1. Introduction

Copper zinc tin sulfide (C

2ZTS

4)-based solar cell material has low-cost constituent elements, optimum energy band-gap (1.4–1.5 eV), and a significant band-edge absorption coefficient (10

4 cm

−1–10

5 cm

−1) in the visible spectrum [

1]. C

2ZTS

4 is not only a low-cost and environmentally friendly material but also a promising p-type absorber material to replace copper indium gallium selenide (CIGS

2) or cadmium telluride (CdTe). However, the power conversion efficiency (PCE) of C

2ZTS

4-based solar cells is still low compared to that of CIGS

2-based ones.

Various techniques to deposit C

2ZTS

4 layers have been developed. Vacuum deposition and solution-based liquid process coatings are representative deposition methods [

2,

3,

4,

5,

6,

7]. Electron beam evaporation has been used to deposit metallic precursors and vapor phase sulfurization to form the film [

2]. The effects of the evaporation sequence of the metallic precursors on film quality and surface characteristics have been studied [

8]. Pulsed laser deposition [

3] and fast co-evaporation [

7] have also been investigated. Several research groups focusing on liquid-based processes introduced the synthesis of C

2ZTS

4 nanocrystals and applied it to fabricate solar cells [

4,

9,

10,

11]. Todorov et al. used hydrazine solvent to dissolve CuS, ZnS, SnS, and S materials and used the spin coating method to deposit the layers on Mo-coated glass [

6]. Spray chemical vapor deposition (CVD) is a low-cost solution-based method that is good for mass production and can be applied to various materials. However, only a few studies have characterized the optical and electrical properties of sprayed C

2ZTS

4 film on glass [

12,

13,

14].

Absorber layers for chalcogenide thin-film solar cells have been grown with various techniques, such as the gas reaction method using toxic H

2S and H

2Se gas [

15], deposition of S- or Se-abundant metallic precursor [

16], or deposition of pure S or Se on precursors [

17]. The absorber layer quality depends on the flux and concentration of chalcogen. Many research groups have studied the effect of optimizing conditions. The amount of S or Se should be high enough to obtain a quality absorber layer and high device performance. However, once the amount exceeds the optimum condition, S or Se residues can be oxidized, which deteriorates the absorber layer surface condition that creates the junction with the buffer layer and thus degrades the device performance.

The maximum PCE with vacuum evaporation is 6.8% [

18], and solution-processed nanocrystal (NC)-C

2ZTS

4-based solar cells have shown about 7.7% PCE [

19]. One significant breakthrough, spin-coating a hydrazine solution-slurry-based C

2ZT(S,Se)

4, achieved 12.6% PCE [

6]. However, reported solar cells that used a spray-deposited C

2ZTS

4 film showed low performance below 1.0% PCE [

20].

Here, we demonstrate C2ZTS4 solar cells fabricated from bottom to top by the spray-CVD technique with aqueous solutions. Titanium dioxide (TiO2) and indium sulfide (In2S3) were used for the window and buffer layers, respectively. Because spraying at a high temperature can result in an interaction between layers, the effect of temperature and the composition of the C2ZTS4 absorber layer was investigated. A non-toxic Cd-free solar cell was realized by using a thin In2S3 film as a buffer layer. The best device performance in this study was 3.34% PCE under AM1.5G 1-sun illumination.

2. Experiments

Glass slides (1″ × 0.5″) coated with transparent fluorine-doped tin oxide (FTO, SnO

2:F, 12 ohm/sq, TFD Inc., Anaheim, CA, USA) were used as the substrate for the fabricated solar cells. The surface of the substrate was cleaned by ultrasonic agitation using acetone and methanol for 10 min, then dried on a hotplate at 120 °C for 10 min. Subsequently, a UV-ozone surface treatment was performed for 1 h to remove organic residuals. The solar cell structure used in this study was FTO/dense-TiO

2/In

2S

3/C

2ZTS

4/Au. All layers from the window to absorber were deposited by the spray pyrolysis method.

