Effect of Thermal Stresses Formed during Air Annealing of Amorphous Lanthanum Cuprate Thin Films Deposited on Silicon Substrate

Abstract

1. Introduction

2. Experimental Details

3. Results

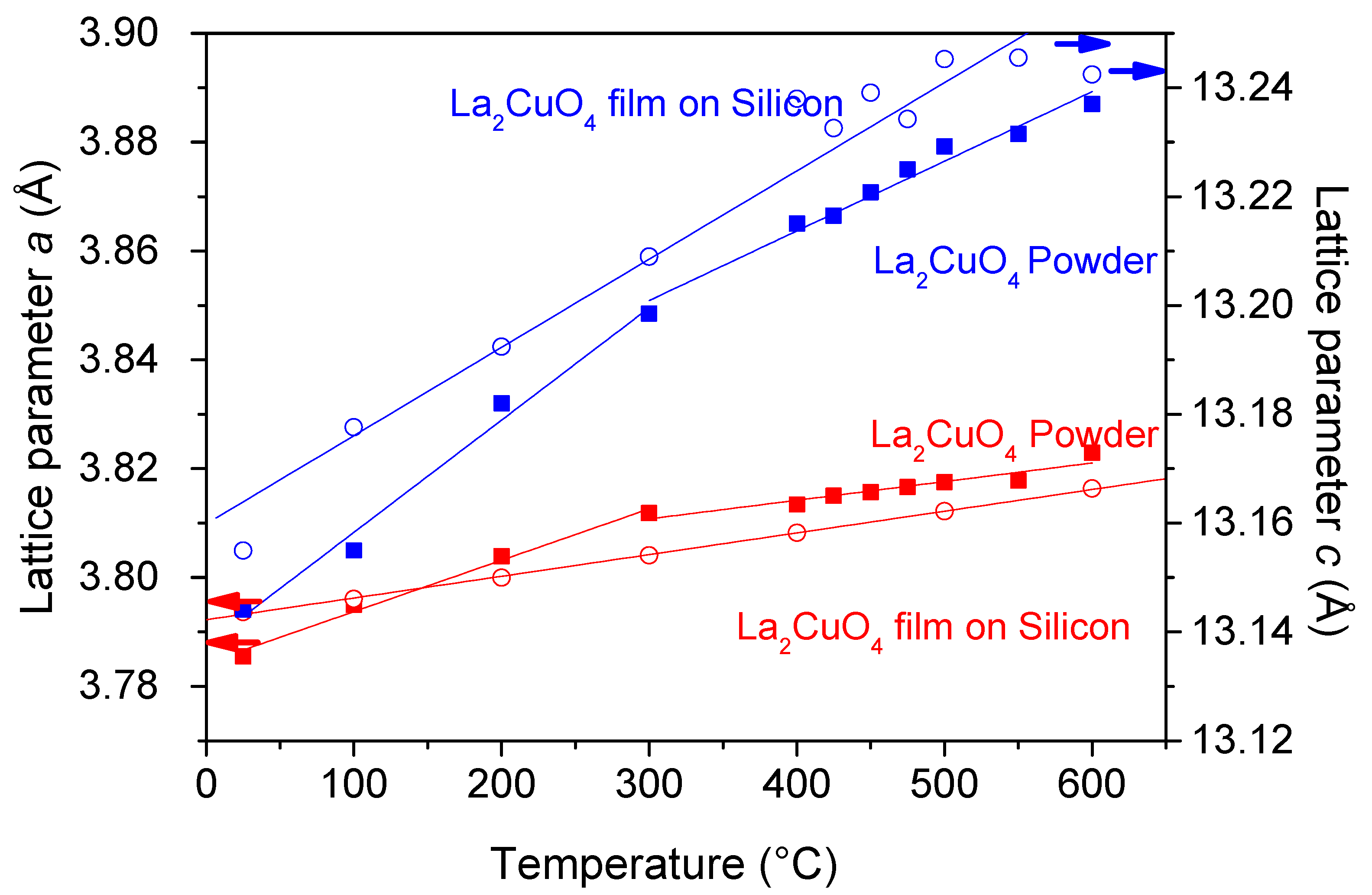

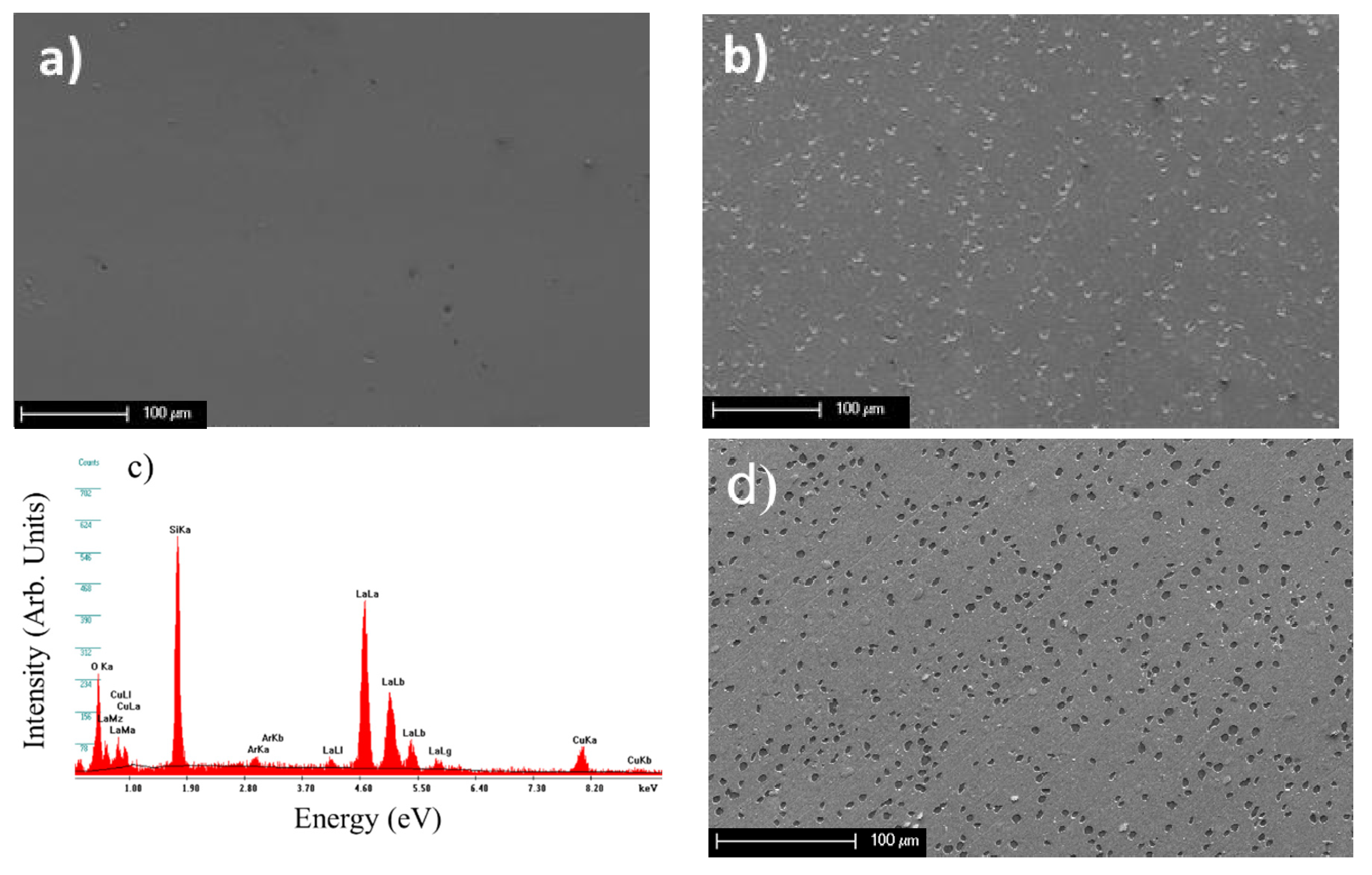

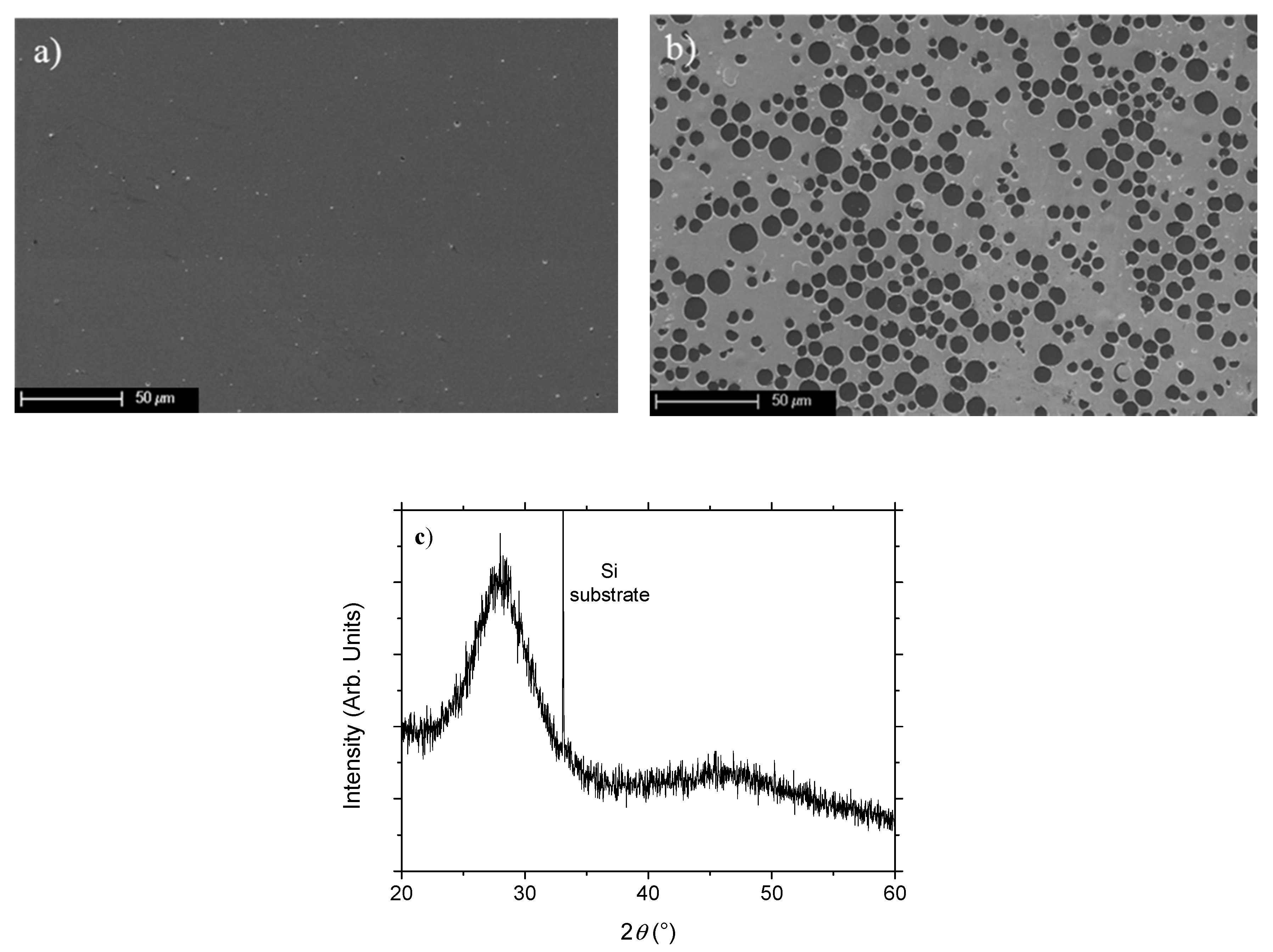

3.1. Structure of As-Deposited and Air Annealed Films

