.Y. Effect of CeO2 on the property of Zn-Ni/CeO2 composite coating. Surf. Technol. 2012, 41, 23–26. (In Chinese) [Google Scholar]

- Beltowska-Lehman, E.; Indyka, P.; Bigos, A.; Szczerba, M.J.; Kot, M. Ni-W/ZrO2 nanocomposites obtained by ultrasonic DC electrodeposition. Mater. Des. 2015, 80, 1–11. [Google Scholar] [CrossRef]

- Walsh, F.C.; Low, C.T.J.; Bello, J.O. Influence of suifactants on electrodeposition of a Ni-nanoparticulate SiC composite coating. Trans. IMF 2015, 93, 147–156. [Google Scholar] [CrossRef]

- Niazi, H.; Yari, S.; Golestani-Fard, F.; Shahmiri, M.; Wang, W.; Alfantazi, A.; Bayati, R. How deposition parameters affect corrosion behavior of TiO2-Al2O3 nanocomposite coatings. Appl. Surf. Sci. 2015, 335, 1242–1252. [Google Scholar] [CrossRef]

- Wang, W.; Hou, F.Y.; Guo, H.T. Relationship between dispersibility of ZrO2 nanoparticles in Ni-ZrO2 electroplated nanocomposite coatings and mechanical properties of nanocomposite coatings. Trans. Nonferr. Metal Soc. China 2004, 14, 186–189. [Google Scholar]

- Liang, Z.P.; Wang, Y.Y.; Jin, H.; Zhou, X.Y.; Liu, X.L. Study on morphology and properties of Ni-Co/ZrO2 composite coatings. Rare Metals Cem. Carbides 2018, 46, 59–63, 67. (In Chinese) [Google Scholar]

- Aruna, S.T.; Bindu, C.N.; Ezhil, S.V.; Grips, V.W.; Rajam, K.S. Synthesis and properties of electrodeposited Ni/ceria nanocomposite coatings. Surf. Coat. Technol. 2006, 200, 6871–6880. [Google Scholar] [CrossRef]

- Ao, Z.H.; Xue, Y.J.; Jiang, S.F.; Zhang, D.Y.; Li, X.H. Effects of different electrodeposition methods on corrosion resistance of Ni-ZrO2 nanocomposite coatings. Surf. Technol. 2015, 44, 72–76. (In Chinese) [Google Scholar]

- Xue, Y.J.; Si, D.H.; Liu, H.B.; Li, J.S.; Lan, M.M. Effects of electrodeposition methods on friction and wear properties of Ni-CeO2 nanocomposite coatings. Chin. J. Nonferr. Metal. 2011, 21, 2157–2162. (In Chinese) [Google Scholar]

- Ranganatha, S.; Venkatesha, T.V.; Vathsala, K. Development of high performance electroless Ni-P-HNT composite coating. Appl. Surf. Sci. 2012, 263, 149–156. [Google Scholar] [CrossRef]

- Qiu, M.; Zhang, R.; Li, Y.C.; Pang, X.X. Effects of CeO2 addition on tribological performance of MoS2 based composite coatings. J. Chin. Rare Earth Soc. 2018, 36, 221–228. (In Chinese) [Google Scholar]

- Bates, B.L.; Witman, J.C.; Zhang, Y. Electrolytic co-deposition of Ni-GrAlY composite coatings using different deposition configurations. Mater. Manuf. Process. 2016, 31, 1232–1237. [Google Scholar] [CrossRef]

- Goto, Y.; Kamebuchi, Y.; Hagio, T.; Kamimoto, Y.; Ichino, R.; Bessho, T. Electrodeposition of copper/carbonous nanomaterial composite coatings for heat-dissipation materials. Coatings 2018, 8, 5. [Google Scholar] [CrossRef]

- Yusuf, M.M.; Radwan, A.B.; Shakoor, R.A.; Awais, M.; Abdullah, A.M.; Montemor, M.F.; Kahraman, R. Synthesis and characterisation of Ni-B/Ni-P-CeO2 duplex composite coatings. J. Appl. Electrochem. 2018, 48, 391–404. [Google Scholar] [CrossRef]

- Anandan, C.; Bera, P. XPS studies on the interaction of CeO2 with silicon in magnetron sputtered CeO2 thin films on Si and Si3N4 substrates. Appl. Surf. Sci. 2013, 283, 297–303. [Google Scholar] [CrossRef]

- Wan, B.; Li, H.X.; Zhou, H.F.; Yang, Q. Effect of indium sulfate on electrochemical behavior of nickel-diamond composite electrodeposition. Electroplat. Finish. 2016, 35, 1103–1106, 1147. (In Chinese) [Google Scholar]

- Xu, Q.Y.; He, W.J. Research progress on rare earth in electroless Ni-P coating. Surf. Technol. 2011, 40, 92–96. (In Chinese) [Google Scholar]

- Zhang, J.Y.; Yang, Q.J. Effects of RE-doped in the bath on nickel-base electroless deposit. Surf. Technol. 2012, 41, 44–46, 50. (In Chinese) [Google Scholar]