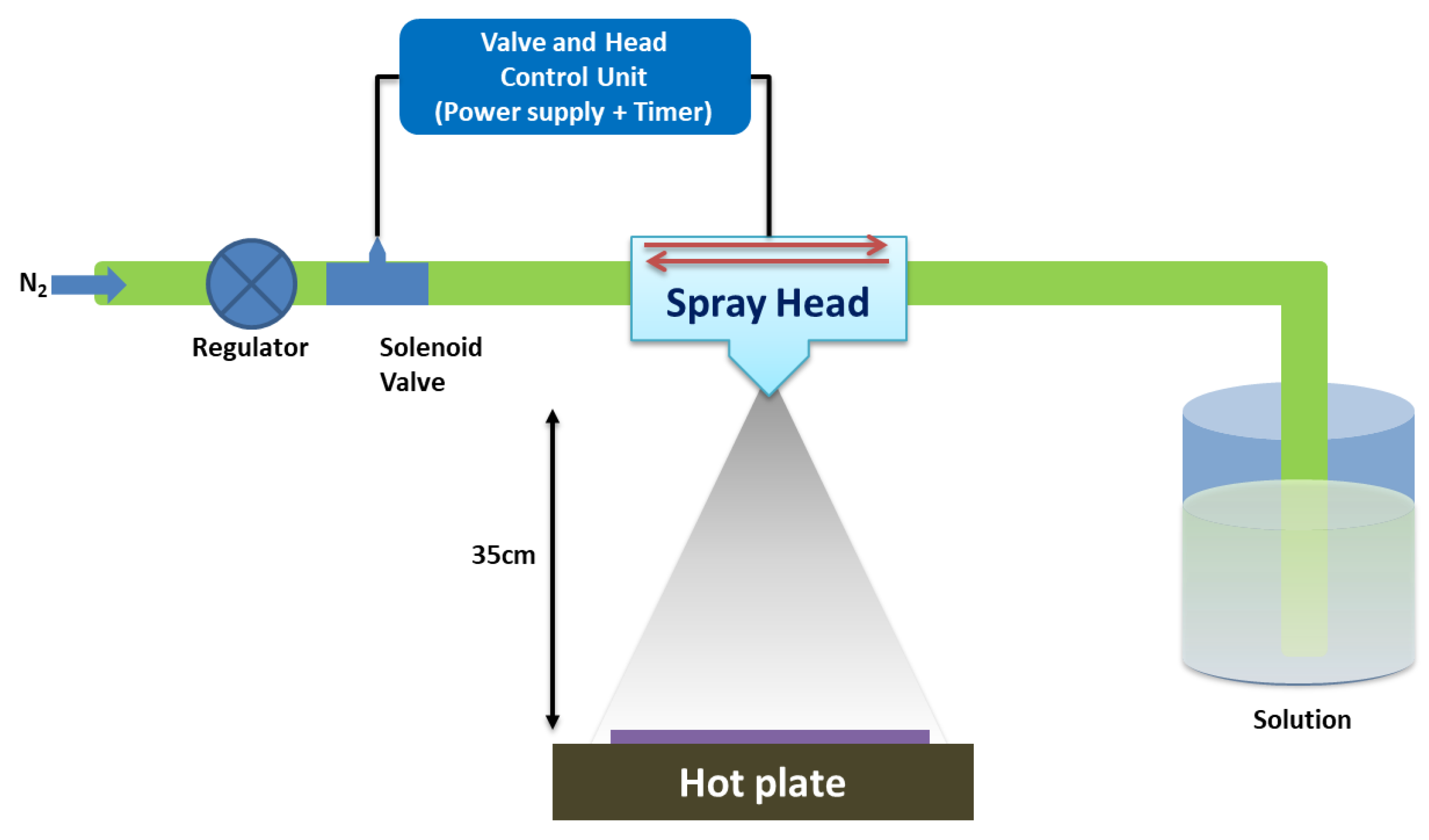

Figure 1 shows the schematic diagram of the laboratory-made spraying system. The system is composed of a brass-nickel-based sprayer (1/4XASR200B, BETE Inc., Greenfield, MA, USA), solenoid valve (P25D1SS-024-D, Aro Inc., Bryan, Oh, USA), and timer-relay (KT-V4S-D, Koyo Inc., Tokyo, Japan). Spraying time, on/off of the solenoid valve, and the interval between sprays were controlled by a valve and head control unit. The spraying head was moved back and forth on a heated substrate, and the distance from the substrate to the head was 35 cm to ensure uniform deposition. Spraying was on full for 2 s. The interval between spray cycles was 10 s to allow the film temperature to stabilize. Nitrogen (N

2) gas was used as a carrier gas, with pressure controlled by the N

2 regulator. On/off of gas flow was controlled by a solenoid valve. A dense-TiO

2 layer was deposited by spray-CVD onto the pre-cleaned FTO substrate [

21], and the spray solution consisted of 80 mM of titanium di-isopropoxide bis(acetylacetonate) (TAA) in isopropyl alcohol (IPA). The spray rate was 5 mL/min, and TiO

2 spraying was performed while the substrate temperature was maintained at 450 °C using a digital hotplate.

The pressure of N

2 carrier gas was 10 psi for TiO

2 and 6 psi for In

2S

3 and C

2ZTS

4. For depositing the In

2S

3 layer, indium chloride (InCl

3) and thiourea ((NH

2)

2CS) dissolved in deionized (DI) water were used as precursors. We kept the ratio of In to S at 1.2:8 since low defect density and high photo-response characteristics had been reported for this ratio [

22]. Cupric chloride dihydrate (CuCl

2·2H

2O), zinc chloride (ZnCl

2), stannic chloride (SnCl

4), and thiourea were dissolved in DI water for spraying the C

2ZTS

4S absorber layer.

The TiO

2 window layer and In

2S

3 buffer layer thicknesses were controlled by solution concentration and spraying cycles. A TiO

2 layer was used for the window layer instead of a conventional ZnO because ZnO has poor chemical stability in acidic conditions, and the spraying solutions for the buffer layer are acidic (pH~5).

Figure S1 shows the TiO

2 thickness measured from cross-section scanning electron microscopy (SEM) images at different TAA concentrations. We used 80 mM TAA solution for 40 nm of the TiO

2 window layer, similar to the intrinsic ZnO layer used in CIGS

2 solar cells [

23].

Figure S2 presents the thickness of In

2S

3 buffer layer for various numbers of spraying cycles. We used 40 spraying cycles for 280 nm of the In

2S

3 buffer layer, which was thicker than the buffer layer of conventional CIGS

2 solar cells (~45 nm). Since the following absorber layer was deposited at high temperature (>360 °C) for 30 min, the buffer layer should be thick enough to block the inter-diffusion of elements from the absorber to the transparent conducting oxide layer. However, the thick buffer layer can degrade the total series resistance and solar cell performance. A metal electrode with gold (Au, 30 nm) and silver (Ag, 70 nm) was deposited by electron beam evaporation over 4.25 × 10

−2 cm

2. The initial thin Au layer was used for matching the energy level between the valence band of C

2ZTS

4 and metal, and the second thick Ag layer was to enhance the contact property between the device electrodes and the measurement probes. The light was incident on the device through the FTO-coated glass substrate.