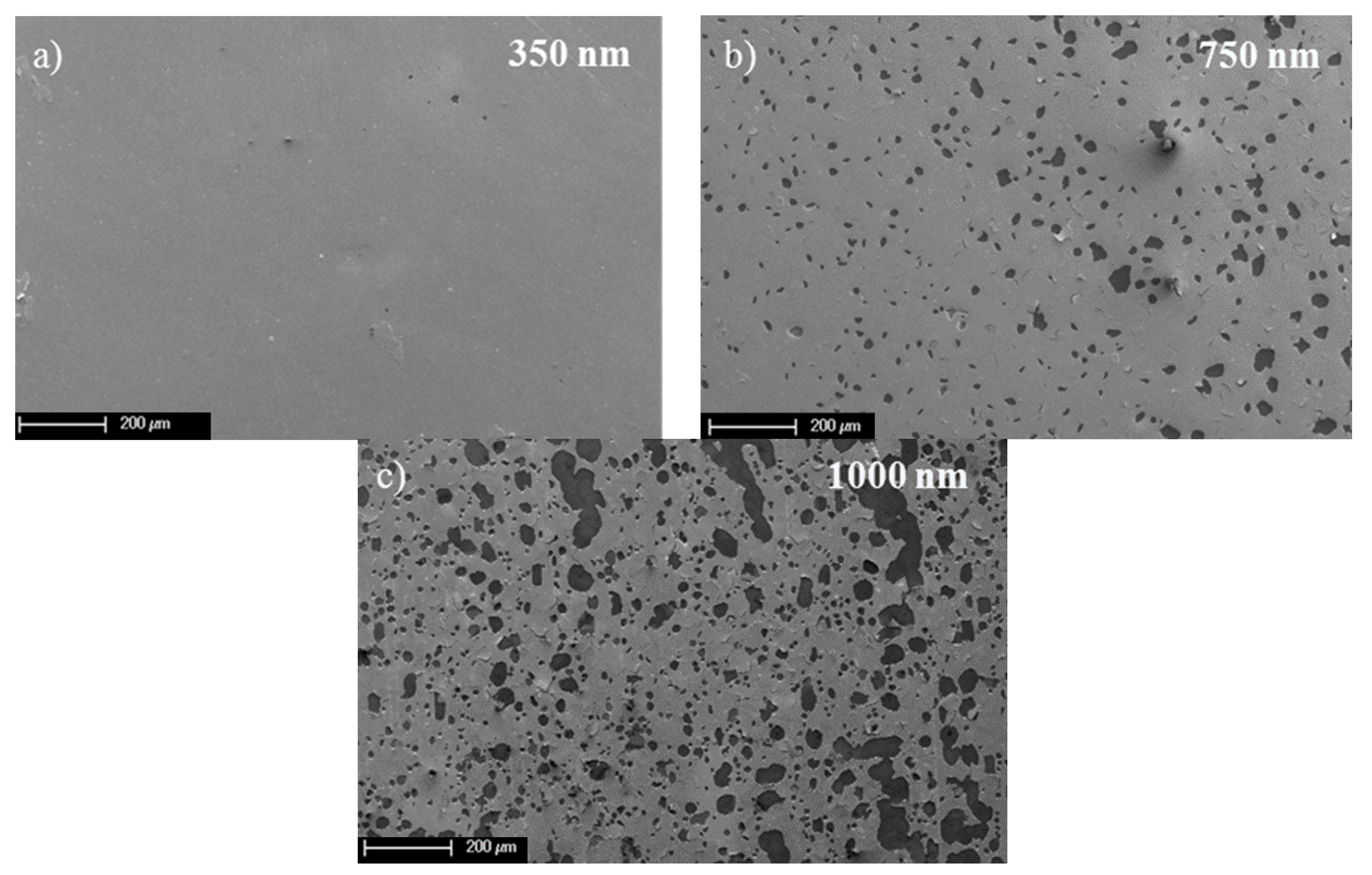

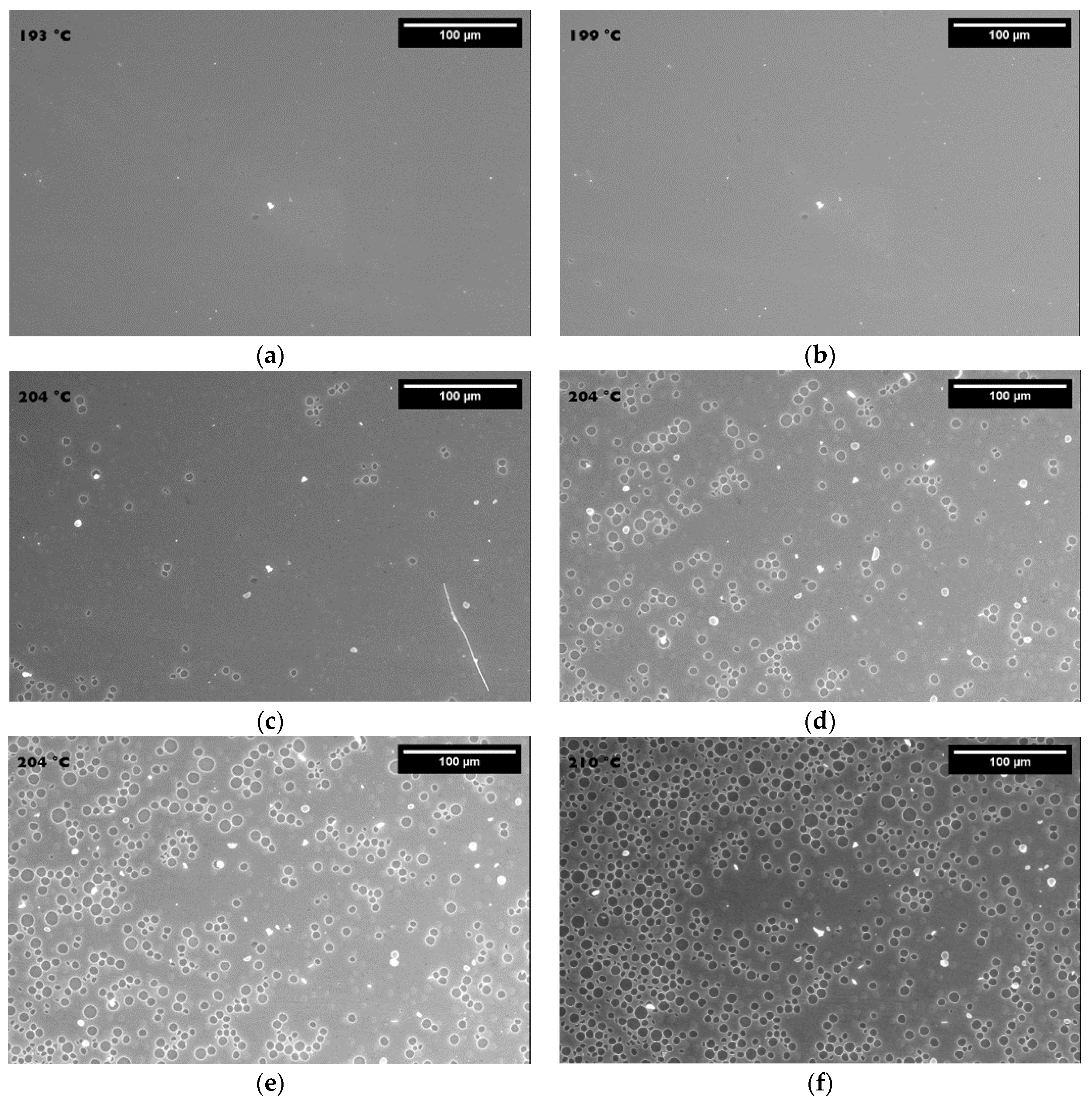

3.2. Effect of Thermal Stress on Film Surface Morphology

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Si, W.; Xi, X.X. Epitaxial-strain-induced insulator-superconductor transition in undoped and lightly doped La2CuO4. Appl. Phys. Lett. 2001, 78, 240. [Google Scholar] [CrossRef]