- Lajevardi, S.A.; Shahrabi, T. Effects of pulse electrodeposition parameters on the peoperties of Ni-TiO2 nanocomposite coatings. Appl. Surf. Sci. 2010, 256, 6775–6781. [Google Scholar] [CrossRef]

| Composition | Content/(g·L−1) | Effect |

|---|---|---|

| NiSO4·6H2O | 200 | Provide Ni2+ |

| NiCl2·6H2O | 30 | Reduce free cations |

| H3PO3 | 20 | Provide P |

| H3BO3 | 30 | pH SRP |

| C6H8O7 | 60 | Buffer, complexing agent |

| CH4N2S | 0.01 | Stabilizer |

| C12H25SO4Na | 0.08 | Surfactant |

| ZrO2 nanoparticles (50 nm) | 10 | Secondary phase nanoparticles |

| CeO2 nanoparticles (100 nm) | 1 | Secondary phase nanoparticles |

| Current Density (A/dm2) | Grain Size (nm) | Crystallinity (%) |

|---|---|---|

| 20 | 8.0 | 35.09 |

| 30 | 6.7 | 32.12 |

| 40 | 6.2 | 49.71 |

| 50 | 6.4 | 69.05 |

| 60 | 7.0 | 74.01 |

| Current Density (A/dm2) | Ni (wt%) | P (wt%) | Zr (wt%) | Ce (wt%) |

|---|---|---|---|---|

| 20 | 90.13 | 1.16 | 3.74 | 4.98 |

| 30 | 88.64 | 0.40 | 4.67 | 6.29 |

| 40 | 85.81 | 0.04 | 3.79 | 10.36 |

| 50 | 90.17 | 0.93 | 2.39 | 6.51 |

| 60 | 90.08 | 1.13 | 3.68 | 5.11 |

| Current Density (A/dm2) | Width (μm) | Height (μm) | Scratch Area (μm2) |

|---|---|---|---|

| 20 | 568.011 | 10.629 | 3670.768 |

| 30 | 563.230 | 10.014 | 3519.558 |

| 40 | 469.269 | 8.757 | 2910.972 |

| 50 | 471.409 | 9.137 | 3045.194 |

| 60 | 512.349 | 8.941 | 3024.932 |

| Current Density (A/dm2) | Ecorr (V) | Icorr (A·cm−2) | Ba (mV) | Bc (mV) | Corrosion Rate (mm/a) |

|---|---|---|---|---|---|

| 20 | −0.78842 | 2.204 × 10−3 | 205.81 | 231.52 | 192.75 |

| 30 | −0.82373 | 7.879 × 10−4 | 562.56 | 263.94 | 6.8915 |

| 40 | −0.45957 | 8.251 × 10−5 | 93.338 | 201.95 | 0.7215 |

| 50 | −0.58009 | 1.609 × 10−4 | 223.78 | 381.96 | 1.4074 |

| 60 | −0.78762 | 2.704 × 10−4 | 438.14 | 181.00 | 2.3651 |

| Current Density (A/dm2) | Rs (Ω·cm−2) (Error) | CPE-T (F·cm−2) (Error) | CPE-P (Error) | Rp (Ω·cm−2) (Error) |

|---|---|---|---|---|

| 20 | 0.14877 (0.00311) | 0.48417 (0.01609) | 0.79896 (0.01491) | 13.03 (1.2813) |

| 30 | 0.22937 (0.00229) | 0.02829 (0.00055) | 0.76371 (0.00471) | 26.70 (0.4169) |

| 40 | 0.39187 (0.00827) | 0.00779 (0.00015) | 0.79891 (0.00435) | 85.31 (1.2665) |

| 50 | 0.20482 (0.00413) | 0.00758 (0.00027) | 0.81415 (0.00727) | 63.41 (1.5542) |

| 60 | 0.21519 (0.00469) | 0.01905 (0.00069) | 0.75339 (0.00795) | 35.28 (1.0580) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Z.; Zhang, H.; Fu, X.; Lin, J.; Shen, M.; Wang, Q.; Duan, S. Effect of Current Density on the Performance of Ni–P–ZrO2–CeO2 Composite Coatings Prepared by Jet-Electrodeposition. Coatings 2020, 10, 616. https://doi.org/10.3390/coatings10070616

Song Z, Zhang H, Fu X, Lin J, Shen M, Wang Q, Duan S. Effect of Current Density on the Performance of Ni–P–ZrO2–CeO2 Composite Coatings Prepared by Jet-Electrodeposition. Coatings. 2020; 10(7):616. https://doi.org/10.3390/coatings10070616

Chicago/Turabian StyleSong, Zhaoyang, Hongwen Zhang, Xiuqing Fu, Jinran Lin, Moqi Shen, Qingqing Wang, and Shuanglu Duan. 2020. "Effect of Current Density on the Performance of Ni–P–ZrO2–CeO2 Composite Coatings Prepared by Jet-Electrodeposition" Coatings 10, no. 7: 616. https://doi.org/10.3390/coatings10070616

APA StyleSong, Z., Zhang, H., Fu, X., Lin, J., Shen, M., Wang, Q., & Duan, S. (2020). Effect of Current Density on the Performance of Ni–P–ZrO2–CeO2 Composite Coatings Prepared by Jet-Electrodeposition. Coatings, 10(7), 616. https://doi.org/10.3390/coatings10070616