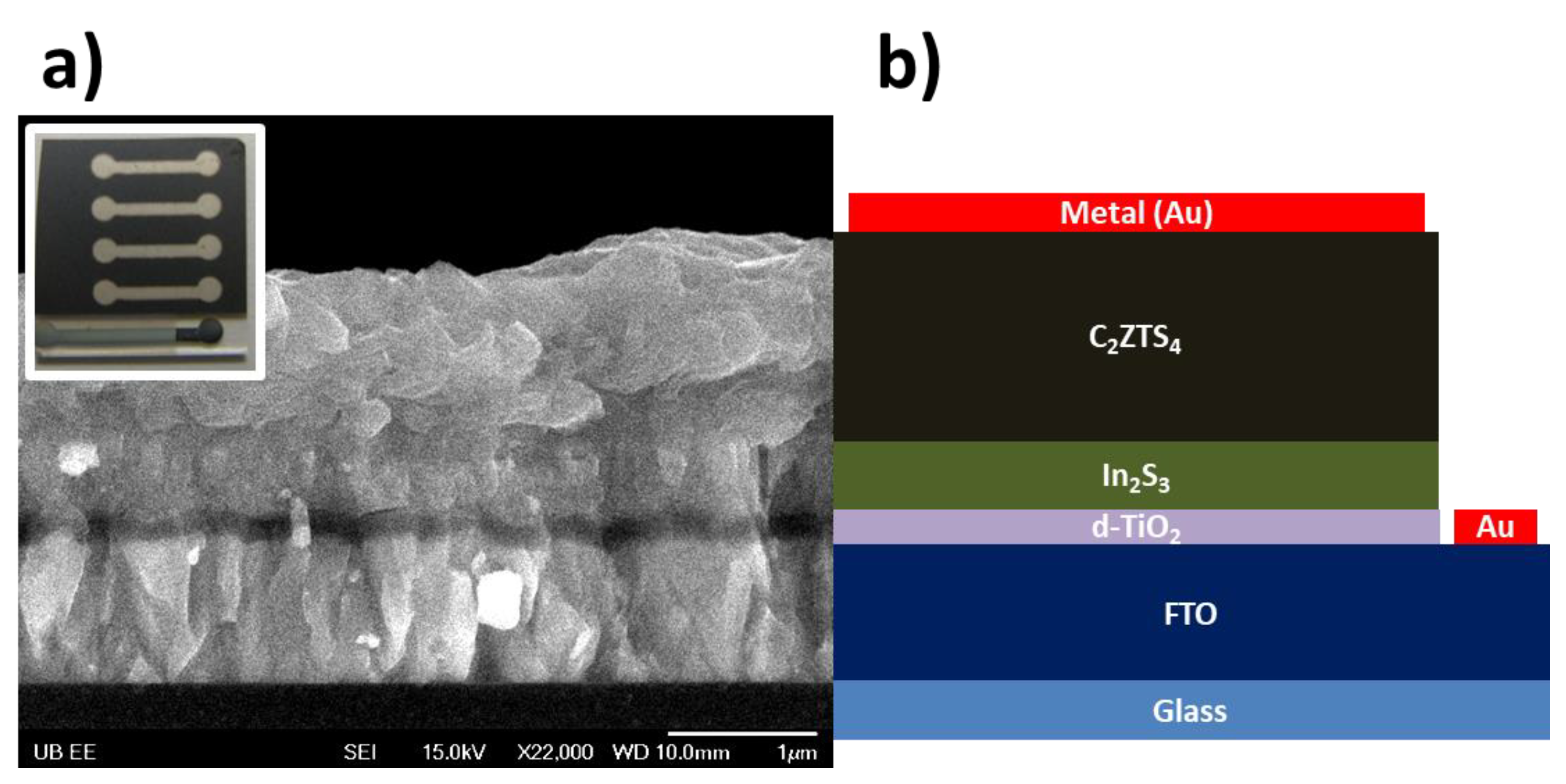

Figure 2 shows the cross-section SEM image, a typical sequential structure of an entirely fabricated C

2ZTS

4 solar cell, and a plan view device photograph (inset), showing the anode contact and the four short cathodes.

In the compositional study of sprayed C2ZTS4 layer, we fixed the substrate temperature at 360 °C and varied the Cu/(Zn + Sn) ratio of the solution from 0.6 to 1.26. We made four solutions in DI water for the main elements: CuCl2 (0.09 M), Zn(CH3CO2)2·2H2O (0.045 M), SnCl4 (0.04 M), and thiourea (0.5 M). The amount of CuCl2 solution was varied from 3 mL to 7 mL to change the Cu/(Zn + Sn) atomic ratio. The spraying solution was made by mixing 5 mL of each solution with the 3 mL to 7 mL CuCl2 and adding DI water to 100 mL. The composition of the main elements of the C2ZTS4 film was measured by energy-dispersive X-ray spectroscopy (EDX). X-ray diffraction (XRD) measurements were performed with 40 kV and 44 mA of voltage and current, respectively. The current-voltage (I-V) characteristic was measured using a Keithley 2400 source meter under calibrated AM 1.5G 1-sun (100 mW/cm2, Oriel) illumination. A 150 W Xenon lamp with Oriel 68805 universal power supply, monochromator (SpectraPro 2300i, Teledyne Prinston Instruments, Trenton, NJ, USA), and a Keithley 6485 picoammeter were used for the external quantum efficiency (EQE) measurement.

3. Results and Discussions

The surface of the C

2ZTS

4 films deposited by evaporation, sputtering, spraying, or other deposition methods showed rough characteristics [

8,

13]. The sprayed C

2ZTS

4 films in this study had a rough surface and different surface characteristics depending on the copper content of the spraying solution.