- Hundley, M.F.; Kwok, R.S.; Cheong, S.W.; Thompson, J.D.; Fisk, Z. Anisotropic electronic and thermal transport properties of lightly oxygen-doped La2CuO4+δ. Phys. C Supercond. 1991, 172, 455–464. [Google Scholar] [CrossRef][Green Version]

- Briois, P.; Oliveira, J.C.; Lapostolle, F.; Perry, F.; Billard, A.; Cavaleiro, A. Synthesis and electrical properties of Ln2CuO4+δ (Ln: Nd or La) mixed conductor sputter deposited coatings. Ionics 2008, 14, 455–461. [Google Scholar] [CrossRef]

- Rial, C.; Morán, E.; Alario-Franco, M.A.; Amador, U.; Andersen, N.H. Room temperature chemically oxidized La2CuO4+y: Phase separation induced by thermal treatment. Phys. C Supercond. Appl. 1997, 278, 122–134. [Google Scholar] [CrossRef]

- Dong, X.L.; Dong, Z.F.; Zhao, B.R.; Zhao, Z.X.; Duan, X.F.; Peng, L.M.; Huang, W.W.; Xu, B.; Zhang, Y.Z.; Guo, S.Q. Direct Observation of Incommensurate Modulation in Phase-Separated Cu-Rich La2CuO4.003. Phys. Rev. Lett. 1998, 80, 2701–2704. [Google Scholar] [CrossRef]