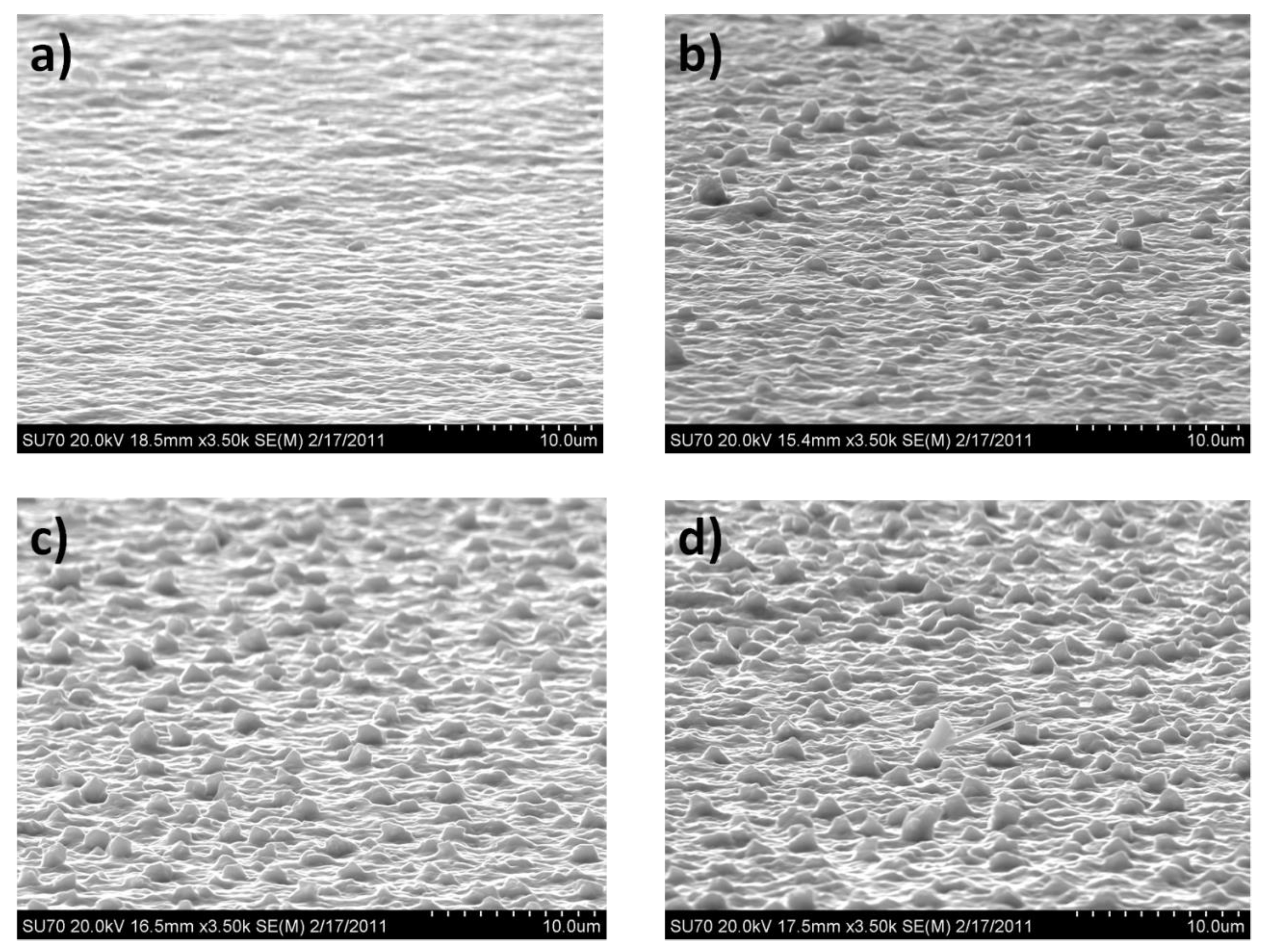

Figure 3 shows the surface SEM images for four copper concentrations. As the copper concentration increased, spherical bumps were created, and the size of the bumps increased. The film composition was measured by EDX and from the cross-section SEM images. It was close to the stoichiometric condition when the Cu/(Zn + Sn) ratio was close to unity. Cu/(Zn + Sn) ratio of 0.8 in the film has been reported as the best condition for high device performance [

24]. The relationship between metal element ratio and solar cell device performance is similar for CIGS

2 solar cells [

15]. When the Cu/(In + Ga) ratio is higher than the optimum condition and close to unity, the bulk absorber layer property is degraded. Lee et al. studied the CIGS

2 absorber layer property by using various electrical characterization methods. It showed a high capacitance value, steep slope of capacitance versus log frequency, and low free carrier density at room temperature. Once the Cu/(In + Ga) ratio exceeds the optimum condition, the short-circuit current density (J

SC) and open-circuit voltage (V

OC) decrease [

25].

Spherical bumps were created as the Cu/(Zn + Sn) ratio increased. The copper concentration of the bumps is much higher than that of the flat film area. Since copper has a high diffusion coefficient at high temperature, the copper atoms diffuse out to the surface during layer deposition.

Table 1 shows the solution composition, EDX results of the film composition, and the compositional analysis of the bump area. As the Cu/(Zn + Sn) ratio increased, the Cu-rich bump size also increased. A non- uniform composition distribution at the surface as well as rough surfaces are not suitable for the deposition of the next layer. Moreover, the rough surface characteristic of the absorber layer degrades the device performance due to the unstable junction formation at the irregular interface between the absorber and the buffer layer. Therefore, we used the inverse stacking sequence structure (superstrate structure) as shown in

Figure 2 instead of the conventional CIGS

2 structure to circumvent the device performance degradation due to the inferior surface characteristics of the sprayed C

2ZTS

4 absorber layer.

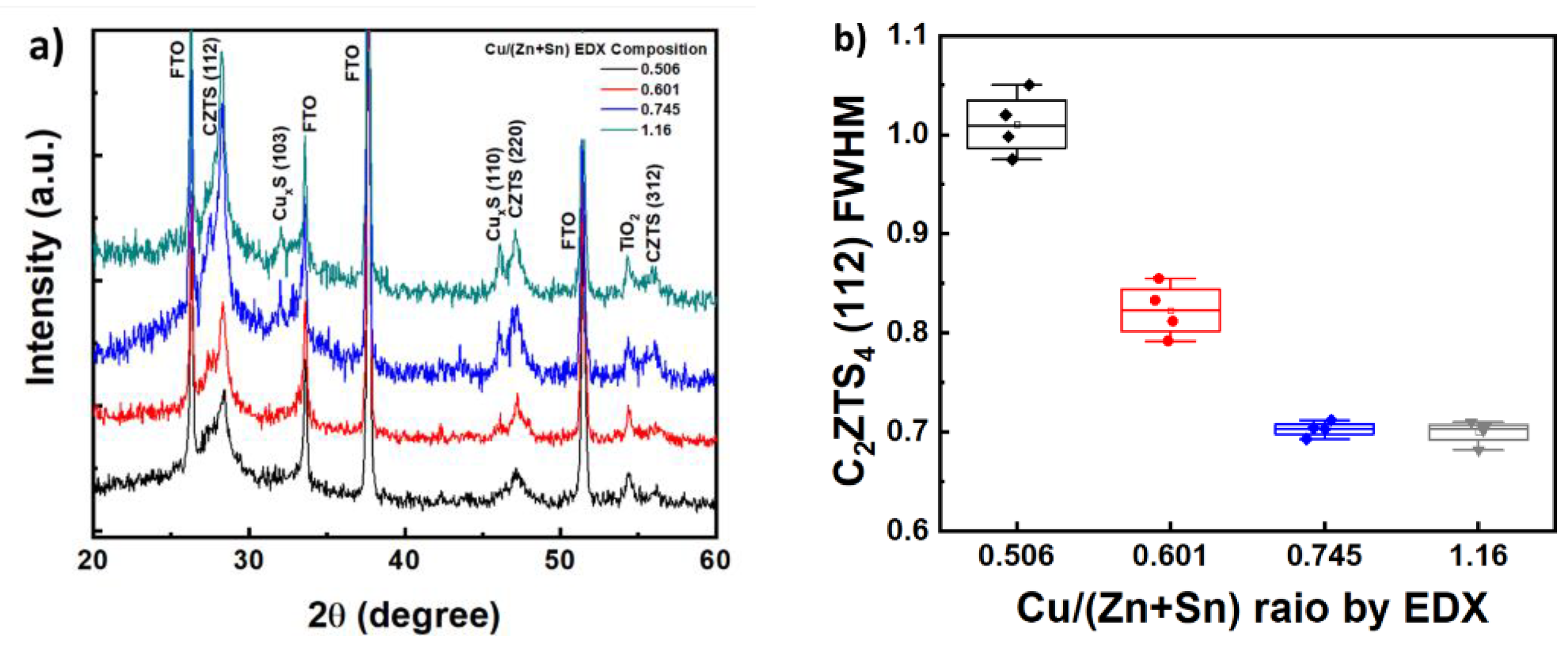

The C

2ZTS

4 absorber layers were characterized using XRD analysis. As shown in

Figure 4, the C

2ZTS

4 film was successfully created on the FTO/TiO

2 substrate. However, when the Cu/(Zn + Sn) ratio was higher than 0.506, the secondary peak around 46.1° increased due to the low formation energy of the Cu

xS phase. When the Cu/(Zn + Sn) ratio was close to 0.8, a characteristic peak around 28.3° of C

2ZTS

4 film became distinct compared to that of samples with low Cu/(Zn + Sn) ratio. A sharp peak of the secondary phase (Cu

xS) also appeared around 46.1° when the Cu content increased. The formation energy of the Cu

xS phase is lower than that of the C

2ZTS

4 form. The increase in the Cu

xS secondary phase peak intensity, shown in

Figure 3, is caused by the creation of high Cu-content bumps on the surface. These secondary phases degrade the junction quality between the buffer layer and the absorber layer, resulting in reduced V

OC and J

SC because they serve as recombination centers in the absorber layer. Although the secondary phase appears on the absorber layer surface, the full width at half maximum (FWHM) of the main C

2ZTS

4 peak (112) decreased to 0.702° with increasing Cu/(Zn + Sn) ratio. Thus, a higher metallic component ratio produces a higher crystal quality of the polycrystalline C

2ZTS

4 layer. However, FWHM does not decrease further once the Cu/(Zn + Sn) ratio reaches ~0.75. Therefore, we fixed the solution concentration with a 0.745 Cu/(Zn + Sn) ratio.

As we observed in the previous studies [

22,

24,

25], the chalcogen element flux and amount of source material is a critical factor for the quality of the absorber layer. We investigated the effect of sulfur concentration in the spraying solution on the final C