- Locquet, J.; Arrouy, F.; Mächler, E.; Despont, M.; Bauer, P.; Williams, E.J. Local electrochemical oxidation/reduction: First step towards a new lithography? Appl. Phys. Lett. 1996, 68, 1999–2001. [Google Scholar] [CrossRef]

- Radaelli, P.G.; Hinks, D.G.; Mitchell, A.W.; Hunter, B.A.; Wagner, J.L.; Dabrowski, B.; Vandervoort, K.G.; Viswanathan, H.K.; Jorgensen, J.D. Structural and superconducting properties of La2-xSrxCuO4 as a function of Sr content. Phys. Rev. B 1994, 49, 4163–4175. [Google Scholar] [CrossRef]

- Grenier, J.C.; Lagueyte, N.; Wattiaux, A.; Doumerc, J.P.; Dordor, P.; Etourneau, J.; Pouchard, M.; Goodenough, J.B.; Zhou, J.S. Transport and magnetic properties of the superconducting La2CuO4+δ phases (0 <δ <0.09) prepared by electrochemical oxidation. Phys. C Supercond. Its Appl. 1992, 202, 209–218. [Google Scholar]

- Sinnarasa, I.; Thimont, Y.; Presmanes, L.; Barnabé, A.; Tailhades, P. Thermoelectric and Transport Properties of Delafossite CuCrO2:Mg Thin Films Prepared by RF Magnetron Sputtering. Nanomaterials 2017, 7, 157. [Google Scholar] [CrossRef]

- García-Wong, A.C.; Pilloud, D.; Bruyère, S.; Mathieu, S.; Migot, S.; Pierson, J.F.; Capon, F. Oxidation of sputter-deposited vanadium nitride as a new precursor to achieve thermochromic VO2 thin films. Sol. Energy Mater. Sol. Cells 2020, 201, 110474. [Google Scholar] [CrossRef]

- Pilloud, D.; Pierson, J.F.; Takadoum, J. Structure and tribological properties of reactively sputtered. Zr–Si–N films Thin Solid Films 2006, 496, 445–449. [Google Scholar] [CrossRef]

- Petitjean, C.; Grafouté, M.; Pierson, J.F.; Rousselot, C.; Banakh, O. Structural, optical and electrical properties of reactively sputtered iron oxynitride film. J. Phys. D Appl. Phys. 2006, 39, 1894–1898. [Google Scholar] [CrossRef]

- Capon, F.; Horwat, D.; Pierson, J.F.; Zaghrioui, M.; Laffez, P. Thermochromic effect in NdNiO3-δ thin films annealed in ambient air. J. Phys. D Appl. Phys. 2009, 42, 182006. [Google Scholar] [CrossRef]

- Orikasa, Y.; Hayashi, N.; Muranaka, S. Effects of oxygen gas pressure on structural, electrical, and thermoelectric properties of (ZnO)3In2O3 thin films deposited by rf magnetron sputtering. J. Appl. Phys. 2008, 103, 113703. [Google Scholar] [CrossRef]

- Stranak, V.; Wulff, H.; Rebl, H.; Zietz, C.; Arndt, K.; Bogdanowicz, R.; Nebe, B.; Bader, R.; Podbielski, A.; Hubick, Z.; et al. Deposition of thin titanium–copper films with antimicrobial effect by advanced magnetron sputtering methods. Mater. Sci. Eng. C 2011, 31, 1512–1519. [Google Scholar] [CrossRef]

- Saadat, M.; George, A.E.; Hewitt, K.C. Densely mapping the phase diagram of cuprate superconductors using a spatial composition spread approach. Phys. C Supercond. 2010, 470, S59–S61. [Google Scholar] [CrossRef]

- Liu, Y.; Wan, S.L.; Li, X.G. Excess oxygen doping in chemically oxidized La2CuO4+δ films studied by x-ray diffraction and Raman scattering. Supercond. Sci. Technol. 2007, 20, 870–874. [Google Scholar]

- Tranvouez, N.; Pierson, J.F.; Capon, F.; Bauer, P. Effect of the deposition process on the composition and structure of sputtered lanthanum cuprate films. Surf. Coat. Technol. 2011, 205, S254–S257. [Google Scholar] [CrossRef]