2ZTS

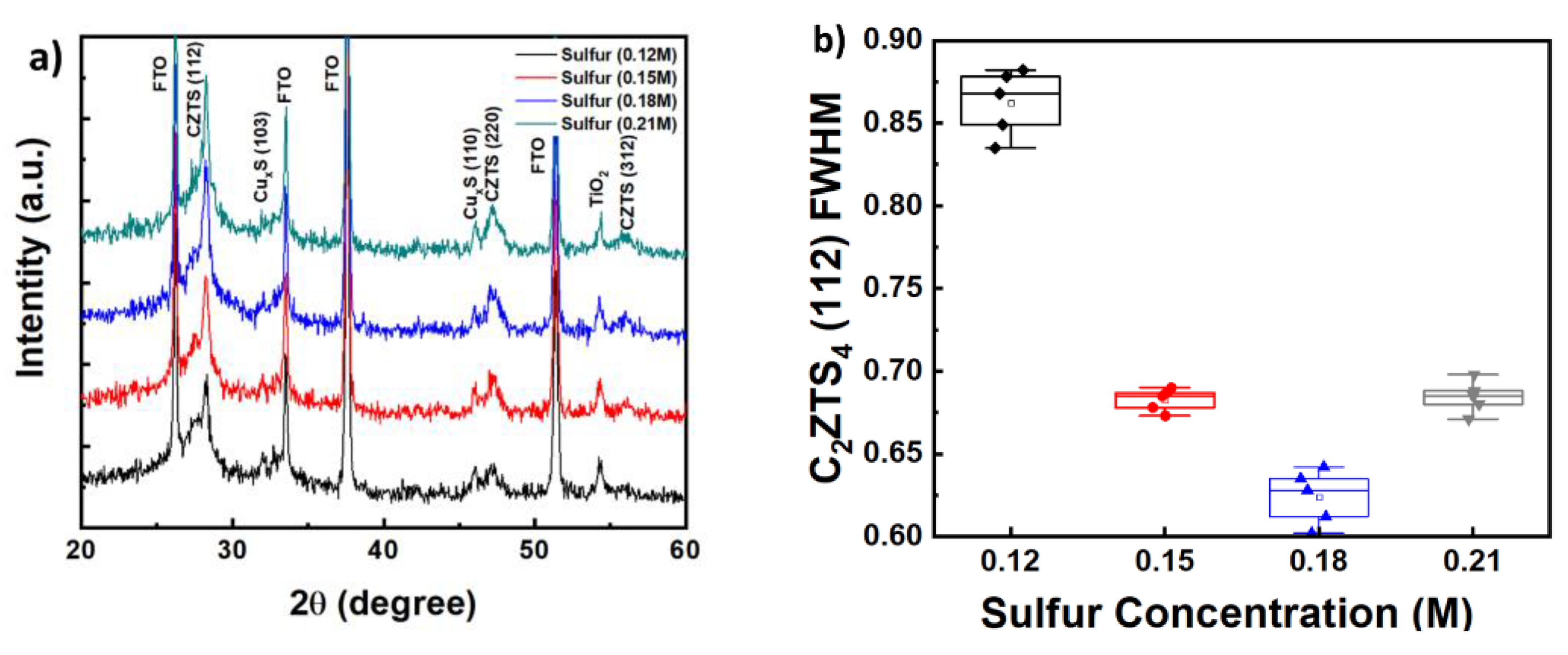

4 absorber film quality. The sulfur concentration was varied from 0.12 M to 0.21 M while the metallic precursor concentration was fixed. The film was deposited on a 360 °C heated FTO substrate.

Figure 5 shows the XRD result of the absorber layer deposited with different sulfur concentrations. The deposited C

2ZTS

4 films showed main (112) and (220) peaks around 28.2° and 47.2°, respectively. The main (112) peak intensity increased at higher sulfur concentrations. However, the FWHM decreased with increasing sulfur concentration, then increased again when the sulfur concentration exceeded the optimum condition. Based on the FWHM changes, 0.18 M S appears to be optimal.

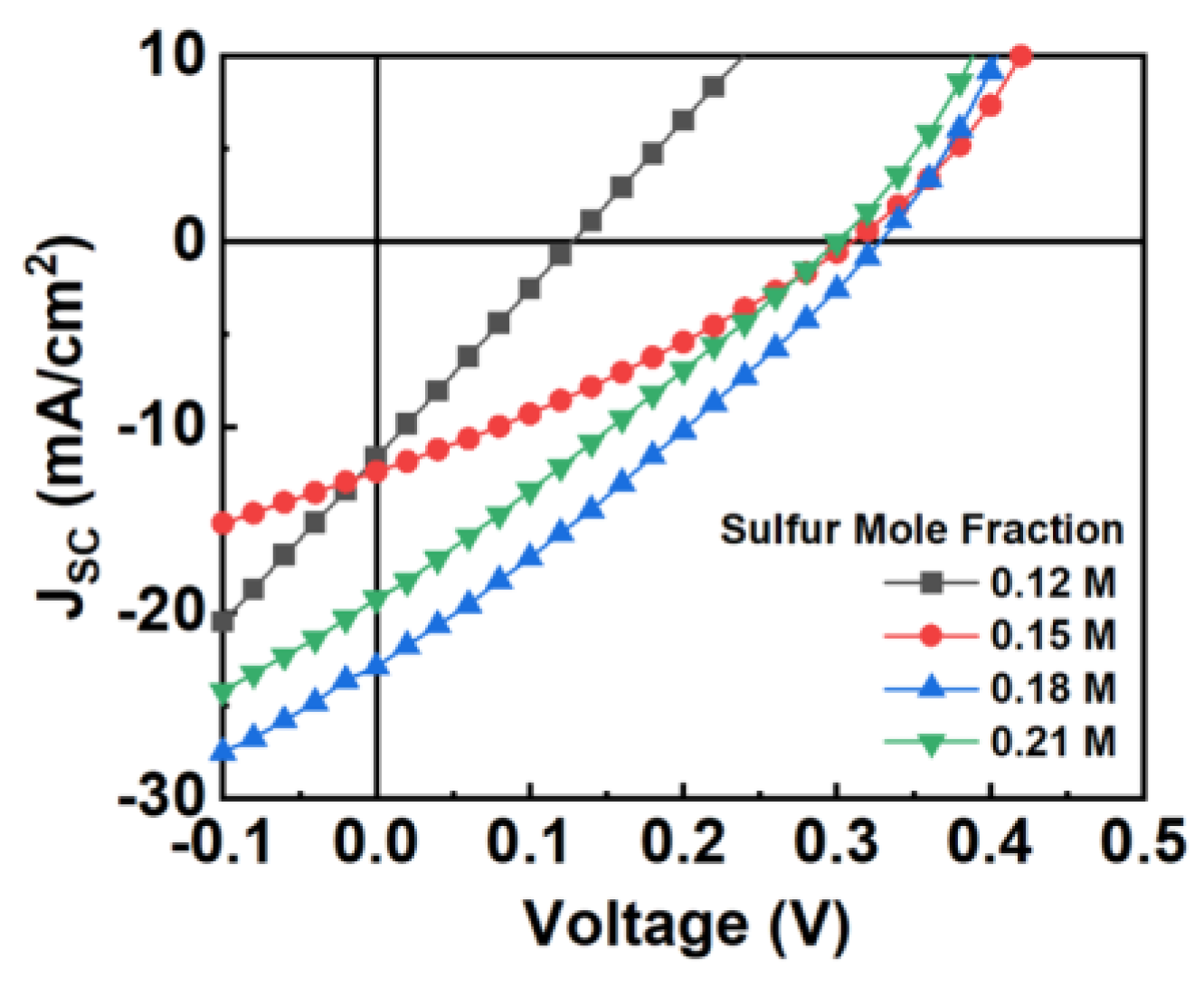

We investigated the electrical characteristics of entirely fabricated devices.

Figure 6 shows the current-voltage results. The generated J

SC and V

OC increased up to 22 mA/cm

2 and 328 mV, respectively, at 0.18 M sulfur. The change of J

SC and V

OC is well-matched with the variation of the FWHM in the XRD results, which reflects the absorber layer quality based on the sulfur concentration. Even for sulfur concentration in the absorber layer over the optimum condition (0.18 M), there was no degradation in the fill factor (FF). It means that the physical and chemical junction characteristic between the In

2S

3 buffer and C

2ZTS

4 absorber are not affected by sulfur concentration. The extracted device parameters are listed with the film XRD FWHM values in

Table 2.

The conventional CIGS

2 solar cell structure has a stacking sequence of glass/Mo/CIGS/CdS/ZnO/metal following the so-called substrate structure. Since the CIGS

2 layer requires a selenization process at high temperature (above 500 °C), the p-n junction performance between CdS and CIGS

2 would be degraded during the high-temperature selenization process if the CIGS

2 is deposited on the CdS buffer layer. Therefore, the CIGS

2 absorber layer should be created on the Mo back contact first, and the CdS buffer layer coated next. Because the absorber layer of the devices is deposited after the buffer layer, the effect of the deposition temperature of the C

2ZTS

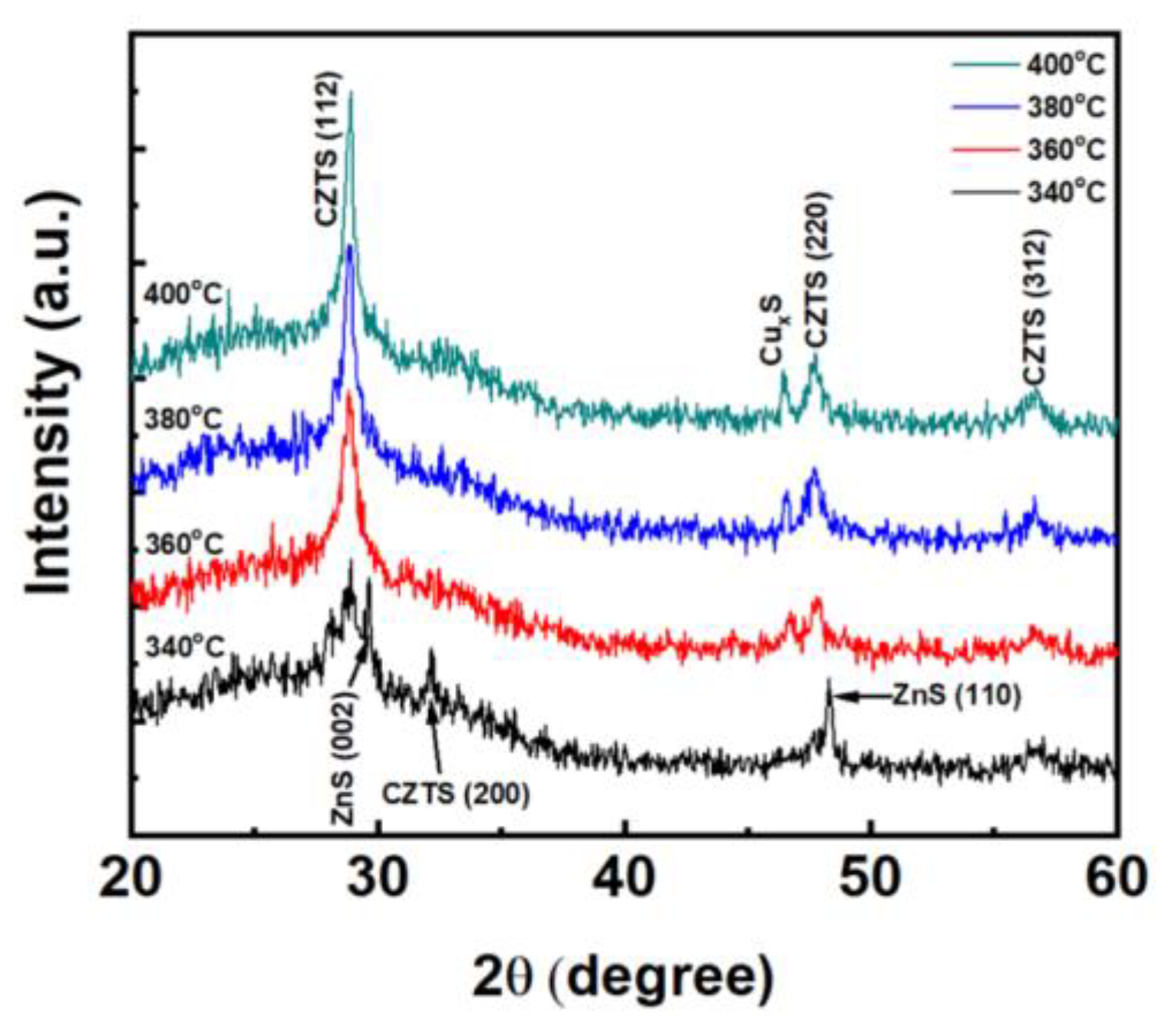

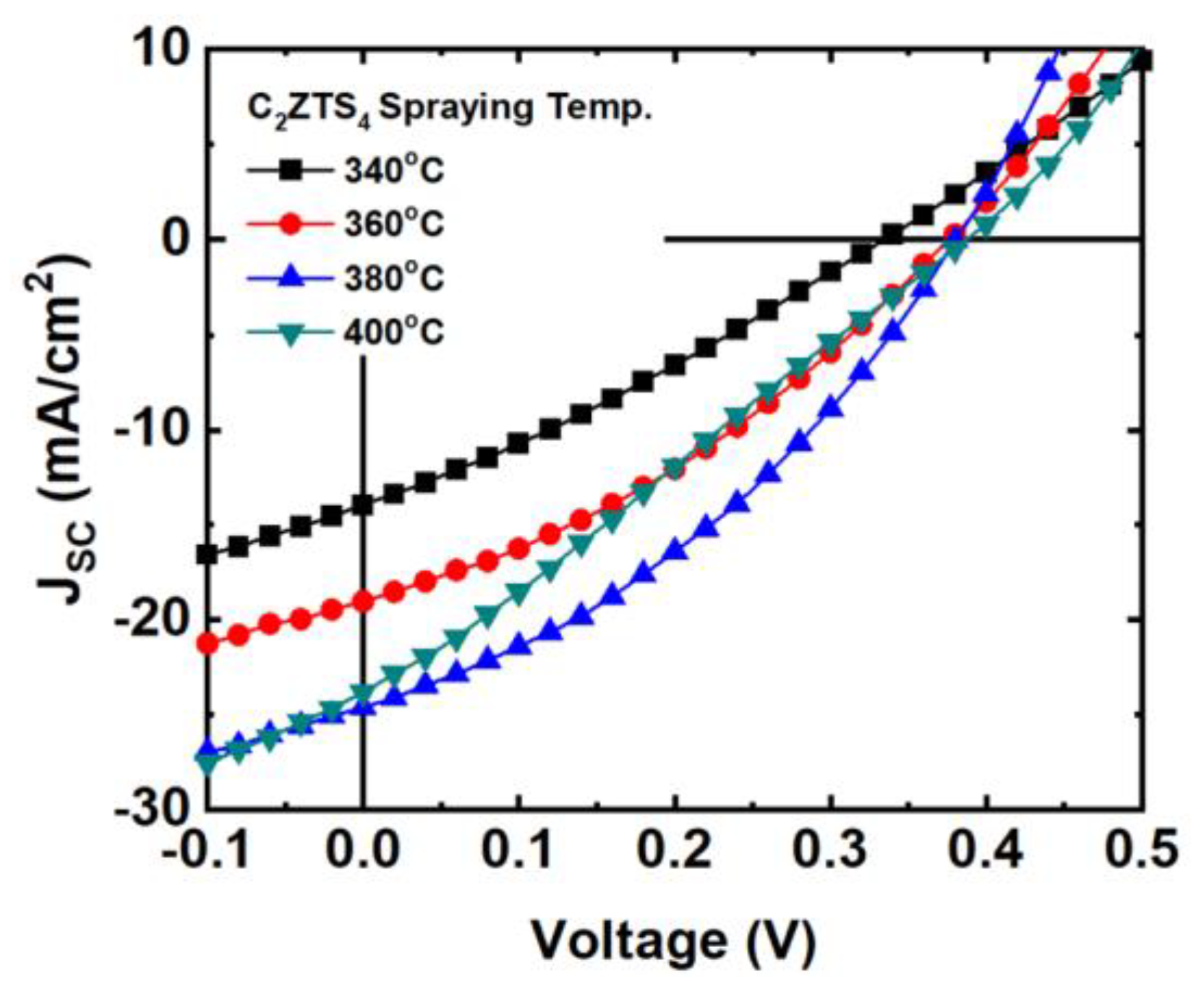

4 absorber layer should be investigated in detail. We used four temperatures to deposit the absorber layers (340 °C, 360 °C, 380 °C, and 400 °C) using the optimum composition of Cu, Zn, Sn, and S. The deposited C

2ZTS

4 films were characterized by XRD, as shown in

Figure 7. Current–voltage characteristics of the resulting devices are presented in

Figure 8, and the extracted solar cell parameters are listed in

Table 3 for different spraying temperatures of the C

2ZTS

4 absorber layer. The C

2ZTS

4 film deposited at a low deposition temperature (340 °C) shows poor crystal quality, and the secondary phase (ZnS) is present. The film has a rough surface morphology and is delaminated from the substrate, which was also observed in the previous CIGS

2 solar cell study [

25]. Therefore, the devices processed at low-temperature show low J

SC and FF, as well as low V

OC, compared to the devices processed at higher temperatures.

In contrast, high-temperature processing (400 °C) yields better C

2ZTS

4 crystal quality with better FWHM and adhesion. However, the device performance of the high-temperature device is degraded by a low FF. Three hypotheses can explain the degradation of FF from high-temperature spraying. One is the degradation of the absorber layer due to the creation of secondary phases. XRD results show the secondary phases such as ZnS or Cu

xS, and these could be recombination centers decreasing FF. If the secondary phases degrade the bulk absorber layer, it causes low photocurrent generation as well as FF. The FF drops without significant loss of J

SC at 400 °C. Therefore, we can conclude that there is no absorber layer degradation. Another plausible explanation for the decreased FF is junction degradation by the high-temperature process. High temperature can enhance the interaction between the In

2S

3 buffer layer and the C