- Zhu, X.; Defaÿ, E.; Guigues, B.; Le Rhun, G.; Dubarry, C.; Aïd, M. Low-temperature fabrication of Ba1-xSrxTiO3 thin films with good dielectric properties on platinized sililcon substrates. J. Eur. Ceram. Soc. 2010, 30, 471–474. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, H.; Liu, P.; Yao, W.; Cao, L. Preparation and conducting performance of LaNiO3 thin film on Si substrate. Thin Solid Films 2005, 471, 48–52. [Google Scholar] [CrossRef]

- Chen, C.; Smith, D.C.; Gay, P.; Ryan, J.F. Flux growth of superconducting La2CuO4 single crystals. Phys. C Supercond. 2000, 341, 535–536. [Google Scholar] [CrossRef]

- Boileau, A.; Capon, F.; Coustel, R.; Laffez, P.; Barrat, S.; Pierson, J.F. Inductive effect of Nd for Ni3+ stabilization in NdNiO3 synthesized by reactive DC co-sputtering. J. Phys. Chem C 2017, 121, 21579–21590. [Google Scholar] [CrossRef]

- Boehm, E.; Bassata, J.M.; Steil, M.C.; Dordor, P.; Mauvy, F.; Grenier, J. C Oxygen transport properties of La2Ni1−xCuxO4+δ mixed conducting oxides. Solid State Sci. 2003, 5, 973–981. [Google Scholar] [CrossRef]

- Watanabe, H.; Yamada, N.; Okaji, M. Linear Thermal Expansion Coefficient of Silicon from 293 to 1000 K. Inter. J. Thermophys. 2004, 25, 221–236. [Google Scholar] [CrossRef]

- Lang, M.; Kürsch, R.; Grauel, A.; Geibel, C.; Steglich, F.; Rietschel, H.; Wolf, T.; Hidaka, Y.; Kumagai, K.; Maeno, Y. Lattice Instabilities in Cuprate Superconductors: A Possible Limiting Mechanism for Tc. Phys. Rev. Lett. 1992, 69, 482–485. [Google Scholar] [CrossRef] [PubMed]

- Audoly, B. Mode-dependent toughness and the delamination of compressed thin films. J. Mech. Phys. Solids 2000, 48, 2315–2332. [Google Scholar] [CrossRef]

- Teixeira, V. Mechanical integrity in PVD coatings due to the presence of residual stresses. Thin Solid Films 2001, 392, 276–281. [Google Scholar] [CrossRef]

- Sasabayashi, T.; Ito, N.; Nishimura, E.; Kon, M.; Song, P.K.; Utsumi, K.; Kaijo, A.; Shigesato, Y. Comparative study on structure and internal stress in tin-doped indium oxide and indium-zinc oxide films deposited by rf magnetron sputtering. Thin Solid Films 2003, 445, 219–223. [Google Scholar] [CrossRef]

- Coupeau, C.; Goudeau, P.; Belliard, L.; George, M.; Tamura, N.; Cleymand, F.; Colin, J.; Perrin, B.; Grilhé, J. Evidence of plastic damage in thin films around buckling structures. Thin Solid Films 2004, 469–470, 221–226. [Google Scholar] [CrossRef]

- Eymery, J.P.; Denanot, M.F. Blisters in as-deposited films of bcc stainless steel. Surf. Coat. Technol. 1996, 80, 251–254. [Google Scholar] [CrossRef]

- Hyun, D.C.; Moon, G.D.; Park, C.J.; Kim, B.S.; Xia, Y.; Jeong, U. Buckling-Assisted Patterning of Multiple Polymers. Adv. Mater. 2010, 22, 2642–2646. [Google Scholar] [CrossRef] [PubMed]

- Romana, L.; Fuchs, G.; Massouras, G.; Thevenard, P. Blister formation in alumina thin films bombarded with xenon ions Radiat. Eff. Defects Solids 1990, 115, 139–143. [Google Scholar] [CrossRef]

- Podor, R.; Pailhon, D.; Ravaux, J.; Brau, H.P. Development of an Integrated Thermocouple for the Accurate Sample Temperature Measurement during High Temperature Environmental Scanning Electron Microscopy (HT-ESEM) Experiments. J. Microscopy 2015, 21, 307–312. [Google Scholar] [CrossRef]