2ZTS

4 absorber layer by the diffusion of high-mobility atoms. As shown in

Table 3, the shunt resistances, which are extracted from −0.2 V to 0 V, increased from low temperature to 380 °C and decreased significantly at 400 °C. It means that the leakage current at the junction is increased during photocurrent generation in the devices processed at high temperatures. The last possibility is contact degradation between C

2ZTS

4 and the final metal contact. Investigation with one-dimensional numerical simulation has shown that higher Schottky barrier heights between layers have significant effects on FF [

26,

27]. In this study, the surface of the C

2ZTS

4 layer processed at high temperatures can be easily oxidized before depositing the metal contact. The oxide interface can be an electrical barrier, resulting in the inflection of the I–V curve between J

SC and V

OC.

As we can see in the 400 °C results, there is no noticeable degradation in J

SC and V

OC. However, the fluctuation of the I–V curve degrades FF. We concluded that the high-temperature process (400 °C) degrades the junction characteristics and surface contact resistance. Therefore we determined the optimum spraying temperature range for the C

2ZTS

4 absorber layer to be 360–380 °C.

Table 3 lists the general electrical parameters, the extracted shunt resistance, and the FWHM variation of XRD results.

The high series resistance (R

s) in the solar cells hass a profoundly negative impact on FF. As we mentioned in the experimental section, a thick In

2S

3 buffer layer ~300 nm, was used to prevent the diffusion of elements during the C

2ZTS

4 layer spraying. However, the thick buffer causes high R

s, and the best cell in this study shows higher than 6 ohms of R

s, calculated by using the one-diode model equation [

28]. Silicon and CIGS

2 based solar cells are usually within a range of 0.1–2 ohm of R

s. Because of the high R

s, the FF of this study is significantly lower than other solar cells.

Further investigations for reducing the thickness of the buffer layer should be carried out. One possible way is to make a thin buffer layer with a blocking layer. Because of the introduction of the blocking layer, the buffer layer should be thin (<10 nm) to compensate for the total series resistance. We can deposit the buffer layer at less than 10 nm of thickness with chemical bath deposition(CBD) or the atomic layer deposition (ALD) method and grow the thin diffusion-blocking layer (<5 nm) that the carrier can tunnel through. This would be the next study in order to reduce the series resistance of spray C2ZTS4 solar cells.