- Etiemble, A.; Der Loughian, C.; Apreutesei, M.; Langlois, C.; Cardinal, S.; Pelletier, J.M.; Pierson, J.F.; Steyer, P. Innovative Zr-Cu-Ag thin film metallic glass deposed by magnetron PVD sputtering for antibacterial applications. J. Alloys Compd. 2017, 707, 155–161. [Google Scholar] [CrossRef]

- Mège-Revil, A.; Steyer, P.; Cardinal, S.; Thollet, G.; Esnouf, C.; Jacquot, P.; Stauder, B. Correlation between thermal fatigue and thermomechanical properties during the oxidation of multilayered TiSiN nanocomposite coatings synthesized by a hybrid physical/chemical vapour deposition process. Thin Solid Films 2010, 518, 5932–5937. [Google Scholar] [CrossRef]

- Mège-Revil, A.; Steyer, P.; Thollet, G.; Chiriac, R.; Sigala, C.; Sanchéz-Lopéz, J.C.; Esnouf, C. Thermogravimetric and in situ SEM characterisation of the oxidation phenomena of protective nanocomposite nitride films deposited on steel. Surf. Coat. Technol. 2009, 204, 893–901. [Google Scholar] [CrossRef]

- Jacquet, P.; Song, B.; Podor, R.; Lautru, J.; Trejo, E.; Cooper, S.J.; Teisseire, J.; Gozhyk, I.; Jupille, J.; Lazzari, R. Direct Observation of Metallic Thin Layers Dewetting by HT-ESEM. Microsc. Microanal. 2019, 25, 69–70. [Google Scholar] [CrossRef]

- Yu, H.H.; He, M.Y.; Hutchinson, J.W. Edge effects in thin film delamination. Acta Mater. 2001, 49, 93–107. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Target diameter and thickness (mm) | 50 and 3 |

| Distance between target and substrates (cm) | 7 |

| Argon flow rate (sccm) | 20 |

| Oxygen flow rate (sccm) | 10 |

| Total pressure (Pa) | 0.6–4.6 |

| Temperature (°C) | Approx. 50 |

| Sample Nature | Apparent TEC Measured Value for the Lattice Parameter a (106 K−1) | Apparent TEC Measured Value for the Lattice Parameter c (106 K−1) | Literature Value |

|---|---|---|---|

| Film on silicon | 10.5 ± 0.1 | 11.0 ± 0.5 | - |

| La2CuO4 powder in orthorhombic form | 15 ± 1 | 13.0 ± 0.5 | 13 [23] |

| La2CuO4 powder in tetragonal form | 10.2 ± 0.2 | 10 ± 2 | - |

| Silicon | 3.2 ± 0.2 | - | 2.9 [24] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tranvouez, N.; Steyer, P.; Malchère, A.; Boulet, P.; Capon, F.; Bauer, J.-P.; Pierson, J.-F. Effect of Thermal Stresses Formed during Air Annealing of Amorphous Lanthanum Cuprate Thin Films Deposited on Silicon Substrate. Coatings 2020, 10, 613. https://doi.org/10.3390/coatings10070613

Tranvouez N, Steyer P, Malchère A, Boulet P, Capon F, Bauer J-P, Pierson J-F. Effect of Thermal Stresses Formed during Air Annealing of Amorphous Lanthanum Cuprate Thin Films Deposited on Silicon Substrate. Coatings. 2020; 10(7):613. https://doi.org/10.3390/coatings10070613

Chicago/Turabian StyleTranvouez, Nolwenn, Philippe Steyer, Annie Malchère, Pascal Boulet, Fabien Capon, Jean-Philippe Bauer, and Jean-François Pierson. 2020. "Effect of Thermal Stresses Formed during Air Annealing of Amorphous Lanthanum Cuprate Thin Films Deposited on Silicon Substrate" Coatings 10, no. 7: 613. https://doi.org/10.3390/coatings10070613

APA StyleTranvouez, N., Steyer, P., Malchère, A., Boulet, P., Capon, F., Bauer, J.-P., & Pierson, J.-F. (2020). Effect of Thermal Stresses Formed during Air Annealing of Amorphous Lanthanum Cuprate Thin Films Deposited on Silicon Substrate. Coatings, 10(7), 613. https://doi.org/10.3390/coatings10070613